Fig. 1 — Typical 30RAP Unit (018-030 Shown)

30RAP010-150 Air-Cooled Chillers and

30RAP011-060 Air-Cooled Chillers

with Greenspeed® Intelligence

with Puron® Refrigerant (R-410A)

Installation Instructions

AquaSnap

50/60 Hz

®

CONTENTS

Page

SAFETY CONSIDERATIONS

INSTALLATION

Storage Recommendations . . . . . . . . . . . . . . . . . . . . . . 2

Step 1 — Place and Rig the Unit

•PLACING UNIT

•RIGGING

• MOUNTING UNIT

Step 2 — Check Compressor Mounting

Step 3 — Connect Cooler Fluid and

Drain Piping

• ALL UNITS

• VICTAULIC COUPLING INSTALLATION

• UNITS WITH FACTORY-INSTALLED

HYDRONIC PACKAGES

•AIR SEPARATION

Step 4 — Fill the Chilled Water Loop

• WATER SYSTEM CLEANING

• FILLING THE SYSTEM

•PUMP VFD

• SENSORLESS CONTROL (CLOSED LOOP) —

ACTIVE SETUP 1

• REMOTE SENSOR (CLOSED LOOP) —

ACTIVE SETUP 2

• REMOTE CONTROLLER (OPEN LOOP) —

ACTIVE SETUP 3

• PREPARATION FOR YEAR-ROUND OPERATION

• FREEZE PROTECTION

• PREPARATION FOR WINTER SHUTDOWN

Step 5 — Make Electrical Connections

• POWER SUPPLY

•POWER WIRING

• CONTROL POWER

Step 6 — Install Accessories

• ELECTRICAL

Step 7 — Check Refrigerant Circuit

• LEAK TESTING

• DEHYDRATION

• REFRIGERANT CHARGE

BACnet Communication Option Wiring

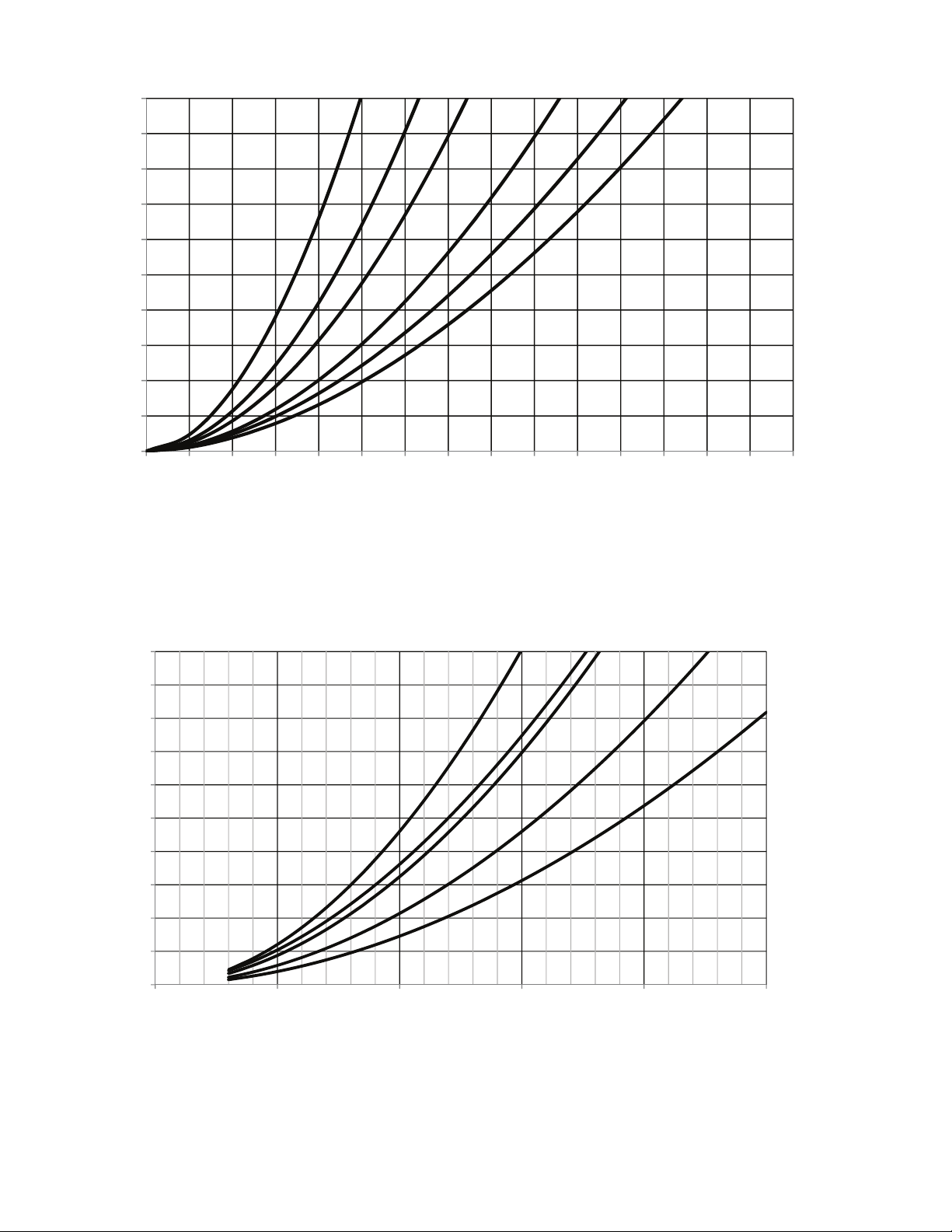

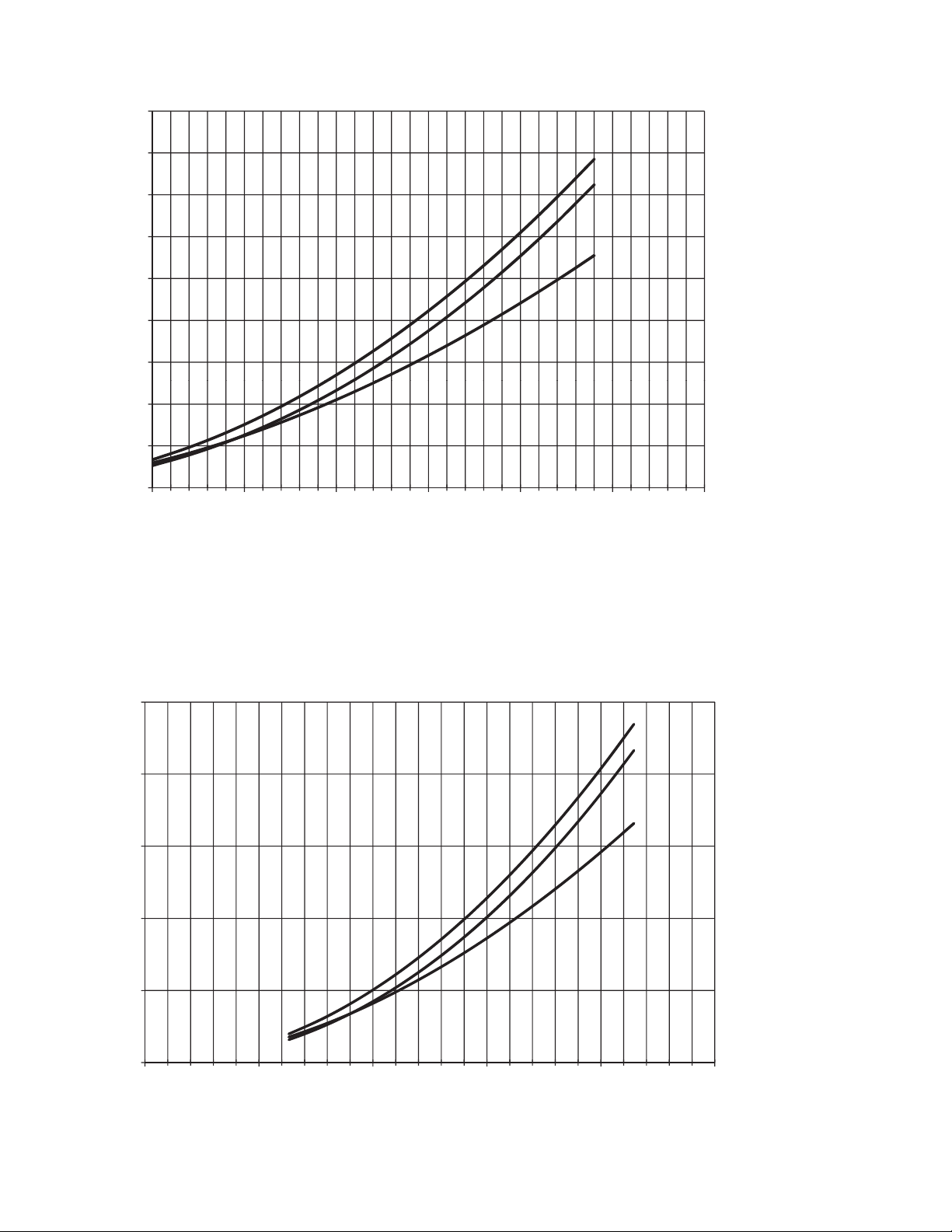

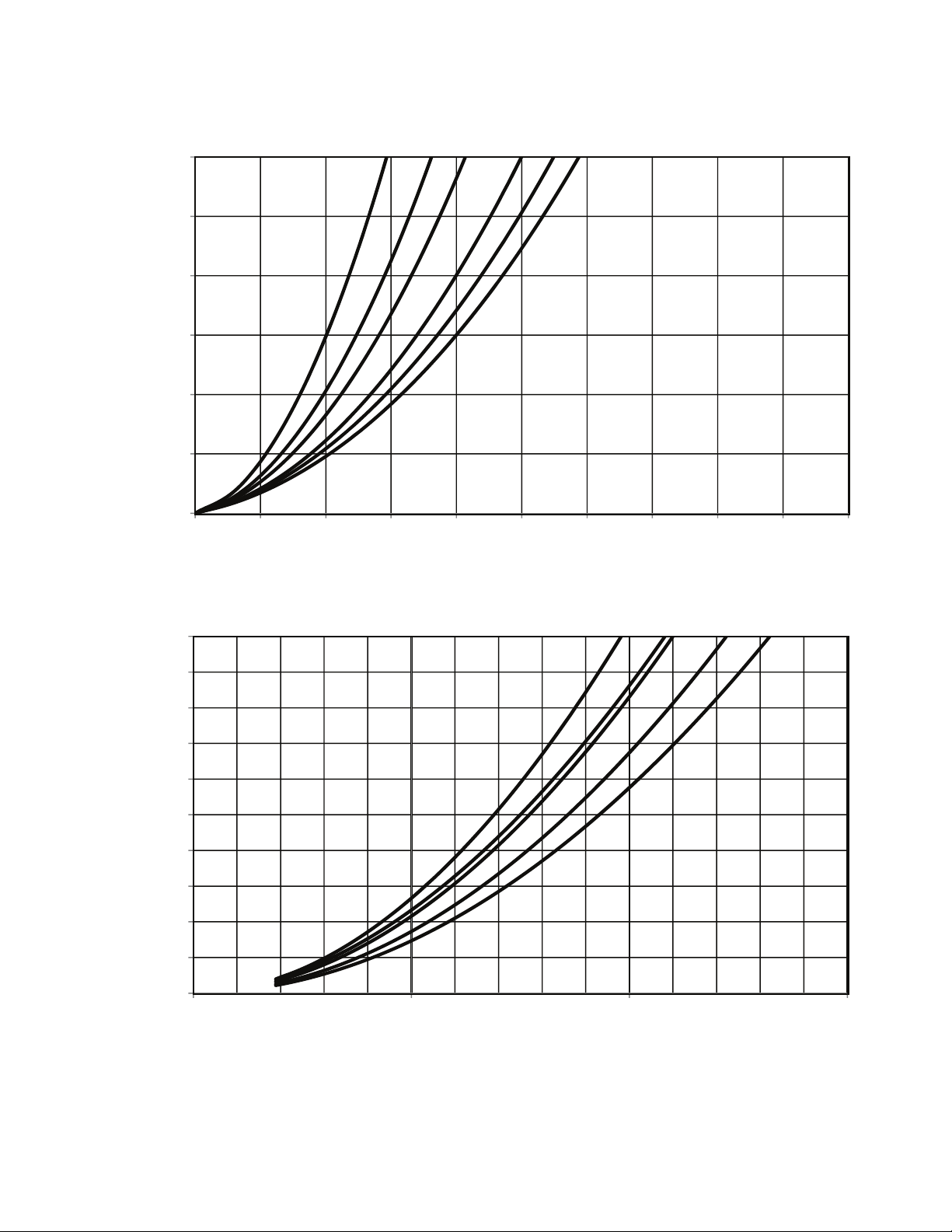

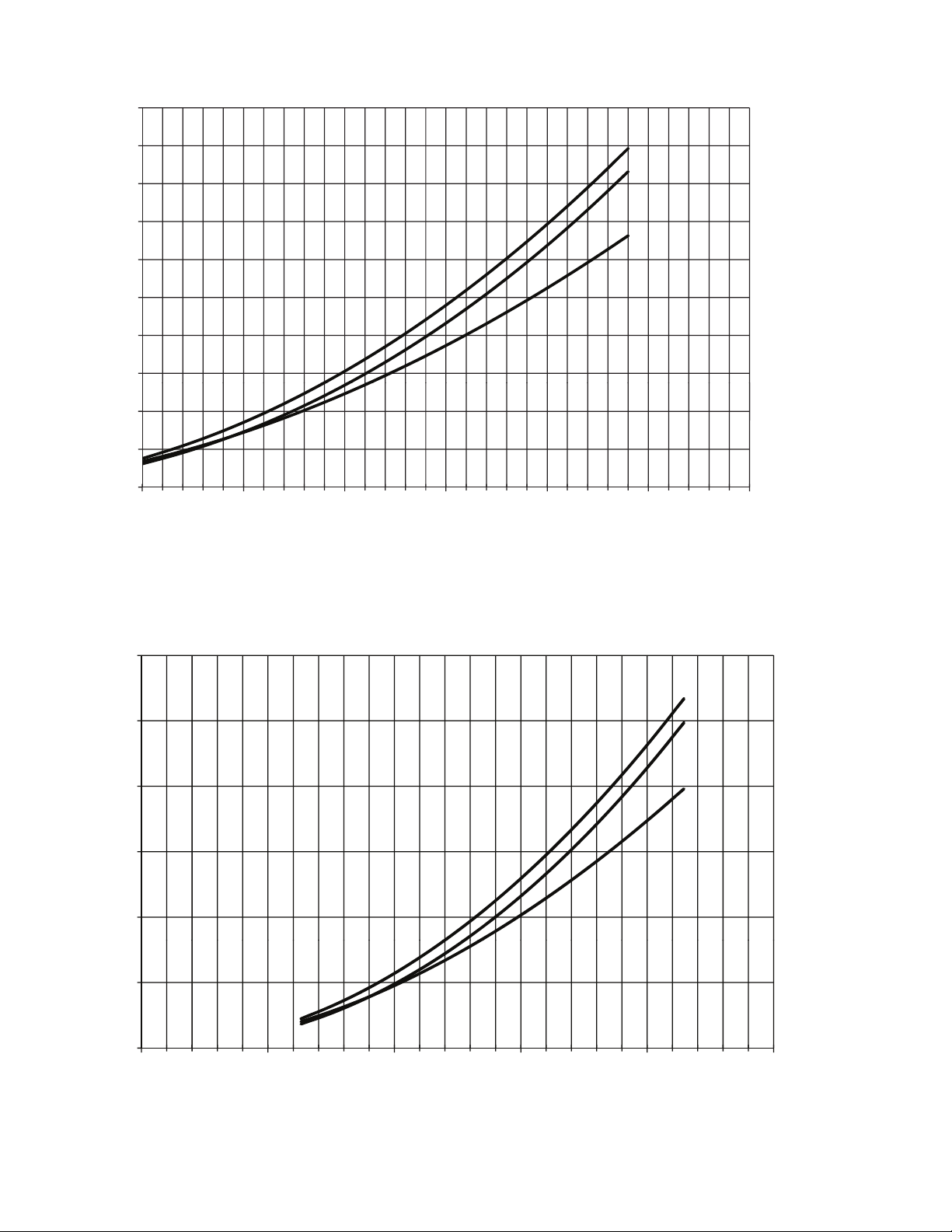

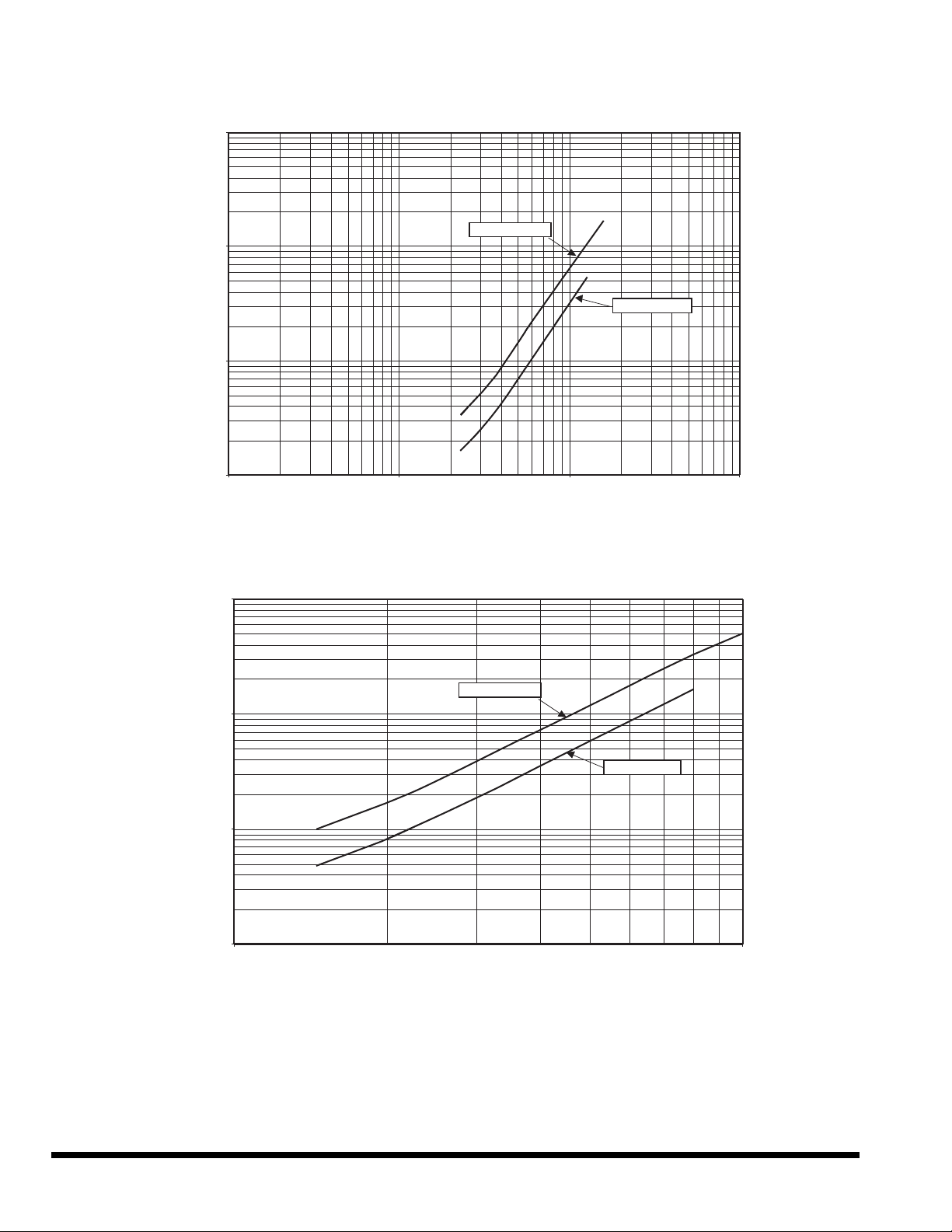

APPENDIX A (PRESSURE DROP CURVES)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . .1,2

. . . . . . . . . . . . . . . . . . 2

. . . . . . . . . 16

. . . . . . . . . . . . 33

. . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . 68

. . . . . . . . . . . . . 68

. . . . . . . . . 69

. . . 72-84

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equip-

ment can be hazardous due to system pressures, electrical

com

ponents, and equipment location (roofs, elevated struc-

tures, etc.).

Only trained, qualified installers and service mechanics

should install, start up, and service

Untrained personnel can perform basic

tions such as cleaning coils. All other operations should be

performed by trained

When working on the equipment, observe precautions in the

literature an

equipment.

