Page 1

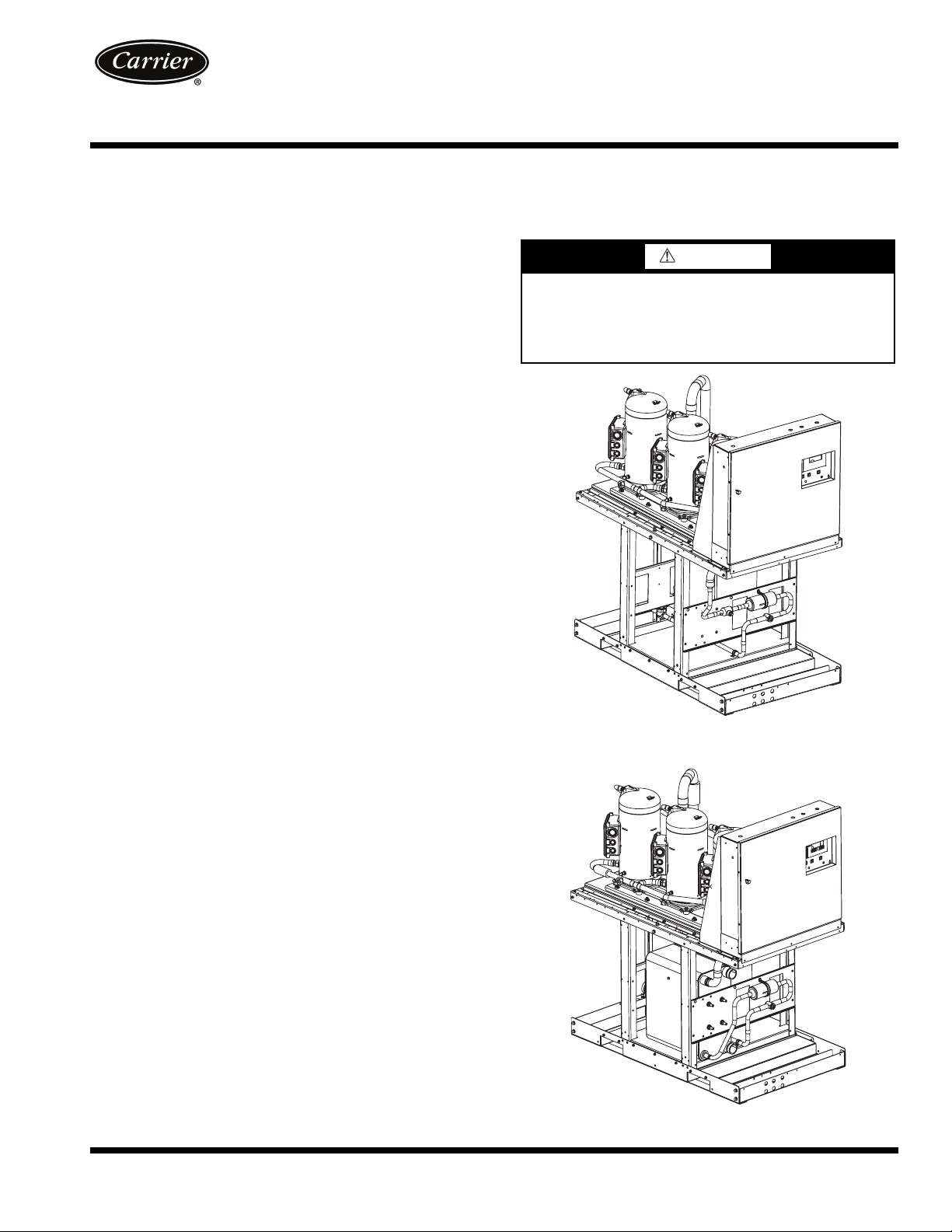

Fig. 1 — 30MPA Unit

a30-5029

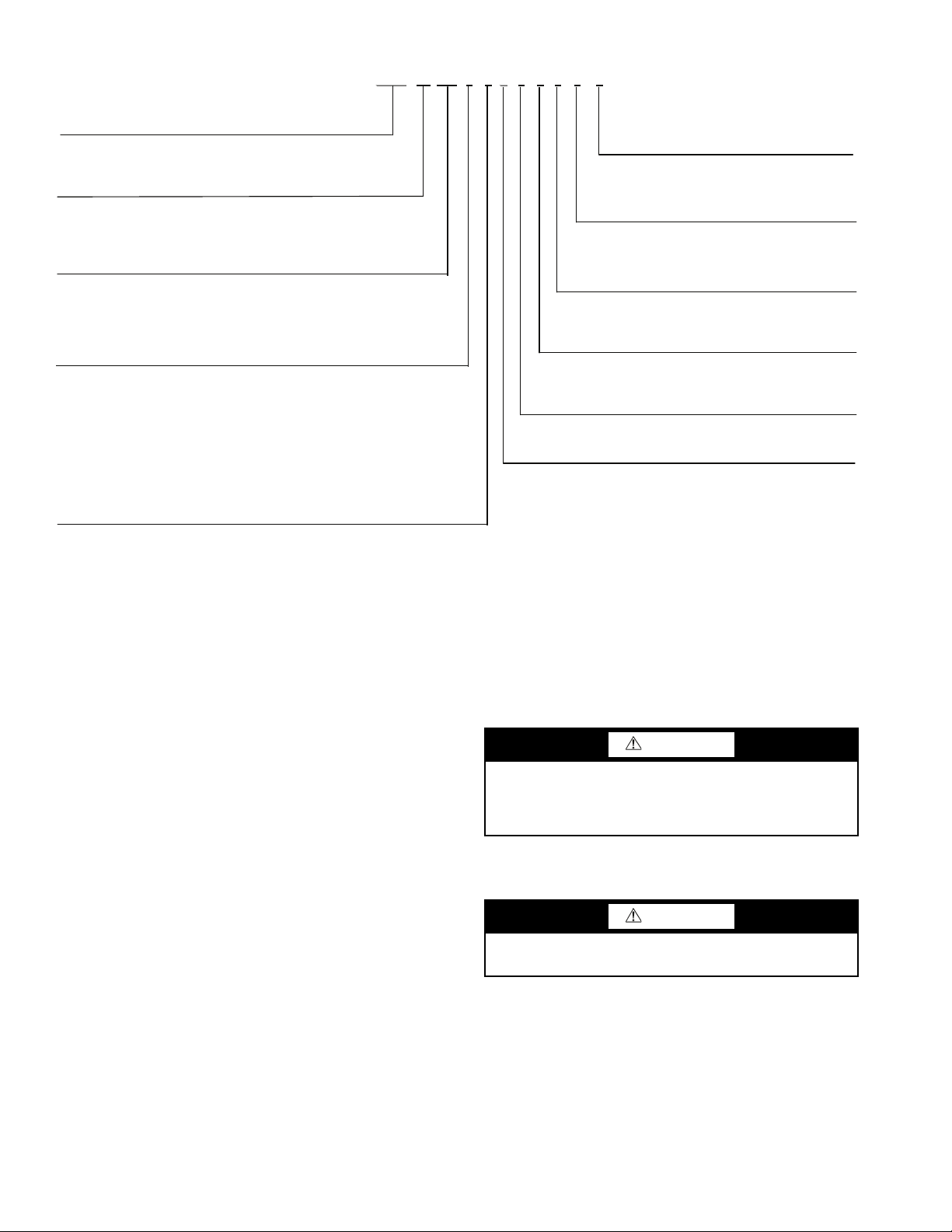

Fig. 2 — 30MPW Unit

a30-5030

30MPA,MPW015-045

with Scroll Compressors

and COMFORTLINK™ Controls

Installation Instructions

AQUASNAP

®

Liquid Chillers

CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . 1,2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Step 1 — Inspect Shipment . . . . . . . . . . . . . . . . . . . . 2

Step 2 — Position the Unit . . . . . . . . . . . . . . . . . . . . . 2

Step 3 — Place the Unit. . . . . . . . . . . . . . . . . . . . . . . . 7

Step 4 — Check Compressor Mounting. . . . . . . . 7

Step 5 — Make Piping Connections. . . . . . . . . . . . 7

• 30MPA SYSTEM CONDENSER

• 30MPW CONDENSER DESCRIPTION

• 30MPW CONDENSER

• EVAPORATOR DESCRIPTION

• EVAPORATOR PIPING

•AIR SEPARATION

Step 6 — Fill the Chilled Water Loop. . . . . . . . . . .13

• WATER SYSTEM CLEANING

• FILLING THE SYSTEM

Step 7 — Make Electrical Connections. . . . . . . . .14

•FLOW SWITCH

• CONTROL BOX, POWER SECTION

• CONTROL BOX, CONTROLS SECTION

• CONTROL BOX, FIELD CONTROL WIRING

SECTION

• UNBALANCED 3-PHASE SUPPLY VOLTAGE

.

