Page 1

Air-Cooled Chillers

Installation Instructions

AQUASNAP ®

30RB060-390

CONTENTS

Page

SAFETY CONSIDERATIONS ...................... 1

INTRODUCTION .................................. 2

INSTALLATION ................................ 2-69

Storage .......................................... 2

Step 1 -- Place, Rig and Mount Unit ............. 2

• PLACING UNIT

• MOUNTING UNIT

• RIGGING UNIT

Step 2 -- Remove Compressor Rack

Holddown Bolts ............................... 36

Step 3 -- Remove Compressor Shipping

Braces ..................................... 36

• FOR UNITS WITH COMPRESSOR SOUND BLAN-

KETS

Step 4 -- Make Cooler Fluid, Heat Reclaim and

Drain Piping Connections ..................... 36

• FREEZE PROTECTION

• UNITS WITH HYDRONIC PUMP PACKAGE

• UNITS WITHOUT HYDRONIC PUMP PACKAGE

• UNITS WITH OPTIONAL HEAT RECLAIM

• HEAD PRESSURE CONTROL

• FOR ALL UNITS

Step 5 -- Fill the Chilled Water and Heat Reclaim

Loop ......................................... 42

• WATER SYSTEM CLEANING

• WATER TREATMENT

• SYSTEM PRESSURIZATION

• FILLINGTHE SYSTEM(S)

• SET WATER FLOW RATE

• PUMP MODIFICATION/TRIMMING

• PUMP VFD

• SENSORLESS CONTROL (CLOSED LOOP)

• REMOTE SENSOR (CLOSED LOOP)

• REMOTE CONTROLLER (OPEN LOOP)

• PREPARATION FOR YEAR-ROUND

OPERATION

• FREEZE PROTECTION

• PREPARATION FOR WINTER SHUTDOWN

• CHILLED WATER SYSTEM

• HEAT RECLAIM SYSTEM

Step 6 -- Make Electrical Connections .......... 53

• POWER SUPPLY

• POWER WIRING

• CONTROL POWER

• FIELD CONTROL OPTION WIRING

• DUAL CHILLER CONTROL OPTION

• CARRIER COMFORT NETWORK -R:

COMMUNICATION BUS WIRING

• NON-CCN COMMUNICATION WIRING

Step 7 -- Install Accessories .................... 66

• NAVIGATOR TM DISPLAY

• REMOTE ENHANCED DISPLAY

• LOW AMBIENT TEMPERATURE OPERATION

• MINIMUM LOAD ACCESSORY

• UNIT SECURITY/PROTECTION ACCESSORIES

• COMMUNICATION ACCESSORIES

• SERVICE OPTIONS

Refrigerant Circuit .............................. 67

Page

• LEAK TESTING

• DEHYDRATION

• REFRIGERANT CHARGE

Optional BACnet Communication Wiring ........ 67

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning

equipment can be hazardous due to system pressures, electrical

components, and equipment location.

Only trained, qualified installers and service mechanics

should install, start up, and service this equipment.

Untrained personnel can perform basic maintenance func-

tions such as cleaning coils. All other operations should be

performed by trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

• Follow all safety codes.

• Keep quenching cloth and fire extinguisher nearby when

brazing.

• Wear safety glasses and work gloves.

• Use care in handling, rigging, and setting bulky

equipment.

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all discon-

nect locations to alert others not to restore power until work

is completed.

IMPORTANT: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with these instructions may cause

radio interference. It has been tested and found to comply

with the limits of a Class A computing device as defined

by FCC (Federal Colmnunications Colmnission, U.S.A.)

regulations, Subpart J of Part 15, which are designed to

provide reasonable protection against such interference

when operated in a colrnnercial enviromnent.

This system uses Puron :R:refrigerant (R-410A), which has

higher pressures than R-22 and other refrigerants. No other

refrigerant can be used in this system. Failure to use gage

set, hoses, and recovery systems designed to handle Puron

refrigerant (R-410A) may result in equipment damage or

personal injury. If unsure about equipment, consult the

equipment manufacturer.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53300093-01 Printed in U.S.A. Form 30RB-18SI Pg 1 2-12 Replaces: 30RB-17SI

Page 2

INTRODUCTION

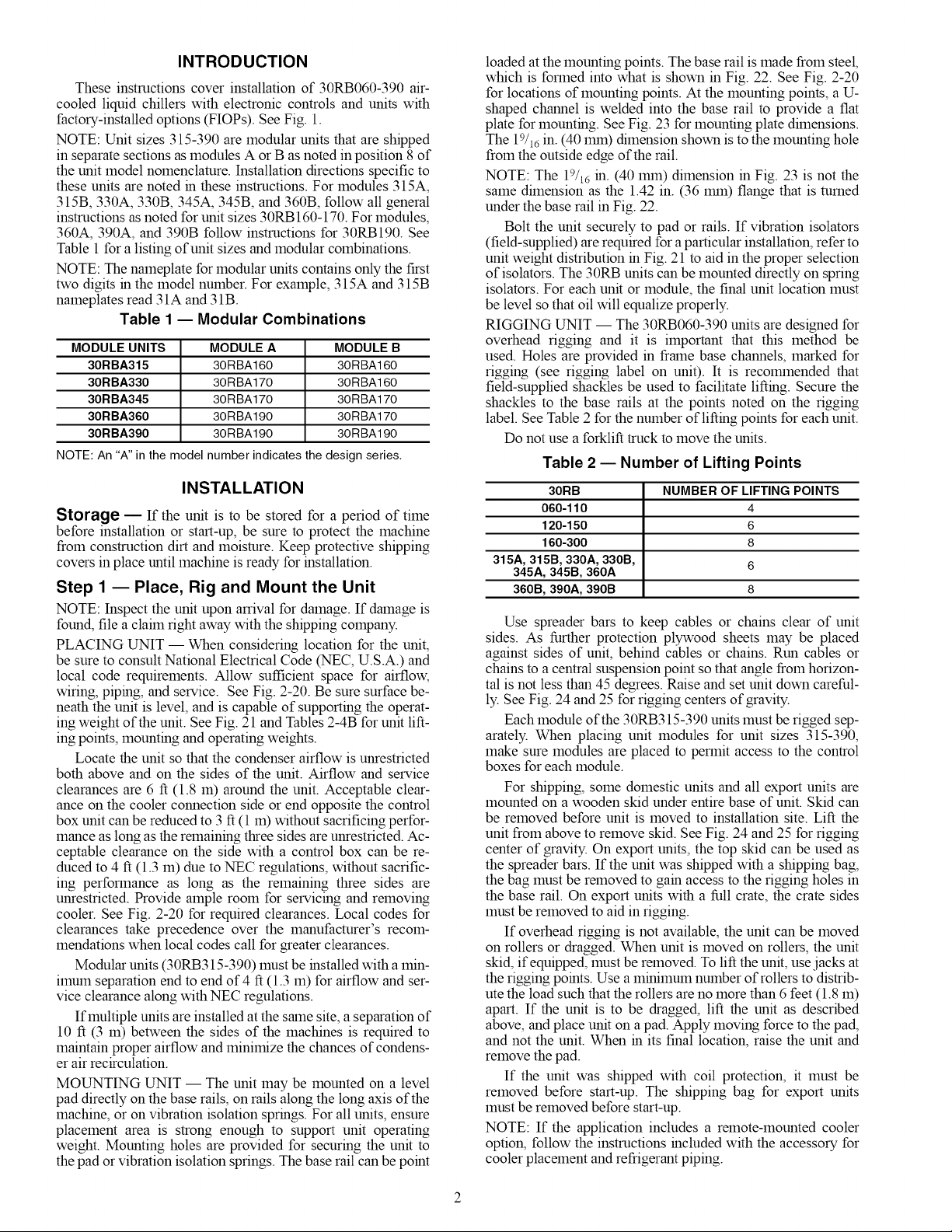

These instructions cover installation of 30RB060-390 air-

cooled liquid chillers with electronic controls and units with

factory-installed options (FlOPs). See Fig. 1.

NOTE: Unit sizes 315-390 are modular units that are shipped

in separate sections as modules A or B as noted in position 8 of

the unit model nomenclature. Installation directions specific to

these units are noted in these instructions. For modules 315A,

315B, 330A, 330B, 345A, 345B, and 360B, follow all general

instructions asnoted for unit sizes 30RB160-170. For modules,

360A, 390A, and 390B follow instructions for 30RB190. See

Table 1for a listing of unit sizes and modular combinations.

NOTE: The nameplate formodular units contains only the first

two digits in the model number. For example, 315A and 315B

nameplates read 31A and 3lB.

Table 1 -- Modular Combinations

MODULE UNITS MODULE A MODULE B

30RBA315 30RBA160 30RBA160

30RBA330 30RBA170 30RBA160

30RBA345 30RBA170 30RBA170

30RBA360 30RBA190 30RBA170

30RBA390 30RBA190 30RBA190

NOTE: An "A" in the model number indicates the design series,

INSTALLATION

Storage -- If the unit is to be stored for a period of time

before installation or start-up, be sure to protect the machine

from construction dirt and moisture. Keep protective shipping

covers in place until machine is ready for installation.

Step 1 E Place, Rig and Mount the Unit

NOTE: Inspect the unit upon arrival for damage. If damage is

found, file a claim right away with the shipping company.

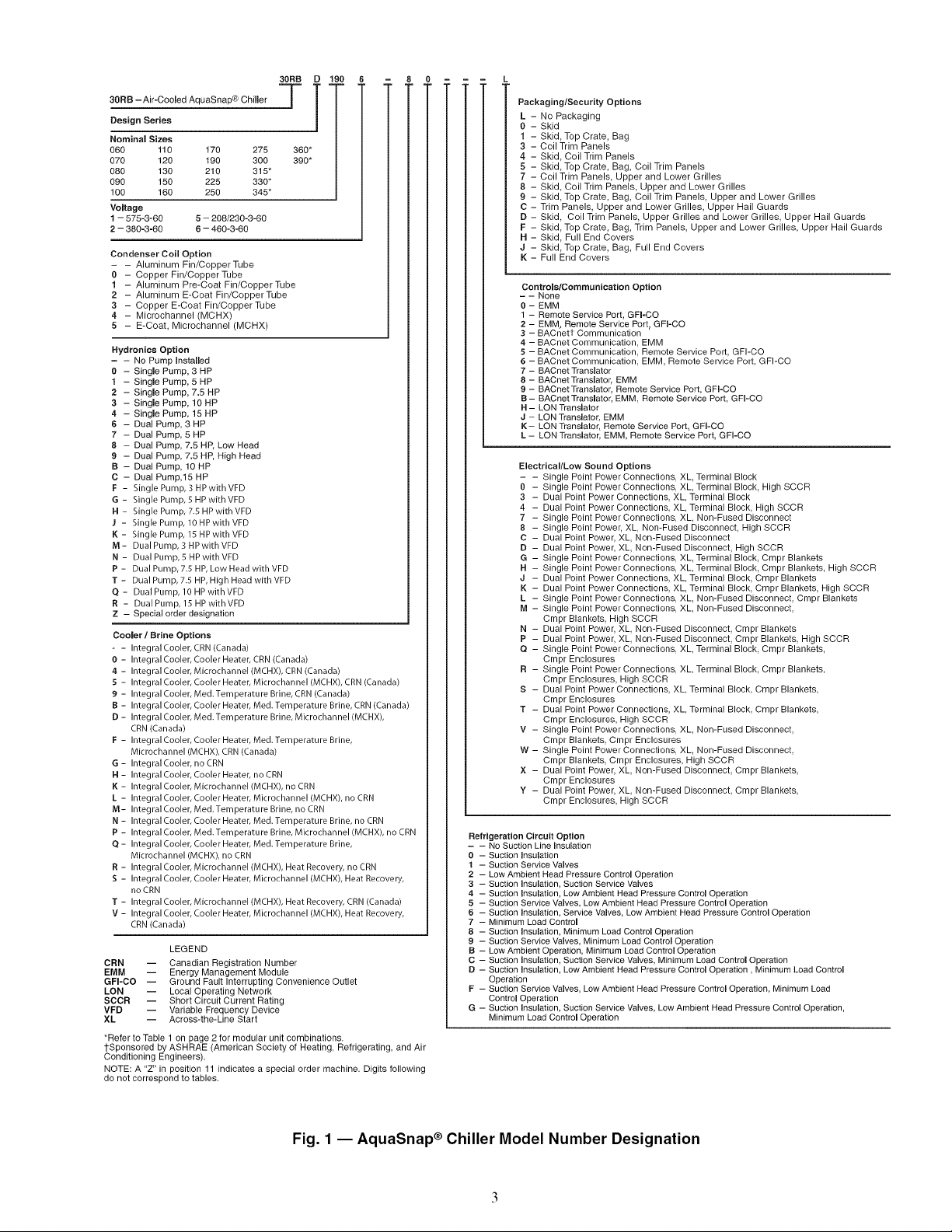

PLACING UNIT- When considering location for the unit,

be sure to consult National Electrical Code (NEC, U.S.A.) and

local code requirements. Allow sufficient space for airflow,

wiring, piping, and service. See Fig. 2-20. Be sure surface be-

neath the unit is level, and is capable of supporting the operat-

ing weight of the unit. See Fig. 21 and Tables 2-4B for unit lift-

ing points, mounting and operating weights.

Locate the unit so that the condenser airflow is unrestricted

both above and on the sides of the unit. Airflow and service

clearances are 6 ft (1.8 m) around the unit. Acceptable clear-

ance on the cooler connection side or end opposite the control

box unit can be reduced to 3 ft (1 m) without sacrificing perfor-

mance as long as the remaining three sides are unrestricted. Ac-

ceptable clearance on the side with a control box can be re-

duced to 4 ft (1.3 m) due to NEC regulations, without sacrific-

ing performance as long as the remaining three sides are

unrestricted. Provide ample room for servicing and removing

cooler. See Fig. 2-20 for required clearances. Local codes for

clearances take precedence over the manufacturer's recom-

mendations when local codes call for greater clearances.

Modular units (30RB315-390) must be installed with a min-

imum separation end to end of 4 ft (1.3 m) for airflow and ser-

vice clearance along with NEC regulations.

If multiple units are installed at the same site, a separation of

10 ft (3 m) between the sides of the machines is required to

maintain proper airflow and minimize the chances of condens-

er air recirculation.

MOUNTING UNIT -- The unit may be mounted on a level

pad directly on the base rails, on rails along the long axis of the

machine, or on vibration isolation springs. For all units, ensure

placement area is strong enough to support unit operating

weight. Mounting holes are provided for securing the unit to

the pad or vibration isolation springs. The base rail can be point

loaded at the mounting points. The base rail is made from steel,

which is formed into what is shown in Fig. 22. See Fig. 2-20

for locations of mounting points. At the mounting points, a U-

shaped channel is welded into the base rail to provide a flat

plate for mounting. See Fig. 23 for mounting plate dimensions.

The 19/16 in. (40 lnrn) dimension shown is to the mounting hole

from the outside edge of the rail.

NOTE: The 19/16 in. (40 lnrn) dimension in Fig. 23 is not the

same dimension as the 1.42 in. (36 lnrn) flange that is turned

under the base rail in Fig. 22.

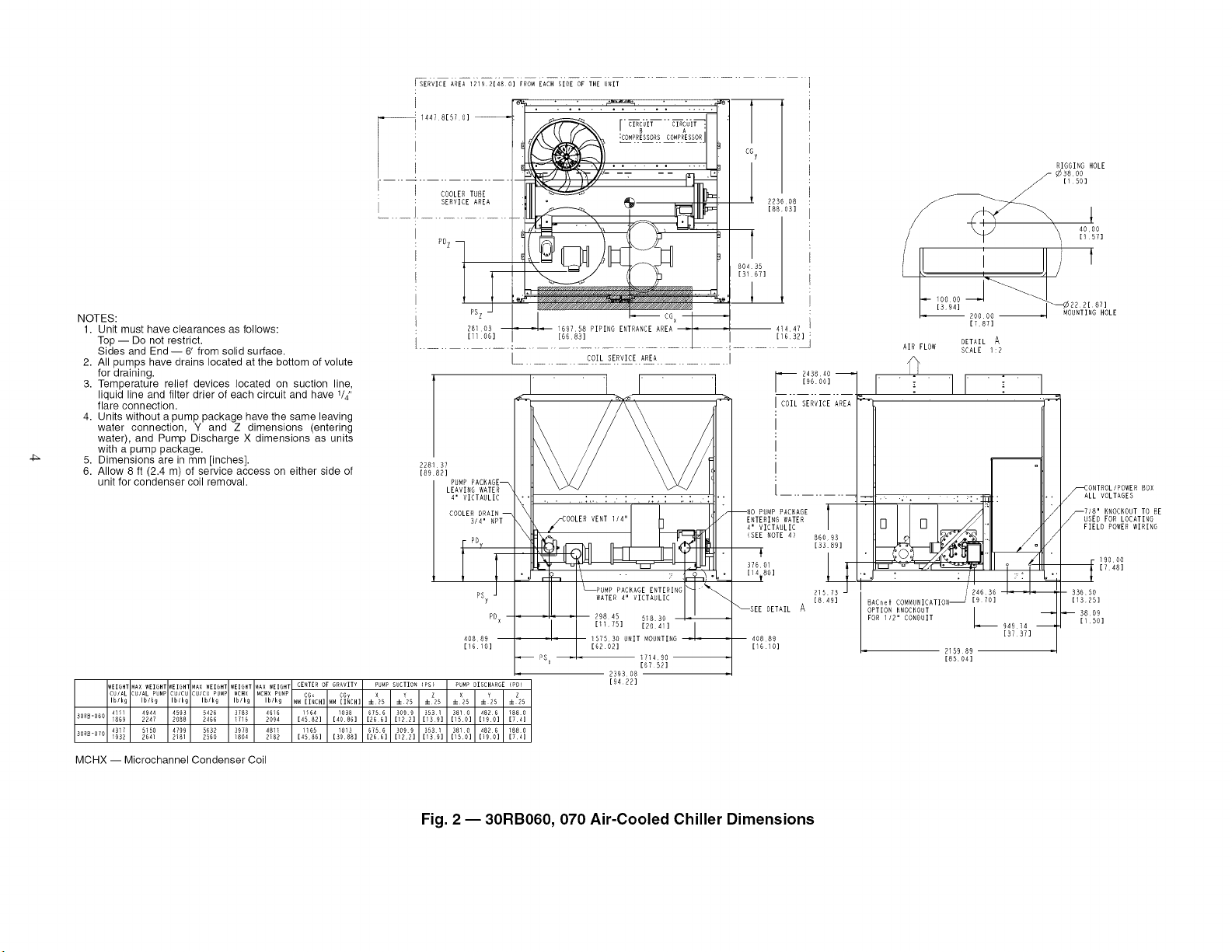

Bolt the unit securely to pad or rails. If vibration isolators

(field-supplied) are required for a particular installation, refer to

unit weight distribution in Fig. 21 to aid in the proper selection

of isolators. The 30RB units can be mounted directly on spring

isolators. For each unit or module, the final unit location must

be level so that oil will equalize properly.

RIGGING UNIT -- The 30RB060-390 units are designed for

overhead rigging and it is important that this method be

used. Holes are provided in frame base channels, marked for

rigging (see rigging label on unit). It is recolnrnended that

field-supplied shackles be used to facilitate lifting. Secure the

shackles to the base rails at the points noted on the rigging

label. See Table 2 for the number of lifting points for each unit.

Do not use a forklift truck to move the units.