• Follow all safety codes.

d on tags, stickers, and labels attached to the

service personnel.

this equipment (Fig. 1).

maintenance func-

• Wear safety glasses and work gloves.

• Keep quenching cloth and fire extinguisher nearby when

brazing

• Use care in handling, rigging, and setting bulky

.

.

equipment.

WARNING

Electrical shock can cause personal injury and death. Shut off

all power to this equipment during installation. There may be

more than one disconnect switch. Tag all disconnect locations

to alert others not to restore power until work is completed.

WARNING

DO NOT USE TORCH to remove any component. System

contains oil and refrigerant under pressure.

To remove a component, wear protective gloves and goggles and proceed as follows:

a. Shut off electrical po

b. Recover refrigerant to relieve all pressure

tem using both high-pressure and low pressure ports.

c. Traces of vapor should be displaced with nitrogen

and the work area

erant in contact with an open flame produces toxic

gases.

d. Cut component connection tubing with tubing cutter

and rem

any oil that may come out of the lines and as a gage

for how much oil to add to the system.

e. Carefully unsweat remaining tubing stubs when nec-

essary. Oil can ignite when

Failure to follow these procedures may

injury or death.

ove component from unit. Use a pan to catch

wer to unit.

from sys-

should be well ventilated. Refrig-

exposed to torch flame.

result in personal

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53300163-01 Printed in U.S.A. Form 30RAP-16SI Pg 1 4-16 Replaces: 30RAP-13SI

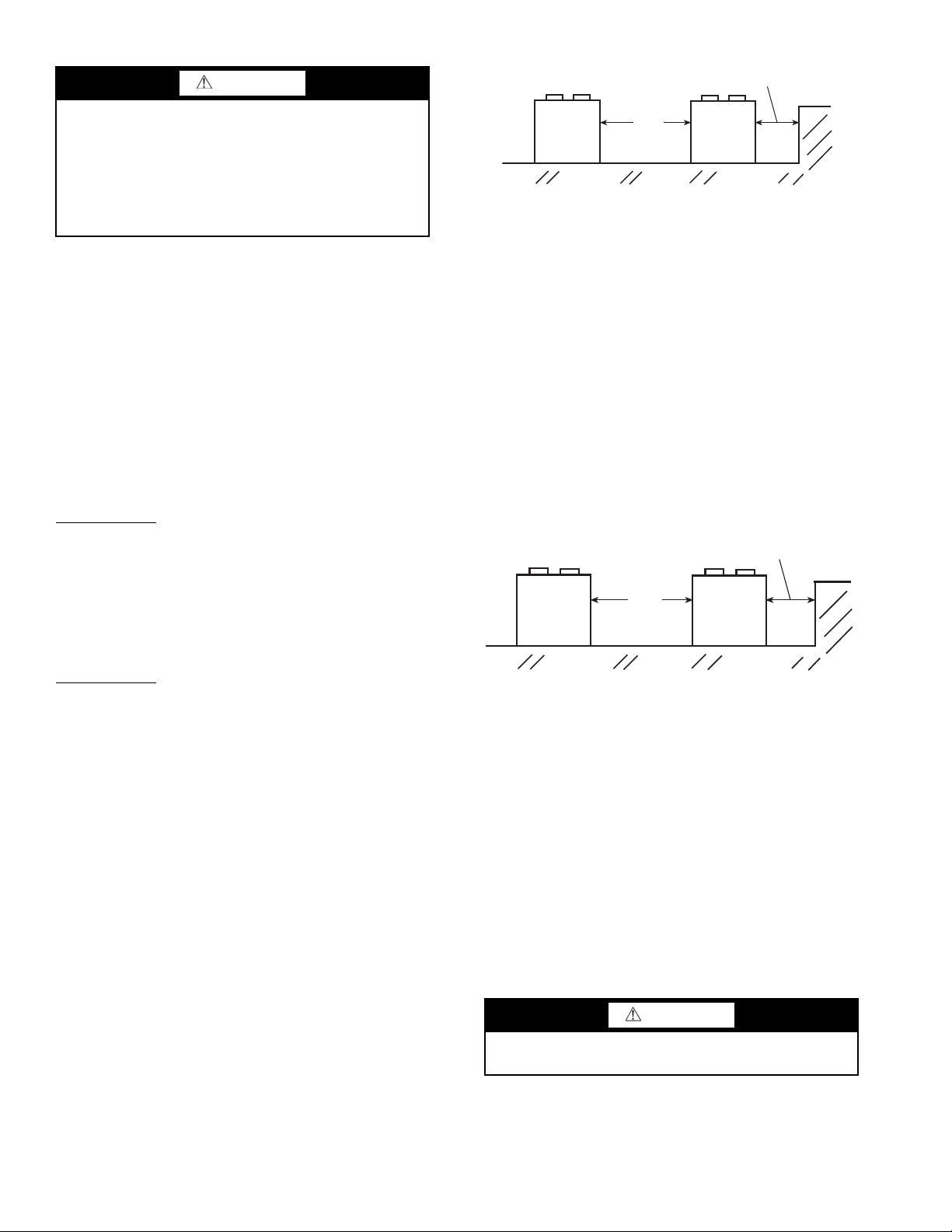

CAUTION

6 ft

(1.8 m)

MINIMUM*

3.5 ft (1.1 m)

MINIMUM†

* Minimum for when coils face each other. Less clearance is

required in other configurations.

† Clearance of 3.5 ft is required when a coil faces the wall. When

there is no coil facing the wall, see the certified drawing for the

required service clearance.

a30-4873

Fig. 2 — 30RAP010-060 Multiple Unit Separation

10 ft

(3 m)

MINIMUM

6 ft (1.8 m)

MINIMUM

a30-4904

Fig. 3 — 30RAP070-150 Multiple Unit Separation

DO NOT re-use compressor oil or any oil that has been

exposed to the atmosphere. Dispose of oil per local codes

and regulations. DO NOT leave refrigerant system open to

air any longer than the actual time required to service the

equipment. Seal circuits being serviced and charge with

dry nitrogen to prevent oil contamination when timely

repairs cannot be completed. Failure to follow these proce

-

dures may result in damage to equipment.

INSTALLATION

Storage Recommendations — The 30RAP air-

cooled chillers are designed for outdoor installations. At

times, a delay in construction or other factors require that a

unit be stored for a period of time prior to installation. The

following guidelines should be used for unit storage.

PROVIDE MACHINE PROTECTION — Place and store

the unit in an area that will protect it from vandalism, acciden

tal contact with vehicles, falling debris or construction waste.

Ideally, do not remove the shipping protection such as the coil

protectors. This will provide additional protection for the unit.

The unit can be stored outdoors.

INSPECTION DURING STORAGE — To ensure faster

installation when the time comes, the following inspection

schedule is recommended:

Every 3 Months — The 30RAP units are shipped with a complete operating charge of R-410A. Check each refrigerant circuit to be sure that there is positive pressure, at least 26 psig

(180 kPa) in the circuit. If a circuit is found to be without pres

sure, contact a qualified refrigeration mechanic. The system

should be pressurized to find the leak. It should be repaired, dehydrated and recharged with refrigerant. If a positive circuit

pressure was not found, the compressor oil should be changed

or at least sampled to determine if moisture is present. If mois

ture is found in the compressor oil, the oil should be changed.

Every 6 Months — Check the unit for damage, both physical

and from wildlife. Check the unit for nests from rodents, birds,

or insects. Depending on location, these organisms can cause

deterioration of components which may result in failure. Con

sider an exterminator if necessary. If damage is found and it

will interfere with the installation, consider repairing the dam

age before installation. Check the unit control box for signs of

moisture. If moisture is found, determine the entry path and

seal the leak.

Step 1 — Place and Rig the Unit

PLACING UNIT — Units are suitable for outdoor use only.

For 30RAP010-060 units, see Fig.

are aligned such that coils face each other, a minimum of

6

ft (1829 mm) separation is recommended. When the parallel arrangement has only one coil drawing air from the space

between chillers, a minimum of 3.5 ft (1067 mm) is recom

mended. When parallel chillers have no coils facing each

other (a back-to-back arrangement), be sure to maintain the

larger of the recommended service clearances associated

with each chiller (see the certified drawings). Due to NEC

(National Electric Code) regulations, a minimum clearance

of 4

ft (1219 mm) must be maintained on the side of the

chiller that has an electrical box. Chiller fan discharge must

be at least as high as adjacent solid walls. Installation in pits

is not recommended.

2. When parallel chillers

For 30RAP070-150 units, see Fig. 3. When chillers are arranged in parallel, a minimum of 10 ft (3048 mm) between

chillers is recommended. Acceptable clearance on the cooler

connection side or end opposite the control box of the unit can

be reduced to 3 ft (1 m) without sacrificing performance as

-

long as the remaining three sides are unrestricted. Acceptable

clearance on the side with a control box can be reduced to 4 ft

(1.3 m) due to NEC (National Electric Code) regulations, with

out sacrificing performance as long as the remaining three

sides are unrestricted. Clearances between chillers in dual

chiller applications may be reduced to 6 ft (1.8 m) without sac

rificing performance provided the remaining sides are unrestricted. For acceptable clearance with layout involving more

than 2 chillers, please contact application engineering.

-

-

-

-

These instructions cover installation of 30RAP010-150 air-

cooled liquid chillers. Refer to Fig.

4 and 5 for model number

to determine factory-installed options.

RIGGING — Preferred method for rigging is with spreader

bars from above the unit. Use shackles in lifting holes. Rig at a

single point with 4 cables for size 010-115 units, 6 cables for size

130 and 150 units, or use spread bars. All panels must be in place

when rigging. See rigging label on unit for details concerning

shipping weights, distance between lifting holes, center of gravi

ty, and lifting ring dimensions. See Tables 1-3 and Fig. 6 for

unit weights. See Tables 4 and 5 for physical data. See Fig. 7

and 8 for rigging label.

If overhead rigging is not possible, place chiller on skid or

-

pad for rolling or dragging. When rolling, use a minimum of

3 rollers. When dragging, pull the pad. Do not apply force to

the unit. When in final position, raise from above to lift unit

off pad.

CAUTION

All panels must be in place when rigging. If they are not,

damage to unit could result.

2

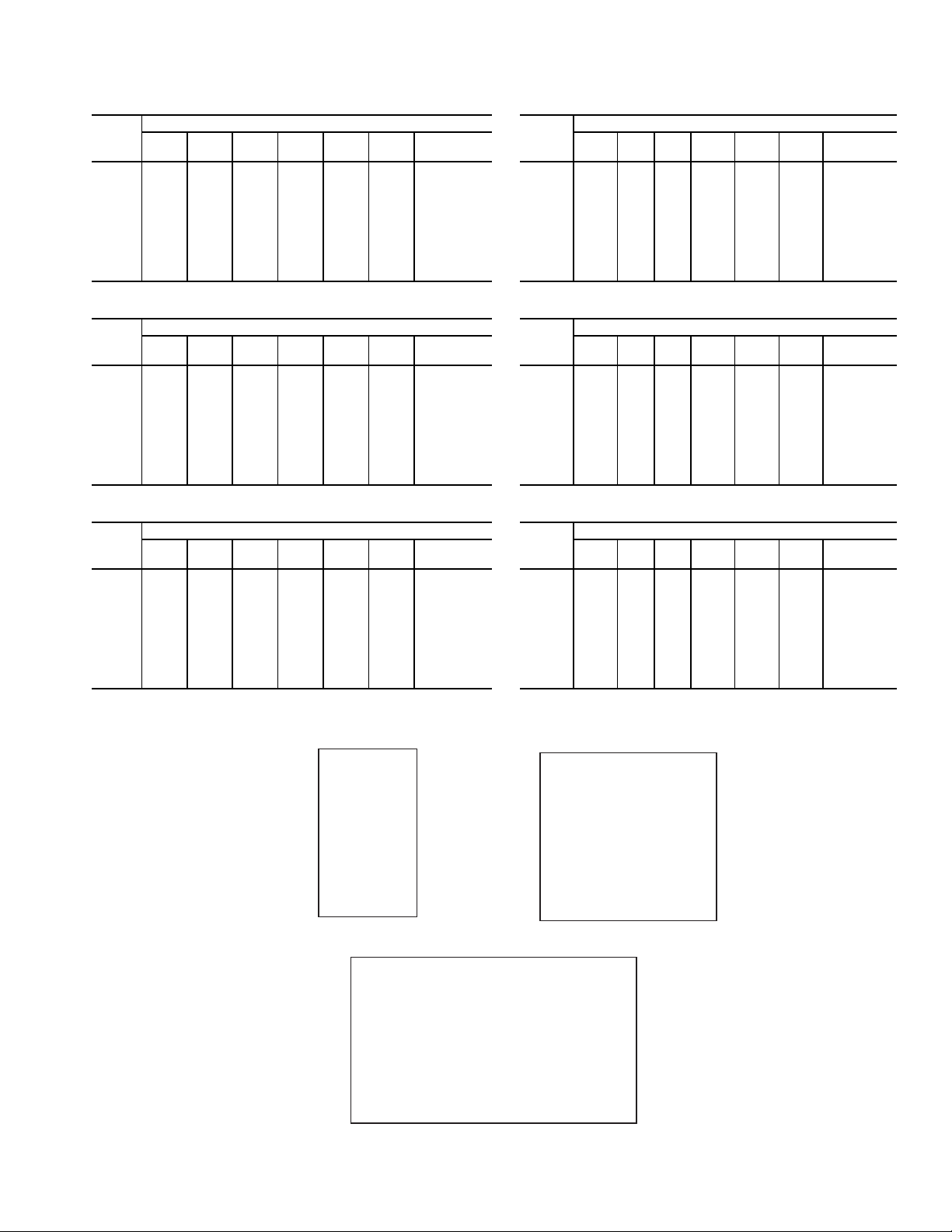

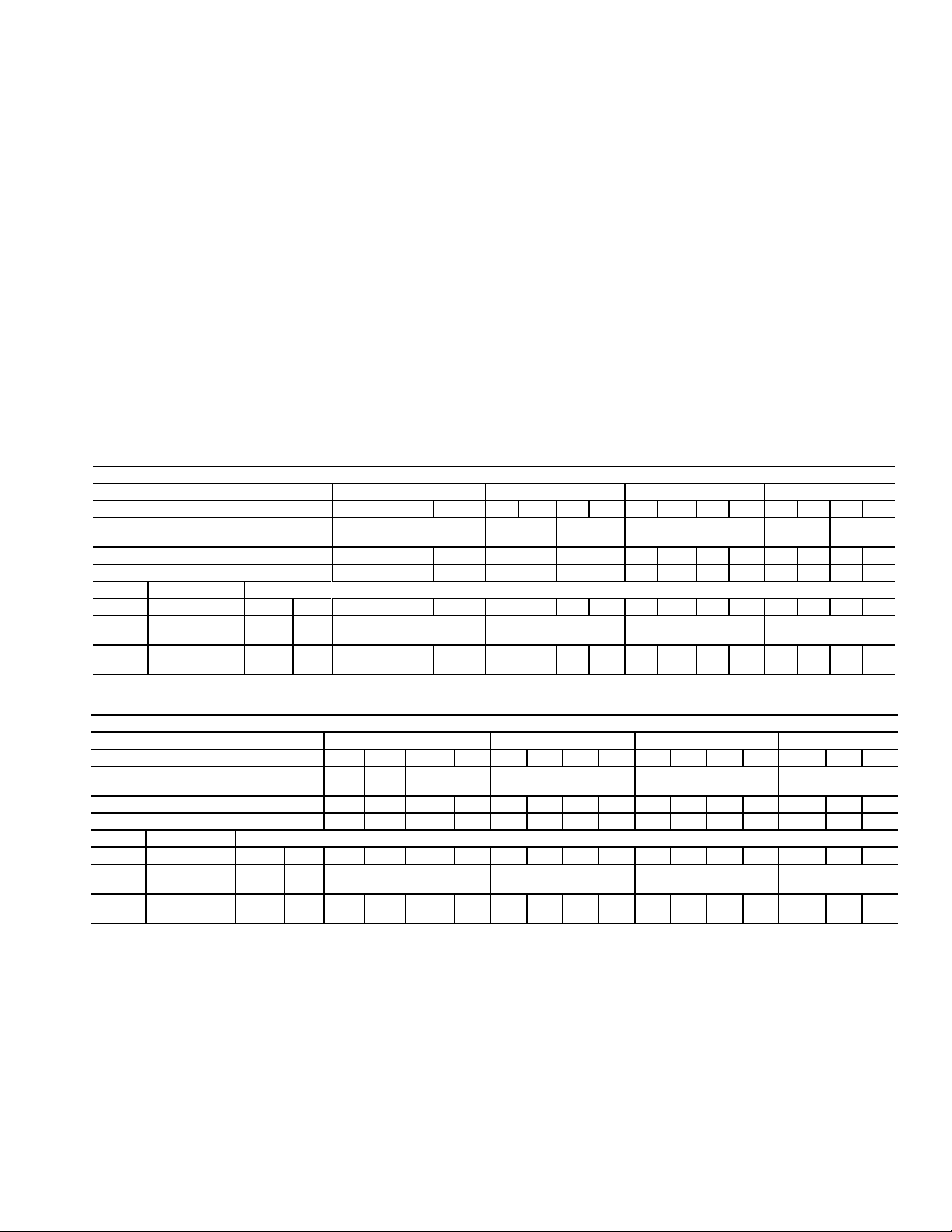

Fig. 4 — AquaSnap® Chiller Model Number Designation, 30RAP010-060

LEGEND

EMM —

Energy Management Module

GFI —

Ground Fault Interrupting

MCHX —

Microchannel Heat Exchanger

SCCR — Short Circuit Current Rating

a30-5718

*High-efficiency variable condenser fans (codes D, F, G, H, J, and K)

are not available on unit sizes 010 and 015, and are the only choices

for sizes 011 and 016.

†Digital compressors (codes 2, 5, 8, C, G, and K) are not available on

unit sizes 011 and 016.

