Page 1

Carrier

Start-Up instructions

OSso/c/e. ‘»nd oo /or7^er

S//ó/^/ z^k^/ {do record r) {

19DA

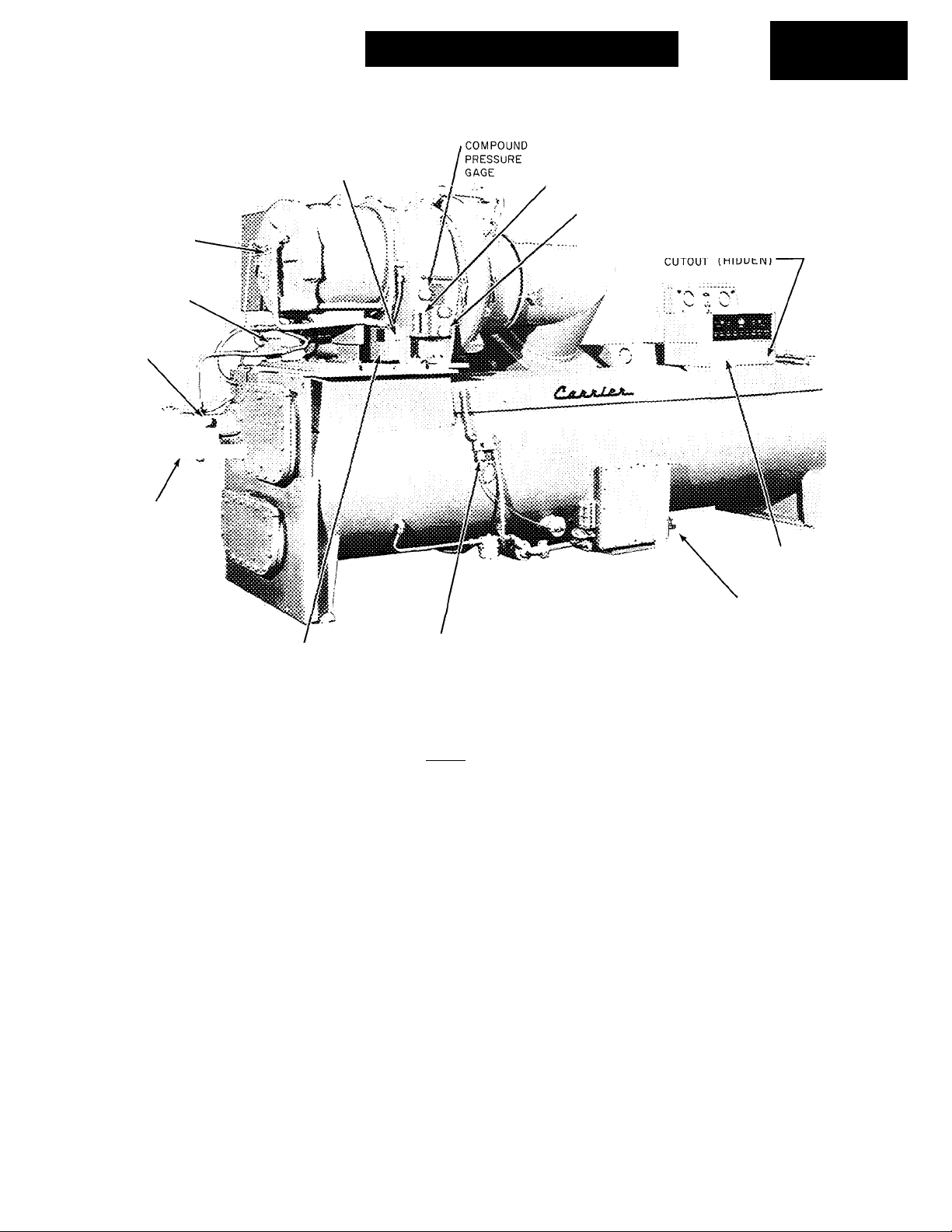

OIL HEATER INDICATOR LIGHT

MOTOR

ROTATION

SIGHT GLASS

LOW OIL PRESSURE

SWITCH

OIL PRESSURE

GAGE

eX

OIL PUMP JL,

ASSEMBLY^

OIL CHARGING

VALVE

---------------------

f—?iii;

a

OIL THERMOSTAT

(HIDDEN)

dr^'^S fcr /~o ôhiio/ô/e {ak)/o^ ZiÂ* )