Table 2 -- Number of Lifting Points

30RB NUMBER OF LIFTING POINTS

060-110 4

120-150 6

160-300 8

315A, 315B, 330A, 330B, 6

345A, 345B, 360A

360B, 390A, 390B 8

Use spreader bars to keep cables or chains clear of unit

sides. As further protection plywood sheets may be placed

against sides of unit, behind cables or chains. Run cables or

chains to a central suspension point so that angle from horizon-

tal is not less than 45 degrees. Raise and set unit down careful-

ly. See Fig. 24 and 25 for rigging centers of gravity.

Each module of the 30RB315-390 units must be rigged sep-

arately. When placing unit modules for unit sizes 315-390,

make sure modules are placed to permit access to the control

boxes for each module.

For shipping, some domestic units and all export units are

mounted on a wooden skid under entire base of unit. Skid can

be removed before unit is moved to installation site. Lift the

unit from above to remove skid. See Fig. 24 and 25 for rigging

center of gravity. On export units, the top skid can be used as

the spreader bars. If the unit was shipped with a shipping bag,

the bag must be removed to gain access to the rigging holes in

the base rail. On export units with a full crate, the crate sides

must be removed to aid in rigging.

If overhead rigging is not available, the unit can be moved

on rollers or dragged. When unit is moved on rollers, the unit

skid, if equipped, must be removed. To lift the unit, use jacks at

the rigging points. Use a minimum number of rollers to distrib-

ute the load such that the rollers are no more than 6 feet (1.8 m)

apart. If the unit is to be dragged, lift the unit as described

above, and place unit on a pad. Apply moving force to the pad,

and not the unit. When in its final location, raise the unit and

remove the pad.

If the unit was shipped with coil protection, it must be

removed before start-up. The shipping bag for export units

must be removed before start-up.

NOTE: If the application includes a remote-mounted cooler

option, follow the instructions included with the accessory for

cooler placement and refrigerant piping.

Page 3

30RB - Air-Cooled AquaSnap® Chiller

Design Series

Nominal Sizes

060 110 170 275 360*

070 120 190 300 390*

080 130 210 315"

090 150 225 330*

100 160 250 345*

Voltage

1 - 575-3-60 5 - 208/230-3-60

2 - 380=3=60 6 - 460-3-60

Condenser Coil Option

- - Aluminum Fin/CopperTube

0 - Copper Fin/Copper Tube

1 - Aluminum Pre-Coat Fin/CopperTube

2 - Aluminum E-Coat Fin/CopperTube

3 - Copper E-Coat Fin/Copper Tube

4 - Microchannel (MCHX)

5 - E-Coat, Microchannel (MCHX)

Hydronioe Option

= - No Pump Installed

0 - Single Pump, 3 HP

1 - Single Pump, 5 HP

2 - Single Pump, 7.5 HP

3 - Single Pump, 10 HP

4 - Single Pump, 15 HP

6 - Dual Pump, 3 HP

7 - Dual Pump, 5 HP

8 - Dual Pump, 7.5 HP, Low Head

9 - Dual Pump, 7.5 HP, High Head

B - Dual Pump, 10 HP

C - Dual Pump,15 HP

F - Single Pump, 3 HP with VFD

G - Single Pump, 5 HP with VFD

H - Single Pump, 7.5 HPwithVFD

J - Single Pump, 10 HP with VFD

I{ - Single Pump, 15 HP with VFD

M - Dual Pump, 3 HP with VFD

N - Dual Pump, 5 HPwithVFD

P - Dual Pump, 7.5 HP, Low Head with VFD

T - Dual Pump, 7.5 HP, High Head with VFD

Q - Dual Pump, 10 HP with VFD

R - Dual Pump, 15 HPwith VFD

Z - Special order designation

Cooler / Brine Options

- - Integral Cooler, CRN (Canada)

0 - Integral Cooler, Cooler Heater, CRN (Canada)

4 - Integral Cooler, Micrechannel (MCHX), CRN (Canada)

5 - Integral Cooler, Cooler Heater, Microchannel (MCHX), CRN (Canada)

£ - IntegralCooler, Med.Temperature Brine, CRN (Canada)

B - Integral Cooler, Cooler Heater, Med. Temperature Brine, CRN(Canada)

D-Integ ral Cooler, Meal. Temperatu re Brine, Microchannel (MCHX),

CRN (Canada)

F - Integral Cooler, Cooler Heater, Med. Temperature Brine,

Micrechannel (MCHX), CRN (Canada)

G - Integral Cooler, no CRN

H - Integral Cooler, Cooler Heater, no CRN

K - Integral Cooler, Micrechannel (MCHX), no CRN

L - Integral Cooler, Cooler Heater, Microchannel (MCHX), no CRN

M- Integral Cooler, Med. Temperatu re Brine, no CRN

N - Integral Cooler, Cooler Heater, Med. Temperature Brine, no CRN

P- IntegralCooler, Med.Temperature Brine, Microchannel(MCHX),no CRN

Q - Integral Cooler, Cooler Heater, Med. Temperature Brine,

Micrechannel (MCHX), no CRN

R - Integral Cooler, Micrechannel (MCHX), Heat Recovery, no CRN

S - Integral Cooler, Cooler Heater, Microchannel (MCHX), Heat Recovery,

no CRN

T - Integral Cooler, Micrechannel (MCHX), Heat Recovery, CRN (Canada)

V - Integral Cooler, Cooler Heater, Microchannel (MCHX), Heat Recovery,

CRN (Canada)

CRN -- Canadian Registration Number

EMM -- Energy Management Module

GFI-CO -- Ground Fault Interrupting Convenience Outlet

LON -- Local Operating Network

SCCR -- Short Circuit Current Hating

VFD -- Variable Frequency Device

XL -- Across-the-Line Start

*Refer to Table 1 on page 2 for modular unit combinations

1-Sponsored by ASHRAE (American Society of Heating, Refrigerating, and Air

Conditioning Engineers).

NOTE: A "Z" in position 11 indicates a special order machine. Digits following

do not correspond to tables.

LEGEND

PackaginglSecurity Options

L - No Packaging

O - Skid

1 - Skid, Top Crate, Bag

3 - Coil Trim Panels

4 - Skid, Coil Trim Panels

5 - Skid, Top Crate, Bag, Coil Trim Panels

7 - Coil Trim Panels, Upper and Lower Grilles

8 - Skid, Coil Trim Panels, Upper and Lower Grilles

9 - Skid, Top Crate, Bag, Coil Trim Panels, Upper and Lower Grilles

C - Trim Panels, Upper and Lower Grilles, Upper Hail Guards

D - Skid, Coil Trim Panels, Upper Grilles and Lower Grilles, Upper Hail Guards

F - Skid, Top Crate, Bag, Trim Panels, Upper and Lower Grilles, Upper Hail Guards

H - Skid, Full End Covers

J - Skid, Top Crate, Bag, Full End Covers

K - Full End Covers

Controls/Communication Option

- - None

0 - EMM

1 - Remote Service Port, GFI-OO

2 - EMM, Remote Service Port, GFI-CO

3 - BACnett Communication

4 - BACnet Communication, EMM

5 - BACnet Communication, Remote Service Port, GFI-CO

6 - BACnet Communication, EMM, Remote Service Port, GFI-CO

7 - BACnet Translator

8 - BACnet Translator, EMM

9 - BACnet Translator, Remote Service Port, GFI-CO

B- BACnet Translator, EMM, Remote Service Port, GFI-CO

H - LON Translator

J - LON Translator, EMM

K- LON Translator, Remote Service Port, GFI-CO

L - LON Translator, EMM, Remote Service Port, GFI=CO

Electrical/Low Sound Options

- - Single Point Power Connections_ XL, Terminal Block

O - Single Point Power Connections_ XL, Terminal Block_ High SCCR

3 - Dual Point Power Connections_ XL, Terminal Block

4 - Dual Point Power Connections_ XL, Terminal Block, High SCCR

7 - Single Point Power Cennections_ XL, Non-Fused Disconnect

8 - Single Point Power, XL_ Non-Fused DisconnecL High SCCR

C - Dual Point Power, XL_ Non-Fused Disconnect

D - Dual Point Power, XL, Non-Fused DisconnecL High SCCR

G - Single Point Power Connections_ XL Terminal Block_ Cmpr Blankets

H - Single Point Power Connections_ XL Terminal Block_ Cmpr Blankets, High SCCR

J - Dual Point Power Connections_ XL Terminal Block, Cmpr Blankets

K - Dual Point Power Connections_ XL Terminal Block, Cmpr Blankets, High SCCR

L - Single Point Power Connections, XL Non-Fused Disconnect, Cmpr Blankets

M - Single Point Power Connections, XL Non-Fused Disconnect,

Cmpr Blankets, High SCCR

N - Dual Point Power, XL, Non-Fused Disconnect, Cmpr Blankets

P - Dual Point Power, XL, Non-Fused Disconnect, Cmpr Blankets, High SCCR

Q - Single Point Power Connections, XL, Terminal Block, Cmpr Blankets,

Cmpr Enclosures

R - Single Point Power Connections, XL, Terminal Block, Cmpr Blankets,

Cmpr Enclosures, High SCCR

S - Dual Point Power Connections, XL, Terminal Block, Cmpr Blankets,

Cmpr Enclosures

T - Dual Point Power Connections, XL, Terminal Block, Cmpr Blankets,

Cmpr Enclosures, High SCCR

V - Single Point Power Connections, XL, Non-Fused Disconnect,

Cmpr Blankets, Cmpr Enclosures

W - Single Point Power Connections, XL, Non-Fused Disconnect,

Cmpr Blankets, Cmpr Enclosures, High SCCR

X - Dual Point Power, XL, Non-Fused Disconnect, Cmpr Blankets,

Cmpr Enclosures

Y - Dual Point Power, XL, Non-Fused Disconnect, Cmpr Blankets,

Cmpr Enclosures, High SCCR

Refrigeration Circuit Option

- - No Suction Line insulation

0 - Suction Insulation

t - Suction Service Valves

2 - Low Ambient Head Pressure Control Operation

3 - Suction Insulation, Suction Service Valves

4 - Suction Insulation, Low Ambient Head Pressure Control Operation

5 - Suction Service Valves, Low Ambient Head Pressure Control Operation

6 - Suction Insulation, Service Valves, Low Ambient Head Pressure Control Operation

7 - Minimum Load Control

8 - Suction Insulation, Minimum Load Control Operation

9 - Suction Service Valves, Minimum Load Control Operation

B - Low Ambient Operation, Minimum Load Control Operation

C - Suction Insulation, Suction Service Valves, Minimum Load Control Operation

D - Suction insulation, Low Ambient Head Pressure Control Operation, Minimum Load Control

Operation

F - Suction Service Valves, Low Ambient Head Pressure Control Operation, Minimum Load

Control Operation

G - Suction Insulation, Suction Service Valves, Low Ambient Head Pressure Control Operation,

Minimum Load Control Operation

Fig. 1 -- AquaSnap ® Chiller Model Number Designation

Page 4

1447 81570] _ _ " C_{'Tj_F '

NOTES:

1.

Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2.

All pumps have drains located at the bottom of volute

for draining.

3.

Temperature relief devices located on suction line,

liquid line and filter drier of each circuit and have 114"

flare connection.

4.

Units without a pump package have the same leaving

water connection, Y and Z dimensions (entering

water), and Pump Discharge X dimensions as units

4:_

with a pump package.

Dimensions are in mm [inches].

5. 228137

6. [8982]

Allow 8 ft (2.4 m) of service access on either side of

unit for condenser coil removal.

WEIGHT MAX WEIGHT IEIGHl MAX WEIGHT WEIGH1 _AX WEIGHT CERTER OF GRAVITY PU_P SUCTION (P8) PUMP DISCHAR6E (PD)

CUIAL CUIAL PU_P CUICU CUICU PUMP MCHX MCHX P_M9 CGx COy X25 vIb/k9 Ib/k9 Ibft9 Ib/k9 Ib/t9 Ib/k9 _M lINCH] _M lINCH] ::H25 :9=!25 :9=X25 ::1:_25 ±!25

41!1 4944 4595 5426 9788 4616 1!04 1098 6756 3099 9581 9810 4826 1880

9088-060 1869 2247 2088 2466 _716 2094 [4582] [4086] [26 6] [122] [139] [150] [190] [74]

4917 5150 4799 5632 3978 4811 1165 1013 6758 3899 9581 3810 4826 1880

9ORS-OHO 1992 2641 2181 2560 1804 2182 [4586] [3988] [266] [122] [1_9] [150] [190] [74]

MCHX -- Microchannel Condenser Coil

"l ....r

L

.............4_ __Y---: -- _ J

COOLEDT8RE UIII_ IIIi_

8ERVIGEAREA:IlIL:_--_',_ _11# _!o_

p_ _ _///////////////_Sf/JA

281[ 06103 _ i_18_ PIPING ENTRANCE AREA' "F ",

[ C?IL SERVICE. ARE_.......... I

4' VICTAULIC

PDX

40889

116i0]

[94221

41447

[1682]

[96 00]

I--D43848--1

COIL SERVICE AREA

ENTERING WATER

860 93

,801

21573

DETAIL A

408 89

[6 O]

[840]

,L,oooo_i ) t

AIR FLOW

i

89]

J_ : qH_

I RAChel ¢O_4MUNICATIONS [9 70]

OPTION KNOCKOUT I

FOR 1/2" CONDUIT

DIGGING HOLE

¢3800

- [1501

LRLRL80000 l _''%_F_0%LE

2159 89

[88 04]

1787]

DETAIL A

SCALE 1:2

k--

[

94914 --

[37 371

ONTROLIPOWED

_ALL VOLTAGES BOX

718' KNOCKOUTTO BE

_--USED FOR LOCATING

FIELD POWER WIRING

1748]

19000

33650

[1825]

8809

[1,50]

Fig. 2 -- 30RB060H 070 Air-Cooled Chiller Dimensions

Page 5

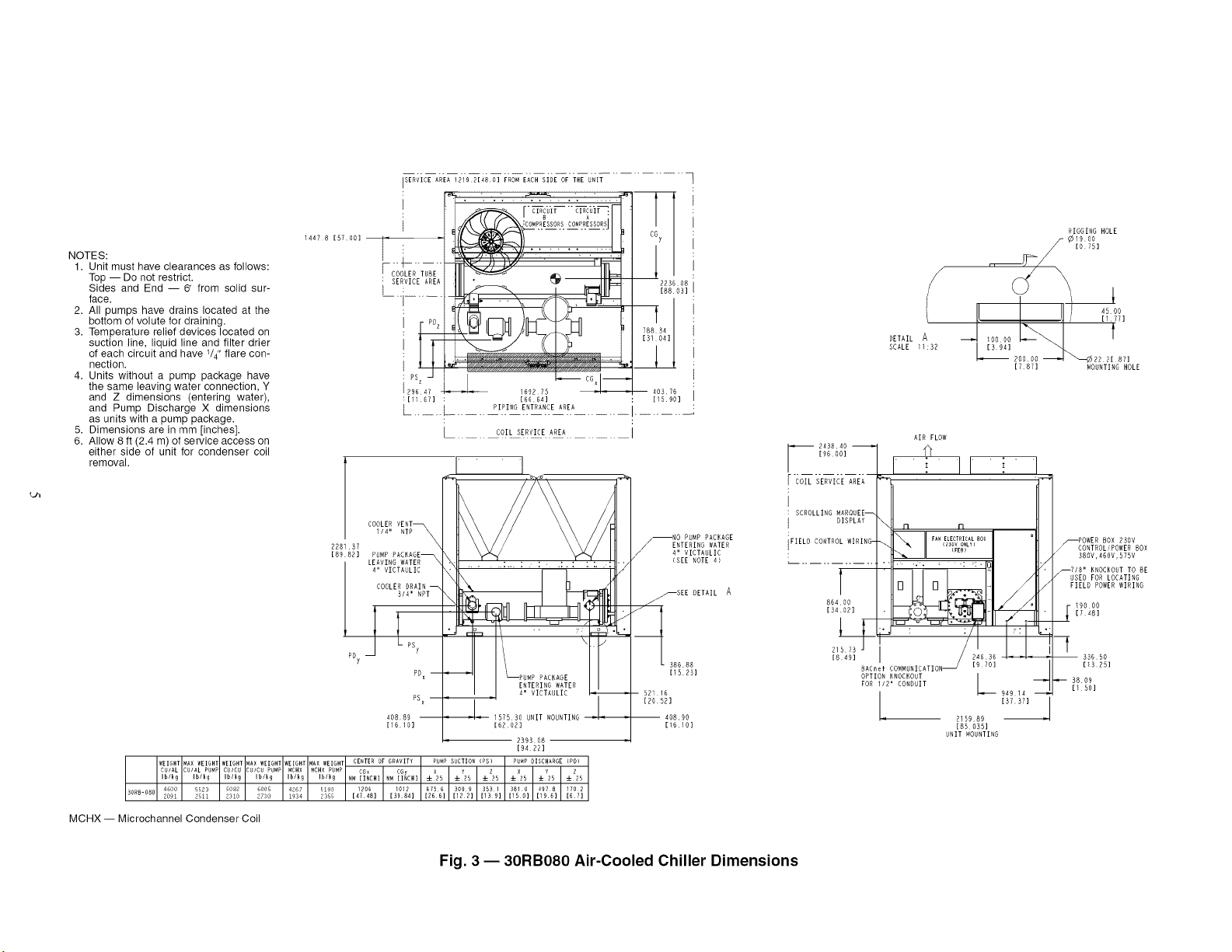

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid sur-

face.

2. All pumps have drains located at the

bottom of volute for draining.

3. Temperature relief devices located on

suction line, liquid line and filter drier

of each circuit and have 1/4" flare con-

nection.

4. Units without a pump package have

the same leaving water connection, Y

and Z dimensions (entering water),

and Pump Discharge X dimensions

as units with a pump package.

5. Dimensions are in mm [inches].

6. Allow 8 ft (2.4 m) of service access on

either side of unit for condenser coil

removal.

14478 [5700]

228187

[8982]

ISERVICE AREA 121921480] FROM EACH SIDE OF THE UNIT

I

I

F OOLER'FTU

' SERVICE AREA

J/x_\L.fFA_u__ CONtRT'Rottll

I__i.....

I

: PSz -

29047

COOLER VENT

1/4" NTP_

PUMP

4" VICTAULIC

:[1107]

L ....