P00030RA 0 66D010

30RA

–

Air-Cooled AquaSnap Chiller

Refrigerant Type

P – Puron

Revision Level

C –

Current Revision Level

Unit Sizes

010 020 045

011 025 050

015 030 055

016 035 060

018 040

Voltage

1 –

575-3-60

2 –

380-3-60

5 –

208/230-3-60

6 –

460-3-60

9 –

380/415-3-50

Condenser Coil and Low Sound Options

5 –

MCHX, Value Sound Fan

6 –

MCHX, E-Coat, Value Sound Fan

D –

MCHX, AeroAcoustic Fan

F –

MCHX, E-Coat, AeroAcoustic Fan

J –

MCHX, AeroAcoustic Fan, Compressor Blanket(s)

K –

MCHX, E-Coat, AeroAcoustic Fan, Compressor Blanket(s)

Hydronic System

0 –

No Pump

2 –

Single Pump, 1.5 Hp

3 –

Single Pump, 3 Hp

4 –

Single Pump, 3 Hp High Head

5 –

Single Pump, 5 Hp

6 –

Single Pump, 5 Hp High Head

7 –

Single Pump, 7.5 Hp

Z –

Single Pump, 10 Hp

9 –

Dual Pump, 1.5 Hp

B –

Dual Pump, 3 Hp

C –

Dual Pump, 3 Hp High Head

D –

Dual Pump, 5 Hp

F –

Dual Pump, 5 Hp High Head

G –

Dual Pump, 7.5 Hp

H – Dua

l Pump, 10 Hp

Ambient/Capacity Control/High SCCR Options*†

0 –

Std Comp

1 –

Hot Gas Bypass

2 –

Digital Comp

3 –

Std Comp, High SCCR

4 –

Hot Gas Bypass, High SCCR

5 –

Digital Comp, High SCCR

6 –

Low Ambient, Std Comp

7 –

Low Ambient, Hot Gas Bypass

8 –

Low Ambient, Digital Comp

9 –

Low Ambient, Std Comp, High SCCR

B –

Low Ambient, Hot Gas Bypass, High SCCR

C –

Low Ambient, Digital Comp, High SCCR

D –

Std Comp, High-Efficiency Variable Condenser Fans

F –

Hot Gas Bypass, High-Efficiency Variable Condenser Fans

G –

Digital Comp, High-Efficiency Variable Condenser Fans

H –

Std Comp, High SCCR, High-Efficiency Variable

Condenser Fans

J –

Hot Gas Bypass, High SCCR, High-Efficiency Variable

Condenser Fans

K –

Digital Comp, High SCCR, High-Efficiency Variable

Condenser Fans

Electrical Options

0 –

No Disconnect, No Cooler Heater

1 –

No Disconnect, Cooler Heater

D –

Non-Fused Disconnect, No Cooler Heater

F –

Non-Fused Disconnect, Cooler Heater

Controls/Communications Options

0 –

Std

1 –

Std, BACnet Communication

5 –

EMM

6 – EMM,

BACnet Communication

B –

EMM, GFI

C – EMM, GFI,

BACnet Communication

H – GFI

J – GFI,

BACnet Communication

Packaging/Security Options

0 –

Std Packaging

4 –

Security Grilles/Hail Guards Only

8 –

Skid Only

D –

Skid, Security Grilles/Hail Guards

J –

Skid, Top Crate, Bag

N –

Skid, Top Crate, Bag, Security Grilles/Hail Guards

®

C

a30-6071

3

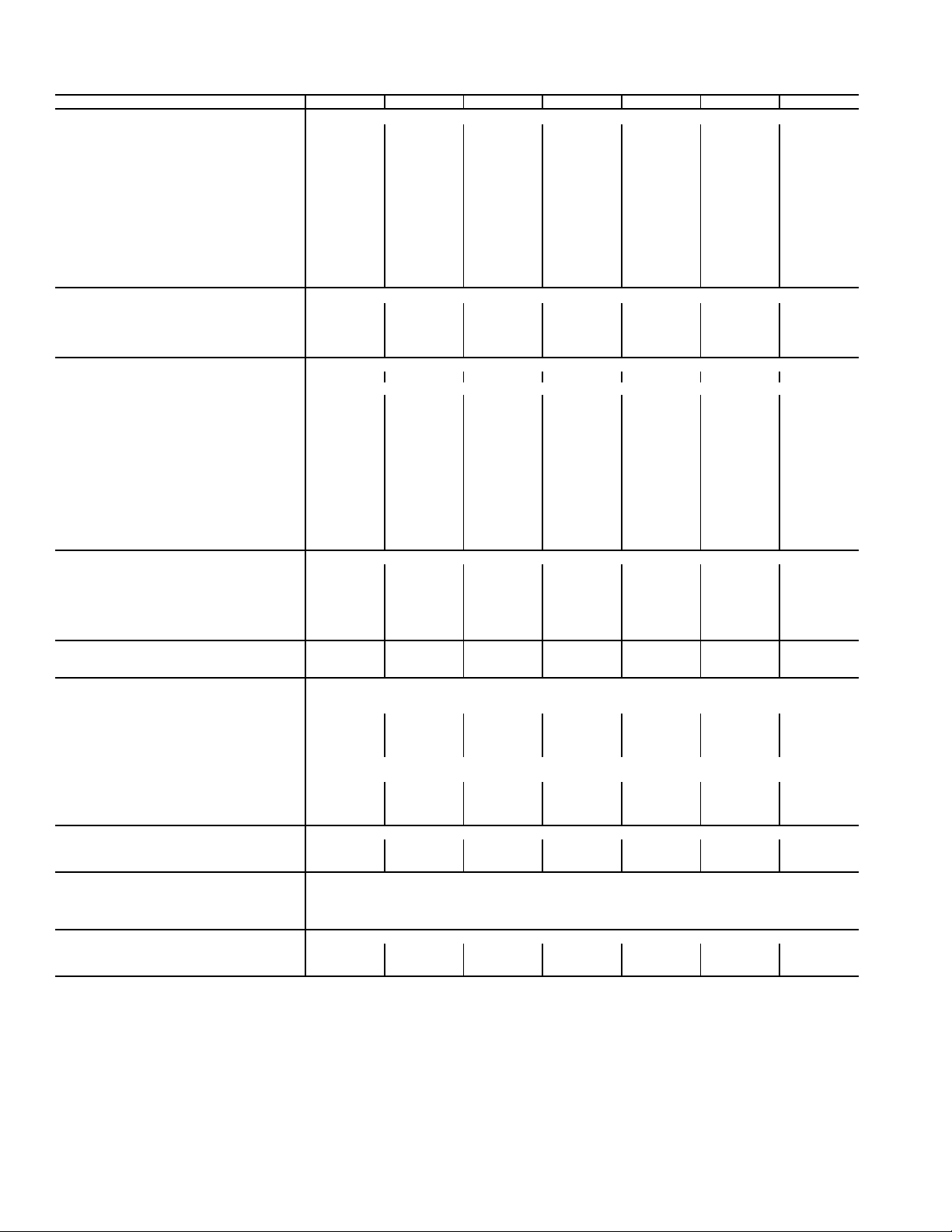

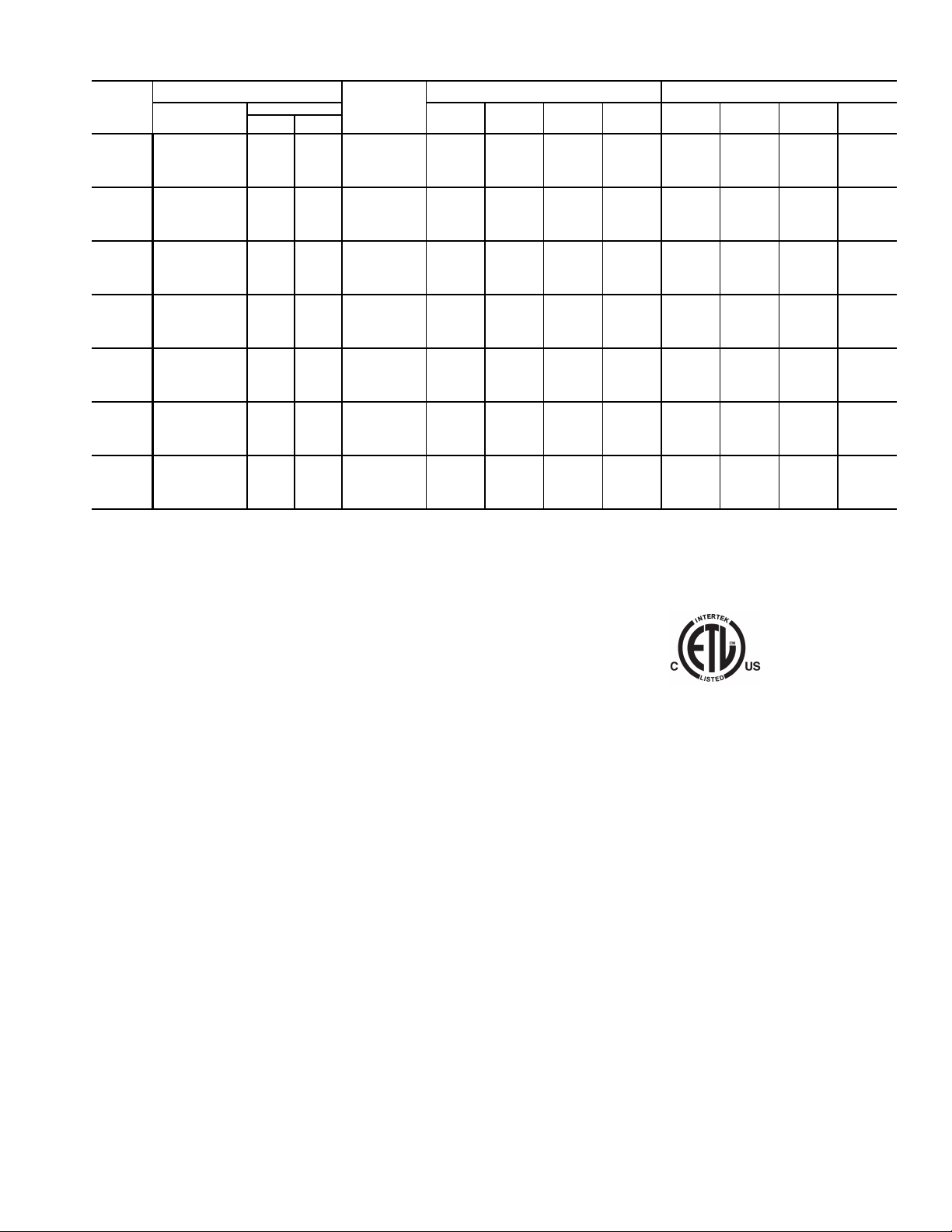

LEGEND

EMM —

Energy Management Module

GFI —

Ground Fault Interrupting

MCHX —

Microchannel Heat Exchanger

SCCR — Short Circuit Current Rating

VFD —

Variable Frequency Drive

Fig. 5 — AquaSnap® Chiller Model Number Designation, 30RAP070-150

P00030RA 0 66D070

30RA

–

Air-Cooled AquaSnap Chiller

Refrigerant Type

P – Puron

Revision Level

B –

Current Revision Level

Unit Sizes

070 115

080 130

090 150

100

Voltage

1 –

575-3-60

2 –

380-3-60

5 –

208/230-3-60

6 –

460-3-60

9 –

380/415-3-50

Condenser Coil and Low Sound Options

0 –

Aluminum/Copper, Value Sound Fan

1 –

Copper/Copper, Value Sound Fan

2 –

Aluminum/Copper, Pre-Coat, Value Sound Fan

3 –

Aluminum/Copper, E-Coat, Value Sound Fan

4 –

Copper/Copper, E-Coat, Value Sound Fan

5 –

MCHX, Value Sound Fan

6 –

MCHX, E-Coat, Value Sound Fan

7 –

Aluminum/Copper, AeroAcoustic™ Fan

8 –

Copper/Copper, AeroAcoustic Fan

9 –

Copper/Aluminum, Pre-Coat, AeroAcoustic Fan

B – Copper/

Aluminum, E-Coat, AeroAcoustic Fan

C –

Copper/Copper, E-Coat, AeroAcoustic Fan

D –

MCHX, AeroAcoustic Fan

F –

MCHX, E-Coat, AeroAcoustic Fan

J –

MCHX, AeroAcoustic Fan, Compressor Blanket(s)

K –

MCHX, E-Coat, AeroAcoustic Fan, Compressor Blanket(s)

L –

Aluminum/Copper, AeroAcoustic Fan, Compressor Blanket(s)

M –

Copper/Copper, AeroAcoustic Fan, Compressor Blanket(s)

N –

Aluminum/Copper, Pre-Coat, AeroAcoustic Fan, Compressor Blanket(s)

P –

Aluminum/Copper, E-Coat, AeroAcoustic Fan, Compressor Blanket(s)

Q –

Copper/Copper, E-Coat, AeroAcoustic Fan, Compressor Blanket(s)