OIL LEVEL SIGHT GLASS

OIL TEMPERATURE GAGE

REFRIGERANT

LOW TEMP CUTOUT

Fig. 1 - 19DA Hermetic Refrigeration Machine

CONDENSER HIGH-PRESSURE

ANTIRECYCLE

TIMER (HIDDEN)

COOLER

CHARGING

VALVE

INTRODUCTION

General - Use this booklet as a guide for initial

start-up of the 19DA Hermetic Centrifugal Re

frigeration Machine. Read and fully understand

these instructions plus all necessary Job Data

before beginning initial start-up. Instructions are

given in the proper sequence for optimum ma

chine performance.

Job Data Required

1. Machine assembly prints

2. Wiring diagrams

3. Starter details

4. 19DA Installation Instructions

5. 19DA Operation and Maintenance Instructions

Equipment and Materials Required

1. Mechanics' tools

2. Volt-ohmmeter

3. Carrier refrigerant drum charging valve

4. 5/8" SAE X 3/4" MPT cooler charging adapter

5. Five to ten ft of copper tubing or plastic hose

6. Halide or electronic leak detector

7. Low-pressure indicator

a. Absolute pressure manometer

b. Wet-bulb indicator

8. Clamp-on ammeter

9. Portable dehydration pump

INITIAL PREPARATIONS

CAUTION: Do not operate refri^rant pump

unless machine is charged with refrigerant.

Do nor start compressor or oil pump, even for

a rotation check, while machine is at vacuum.

Check rotation only after compressor has been

charged with oil and machine has been charged

with refrigerant.

Machine Tightness - A shipping vacuum was ap

plied to the refrigerant side of the 19DA machine

before shipment from the factory. Over a period

of time, during shipment or storage, part of this

vacuum may be lost. The loss of a small amount

of vacuum may be acceptable and within Carrier's

machine tightness standards. To determine if the

vacuum loss is acceptable or not requires the

following steps:

© Carrier Corporation 1966

Form 19DA-1SS

Page 2

PURGE PUMP

SWITCH

CHILLED WATER

LOW TEMP CUTOUT

PURGE VALVE OPERATION PLATE

PURGE OPERATING VALVES (6)

Fig. 2 - 19DA Rear View

Record and date vacuum reading shown on

1.

compound pressure gage located on compres

sor (Fig. 1).

With this reading and the reading taken when

2.

the machine was received, determine vacuum

leak rate using the following formula:

Leak Rate = Vacuum loss

H- No. of days between readings

3. If vacuum leak rate is 0.05 in. Hg or less per

24 hours, the machine is sufficiently tight.

If vacuum leak rate exceeds this rate, per

form "Refrigerant Pressure Test” and cor

rect leakage.

EXCESSIVE OR TOTAL VACUUM LOSS - Ex

cessive or total vacuum loss can be caused by

accidental opening of a valve or other connec

tion. If this is suspected, proceed as follows:

1. Install a mercury manometer (absolute pres

sure type) to the cooler charging valve (Fig. 1).

A dial type gage can not indicate the small

amount of leakage acceptable during a short

period of time.

2. Pull a vacuum on the machine equal to 25 in.

Hg. Use external vacuum pump or energize

purge pump (Fig. 2) using operation No. 2

described on the purge valve operation plate

shown on Fig. 2.

3. Let the machine stand with this vacuum, and

then perform the leak rate check previously

outlined.

4. If the vacuum leak rate is 0.05 in. Hg or less

per 24 hours, the machine is sufficiently tight.

Perform all steps under "Machine Dehydra

tion" (pg 3).

5. If the vacuum leak rate exceeds 0.05 in. Hg

per 24 hours, perform all steps under "Re

frigerant Pressure Test" (pg 2) and correct

leakage. Perform all steps under "Machine

Dehydration."

6. Remove the mercury manometer from cooler

charging valve.

REFRIGERANT PRESSURE TEST

1. Pull approximately five inches of vacuum on

the machine by energizing machine purge pump

(Fig. 2). Use operation No. 2 described on the

purge valve operation plate or with an external

vacuum pump connected to the cooler charging

valve (Fig. 1).

2. Charge approximately one gallon of Refrig

erant 11 thru the cooler charging valve. Refer

to refrigerant charging instructions (pg 4).

3. Increase pressure to eight to ten psi with dry

air or nitrogen thru the cooler charging valve.

