Carrier 25HCD Quick Start Manual

25HBB, 25HBC, 25HCD

Comfortt Series Heat Pumps

with Puronr Refrigerant

1–1/2 To 5 Nominal Tons

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory–authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes and

current editions of the National Electrical Code (NEC) NFPA 70.

In Canada, refer to current editions of the Canadian electrical code

CSA 22.1.

!

Recognize safety information. This is the safety–alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words; DANGER, WARNING, and

CAUTION. These words are used with the safety–alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

!

WARNING

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

!

INSTALLATION RECOMMENDATIONS

NOTE: In some cases noise in the living area has been traced to

gas pulsations from improper installation of equipment.

1. Locate unit away from windows, patios, decks, etc. where

unit operation sound may disturb customer.

2. Ensure that vapor and liquid tube diameters are appropriate

for unit capacity.

3. Run refrigerant tubes as directly as possible by avoiding unnecessary turns and bends.

4. Leave some slack between structure and unit to absorb vibration.

5. When passing refrigerant tubes through the wall, seal opening with RTV or other pliable silicon–based caulk (see Fig.

1).

6. Avoid direct tubing contact with water pipes, duct work,

floor joists, wall studs, floors, and walls.

7. Do not suspend refrigerant tubing from joists and studs with

.

a rigid wire or strap which comes in direct contact with

tubing (see Fig. 1).

8. Ensure that tubing insulation is pliable and completely surrounds vapor tube.

9. When necessary, use hanger straps which are 1 in. wide and

conform to shape of tubing insulation (see Fig. 1).

10. Isolate hanger straps from insulation by using metal sleeves

bent to conform to shape of insulation.

OUTDOOR WALL INDOOR WALL

CAULK

INSULATION

HANGER STRAP

(AROUND SUCTION

TUBE ONLY)

1” (25.4 mm)

MIN

THROUGH THE WALL

SUSPENSION

LIQUID TUBE

SUCTION TUBE

JOIST

INSULATION

SUCTION TUBE

LIQUID TUBE

A07588

Fig. 1 -- Connecting Tubing Installation

When outdoor unit is connected to factory–approved indoor unit,

outdoor unit contains system refrigerant charge for operation with

AHRI rated indoor unit when connected by 15 ft. (4.57 m) of

field–supplied or factory accessory tubing. For proper unit

operation, check refrigerant charge using charging information

located on control box cover and/or in the Check Charge section of

this instruction.

IMPORTANT: Maximum liquid–line size is 3/8–in. OD for all

residential applications including long line.

IMPORTANT: Always install the factory–supplied liquid–line

filter drier. Obtain replacement filter driers from your distributor or

branch.

INSTALLATION

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when handling

parts.

Check Equipment and Job Site

Unpack Unit

Move to final location. Remove carton taking care not to damage

unit.

Inspect Equipment

File claim with shipping company prior to installation if shipment

is damaged or incomplete. Locate unit rating plate on unit corner

panel. It contains information needed to properly install unit.

Check rating plate to be sure unit matches job specifications.