WARNING

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all disconnect locations to alert others not to restore power until work

is completed.

GENERAL

These installation instructions cover the 30MPA, MPW units

with ComfortLink controls. The 30MPA units are condenserless

units and the 30MPW units are all fluid cooled.

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment (Fig. 1

and 2) can be hazardous due to system pressures, electrical

components, and equipment location (roofs, elevated structures, etc.). Model number structure is shown in Fig. 3.

Only trained, qualified installers and service technicians

should install, start up, and service this equipment.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging, and setting bulky

equipment.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53300054-01 Printed in U.S.A. Form 30MP-1SI Pg 1 910 1-10 Replaces: New

Page 2

INSTALLATION

30MP

A0306 -

30MP – Aquasnap® Liquid Chiller with ComfortLink™ Controls

Condenser Option

A – Chiller without Condenser (Air-Cooled)

Design Revision Level

W – Chiller with Condenser (Water-Cooled)

- – Initial Release

Voltage Options

1 – 575-3-60

5 – 208/230-3-60

6 – 460-3-60

Unit Size – Nominal Tons (kW)

015 – 15 (54) 040 – 40 (138)

020 – 20 (71) 045 – 45 (161)

030 – 30 (108)

2 – 380-3-60

0

Sound/Mounting Options

0 – None

1 – S

ound Enclosure Panels

3 – Height Adjustment Kit

4 – Height Adjustment Kit, Sound Enclosure Panels

9 – Mobility Kit (Wheels)

B – Mobility Kit (Wheels), Sound Enclosure Panels

D – Height Adjustment Kit, Mobility Kit (Wheels)

F – Height Adjustment Kit, Mobility Kit (Wheels), Sound Enclosure Panels

0

Comfort Cooling/Medium Temp Brine Options

0 – Comfort Cooling Duty (32-60 F) (Std)

7 – Medium Temperature Brine (15-32 F)

0

Capacity Control Options

0 – Standard

1 – Hot Gas Byp

ass

0

Disconnect Options

0 – Standard (Terminal Block)

1 – Non-Fused Disconnect Switch

0

Controls/Interface Options

0 – Scrolling Marquee Display (Std)