DO NOT EXCEED TEN PSI.

4. Test all joints, valves, fittings, flanges, etc.

with a halide or electronic leak detector.

CAUTION: Due to rupture disc limitations :

DO NOT EXCEED TEN PSI.

Page 3

5. Repair any leaks found.

6. Reinspect joints and flanges with the leak de

tector to ensure that all leaks have been found

and repaired.

Machine Dehydration - The refrigerant side of

the 19DA machine is dehydrated at the factory.

It is usually not necessary to repeat dehydration

at initial start-up. However, if the machine has

been open for a considerable length of time due

to compressor removal, or if there was excessive

loss of shipping vacuum, it is recommended that

dehydration be repeated.

WARMING: Do not start compressor or oil

pump even for a rotation check while machine ;

is under dehydration vacuum.

NOTE: Dehj'dration is rea'dily accomplished at

normal room temperature. If room temper

ature is high, dehydration takes pbace more

quickly. At low room temperature, dehydra

tion is extremely difficult and special tech

niques must be applied. Contact your Carrier

representative.

Perform dehydration as follows:

CHECK WATER FLOW RATE - Water flows thru

cooler and condenser must meet job require

ments. Measure water pressure drop across

cooler and condenser or across the pumps. Check

to see that water flow rates agree with the de

sign flow.

Follow the instructions on the caution tag

attached to the oil cooler which reads:

CAUTION: Clean water at 85 F maximum

temperature to be provided. Valves and/or

controls to limit the following:

Max inlet working press. 100 psi

Water vel in tube, ft/sec 10 max - 6 min ;

Water flow, gaL/min 7 max - 4 min :

Water press, drop, psi diff 5 max - 2 min ;

The necessary valves and/or controls are

field supplied.

Field Wiring - Prior to starting equipment, refer

to wiring diagrams provided in Job Data and

check power supply as follows:

1. Connect a voltmeter across power wires to

compressor motor starter and measure volt

age. Compare this reading with voltage rating

on compressor and starter nameplates.

1. Connect dehydration pump to the cooler charg

ing valve (Fig. 1).

2. Ensure that all valves on the purge assembly

are closed (Fig. 2). Purge valve Identification

numbers are found on the purge valve opera

tion plate at the valves.

3. Remove the A-B swing connection (shown under

Valve Locations on the purge valve operation

plate) and connect a mercury manometer (ab

solute pressure type) to the bottom common

connection.

4. Operate dehydration pump until manometer

reads 0.20 in. Hg (29.80 inches of vacuum

at 30 inches barometer); continue to operate

pump for two more hours.

5. Close cooler charging valve; stop dehydration

pump; record manometer reading.

6. After a two hour waiting period, take another

manometer reading. If reading has not in

creased, dehydration is complete. If reading

has increased, repeat steps 4 and 5.

7. If the reading continues to rise after several

dehydration attempts, suspect a machine leak.

If this is the case, repeat the refrigerant

pressure test.

2. Connect voltmeter across power wires to oil

pump starter and measure voltage. Compare

this reading with voltage rating on oil pump

nameplate.

3. Compare ampere rating on starter nameplate

with ampere rating on motor nameplate for

agreement.

4. Test motor and motor supply cable insulation

resistance using a five-hundred volt insulation

tester such as a megohmeter. Proceed as

follows:

a. Open starter main disconnect switch.

b. Test the three phases of compressor motor,

phase to phase, and phase to ground, with

tester connected on the motor side of the

starter contactor in the starter. Take re

sistance readings at ten-second and sixtysecond intervals for each phase.

c. Divide sixty-second resistance reading by

ten-second reading. This gives polarization

ratio. The polarization ratio must be 1.15

or higher. The ten-second and sixty-second

resistance readings must be 5.0 megohms

or higher.

Inspect Piping - Refer to piping diagrams pro

vided in Job Data and inspect chilled water piping,

condenser water piping, and water piping to oil

cooler. Ensure that flow direction is correct in

all cases and that all specified piping require

ments are met.

NOTE: The above procedure will check condi

tion of compres-sor motor and motor supply

cable insulation. If above requix'ements are

not met, repeat the test at motor terminals

with motor supply cables disconnected.

Page 4

Check Starter - Before starting the 19DA, check

starter as follows:

1. Remove the contactor arc chutes. Be sure con

tactors move freely, and that shipping string

has been removed. Replace arc chutes.