Install on a Solid, Level Mounting Pad

If conditions or local codes require the unit be attached to pad, tie

down bolts should be used and fastened through knockouts

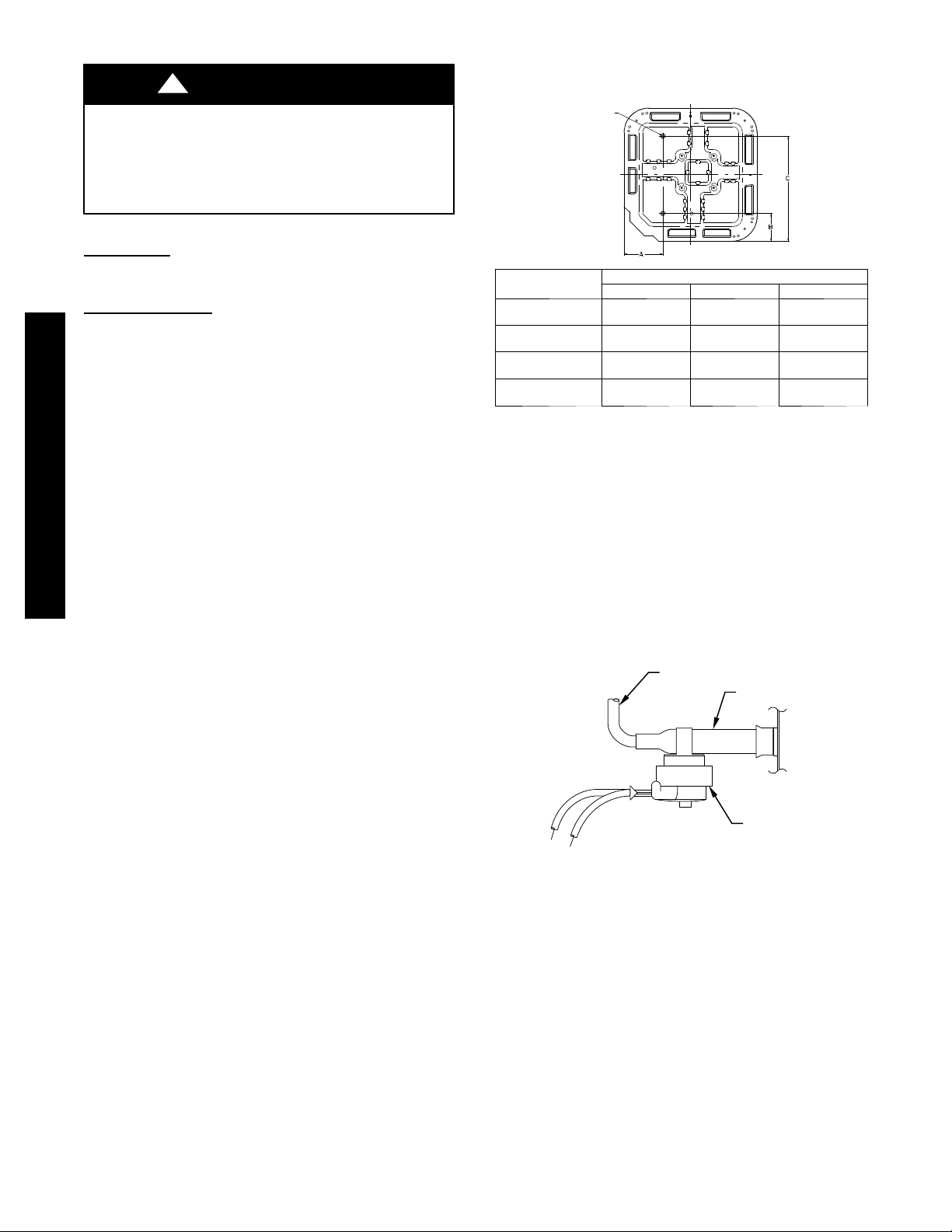

provided in unit base pan. Refer to unit mounting pattern in Fig. 2

to determine base pan size and knockout hole location.

For hurricane tie downs, contact distributor for details and PE

Certification (Professional Engineer), if required.

On rooftop applications, mount on level platform or frame. Place

unit above a load–bearing wall and isolate unit and tubing set from

25HBB / 25HBC / 25HCD

structure. Arrange supporting members to adequately support unit

and minimize transmission of vibration to building. Consult local

codes governing rooftop applications.

Roof mounted units exposed to winds above 5 mph may require

wind baffles. Consult the Service Manual – Residential Split

System Air Conditioners and Heat Pumps for wind baffle

construction.

NOTE: Unit must be level to within ±2° (3/8 in/ft,9.5 mm/m)

per compressor manufacturer specifications.

Clearance Requirements

When installing, allow sufficient space for airflow clearance,

wiring, refrigerant piping, and service. Allow 24 in. (609.6 mm)

clearance to service end of unit and 48 in. (1219.2 mm) (above

unit. For proper airflow, a 6–in. (152.4 mm) clearance on 1 side of

unit and 12–in. (304.8 mm) on all remaining sides must be

maintained. Maintain a distance of 24 in. (609.6 mm) between

units or 18 in. (457.2 mm) if no overhang within 12 ft. (3.66 m).

Position so water, snow, or ice from roof or eaves cannot fall

directly on unit.

NOTE: 18” (457.2 mm) clearance option described above is

approved for outdoor units with wire grille coil guard only.