Hydronic System

Ambient/Capacity Control/High SCCR Options

0 –

Std Comp

1 –

Hot Gas Bypass

2 –

Digital Comp

3 –

Std Comp, High SCCR

4 –

Hot Gas Bypass, High SCCR

5 –

Digital Comp, High SCCR

6 –

Low Ambient, Std Comp

7 –

Low Ambient, Hot Gas Bypass

8 –

Low Ambient, Digital Comp

9 –

Low Ambient, Std Comp, High SCCR

B –

Low Ambient, Hot Gas Bypass, High SCCR

C –

Low Ambient, Digital Comp, High SCCR

D –

Std Comp, Suction Service Valve

F –

Hot Gas Bypass, Suction Service Valve

G –

Digital Comp, Suction Service Valve

H –

Std Comp, High SCCR, Suction Service Valve

J –

Hot Gas Bypass, High SCCR, Suction Service Valve

K –

Digital Comp, High SCCR, Suction Service Valve

L –

Low Ambient, Std Comp, Suction Service Valves

M –

Low Ambient, Hot Gas Bypass, Suction Service Valves

N –

Low Ambient, Digital Comp, Suction Service Valves

P –

Low Ambient, Std Comp, High SCCR, Suction Service

Valves

Q –

Low Ambient, Hot Gas Bypass, High SCCR, Suction Service

Valves

R –

Low Ambient, Digital Comp, High SCCR, Suction Service

Valves

Electrical Options

Controls/Communications Options

0 –

Std

1 –

Std, BACnet Communication

5 –

EMM

6 – EMM,

BACnet Communication

B –

EMM, GFI

C – EMM, GFI,

BACnet Communication

H – GFI

J – GFI,

BACnet Communication

Packaging/Security Options

0 –

Std Packaging

4 –

Security Grilles/Hail Guards Only

8 –

Skid Only

D –

Skid, Security Grilles/Hail Guards

J –

Skid, Top Crate, Bag

N –

Skid, Top Crate, Bag, Security Grilles/Hail Guards

®

0 –

No Pump

1 –

Single Pump, 3 Hp

2 –

Single Pump, 5 Hp

3 –

Single Pump, 7.5 Hp

4 –

Single Pump, 10 Hp

5 –

Single Pump, 15 Hp

6 –

Dual Pump, 3 Hp

7 –

Dual Pump, 5 Hp

8 –

Dual Pump, 7.5 Hp

9 –

Dual Pump, 10 Hp

B –

Dual Pump, 15 Hp

D –

Single Pump, 5 Hp with VFD

F –

Single Pump, 7.5 Hp with VFD

G –

Single Pump, 10 Hp with VFD

H –

Single Pump, 15 Hp with VFD

J –

Dual Pump, 3 Hp with VFD

K –

Dual Pump, 5 Hp with VFD

L –

Dual Pump, 7.5 Hp with VFD

M –

Dual Pump, 10 Hp with VFD

N –

Dual Pump, 15 Hp with VFD

0 – Single Point,

No Disconnect, No Cooler Heater

1 – Single Point,

No Disconnect, Cooler Heater

2 – Single Point,

Non-Fused Disconnect, No Cooler Heater

3 – Single Point,

Non-Fused Disconnect, Cooler Heater

4 – Dual Point,

No Disconnect, No Cooler Heater

5 – Dual Point,

No Disconnect, Cooler Heater

B

a30-6072

4

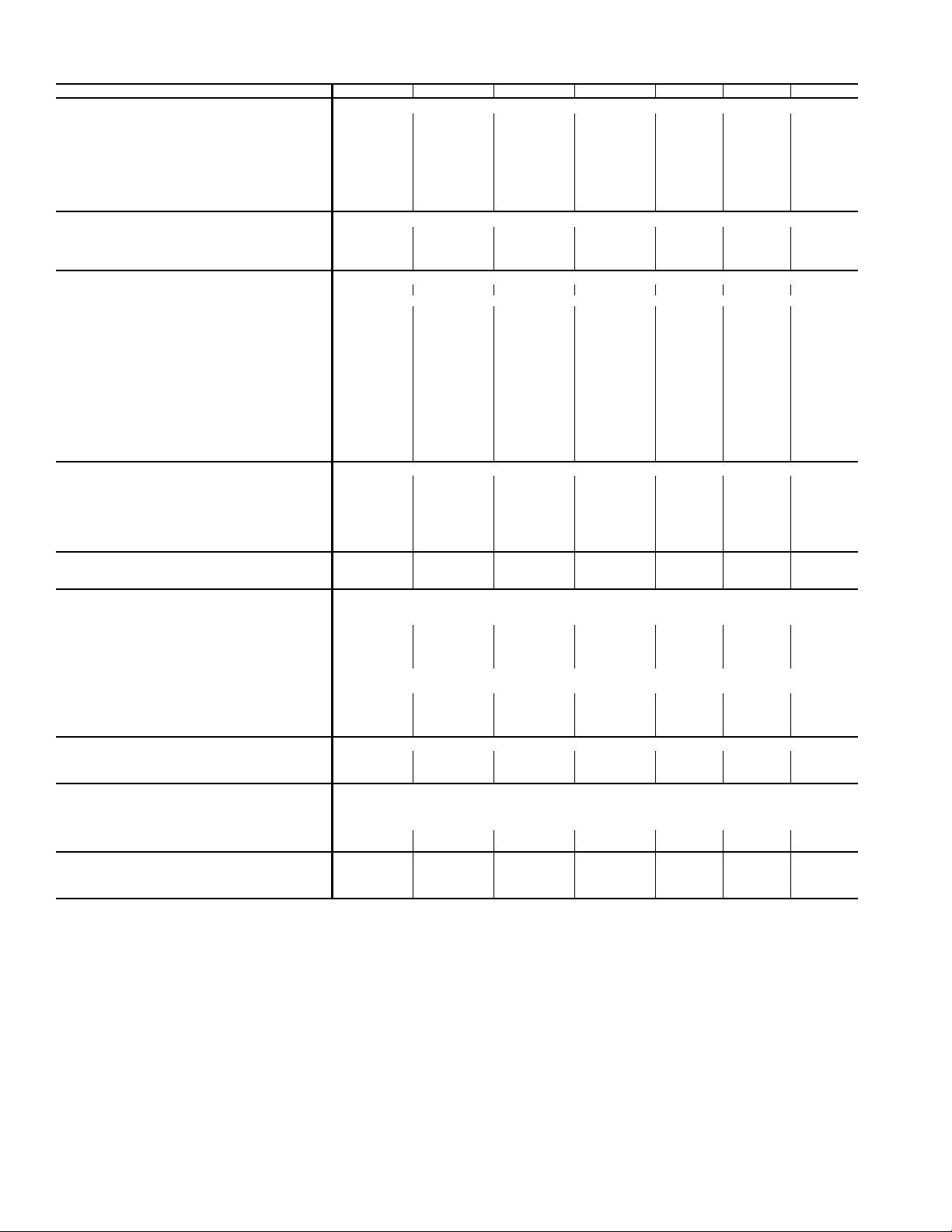

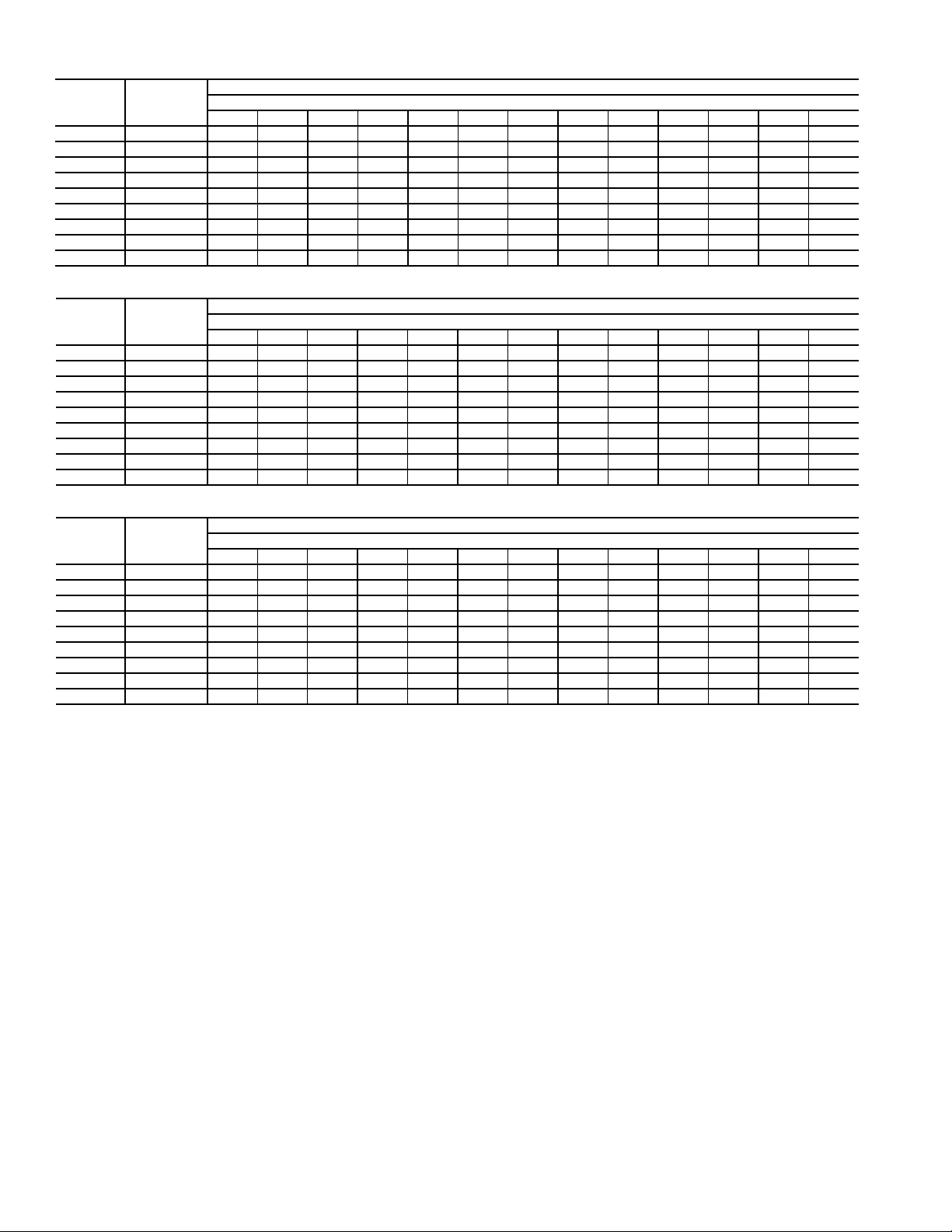

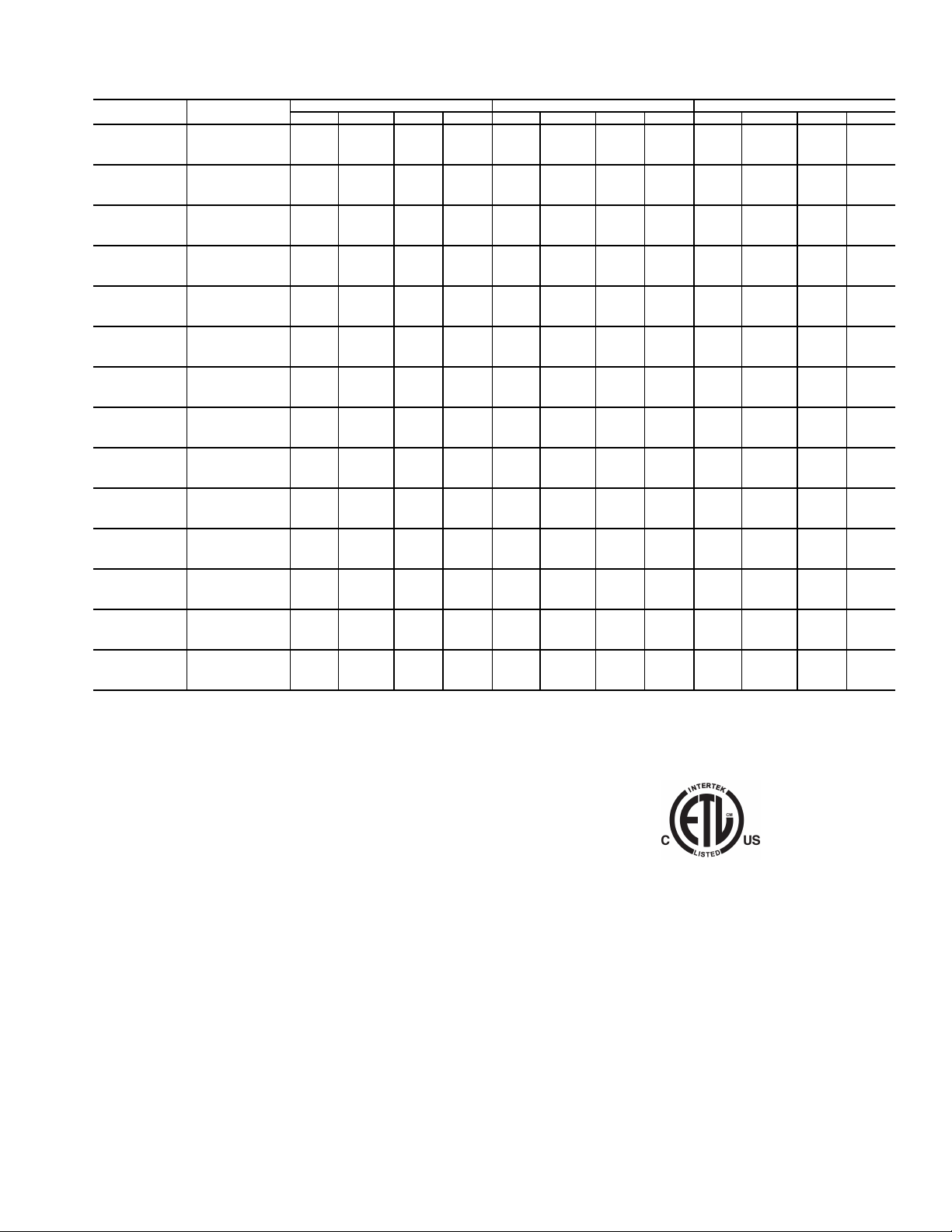

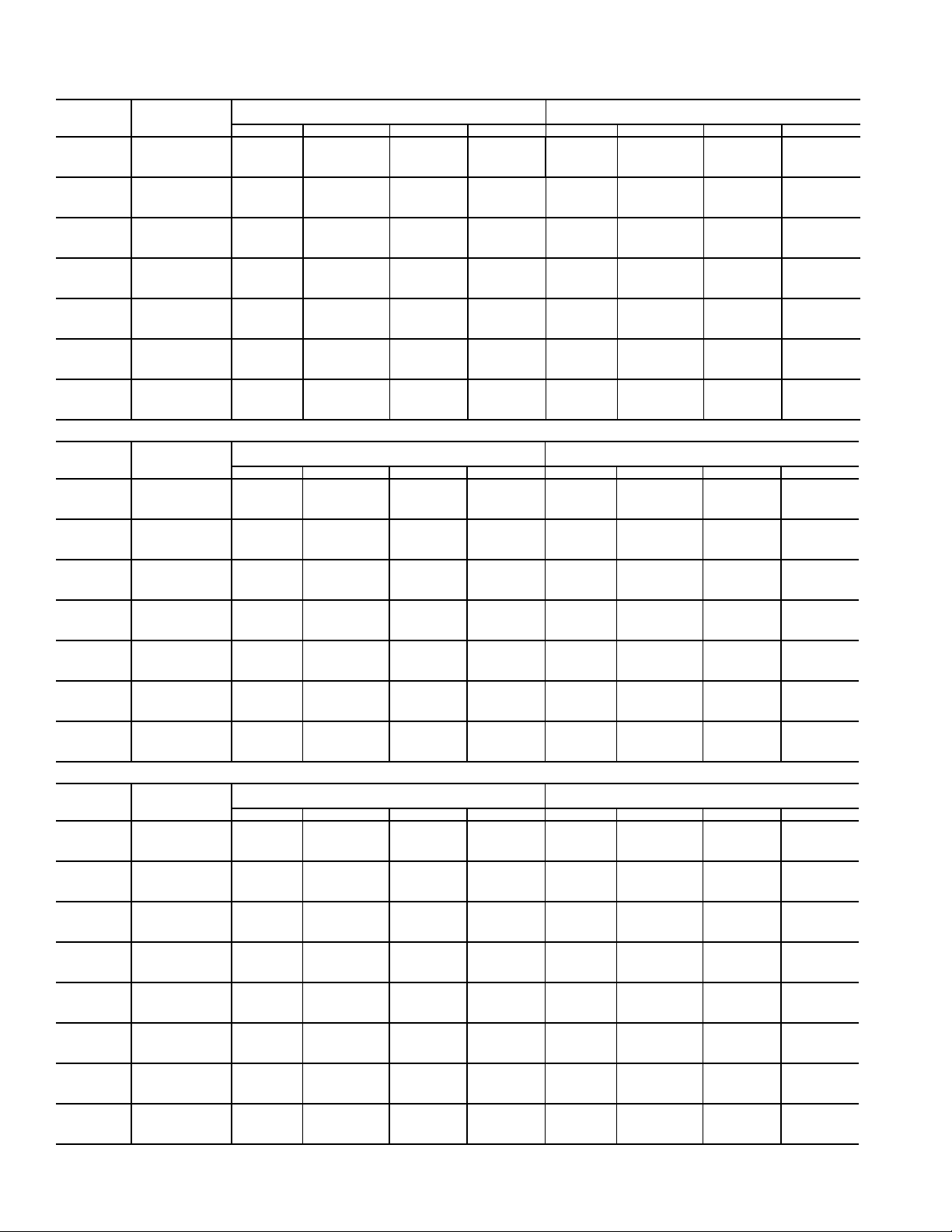

Table 1 — MCHX Unit Operating Weights

MCHX STANDARD UNITS

30RAP

SIZE

010 188 209 161 146 — — 704 010 86 95 73 66 — — 319

011 216 209 161 176 — — 762 011 98 95 73 80 — — 346

015 193 213 163 149 — — 718 015 88 97 74 67 — — 326

016 245 213 163 179 — — 800 016 111 97 74 81 — — 363

018 363 264 209 288 — — 1125 018 165 120 95 131 — — 510

020 365 266 211 290 — — 1133 020 166 121 96 132 — — 514

025 393 290 237 321 — — 1242 025 178 132 108 146 — — 564

030 405 301 246 331 — — 1283 030 184 136 112 150 — — 582

035 652 730 413 369 — — 2163 035 296 331 187 167 — — 981

040 704 697 390 394 — — 2185 040 319 316 177 179 — — 991

045 675 758 425 379 — — 2238 045 306 344 193 172 — — 1015

050 732 724 401 405 — — 2263 050 332 328 182 184 — — 1026

055 744 762 437 427 — — 2369 055 337 346 198 194 — — 1075

060 746 762 438 429 — — 2375 060 338 346 199 195 — — 1077

070 930 984 727 770 — — 3410 070 422 446 330 349 — — 1547

080 936 1038 791 877 — — 3641 080 425 471 359 398 — — 1652

090 952 1057 800 888 — — 3697 090 432 479 363 403 — — 1677

100 779 805 963 617 595 931 4690 100 353 365 437 280 270 422 2127

115 796 824 1027 697 672 991 5008 115 361 374 466 316 305 450 2272

130 1100 1179 1430 680 682 1380 6451 130 499 535 649 309 309 626 2926

150 1120 1205 1554 779 781 1499 6938 150 508 546 705 353 354 680 3147

A B C D E F Total Weight A B C D E F Total Weight

WEIGHT AT MOUNTING POINTS (lb)

30RAP

SIZE

MCHX SINGLE PUMP UNITS

30RAP

SIZE

010 215 264 213 174 — — 866 010 98 120 97 79 — — 393

011 243 264 213 204 — — 924 011 110 120 97 93 — — 419

015 220 268 215 177 — — 880 015 100 122 98 80 — — 399

016 272 268 215 207 — — 962 016 123 122 98 94 — — 436

018 404 306 249 329 — — 1288 018 183 139 113 149 — — 584

020 406 308 251 331 — — 1296 020 184 140 114 150 — — 588

025 434 332 277 362 — — 1405 025 197 151 126 164 — — 637

030 446 342 286 372 — — 1446 030 202 155 130 169 — — 656

035 677 877 537 415 — — 2507 035 307 398 244 188 — — 1137

040 728 846 513 441 — — 2529 040 330 384 233 200 — — 1147

045 701 906 550 425 — — 2582 045 318 411 249 193 — — 1171

050 756 873 524 453 — — 2606 050 343 396 238 206 — — 1182

055 768 910 561 474 — — 2713 055 349 413 254 215 — — 1231

060 771 910 562 476 — — 2719 060 350 413 255 216 — — 1233

070 1036 1032 871 874 — — 3812 070 470 468 395 396 — — 1729

080 1054 1070 963 948 — — 4035 080 478 485 437 430 — — 1830

090 1063 1082 967 950 — — 4061 090 482 491 438 431 — — 1842

100 1105 871 886 823 554 850 5089 100 501 395 402 373 252 385 2308

115 1121 892 948 904 631 912 5407 115 508 405 430 410 286 414 2453

130 1418 1252 1415 817 615 1333 6850 130 643 568 642 370 279 605 3107

150 1437 1280 1537 916 714 1453 7337 150 652 581 697 415 324 659 3328

A B C D E F Total Weight A B C D E F Total Weight

WEIGHT AT MOUNTING POINTS (lb)

30RAP

SIZE

MCHX DUAL PUMP UNITS

30RAP

SIZE

010 242 319 266 202 — — 1029 010 110 145 121 92 — — 467

011 270 319 266 232 — — 1087 011 123 145 121 105 — — 493

015 247 323 268 205 — — 1043 015 112 147 121 93 — — 473

016 299 323 268 235 — — 1125 016 136 147 121 107 — — 510

018 445 347 288 370 — — 1450 018 202 157 131 168 — — 658

020 447 349 290 372 — — 1458 020 203 158 132 169 — — 661

025 475 373 316 403 — — 1567 025 216 169 144 183 — — 711

030 487 383 325 413 — — 1608 030 221 174 147 187 — — 729

035 705 1022 664 459 — — 2850 035 320 463 301 208 — — 1293

040 755 992 639 486 — — 2872 040 343 450 290 221 — — 1303

045 729 1051 677 469 — — 2925 045 331 477 307 213 — — 1327

050 783 1019 649 499 — — 2950 050 355 462 295 226 — — 1338

055 796 1055 687 518 — — 3056 055 361 479 312 235 — — 1386

060 798 1056 688 520 — — 3062 060 362 479 312 236 — — 1389

070 1123 1036 928 1005 — — 4092 070 509 470 421 456 — — 1856

080 1159 1094 1038 1099 — — 4390 080 526 496 471 499 — — 1991

090 1167 1104 1041 1099 — — 4411 090 529 501 472 499 — — 2001

100 1353 908 820 990 506 797 5374 100 614 412 372 449 229 361 2438

115 1367 931 881 1070 583 860 5692 115 620 422 400 485 264 360 2582

130 1658 1297 1404 922 559 1295 7135 130 752 588 637 418 254 587 3236

150 1676 1326 1526 1020 659 1415 7622 150 760 601 692 463 299 642 3457

NOTE: See Fig. 6 for unit mounting points.

A B C D E F Total Weight A B C D E F Total Weight

WEIGHT AT MOUNTING POINTS (lb)

30RAP

SIZE

WEIGHT AT MOUNTING POINTS (kg)

WEIGHT AT MOUNTING POINTS (kg)

WEIGHT AT MOUNTING POINTS (kg)

5

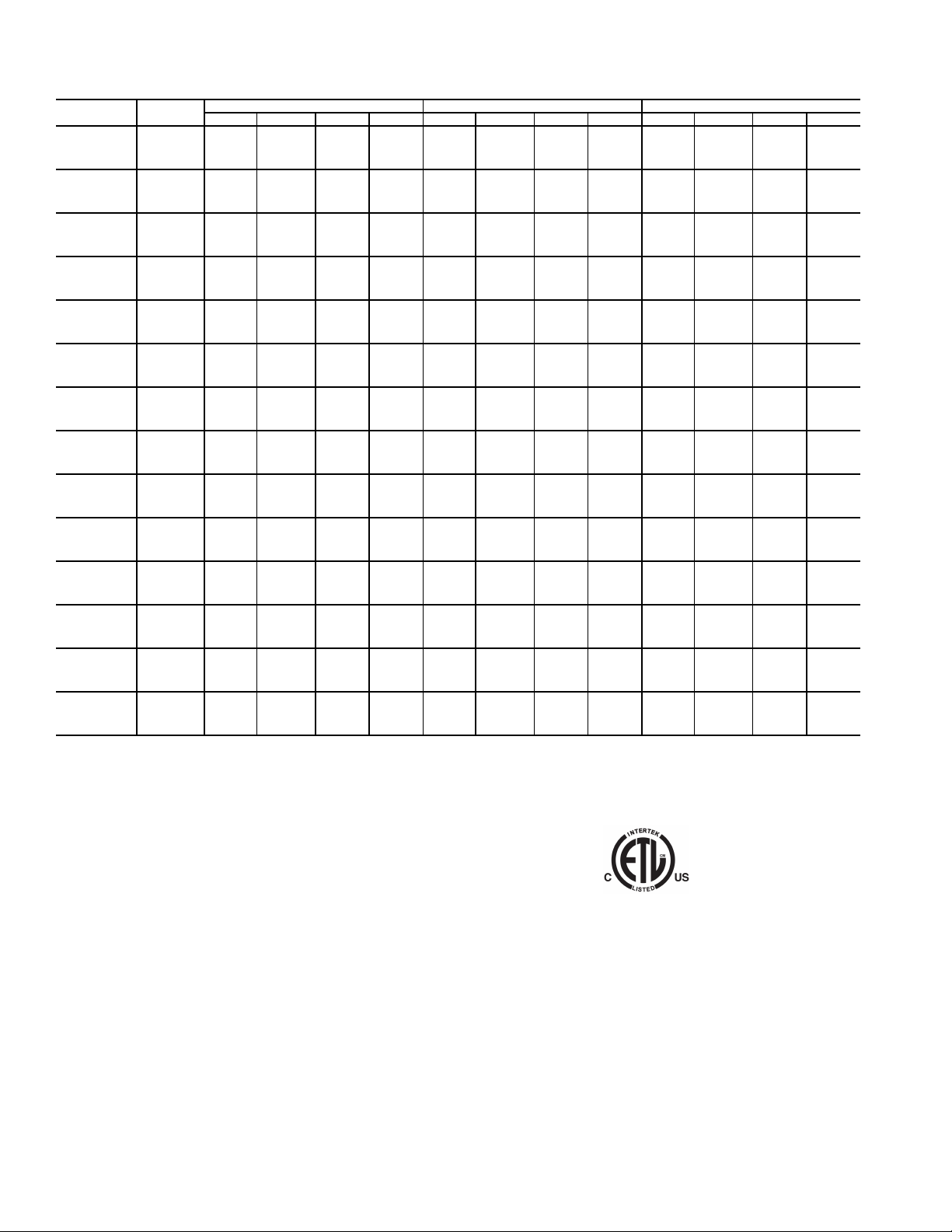

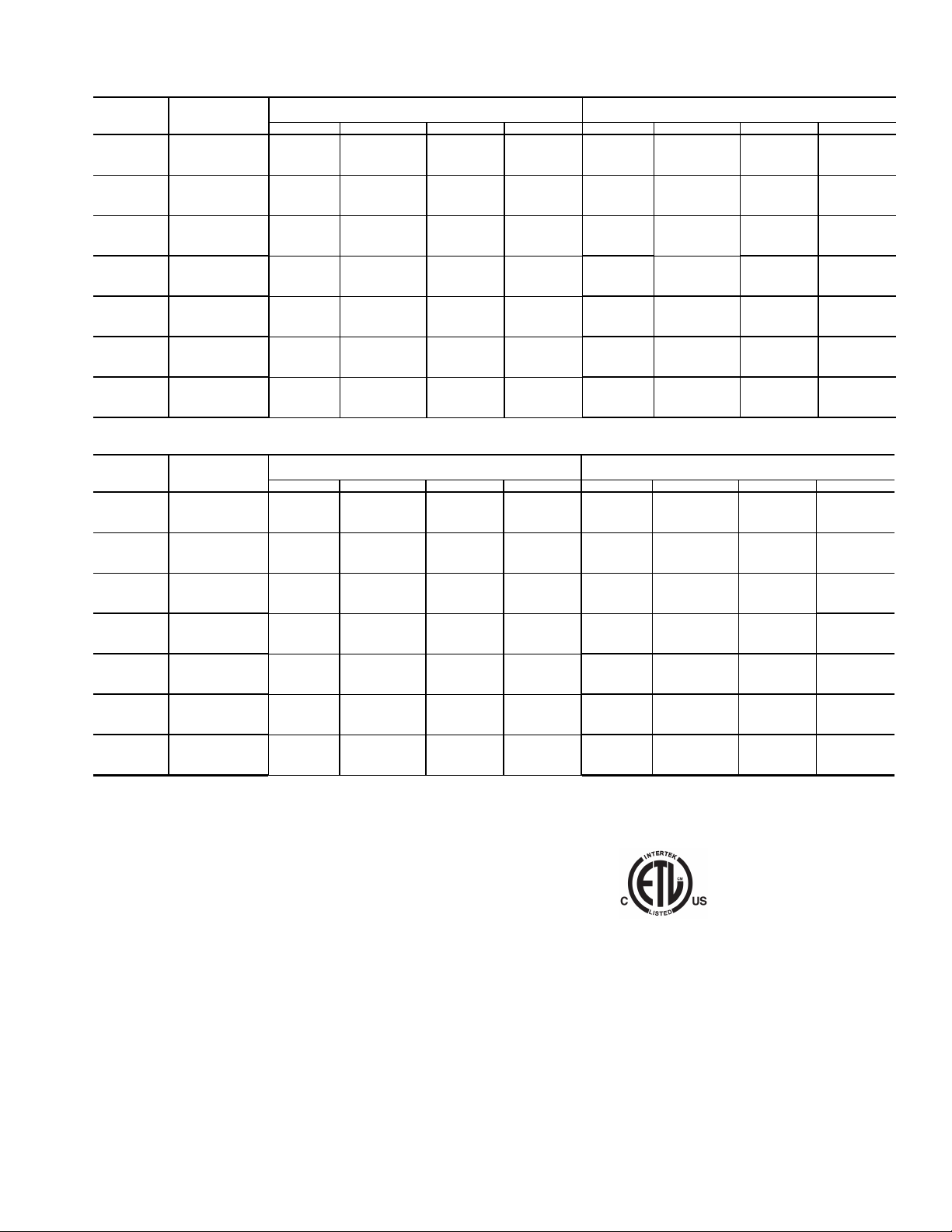

Table 2 — RTPF Unit Operating Weights (

AL/CU COIL NO PUMP UNITS

Al/Cu Coil)

30RAP

SIZE

070 1017 1030 862 851 — — 3759 070 461 467 391 386 — — 1705

080

090

100

115

130

150

A B C D E F

1062 1100 968 935

1035 1153 1018 914

887 911 1179 724

913 940 1261 813

1183 1261 1596 763

1213 1296 1739 871

WEIGHT AT MOUNTING POINTS (lb)

— —

— —

702 1145

789 1223

765 1545

873 1682

Total

Weight

4064

4119

5548

5939

7113

7673

30RAP

SIZE

080

090

100

115

130

150

WEIGHT AT MOUNTING POINTS (kg)

A B C D E F

482 499 439 424

469 523 462 414

402 413 535 328

414 427 572 369

537 572 724 346

550 588 789 395

— —

— —

319 519

358 555

347 701

396 763

AL/CU COIL SINGLE PUMP UNITS

30RAP

SIZE

070 1126 1140 954 942 — — 4161 070 511 517 433 427 — — 1887

080

090

100

115

130

150

A B C D E F

1164 1206 1062 1025

1126 1255 1108 994

1215 982 1098 929

1240 1012 1178 1019

1506 1337 1577 901

1534 1373 1718 1009

WEIGHT AT MOUNTING POINTS (lb)

— —

— —

664 1059

750 1140

696 1495

804 1634

Total

Weight

4457

4483

5947

6338

7512

8072

30RAP

SIZE

080

090

100

115

130

150

WEIGHT AT MOUNTING POINTS (kg)

A B C D E F

528 547 482 465

511 569 502 451

551 445 498 421

562 459 534 462

683 606 715 409

696 623 779 458

— —

— —

301 480

340 517

316 678

365 741

AL/CU COIL DUAL PUMP UNITS

30RAP

SIZE

070 1201 1216 1018 1005 — — 4441 070 545 552 462 456 — — 2014

080

090

100

115

130

150

LEGEND

AL/CU — Aluminum Fin/Copper Tube

A B C D E F

1237 1282 1128 1089

1197 1333 1177 1057

1459 1023 1034 109

1483 1055 1113 1180

1744 1383 1565 1005

1771 1421 1706 1112

WEIGHT AT MOUNTING POINTS (lb)

— —

— —

622 1004

708 1085

641 1458

750 1597

Total

Weight

4737

4763

6232

6623

7797

8357

30RAP

SIZE

080

090

100

115

130

150

NOTE: See Fig. 6 for unit mounting points.