5 – Scrolling Marquee Display, EMM

5

Packaging Options

5 – Bag

B – Export Crate

Fig. 3 — 30MP Model Number Nomenclature

LEGEND

EMM — Energy Management Module

LON — Local Operating Network

UPC — Unitary Protocol Controller

a30-5038

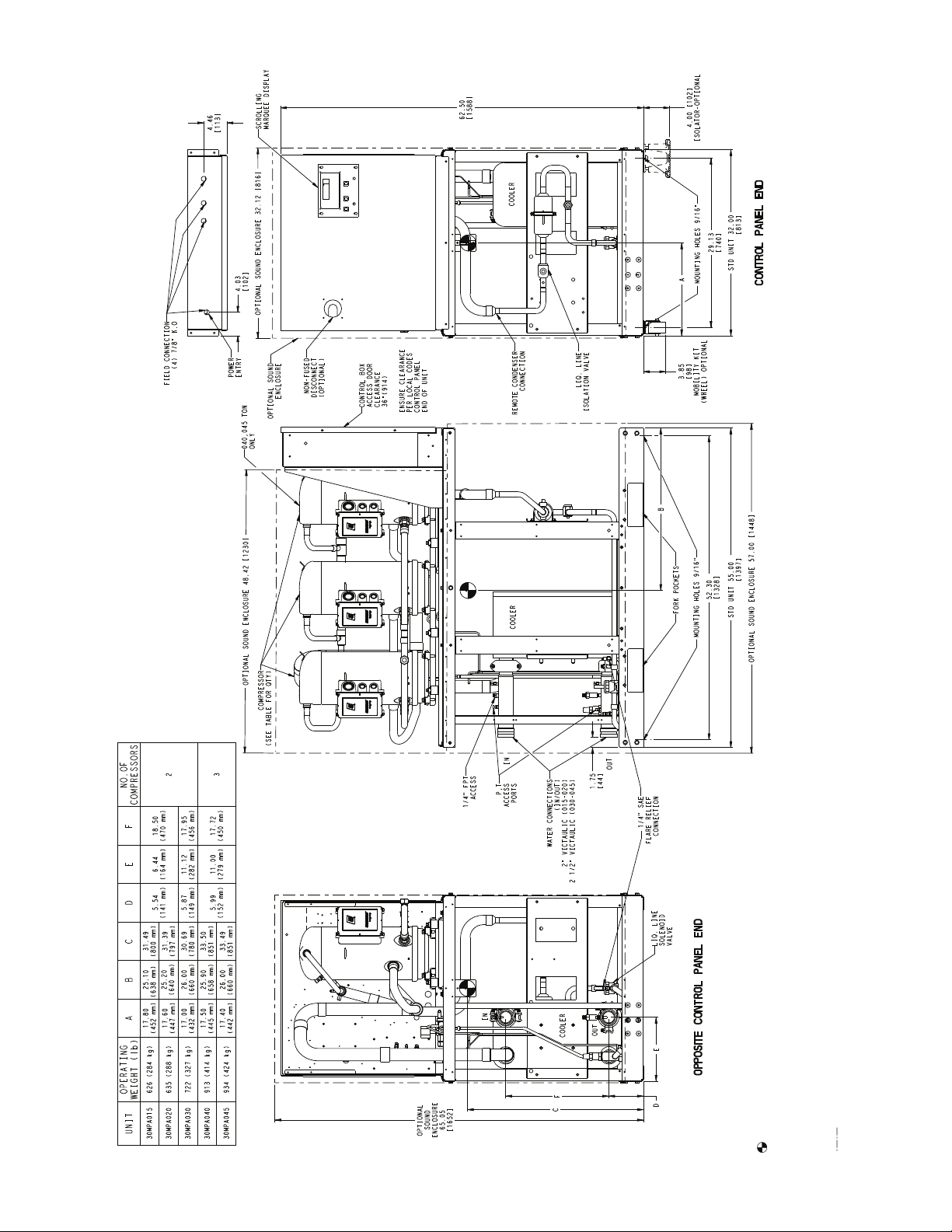

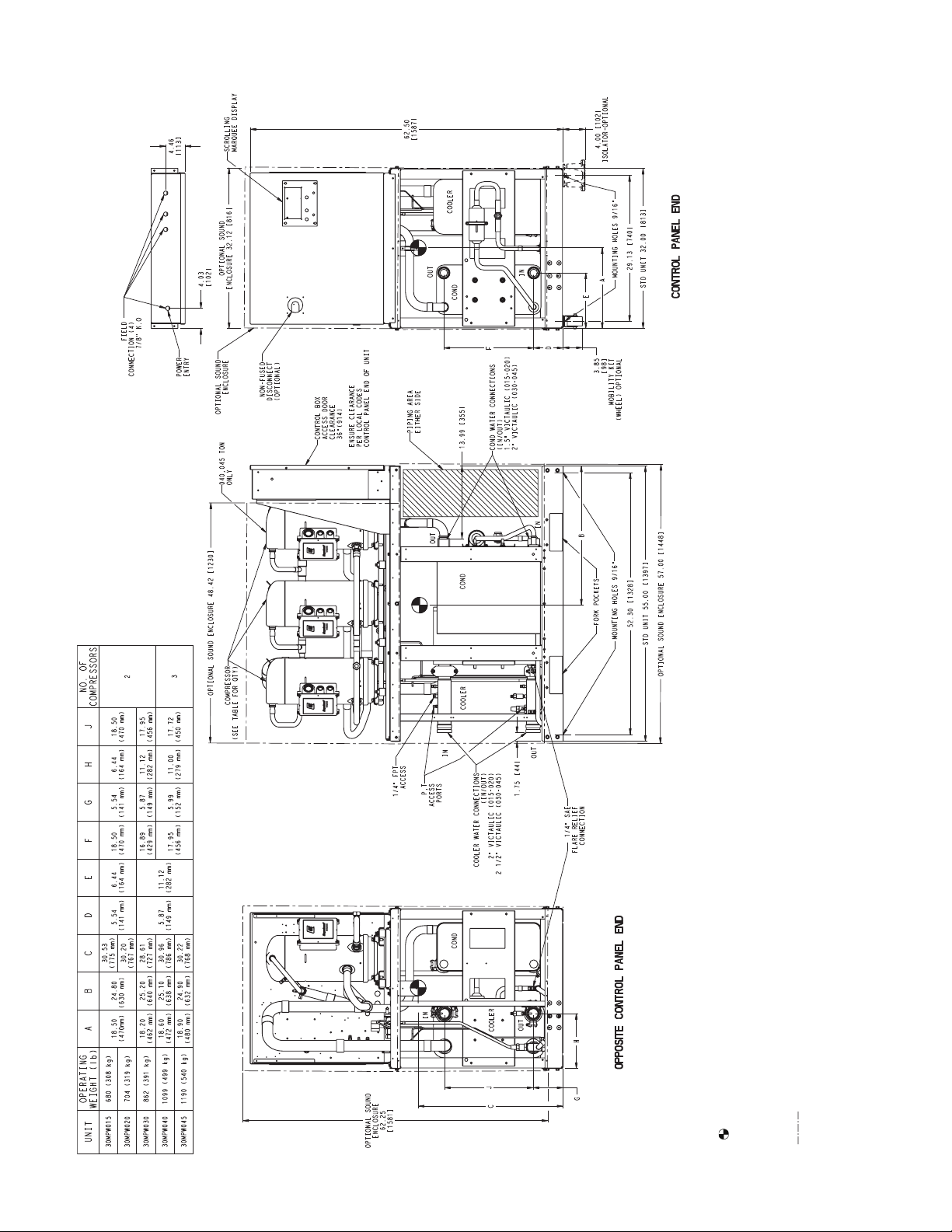

Location —

er because of sensitive control mechanisms and electronic

devices. Locate unit indoors. See Fig. 4 and 5 for unit dimensional details.

When considering location, consult National Electrical

Code (NEC) and local code requirements. Allow sufficient

space for wiring, piping, and service. Install unit in an area

where it will not be exposed to ambient temperatures below

50 F (10 C).

Allow 36 in. (914 mm) in front of the unit for control box

access door. Additional clearance may be required per local

codes. Prior to installation determine which direction compressor will be removed, and leave 3 to 4 ft (914 to 1219 mm)

clearance for removal.

On all units leave 3 ft (0.9 m) of clearance behind the unit to

make water/brine connections to the evaporator, accessing the

TXV (thermostatic expansion valve), fluid thermistors, and

proof of flow switch.

On all units, leave 2 ft (610 mm) on one side for making refrigeration connections (30MPA) or fluid connections

(30MPW) to condenser. See Fig. 4 and 5.

The floor must be strong enough to support the unit operating weight (see Tables 1A and 1B and Fig. 4-6). If necessary,

add a supporting structure (steel beams or reinforced concrete

slabs) to the floor to transfer weight to nearest beams.

Do not store units in an area exposed to weath-

Additional weight of factory-installed sound enclosure op-

tion is 75 lb (34 kg).

CAUTION

Be sure interconnecting piping and electrical conduits

Step 1 — Inspect Shipment — Inspect unit for dam-

age or missing parts. If damaged, or if shipment is incomplete,

file a claim immediately with the shipping company.

are suspended freely, and are not in contact with any

adjacent walls. Be sure unit capillaries are not rubbing

against anything. Damage to unit or walls may result.

Unit is top heavy. Unit may tip if handled without care.

Damage to unit or injury may result.

CAUTION

Step 2 — Position the Unit — The unit may be

moved by means of rollers under the rails or a forklift truck.

If accessory mobility kit is to be used, install this accessory

after bringing unit into building and before moving the unit to

its final location per installation instructions provided with the

accessory. The factory-installed mobility kit option consists of

4 swivel-type wheels that are field-mounted to the legs of the

unit. See Fig. 7.

NOTE: The wheels are equipped with a thumb-screw brake.

2

Page 3

52.30

1328[]

STD UNIT 55.00

1397[]

OPTIONAL SOUND ENCLOSURE 57.00 [1448]

29.13

740[]

STD UNIT 32.00

813[]

62.50

1588[]

OPTIONAL SOUND ENCLOSURE 32.12 [816]

MOBILITY KIT

(WHEEL) OPTIONAL

3.85

98[]

E

D

F

OPTIONAL SOUND ENCLOSURE 48.42 [1230]

OPTIONAL

SOUND

ENCLOSURE

65.05

[1652]

4.00 [102]

ISOLATOR-OPTIONAL

C

B

A

4.03

102[]

1.75

44[]

4.46

[113]

UNIT

OPERATING

WEIGHT (lb)

ABCDEF

NO.OF

COMPRESSORS

30MPA015 626 (284 kg)

17.80

(452 mm)

25.10

(638 mm)

31.49

(800 mm)

5.54

(141 mm)

6.44

(164 mm)

18.50

(470 mm)

230MPA020 635 (288 kg)

17.60

(447 mm)

25.20

(640 mm)

31.39

(797 mm)

30MPA030 722 (327 kg)

17.00

(432 mm)

26.00

(660 mm)

30.69

(780 mm)

5.87

(149 mm)

11.12

(282 mm)

17.95

(456 mm)

30MPA040 913 (414 kg)

17.50

(445 mm)

25.90

(658 mm)

33.50

(851 mm)

5.99

(152 mm)

11.00

(279 mm)

17.72

(450 mm)

3

30MPA045 934 (424 kg)

17.40

(442 mm)

26.00

(660 mm)

33.49

(851 mm)

COMPRESSOR

(SEE TABLE FOR QTY)

OUT

IN

OPTIONAL SOUND

ENCLOSURE

FIELD CONNECTION

(4) 7/8" K.O

NON-FUSED

DISCONNECT

(OPTIONAL)

1/4" FPT

ACCESS

P,T

ACCESS

PORTS

1/4" SAE

FLARE RELIEF

CONNECTION

POWER

ENTRY

WATER CONNECTIONS

(IN/OUT)

2" VICTAULIC (015-020)

2 1/2" VICTAULIC (030-045)

COOLER

COOLER

COOLER

CONTROL PANEL END

OPPOSITE CONTROL PANEL END

MOUNTING HOLES 9/16"

-

MOUNTING HOLES 9/16"

-

IN

OUT

040,045 TON

ONLY

FORK POCKETS

SCROLLING

MARQUEE DISPLAY

REMOTE CONDENSER

CONNECTION

LIQ. LINE

ISOLATION VALVE

LIQ. LINE

SOLENOID

VALVE

CONTROL BOX

ACCESS DOOR

CLEARANCE

36"(914)

ENSURE CLEARANCE

PER LOCAL CODES

CONTROL PANEL

END OF UNIT

Fig. 4 — Dimensions — 30MPA015-045 Units

NOTES:

1. Operating weight includes weight of water and refrigerant.

2. Denotes center of gravity.

3. Dimensions are shown in inches. Dimensions in [ ] are in

millimeters.