[66 64]

PIPING ENTRANCE AREA

COIL SERVICE AREA

CGy

T

223608

[8803]

78834

[}_ 04]

40876

[15901

NO PUMP PACKAGE

ENTERING WATER

_4" VICTAULIC

<SEE NOTE 4)

_SEE OETAIL A

243840

[9600]

COIL SERVICE AREA

SCROLLING IARQUEE_

_ISPLAY

FIELD CONTROL WIRING-

/

DETAIL A

SCALE 11:32

AIR FLOW

¢

_ n n

FANELECTRICALBOX

(230VONLY)

(FEB)

RIGGING HOLE

[0751

20_2221871

[787] MOUNTING HOLE

POWERBOX 290V

_CONTROL/POWER BOX

380V,460V,GTGV

_7/8" KNOCKOUT TO HE

USED FOR LOCATING

FIELD POWER WIRING

/

[748]

- 90 00

WEIGHT MAX WEIGHT WEIGH1 _AX WEIGHT WEIGHI _AX WEIGHT

CU/AL CUfAL PUMP CU/CU ;UfCU PUMP MCHX MCHX PUMP

Ib/k_ Ib/I g Ib/I 9 Ib/k 9 Ib/k 9 Ib/k_

3ONB-OHO 4600 5523 5082 6005 4267 5190

2091 2511 2310 2730 1934 2355

MCHX -- Microchannel Condenser Coil

[1610]

CENTER OF GRAVITY PUMP SUCTION (PS) PUMP OISCBARGE [PD)

CGx CGp

[9422]

Fig. 3 -- 30RB080 Air-Cooled Chiller Dimensions

[20521

38688

[1523]

[1610]

[8491 670 ] , ,

BACneI COMMUNICATION _

FOR 1/2' CONDUIT _

OPTION KNOCKOUT L

• [57 37]

UNIT _40UNTI NG

215989

[85 035]

94914

9809

11 50]

33650

[1328]

Page 6

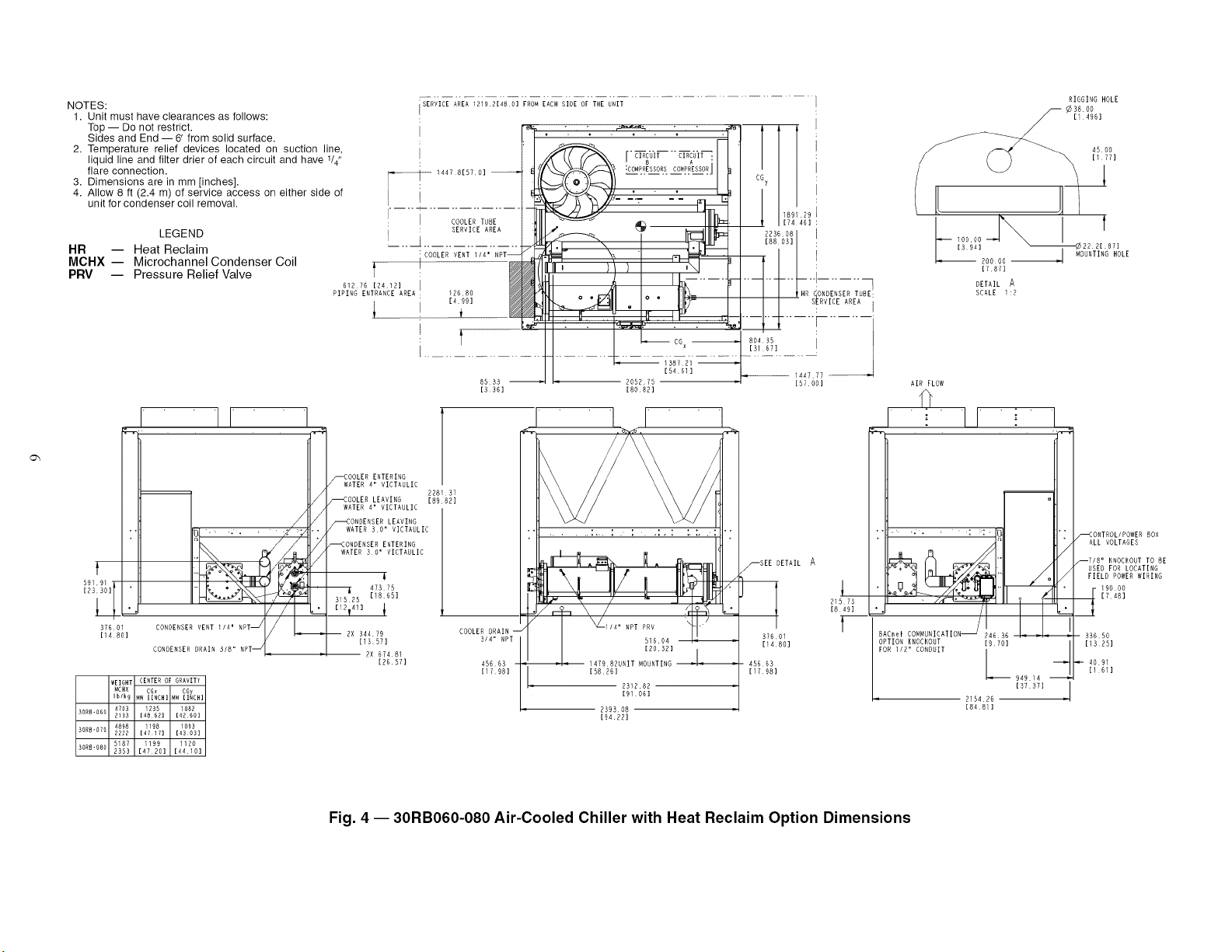

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suction line,

liquid line and filter drier of each circuit and have 1/4"

flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on either side of

unit for condenser coil removal.

LEGEND

HR -- Heat Reclaim

MCHX -- Microchannel Condenser Coil

PRV -- Pressure Relief Valve

SERVICEAREA_2192148G]FRoMiACHS_OiSrT_&Z

_- 1447 81570]

; COOLER TUBE

I SERVICE AREA

r

612 16 [2412] i

PIPING ENTRANCE AREA : 12680

[499]

I

RIGGING HOLE

--¢ 3809

114961

CG7

I 1891 29

[74 46] '

t

2236 08

[88 03] i

t

k_I[ IIII_ I

138721

8533

[3361

2052,75

[8082]

154611

_ -- 144777 _]

' H _!!_ES EAHR!_8E

[57 OO]

_ 2OO OO J WOUNTING HOLE

[787]

DETAILA

SCALE 1:2

AIR FLOW

J

I I I 1

Q'h

'_--_1 _'_ "--COOLER ENTERING

WATER 4" VICTAULIC

--COOLER LEAVING 189 82]

WATER 4 I VICTAULIC

_.ql'" . ; _ WATER 30" VICTADLIC

f :

[23 30]

i • -, _, , 47375

5 '9'l 1

37601 CONDENSER VENT 1/4' RPT CO0 R

WEIGHT CENTER OF GRAVITY

_CHX CGx CGy

Iblk9 _M lINCH] M_ lINCH]

4703 235 1082

HORB-060 2133 [40 62] [4H HO]

30R_.O10 4898 198 1093

2221 [4! 17] [43 03]

30RlJ-080 587 199 1120

2353 [4720] [_410]

_- _,_* _'_I " I --CONDENSER ENTERING

Z/I I_1 ['2,411 ,

CONDENSER DRAIN ' 2 2X 67481

-_ONDERSER LEAVING

WATER 3 0 I VICTAULIC

25 [181651

[13571 3/4" NPT

[26 57] 45663

228 37

[17 98]

[94.22]

_SEE DETAIL A

37601

11480]

45663

21573

[849]

I E I I " 1

I

t

_'_//' I I".L_

"_OR[1 /2ll c_NOUIT 2154[/ _J_ZHJ]

[848]

/-_ONTROL/POWER 80X

ALL VOLTAGES

_718" RNOCROUT TO BE

USED FOR LOCATING

FIELD POWER WIRING

[748]

_[ 9000

33650

[1325]

4091

[1 61]

Fig. 4 -- 30RB060-080 Air-Cooled Chiller with Heat Reclaim Option Dimensions

Page 7

SERVICE AREA 1219 2148 O] FROM EACH SIDE OF THE UNIT

: _-- ----

"T

CG x

e

, CGy

.... i 223608

i _ i_ I 188031

78835

3104]

DETAIL _ RIGGING HOLE

[787]

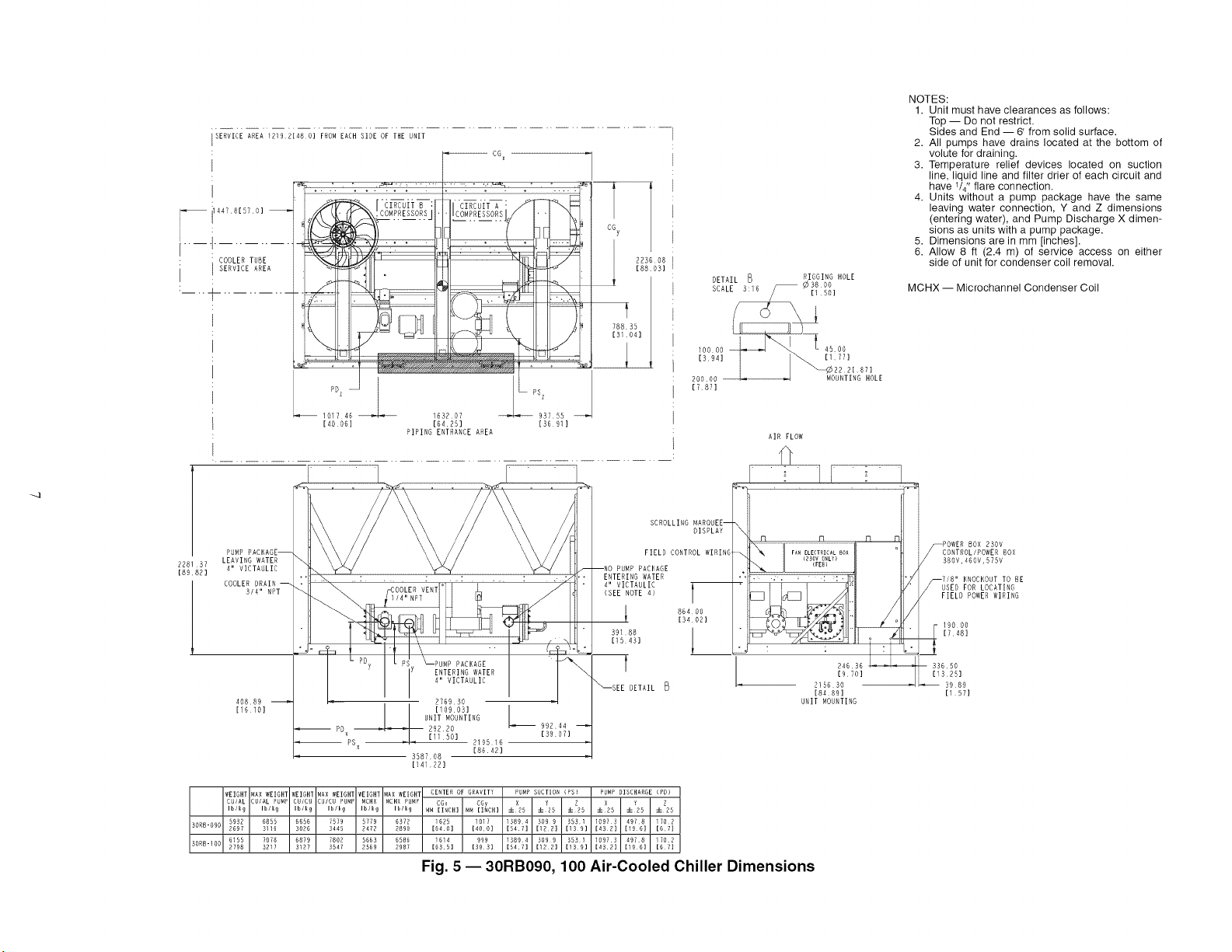

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. All pumps have drains located at the bottom of

volute for draining.

3. Temperature relief devices located on suction

line, liquid line and filter drier of each circuit and

have 1/4" flare connection.

4. Units without a pump package have the same

leaving water connection, Y and Z dimensions

(entering water), and Pump Discharge X dimen-

sions as units with a pump package.

5. Dimensions are in mm [inches].

6. Allow 8 ft (2.4 m) of service access on either

side of unit for condenser coil removal.

MCHX -- Microchannel Condenser Coil

1017 46

[40 06]

163207 7 55

164251 [5691]

PIPING ENTRANCE AREA

AIR FLOW

fl

; II "

--4

SCROLLING MAROUEE--

DISPLAY

PUMP PACKA(

LEAVING WATER

228137

[89821

COOLER

3/4" NPT

PACKAGE

ENTERING WATER

_" VICTAULIC

40889

[1610]

PD× 29220 99244

pS x [11 501

WEIGHT MAX WEIGH1 WEIGHT MAX WEIGHT WEIGHT _AX WEIGHT CENTER OF GRAVITY PUMP SUCTION (PSI

CUIAL CU/AL PHMF CUICN CU/CU PUMP MCHX MCHX PUMP CGx CGy Y !Ib/kR Ib/kg IDleR Ib/kg Ib/k9 Ib/k9 MM lINCH[ MM lINCH[ ±X25 ±25 • 25

30R8-090 5992 6855 6656 7579 5779 6572 1625 1017 13894 3099 9551

2697 3116 3096 3445 2472 2890 [640] [4OO] [547] [199] [19 9]

5ORH-]OO 6155 7078 6879 7809 5663 6586 i614 999 13894 309 9 353 1

2798 5217 3127 3547 2569 2987 [635] [993] [547] [122] [159]

276930

UNIT MOUNTING

t [109031 L_

358708

[14i221

219510

[86421

[39071

FIELD CONTROL WIRING

PUMP PACKAGE

ENTERING WATER

(SEE NOTE 4)

4" VICTAULIC T

[1543]

39188 ___

_SEE DETAIL

PUMP DISCHARGE (PD}

i X25 ±Y25 ±Z25

1097 9 497¸8 _702

[43 R] [19 0] [67]

I097¸3 497¸8 170¸2

[432[ [INOI [6¸7[

86400

[3402]

_ F! O _ _ 43 FPOWEH BOX 230V

k\ II I

\_., II < .... !! / / CONTROL/POWER

24636 _i ' -- 33650

[970] [1325]

215630 _ 3989

[8489] [157]

UNIT MOUNTING

Fig. 5 --30RB090, 100 Air-Cooled Chiller Dimensions

#

380V,460V,575V

FIELD POWERWIRING

[7481

, _ 19000

Page 8

SERVICE AREA i219 2148 O] FROM EACH SIDE OF THE UNIT

_ iA4781570]

COOLER TUBE

SERVICE AREA

...<-_j,

LL_

PDz PS z

e__, _/////////__///,/////J//////_//_ ,_le

- - - 244609 - - 916,15 -

22484 -

[885]

_OR_.

- ]-¢i_ _

196301 136,071

PIPING ENTRANCE AREA

CG X

rOe ¸

"1

76194

[30OO]

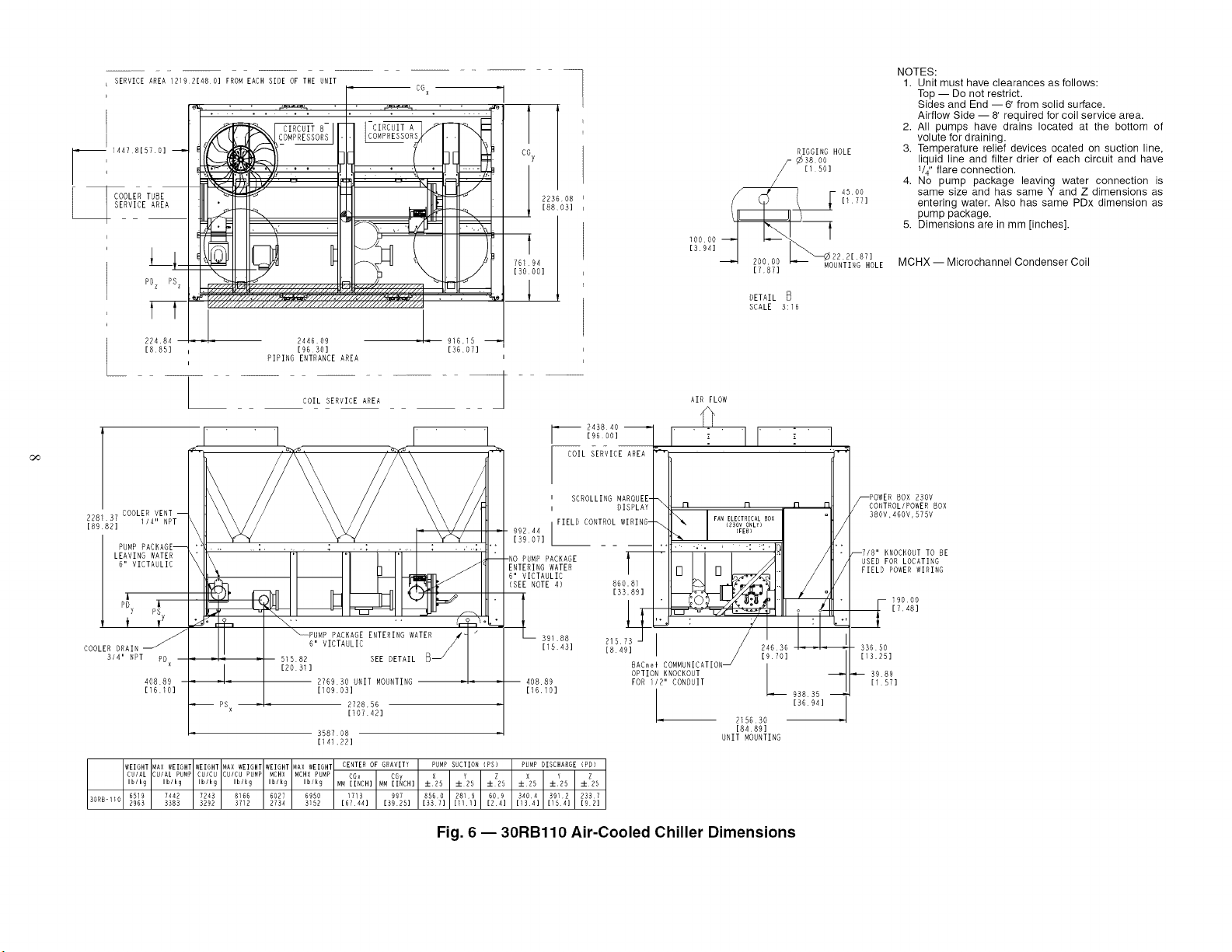

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End --6' from solid surface.

Airflow Side -- 8' required for coil service area.

l

CGy

2236

[88

RIGGING HOLE

¢3800

[150]

2. All pumps have drains located at the bottom of

volute for draining.

3. Temperature relief devices ocated on suction line,

liquid line and filter drier of each circuit and have

V4" flare connection.

4. No pump package leaving water connection is

same size and has same Y and Z dimensions as

entering water. Also has same PDx dimension as

pump package.