WEIGHT AT MOUNTING POINTS (kg)

A B C D E F

561 581 512 494

543 605 534 479

662 464 469 495

673 478 505 535

791 627 710 456

803 645 774 504

— —

— —

282 455

321 492

291 661

340 724

Total

Weight

1843

1868

2516

2694

3226

3480

Total

Weight

2022

2033

2697

2875

3407

3661

Total

Weight

2149

2160

2827

3004

3536

3790

6

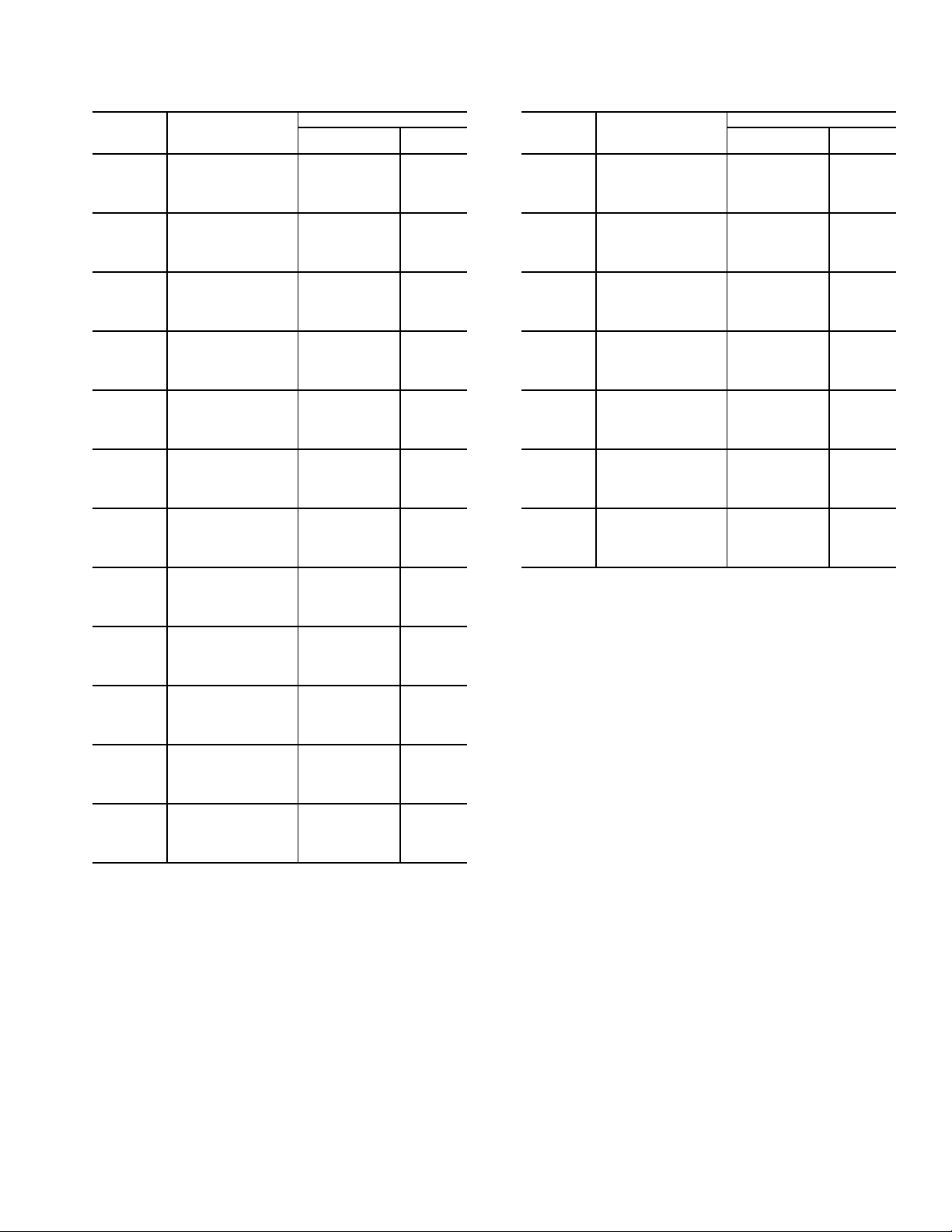

Table 3 —

B

A

C

D

CONTROL

BOX

SIDE

30RAP010-030

UNITS

30RAP035-090

UNITS

a30-4861

Fig. 6 — Unit Mounting Points

30RAP100-150

UNITS

a30-5439

RTPF Unit Operating Weights (Cu/Cu Coil)

CU/CU COIL NO PUMP UNITS

30RAP

SIZE

WEIGHT AT MOUNTING POINTS (lb)

A B C D E F

Total

Weight

30RAP

SIZE

WEIGHT AT MOUNTING POINTS (kg)

A B C D E F

070 1179 1194 999 987 — — 4359 070 535 542 453 448 — — 1977

080

1250 1294 1140 1100

090

1216 1354 1196 1073

100

115

130

150

992 1016 1389 829

1033 1060 1501 933

1319 1395 1867 898

1363 1445 2039 1021

— —

— —

808 1354

909 1463

900 1814

1023 1981

4784

4839

6388

6899

8193

8873

080

090

100

115

130

150

567 587 517 499

552 614 542 487

450 461 630 376

469 481 681 423

598 633 847 407

— —

— —

366 614

412 664

408 823

618 655 925 463 464 899 4025

CU/CU COIL SINGLE PUMP UNITS

30RAP

SIZE

A B C D E F

WEIGHT AT MOUNTING POINTS (lb)

Total

Weight

30RAP

SIZE

070 1288 1304 1091 1078 — — 4761 070 584 591 495 489 — — 2160

080

1352 1401 1233 1191

090

1307 1456 1285 1154

100

1317 1090 1308 1030

115

1357 1135 1418 1135

130

1639 1474 1846 1035

150

1682 1525 2017 1158 955 1935 9272 150 763 692 915 525 433 878 4206

— —

— —

773 1268

873 1379

832 1766

5177

5203

6787

7298

8592

080

090

100

115

130

WEIGHT AT MOUNTING POINTS (kg)

A B C D E F

613 635 559 540

593 660 583 524

597 494 593 467

615 515 643 515

743 668 837 469

— —

— —

351 575

396 626

377 801

CU/CU COIL DUAL PUMP UNITS

30RAP

SIZE

A B C D E F

WEIGHT AT MOUNTING POINTS (lb)

Total

Weight

30RAP

SIZE

070 1364 1381 1156 1141 — — 5041 070 618 626 524 518 — — 2287

080

1425 1476 1300 1255

090

1378 1534 1355 1216

100

1558 1134 1246 1187

115

1597 1181 1356 1291

130

1875 1523 1834 1137

150

1917 1575 2004 1260

— —

— —

735 1211

836 1323

778 1730

902 1899

5457

5483

7072

7583

8877

080

090

100

115

130

9557 150 870 715 909 571 406 861 4335

LEGEND NOTE: See Fig. 6 for unit mounting points.

CU/CU — Copper Fin/Copper Tube

WEIGHT AT MOUNTING POINTS (kg)

A B C D E F

647 670 590 569

625 696 614 552

707 514 565 539

724 536 615 586

851 691 832 516

— —

— —

333 549

379 600

353 785

Total

Weight

2170

2195

2898

3129

3716

Total

Weight

2348

2360

3078

3310

3897

Total

Weight

2475

2487

3208

3440

4026

C

CONTROL

BOX

SIDE

B

A

B

CONTROL

BOX

SIDE

A

C

F

D

E

D

7

Table 4 —

Physical Data, 30RAP — English

UNIT 30RAP 010 011 015 016 018 020 025

OPERATING WEIGHT (lb)

MCHX Condenser Coil, No Pump 704 762 718 800 1125 1133 1242

MCHX Condenser Coil, Single Pump

(60 Hz only)

MCHX Condenser Coil, Dual Pump

(60 Hz only)

Al-Cu Condenser Coil, No Pump — — — — — — —

Al-Cu Condenser Coil, Single Pump

(60 Hz only)

Al-Cu Condenser Coil, Dual Pump

(60 Hz only)

Cu-Cu Condenser Coil, No Pump — — — — — — —

Cu-Cu Condenser Coil, Single Pump

(60 Hz only)

Cu-Cu Condenser Coil, Dual Pump

(60 Hz only)

REFRIGERANT TYPE R-410A, EXV Controlled System

Total Refrigerant Charge (lb) 8.6 8.3 9.6 10.0 14.6 15.2 16.7

Refrigerant Charge (lb) Ckt A/Ckt B 8.6/— 8.3/— 9.6/— 10.0/— 14.6/— 15.2/— 16.7/—

Total Refrigerant Charge RTPF (lb) — — — — — — —

Refrigerant Charge RTPF (lb)

Ckt A/Ckt B

COMPRESSORS Scroll, Hermetic

Quantity 1 2 1 2 2 2 2

Speed (Rpm)

(Qty) Tons, Ckt A (1) 11 (2) 6/4 (1) 15 (2) 9/6 (2) 9 (2) 10 (2) 13

(Qty) Tons, Ckt B — — — — — — —

Oil Charge (Pt) Ckt A/Ckt B 6.9/— 6.4/—

No. Capacity Steps

Standard 1 2 1 2 2 2 2

With Hot Gas Bypass — — — — 3 3 3

Digital Compressor Option 13 21 13 21 22 22 22

Minimum Capacity Step (%)

Standard 100 40 100 40 50 50 50

With Hot Gas Bypass — — — — 20 24 29

Digital Compressor Option 20 20 20 20 17 17 17

Capacity (%)

Circuit A 100 100 100 100 100 100 100

Circuit B — — — — — — —

COOLER Brazed, Direct-Expansion Plate Heat Exchanger

Weight (lb) (empty) 22.4 22.4

Net Fluid Volume (gal) 0.6 0.6 0.8 0.9 0.9 1.2 1.4

Maximum Refrigerant Pressure (psig) 505 505 505 505 505 505 505

Maximum Water-Side Pressure

Without Pump(s) (psig)

Maximum Water-Side Pressure

With Pump(s) (psig)

CHILLER WATER CONNECTIONS (in.)

Inlet and Outlet, Victaulic (IPS Carbon Steel)* 2 2 2 2 2 2 2

Drain (NPT)

CONDENSER FANS

Standard Low-Sound AeroAcoustic™ Type Plastic Type, Axial, Vertical Discharge

Fan Speed (Rpm) 850 (60 Hz)/710 (50 Hz)

No. Blades...Diameter (in.) 9...30 9...30 9...30 9...30 9...30 9...30 9...30

No. Fans 1 1 1 1 2 2 2

Total Airflow 60 Hz (Cfm) 9400 9400 9400 9400 17,500 17,500 19,400

Total Airflow 50 Hz (Cfm) 7849 7849 7849 7849 14,613 14,613 16,199

Optional Value Sound Type

Fan Speed (Rpm) 1140 (60 Hz)/950 (50 Hz)

No. Blades...Diameter (in.) 4...30 4...30 4...30 4...30 4...30 4...30 4...30

No. Fans 1 1 1 1 2 2 2

Total Airflow 60 Hz (Cfm) 10,100 10,100 10,100 10,100 18,500 18,500 20,900

Total Airflow 50 Hz (Cfm) 8434 8434 8434 8434 15,448 15,448 17,452

CONDENSER COILS Novation

Quantity (Ckt A/Ckt B) 1/— 1/— 1/— 1/— 1/— 1/— 1/—

Total Face Area (sq ft) 17 19 17 19 26 26 33

Maximum Refrigerant Pressure (psig) 656 656 656 656 656 656 656

HYDRONIC MODULE (Optional, 60 Hz only)†

Pump Single or Dual, Centrifugal Monocell Pump(s), 3500 Rpm. D

Expansion Tank Volume (gal)

Total/Acceptance 4.4/3.2

CHASSIS DIMENSIONS (ft - in.)

Length 5-7 5-7 5-7 5-7 7-5 7-5 7-5

Width 3-5 3-5 3-5 3-5 3-5 3-5 3-5

Height 5-6 5-6 5-6 5-6 5-6 5-6 6-6

EXV — Electronic Expansion Valve

MCHX — Microchannel Heat Exchanger

RTPF — Round Tube, Plate Fin (Condenser Coil)

LEGEND

866 924 880 962 1288 1296 1405

1029 1087 1043 1125 1450 1458 1567

— — — — — — —

— — — — — — —

— — — — — — —

— — — — — — —

— — — — — — —

3500 (60 Hz)/2900 (50 Hz)

6.9/—

9.1/—

13.8/— 13.8/— 13.8/—

27.5 31.8 31.8 40.3 46.3

300 300 300 300 300 300 300

150 150 150 150 150 150 150

1

/

4

Pump(s), Strainer with Blowdown Valve, Expansion Tank,

1

/

4

1

/

4

Propeller Type, Axial, V

®

MCHX Aluminum Tube, Aluminum Fin

*Unit connection is IPS Carbon Steel piping.

†Flow switch and strainer are standard on all units, with or without hydronic

package.

NOTE: 30RAP chillers with Greenspeed

sizes 010, 015, and 070-150.

1

/

4

1

/

4

1

/

4

ertical Discharge

Pressure Taps, Drain and Vent Plugs, Flow Switch, and

Balance Valve

ual pumps with check valves and isolation valves.

®

intelligence are not available on unit

1

/

4

8

Table 4 — Physical Data, 30RAP — English (cont)

UNIT 30RAP 030 035 040 045 050 055 060

OPERATING WEIGHT (lb)

MCHX Condenser Coil, No Pump 1283 2163 2185 2238 2263 2369 2375

MCHX Condenser Coil, Single Pump

(60 Hz only)

MCHX Condenser Coil, Dual Pump

(60 Hz only)

Al-Cu Condenser Coil, No Pump — — — — — — —

Al-Cu Condenser Coil, Single Pump

(60 Hz only)

Al-Cu Condenser Coil, Dual Pump

(60 Hz only)

Cu-Cu Condenser Coil, No Pump — — — — — — —

Cu-Cu Condenser Coil, Single Pump

(60 Hz only)

Cu-Cu Condenser Coil, Dual Pump

(60 Hz only)

REFRIGERANT TYPE

Total Refrigerant Charge (lb) 19.6 29.2 29.9 33.5 33.7 34.3 34.5

Refrigerant Charge (lb) Ckt A/Ckt B 19.6/— 14.3/14.9 14.9/15.0 16.5/17.0 16.7/17.0 16.9/17.4 17.1/17.4

Total Refrigerant Charge RTPF (lb) — — — — — — —

Refrigerant Charge RTPF (lb)

Ckt A/Ckt B

COMPRESSORS

Quantity 2 4 4 4 4 4 4

Speed (Rpm) 3500 (60 Hz)/2900 (50 Hz)

(Qty) Tons, Ckt A (2) 15 (2) 10 (2) 10 (2) 11 (2) 13 (2) 13 (2) 15

(Qty) Tons, Ckt B — (2) 9 (2) 11 (2) 13 (2) 13 (2) 15 (2) 15

Oil Charge (Pt) Ckt A/Ckt B

No. Capacity Steps

Standard 2 4 4 4 4 4 4

With Hot Gas Bypass 3 5 5 5 5 5 5

Digital Compressor Option 22 44 44 44 44 44 44

Minimum Capacity Step (%)

Standard 50 23 23 24 25 23 25

With Hot Gas Bypass 32 9 11 12 14 13 16

Digital Compressor Option 17 9 8 8 8 8 8

Capacity (%)

Circuit A 100 54 47 47 50 46 50

Circuit B — 46 53 53 50 54 50

COOLER

Weight (lb) (empty) 99.3 99.4

Net Fluid Volume (gal) 2.62 2.6 3.3 3.5 4.1 5.0 5.0

Maximum Refrigerant Pressure (psig) 565 565 565 565 565 565 565

Maximum Water-Side Pressure

Without Pump(s) (psig)

Maximum Water-Side Pressure

With Pump(s) (psig)

CHILLER WATER CONNECTIONS (in.)

Inlet and Outlet, Victaulic (IPS Carbon Steel)* 2 2

Drain (NPT)

CONDENSER FANS

Standard Low-Sound AeroAcoustic™ Type Plastic Type, Axial, Vertical Discharge

Fan Speed (Rpm) 850 (60 Hz)/710 (50 Hz)

No. Blades...Diameter (in.) 9...30 9...30 9...30 9...30 9...30 9...30 9...30

No. Fans 2 3 3 3 3 4 4

Total Airflow 60 Hz (Cfm) 19,400 29,600 29,600

Total Airflow 50 Hz (Cfm) 16,199 24,716 24,716 25,468 25,468 32,398 32,398

Optional Value Sound Type

Fan Speed (Rpm) 1140 (60 Hz)/950 (50 Hz)

No. Blades...Diameter (in.) 4...30 4...30 4...30 4...30 4...30 4...30 4...30

No. Fans 2 3 3 3 3 4 4

Total Airflow 60 Hz (Cfm) 20,900 32,000 32,000 33,300 33,300 41,800 41,800

Total Airflow 50 Hz (Cfm) 17,452 26,720 26,720 27,805 27,805 34,903 34,903

CONDENSER COILS Novation

Quantity (Ckt A/Ckt B) 1/— 1/1 1/1 1/1 1/1 1/1 1/1

Total Face Area (sq ft) 33 53 53 66 66 66 66

Maximum Refrigerant Pressure (psig) 656 656 656 656 656 656 656

HYDRONIC MODULE (Optional, 60 Hz only)†

Pump Single or Dual, Centrifugal Monocell Pump(s), 3500 Rpm. Dual pumps with

Expansion Tank Volume (gal)

Total/Acceptance 4.4/3.2 10.3/10.3

CHASSIS DIMENSIONS (ft - in.)

Length 7-5 7-5 7-5 7-5 7-5 7-5 7-5

Width 3-5 7-9 7-9 7-9 7-9 7-9 7-9

Height 6-6 5-6 5-6 6-6 6-6 6-6 6-6

LEGEND *Unit connection is IPS Carbon Steel piping.

EXV — Electronic Expansion Valve

MCHX — Microchannel Heat Exchanger

RTPF — Round Tube, Plate Fin (Condenser Coil)

1446 2507 2529 2582 2606 2713 2719

1608 2850 2872 2925 2950 3056 3062

— — — — — — —

— — — — — — —

— — — — — — —

— — — — — — —

R-410A, EXV Controlled System

— — — — — — —

Scroll, Hermetic

13.8/— 13.8/13.8 13.8/13.8 13.8/13.8 13.8/13.8 13.8/13.8 13.8/13.8

Brazed, Direct-Expansion Plate Heat Exchanger

117.9 125.3 137.5 160.4 160.4

300 300 300 300 300 300 300

150 150 150 150 150 150 150

1

/

1

/

4

2

1

/

4

21/

2

1

/

4

21/

2

1

/

4

21/

2

1

/

4

21/

2

1

/

2

30,500 30,500 38,800 38,800

Propeller Type, Axial, V

Pump(s), Strainer with Blowdown Valve,

†Flow switch and strainer are standard on all units, with or without hydronic

package.