Units with louver panels require 24” (609.6 mm) between units.

On rooftop applications, locate unit at least 6 in. above roof

surface.

3/8–in. (9.53 mm) Dia.

Tiedown Knockouts in

Basepan(2) Places

View From Top

UNIT BASE PAN

Dimension in. (mm)

23 X 23

(585 X 585)

26 X 26

(660 X 660)

31–1/2 X 31–1/2

(800 X 800)

35 X 35

(889 X 889)

TIEDOWN KNOCKOUT LOCATIONS in. (mm)

A B C

7–3/4 (196.8) 4–13/32 (111.9) 18–1/32 (457.9)

9–1/8 (231.8) 4–7/16 (112.7) 21–1/4 (539.8)

9–1/8 (231.8) 6–9/16 (166.7) 24–11/16 (627.1)

9–1/8 (231.8) 6–9/16 (166.7) 28–7/16 (722.3)

A05177

Fig. 2 -- Tiedown Knockout Locations

Operating Ambient

The minimum outdoor operating ambient in cooling mode without

accessory is 55°F (12.78°C), and the maximum outdoor operating

ambient in cooling mode is 125°F (51.67°C). The maximum

outdoor operating ambient in heating mode is 66 °F (18.89°C).

Check Defrost Thermostat

Check defrost thermostat to ensure it is properly located and

securely attached. There is a liquid header with a distributor and

feeder tube going into outdoor coil. At the end of the one of the

feeder tubes, there is a 3/8 in. O.D. stub tube approximately 2 in.

(50.8 mm) long (see Fig. 3). The defrost thermostat should be

located on stub tube. Note that there is only one stub tube used

with liquid header, and on most units it is the bottom circuit.

FEEDER TUBE

STUB TUBE

DEFROST

THERMOSTAT

A97517

Fig. 3 -- Defrost Thermostat Location

2

Table 1 – Accessory Usage

REQUIRED FOR LOW–AMBIENT

Accessory

Accumulator Standard Standard Standard

Ball Bearing Fan Motor Ye s { No No

Compressor Start Assist Capacitor and

Relay

Crankcase Heater Ye s

Evaporator Freeze Thermostat Ye s No No

Hard Shutoff TXV Ye s Ye s Yes

Isolation Relay Yes No No

Liquid Line Solenoid Valve No See Long–Line Application Guideline No

Motor Master Control or

Low Ambient Switch

Support Feet Recommended No Recommended

* For tubing line sets between 80 and 200 ft. (24.38 and 60.96 m) and/or 20 ft. (6.09 m) vertical differential, refer to Residential Piping and Longline Guideline. .

{ Additional requirement for Low–Ambient Controller (full modulation feature) MotorMasterr Control.

COOLING APPLICATIONS

(Below 55F / 12.8C)

Ye s Ye s No

Ye s No No

REQUIRED FOR

LONG LINE APPLICATIONS*

Ye s

REQUIRED FOR

SEA COAST APPLICATIONS

(Within 2 miles / 3.22 km)

No

Always Ask For

Make Piping Connections

!

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could result in personal injury

or death.

Relieve pressure and recover all refrigerant before system

repair or final unit disposal.

Use all service ports and open all flow–control devices,

including solenoid valves.

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

If ANY refrigerant tubing is buried, provide a 6–in (152.4

mm). vertical rise at service valve. Refrigerant tubing lengths

up to 36–in (914.4 mm). may be buried without further special

consideration. Do not bury lines longer than 36 in (914.4 mm).

Outdoor units may be connected to indoor section using accessory

tubing package or field–supplied refrigerant grade tubing of correct

size and condition. For tubing requirements beyond 80 ft,

substantial capacity and performance losses can occur. Following

the recommendations in the Residential Piping and Long Line

Guideline will reduce these losses. Refer to Table 1 for accessory

requirements. Refer to Table 2 for field tubing diameters.

There are no buried–line applications greater than 36 in. (914.4

mm)

If refrigerant tubes or indoor coil are exposed to atmosphere, they

must be evacuated to 500 microns to eliminate contamination and

moisture in the system.