4. Allow 36-in. (914 mm) clearance on control panel end, opposite

control panel end and above the unit. All clearances must be in

accordance with local codes.

5. Denotes accessory or factory-installed option.

a30-5032

3

Page 4

Fig. 5 — Dimensions — 30MPW015-045 Units

NOTES:

1. Operating weight includes weight of water and refrigerant.

2. Denotes center of gravity.

3. Dimensions are shown in inches. Dimensions in [ ] are in

millimeters.

4. Allow 36-in. (914 mm) clearance on control panel end, opposite

control panel end and above the unit. All clearances must be in

accordance with local codes.

5. Denotes accessory or factory-installed option.

a30-5033

910

4

Page 5

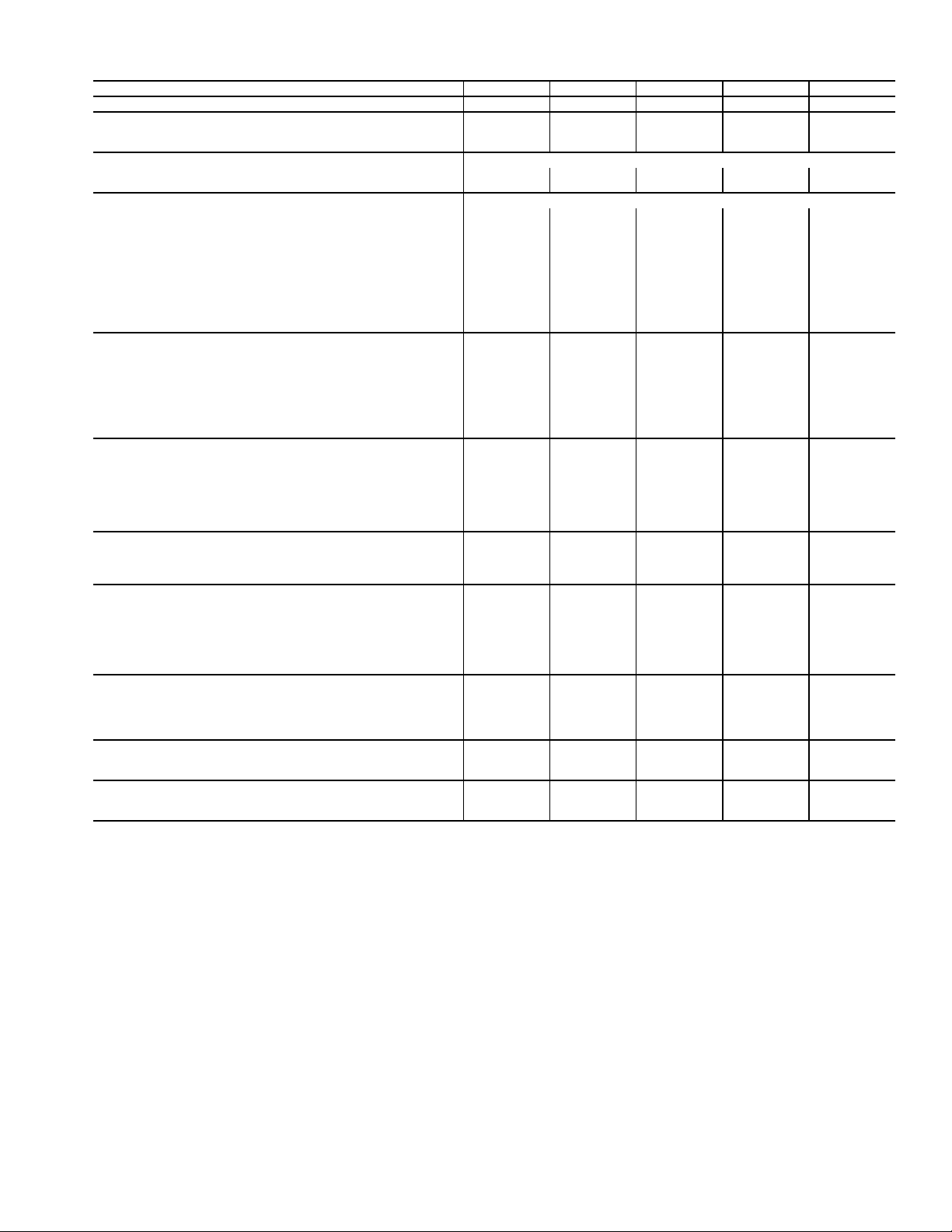

Table 1A — 30MPA Air-Cooled and 30MPW Liquid-Cooled Units — English

UNIT 30MPA,MPW 015 020 030 040 045

NOMINAL TONS 15 20 30 40 45

OPERATING WT (lb)

MPA 626 635 722 913 934

MPW 680 704 862 1099 1190

REFRIGERANT (lb) R-410A

MPA —————

MPW 11.6 15.2 23.1 29.4 34.4

COMPRESSOR Scroll, Hermetic

Quantity 22233

Speed (rpm) 3500 3500 3500 3500 3500

Compressor Nominal Tons 7.510151315

Oil Charge (pt) 10.6 13.8 13.8 20.6 20.6

Capacity Control — Standard

No. of Steps 22233

Minimum Step Capacity (%) 50 50 50 33 33

Capacity Control — Optional Hot Gas Bypass

No. of Steps 33344

Minimum Step Capacity (%) 18 25 34 21 22

EVAPORATOR

Weight (lb, empty) 27.5 40.3 91.8 122.3 128.3

Net Fluid Volume (gal.) 0.8 1.2 2.4 3.2 3.4

Maximum Refrigerant Pressure (psig) 650 650 650 650 650

Maximum Fluid-Side Pressure (psig) 300 300 300 300 300

Water Connections (in.)

Inlet and Outlet (Victualic) 222

Drain (NPT)

CONDENSER (30MPW Only)

Weight (lb, empty) 34.9 43.6 104.6 136.7 188.3

Net Fluid Volume (gal.) 1.2 1.6 2.9 4.1 5.9

Maximum Refrigerant Pressure (psig) 650 650 650 650 650

Maximum Fluid-Side Pressure (psig) 300 300 300 300 300

Water Connections (in.)

Inlet and Outlet (Victualic) 222

1

/

2

1

/

2

CHASSIS DIMENSIONS (in.)

Length 55 55 55 55 55

Width 32 32 32 32 32

Height 63 63 63 63 63

MINIMUM SYSTEM FLUID VOLUME (gal. per Ton)

Normal Air Conditioning

Standard 66644

Optional Hot Gas Bypass 44433

Low Outdoor Ambient Cooling Operation (30MPA Units)

Standard 10 10 10 88

Optional Hot Gas Bypass 77766

CAPACITY STEPS

Step 1 100% 100% 100% 100% 100%

Step 2 50% 50% 50% 67% 67%

Step 3 18%* 25%* 34%* 33% 33%

Step 4 — — — 21%* 22%*

MINIMUM FLOW RATES (gpm)

Evaporator 22 28 43 55 64

Condenser 22 28 43 55 64

MAXIMUM FLOW RATES (gpm)

Evaporator 74 97 148 188 220

Condenser 74 97 148 188 220

* With optional hot gas bypass. NOTES:

1. Operating weight includes refrigerant operating charge and

weight of fluid in the heat exchangers.

2. 30MPW units are shipped with full operating charge.