2. If starter has been left on jobsite for a consid

erable period of time, check contactors for

dirt and rust. Clean contact magnet surfaces

with emery cloth. Apply a very thin coating

of vaseline to magnet surfaces, then wipe it

off. If starter has been in a dusty atmosphere,

vacuum clean starter cabinet and wipe with a

lint-free cloth.

3. Remove fluid cups from magnetic overload

relays. Add dashpot oil to cups per instructions

on relay nameplate. Dashpot oil is shipped in

small vials usually attached to starter frame

near relays. Use only the dashpot oil shipped

with starter. Do not substitute. Overload re

lays are factory set for 111 percent of motor

full load amperage and resetting is not nor

mally required.

4. Check transfer timer for proper time setting.

On Star-Delta starters, timers have adjust

able ranges of ten seconds to three minutes

and are factory set for one minute. On Auto-

Transformer starters, timers have adjustable

ranges of ten to forty seconds and are factory

set for thirty seconds.

5. With main disconnect switch open, manually

open and close main control relay (ICR) to be

sure it operates freely.

Charge Oil - Use oil shipped with the machine.

Any substitute must meet Carrier's oil specifica

tion outlined in 19DA Operation and Maintenance

Instructions.

Charge oil thru the oil reservoir charging

valve (Fig. 1). With machine at vacuum, oil is

drawn from the oil container. Continue charging

until oil reaches middle of sight glass (Fig. 1).

3/4 GLOBE

VALVE

5/8"SAE FLARE x

3/4"MPT ADAPTER

Fig. 3 - Drum Charging Valve and Fitting

3. Start chilled water pump and circulate chilled

water during charging process.

4. If machine pressure is eighteen inches of mer

cury (32 F) vacuum or lower, keep refrigerant

drum upright, open valves and admit refrig

erant gas to cooler. The machine under vacuum

will boil off liquid refrigerant, and raise ma

chine pressure, preventing possible freeze-up.

5. Charge the machine with the proper quantity

of refrigerant for the machine size given on

a tag attached to the cooler charging valve

(Fig. 1) or in Table 1.

NOTE: The refrigerant supplied v/ith this ?

machine is in excess of that required for ^

initial charging. Use the correct amount as

shown in T^>ie 1.

The machine under vacuum will draw refrig

erant from the drum.

6. After machine has been started, it may be

necessary to adjust refrigerant charge for

optimum machine performance.

/5

I

CAUTION: After charging oil, energize the

oil heater to minimize absorption of refrig

erant by the oil. The oil heater indicator light

(Fig. 1) comes on when heater is energized.

Set oil heater thermostat (Fig. 1) to maintain s

a minimum oil reservoir temperature of 145 F i

at shutdown.

Charging Refrigerant - To charge the 19DA ma

chine, proceed as follows:

1. Install a charging valve on the 3/4-inch drum

opening as shown in Fig. 3. When the 3/4-inch

pipe nipple is screwed into the drum opening,

the nipple forces the bottle cap off its seat.

2. Connect a short piece of clear plastic hose or

copper tubing from drum valve to cooler charg

ing valve located beneath float chamber.

NOTE: Refer to "Trimming Refrigerant

Charge” (pg II) for full load adjustment.

Table 1 - Charging Quantity

MACHINE

CHARGING

MACHINE

SIZE WT (lbs) SIZE

19DA-102

19DA-112 400

19DA-131

19DA-147 450

400

425

19DA-228

19DA-255

19DA-284

19DA-325

19DA-160 525 19DA-362

19DA-182 550 19DA-397

19DA-198 575

CHARGING

WT (lbs)

575

850

880

900

935

960

Page 5

Check Operation of Safety Controls - Disconnect

main motor leads at starter to prevent compressor

motor operation while performing safety control

check. Push the START button. Manually open

.f

the following safety controls to be sure they de

energize the ICR coil, causing the main starter

contacts to open and stop the compressor. Anti

recycle timer, item 6, Table 2, can be set for

minimum time per this safety check.

1. Chilled water low-temperature cutout and re

cycle switch (item 1, Table 2).

2. Chilled water flow switch (in chilled waterline).

3. Refrigerant low-temperature cutout switch

(item 2, Table 2).

4. Low oil pressure cutout switch (item 5, Table 2).

5. Condenser high-pressure cutout switch (item 4,

Table 2).

6. Bearing and motor winding high-temperature

cutout switch (in motor terminal box - remove

one wire to OPEN switches).