5. Dimensions are in mm [inches].

t

17871

DETAIL

SCALE 3:16

MCHX -- Microchannel Condenser Coil

I

COIL SERVICE AREA

]

AIR FLOW

fl

196o01 ' ' : ' ' ' : "

[-_ 2438 40

Go

COOLER VENT

228137 1/4" NPT

[8982]

PUMP

COOLER ORAIN

3/4" NPT pD x

40889

[1610]

WEIGHT MAX WEIGHT WEIGHT 4AX WEIGHT WEIGHT _AX WEIGHT CENTER OF GRAVITY PUMP SUCTION (PS) PUMP DISCHARGE (PD)

CUIAL CUIAL PUMP CUICU :UICU PU_P MCHX NCHX PUMP CGx CG 7 [I11] [134]Ib/k9 Ib/k9 Ib/k9 Ib/k9 Ib/k9 Ib/k9 MM[67[INCH]44] HM[3925][INCH] ±X25 4-!25 4-! 25 4-!25 4-Y25 4-!2530RR-110 6519 7442 7243 8166 6027 6950 1713 997 8560 2819 60.9 3404 9912 2337

2963 3383 3292 3712 2734 3162 [337] [R4] [164] [92]

I [20311

. 276930 UNIT MOUNTING

PSx 2728,56

6" VICTAULIC

51582 SEE DETAIL

[I09031

[10742]

9587 08

[i41,22]

,RUMR,ACKAO ...." ' : ::; /f(:

ENTERINGWATER I I n n // / ii /

6" VICTAULIC ' I u _>\I _3;_"_7"_ / II/

<SEE NOTE 4) 860.8' I I _-'_i r,_'J_t,-(_{--_'kl / I)_

Fig. 6 --30RB110 Air-Cooled Chiller Dimensions

COIL S-ERDICE AREA _ [_

I SCROLLING MARQUEE- _ [I

i DISPLAY n n Iq IqJl

,FIELD CONTROL WIRING-_, _'_ i FAN(E2L_EoCvTRoI_LAyL)BOX "tl /

- _9188 21_73/ / I I -

[ls:43] [8491 / 2A6: ,. :!. :

408.89 FOR /2" CONDUIT

[16.i0] _ 93835

" ' / [9 70]

RAChel COMMUNICATION_ I

OPTION KNOCKOUT I

I 215630

[84 89]

UNIT MOUNTING

[36 94]

H

POWER BOX 230V

CONTROL/POWER BOX

380V,460V,S75V

_718" KNOCKOUT TO BE

USED FOR LOCATING

FIELD POWER WIRING

[748]

r- 19000

33650

[i3.25]

-- 3989

[1.571

Page 9

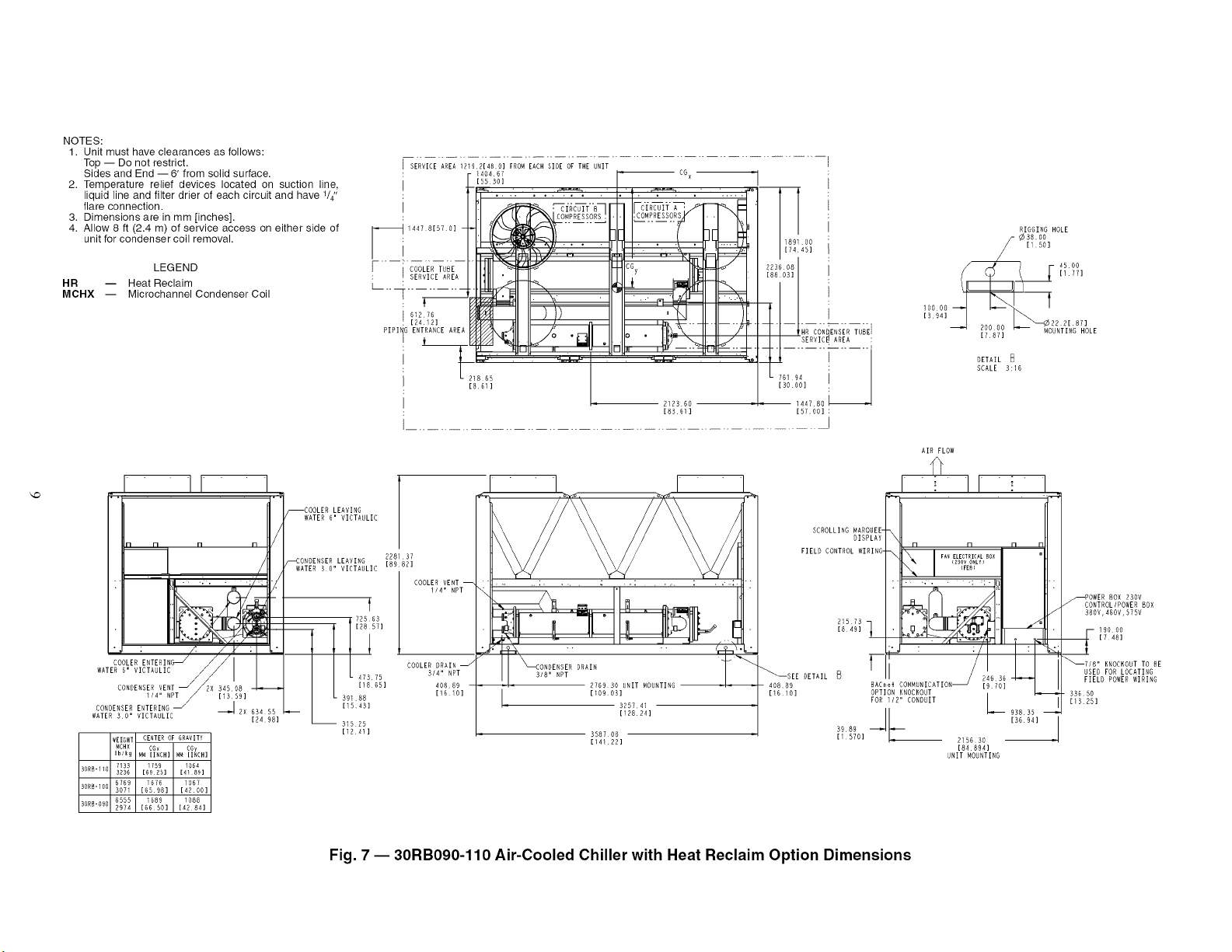

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suction line,

liquid line and filter drier of each circuit and have 1/4"

flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on either side of

unit for condenser coil removal.

LEGEND

HR -- Heat Reclaim

MCHX -- Microchannel Condenser Coil

_D

SERVICE AREA 1R19 R[48 O] FROM EACH SIDE OF THE UNIT

--1[;!43_; . , ,

-- 1.1 -__cG,

A47,[STDI

!t_:_, _ ))) II II ,Yq II II )

PIPIIG ENTRANCE ARE ___j_ E o__ [] __

I 212360

: [83 61 ]

......................

"1

T

223608

[88 03] /

=e ........ T ..... i

SERVICEAREAi i

144780 L_

[57 OO] :

I

[3941

AIR FLOW

.q

_/¢SHDD

[78Tl

DETAIL

SCALE 3:15

RIGGING HOLE

' 4500

[150 1

[177]

T_LE

COOLER

EONOENGERENJN:"L/

WEIGHT CENTER OF GRAVITY

MCH× CGx C5

Ib/kg MM _CH M_ _CH

BORR-HC 7133 1759 1064

3256 [6955] [41HP]

3HRK-IOC 6769 i576 1067

3071 [5598] [4200]

30RH-OPC 6555 i689 1088

29YA [5650] [A28A]

[i3 59]

SCROLLING _ARQUEE- __

WATER 30" VICTAULIC

[8982]

FIELD CONTROL WIPING- IFA_'_EpI'KEoCvTRoINCZ_YL}BOX

f

H8 55]

39_88

[1241]

[1610]

I, [lORD3]

3587 08

114122[

325741

[12824]

Fig. 7- 30RB090-110 Air-Cooled Chiller with Heat Reclaim Option Dimensions

DETAIL _ F _'] : )/246[

_0889 8ACrei COMMUNICATION_ [9 70]

[15 1O] OPTION KNOCKOUT

DISPLAY n n

II\ i .....

:.. ... , .: ::.!?

215 73 "

[849] 1

3989 Jl_

[15701

II • Z_

FOR /2" CONDUIT

215530

[8_894]

UNIT #OUNTING

L

L 93835 _

[35941

POWER BOX 230V

//_CONTROLIPOWER 80X

J

380V,46OV,S75V

[748]

19000

_7/8" KNOCKOUTTO 8E

USED FOR LOCATING

FIELD POWER WIRING

33550

[1325]

Page 10

SERVICE AREA 121921480] FROM EACH SIDE OF THE UNIT

-- CTSA x

COOLER TUNE

RVICE AREA

l l

PDz PBz

! f

I4R$o, _gN_ol INN03,

[

COOLER VENT_

I/4" NTP

RUMP

LEAVING WATER

228137 N" VICTAULIC

[8982]

[1610]

COOLER DRAIN

314" NPT

WEIGHT 4AX WEIGH1 WEIGHT MAX WEIGHT WEIGHT 4AX WEINHI CENTER OF GRAVITY PUMP SUCTION (PS)

CU/AL ]U/AL PUMF CU/CU CUICU PUMP _CHX MCBX PUMP CGx COy X Y Z

Ib/_g Ib/kg IbiS9 Ib/kg Ib/kR Ib/kR M_ :INCH] _M :INCH: /=25 /:25 /=25

7990 8615 8594 9457 7119 8042 2846 993 18085 2819 609

30RB-12C 3488 9907 5871 4290 3229 3948 [9296] [5909] [712] [1!1] [24]

30RR-15C 8045 8958 9010 9953 7402 8825 2272 988 ]8085 2819 609

3649 4068 4087 4500 3358 3776 [8945] [5870] [712] [111] [24]

PN× 44092 ENTERING WATER [4563]

_IRIRGENTRANCERREA

COILGENVICEAREA

F CG X

198165

[7802]

_Ro:ILc??:ING

[17361 6" VICTAULIC

478]08

[18823]

PUHP DISCHARGE _PU) COOLER TUNE

Y

/=XR5 /=95 /=!25 CTNA x

1866_ 5912 2837 1447 8

[598] [154: [92] [570]

1386_ 5912 2337 1447B

[538] [_541 [92] [570]

2970.06

[H6 99]

_ERVICE AREA

MM :INCH]

188 03]

PUMP PACKAGE

ENTERING WATER

_SEE DETAIL

[1610]

39188

[i543]

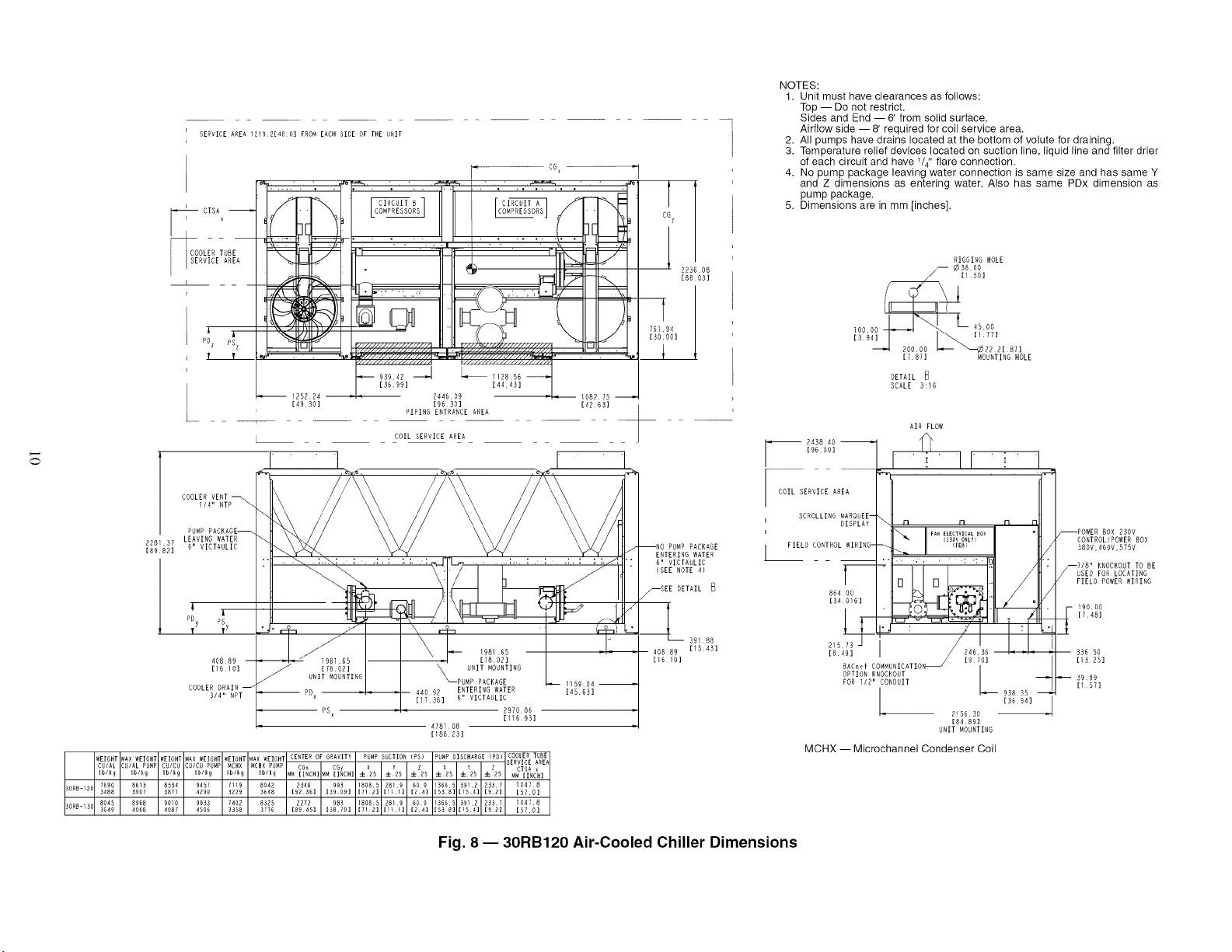

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

Airflow side -- 8' required for coil service area.

2. All pumps have drains located at the bottom of volute for draining.

3. Temperature relief devices located on suction line, liquid line and filter drier

of each circuit and have 1/4" flare connection.

4. No pump package leaving water connection is same size and has same Y

and Z dimensions as entering water. Also has same PDx dimension as

pump package.

5. Dimensions are in mm [inches].

RIGGING HOLE

(

R000N NI8.

.871 ,O NTIN8ROLE

DETAIL

SCALE 3;16

AIR FLOW

_ 243840IgDool I fl

COIL SERVICE AREA

SCROLLING HANOUEE--

: DISPLAY _ n

FIELD CONTROL WIRING- __

B64_

215 73 J / I

BAC_el

OPTION KNOCKOUT

FOR I/2" CONDUIT

MCHX -- Microchannel Condenser Coil

_ I1

COMHURICATION_ [9 701

2156¸30 [3H94] J

[8489]

UNIT MOUNTING

" 1

n n

L 93895 _

--POWER BOX 290V

CONTROL/POWER BOX

380V,4HOV,575V

7/8" KNOCKOUT TO BE

/--USED FOR LOCATING

FIELD POWER WIRING

[!48]

j 900N

3365o

[1325]

3989

[157]

Fig. 8 -- 30RB120 Air-Cooled Chiller Dimensions

Page 11

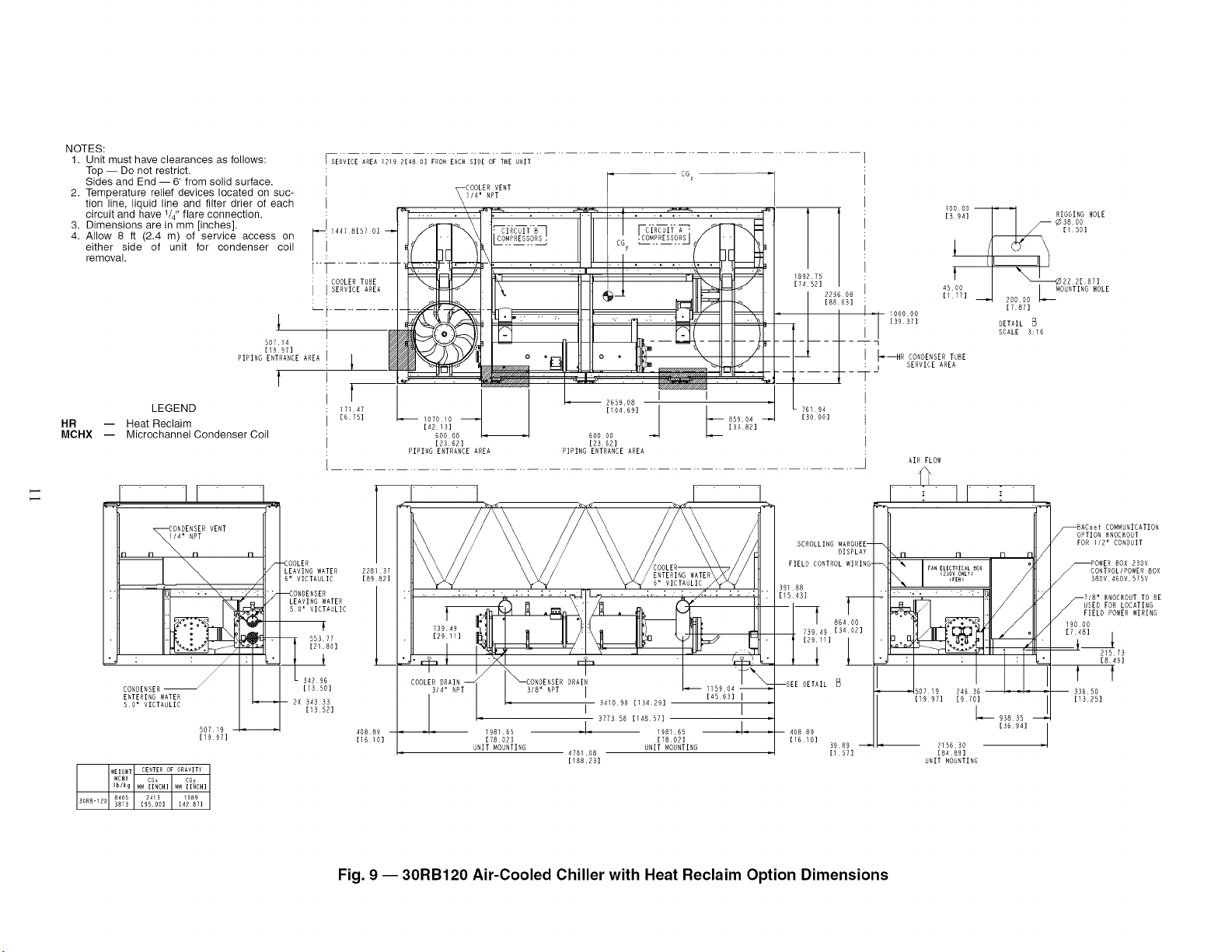

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suc-

tion line, liquid line and filter drier of each

circuit and have 1/4"flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on

either side of unit for condenser coil

removal.

PIPING ENTRANCE AREA

LEGEND

HR

MCHX --

Heat Reclaim

Microchannel Condenser Coil

R R n

,I...... r II" 'nI

WEIGHT CERTER OF GRAVITY

NCHX CGx CGy

Ib/kg [95001 [4287]

HOHH-120 8HOH 24_3 IOH9

3813

10_DE_;_8 VENT

_ OOLER

b07 19 40889

[19 97] [16101

M_ lINCH] MM lINCH]

• LEAVING WATER

[SERVICE AREA 1219 2148 HI FROMEACH SIDE OF THE UNIT

I

: _÷OOLE_p_ENT

I

.-!447.978,

[

: COOLER TUBE

I SERVICE AREA

50114

[199F]

LEAVING WATER 228137

6" VICTAULIC 18982]

SO' VICTAULIC

342 96

[1350]

17147

1675]

i

t

]

] 189275 1 ', 22 2[ 871

F --q

,_,. _-

107010 85904

[4213] [3382]

60000 60000

[2362] [2362]

PIPING ENTRANCE AREA PIPING ENTRANCE AREA

...... :,. : :- ,:,: :.:, :,:.,] :,. : : /.,.,: :.:, .,,.,

I29i'1 _, _ -

-+* Ii×'_O,0ENSER_PORAIN '_&_--

COOLER DRAIN

3/4;' NPT I 318" NPT I _ 1159 04

U

I

198165 ,,I, 198165 [

178 02] [78 02]

UNIT WOUNTING UNIT WOUNTING

[104,69]

I

341098 [134 29] I

I

377358 [148 57]

[188.23]

39188

D543]

--SEE DETA _

[45 63] I

i

15 94] _ RIGGING HOLE

174 52] [1 771 J 200 00_

2286 08

[88.03] i [7871

: [89.371 DETAIL _

I SCALE 3:10

1 _--HR CONDENSER TUBE

; I SERVICE AREA

[30001

4500 MOUN:rI RG HOLE

AIR FLOW

I _ I I_ " I

SCROLl NAROUEE--

FIELD CONTROL WIRING-

DISPLAY

I 86 0

738_9I3_:_21

[29 i] 1

.99..701

L-9_83s I

408 89

[1610]

3989

[15F]

215680 [30941 .