1

/

2

1

/

2

1

/

2

2 1/

1

2 1/

2

/

2

2

21/

21/

2

1

/

2

2

5

Page 6

Table 1B — 30MPA Air-Cooled and 30MPW Liquid-Cooled Units — SI

UNIT 30MPA,MPW 015 020 030 040 045

NOMINAL KW 54 71 108 138 161

OPERATING WT (kg)

MPA 284288 327 414 424

MPW 308 319 391 499 540

REFRIGERANT (kg) R-410A

MPA —————

MPW 5.2 6.9 10.5 13.3 15.6

COMPRESSOR Scroll, Hermetic

Quantity 22233

Speed (r/s) 58 58 58 58 58

Compressor Nominal kW 26 35 53 45 53

Oil Charge (L) 5.0 6.5 6.5 9.8 9.8

Capacity Control — Standard

No. of Steps 22233

Minimum Step Capacity (%) 50 50 50 33 33

Capacity Control — Optional Hot Gas Bypass

No. of Steps 33344

Minimum Step Capacity (%) 18 25 34 21 22

EVAPORATOR

Weight (kg, empty) 12.5 18.3 41.6 55.5 58.2

Net Fluid Volume (L) 2.9 4.6 8.9 12.0 13.0

Maximum Refrigerant Pressure (kPa) 44824482448244824482

Maximum Fluid-Side Pressure (kPa) 2068 2068 2068 2068 2068

Water Connections (in.)

Inlet and Outlet (Victualic) 222

Drain (NPT)

CONDENSER (30MPW)

Weight (kg, empty) 15.8 19.8 47.4 62.0 85.4

Net Fluid Volume (L) 4.5 5.9 11.1 15.4 22.4

Maximum Refrigerant Pressure (kPa) 44824482448244824482

Maximum Fluid-Side Pressure (kPa) 2068 2068 2068 2068 2068

Water Connections (in.)

Inlet and Outlet (Victualic) 1

1

/

2

1

/

2

11/

1

/

2

2

CHASSIS DIMENSIONS (mm)

Length 1397 1397 1397 1397 1397

Width 813 813 813 813 813

Height 1600 1600 1600 1600 1600

MINIMUM SYSTEM FLUID VOLUME (L per kW)

Normal Air Conditioning

Standard 23 23 23 15 15

Optional Hot Gas Bypass 15 15 15 11 11

Low Outdoor Ambient Cooling Operation (30MPA Units)

Standard 38 38 38 30 30

Optional Hot Gas Bypass 25 25 25 23 23

CAPACITY STEPS

Step 1 100% 100% 100% 100% 100%

Step 2 50% 50% 50% 67% 67%

Step 3 18%* 25%* 34%* 33% 33%

Step 4 — — — 21%* 22%*

MINIMUM FLOW RATES (L/s)

Evaporator 1.4 1.8 2.7 3.5 4.0

Condenser 1.4 1.8 2.7 3.5 4.0

MAXIMUM FLOW RATES (L/s)

Evaporator 4.7 6.1 9.3 11.9 13.9

Condenser 4.7 6.1 9.3 11.9 13.9

* With optional hot gas bypass. NOTES:

1. Operating weight includes refrigerant operating charge and

weight of fluid in the heat exchangers.

2. 30MPW units are shipped with full operating charge.

1

/

2

1

/

2

2 1/

1

2

/

2

21/

2

1

/

2

222

6

Page 7

B

A

C

D

CONTROL

PANEL

SIDE

WEIGHT DISTRIBUTION AT EACH MOUNTING

HOLE — Lb (kg)

UNIT 30MP

MOUNTING HOLE

ABCD

A015 156 (71)

A020 159 (72)

A030 181 (82)

A040 228 (104)

A045 234 (106)

W015 170 (77)

W020 176 (80)

W030 216 (98)

W040 275 (125)

W045 298 (135)

Fig. 6 — Mounting Hole Weight Distribution

a30-5040

Fig. 7 — Mobility Kit

a30-5041

Step 3 — Place the Unit

NOTE: These units are not suitable for unprotected outdoor

use.

Carrier recommends that these units be located in the basement or on the ground floor. However, if it is necessary to locate the unit on an upper floor, be sure the structure has been

designed to support the unit weight. If necessary, add structural

support to floor. Also, be sure the surface for installation is

level. Refer to Fig. 4 and 5 for space requirements and weight

distribution.

Only electrical power connections, water connections for

condenser, fluid connections for evaporator, and strainer installation are required for 30MPW installation. Installation of

30MPA units varies only in field piping required for the remote

condenser.

When the unit is in its final position, remove the packaging

and remove the mobility kit wheels (if equipped). Remove

3

/8-in. wheel nuts to remove wheels from unit legs. Level the

unit (using a level), and bolt the unit to the floor or pad.

If unit is to be mounted on unit external vibration

isolators, follow the mounting instructions included with

the accessory vibration isolator.

If unit has accessory leveling kit installed, follow the instructions provided with the accessory to make sure unit is level and in the correct position.

Step 4 — Check Compressor Mounting — As

shipped, units with two compressors are held down with 6 bolts

through rubber grommets. All units with three compresors are

held down with 8 bolts per pair through grommets. After unit is

installed, verify mounting bolt torque 7 to10 ft-lb (9 to 14 Nm).

Step 5 — Make Piping Connections — See

Fig. 8 and 9 for typical piping applications.

30MPA SYSTEM CONDENSER — For detailed condenser

piping installation instructions for 30MPA systems, refer to

separate instructions packaged with the remote condenser

units.

Condenser refrigerant piping for 30MPA units should be

sized to minimize the amount of refrigerant required.

The 30MPA units that use air-cooled evaporative condensers must have adequate means for head pressure control when

operating below 60 F (15.6 C).

Carrier recommends that a field-supplied pressure relief device be installed in each discharge line of 30MPA units. Most

local codes require the discharge line relief valve to be vented

directly to the outdoors. The vent must not be smaller than the

discharge line relief valve outlet.

30MPW CONDENSER DESCRIPTION — All 30MPW

units use a brazed-plate heat-exchanger-type condenser. These

heat exchangers are made of embossed plates of acid-resistant

stainless steel. Every other plate is reversed so that the ridges

of the herringbone pattern intersect one another on adjacent

plates, forming a lattice of contact points. These plates are

vacuum-brazed together to form a compact and pressureresistant heat exchanger.

After brazing, the impressions in the plates form 2 separate

systems of channels where the refrigerant and water flows are

counterflow. The number of plates varies depending on unit

tonnage. The condensers provide approximately 10º to 12º F

(6º to 8º C) liquid subcooling at the standard Air Conditioning,

Heating and Refrigeration Institute (AHRI) rating condition.

30MPW CONDENSER — When facing the unit control box,

the condenser is the uninsulated heat exchanger located on the

left-hand side. The water connections are on the right-hand

side of the heat exchanger with the LIQUID-IN connection at

the bottom, and the LIQUID-OUT connection at the top.

A strainer with a minimum of 40 mesh must be installed

within 10 ft (3 m) of the condenser water inlet to prevent debris

from clogging or damaging the heat exchanger. The strainer is

required for operation and is available as an accessory.

To install the victaulic coupling (see Fig. 10):

1. Lubricate the gasket lips and stretch the gasket over

the end of the heat exchanger coupling. Avoid twisting

the gasket when installing.

2. Bring the pipe and heat exchanger coupling ends together

into alignment. Slide the gasket so that it is centered over

the ends. Apply a light film of lubricant to the gasket, or

to the outside diameter of the pipe. Avoid twisting the

gasket during installation.

7

Page 8

NOTES:

1. Chiller must be installed level to maintain proper compressor oil return.

2. Wiring and piping shown are general points-of-connection guides only and are not intended for a spe-

cific installation. Wiring and piping shown are for a quick overview of system and are not in accordance

with recognized standards. Units should be installed using certified drawings.

3. All wiring must comply with applicable local and national codes.

4. All piping must follow standard piping techniques. Refer to Carrier System Design Manual or appropri-

ate ASHRAE (American Society of Heating, Refrigerating, and Air Conditioning Engineers) handbook

for details.

5. See Tables 1A and 1B for minimum system fluid volume. This system may require the addition of a

holding tank to ensure adequate volume.

6. A strainer with a minimum of 40 mesh must be installed within 10 ft (3 m) of the evaporator fluid inlet to

prevent debris from clogging or damaging the heat exchanger. This strainer is required and is available

as an accessory.