7. Oil pump starter auxiliary contact (in oil pump

starter).

8. Chilled water and condenser water pump safety

interlocks (in pump starters).

9. Any other interlock shown on job blueprint.

Purge - Open all purge operating valves (Fig. 2).

Place valves in NORMAL AUTOMATIC position.

Operate purge pump momentarily by placing purge

switch in MANUAL position. Then place purge

switch in AUTO position.

compressor motor come up to speed, then press

machine STOP button. Check motor rotation thru

sight glass in the motor end bell (Fig. 1). Motor

rotation must be clockwise to result in coun

terclockwise rotation of the compressor (when

viewed from motor end).

COMPRESSOR OPERATION

1. Press machine START button and let com

pressor come up to speed. Press machine

STOP button and listen for any unusual sounds

coming from the compressor and transmission

housing as compressor coasts to a stop.

NOTE: The antirecycietimerprevents rapid

recycling of the compressor and is factory

set to allow one start every twenty minutes, ;

2. Press machine START button and let compres

sor continue running. Check oil pressure and

oil temperature (Fig. 1).

3. Ensure that condenser water and chilled water

are circulating, and that chilled water tem

perature does not drop below the design tem

perature shown in Job Data.

4. Ensure that the refrigerant agitator solenoid

valve(s) are operating. The agitator valve(s)

are open when the inlet guide vanes are closed.

When the vanes open, and the vane motor crank

angle reaches approximately 42° from the ver

tical centerline, the valve closes. The two

valves on the 19DA31 size compressor operate

in step sequence at approximately 42° and 28°

vane motor crank angle.

While the inlet guide vanes are being opened

START-UP

Preliminary Checks

WATER SUPPLY - Before checking compressor

rotation, ensure that water supplies to the cooler,

condenser, and oil cooler are available, and that

the water pumps are running.

COMPRESSOR ROTATION - Set capacity control

to MANUAL (Honeywell), or HOLD (BarberColman). Press machine START button and let

manually (see "Motor Overload Module"),

listen for the sound of the refrigerant agitator

solenoid valve(s) closing.

Setting Safety Controls - Before setting safety

controls, set the capacity control to MANUAL

(Honeywell) position or HOLD (Barber-Colman).

Place a clamp-on ammeter on one of the three

starter leads and slowly open prewhirl vanes.

(Do not exceed 100 percent full load amperage.)

Perform the safety checks in the following table;

Table 2 - Setting Safety Controls

SAFETY OR CONTROL DEVICE RECOMMENDED SETTING

1. Chilled Water Low-Temperature

Cutout and Recycle Switch (Fig. 2)

-TEMPERATURE ADJUSTMENT

1. Set this switch to break at approximately 5 F below de

sign chilled water temperature, or at 36 F, whichever

is higher.

2. Set the differential at 10 F plus or minus 1 F so that

when the machine shuts down automatically at approx

imately 5 F below the design chilled water temperature

it will restart at approximately 5 F above the design

water temperature.

3. This control must break ahead of the refrigerant lowtemperature cutout switch or the machine will not re

cycle automatically.

Page 6

Table 2 - Setting Safety Controls (Contd)

SAFETY OR CONTROL DEVICE RECOMMENDED SETTING

2. Refrigerant Low-Temperature

Cutout (Fig. 1)

1. Install jumper wire or mechanical block in the chilled

water low-temperature cutout and recycle control.

2. Set the refrigerant low-temperature cutout at 33 F while

reading the temperature gage on side of float chamber.

3. Remove jumper wire or block.

3. Oil Heater Thermostat (Fig. 1)

4. Condenser High-Pressure

Cutout (Fig. 1)

CUTOUT ADJUSTMENT .-••c '

COVER-

„

......

........... , BUTTON

CUTOUT SCALE

RESET

5. Low Oil Pressure Cutout (Fig. 1)

RANGE (CUT-IN) .

DIAL ADJUSTMENT

REMOVE METAL

COVER

------

CUTOUT

ADJUSTMENT

Set the oil heater thermostat to maintain a minimum oil

reservoir temperature of 145 F at shutdown.

The condenser high-pressure cutout switch is factory set

to shut the machine down when the condenser pressure

reaches approximately fifteen psig. Isolate the switch, and

check switch setting with a metered supply of air.