[84 89]

UNIT MOUNTING

8ACDei COWWUNICATION

_OPTION KNOCKOUT

FOR 1/2" CONDUIT

POWER 80X 230V

_CONTROLIPOWER BOX

/ 380V,460V,575V

USED FOR LOCATING

718" KNOCKOUT TO BE

FIELD POWER WIRING

19000

1748]_

{' 21573

1849]

f f

33650

[1325]

Fig. 9 -- 30RB120 Air-Cooled Chiller with Heat Reclaim Option Dimensions

Page 12

SERVICE AREA 1219 2[48 O] FROM EACH SIDE OF THE UNIT r HOD OO ]A

m,. ,KAK,_/ .r I _°.

=78 i 8765 •

i! _O_=_ETX_EAII1°1_ I'1/ 11"1 4F_

,JJ

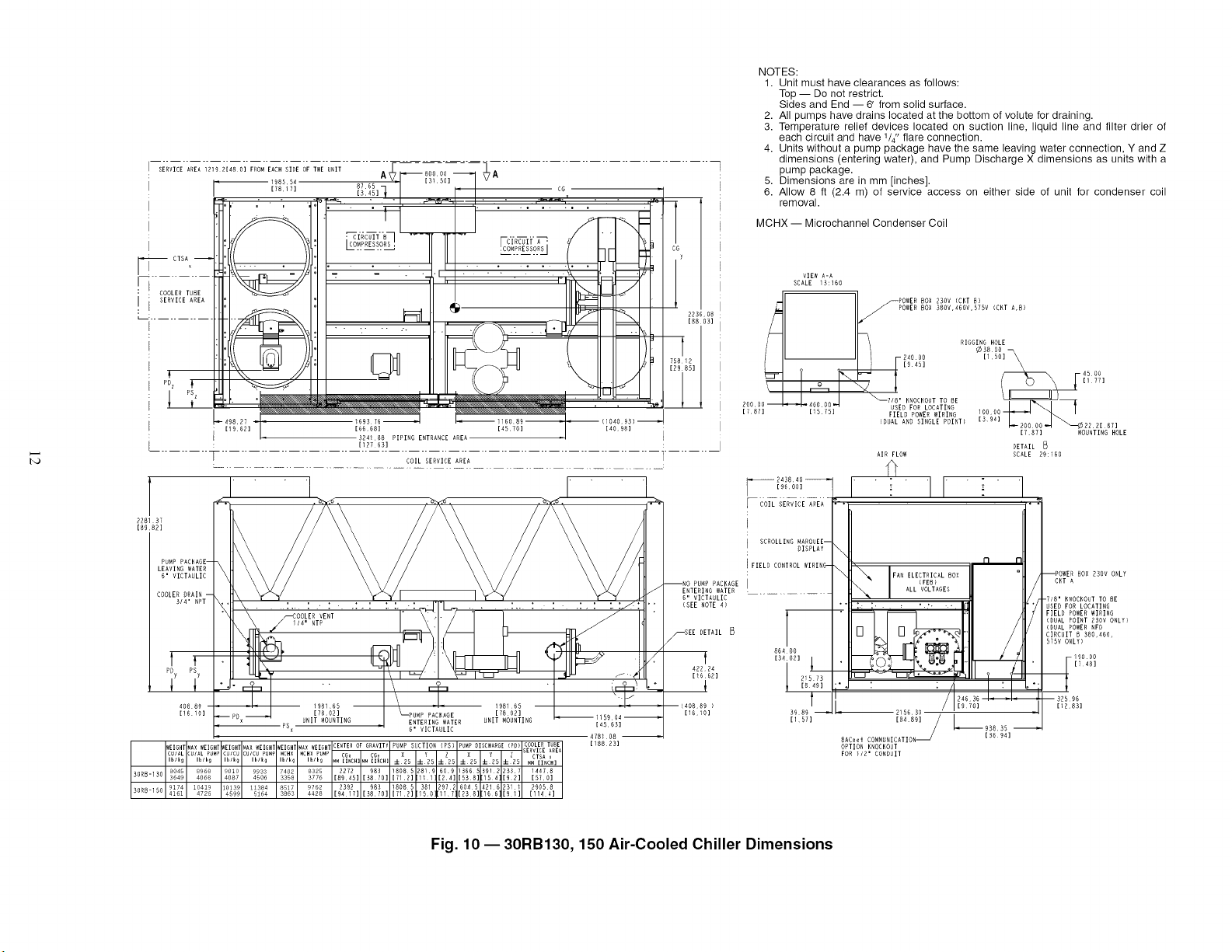

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. All pumps have drains located at the bottom of volute for draining.

3. Temperature relief devices located on suction line, liquid line and filter drier of

each circuit and have 1/4" flare connection.

4. Units without a pump package have the same leaving water connection, Y and Z

dimensions (entering water), and Pump Discharge X dimensions as units with a

pump package.

5. Dimensions are in mm [inches].

6. Allow 8 ft (2.4 m) of service access on either side of unit for condenser coil

removal.

MCHX -- Microchannel Condenser Coil

VIEW A-A

SCALE 13:160

POWER @OR 3DOV,460V,575V (CRT A,8)

Co

r

!-"- 498.2F • 1693 76_ _ 116089 1040 9_

: [19 E2] [GR 68] [4D 70] [40 98]

i " H241 88 PIPING ENTRANCE AREA

[127 63]

PACKAGE

ENTERING WATER

6' VICFAULIC

/

i 45 OR

IJ TI

PUMP PACKAGE

\

._, _J _'_"HHOGHONTTOOE__

200 O0--

[787]

RVICE AREA =

SCROLLI_,GAAROUEE--

DISPLAY

FIELD TROL WIRING-

.....

21573

[849]

39 AR

[15/]

POWER DOX D3OV (CKT D)

J ! 24000 [150]

Q I1 77]

[ 5 51 lOO DO

;De USEDEONLOGAFING__

[945]

FIELD POWER AIRING

(DUAL AND SINGLE POINTI [394] 22 2[ 87]

AllOW SCALE 29:160

RIGGING HOLE

¢3800_

[787] _OUNTIRG HOLE

DETAIL

\

--ROW 230V ONLY

CKT A

-718' HNOCKOUT TO BE

USED FOR LOCATING

FIELD POWER WIRING

(DUAL POINT 230V ONLY)

(DUAL POWER NFD

CIRCUIT _ 380,460,

575V ONLY)

• _;Q_C2f",._:_J' 1_] "

-190 DO

32596

[1283]

_AC_i COAAUNICATION_

OPTION KNOCKO T

FOR )/2' CO@IT

'H_DR'/ L____3D3D_

[36 941

Fig. 10- 30RB130, 150 Air-Cooled Chiller Dimensions

Page 13

#

LEAVING WATER

i_1" VICTANLIC

ORDENSER

\

I

: .I COOLERTUBE

!iSERN'BBAREA

:6O0OO

1[BH H2]

PIPING :ENTERANCEAREA

I

it

:l/H OO

I IRBHI 123 HB] 123B21 .

L .......... !IP_N.!ENT_RANC!.AR__EA.................... P__'P.I._OE;'.TBRjR.?E__'R.E.'- .............................. i

1 I

LEGEND

HR -- Heat Reclaim

MCHX -- Microchannel Condenser Coil

POWER BOX H3OV {CRY B}

POWERBOX 380V,gHOV,DYHV [CRT A,B)

D31

_/ _BSED FOR LOCATIRG

i I/8" KNOCKOUT TO BE

: HOOOOJ_-J 4OOO0 _ FIELD POWER WIRING

_..% [78Yl [15751

'-I RIGGING HOLE

" ' i_]\BETAIL D

_REAI VIEW A-A [IHO] SCALE

I SCALE 13:IHO

[31511 AllOW [7871 MOUNTING HOLE

{DUAL AND SINGLE POINT)

38 OO _

lOO nn_ _1 L4B OR

[_ 9_] [177]

II

POWER BOX 23ON ONLY-

7/8' RNOCROBT TO BE --

-SCROLLING RARQBEE FIELD POWER WIRINGDISPLAY {DUAL POINT 2HOV ONLY)

n n n n

ALL VOLTAGES

_'_ FAN ELECTRICAL(FEB)90X /

CRY A

USED FOR LOCATING

29:160

3DR WEIGHTCERTEROF GRAVITY8814

_-130 HRR8

96 90

19 9HI

49

11]

.+

39 89

[1 :::_t C.....ICATIOR_ UA]T NFLNTINO L'_HS8 9H

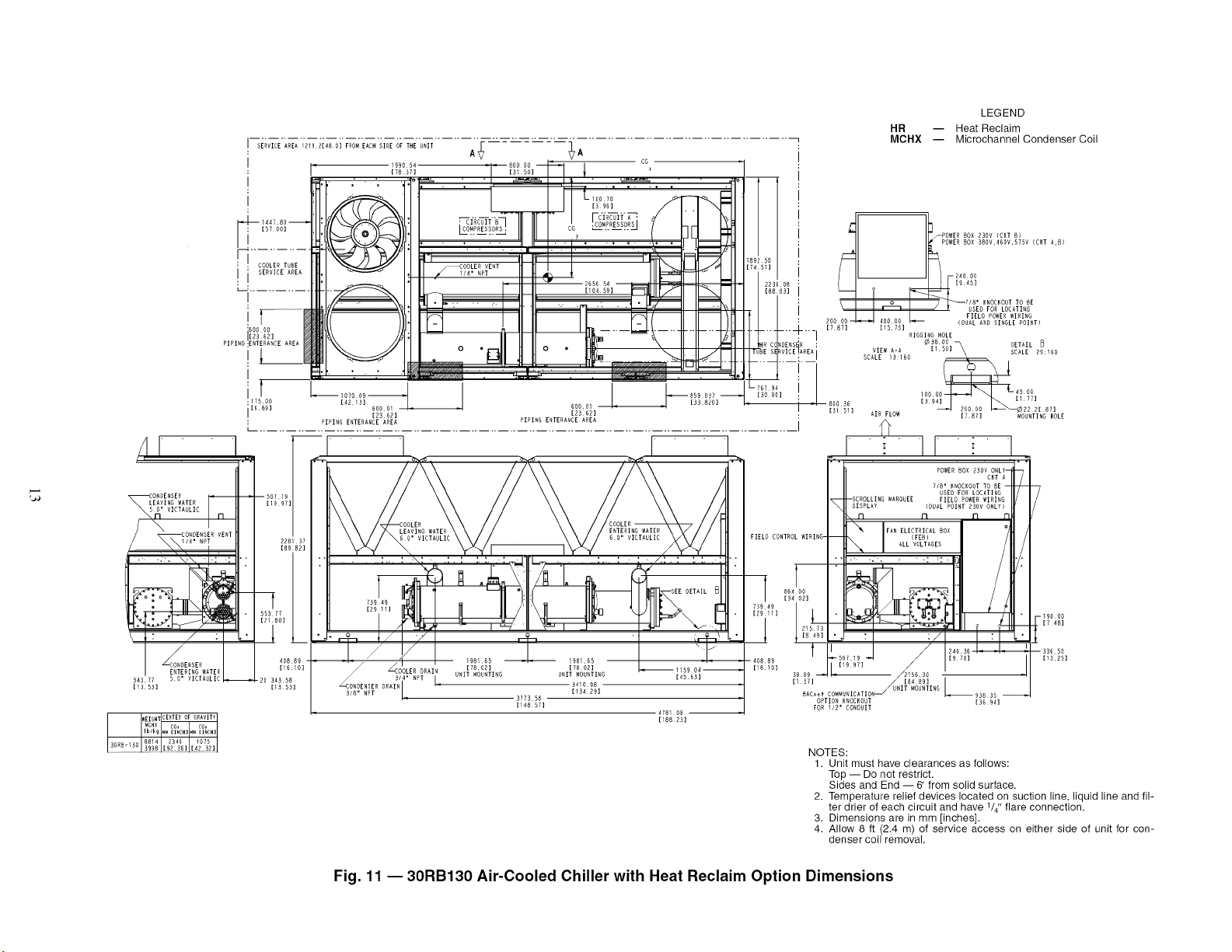

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suction line, liquid line and fil-

ter drier of each circuit and have V4" flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on either side of unit for con-

denser coil removal.

[3B 941

• -190 09

[1 48]

33659

[192§]

Fig. 11 --30RB130 Air-Cooled Chiller with Heat Reclaim Option Dimensions

Page 14

SERVICE AREA 12_92140H] FROM EACH SIDE OF THE UNIT

7A

LEGEND

HR -- Heat Reclaim

MCHX -- Microchannel Condenser Coil

[H440]

PU¢_ 290880

80X DDOV (CRT 8)

POWER 50X DBOV,46OV,RTRV (CHT Ar5)

I

SERVICE AREA

i COOLER TUBE

KNOCKOUT TO DE

USED FOR LOCATING

I--

OOOOO

[BR6B]

78658

[R979]

SOU B6

[31Sl] AIR FLOW

RIGGIRG HOLE

E

FIELD CONTROL WIRING POWER 80x 8ROY ONLY-

SCROLLING t_AROREE 718' HI,OCEO T TO 8E

81SPLAY USED FOR LOCATI G

Z

OOLER

LEAVING WATER

.. X .:/. : .. : -. ,:,: :.:, .-:,:,,,_j .. ,;,., ; ,- ; -,/,.': ; ' ;, ,.'_'-_

8ETAIL _

8H4OO

[34 OR]

"_ lq Fl Fl {q

.; .......

.. i

H4R!.... DDH-

GE'VENT"'RG'I I ,,.....

1/4" NPT _DX 343 58

WEIGHT CENTER OF GRAVITY

- _ 9929

30_8-1Rv 4504

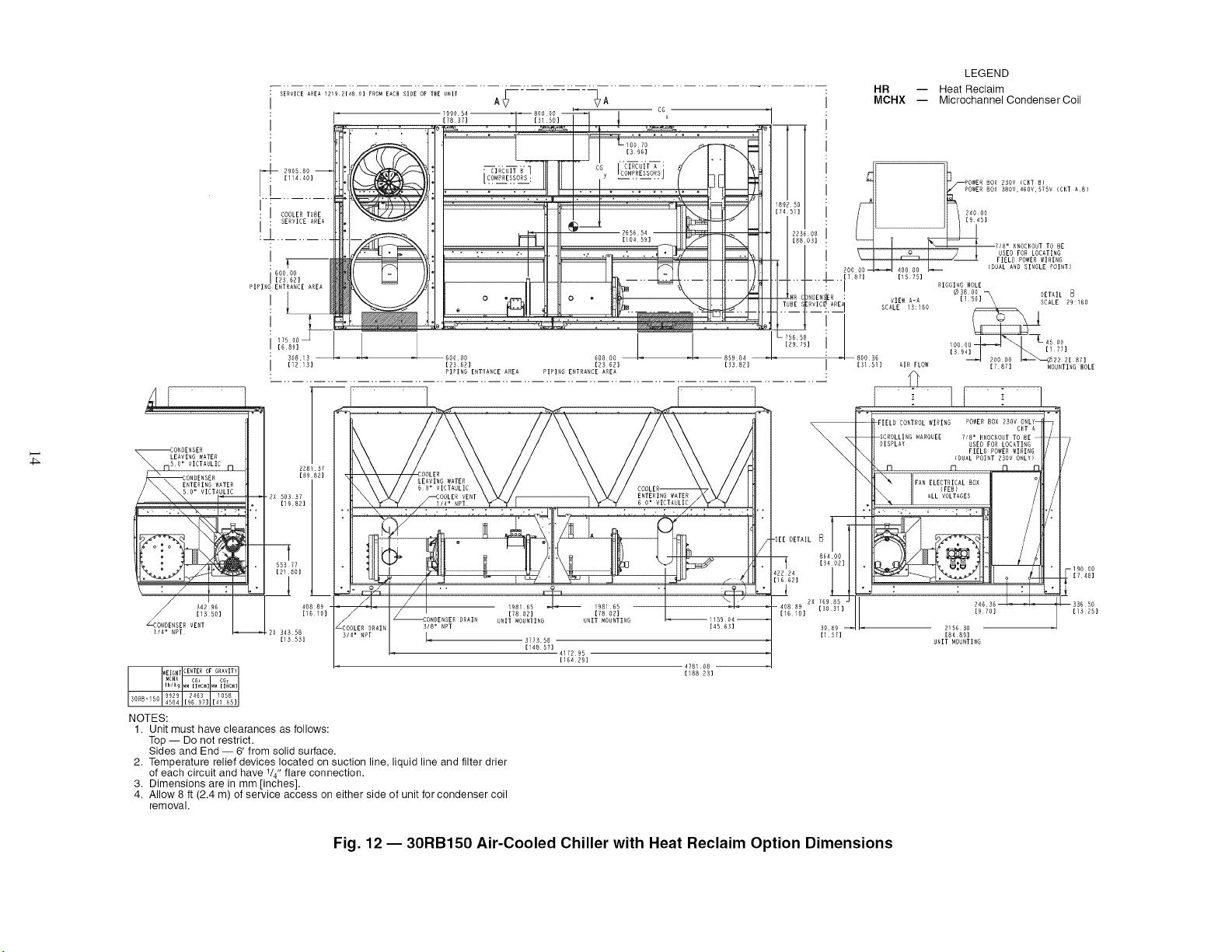

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suction line, liquid line and filter drier

of each circuit and have 1/4" flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on either side of unit for condenser coil

removal.

[13 53]

I o / iH81HR _HSlHR

OLER 0RAIR 3909

4' NRT I= [157]

/

_ONDENSE8 DRAIN UNI_T8 021 [70021

Of 8" NPT [45 BD]

MOUNTING RNIT MOUNTING _118904_

3773 58

[14887] 417RRH

[16429]

478100 --

[188 8D]

_- 40889 2x T6985 -

[161G]

[HO31]

2186H0

[8469]

UNIT MOUNTING

FIELD POWER WIRING

(DUAL AND SINGLE POINT)

RDOO _ UFTAII

5O ....

[ ] SCALE 29:160

Do0 00 I--,_'-_72 8[ 8T]

[78T] MOUNTING BOLE

GET A '

FIELD POWER _VIRING

(DUAL POINT 2BOY ONLY)

/

24636--

[H7O]

--190 OR

. [748]

1

--33650

[IDZ$]

Fig. 12- 30RB150 Air-Cooled Chiller with Heat Reclaim Option Dimensions

Page 15

SERVICE AREA 121921480] FROM EACH SIDE OF THE UNIT

I

I

157001

r

r_ 14478

COOLER TUBE

SERVICE AREA

RSz R9z

I I

76951

[3030]

i [58421 [57341

I COIL SERVICE AREA

• "- " "- :. rrl C- "-"

E

==CT_ l_///_./_///////////////////_.////////////////_///y/////_/_..-I_////////A

i..... 7

I I

AV &

].............................