7. Piping, wiring, switches, vents, strainers, drains, and vibration isolation are all field-supplied.

Fig. 8 — Typical Piping with Liquid-Cooled 30MPW Chiller

a30-4997

8

Page 9

NOTES:

1. Chiller must be installed level to maintain proper compressor oil

return.

2. Wiring and piping shown are general points-of-connection guides

only and are not intended for a specific installation. Wiring and piping shown are for a quick overview of system and are not in accordance with recognized standards. Units should be installed using

certified drawings.

3. All wiring must comply with applicable local and national codes.

4. All piping must follow standard piping techniques. Refer to Carrier

System Design Manual part 3, Carrier E20-II software Refrigerant

Piping program, or appropriate ASHRAE (American Society of

Heating, Refrigerating, and Air Conditioning Engineers) handbook

for details on proper piping sizes and design.

5. See Tables 1A and 1B for minimum system fluid volume. This system may require the addition of a holding tank to ensure adequate

volume.

6. Hot gas lines should rise above refrigerant level in condenser circuit. Double riser may be required; check unit minimum capacity.

7. Trap should be installed on hot gas lines to prevent condenser oil

and refrigerant vapor migration from accumulating in compressor

during off cycle.

8. Pitch all horizontal lines downward in the direction of refrigerant

flow.

9. Provide support to liquid and gas lines near the connections to the

condenser coil.

10. For pressure relief requirements, see latest revision of ASHRAE

Standard 15, Safety Code for Mechanical Refrigeration.

11. A strainer with a minimum of 40 mesh must be installed within 10 ft

(3 m) of the evaporator fluid inlet to prevent debris from clogging or

damaging the heat exchanger. This strainer is required and is available as an accessory.

12. Piping, wiring, switches, vents, strainers, drains, and vibration isolation are all field-supplied.

Fig. 9 — Typical Piping with 30MPA Unit and 09DP Remote Air-Cooled Condenser

09DP

AIR-COOLED

CONDENSER

a30-4998

9

Page 10

3. Install the inside coupling half over the gasket and then

Fig. 10 — Install the Victualic Coupling

a30-1245

install the outer half. Connect with nuts and bolts. Tighten

the nuts equally on both sides. Ensure there is no gap between the two halves of the coupling.

4. Alternately tighten the nuts with a wrench to draw the

coupling halves together uniformly. The joint is now

complete.

30MPW UNITS — In order to minimize the water pressure

drop in the system, use as few bends as possible in the field

water piping, and run the lines as short as possible. Size the

water lines according to the available pump pressure (not necessarily the connection size), especially on cooling tower applications. See Carrier System Design Manual, Part 3, Piping Design.

See Fig. 11 for condenser pressure drops.

Set water regulating valve, if installed, to maintain design

head pressure. Do not adjust to compensate for high head pressures caused by fouled condensers, excess refrigerant, or the

presence of noncondensables. Due to changes in water temperature, it may be necessary to adjust the valve seasonally. After

adjusting for design head pressure, shut unit down. The water

regulating valve should shut off the flow of water in a few minutes. If it does not, raise head pressure setting. Make sure that

the capillary tube from each water regulating valve is connected to the proper condenser access fitting.

Provide a means for draining the system in the winter (if not

used) and for maintenance.

Water leaving the condenser is under pressure and should

not be connected directly into sewer lines. Check local codes.

EVAPORATOR DESCRIPTION — All 30MP units use a

brazed-plate heat-exchanger type evaporator. The heat exchanger is constructed essentially the same as the brazed-plate

condenser used on 30MPW units. See 30MPW Condenser Description section on page 7 for more details. Similar to the condenser, the evaporator can only be chemically cleaned. See Fig.

12 for evaporator pressure drops.

EVAPORATOR PIPING — Plan evaporator fluid piping for

minimum number of changes in elevation, and for the fewest

number of bends possible. Install manual or automatic vent

valve at high points in the line. Maintain system pressure by

using a pressure tank or a combination of relief and reducing

valves.

A strainer with a minimum of 40 mesh must be installed

within 10 ft of the evaporator fluid inlet to prevent debris from

clogging or damaging the heat exchanger. This strainer is required and is available as an accessory.

See Carrier System Design Manual, Part 3, Piping Design,

for chilled fluid piping details.

The evaporator fluid inlet and outlet connections are victualic. The fluid enters at the top connection and leaves at the

bottom connection. Procedures for making the connections are

the same as for the 30MPW condensers. See 30MPW Condenser section on page 7 for more details.

Run the pump for 10 minutes, then clean the strainer before

starting the unit.

An evaporator flow switch is standard on all units. This is a

thermal dispersion type switch that is installed in the evaporator fluid outlet. The switch is set to open when the evaporator

fluid flow drops below the minimum set point.

For variable primary flow applications, it may be necessary

to adjust the flow switch set point to avoid nuisance trips. Contact Carrier service engineering for the mthod needed to adjust

the switch.

See Table 1 for minimum flow rates and loop volume.

The thermistors used to sense entering and leaving fluid

temperature are factory-installed in the evaporator entering and

leaving fluid nozzles.

AIR SEPARATION — For proper system operation, it is

essential that water loops be installed with proper means to

manage air in the system. Free air in the system can cause

noise, reduce terminal output, stop flow, or even cause pump

failure due to pump cavitation. For closed systems, equipment

should be provided to eliminate all air from the system.

The amount of air that water can hold in solution depends

on the pressure and temperature of the water/air mixture. Air is

less soluble at higher temperatures and at lower pressures.

Therefore, separation can best be done at the point of highest

water temperature and lowest pressure. Typically, this point

would be on the suction side of the pump as the water is returning from the system or terminals. Generally speaking, this is

the best place to install an air separator, if possible.

1. Install automatic air vents at all high points in the system.

(If the 30MP unit is located at the high point of the

system, a vent can be installed on the piping entering the

heat exchanger on the ¼-in. NPT female port.)

2. Install an air separator in the water loop, at the place

where the water is at higher temperatures and lower

pressures — usually in the chilled water return piping.

On a primary-secondary system, the highest temperature

water is normally in the secondary loop, close to the

decoupler. Preference should be given to that point on the

system (see Fig. 13). In-line or centrifugal air separators

are readily available in the field.

It may not be possible to install air separators at the place of

lowest pressure and highest temperature. In such cases, preference should be given to the points of highest temperature. It is

important that pipe be sized correctly so that free air can be

moved to the point of separation. Generally, a water velocity of

at least 2 feet per second will keep free air entrained and

prevent it from forming air pockets.

Automatic vents should be installed at all physically elevated points in the system so that air can be eliminated during

system operation. Provision should also be made for manual

venting during the water loop fill. It is important that the

automatic vents be located in accessible locations for

maintenance purposes, and that they be located where they can

be prevented from freezing.

10

Page 11

120

1

100

80

Drop (kPa)

40

60

Water Pressur

e

20

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Liters/second

12 3

5

4

40

35

1

5

4

3

2

25

30

Drop ()

15

20

Water Pressure

5

10

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240

GPM

Fig. 11 — Condenser Water Pressure Drop

ENGLISH

SI

LEGEND

1 — 30MP015

2—30MP020

3—30MP030

4—30MP040

5—30MP045

a30-5037

a30-5036

11

Page 12

120

3

100

1

80

Drop (kPa)

40

60

Water Pressur

e

20

0

012345678910111213

Liters/second

1

2

3

4

5

0

5

10

15

20

25

30

35

40

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200

Water Pressure Drop ()

GPM

15

4

3

2

Fig. 12 — Evaporator Water Pressure Drop

ENGLISH

SI

LEGEND

1 — 30MP015

2—30MP020

3—30MP030

4—30MP040

5—30MP045

a30-5035

a30-5034

12

Page 13

Step 6 — Fill the Chilled Water Loop

Distribution Pump

Expansion

Tank(s)

Air Separator

with Vent

Decoupler

Chiller 1

Chiller 2

Zone 1

Zone 2

Zone 3

NOTE: Expansion tanks must be disconnected for chillers placed parallel in the primary water loop.