Opens switch contacts on drop in oil pressure. Cutout at

9 psi differential. Cut-in at 14 psi differential. While op

erating pump manually, note and record reservoir pres

sure on gage. Remove cap and gasket from oil pressure

regulating valve. Loosen locknut. Turn adjusting screw

counterclockwise to lower oil pressure to within 4 psi of

reservoir pressure. Reset differential to adjust cutout. Set

range (cut-in) by turning adjusting dial clockwise, raising

oil pressure.

6. Antirecycle Timer (Fig. 1)

/TIME SETTING

'LOCKNUT

' N

TIMER

SWITCHES

Time setting is factory set for 20 minutes. Limits the num

ber of machine starts to three per hour.

Page 7

Calibrating Electronic Controls - Honeywell (Fig. 4) or Barber-Colman (Fig. 5)

Table 3 - Motor Overload Module

m

SEQUENCE

1. Check Voltage Signal

from current trans

former - (leads

disconnected)

2. Recheck voltage

signal (leads

connected)

B-C

H

X

X

X

X

X

X

X

A. Shut down compressor:

X

X

X

1. Rotate CRl (6) and CR2 (7) calibration screws fully clockwise.

2. Disconnect leads to terminals 23 and 24 on terminal strip.

3. Place clamp on ammeter on one of three incoming starter wires.

X B. Start compressor:

X

1. Press START button.

2. Open vanes manually by depressing INCREASE button (5).

X

3. Place the capacity control switch (15) on HIGHER position to

NOTE; At- iOO percent Ml load current^ voltmeter must

read at least 0.55 volts. If not in this range, check sizing

of resistor in starter.

X

X

X

X

X

X

A. Shut down compressor:

X

X

X

X

1. Remove voltmeter from leads.

2. Replace leads to terminals 23 and 24.

3. Attach voltmeter to terminals 23 and 24.

B. Start the compressor:

1. Open vanes manually. Voltmeter must read between 0.45-0.55

X

X

X

X

2. Press STOP button and remove voltmeter.

PROCEDURE

Attach voltmeter to these leads.

open vanes manually.

volts at 100 percent full load current.

3. Calibrate motor

current settings

(compressor

operating)

H = Honeywell

B-C = Barber-Colman

A. Barber-Colman:

X

X

1. Open vanes manually until motor current reaches 108 percent

of nameplate current.

2. Adjust CRl calibration screw (6) until vanes begin to close.

Observe movement of vane motor linkage.

3. Set capacity control switch (15) on HIGH. When motor reaches

X

103 percent of full load amperage, adjust CR2 calibration

screw (7) until vanes stop moving.

B. Honeywell:

1. When motor current reaches 103 percent of rated amperage,

X

adjust calibration screw (18) until relay CR2 (23) is open and

relay CRl (22) is closed.

2. Hold relay CR2 (23) closed, and open vanes with INCREASE

X

button (5). When motor current reaches 108 percent of rated

amperage, relay CRl (22) should open.

C. Honeywell and Barber-Colman:

X

X

1. Close vanes and open again to recheck 103 percent and 108

percent settings.

Page 8

Calibrating Electronic Controls - Honeywell Only (Fig. 4)

Table 4 - Chilled Water Module

SEQUENCE

1. Set Differential

Adjustment

2. Calibrate Chilled

Water Temperature

Setting

3. Adjust Capacity

Balance

4. Observe Automatic

Operation

PROCEDURE (Compressor Operating)

A. Place capacity control switch (8) in MANUAL position.

B. Set throttling range screw (19) on counterclockwise stop.

C. Operate machine manually until leaving chilled water temperature is

within the range of the chilled water thermostat (35 F to 55 F).

D. Adjust differential screw (15) for a 3/4 F movement of the chilled water

thermostat (4) between the operation of relay CRO (25) and CRC (24).

A. Open vanes manually until chilled water temperature reaches design

temperature. Place chilled water thermostat in center of dial. (Lowest

division on left corresponds to 35 F. Each division represents IF.)

B. Adjust calibration screw (17) until relay CRC (24) is closed and relay

CRO (25) is open.

A. Connect an a-c voltmeter across test jack (21) and terminal J28. Use

50- or 60-volt scale.

B. Turn chilled water thermostat (4) clockwise or counterclockwise to

obtain lowest voltage reading on voltmeter.

C. Turn capacity balance screw (16) clockwise or counterclockwise until

voltage decreases further.