NOTE: 30RAP chillers with Greenspeed

sizes 010, 015, and 070-150.

®

MCHX Aluminum Tube, Aluminum Fin

Expansion Tank, Pressure Taps, Drain and Vent Plugs, Flow Switch, and

Balance Valve

ertical Discharge

check valves and isolation valves.

®

intelligence are not available on unit

21/

1

/

2

2

9

Table 4 — Physical Data, 30RAP — English (cont)

UNIT 30RAP 070 080 090 100 115 130 150

ERATING WEIGHT (lb)

OP

MCHX Condenser Coil, No Pump 3410 3641 3697 4690 5008 6451 6938

MCHX Condenser Coil, Single Pump (60 Hz only) 3812 4035 4061 5089 5407 6850 7337

MCHX Condenser Coil, Dual Pump (60 Hz only) 4092 4390 4411 5374 5692 7135 7622

Al-Cu Condenser Coil, No Pump 3759 4064 4119 5548 5939 7113 7673

Al-Cu Condenser Coil, Single Pump (60 Hz only) 4161 4457 4483 5947 6338 7512 8072

Al-Cu Condenser Coil, Dual Pump (60 Hz only) 4441 4737 4763 6232 6623 7797 8357

Cu-Cu Condenser Coil, No Pump 4359 4784 4839 6388 6899 8193 8873

Cu-Cu Condenser Coil, Single Pump (60 Hz only) 4761 5177 5203 6787 7298 8592 9272

Cu-Cu Condenser Coil, Dual Pump (60 Hz only) 5041 5457 5483 7072 7583 8877 9557

REFRIGERANT TYPE R-410A, EXV Controlled System

Total Refrigerant Charge MCHX (lb) 60.5 70.2 71.0 88.3 100.9 110.4 119.5

Refrigerant Charge MCHX (lb) Ckt A/Ckt B 25.5/35 35.1/35.1 35.5/35.5 39.3/49.0 50.6/50.3 51.2/59.2 60.0/59.5

Total Refrigerant Charge RTPF (lb) 150.0 169.2 170.0 192.0 213.0 239.2 264.0

Refrigerant Charge RTPF (lb) Ckt A/Ckt B 65.5/84.5 84.6/84.6 85.0/85.0 87.0/105.0 106.5/106.5 107.5/131.7 132.0/132.0

COMPRESSORS Scroll, Hermetic

Quantity 5665666

Speed (Rpm) 3500 (60 Hz)/ 2900 (50Hz)

(Qty, Tons) Ckt A (2) 15 (3) 13 (3) 15 (1) 20 (1) 25 (3) 20 (3) 20 (3) 25

(Qty, Tons) Ckt B (3) 15 (3) 15 (3) 15 (3) 20 (3) 20 (3) 25 (3) 25

Oil Charge (Pt) Ckt A/Ckt B

No. Capacity Steps

Standard 5665666

With Hot Gas Bypass 6776777

Digital Compressor Option 55 66 66 — — — —

Minimum Capacity Step (%)

Standard 20 15 17 19 17 15 17

With Hot Gas Bypass 13 9 11 13 11 9 11

Digital Compressor Option 7 5 6 — ———

Capacity (%)

Circuit A 40 46 50 43 50 44 50

Circuit B 60 54 50 57 50 56 50

COOLER Brazed, Direct-Expansion Plate Heat Exchanger

Weight (lb) (empty) 197 228 245 267 304 334 378

Net Fluid Volume (gal) 4.3 5.0 6.8 7.4 8.6 9.5 10.9

Maximum Refrigerant Pressure (psig) 450 450 450 450 450 450 450

Maximum Water-Side Pressure

Without Pump(s) (psig)

Maximum Water-Side Pressure

With Pump(s) (psig)

CHILLER WATER CONNECTIONS (in.)

Inlet and Outlet, Victaulic (IPS Carbon Steel)* 3334444

Drain (NPT)

CONDENSER FANS

Standard Low-Sound AeroAcoustic™ Type Plastic Type, Axial, Vertical Discharge

Fan Speed (Rpm) 850 (60 Hz)/710 (50 Hz)

No. Blades...Diameter (in.) 9...30 9...30 9...30 9...30 9...30 9...30 9...30

No. Fans 56678910

Total Airflow, 60 Hz (Cfm) 48,500 58,200 58,200 67,900 77,600 87,300 97,000

Total Airflow, 50 Hz (Cfm) 40,512 48,614 48,614 56,716 64,819 72,921 81,024

Optional Value Sound Type

Fan Speed (Rpm) 1140 (60 Hz)/950 (50 Hz)

No. Blades...Diameter (in.) 4...30 4...30 4...30 4...30 4...30 4...30 4...30

No. Fans 56678910

Total Airflow, 60 Hz (Cfm) 51,250 61,500 61,500 71,750 82,000 92,250 102,500

Total Airflow, 50 Hz (Cfm) 42,809 51,371 51,371 59,932 68,494 77,056 85,618

CONDENSER COILS Novation

Quantity (Ckt A/Ckt B) 2/3 3/3 3/3 3/4 4/4 4/5 5/5

Total Face Area (sq ft) 124.7 149.6 149.6 174.5 199.4 224.4 249.3

Maximum Refrigerant Pressure (psig) 656 656 656 656 656 656 656

HYDRONIC MODULE (Optional, 60 Hz Only)†

Pump

Expansion Tank Volume (gal)

Total/Acceptance ———————

CHASSIS DIMENSIONS (ft - in.)

Length 12-7 12-7 12-7 15-11 15-11 19-4 19-4

Width 7-47-47-47-47-47-47-4

Height 6-66-66-66-66-66-66-6

LEGEND

EXV — Electronic Expansion Valve

MCHX — Microchannel Heat Exchanger

RTPF — Round Tube, Plate Fin (Condenser Coil)

*Unit connection is IPS Carbon Steel piping.

†Flow switch and strainer are standard on all units, with or without hydronic

ckage.

pa

NOTE: 30RAP chillers with Greenspeed intelligence are not available on unit

010, 015, and 070-150.

sizes

13.8/20.6 20.6/20.6 20.6/20.6

28.4/42.6

42.6/42.6 42.6/42.6 42.6/42.6

300 300 300 300 300 300 300

150 150 150 150 150 150 150

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

Propeller Type, Axial, Vertical Discharge

®

MCHX Aluminum Tube, Aluminum Fin or RTPF

Pump(s), Strainer with Blowdown Valve, Expansion Tank, Pressure Taps, Drain and Vent Plugs, Flow Switch,

Single or Dual, Centrifugal Monocell Pump(s), 3500 Rpm. Dual pumps with check valves and isolation

and Balance Valve

valves.

10

Table 5 — Physical Data, 30RAP — SI

UNIT 30RAP 010 011 015 016 018 020 025

OPERATING WEIGHT (kg)

MCHX Condenser Coil, No Pump 319 346 326 363 510 514 564

MCHX Condenser Coil, Single Pump

(60 Hz only)

MCHX Condenser Coil, Dual Pump

(60 Hz only)

Al-Cu Condenser Coil, No Pump — — — — — — —

Al-Cu Condenser Coil, Single Pump

(60 Hz only)

Al-Cu Condenser Coil, Dual Pump

(60 Hz only)

Cu-Cu Condenser Coil, No Pump — — — — — — —

Cu-Cu Condenser Coil, Single Pump

(60 Hz only)

Cu-Cu Condenser Coil, Dual Pump

(60 Hz only)

REFRIGERANT TYPE R-410A, EXV Controlled System

Total Refrigerant Charge (kg) 3.8 3.8 4.4 4.5 6.6 7.1 7.6

Refrigerant Charge (kg) Ckt A/Ckt B 3.8/— 3.8/— 4.4/— 4.5/— 6.6/— 7.1/— 7.6/—

Total Refrigerant Charge RTPF (kg) — — — — — — —

Refrigerant Charge RTPF (kg)

Ckt A/Ckt B

COMPRESSORS Scroll, Hermetic

Quantity 1 2 1 2 2 2 2

Speed (R/s)

(Qty) kW, Ckt A (1) 38 (2) 21/14 (1) 53 (2) 31/21 (2) 32 (2) 35 (2) 46

(Qty) kW, Ckt B — — — — — — —

Oil Charge (L) Ckt A/Ckt B 3.3/— 3/—

No. Capacity Steps

Standard 1 2 1 2 2 2 2

With Hot Gas Bypass — — — — 3 3 3

Digital Compressor Option 13 21 13 21 22 22 22

Minimum Capacity Step (%)

Standard 100 40 100 40 50 50 50

With Hot Gas Bypass — — — — 20 24 29

Digital Compressor Option 20 20 20 20 17 17 17

Capacity (%)

Circuit A 100 100 100 100 100 100 100

Circuit B — — — — — — —

COOLER Brazed, Direct-Expansion Plate Heat Exchanger

Weight (kg) (empty) 10.1 10.1 12.5 14.4

Net Fluid Volume (L) 2.3 2.3 3.0 3 3.4 4.5 5.3

Maximum Refrigerant Pressure (kPa) 3482 3482 3482 3482 3482 3482 3482

Maximum Water-Side Pressure

Without Pump(s) (kPa)

Maximum Water-Side Pressure

With Pump(s) (kPa)

CHILLER WATER CONNECTIONS (in.)

Inlet and Outlet, Victaulic (IPS Carbon Steel)* 2 2 2 2 2 2 2

Drain (NPT)

CONDENSER FANS

Standard Low-Sound AeroAcoustic™ Type Plastic Type, Axial, Vertical Discharge

Fan Speed (R/s) 14.2 (60 Hz)/11.8 (50 Hz)

No. Blades...Diameter (mm) 9...762 9...762 9...762 9...762 9...762 9...762 9...762

No. Fans 1 1 1 1 2 2 2

Total Airflow 60 Hz (L/s) 4437 4437 4437 4437 8260 8260 9157

Total Airflow 50 Hz (L/s) 3705 3705 3705 3705 6897 6897 7646

Optional Value Sound Type

Fan Speed (R/s)

No. Blades...Diameter (mm) 4...762 4...762 4...762 4...762 4...762 4...762 4...762

No. Fans 1 1 1 1 2 2 2

Total Airflow 60 Hz (L/s) 4767 4800 4767 4800 8732 8732 9865

Total Airflow 50 Hz (L/s) 3981 3981 3981 3981 7291 7291 8237

CONDENSER COILS Novation

Quantity (Ckt A/Ckt B) 1/— 1/— 1/— 1/— 1/— 1/— 1/—

Total Face Area (sq m) 1.6 1.8 1.6 1.8 2.4 2.4 3.1

Maximum Refrigerant Pressure (kPa) 4523 4523 4523 4523 4523 4523 4523

HYDRONIC MODULE (Optiona

Pump Single or Dual, Centrifugal Monocell Pump(s), 3500 Rpm. Dual pump

Expansion Tank Volume (L)

Total/Acceptance 17.4/12.3

CHASSIS DIMENSIONS (mm)

Length 1689 1689 1689 1689 2242 2242 2242

Width 1029 1029 1029 1029 1025 1025 1025

Height 1689 1689 1689 1689 1689 1689 1994

l, 60 Hz Only)†

LEGEND

EXV — Electronic Expansion Valve

MCHX — Microchannel Heat Exchanger

RTPF — Round Tube, Plate Fin (Condenser Coil)

393 419 399 436 584 588 637

467 493 473 510 658 661 711

— — — — — — —

— — — — — — —

— — — — — — —

— — — — — — —

— — — — — — —

58.3 (60 Hz)/48.3 (50 Hz)

3.3/—

4.3/—

6.5/— 6.5/— 6.5/—

14.4 18.3 21.0

2068 2068 2068 2068 2068 2068 2068

1034 1034 1034 1034 1034 1034 1034

1

/

4

Pump(s), Strainer with Blowdown Valve, Expansion Tank, Pre

1

/

4

1

/

4

Propeller Type, Axial, Vertical Discharge

19.0 (60 Hz)/15.8 (50 Hz)

®

MCHX Aluminum Tube, Aluminum Fin

1

/

4

Balance Valve

ssure Taps, Drain and Vent Plugs, Flow Switch, and

1

/

4

s with check valves and isolation valves.

1

/

4

*Unit connection is IPS Carbon Steel piping.

†Flow switch and strainer are standard on all units, with or without hydronic

package.

NOTE: 30RAP chillers with Greenspeed intelligence are not available on unit

10, 015, and 070-150.

sizes 0

1

/

4

11

Table 5 — Physical Data, 30RAP — SI (cont)

UNIT 30RAP 030 035 040 045 050 055 060

OPERATING WEIGHT (kg)

MCHX Condenser Coil, No Pump 582 981 991 1015 1026 1075 1077

MCHX Condenser Coil, Single Pump

(60 Hz only)

MCHX Condenser Coil, Dual Pump

(60 Hz only)

Al-Cu Condenser Coil, No Pump — — — — — — —

Al-Cu Condenser Coil, Single Pump

(60 Hz only)

Al-Cu Condenser Coil, Dual Pump

(60 Hz only)

Cu-Cu Condenser Coil, No Pump — — — — — — —

Cu-Cu Condenser Coil, Single Pump

(60 Hz only)

Cu-Cu Condenser Coil, Dual Pump

(60 Hz only)

REFRIGERANT TYPE R-410A, EXV Controlled System

Total Refrigerant Charge (kg) 8.9 13.4 13.6 15.6 15.7 15.6 15.7

Refrigerant Charge (kg) Ckt A/Ckt B 8.9/— 6.8/6.7 6.8/6.8 7.8/7.8 7.8/7.8 7.7/7.9 7.8/7.9

Total Refrigerant Charge RTPF (kg) — — — — — — —

Refrigerant Charge RTPF (kg)

Ckt A/Ckt B

COMPRESSORS Scroll, Hermetic

Quantity 2 4 4 4 4 4 4

Speed (R/s)

(Qty) kW, Ckt A (2) 53 (2) 35 (2) 35 (2) 38 (2) 46 (2) 46 (2) 53

(Qty) kW, Ckt B — (2) 32 (2) 38 (2) 46 (2) 46 (2) 53 (2) 53

Oil Charge (L) Ckt A/Ckt B

No. Capacity Steps

Standard 2 4 4 4 4 4 4

With Hot Gas Bypass 3 5 5 5 5 5 5

Digital Compressor Option 22 44 44 44 44 44 44

Minimum Capacity Step (%)

Standard 50 23 23 24 25 23 25

With Hot Gas Bypass 32 9 11 12 14 13 16

Digital Compressor Option 17 9 8 8 8 8 8

Capacity (%)

Circuit A 100 54 47 47 50 46 50

Circuit B — 46 53 53 50 54 50

COOLER Brazed, Direct-Expansion Plate Heat Exchanger

Weight (kg) (empty) 45 45.1 53.5 56.8

Net Fluid Volume (L) 9.9 9.8 12.5 13.2 15.5 18.9 18.9

Maximum Refrigerant Pressure (kPa) 3896 3896 3896 3896 3896 3896 3896

Maximum Water-Side Pressure

Without Pump(s) (kPa)

Maximum Water-Side Pressure

With Pump(s) (kPa)

CHILLER WATER CONNECTIONS (in.)

Inlet and Outlet, Victaulic

(IPS Carbon Steel)*

Drain (NPT)

CONDENSER FANS

Standard Low-Sound AeroAcoustic™ Type Plastic Type, Axial, Vertical Discharge

Fan Speed (R/s) 14.2 (60 Hz)/11.8 (50 Hz)

No. Blades...Diameter (mm) 9...762 9...762 9...762 9...762 9...762 9...762 9...762

No. Fans 2 3 3 3 3 4 4

Total Airflow 60 Hz (L/s) 9157 13 971 13 971 14 396

Total Airflow 50 Hz (L/s) 7646 11 666 11 666 12 021 12 021 15 292 15 292

Optional Value Sound Type

Fan Speed (R/s) 19.0 (60 Hz)/15.8 (50 Hz)

No. Blades...Diameter (mm) 4...762 4...762 4...762 4...762 4...762 4...762 4...762

No. Fans 2 3 3 3 3 4 4

Total Airflow 60 Hz (L/s) 9865 15 104 15 104 15 718 15 718 19 730 19 730

Total Airflow 50 Hz (L/s) 8237 12 612 12 612 13 124 13 124 16 474 16 474

CONDENSER COILS Novation

Quantity (Ckt A/Ckt B) 1/— 1/1 1/1 1/1 1/1 1/1 1/1

Total Face Area (sq m) 3.1 4.9 4.9 6.1 6.1 6.1 6.1

Maximum Refrigerant Pressure (kPa) 4523 4523 4523 4523 4523 4523 4523

HYDRONIC MODULE (Optional, 60 Hz Only)†

Pump Single or Dual, Centrifugal Monocell Pump(s), 3500 Rpm. D

Expansion Tank Volume (L)

Total/Acceptance 17.4/12.3 39.0/39.0

CHASSIS DIMENSIONS (mm)

Length 2242 2248 2248 2248 2248 2248 2248

Width 1025 2350 2350 2350 2350 2350 2350

Height 1994 1689 1689 1994 1994 1994 1994

LEGEND

EXV — Electronic Expansion Valve

MCHX — Microchannel Heat Exchanger

RTPF — Round Tube, Plate Fin (Condenser Coil)

656 1137 1147 1171 1182 1231 1233

729 1293 1303 1327 1338 1386 1389

— — — — — — —

— — — — — — —

— — — — — — —

— — — — — — —

— — — — — — —

58.3 (60 Hz)/48.3 (50 Hz)

6.5/— 6.5/6.5 6.5/6.5 6.5/6.5 6.5/6.5 6.5/6.5 6.5/6.5

62.4 72.8 72.8

2068 2068 2068 2068 2068 2068 2068

1034 1034 1034 1034 1034 1034 1034

2 2

1

/

4

/

2

1

/

4

21/

2

1

/

4

21/

2

1

/

4

21/

2

1

/

4

21/

2

1

/

2

21/

1

1

14 396 18 314 18 314

Propeller Type, Axial, V

®

MCHX Aluminum Tube, Aluminum Fin

Pump(s), Strainer with Blowdown Valve, Expansion Tank, Pressure Taps, Drain and Vent Plugs, Flow Switch, and

Bala

ertical Discharge

nce Valve

ual pumps with check valves and isolation valves.

*Unit connection is IPS Carbon Steel piping.

†Flow switch and strainer are standard on all units, with or without hydronic

package.

NOTE: 30RAP chillers with Greenspeed intel

sizes 010, 015, and 070-150.

ligence are not available on unit

2

/

2

12

Table 5 — Physical Data, 30RAP — SI (cont)

UNIT 30RAP 070 080 090 100 115 130 150

OPERATING WEIGHT (kg)

MCHX Condenser Coil, No Pump 1547 1652 1677 2127 2272 2926 3147

MCHX Condenser Coil, Single Pump (60 Hz only) 1729 1830 1842 2308 2453 3107 3328

MCHX Condenser Coil, Dual Pump (60 Hz only) 1856 1991 2001 2438 2582 3236 3457

Al-Cu Condenser Coil, No Pump 1705 1843 1868 2517 2694 3226 3480

Al-Cu Condenser Coil, Single Pump (60 Hz only) 1887 2022 2033 2698 2875 3407 3661

Al-Cu Condenser Coil, Dual Pump (60 Hz only) 2014 2149 2160 2827 3004 3537 3791

Cu-Cu Condenser Coil, No Pump 1977 2170 2195 2898 3129 3716 4025

Cu-Cu Condenser Coil, Single Pump (60 Hz only) 2160 2348 2360 3079 3310 3897 4206

Cu-Cu Condenser Coil, Dual Pump (60 Hz only) 2287 2475 2487 3208 3440 4027 4335

REFRIGERANT TYPE R-410A, EXV Controlled System

Total Refrigerant Charge MCHX (kg) 27.5 31.8 32.2 40.1 45.8 50.1 54.2

Refrigerant Charge MCHX (kg) Ckt A/Ckt B 11.6/15.9 15.9/15.9 16.1/16.1 17.8/22.3 23.0/22.8 23.2/26.9 27.2/27.0

Total Refrigerant Charge RTPF (kg) 68.0 76.8 77.2 87.1 96.6 108.5 119.8

Refrigerant Charge RTPF (kg) Ckt A/Ckt B 29.7/38.3 38.4/38.4 38.6/38.6 39.5/47.6 48.3/48.3 48.8/59.7

COMPRESSORS Scroll, Hermetic

Quantity 5 6 6 5 6 6 6

Speed (R/s) 58.3 (60 Hz)/48.3 (50 Hz)

(Qty, kW) Ckt A (2) 53 (3) 46 (3) 53 (1) 70 (1) 87.9 (3) 70 (3) 70 (3) 87.9

(Qty, kW) Ckt B (3) 53 (3) 53 (3) 53 (3) 70 (3) 70 (3) 87.9 (3) 87.9

Oil Charge (L) Ckt A/Ckt B

No. Capacity Steps

Standard 5 6 6 5 6 6 6

With Hot Gas Bypass 6 7 7 6 7 7 7

Digital Compressor Option 55 66 66 — — — —

Minimum Capacity Step (%)

Standard 20 15 17 19 17 15 17

With Hot Gas Bypass 13 9 11 13 11 9 11

Digital Compressor Option 7 5 6 — — — —

Capacity (%)

Circuit A 40 46 50 43 50 44 50

Circuit B 60 54 50 57 50 56 50

COOLER Brazed, Direct-Expansion Plate Heat Exchanger

Weight (kg) (empty) 89.4 103.4 111.1 121.0 137.7 151.3 171.2

Net Fluid Volume (L) 16.3 18.9

Maximum Refrigerant Pressure (kPa) 3103 3103 3103 3103 3103 3103 3103

Maximum Water-Side Pressure

Without Pump(s) (kPa)

Maximum Water-Side Pressure

With Pump(s) (kPa)

CHILLER WATER CONNECTIONS (in.)