Fig. 13 — Typical Air Separator and Expansion Tank Location on Primary-Secondary Systems

a30-3226

WATER SYSTEM CLEANING — Proper water system

cleaning is of vital importance. Excessive particulates in the

water system can cause excessive pump seal wear, reduce or

stop flow, and cause damage of other components. Water

quality should be maintained within the limits indicated in

Table 2. Failure to maintain proper water quality may result in

heat exchanger failure.

CAUTION

Failure to properly clean all piping and components of the

chilled water system before unit start-up may result in

plugging of the heat exchanger, which can lead to poor performance, nuisance alarms and damage from freezing.

Freezing damage caused by an improperly cleaned system

represents abuse and may impair or otherwise negatively

affect the Carrier product warranty.

1. Install a temporary bypass around the chiller to avoid circulating dirty water and particulates into the pump package and chiller during the flush. Use a temporary circulating pump during the cleaning process. Also, be sure that

there is capability to fully drain the system after cleaning.

(See Fig 14.)

2. Be sure to use a cleaning agent that is compatible with all

system materials. Be especially careful if the system

contains any galvanized or aluminum components. Both

detergent-dispersant and alkaline-dispersant cleaning

agents are available.

3. It is a good idea to fill the system through a water meter.

This provides a reference point for the future for loop

volume readings, but it also establishes the correct

quantity of cleaner needed in order to get the required

concentration.

4. Use a feeder/transfer pump to mix the solution and fill the

system. Circulate the cleaning system for the length of

time recommended by the cleaning agent manufacturer.

a. After cleaning, drain the cleaning fluid and flush the

system with fresh water.

b. A slight amount of cleaning residue in the system can

help keep the desired, slightly alkaline, water pH of 8

to 9. Avoid a pH greater than 10, since this will

adversely affect pump seal components.

c. A side stream filter is recommended (see Fig. 15)

during the cleaning process. Filter side flow rate

should be enough to filter the entire water volume

every 3 to 4 hours. Change filters as often as necessary during the cleaning process.

Alkalinity (HCO

Sulfate (SO

HCO

Electrical Conductivity 10 – 500S/cm

pH 7.5 – 9.0

Ammonium (NH

Chorides (Cl

Free chlorine (Cl

Hydrogen Sulfide (H

Free (aggressive) Carbon

Dioxide (CO

Total Hardness (dH) 4.0 – 8.5

Nitrate (NO

Iron (Fe) Less than 0.2 ppm

Aluminum (Al) Less than 0.2 ppm

Manganese (Mn) Less than 0.1 ppm

*Sulfides in the water quickly oxidize when exposed to air, requiring that

†Dissolved carbon dioxide can either be calculated from the pH and

FILLING THE SYSTEM — The initial fill of the chilled

water system must accomplish three purposes:

The pressure created by an operating pump affects system

pressure at all points except one — the connection of the

compression tank to the system. This is the only location in the

system where pump operation will not give erroneous pressure

indications during the fill. Therefore, the best location to install

the fill connection is close to the expansion tank. An air vent

should be installed close by to help eliminate air that enters

during the fill procedure.

13

d. Remove temporary bypass when cleaning is

complete.

Table 2 — Water Quality Characteristics

and Limitations

WATER CHARACTERISTIC QUALITY LIMITATION

-

/SO

3

no agitation occur as the sample is taken. Unless tested immediately

at the site, the sample will require stabilization with a few drops of one

Molar zinc acetate solution, allowing accurate sulfide determination up

to 24 hours after sampling. A low pH and high alkalinity cause system

problems, even when both values are within the ranges shown. The

term pH refers to the acidity, basicity, or neutrality of the water supply.

Below 7.0, the water is considered to be acidic. Above 7.0, water is

considered to be basic. Neutral water contains a pH of 7.0.

total alkalinity values, shown below, or measured on the site using a

test kit. Dissolved Carbon Dioxide, PPM = TA x 2

= Total Alkalinity, PPM as CaCO

-

) 70 – 300 ppm

3

2-

) Less than 70 ppm

4

2-

4

) Less than 2 ppm

3

-

) Less than 300 ppm

) Less than 1 ppm

2

S)* Less than 0.05 ppm

2

)†

2

) Less than 100 ppm

3

Greater than 1.0

Less than 5 ppm

.

3

[(6.3-pH)/0.3]

where TA

1. The entire piping system must be filled with water.

2. The pressure at the top of the system must be high enough

to vent air from the system (usually 4 psig is adequate for

most vents).

3. The pressure at all points in the system must be high

enough to prevent flashing in the piping or cavitation in

the pump.

Page 14

x

x

DILUTED

CLEANING

AGENT

SYSTEM

POT FEEDER AND

TRANSFER PUMP

30MPUNIT

TO DRAIN

TEMPORARY

PUMP

TEMPORARY

BYPASS

Fig. 14 — Typical Set Up for Cleaning Process

a30-5047

SYSTEM

Fig. 15 — Cleaning Using a Side Stream Filter

a30-5048

POT FEEDER AND

TRANSFER PUMP

TEMPORARY

PUMP

TO DRAIN

SIDE

STREAM

FILTER

DILUTED

CLEANING

AGENT

Ensure the following when filling the system:

1. Remove temporary bypass piping and cleaning/flushing

equipment.

2. Check to make sure all drain plugs are installed.

3. Open the blow-down valve to flush the strainer.

Normally, a closed system needs to be filled only once. The

actual filling process is generally a fairly simple procedure. All

air should be purged or vented from the system. Thorough

venting at the high points and circulation at room temperature

for several hours is recommended.

NOTE: Local codes concerning backflow devices and other

protection of the city water system should be consulted and

followed to prevent contamination of the public water

supply. This is especially important when antifreeze is used

in the system.

Set Water Flow Rate

— Once the system is cleaned, pressurized, and filled, the flow rate through the chiller needs to be

established.

NOTE: Carrier recommends a differential pressure gage when

measuring pressures across the pumps or balancing valves.

This provides for greater accuracy and reduces error build-up

that often occurs when subtracting pressures made by different

gages.

On primary/secondary systems, it is advisable to set the

30MP balancing valve to maintain design flow plus 10%

through the chiller.

A rough estimate of water flow can also be obtained from

measuring the pressure drop across the 30MP heat exchanger.

Figures 11 and 12 show the relationship between gpm and heat

exchanger pressure drop. It should be noted that these curves

are for “clean” heat exchangers; they do not apply to heat exchangers with fouling. Adjust the external balancing valve until

the correct pressure drop is obtained for the required gpm.

x

30MPUNIT

x

TEMPORARY

BYPASS

Step 7 — Make Electrical Connections — All

field wiring must comply with local code requirements.

Electrical data for the complete unit and for the compressors is

shown in Table 3. See Fig. 16 for field wiring connections. A

field-supplied branch circuit disconnect switch that can be

locked in either OPEN or OFF position must be installed.

Control circuit power is 24 v on all units. Factory-installed

control transformer (TRAN 1) uses line voltage for all units.

All control transformers are factory-installed and wired. For

208/230-3-60 units operating at 208-3-60 line voltage, TRAN1

primary connections must be moved to terminals H3 and H4.

Inside the control box are terminals for field power and ground

(earth) wiring. A ground wire must be installed with each field

power supply. Compressors are wired for across-the-line start.

Refer to Table 3 for electrical data.

FLOW SWITCH — A condenser flow switch is available as

an accessory for all 30MPW units, and can be field-installed.

The Carrier flow switch accessory (part no. 30MP-900---004)

is available for this purpose. Flow switch wiring terminals are

located in the field wiring compartment of the control box. The

flow switch should be wired between terminals LVT-16 and

LVT-17 for all units.

CONTROL BOX, POWER SECTION — The electrical

power supply is brought in through the top left-hand side of the

control box. Pressure-lug connections on the terminal blocks

are suitable for only for copper conductors.