D. Repeat above steps to decrease voltage to approximately one volt.

A. Place capacity control (8) on THERMO position and thermostat (4) at

design chilled water temperature.

B. Turn throttle range screw (19) clockwise 1/3 of its total travel if chilled

water temperature "hunts.”

C. Recalibrate as in sequences 1 thru 4.

Calibrating Electronic Controls - Barber-Colman Only (Fig. 5)

Table 5 - Chilled Water Module

SEQUENCE

1. Adjust Capacity

Balance

A. Rotate throttling range screw (17) to counterclockwise position.

B. Operate vanes manually until chilled water temperature drops to design

PROCEDURE (Compressor Operating)

temperature.

C. Place capacity control switch (15) on HOLD.

D. Set chilled water thermostat (3) to dial center. (Lowest division on left

corresponds to 35 P. Each division represents IE.)

E. Connect COMMON plug of an a-c voltmeter to terminal X on amplifier

and other plug to terminal T. Use 12-volt scale.

F. Adjust temperature bridge calibration screw (18) until voltage becomes

minimum.

G. Adjust capacity balance screw (16) until voltage decreases further. Re

peat steps above to decrease voltage to one volt or lower.

H. Remove voltmeter.

2. Differential Setting

NOTE: A differential resistor is factor^'installed between terminals X

and Y (10) OR the cMlled water amplifier to give approximately 1 F dif- ;

ferential between the operation of microrelays CRC and CRO (19).

3. Observe Automatic

Operation

A. Place capacity control switch (15) on AUTO position.

B. Rotate throttling range screw (17) clockwise 1/3 of total travel if chilled

water temperature "hunts."

NOTE: If timottling range is added, recalibrate as in sequences 1 thru 3.

Page 9

1 ELECTRONIC CONTROL ON-OFF SWITCH

a MACHINE START BUTTON

3 VANE DECREASE BUTTON

4 CHILLED WATER THERMOSTAT

5 VANE INCREASE BUTTON

6 MACHINE STOP BUTTON

7 OIL PUMP AUTO-MANUAL SWITCH

8 CAPACITY CONTROL THERMOSTATIC-MANUAL

SWITCH

9 3-AMP FUSE - SAFETY CONTROL CIRCUIT

10 3-AMP FUSE - REFRIGERANT PUMP

11 OIL PUMP TIME DELAY RELAY

12 RELAY R-4

13 RELAY R-2

14 RELAY R-1

15 DIFFERENTIAL ADJUSTING SCREW

16 CAPACITY BALANCE ADJUSTING SCREW

17 CALIBRATION ADJUSTING SCREW - CHILLED WATER

18 CALIBRATION ADJUSTING SCREW - MOTOR LOAD

19 THROTTLING RANGE ADJUSTING SCREW

20 ELECTRICAL DEMAND CONTROL KNOB

21 TEST JACK

22 RELAY CRl

23 RELAY CR2

24 RELAY CRC

25 RELAY CRO

Fig. 4 - Honeywell Controls

Page 10

1 ELECTRONIC CONTROL ON-OFF SWITCH 11

2 MACHINE START BUTTON 12

3 CHILLED WATER THERMOSTAT 13

4 MACHINE STOP BUTTON 14

5 OIL PUMP AUTO-MANUAL SWITCH 15

6 CR1 CALIBRATION ADJUSTING SCREW - MOTOR LOAD 16

7 CR2 CALIBRATION ADJUSTING SCREW - MOTOR LOAD 17

8 MOTOR LOAD MICRORELAY 18

9 ELECTRICAL DEMAND CONTROL KNOB

10 MODULE TERMINALS (HIDDEN) 19

Fig. 5 - BarbeT-Colman Controls

10

RELAYS R1 (TOP), R2 (BOTTOM), (HIDDEN)

OIL PUMP TIME DELAY RELAY

3-AMP FUSE - REFRIGERANT PUMP

3-AMP FUSE - SAFETY CONTROL CIRCUIT

CAPACITY CONTROL AUTO-MANUAL SWITCH

CAPACITY BALANCE ADJUSTING SCREW - SENS

THROTTLING RANGE ADJUSTING SCREW

CALIBRATION ADJUSTING SCREW - TEMPERATURE

BRIDGE

CHILLED WATER MICRORELAY

t

Page 11

Calibrating Pneumatic Transducer - Pneumatic

control is accomplished by a transformer which

converts a 3-15 psi pneumatic signal regulated

by a thermostat sensing chilled water temper

ature into an electrical signal. The electrical

signal is transmitted to either a Barber-Colman

or Honeywell Electronic Chilled Water Module

to provide chilled water temperature control. The

same transducer is used for both Barber-Colman

(Fig. 5) and Honeywell (Fig. 4).