Inlet and Outlet, Victaulic (IPS Carbon Steel)* 3 3 3 4 4 4 4

Drain (NPT)

CONDENSER FANS

Standard Low-Sound AeroAcoustic™ Type Plastic Type, Axial, Vertical Discharge

Fan Speed (R/s) 14.2 (60 Hz)/11.8 (50 Hz)

No. Blades...Diameter (mm) 9...762 9...762 9...762 9...762 9...762 9...762 9...762

No. Fans 5 6 6 7 8 9 10

Total Airflow, 60 Hz (L/s) 22 890 27 467 27 467 32 045 36 623 41 201 45 779

Total Airflow, 50 Hz (L/s) 19 120 22 943 22 943 26 767 30 591 34 415 38 239

Optional Value Sound Type

Fan Speed (R/s) 19.0 (60 Hz)/15.8 (50 Hz)

No. Blades...Diameter (mm) 4...762 4...762 4...762 4...762 4...762

No. Fans 5 6 6 7 8 9 10

Total Airflow, 60 Hz (L/s) 24 187 29 025 29 025 33 862 38 700 43 537 48 375

Total Airflow, 50 Hz (L/s) 20 204 24 245 24 245 28 285 32 326 36 367 40 407

CONDENSER COILS Novation

Quantity (Ckt A/Ckt B) 2/3 3/3 3/3 3/4 4/4 4/5 5/5

Total Face Area (sq m) 11.6 13.9 13.9 16.2 18.5 20.8 23.2

Maximum Refrigerant Pressure (kPa) 4523 4523 4523 4523 4523 4523 4523

HYDRONIC MODULE (Optiona

Pump Single or Dual, Centrifugal Monocell Pump(s), 3500 Rpm. Dual

Expansion Tank Volume (L)

Total/Acceptance

CHASSIS DIMENSIONS (mm)

Length 3826 3826 3826 4864 4864 5893 5893

Width 2241 2241 2241 2241 2241 2241 2241

Height 1976 1976 1976 1976 1976 1976 1976

LEGEND

EXV — Electronic Expansion Valve

MCHX — Microchannel Heat Exchanger

RTPF — Round Tube, Plate Fin (Condenser Coil)

*Unit connection is IPS Carbon Steel piping.

†Flow switch and strainer are standard on all units, with or without hydronic

ckage.

pa

NOTE: 30RAP chillers with Greenspeed intelligence are not available on unit

010, 015, and 070-150.

sizes

l, 60 Hz Only)†

6.5/9.7 9.7/9.7 9.7/9.7 13.4/20.1 20.1/20.1 20.1/20.1 20.1/20.1

25.7 28.0 32.5 35.9 41.2

2068 2068 2068 2068 2068 2068 2068

1034 1034 1034 1034 1034 1034 1034

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

Propeller Type, Axial, Vertical Discharge

4...762 4...762

®

MCHX Aluminum Tube, Aluminum Fin or RTPF

Pump(s), Strainer with Blowdown Valve, Expansion Tank, Pr

and Balance Valve

essure Taps, Drain and Vent Plugs, Flow Switch,

pumps with check valves and isolation valves.

— — — — — — —

59.9/59.9

1

/

2

13

Fig. 7 — Unit Rigging Label Detail (010-060 Sizes)

14

38AP503120

Fig. 8 — Unit Rigging Label Detail (070-150 Sizes)

a30-5719

CAUTION - NOTICE TO RIGGERS:

ALL PANELS MUST BE IN PLACE WHEN RIGGING. DO NOT FORK THIS UNIT WITHOUT SKID.

NOTES:

RIG WITH FOUR CABLES USING A MINIMUM 24 FT. (7315MM) LENGTH FOR 070-115 SIZES. RIG

1.

WITH SIX CABLES FOR 130, 150 TON.

2.

CENTRAL LIFTING POINTS MUST BE A MINIMUM OF 12 FT. (3658MM) ABOVE THE TOP OF THE

UNIT.

LIFTING HOLES PROVIDED ARE 2.5 IN. (63.5MM) DIAMETER. 30RAP130 AND 30RAP150 HAVE

3.

A MIDDLE LIFTING HOLE, WHICH IS LOCATED 115.5 IN. (2921 MM) FROM THE CONTROL BOX

SIDE LIFTING HOLE.

4.

CHECK BILL OF LADING FOR SHIPPING WEIGHT OF UNIT.

MAX. SHIP WT.

MODEL

W/O PACKAGING

NUMBER

30RAP070 3991

30RAP080

30RAP090

30RAP100

30RAP115

30RAP130

30RAP150 7485 3394

30RAP070

30RAP080

30RAP090

30RAP100

30RAP115

30RAP130

30RAP150

LBS KGS LBS KGS LBS KGS LBS KGS LBS KGS LBS KGS

30RAP 070,080,090

30RAP 100,115,130,150

MCHX COILS

1810 4121 1869

1945

4289

1955

4310

2389

5267

2528

5575

3179

7010

LIFTING HOLES

A

IN

MM IN MM IN

2235

88.0

2235 131.6 3343

88.0

2235 131.6 3343

88.0

2235 171.8 4364 87.1 2212 45.3

88.0

2235

88.0

2235 212.1 5387

88.0

2235

88.0

DEDUCT THESE VALUES FOR UNITS WIT H NO PUMP OPTIONS

MAX. SHIP WT.

W/PACKAGING

4419 2004

4440 2014

5417 2457 6125

5725 2596 6507

7190 3261 7672

7665 3476

131.6 3343

171.8 4364

212.1 5387

SINGLE PUMP DEDUCT LBS/KGS

MAX. SHIP WT.

W/O PACKAGING

4340

4637

4663

8220 3728

B

68.8 1748 44.4

70.7

70.8 1798 46.5

90.5

104.3

108.1 2746 45.3

280/127

285/129

AL-CU COILS CU-CU COILS

1968 4470 2027

2103

2114

2778

2951

3479

CENTER OF GRAVITY

X

MM IN

1796

2299

2649

MAX. SHIP WT.

W/PACKAGING

4767 2194

4793 2205

6275 2846 6965

6657 3019 7467

7852 3561 8752

8400 3809

Y

44.9 1140

45.2 1148

45.4 1153

NO PUMP DEDUCT LBS/KGS

MAX. SHIP WT.

W/O PACKAGING

4940

5357

5383

9420 4272

MM

1128

1181

1151

1151

635/288

675/306

MAX. SHIP WT.

W/PACKAGING

2240 5070 2299

2429

5487 2520

2441

5513 2532

3159

7118 3228

3386

7617 3454

3969

8932 4051

9600 4354

15

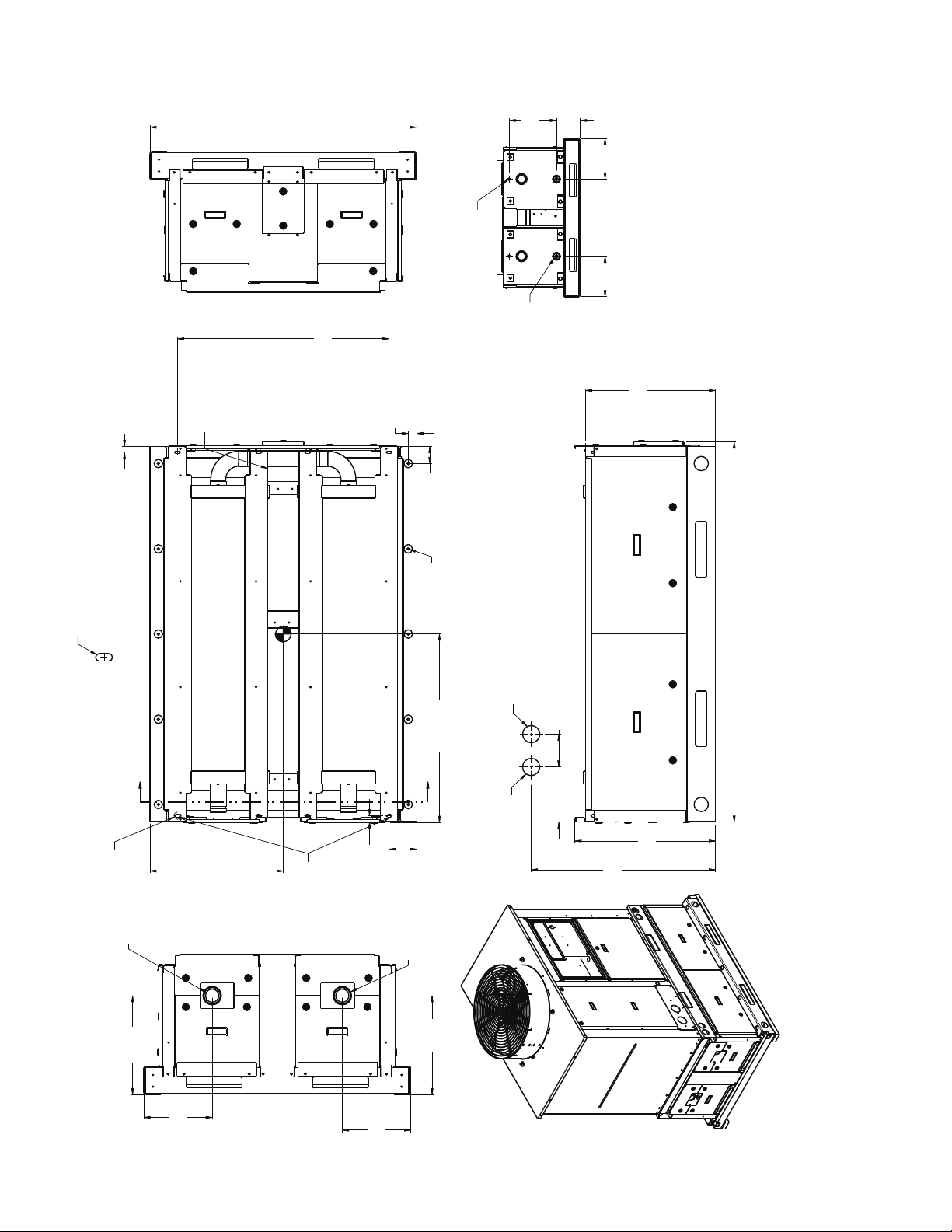

MOUNTING UNIT — When unit is in proper location, use

of mounting holes in base rails is recommended for securing

unit to supporting structure, or for mounting unit on vibration

isolators if required. See Fig.

are field supplied. Be sure unit is level to within 1/8 in.

(3.2 mm) per foot for proper oil return to compressor.

9-17. Fasteners for mounting unit

Step 2 — Check Compressor Mounting — As

shipped, units with single compressors are held down with 4

bolts through rubber grommets. All units with tandem com

pressors are held down with 6 bolts per pair through grommets.

After unit is installed, verify mounting bolt torque 7 to 10 ft-lb

(9.5 to 13.6 Nm).

For 30RAP100-150 units, RED bolts from compressor

mounting rail must be removed. These RED bolts are for ship

ping purposes only. Also remove the shipping braces that tie

the compressors in a circuit together. Using a 15-mm socket,

loosen each bolt and nut on each compressor tab and remove

all braces before unit start-up.

Step 3 — Connect Cooler Fluid and Drain Piping

ALL UNITS — These chillers are supplied with factoryinstalled strainer (including blow-down valve) in the entering

fluid piping and flow switch in the leaving fluid piping. Flow

switch wiring is factory installed.

CAUTION

Do not circulate water through unit without strainer in

place. Failure to use the strainer represents abuse and may

impair or otherwise negatively affect the Carrier product

warranty.

Piping connections are located on the front of the chiller

when facing the control panel for sizes 010-030 and at the end

opposite the control panel for sizes 035-060. For sizes 070-150,

piping connections are on the right side when facing the control

panel and (Circuit B) of the chiller. See Fig.

model. See Fig. 18-20 for accessory storage tank dimensions.

All sizes have carbon steel Victaulic IPS connections as

shown in the physical data tables. Any connecting pipe to the

-

-

30RAP unit must be of a material that will not cause any gal

vanic corrosion. For this reason, dissimilar metals must not be

used unless joined by a dielectric coupling.

Provide a means of venting air from the high point of the

field-installed piping as required. Install field-supplied drains

in both the entering and leaving fluid connections.

After field piping is complete, freeze-up protection is recommended using inhibited glycol or other suitable inhibited

antifreeze solution and electric heat tapes in areas where piping

is exposed to low ambient temperatures (34 F [1° C] or below).

Heat tapes should possess a rating for area ambient tempera

tures and be covered with a suitable thickness of closed-cell insulation. Route power for heating tapes from a separately fused

disconnect. Identify disconnect as heat tape power source with

a warning that power must not be turned off except when unit

is being serviced.

Installation of water systems should follow sound engineering practice as well as applicable local and industry standards.

Improperly designed or installed systems may cause unsatisfactory operation and/or system failure. Consult a water treatment specialist or appropriate literature for information regarding filtration, water treatment, and control devices.

9-17, depending on

-

-

16

17

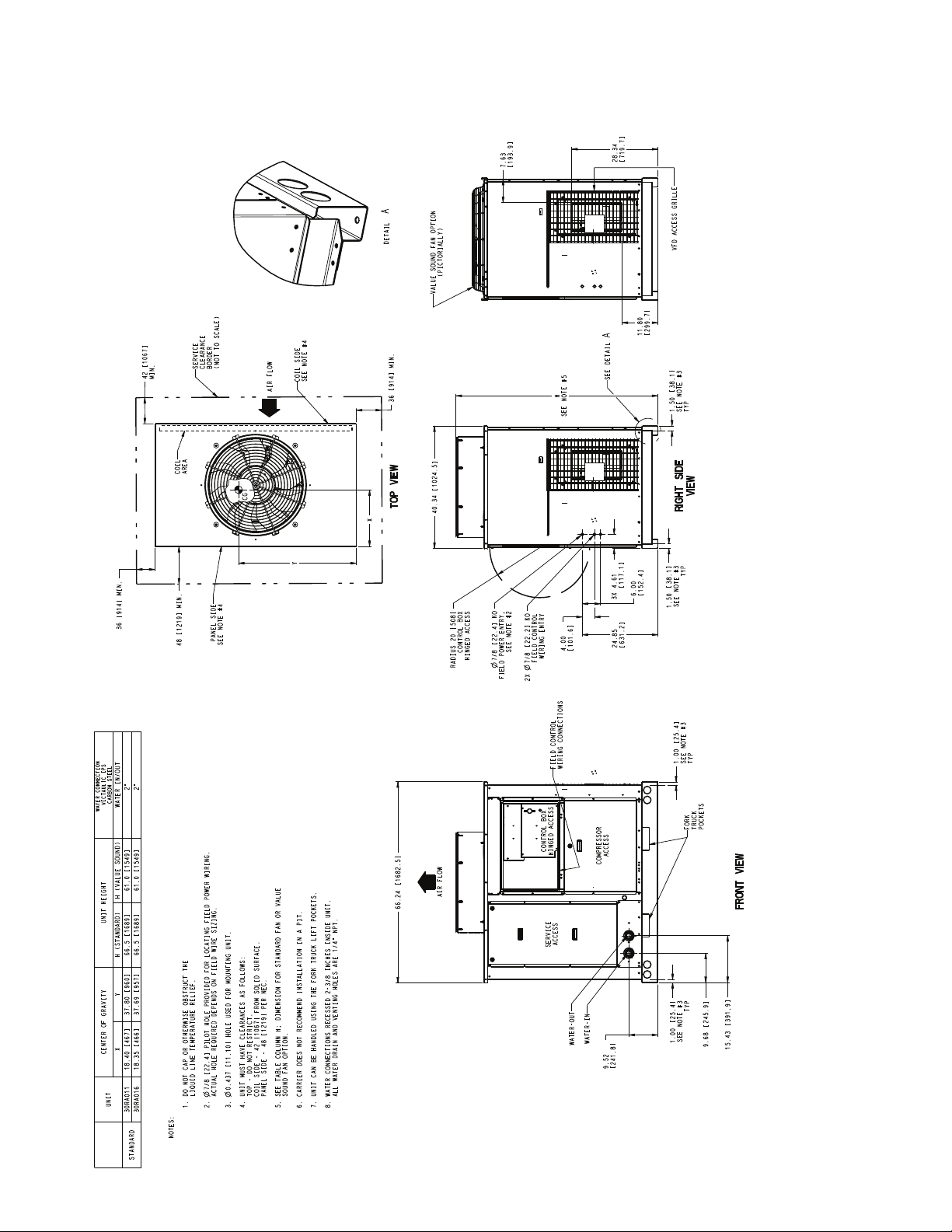

Fig. 9 — Dimensions — 30RAP010 and 015 Units

DIMENSIONS ARE IN INCHES [MM]

Fig. 10 — Dimensions — 30RAP011 and 016 Units

18

Fig. 11 — Dimensions — 30RAP018-030 Units with Fixed Speed Fans

DIMENSIONS ARE IN INCHES [MM]

19

Fig. 12 — Dimensions — 30RAP018-030 Units with Greenspeed

®

Intelligence

DIMENSIONS ARE IN INCHES [MM]

20

DIMENSIONS ARE IN INCHES [MM]

Fig. 13 — Dimensions — 30RAP035-060 Units with Fixed Speed Fans

21

Fig. 14 — Dimensions — 30RAP035-060 Units with Greenspeed

®

Intelligence

DIMENSIONS ARE IN INCHES [MM]

22

23

Fig. 15 — Dimensions — 30RAP070-090 Units

24

Fig. 16 — Dimensions — 30RAP100,115 Units

25

Fig. 17 — Dimensions — 30RAP130,150 Units

Fig. 18 — Accessory Storage Tank 30RA-900-050 Dimensions — 30RAP010-016 Units

2 X 1" [25]

a30-5429

TANK

ACCESS

TANK

ACCESS

.88" [22.35]Ø KNOCKOUT

FOR POWER TO CONTROL BOX

[1193]

3' 10-63/64"

C.B.