The control box power section contains the following

components:

• power terminal block

• optional disconnect switch

• compressor circuit breaker(s)

• compressor contactor(s)

• current sensor boards

• control transformer

• ground lug

• neutral terminal (380-3-60 units only)

• crankcase heater relay (30MPA units only)

•fuses

CONTROL BOX, CONTROLS SECTION — The control

box controls section contains the following components:

• main base board (MBB)

• scrolling marquee display

• optional energy management module

• control-circuit breakers for 24-v circuits

• control-circuit ON-OFF switch

• unit Enable/Off/Remote contact switch

• unit Alarm/Alert indicator light

CONTROL BOX, FIELD CONTROL WIRING SEC-

TION — Inside this section is the low-voltage, field-wiring

terminal strip (LVT). All low-voltage field-wiring connections

are made to this terminal block. There are three

knockouts provided for field wiring in this section. Connections for condenser flow switch, chilled fluid pump interlock,

condenser pump interlock, remote alarm output, condenser

output, and dual chiller thermistor accessory are made at these

locations. See Fig. 16 for specific location of connections.

The unit has the capability to control field-supplied devices.

They are: alarm signal, condenser pump or condenser fan output, and chilled water pump output. The unit provide 24-v

power with a minimum 5 va rating per output allowed.

UNBALANCED 3-PHASE SUPPLY VOLTAGE — Never

operate a compressor where a phase imbalance in the supply

voltage is greater than 2%. Use the following formula to deter-

mine the percent voltage imbalance:

% Voltage Imbalance =

100 x

max voltage deviation from average voltage

average voltage

14

7

/8-in. (22 mm)

Page 15

EXAMPLE: Supply voltage is 240-3-60.

AB = 243 v

BC = 236 v

AC = 238 v

Average Voltage =

243 + 236 + 238

3

= 239 v

Determine maximum deviation from average voltage:

(AB) 243 – 239 = 4 v

(BC) 239 – 236 = 3 v

Table 3 — Electrical Data — 30MPA,MPW Units

UNIT SIZE

30MPA,MPW

015

020

030

040

045

ICF — Maximum instantaneous current flow during starting.

kcmil — Thousand circular mils

LRA — Locked rotor amps.

MCA — Minimum circuit amps (for wire sizing). Complies with

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code (U.S.A.)

Rec

Fuse

*Supply Range — Units are suitable for use on electrical systems

where voltage supplied to the unit terminals is not below or above

the listed range limits.

NOTES:

1. All units have one field power terminal block.

2. Maximum incoming wire size is as follows:

For units with terminal block:

350 kcmil for unit sizes 030-045; 208/230-3-60 voltages.

2/0 for all other unit sizes; all voltages.

For units with optional non-fused disconnect:

350 kcmil for unit sizes:

030-045; 208/230-3-60 voltages.

045; 380-3-60 voltage.

NEC, Section 430-24.

— Recommended dual element fuse amps (150% of com-

pressor RLA). Size up to the next standard fuse size.

VOLTS

NAMEPLATE

(3 ph, 60 Hz)

208/230 187253

380 342 418 123 37.6 139.7 50 45

460 414 508 95 33.1 109.7 45 40

575 518 632 80 27.5 92.2 35 35

208/230 187253

380 342 418 145 53.4 168 .7 70 60

460 414 508 125 40.3 142.9 50 45

575 518 632 80 32.2 94.3 45 40

208/230 187253

380 342 418 196 76.5 230.0 110 90

460 414 508 179 60.5 205.9 8070

575 518 632 132 53.3 155.7 70 60

208/230 187253

380 342 418 139 87.4 192.

460 414 508 150 75.1 196.2 90 90

575 518 632 109 64.7 148.88070

208/230 187253

380 342 418 196 110.5 264.0 125 125

460 414 508 179 87.4 232.8 110 100

575 518 632 132 77.0 179.4 100 90

LEGEND

VOLTAGE* COMPRESSOR UNIT

Min Max

Quantity

2

2

2

3

3

(AC) 239 – 238 = 1 v

Maximum deviation is 4 v.

Determine percent voltage imbalance:

4

% Voltage Imbalance = 100 x

239

=1.7%

This amount of phase imbalance is satisfactory as it is below

the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance

is more than 2%, contact your local utility company

immediately.

LRA

(ea.)

195 66.4 224.5 90 80

239 80.6 274.8 110 90

340 125.6 395.8 175 150

300 166.7 402.6 200 200

340 181.4 451.6 225 200

3/0 for unit sizes:

015,020; 208/230-3-60 voltages.

020-040; 380-3-60 voltage.

030-045; 460-3-60 and 575-3-60 voltages.

2 AWG for unit sizes:

015; 380-3-60 voltage.

015-020; 460-3-60 and 575-3-60 voltages.

3. Additional control circuit power is not required.

4. Any field modification of factory wiring must be in compliance

with all applicable codes. Field-installed power wires must be

rated 75 C minimum.

5. Use copper conductors only.

6. Control circuit power supply is 24-v single phase. Control

power is supplied by the factory-installed control transformer.

MCA ICF MOCP

8 110 100

Rec

Fuse

15

Page 16

Fig. 16 — Typical Low Voltage Control Wiring

NOTES:

1. Factory wiring is in accordance with UL 1995 standards. Field modifications or additions must be in

compliance with all applicable codes.

2. All units or modules have single point primary power connection. Main power must be supplied

from a field or factory supplied disconnect.

3. Wiring for main field supply must be rated 75 C. Use copper conductors only.

a. Incoming wire size range for terminal block with MCA up to 120 amps is 14 AWG (American

Wire Gage) to 2/0.

b. Incoming wire size range for terminal block with MCA from 120.1 amps to 310 amps is 6 AWG

to 350 kcmil.

c. Incoming wire size range for non-fused disconnect with MCA up to 50 amps is 10 AWG to

2 AWG.

d. Incoming wire size range for non-fused disconnect with MCA from 50.1 amps to 90 amps is 6

AWG to 3/0.

e. Incoming wire size range for non-fused disconnect with MCA from 90.1 amps to 250 amps is 4

AWG to 350 kcmil.

4. Refer to certified dimensional drawings for exact locations of the main power and control power

entrance locations.

5. Terminal 24 of the LVT is for controlof chilled water pump (CWP) starter. Terminal 20 of the LVT is

for control of condenser pump (CNP) starter or condenser fan relay (CFR). The maximum load

allowed for the relays is 5 VA sealed. 10 VA inrush at 24 VAC. Field power supply is required.

6. Terminal 25 of LVT is for an alarm relay. The maximum load allowed for alarm relay is 5 VA sealed,

10 VA inrush at 24 VAC. Field power supply is not required.

7. Make approprate connections to LVT as shown for energy management board options. The con-

tacts for demand limit and ice done options must be rated for dry circuit application capable of han-

dling 24 VAC load up to 50 mA. Installation of optional energy management board required.

8. Remove jumper between terminals 16 and 17 when field chilled water pump interlock (CWPI) is

installed.

9. Terminals 18 and 19 of LVT are for floating point control of condenser water valve (CWV). Teminal

18 commands valve closed. Terminal 19 commands valve open. The maximum load allowed for

condenser water valve is 5.5 VA at 24 VAC. Field power supply is not required.

10. All discrete inputs are 24 VAC.

LEGEND

ALMR — Alarm Relay (24 V) 5 VA Max

AWG — American Wire Gage

CFR — Condenser Fan Relay

CNFS — Condenser Flow Switch

CNP — Condenser Pump

CNPI — Condenser Pump Interlock

CWP — Chilled Water Pump

CWPI — Chilled Water Pump Interlock

CWV — Condenser Water Valve

EMM — Energy Management Module

LV T — Low Voltage Terminal Strip

NEC — National Electrical Code

OAT — Outside Air Temperature

SPT — Space Temperature

a30-5039

Copyright 2010 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53300054-01 Printed in U.S.A. Form 30MP-1SI Pg 16 910 1-10 Replaces: New

Loading...

Loading...