. .B3H3_ L----.sogs

3212 K3 PIPING EHTRAHCE AREA

[12H 47]

,t

@

99325

[78 47]

<DUAL AND SIHGLE POIRT)

l

CGy

1

R2_ 08

[He U3] I

t

75558

[29 751

1

I

, _ 249840

[9HOO]

COIL SERVICE AREA

//8" KAODKOUTTO BE _ VIEW-A-A

SED FOR LOCATING

FIELD POWER WIRIG

: 24000

200 D0 4,JNOO OR L--" "'Z_""",,._SEE DETAIL E}

[7BK] [1§ l§]

RETAIL B _/A] / [ 50]

SCALE 3:16

[787]

AIR FLOW_

_1 i' II i'

POWER BOX 2SOY {CKT R)

POWER BOX

380V,46OV,575V (CKT A,B}

19 45]

RIGGING HOLE

/- ¢3800

228137 LEAVING WATER

[89 H2] 6" VICTAULIC

WEIGHT_AX WEIGHT

CUIAL UUIAL PU_P

Iblk_ Iblk9

30RB-_40 10264 1151_

315AIB,330_ 4666 523Z

KORR-_IO I0_0_ 11846

50A•345A/N,KGOJ4B19 5385

WEIGHT_AX WEIGHT WEIGHT AAXWIIGBl CENTER OF GRAVITY PUMPSUCTIO_ PU_APUISCBARGE(PR)

CU/C_ ZU/CU P_MP _CHX _ACHXPU_P CGx CG_

...................................... !25 ±!_5 ±!25 =H!25:1:!25

H4!2 _n7 94/5 107z0 N045 994 BOB 4 5SRlo] NN/ 2 NR392 42164 3_114

5215 5TNt 4297 4860 [120 66] [39 13] IT1 2] [1 [11 7] [_48] [166] [91]

]807 3052 9799 11044 _la 978 808 4; 381 297 2 885 92 4Rl_a 23114

5567 5933 4443 5009 [122 591 [3051 [71 21 [1R0] [11 71 [K481 [1561 19;1

MCHX -- Microchannel Condenser Coil

SCROLLING MARQUEE--

DISPLAY

FIELB CONTROL WIRING-

-_

3/A" RPT)

OOLER VERT I14' RPT i"

,;i. ,-_ _- _..,_ ' 4,

408 89 - _!- R38[_\305, H" VICTA LIC 276_ 30[8184' _1_

[i6 10] IRA 01HI I [i0R 03]

UNIT MOUHTIRG I UNIT MOUNTING

RSx _ I _ 46406

[235 2HI

[ H3 94]

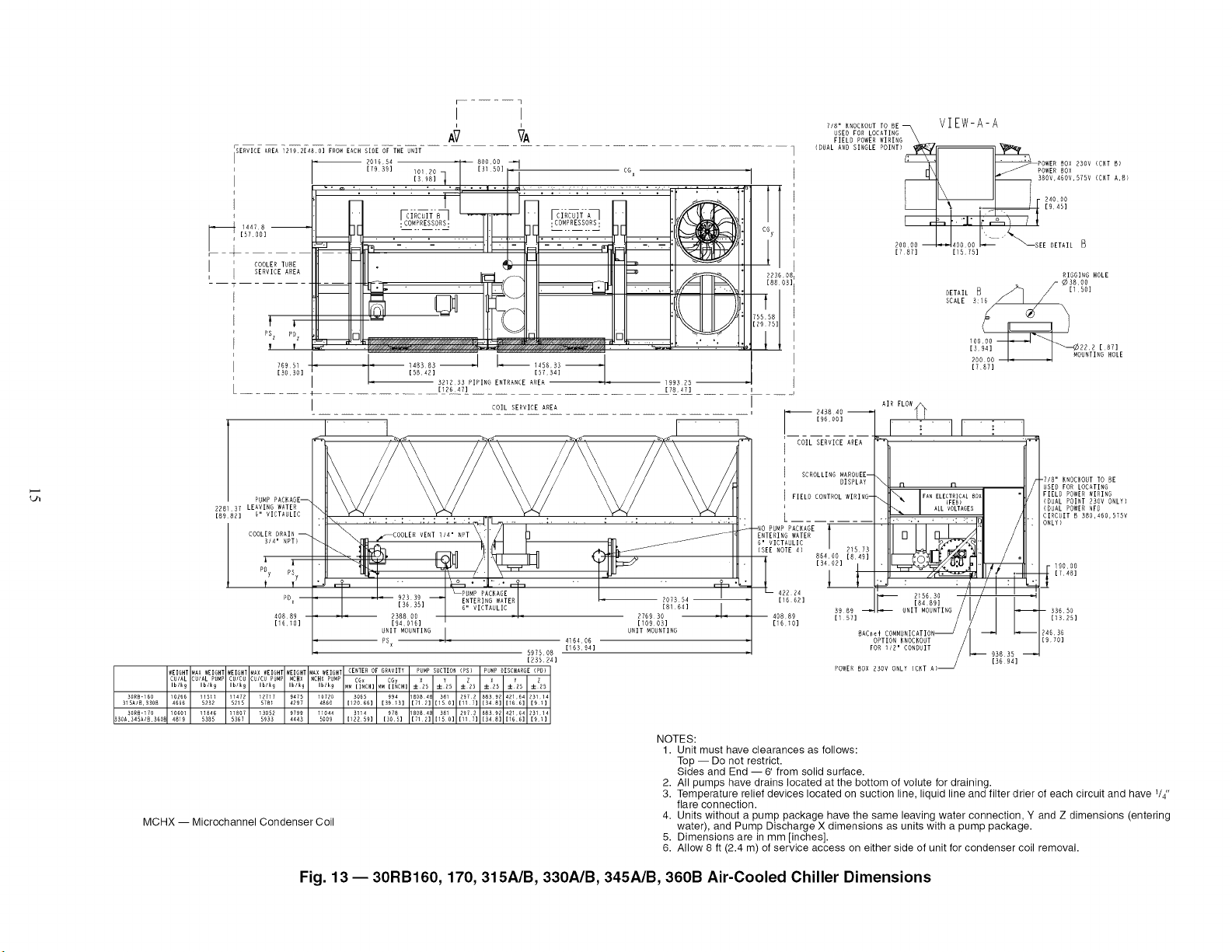

NOTES:

1. Unit must have clearances as follows:

2. All pumps have drains located at the bottom of volute for draining•

3. Temperature relief devices located on suction line, liquid line and filter drier of each circuit and have VA"

4. Units without a pump package have the same leaving water connection, Y and Z dimensions (entering

5. Dimensions are in mm [inches]•

6. Allow 8 ft (2.4 m) of service access on either side of unit for condenser coil removal•

Top -- Do not restrict•

Sides and End --6' from solid surface•

flare connection•

water), and Pump Discharge X dimensions as units with a pump package•

1 WATER

H' VICTAULIC

{SE NOTE 4)

422 24

[16 HE]

40889

1i6101

86400 [84R]

3989 _ _ UNIT MONTIHG

[ KK]

POWER BOX 230V ONLY (CHT A)_

Fig. 13- 30RB160, 170, 315A/B, 330A/B, 345A/B, 360B Air-Cooled Chiller Dimensions

n n

FAN ELECTRICALBOX

(FEB)

:._ I ALLVOLTAGESI

It_ : °,

215630

BAC_¢i COFA_AUAICATION

OPTION KNOCKOUT

FOR 112' CORBUIT

93835

[36 94]

-7/8" KNOCKOUT TO BE

USED FOR LOCATING

FIELD ROWER WIRING

(DUAL ROIHT 230V OHLY)

_DUAL POWER NFD

CIRCUIT R 380,4HO,KYSV

OHLY)

[148]

- 9000

-- 33650

[1325]

24636

[gYo]

Page 16

CONDENSERS

ENTERING WATER

80' VICTAULIC

2X 34333 --

[13 521

WEIGHT CENTER OF GRAVITY

_CHX CG_ CGy

Ib/_9 _M [l_CN] _M lINCH]

30RN-160 I0991 3124 _001

3_SAIB,3308 4986 [122991 [394]1

30RN-I?O 11315 3168 98_

330A,345AIB,360_ 5_33 [124741 [38821

2X 503 31 228

[i0 82] [89 8_]

-_ONOENSER

LEAVING WATER

50" VICTAULIC

583!81

8ol ,

343_8_

113,841

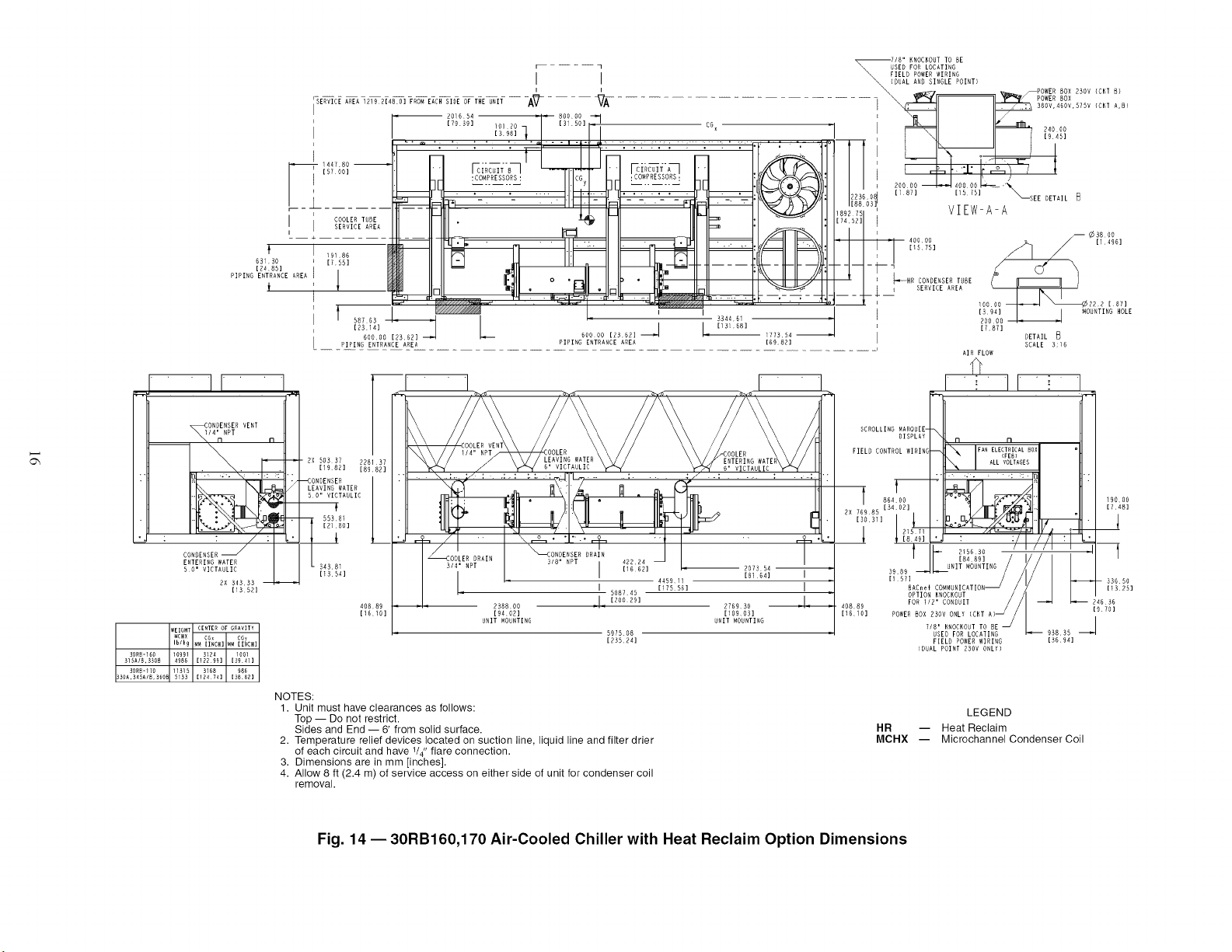

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suction line, liquid line and filter drier

of each circuit and have VA"flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on either side of unit for condenser coil

removal.

K/4' NRT

Fig. 14 -- 30RB160,170 Air-Cooled Chiller with Heat Reclaim Option Dimensions

SCROLLING _AROUEE-

FIELD CONTROL WIRING

864!00

2x 76985 [34 0R]

.08_1I L

40889

[1610]

HR

MCHX

DISPLAY

RAChel

OPTION KNOCKOUT

FOR 1/2' CONDUIT

7/8' KNOCKOUT TO BE

USEO FOR LOCATING

FIELD POWER WIRING

_DUAL POINT 230V ONLY)

LEGEND

-- Heat Reclaim

-- Microchannel Condenser Coil

:i_

L 83650

93835 _'J

[3094]

24536

[970]

19000

[9A81

[13251

Page 17

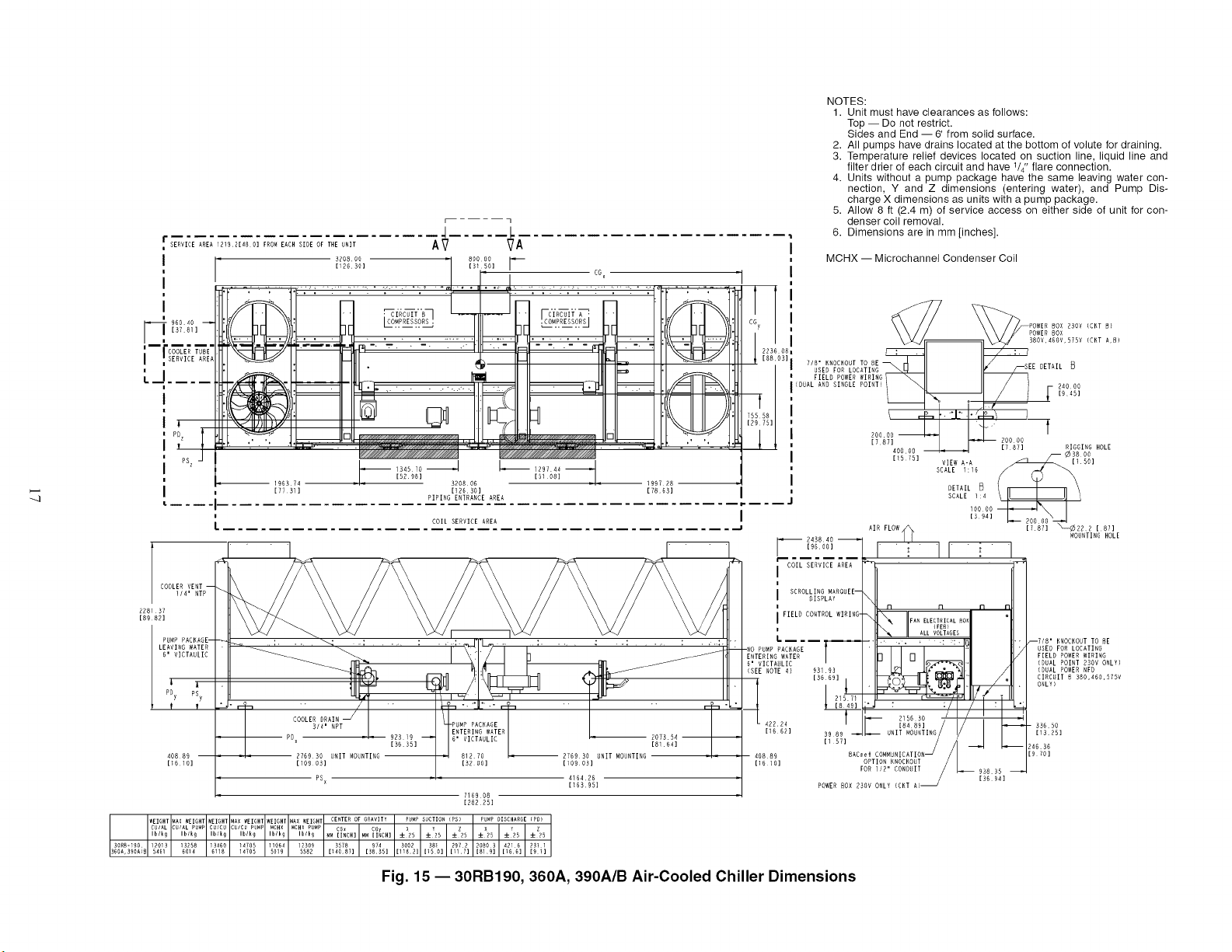

r SERVICE AREA 1219 2148 O] FRON EACH SIDE OF THE £,NIT

! "

I

!

I

[3F 811

F! 96040

I [SERVICE AREI

I

LJ

!

I

|

==.- -=r

I,

iP:I

!

PSz J

I

|

I

L

b .i

-- 196374

[F7311

F--

•I..... ]

A_7 VA

320806 199728

[12630] 17863]

PIPING ENTRANCE AREA

COIL SERVICE AREA

12974.__I[PE98] [5108]

\'_-tFt!-J/

/€::::=11 II:::::_\

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End --6' from solid surface.

2. All pumps have drains located at the bottom of volute for draining.

3. Temperature relief devices located on suction line, liquid line and

filter drier of each circuit and have 1/4" flare connection.

4. Units without a pump package have the same leaving water con-

nection, Y and Z dimensions (entering water), and Pump Dis-

charge X dimensions as units with a pump package.

5. Allow 8 ft (2.4 m) of service access on either side of unit for con-

denser coil removal.

6. Dimensions are in mm [inches].

, MCHX -- Microchannel Condenser Coil

"1 !

C 7 POV,'ERBOX

2236 08!

I [88 03]| 7/8' HROCHOUT TOIE _

l USED FOR LOIATI G

I FIELD POWER WIR HG [-- DETAIL B

(DUAL AND SINGLE POINT) _ 2NOOO

I ' L ,R,P,

_:_, ! _-

// I _o0oo

_ I [7871

I

I

.J

(SEE NOTE 4)

!

I

!

J

[9DOO]

243840

l COIL SERVICE AREA

!

l SCROLLING MARQUEE--

DISPLAY

i FIELG COHTROLWIRIRG-

!

L .....