ACCESS

BOX END

CONTROL

TANK

ACCESS

2 X 3' 1-1/4" [946]

CHILLER MOUNTING SLOT

1-1/2"

[38.1]

3" [76.2]

MOUNTING HOLES,

FOUR CORNERS (TYP)

2 PLCS

1/4" VENT

[357.25]

2 X 14.07

2 PLCS

2" SQ DRAIN

[178.68]

2 X 7.03

[305.66]

2 X 12.03

2 PLCS

SECTION A-A

[305.64]

2 X 12.03

TANK ACCESS

[581]

1' 10-7/8"

BOX END

CONTROL

Ø7/16" [11] X 1" [25] LG SLOT

SEE DETAIL A

DETAIL A

AT (4) PLCS

A

Ø2-1/2 IN. VICTAULIC WATER

INLET/OUTLET

[442]

1' 5-13/32"

TANK

ACCESS

1' 11-1/2" [597]

CENTER OF GRAVITY

TANK

ACCESS

CHILLER MOUNTING SLOT

TANK

ACCESS

TANK

ACCESS

[27]

2 X 1-1/16"

[124]

2 X 4-7/8"

Ø2-1/2" VICTAULIC WATER

Ø .395/.405 (TYP)

MOUNTING HOLES

MIDDLE EACH SIDE

2' 9-15/32" [850]

CENTER OF GRAVITY

A

INLET/OUTLET

[442]

1' 5-13/32"

CHILLER WATER OUT (REF)

CHILLER WATER IN (REF)

[146]

5-3/4"

[248]

9-25/32"

TANK ACCESS

[823]

2' 8-13/32"

[628]

2' 47/64"

[1700]

5' 6-15/16"

[306]

1' 1/32"

[306]

1' 1/32"

26

1' 5-13/32"

[442]

1' 1/32"

[305]

TANK

ACCESS

TANK

ACCESS

TANK

ACCESS

TANK

ACCESS

1' 1/32"

[306]

1' 5-13/32"

[442]

Ø2-1/2" VICTAULIC WATER

INLET/OUTLET

SEE DETAIL A

A

1' 11-17/32" [597]

CENTER OF GRAVITY

CHILLER MOUNTING SLOT

1" [26]

2 X 4-7/8"

[124]

Ø2-1/2" VICTAULIC WATER

INLET/OUTLET

CHILLER WATER IN (REF)

1' 3-7/16" [392]

2' 8-13/32"

[823]

2' 23/32"

[628]

7' 4-31/32"

[2260]

TANK ACCESS TANK ACCESS

5-3/4"

[146]

CHILLER WATER OUT (REF)

3' 8-1/2" [1130]

CENTER OF GRAVITY

DETAIL A

AT (4) PLCS

Ø7/32" [6] X 1" [25] LG SLOT

2 X 1" [25]

Ø.88" (22.35) KNOCKOUT FOR

POWER TO THE CONTROL BOX

TANK

ACCESS

TANK

ACCESS

2 X 3' 1-1/4" [946]

CHILLER MOUNTING

SLOT

CONTROL

BOX END

TANK

ACCESS

Ø.395/.405 (TYP)

MOUNTING HOLES,

MIDDLE EACH SIDE

3" [76.2]

MOUNTING HOLES

FOUR CORNERS (TYP)

1-1/2"

[38.1]

2" SQ DRAIN

2 PLCS

TANK ACCESS

CONTROL

BOX END

1' 10-7/8"

[581]

SECTION A-A

2 PLCS

2 X 12.2

[305.24]

2 X 12.03

[305.52]

2 X 7.03

[178.68]

2 X 14.07

[357.25]

1/4" VENT

2 PLCS

3' 10-63/64"

[1193]

C.B.

ACCESS

Fig. 19 — Accessory Storage Tank 30RA-900-051 Dimensions — 30RAP018-030 Units

a30-5430

27

Fig. 20 — Accessory Storage Tank 30RA-900-052 Dimensions — 30RAP035-060 Units

1' [305]

1' 5-13/32"

[442]

TAN K

ACCESS

TAN K

ACCESS

TAN K

ACCESS

1' 1/16"

[306]

1' 5-13/32"

[442]

CHILLER MOUNTING SLOT

Ø2-1/2" VICTAULIC WATER

INLET/OUTLET

DETAIL A

AT (4) PLCS

Ø7/32" [6] X 1" [25] LG SLOT

SEE DETAIL A

1-1/2"

[38.1]

3" [76.2]

MOUNTING HOLES,

FOUR CORNERS (TYP)

A

4' 1-3/8" [1254]

CENTER OF GRAVITY

3' 7-31/32"

[111 7]

MOUNTING HOLES

3' 7-31/32"

[111 7]

A

3' 8-1/2" [1130]

CENTER OF GRAVITY

3' 8-3/32" [1120]

4' 6-5/8"

[1387]

2' 10-3/32"

[866]

2' 47/64"

[628]

TAN K

ACCESS

TAN K

ACCESS

TAN K

ACCESS

CONTROL

BOX END

1' 10-7/8"

[581]

7' 4-31/32"

[2260]

CHILLER WATER OUT

FAR SIDE (REF)

2 X 12.02

[305.23]

2 X 22.94

[582.56]

2" SQ DRAIN

4 PLCS

CHILLER WATER IN

FAR SIDE (REG)

2 X 0' -1 1/6"

2 X 0' -4 7/8"

2 X 28.84

[732.43]

SECTION A-A

2 PLCS

CONTROL

BOX END

MOUNTING HOLES

Ø.88" (22.35) KNOCKOUT FOR

POWER TO THE CONTROL BOX

2 X 7' 5" [2260]

CHILLER MOUNTING SLOT

TAN K

ACCESS

CONTROL

BOX END

Ø.88" (22.35) KNOCKOUT FOR

POWER TO THE CONTROL BOX

TAN K

ACCESS

Ø.395/.405 (TYP)

MOUNTING HOLES,

MIDDLE EACH SIDE

TANK

ACCESS

8' 2-3/4"

[2508]

1/4" VENT

4 PLCS

2 X 22.90

[581.65]

2 X 12.06

[306.43]

4 X 14.07

[357.25]

4 X 7.03

[178.68]

TANK

ACCESS

TANK

ACCESS

TANK

ACCESS

C.B.

ACCESS

C.B.

ACCESS

a30-5431

28

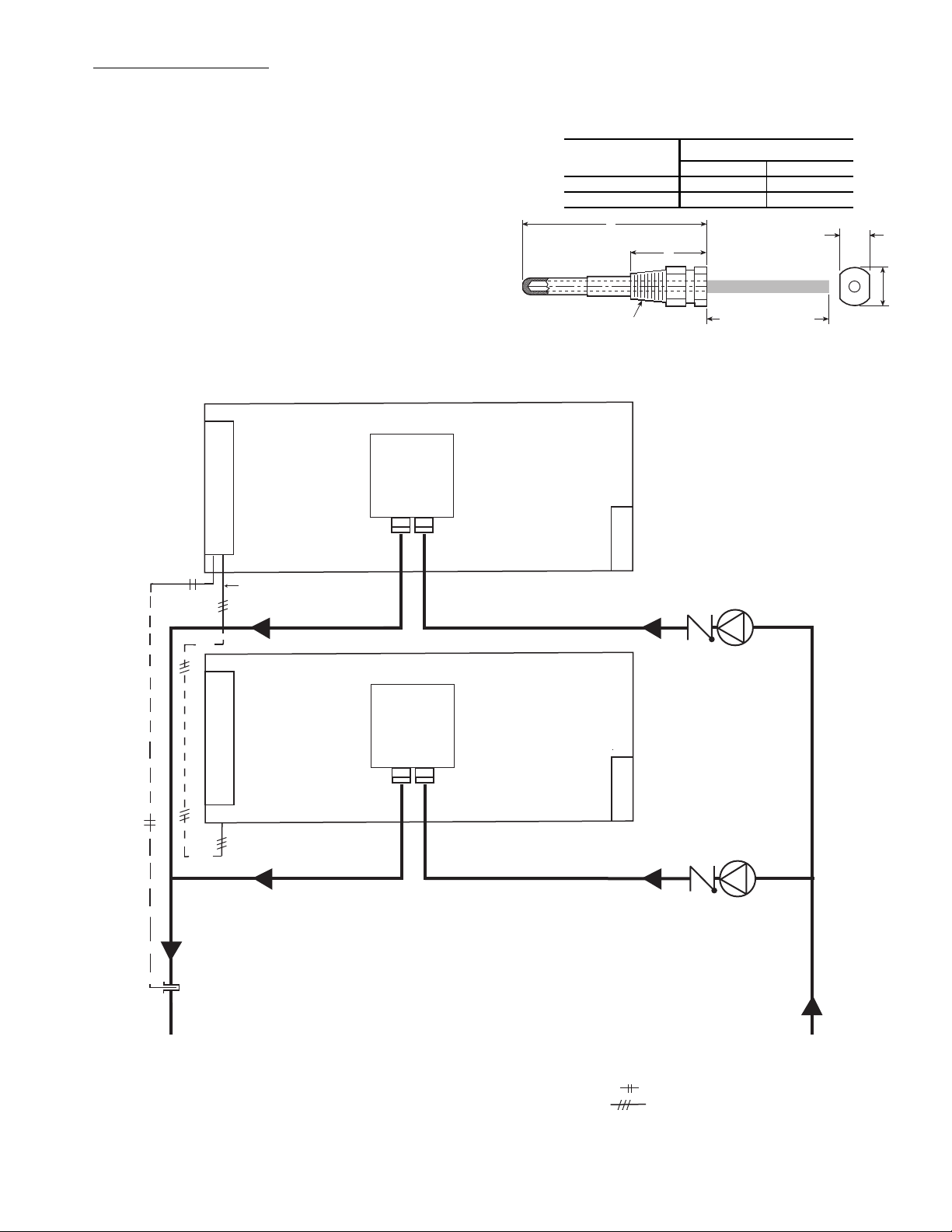

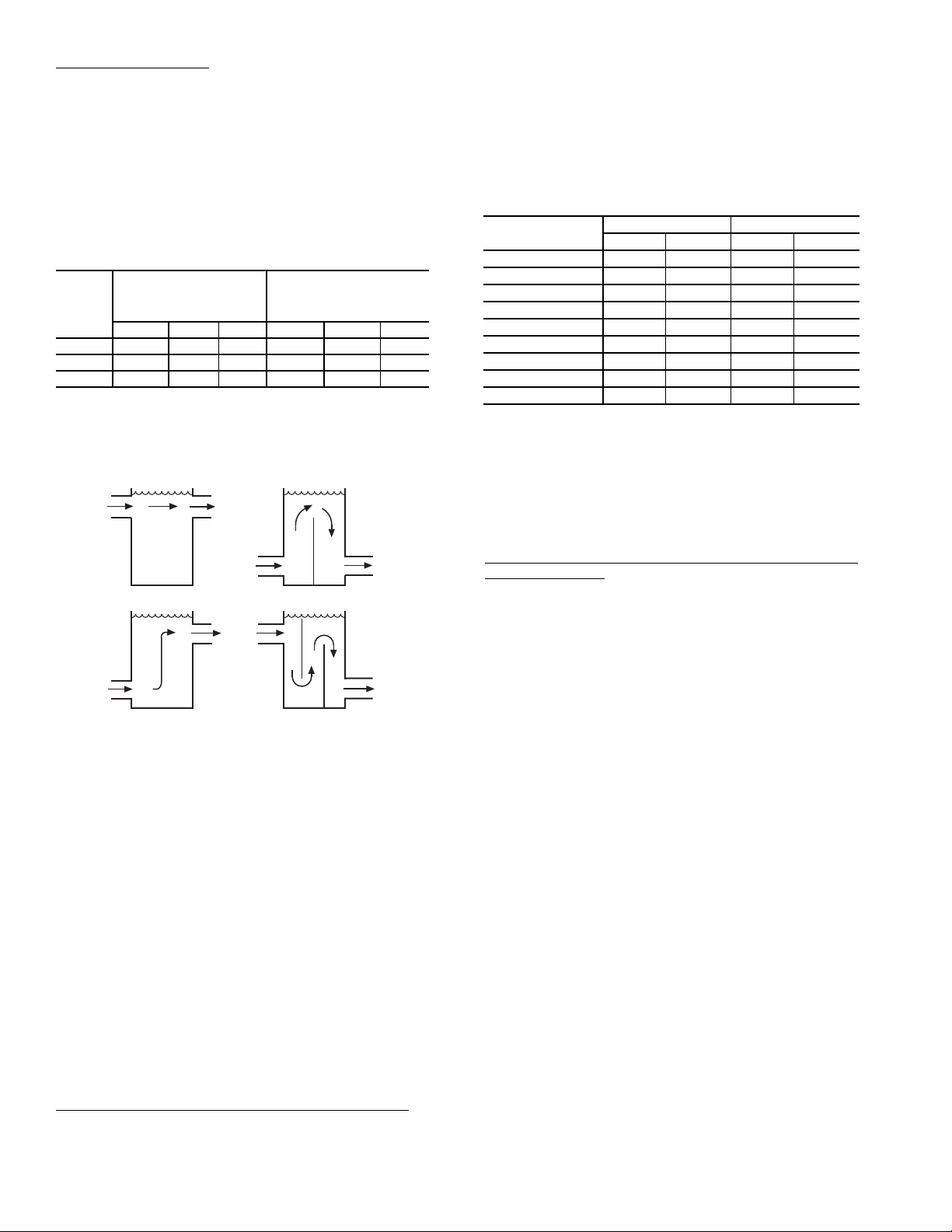

Dual Chiller Control Option — If the dual chiller algorithm is

A

B

1/4 N.P.T.

0.505/0.495

0.61

DIA

6” MINIMUM

CLEARANCE FOR

THERMISTOR

REMOVAL

Fig. 21 — Dual Leaving Water Thermistor Well

PART

NUMBER

DIMENSIONS in. (mm)

A B

10HB50106801 3.10 (78.7) 1.55 (39.4)

10HB50106802 4.10 (104.1) 1.28 (32.5)

Fig. 22 — Dual Chiller Piping Diagram

Depending on piping sizes, use either:

• HH79NZ014 sensor/10HB50106801 (3-in. sensor/well)

• HH79NZ029 sensor/10HB50106802 (4-in. sensor/well)

NOTE: This is a simplified piping diagram—not all hydronic specialties are shown.

Pump and Check Valve

or Isolation Valve

Pump and Check Valve

or Isolation Valve

Dual Chiller

LWT Sensor

and Well

Control

Box

Cooler

Master Chiller

Slave Chiller

Control

Box

Cooler

CCN Bus

LEGEND

LWT —

Leaving Water (Fluid) Temperature

—

Field Wiring

—

Field Communication Wiring

utilized the machines must be installed in parallel. An additional chilled water sensor must be installed. Install

the well in the

common leaving water header. See Fig. 21 and 22.

Parallel chiller control with dedicated

pumps is recommended. Chiller must start and stop its own water pump located in its own piping. If pumps are not dedicated for each

chiller, then isolation valves are required. Each chiller m

ust

open and close its own isolation valve through the unit control

(the valve must be connected to the pump outputs). See Fig. 22.

Do not relocate the chiller’s leaving water thermistors. They

must

remain in place for the unit to operate properly. The

thermistor well is a

1

/4-in. NPT fitting for mounting the well in

the piping. Select a location that will allow for removal of the

thermistor without any restrictions. Once the well is installed,

insert the thermistor into the well utilizing thermal conductive

grease. Once the thermistor is in place, it is recommended that

a thermistor wire loop be made and secured with a wire tie to

the well. Attach the dual leaving water temperature thermistor

to LVT-22 and 23. A Carrier Comfort Network® (CCN) bus

must be connected between the two chillers. For more information regarding Communication Bus Wiring, see the Carrier

Comfort Network®

(CCN) Interface section of the Controls,

Start-Up, Operation, Service, and Troubleshooting guide.

29

VICTAULIC COUPLING INSTALLATION

1. The outside surface of the pipe, between the groove and

the pipe end, must be smooth and free from indentations,

projections (including weld seams), and roll marks to en

sure a leak-tight seal. All oil, grease, loose paint, and dirt

must be removed.

2. Apply a thin coat of Victaulic lubricant or silicone lubricant to the gasket sealing lips and exterior.

CAUTION

Always use a compatible lubricant to prevent the gasket

from pinching or tearing during installation. Failure to fol

low this instruction could result in joint leakage.

3. Position the gasket over the pipe end. Make sure the gasket does not overhang the pipe end.

4. Align and bring the two pipe ends together. Slide the gasket into position and center it between the groove in each

pipe end. Make sure no portion of the gasket extends into

the groove in either pipe end.

5. Install the housings over the gasket.

NOTE: Make sure the housings’ keys engage the

grooves completely on both pipe ends.

-

CAUTION

Make sure the gasket does not become rolled or pinched

while installing the housings. Failure to follow this instruc

tion could cause damage to the gasket, resulting in joint

leakage.

6. Install the bolts, and thread a nut finger-tight onto each

bolt. For couplings supplied with stainless steel hardware,

apply an anti-seize compound to the bolt threads. Make

sure the oval neck of each bolt seats properly in the bolt

hole.

7. Tighten the nuts evenly by alternating sides until metalto-metal contact occurs at the bolt pads. Make sure the

housings’ keys engage the grooves completely.

NOTE: It is important to tighten the nuts evenly to prevent gasket pinching.

8. Visually inspect the bolt pads at each joint to ensure metal-to-metal contact is achieved.

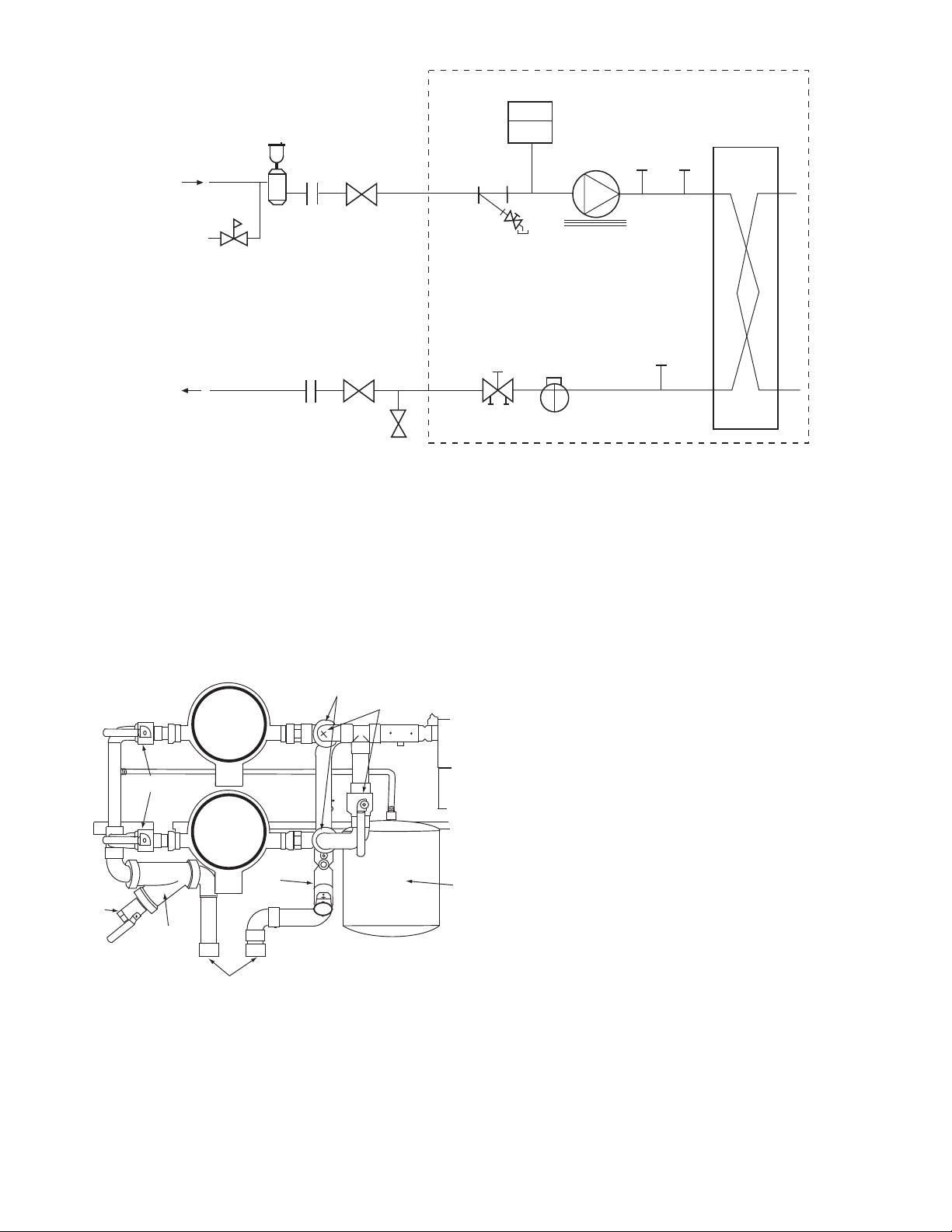

UNITS WITH FACTORY-INSTALLED HYDRONIC

PACKAGES —

hydronic packages are designed for use with closed sys

tems, meaning that there is no more than one water-air interface in the water loop. Cooling tower loops, for example,

have two water-air interfaces (sump and nozzles) and would

thus be classified as open, whereas a correctly designed

chilled water loop with the only water-air interface being in

the expansion tank is closed. Since closed and open water

The 30RAP chillers with factory-installed

-

systems behave very differently, these instructions assume

that the chilled water loop is closed. A system installed in

correctly such that air is not handled properly — pipe leaks,

-

-

vent leaks, air in pipes, etc. — may behave as an open sys

tem and thus have unsatisfactory operation. Pump seal wear

can also cause leaks that cause poor system operation.

Proper closed system design and installation procedures

should be followed closely. The system must be constructed

with pressure-tight components and thoroughly tested for

installation leaks. Factory-supplied hydronic systems are avail

able with single or dual (for back-up) pumps.