MOTOR OVERLOAD MODULE - Calibrate as

outlined under the motor overload sections under

Barber-Colman or Honeywell.

CHILLED WATER MODULE - Calibrate the

Chilled Water Module as outlined in Table 6 for

Barber-Colman or Honeywell.

Table 6 - Chilled Water Module

SEQUENCE PROCEDURE

RESISTANCE COIL WIPER

ARM

1. Supply fixed air

signal to trans

ducer (Fig. 6)

2. Preset chilled

water thermostat

set point

3. Add throttling

range

4. Place machine in

manual control

and start the

compressor

5. To complete the

electro-pneumatic

chilled water con

trol calibration

Use either air signal from

control thermostat or sep

arate air supply (such as

a medical aspirator) to

introduce 9 psi signal to

transducer diaphragm and

hold.

Coil wiper arm (Fig. 6),

should be in center of re

sistance coil.

Turn thermostat dial (4)

Honeywell (Fig. 4), or (3)

Barber-Colman (Fig. 5) to

center of scale (vertical).

Turn the throttling range

screw (19) Honeywell, or

(17) Barber-Colman 1/3

of total clockwise travel.

Turn switch (8) Honeywell

to MANUAL position.

Place the capacity con

trol switch (15) Barber-

Colman on HOLD.

Refer to Table 5- Barber-

Colman, perform steps 1

(E thru H), and 3 (A and

B) or refer to Table 4 Honeywell, perform steps

1 (D), 2 (B), 3 (A thru D),

and 4 (A and B).

CONTROL AIR

SUPPLY

Fig. 6 - 19DA Transducer Assembly

(For either Honeywell or

Barber-Colman)

Trimming Refrigerant Charge - After the ma

chine has been placed in operation, it may be

necessary to adjust the refrigerant charge to

obtain optimum machine performance.

When a machine full load is available, add the

remaining refrigerant slowly until the difference

between the leaving chilled water temperature and

the cooler temperature reaches design conditions

or becomes a minimum. Shut the machine down

and allow refrigerant to drain to the cooler, mark

the level indicator and maintain that shutdown

refrigerant level.

11

Page 12

INSTRUCTING THE CUSTOMER OPERATOR

Use the following as a guide in giving operat

ing instructions to the customer operator:

1. Be sure that the customer operator has a

copy of the 19DA Operation and Maintenance

Instructions and has read them carefully.

2. Point out the following components and ex

plain function of each.

a. Control Panel

b. Automatic Thermal Purge System

c. Compressor-Motor-Transmission

Assembly

(1) Prewhirl Guide Vanes, Vane Motor

and Linkage

(2) Refrigerant-Cooled Motor

(3) Transmission

d. Unishell Cooler-Condenser

(1) Float Chamber

(2) Rupture Disc

(3) Refrigerant Charging Line

(4) Refrigerant Agitator Lines

(5) Purge Collection Chamber

e. Oil Cooler-Filter-Pump Assembly

f. Auxiliary Gages and Thermometers

3. Describe the Refrigeration Cycle.

4. Describe the Compressor Lubricating Oil

System.

a. Oil heater and thermostat function and

setting of oil temperature

b. Oil level requirements

5. Point out safety and operating controls and

explain function of each.

a. Standard Controls

b. Special Controls (if installed)

6. Explain Oil Cooler Water System.

a. Solenoid Valve

b. Water Plug Cock

7. Describe Purge Cycle.

a. Valve Designation

b. Controls and Settings

c. Importance of proper purge operation

8. Review general maintenance items.

a. Daily, Monthly, Yearly

b. Extended Shutdowns

c. Point out importance of maintaining Log

Sheet

d. Importance of water treatment

9. Check operator's knowledge of machine.

a. Start and Stop Procedure

b. Safety and Operating Controls •

10. Advise the customer operator regarding

spare parts ordering and Carrier service

available.

11. Review the Operation and Maintenance In

structions.

Manufacturer reserves the right to change any product specifications without notice

Tab 15 Form 19DA-1SS Supersedes 19D2-4005 Printed in U.S.A.

9-66 Code MA Catalog No. 591-912

Loading...

Loading...