Outdoor Unit Connected To Factory Approved Indoor

Unit

Outdoor unit contains approximate system refrigerant charge for

operation with approved AHRI rated indoor unit when connected

by 15 ft (4.57 m) of field–supplied or factory–accessory tubing,

and factory supplied filter drier. Some indoor units require

additional subcooling to achieve optimal heating performance.

Using Table 5 or 6– Additional Subcooling Required, check

refrigerant charge for maximum efficiency

WARNING

CAUTION

Refrigerant Tubing and Sweat Connections

Connect vapor tube to fitting on outdoor unit vapor service valves

(see Table 2). Connect liquid tubing to adapter tube on liquid

service valve. Use refrigerant grade tubing.

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Service valves must be wrapped in a heat–sinking material

such as a wet cloth while brazing.

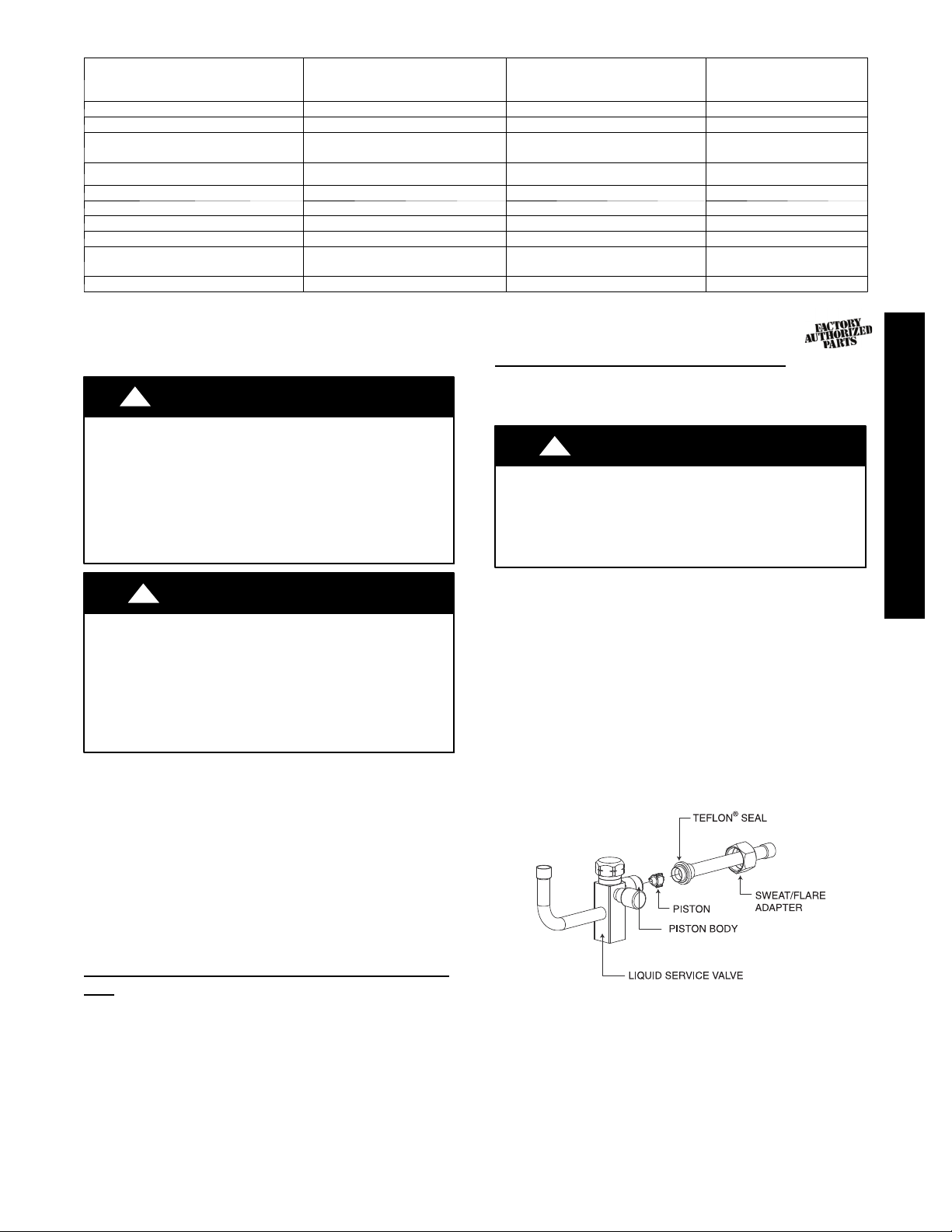

Remove plastic retainer holding outdoor piston in liquid service

valve, leaving the piston and piston retainer inside the valve.