WATER T

93193

IRK R9] 1

I 21571

[8491

SCALE 1:16

DETAIL

SCALE 1:4

f

8AC_¢i

OPTION KNOCKOUT

FOR i12" COHDUIT_

POWER BOX _3OV ONLY (CKT A)

_80V,NEOV,PlSV (CHT A,B)

_7/8' KNOCKOUT TO BE

USED FOR LOCATING

FIELD POWER WIRING

(DUAL POINT ERPV ONLY)

(DUAL POWER RFD

CIRCUIT B 38D,NHO,575V

ONLY)

- 33650

[1325]

24636

[R FO]

RIGGING HOLE

-- ¢380P

MOUNTING HOLE

[87]

Fig. 15 --30RB190, 360A, 390A/B Air-Cooled Chiller Dimensions

Page 18

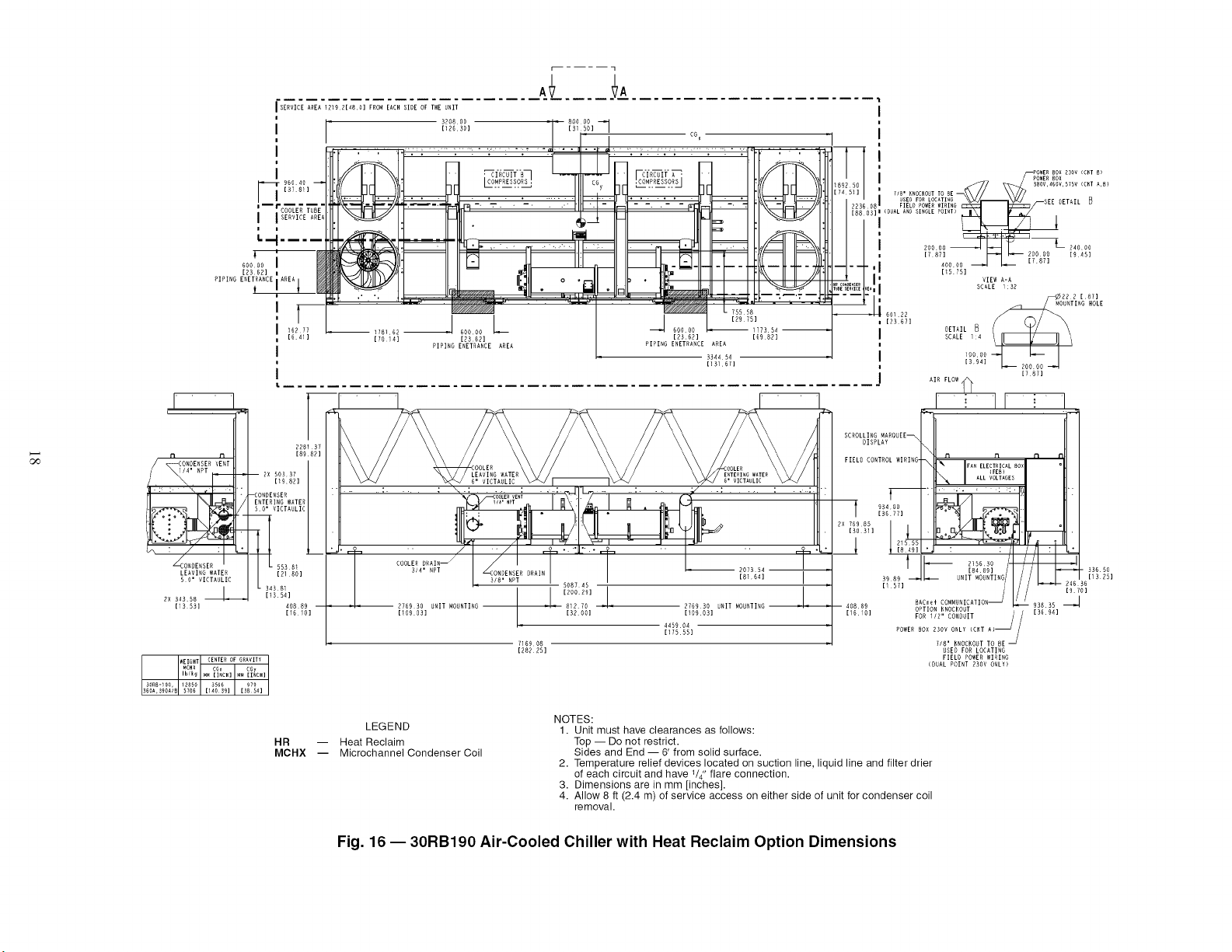

A?

i

CG

_i 60000

OR,DENSER VE'_T

_ONDE_SENI

WEIGHT CENTER OF GRAVITY

_CHX CG CGy

Iblk9 H_ [I_CH] MM [I_CH]

360A,_90A_ $706 [140_9] [385_]SORD-_90 128S0 3566 _79

COOLER DRAI_S

LEGEND

HR -- Heat Reclaim

MCHX -- Microchannel Condenser Coil

3344 54

[13167]

[28225]

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suction line, liquid line and filter drier

of each circuit and have V4" flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on either side of unit for condenser coil

removal.

SCROLLING MAROVEE_

FIELD CONTROL WIRI_6

T

-l!......

9_400

[SGlF]

39 8

408

[6

POWER BOX 230v ONLY (CNT A)_ I

[394]

o

BAC_el COMF'U_ICATIO, _ 93835

OPTION RROCKO_T _ [3S 94]

FOR IE" CONDVIT I /

7/8" RNOCKOVT TO BE _

USED FOR LOCATIRG

FIELD POWER WIRIRG

(DUAL _OINT 2_OV O_LY)

[7 87]

[9 70]

Fig. 16- 30RB190 Air-Cooled Chiller with Heat Reclaim Option Dimensions

Page 19

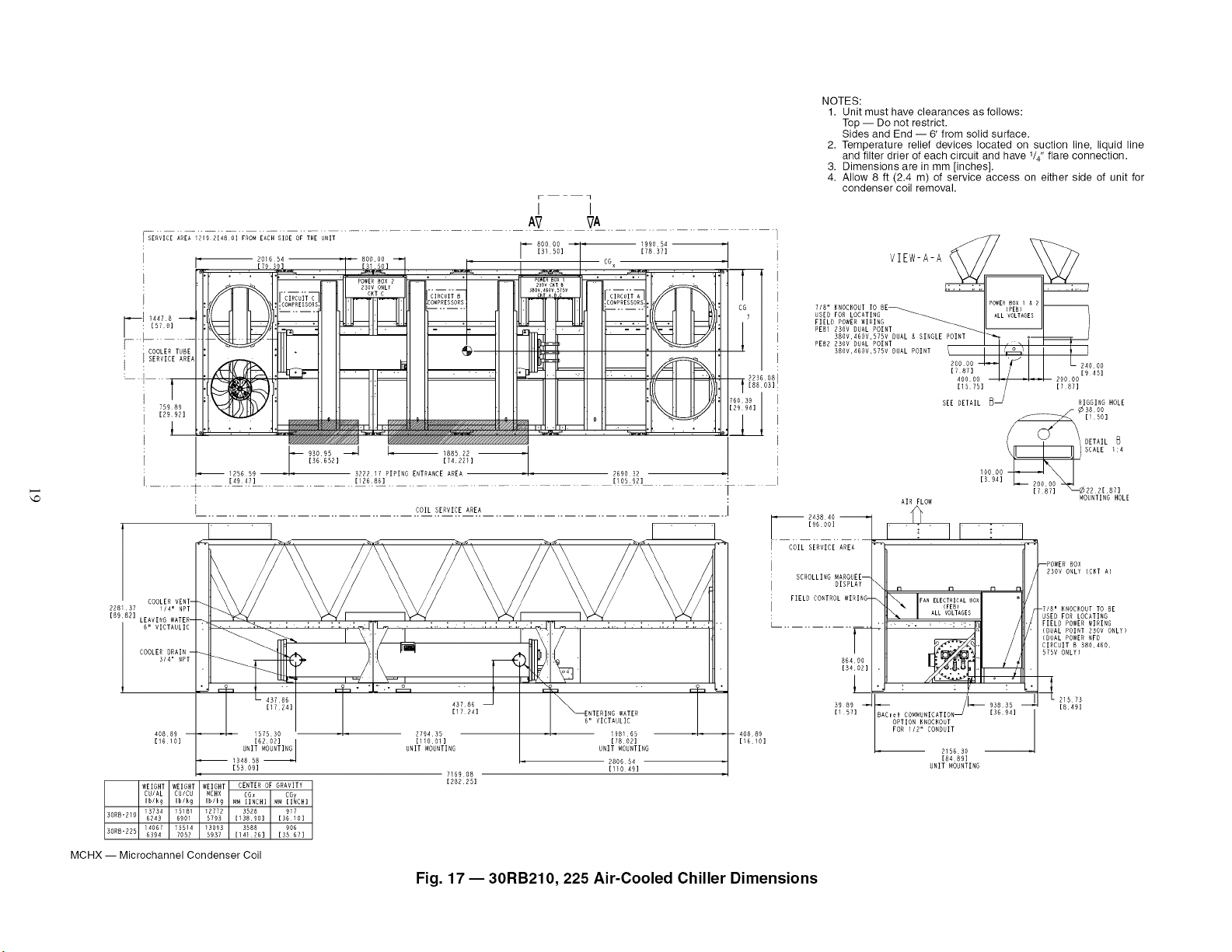

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict•

Sides and End -- 6' from solid surface•

2. Temperature relief devices located on suction line, liquid line

and filter drier of each circuit and have V4" flare connection•

3. Dimensions are in mm [inches]•

4. Allow 8 ft (2.4 m) of service access on either side of unit for

condenser coil removal•

I SERVICE AREA 1219 2148 O] FROM EACH SIDE OF THE UNIT

I"_ I 14478 L_ .....

: COOLER T

J ISERVICE_AI

i 1256 59 _22217 PIPIR¢ ENTR%RCE AREA 2690 K2

_ _ _ .R_:_.................................................................................. _!_9_,....... __..................

........... COIL SERVICE AREA I

COOLER

228137 i/4' NPT

[8982] LEAVIRG WI[ER-

6" VICTAULIC

COOLER

3/4'

40889 157530 • • 279435 198105 40889

[1E1O] [6202] / [1i001] [7802] [i6iO]

WEIGHT WEIGHT WEIGHT CENTER OF GRAVITY

CUIAL CU/CU MCHX CG CGy

Ib/k9 Ib/k9 Ib/kR W_ [I_GH] MW LINCH]

KOR_-210 _37S4 _5_81 _2772 3528 9H

624D 6901 5793 [13890] [3610]

_4067 _5514 _3093 3588 906

KORK-225 6394 7052 5937 [_4_26] [3567]

MCHX -- Microchannel Condenser Coil

• • L 4378H

UNIT MOUNTINGJ UNIT MOUNTING UNIT MOUNTING

-- IR_R _R 280654

1530D] [I1049]

[3i 50]

POWERBOX 2 _" .....

2NOVWRLY ......

• - CO_4PRESSORS

CIRCUIT H

_//_///A. i i. v///////_, _//////////////////////////////////_ TUT--

K3OD_--4 I_ ,8Ks22

[DO 652 ] [74 221 ]

[12686]

[1724] 43786 J \_

[17241 _ENTERING WATER

I169 08

[28225]

POW[R BOX I

2_OvCKIB

_OV,_S_VmDV

Fig. 17- 30RB210, 225 Air-Cooled Chiller Dimensions

199054

[78 31]

t_

• x

• .. _T _ - ..

,CO'_PRESSORS,

6" VICTAULIC

223(

700 39

: SCROLLING MAROUEE--

i DISPLAY

i FIELD CONTROL WIRING-

L ........T

VIEW-A-A

718" KNOCKOUT

USEO FOR LOCATING

FIELD POWER WIRING

PE812NOV DUAL POINT

(_¢38 O0

I00D01394]_SCALER2 2[ 8Y11:4

AIR FLOW MOUNTING HOLE

Do, I ' II I

COIL SERVICE AREA

--P( B0X

230V ONLY {CKT A)

n n n n /

........ "" ' : : " Ib _ / FIELD POWER WIRING

80400

[34102]

3989

[157]

BAC_ef COMMUNICATION _ [36941

ALL VOLTAGES -7 8' NNOCKOUT TO BE

•. CU IT B 380,460,

.. 57! ONLY)

/1_ I 2_sKs

OPTION KHOCNOUT

FOR 112" CONDUIT

215HS0

[8489]

UNIT WOUNTING

/

/

USED FOR LOCATING

(DUAL POWER RFO

93835 _ 8 49

[i 50]

DETAIL

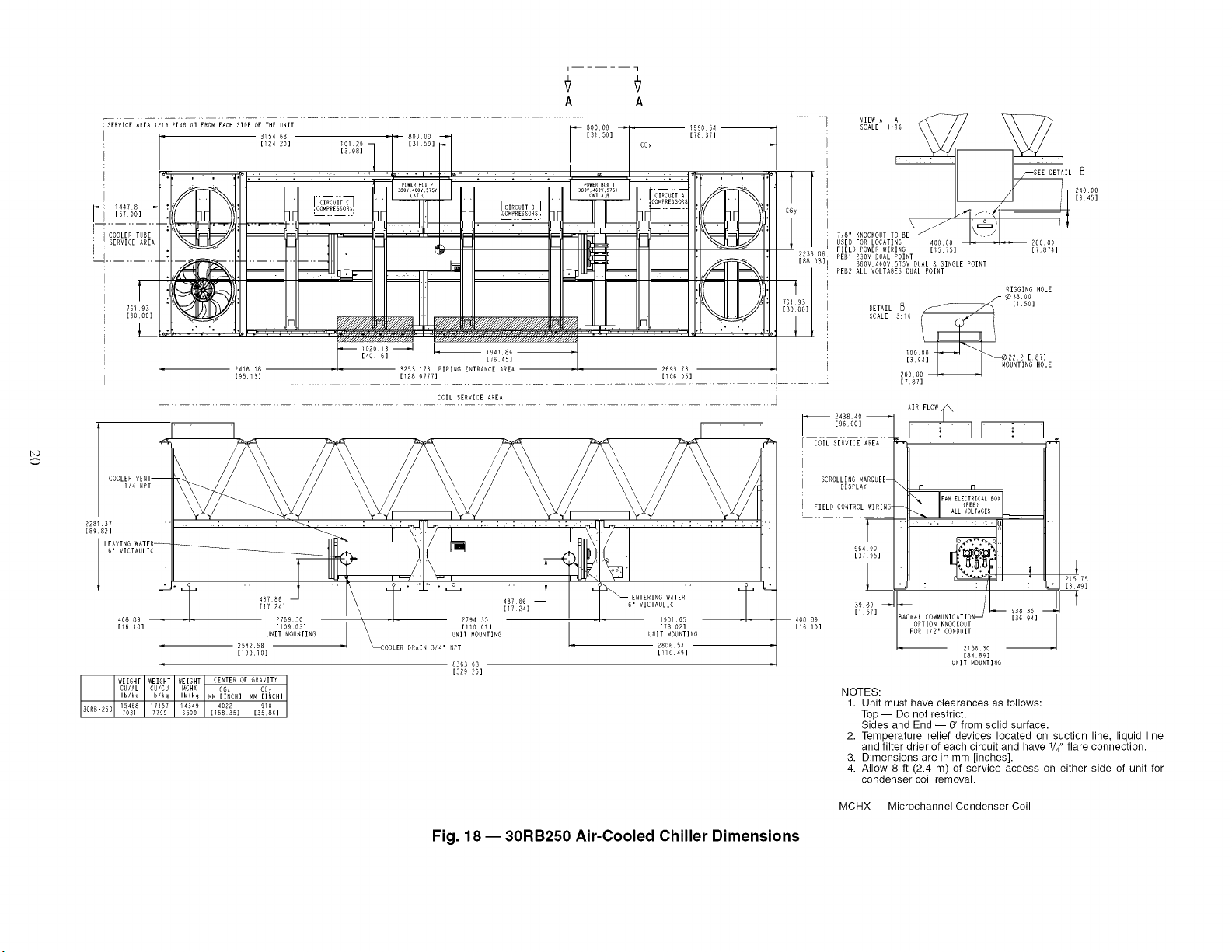

Page 20

A A

_SESERVICEAREA 9219214H0] FROM EACH SIDE OF THE UNIT 990 54 SCALE I: 6

I • 3_DA_3 .... 80000_ _"

12429 :01 2O 7 3150 = =,

I : "'" ; ''_i ..... "'" :': "J" "'" ; SEEDETAIL 6

i _ _ 24000

4478

['_[5700] ]E : '- : ]E ............. CGy

::: ttl/ 7/8" KNOCKOUTTO BE_ '\'J' '

........................ [88 03] I PEB1 POINT

_ _ PEB2 ALL VOLTAGES DUAL POIHT

FIELD POWER WIRIHG [1575] [787A]

08II USED FOR LOCATING 40000 ,_ _,::, 20000

380V,A6OV,D75V DUAL & SIHGLE POIHT

] DETAIL _ _ .... _._ [150]

/- _3800

RIGGIHG HOLE

" [9513] [1280777] [10605] i 20000

.............................................................................................................................. [787]

241618 3253173 PIPING ENTRANCE AREA 269373 UNTING HOLE

[4016] [7645] [3 ]

.................................. _.olA S!R_!A_ER....................................

I---;::!°:; :LO,.f ......

I,O

SGROL ;#L :ROUEEq'-I10 n II

21575

[849]

f

[329 26]

40889

[16 10] OPTION KHOCHOUT

[1571 ef COFA_UHICATIOH [36941

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suction line, liquid line

and filter drier of each circuit and have V4" flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on either side of unit for

condenser coil removal.

FOR /2' EOt_DUIT

UNIT MOUNTIHG

MCHX -- Microchannel Condenser Coil

2 56 30

[84 89]

_ 93835 _

Fig. 18- 30RB250 Air-Cooled Chiller Dimensions

Page 21

• i

SERVICE AREA 1219 2148 O] FRO_ EACH SIDE OF THE _,RIT

I

j [79 3D] [ 09 53]

i: r_ZO16SA R:GRDO ,,1, ,1 HGDOD

[31 50]

I .:_.E3D6 .:oH,o:.=,o, . :. : -;,

CIRCUITC_ ...... "CIRCUIT_ I CIRCUITA_

VIEW A - A

SCALE 9:160

I

T

CGy

POWER ELECTRICAL i0_

SEE DETAIL B

" 2097 Al 3227 68 D,o_i, r_TD^_rr _Dr_ A23i 79

I

: COIL SERVICE AREA

L

[82 56] [27061 [16H g ]

I

..... j__ ,__

........... j

1

t

75939

[299D:

1

I

7/8" KNOCKOUT TO BE 40606 2O0O0

223608 :

[66 [

F_R_LOCATING [15 75] [787]

SED

FIELD POWER WIRING

PEG1 230V DUAL POINT

: 380V,466V,S75V DUAL & SINGLE POINT

PEG2 ALL VOLTAGES DUAL POINT

SCALE 9:40 [1501

DETHIL_

,DoDo4---_'--..i q

[394] _- 20000 --"4_ '_ (

RIGGING HOLE

4500

r"TlI [_j !_

' MOUHTING HOLE

AIR FLOW

_..:-_.!Ii6°!!_..- - _ _

I'D

COILSERVICE_REA_ _

SCROLLING"_RONEE--.II II

OISRLA,\LO 0 tl

L: FIELD CONTROL.......WIRING- _ ray....._L_C_IC_LBOX _I l

AG_6R 6Kc0. HIRATION ?_2_, J _;!I_D_

h_ 215630

[84691

UNIT MOHRTING

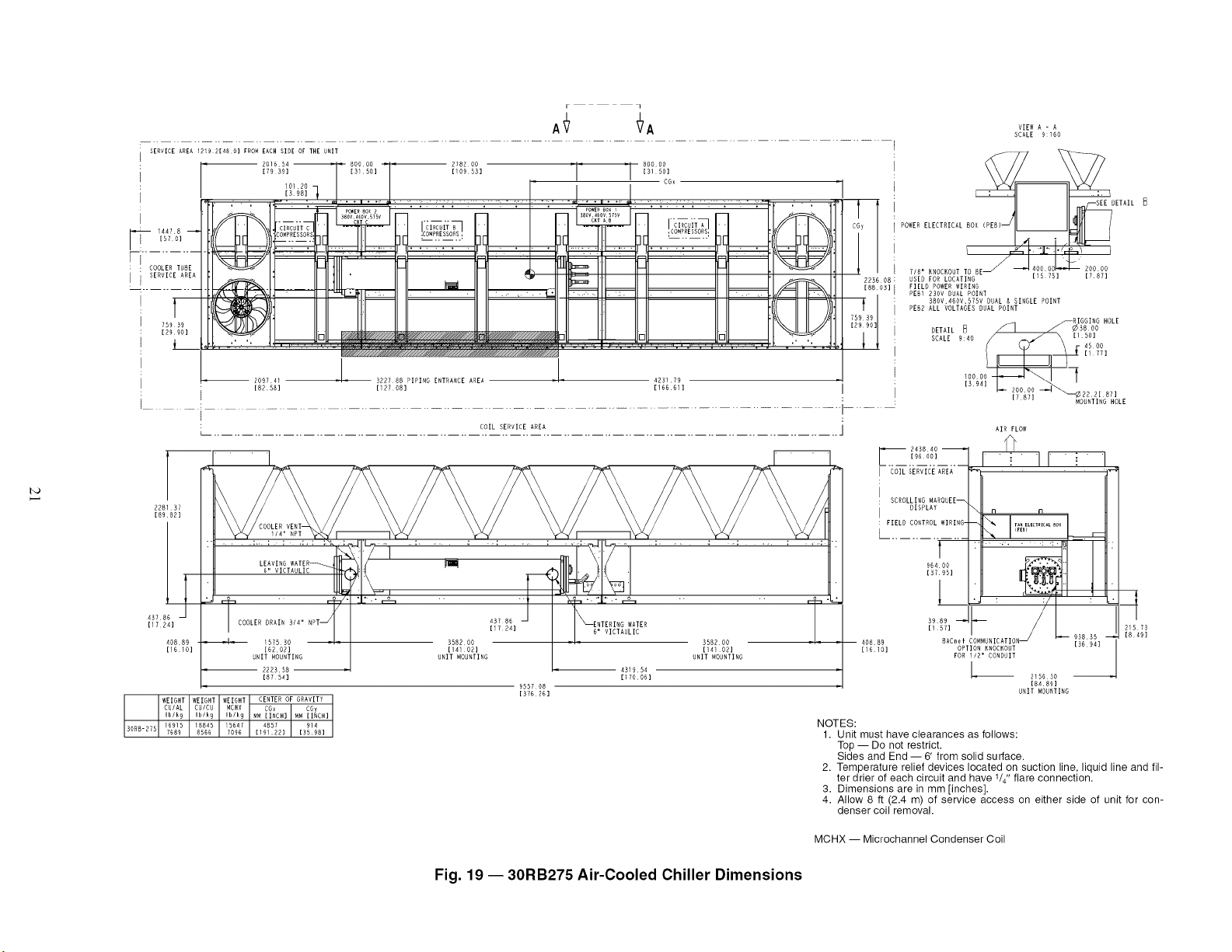

Fig. 19- 30RB275 Air-Cooled Chiller Dimensions

NOTES:

1. Unit must have clearances as follows:

Top -- Do not restrict.