Connect sweat/flare adapter provided, to valve. (See Fig. 4.)

Connect refrigerant tubing to fittings on outdoor unit vapor and

liquid service valves. Service valves are closed from factory and

ready for brazing. After wrapping service valve with a wet cloth,

tubing set can be brazed to service valve using either silver bearing

or non–silver bearing brazing material. Do not use soft solder

(materials which melt below 800°F/427°C). Consult local code

requirements. Refrigerant tubing and indoor coil are now ready for

leak testing. This check should include all field and factory joints.

NOTE: Some outdoor units contain a mechanical fitting at the

liquid distributor. This connection is not field serviceable and

should not be disturbed.

CAUTION

A05226

Fig. 4 -- Liquid Service Valve

25HBB / 25HBC / 25HCD

3

Table 2 – Refrigerant Connections and Recommended Liquid

Y

and Vapor Tube Diameters (In.)

UNIT SIZE

18, 24 3/8 3/8 5/8 5/8

30, 36 3/8 3/8 3/4 3/4

42, 48 3/8 3/8 7/8 7/8

60 3/8 3/8 7/8 1–1/8

* Units are rated with 25 ft. (7.6 m) of lineset. See Product Data sheet for performance

data when using different size and length linesets.

Notes:

1. Do not apply capillary tube indoor coils to these units.

2. For Tubing Set lengths between 80 and 200 ft. (24.38 and 60.96 m) horizontal or

20 ft. (6.09 m) vertical differential 250 ft. (76.2 m) Total Equivalent Length, refer to

the Residential Piping and Longline Guideline – Air Conditioners and Heat Pumps

using Puron refrige rant.

Connection

LIQUID RATED VAPOR

Diameter

Tub e

Diameter

Connection

Diameter

Installing with Indoor Piston

Outdoor Unit Connected to Factory Approved Indoor Unit

Check piston size shipped with indoor unit to see if it matches

required indoor piston size. If it does not match, replace indoor

piston with correct piston size.

NOTE: Correct pistons are shipped with outdoor units in the

accessory bag and are only qualified for piston fan coils. Example

fan coils with piston: FB4C and FY5B (1.5 through 4 ton)

When changing indoor piston, use a back−up wrench. Hand

tighten hex nut, then tighten with wrench 1/2 turn. Do not exceed

30 ft−lbs. The indoor piston contains a Teflon ring (or seal) which

is used to seat against the inside of distributor body, and must be

installed properly to ensure proper seating. See Fig. 5.

13/16” BRASS HEX NUT

25HBB / 25HBC / 25HCD

TEFLON® SEAL

TEFLON®

RINGS

PISTON

PISTON RETAINER

3/4” BRASS HEX BOD

“H” DISTRIBUTOR

Fig. 5 -- Indoor Piston Installation

Install Liquid Line Filter Drier Indoor

Refer to Fig. 6 and install filter drier as follows:

1. Braze 5 in. (127 mm) liquid tube to the indoor coil.

2. Wrap filter drier with damp cloth.

3. Braze filter drier to 5 in. (127 mm) long liquid tube from

step 1.

4. Connect and braze liquid refrigerant tube to the filter drier.

Tub e

Diameter

A10342

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Installation of filter drier in liquid line is required.

Evacuate Refrigerant Tubing and Indoor Coil

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used (see triple evacuation

procedure in service manual). Always break a vacuum with dry

nitrogen.

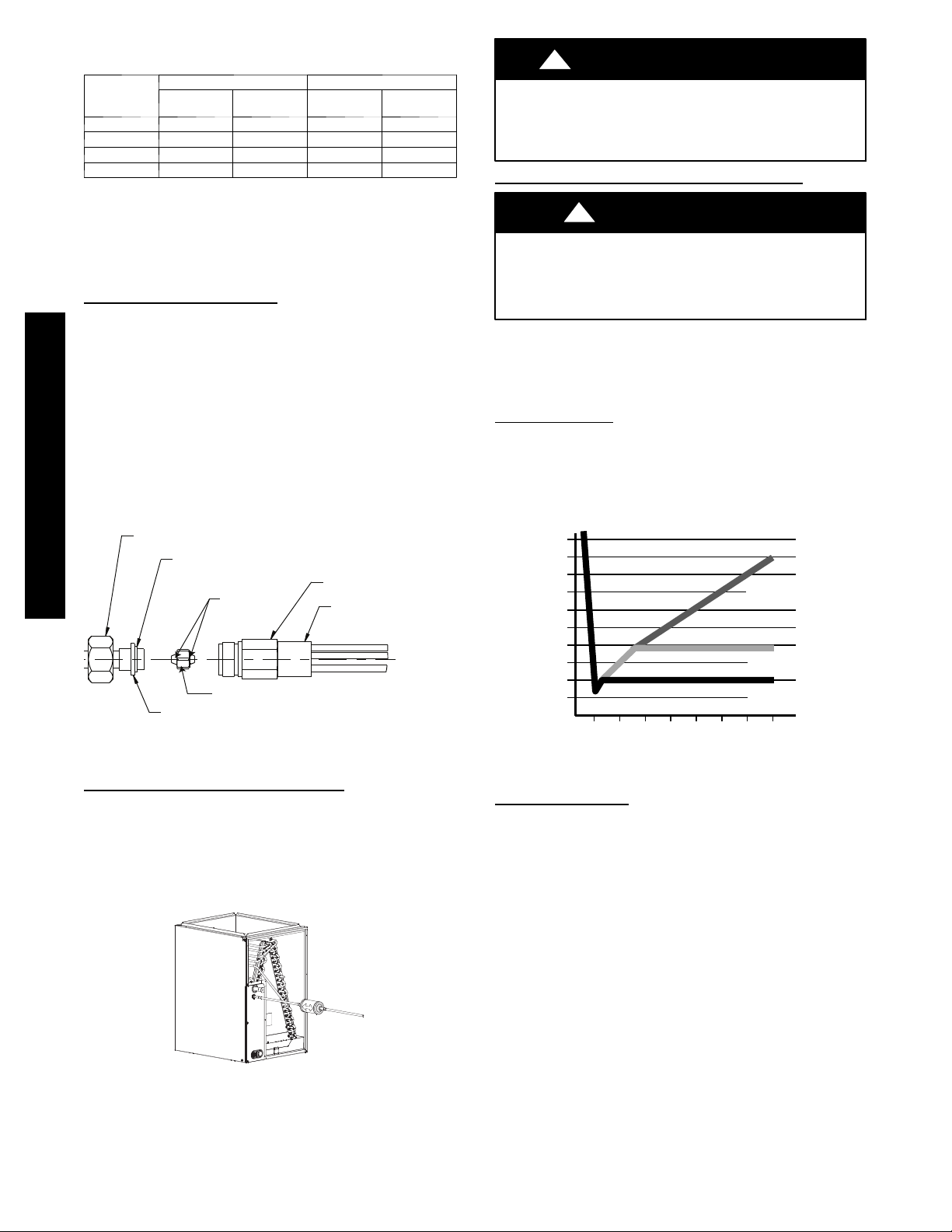

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum method

is the most positive way of assuring a system is free of air and

liquid water. A tight dry system will hold a vacuum of 1000

microns after approximately 7 minutes. (See Fig. 7.)

5000

4500

4000

3500

3000

2500

2000

MICRONS

1500

1000

500

01234567

MINUTES

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

A95424

A95424

Fig. 7 -- Deep Vacuum Graph

Final Tubing Check

IMPORTANT: Check to be certain factory tubing on both indoor

and outdoor unit has not shifted during shipment. Ensure tubes are

not rubbing against each other or any sheet metal. Pay close

attention to feeder tubes, makings sure wire ties on feeder tubes are

secure and tight.

Be sure field wiring complies with local and national fire, safety,

and electrical codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit

protection device.

NOTE: Operation of unit on improper line voltage constitutes

abuse and could affect unit reliability. See unit rating plate. Do not

install unit in system where voltage may fluctuate above or below

permissible limits.

Fig. 6 -- Liquid Line Filter Drier

A05227

4

Loading...

Loading...