Sides and End --6' from solid surface.

2. Temperature relief devices located on suction line, liquid line and fil-

ter drier of each circuit and have V4" flare connection.

3. Dimensions are in mm [inches].

4. Allow 8 ft (2.4 m) of service access on either side of unit for con-

denser coil removal.

MCHX -- Microchannel Condenser Coil

Page 22

7

SCALE 1:10

/i

[96001

VIEW A-A __

T--

86400

[3402]

£__

b 4000

I°!

"M:oDoSEEDETAIL

AIR FLOW

n n

L_

215630

[84894]

UNIT MOUNTING

)WE__ox z BOXi

F SERVICE AREA 1219214801 FROM EACH SlgE OF THE UNIT -- 315854

I

14478 _

[SY DO] _ I--I ,'CI_'CUIT C_ _ FI ,'CI_CJIT _ _ i ,'CI_CUIT A_I_I _

COOLERTUBE L _;

SERVIGEAREA_ _ _

I [126 40] [31150] / / Lbx

....... 1_ ..m..-- .11. ii II * C II II , L

I

I,O

I,O

321054 ..... t

bd:co,,_ESSO_: bd:RO,_._ESSO% [ :COM_ESSOmbd

::_ -- " L " .... ' ' __ __ " " ' "

V////////////////////////////////////////////_

3295 57 I 3342 24 "I .... 326

[12975] [131,58] [16194]

VENT_

I14" NPT \

\

PIPING ENTRANCE AREA

I

2281 37

[8982]

CgT ¢ CET a,a

COIL SERVICE AREA

[12435]

t

CGy

I 223

761 93

[3000]

I

i

[88

4

t

T

7/8" HNOCROUT TO

USED FOR LOCATING

FIELD POWER WIRING [i575]

PEBI 230V DUAL POINT

380V,46OV,S75V DUAL & SINGLE POINT

PEB2 ALL VOLTAGES DUAL POINT

'_ 43840

j--cdiT-siR_7__ A_i_

SCROLLING WAROUEE--

: DISPLAY

FIELD CONTROL WIRING-

: : ...............

1

40889

[16 10]

COOLER DRAIN J

[13455]

.... 1,,

[1724] H" VICTAULIC I [17:

43786ENTERINGWATER_ ,I I L4372_8° L

358200 -. 3582100 .

[141024] 1141 084]

UNIT WOUNTING UNIT MOUNTING

• 431954

1075108

[42327]

[17OOH]

40889

[iR1O]

BACker COMWUNICATION 3989 -

OPTION KNOCKOUT I HSY]

FOR I/2" CONDUIT

POWER ELECTRICAL 80X (PEH)

•. :-I

[945]

21573

[8 49]

RIGGING HOLE

[7 874] _- ¢)3800

[7871

DETAIL B

SCALE 1:5

1

_t

93835

[3694]

[1501

NOTES:

MCHX -- Microchannel Condenser Coil

Fig. 20 -- 30RB300 Air-Cooled Chiller Dimensions

1. Unit must have clearances as follows:

Top -- Do not restrict•

Sides and End -- 6' from solid surface.

2. Temperature relief devices located on suction line, liquid line and

filter drier of each circuit and have 1/4" flare connection•

3. Dimensions are in mm [inches]•

4. Allow 8 ft (2.4 m) of service access on either side of unit for con-

denser coil removal•

Page 23

AUCU COIL UNITS WITHOUT PUMP -- ENGLISH

UNIT

30RB

O6O

O70

O8O

O9O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

210

225

25O

275

3OO

MOUNTING WEIGHT (Ib)

No Pump AI/Cu*

4111

4317

4600

6932

Total

6155

MOUNTING WEIGHT (Ib) No Pump AI/Cu*

6519

A I B I o I o I E I F ITota'

731 I 1762 I 809 I 986 I 2347 I 1086I 7,690

728 I 1850 I 818 I 1168 I 2531 I 949 I 8,045

893 I 2085 I 888 I 1228 I 2864 I 1217I 9,174

1106 2189 I 1104 I 1483 I 2923 I 1463 110,266

1142 2220 1108 1487 3039 1606 10,601

AIBIoIoIEIFIGI"I

1094 I 1388 I 1484 I 1101 I 1479 I 2004 I 1938 I 1526 I

916 I 1804 I 2139 I 853 I 1311I 3044 I 2440 I 1228I

947 I 1836 I 2144 I 855 I 1313I 3049 I 2569 I 1354I

1122 I 2271 I 2133 I 850 I 1307 I 3036 I 3166 I 1884I

627 2269 I 2808 I 1292 I 1866 I 3808 I 3169 I 1080 I

899 2602 2792 1284 1859 3796 3640 1436

MOUNTING WEIGHT (Ib) No Pump AI/Cu*

CU/CU COIL UNITS WITHOUT PUMP -- ENGLISH

UNIT

30RB

O6O

O7O

O8O

O9O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

210

225

25O

275

3OO

MOUNTING WEIGHT (Ib)

No Pump Cu/Cut

1014I 1089 I 1393 I 1333 I 4,799

1106I 1081 I 1431 I 1464 I 8,082

1342I 1884 I 2020 I 1711 I 6,656

1388I 1619 I 2126 I 1780 I 6,879

1503 1638 2139 1967 7,243

MOUNTING WEIGHT (Ib) No Pump Cu/Cut

_l_lololEl_lTota'

837 I 1980 I 917 I 1088 I 2551 I 1161 I 8,634

880 I 2100 I 940 I 1288 I 2764 I 1069 I 9,010

1018I 2334 I 1009 I 1348 I 3097 I 1336 I10,139

1252 2497 I 1266 I 1642 I 3218 I 1899 111,472

1289 2528 1270 1645 3334 1742 11,807

MOUNTING WEIGHT (Ib) No Pump Cu/Cuf

_I_I°I°IEI_IGI"I

1257I 1698 I 1691 I 1263 I 1638 I 2199 I 2133 I 1684 I

1018I 2045 I 2410 I 978 I 1427 I 3297 I 2681 I 1326 I

1049I 2078 I 2415 I 981 I 1429 I 3301 I 2810 I 1452 I

1283 I 2577 I 2404 I 976 I 1423 I 3288 I 3463 I 1744 I

732 2554 I 3193 I 16Ol I 2059 I 4185 I 3446 I 1175 I

1064 2950 3179 1494 2053 4172 3974 1591

MCHX COIL UNITS WITHOUT PUMP -- ENGLISH

UNIT No Pump MCHX**

060 3,783

070 3,978

080 4,267

090 5,449

30RB _ Total

100 5,883

110 8,027

UNIT MOUNTING WEIGHT (Ib) No Pump MCHX**

3o._ _lBlololEl_lTota,

120 660 I 1614 I 737 I 918 I 2210 I 988 I 7,119

130 648 I 1683 I 738 I 1088 I 2377 I 870 I 7,402

150 810 I 1914 I 808 I 1146 I 2706 I 1136 I 8,617

160 1020 2020 I 1019 I 1368 I 2698 I 1350 I 9,475

170 1055 2052 1024 1374 2809 1485 9,799

UNIT MOUNTING WEIGHT (Ib) No Pump MCHX**

MOUNTING WEIGHT (Ib)

3o._ _ i _ i o i o i E I _ I G I . I

190 1007 I 1278 I 1367 I 1014 I 1362 I 1846 I 1785 I 1405 I

210 882 I 1677 I 1989I 793 I 1219 I 2831 I 2269 I 1142 I

225 881 I 1709 I 1996I 796 I 1222 I 2838 I 2391 I 1260 I

250 1041 I 2107 I 1979 I 789 I 1212 I 2818 I 2937 I 1469 I

275 580 2099 I 2594 I 1198 I 1726 I 3523 I 2931 I 999 I

300 830 2401 2576 1185 1716 3502 3359 1324

*Condenser Coil: Aluminum Fins/Copper Tubing.

?Condenser Coil: Copper Fins/Copper Tubing.

** Condenser Coil: Microchannel (MCHX) Design.

Total

12,013

13,734

14,067

16,468

16,915

18,306

Total

13,460

15,181

15,514

17,157

18,845

20,477

Total

11,064

12,772

13,093

14,349

16,647

16,893

AUCU COIL UNITS WITHOUT PUMP-- SI

UNIT

30RB

O6O

O7O

080

O9O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

210

225

25O

275

3OO

UNIT

30RB

O6O

O7O

O8O

O9O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

210

225

25O

275

3OO

MOUNTING WEIGHT (kg)

No Pump AI/Cu*

1869

1962

2091

_ Total

MOUNTING WEIGHT (kg) No Pump AI/Cu*

2697

2798

2963

A I _ I o I o I E I F ITota'

332 I 799 I 367 I 447 I 1065 I 479 I 3488

330 I 839 I 371 I 830 I 1148I 431 I 3649

408 I 946 I 403 I 887 I 1299I 882 I 4161

603 998 I 502 I 674 I 1328 I 668 I 4666

519 1009 503 676 1381 730 4819

_ I B I o I o I E I _ I G I " ITota'

497 I 631 I 674 I 500 I 672 I 911 I 881 I 694 I 5461

416 I 820 I 972 I 388 I 596 I 1384 I 1109I 688 I 6243

431 I 838 I 976 I 389 I 697 I 1386 I 1168I 618 I 6394

610 I 1032 I 970 I 386 I 694 I 1380I 1439 I 720 I 7031

288 1032 I 1278 I 687 I 848 I 1731 I 1440 I 491 I 7689

409 1183 1269 584 845 1725 1654 652 8321

MOUNTING WEIGHT (kg) No Pump AI/Cu*

CU/CU COIL UNITS WITHOUT PUMP -- SI

MOUNTING WEIGHT (kg)

No Pump Cu/Cul"

2088

2181

2310

_ Total

MOUNTING WEIGHT (kg) No Pump Cu/Cu'i-

_l_lclolEIFITota'

380 I 8981 416 I 494 I 1157 I 527 13871

386 I 9521 426 I 884 112541 485 14087

461 I 1089 I 488 I 611 I 1408I 606 I 4599

669 1135 I 678 I 746 114631 727 16215

586 1149 577 748 1516 792 5367

MOUNTING WEIGHT (kg) No Pump Cu/Cuf

3026

3127

3292

_ I _ I c I o I E I _ I G I " ITota'

671 I 7251 7691 574 I 744 I lOOOI 970 I 765 16118

463 I 930 I 1098 I 445 I 649 I 1498I 1219 I 603 I 6901

477 I 944 I 1098 I 446 I 680 I 1601I 1277 I 660 I 7052

683 I 1171 I 1093 I 444 I 647 I 1494I 1574 I 793 I 7799

333 1161 I 1451I 682 I 936 I 1902 I 1566 I 634 I 8566

484 1341 1445 679 933 1896 1807 723 9308

MCHX COIL UNITS WITHOUT PUMP-- SI

UNIT

ourlD

O6O

O7O

O8O

O9O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

210

225

25O

275

3OO

MOUNTING WEIGHT (kg)

No Pump MCHX**

A B C D Total

363 381 498 474 1716

372 391 533 508 1804

413 403 552 588 1934

483 582 789 838 2472

489 597 815 888 2589

553 607 824 750 2734

MOUNTING WEIGHT (kg) No Pump MCHX**

_l_lololEl_lTota'

299 I 732 I 334 I 418 I 1002 I 447 I 3229

294 I 763 I 335 I 493 I 1078 I 394 I 3358

367 I 868 I 365 I 620 I 1227 I 618 I 3863

463 916 I 492 I 620 I 1224 I 612 I 4297

478 931 464 623 1274 673 4443

MOUNTING WEIGHT (kg) No Pump MCHX**

A I _ I o I o I E I F I G I " ITota'

457 I 580 I 620 I 460 I 618 I 837 I 810 I 637 I 5019

386 I 761 I 902 I 360 I 883 I 1284 I 1029 I 818 I 5793

400 I 775 I 908 I 361 I 884 I 1287 I 1084 I 871 I 5937

472 I 986 I 898 I 388 I 880 I 1277 I 1332 I 666 I 6809

263 952 I 1176 I 542 I 783 I 1698 I 1329 I 453 I 7096

376 1089 1168 537 778 1588 1523 600 7659

Fig. 21 -- Unit Weights

23

Page 24

AL/CU COIL UNITS WITH SINGLE PUMP -- ENGLISH

UNIT

30RB

O6O

O7O

O8O

O9O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

MOUNTING WEIGHT (Ib)

Single Pump AI/Cu*

A i B i c i o ITota,

1085I 1127 I 1230 I 1184 I 4626

1107I 1150 I 1312 I 1263 I 4832

1193I 1164 I 1354 I 1388 I 8100

1353I 1620 I 1885 I 1675 I 6432

1366 1655 I 1991 I 1644 I 6655

1565 1653 1974 1868 7059

MOUNTING WEIGHT (Ib)Single Pump AI/Cu*

731 2062 960 961 2460 1056 8,230

728 2149 969 1144 2645 949 8,585

893 2486 1031 1165 3035 1217 9,827

I A B C D E F Total

1238 2583 1104 1483 3155 1357 10,919

1279 2609 1108 1487 3276 1495 11,254

MOUNTING WEIGHT (Ib)Single Pump AI/Cu*

CU/CU COIL UNITS WITH SINGLE PUMP -- ENGLISH

UNIT

O60

O70

O80

O90

100

110

UNIT

120

130

150

30RB I

160

170

UNIT

30RB

190

*Condenser Coil: Aluminum Fins/Copper Tubing.

1-Condenser Coil: Copper Fins/Copper Tubing.

** Condenser Coil: Microchannel (MCHX) Design.

MOUNTING WEIGHT (Ib)

Single Pump Cu/Cut

A B C D Total

1208 1250 1348 1302 5,108

1230 1273 1430 1381 5,314

1317 1287 1472 1506 5,582

1537 1808 2060 1753 7,156

1549 1841 2166 1823 7,379

1749 1839 2150 2045 7,783

MOUNTING WEIGHT (Ib) Single Pump Cu/Cul"

A B C D E F Total

837 2280 1068 1065 2664 1161 9,074

850 2399 1091 1264 2877 1069 9,550

1015 2738 1153 1284 3269 1336 10792

1382 2894 1266 1642 3447 1495 12125

1424 2920 1270 1648 3569 1633 12460

MOUNTING WEIGHT (Ib) Single Pump Cu/Cul"

Total

12,666

Total

14,113

AL/CU COIL UNITS WITH SINGLE PUMP -- SI

UNIT

06O

07O

08O

09O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

UNIT

06O

07O

08O

09O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

MOUNTING WEIGHT (kg)

Single Pump AI/Cu*

A B C D Total

493 512 559 538 2103

503 523 597 574 2196

542 529 616 631 2318

615 736 857 716 2924

621 752 905 747 3025

711 751 897 849 3209

MOUNTING WEIGHT(kg) Single Pump AI/Cu*

A B C D E F Total

332 935 435 436 1116 479 3733

330 975 440 519 1200 431 3894

405 1128 468 528 1377 552 4458

I

563 1174 502 674 1434 617 4963

582 1186 503 676 1489 679 5116

MOUNTING WEIGHT(kg) Single Pump AI/Cu*

CU/CU COIL UNITS WITH SINGLE PUMP -- SI

MOUNTING WEIGHT (kg)

Single Pump Cu/Cut

A B C D Total

549 568 613 592 2322

559 579 650 628 2415

599 585 669 684 2537

699 821 937 797 3253

704 837 985 828 3354

795 836 977 930 3538

MOUNTING WEIGHT (kg)Single Pump Cu/Cut

380 1034 484 483 1209 527 4116

386 1088 495 573 1305 485 4332

461 1241 523 583 1483 606 4895

I A B C D E F Total

628 1315 575 746 1567 680 5511

647 1327 577 748 1622 742 5664

MOUNTING WEIGHT (kg)Single Pump Cu/Cut

Total

5757

Total

6415

30RB060-110

B_

cooler

Compressors

c D

30RB160,170,315A, 315B, 330A, 330B,

c B_

D E

NOTE: Corner weights are calculated at mount-

ing locations. Refer to Fig. 2-20 (certified draw-

ings) for mounting locations.

345A, 345B, 360B

cooler

30RB120-150

c B_

cooler

D E F

30RB190-300, 360A, 390A, 390B

cooler

Fig. 21 -- Unit Weights (cont)

24

Page 25

MCHX COIL UNITS WITH SINGLE PUMP -- ENGLISH

UNIT

30RB

O6O

O7O

O8O

O9O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

MOUNTING WEIGHT (Ib)

Single Pump MCHX**

A i . i o i DITot"'

1008 I 1047 I 1143 I 1100 I 4298

1030I 1069 I 1220 I 1174 I 4493

1115I 1088 I 1266 I 1298 I 4767

1251 I 1498 I 1743 I 1457 I 5949

1265 1532 I 1844 I 1522 I 6163

1456 1537 1836 1738 6567

MOUNTING WEIGHT (Ib)Single Pump MCHX**

A B C D E F Total

660 1914 887 891 2322 985 7,659

648 1982 888 1064 2490 870 7,942

810 2316 948 1083 2877 1136 9,170

1148 2395 1024 1376 2926 1259 10,128

1188 2423 1029 1381 3043 1388 10,452

MOUNTING WEIGHT (Ib)Single Pump MCHX**

Total

11,717

MCHX COIL UNITS WITH SINGLE PUMP -- SI

UNIT

06O

07O

08O

09O

100

110

UNIT

30RB

120

130

150

160

170

UNIT

30RB

190

MOUNTING WEIGHT (kg)

Single Pump MCHX**

A B C D Total

457 475 518 499 1949

467 485 553 532 2037

506 493 574 589 2162

567 679 790 661 2697

574 695 836 690 2795

660 697 833 788 2978

MOUNTING WEIGHT(kg) Single Pump MCHX**

A B C D E F Total

299 868 402 404 1053 447 3474