Page 1

17EX

Externally Geared Centrifugal Liquid Chillers

50/60 Hz

1500 to 2250 Nominal Tons (5280 to 7910 kW)

Start-Up,Operation,andMaintenanceInstructions

SAFETY CONSIDERATIONS

Centrifugal liquid chillers are designed to provide safe

and reliable service when operated within design specifications. When operating this equipment, use good judgment and safety precautions to avoid damage to equipment and property or injury to personnel.

Be sure you understand and follow the procedures and

safety precautions contained in the chiller instructions

as well as those listed in this guide.

DO NOT VENT refrigerant relief valves within a building. Outlet

from rupture disc or relief valve must be vented outdoors in accordance with the latest edition of ASHRAE (American Society of

Heating, Refrigeration, and Air Conditioning Engineers) 15. The

accumulation of refrigerant in an enclosed space can displace oxygen and cause asphyxiation.

PROVIDE adequate ventilation in accordance with ASHRAE 15,

especially for enclosed and low overhead spaces. Inhalation of high

concentrations of vapor is harmful and may cause heart irregularities, unconsciousness, or death. Misuse can be fatal.Vaporisheavier

than air and reduces the amount of oxygen available for breathing.

Product causes eye and skin irritation. Decomposition products are

hazardous.

DO NOT USE OXYGEN to purge lines or to pressurize a chiller

for any purpose. Oxygen gas reacts violently with oil, grease, and

other common substances.

NEVER EXCEED specified test pressures, VERIFY the allowable

test pressure by checking the instruction literature and the design

pressures on the equipment nameplate.

DO NOT USE air for leak testing. Use only refrigerant or dry

nitrogen.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly installed and

functioning before operating any machine.

DO NOT WELD OR FLAME CUT any refrigerant line or vessel

until all refrigerant (liquid andvapor)hasbeenremovedfromchiller.

Traces of vapor should be displaced with dry air or nitrogen and

the work area should be well ventilated. Refrigerant in contact with

an open flame produces toxic gases.

DO NOT USE eyebolts or eyebolt holes to rig chiller sections or

the entire assembly.

DO NOT work on high-voltage equipment unless you are a qualified electrician.

DO NOTWORKON electrical components, including control panels, switches, starters, or oil heater until you are sure ALLPOWER

IS OFF and no residual voltage can leak from capacitors or solidstate components.

LOCK OPENANDTAGelectrical circuits during servicing.IF WORK

IS INTERRUPTED, confirm that all circuits are deenergized before resuming work.

AVOID SPILLING liquid refrigerant on skin or getting it into the

eyes. USE SAFETY GOGGLES. Wash any spills from the skin

with soap and water .If any enters the eyes, IMMEDIATELYFLUSH

EYES with water and consult a physician.

NEVER APPLY an open flame or live steam to a refrigerant cylinder. Dangerous overpressure can result. When necessary to heat

refrigerant, use only warm (110 F [43 C]) water.

DO NOT REUSE disposable (nonreturnable) cylinders or

attempt to refill them. It is DANGEROUS AND ILLEGAL. When

cylinder is emptied, evacuate remaining gas pressure, loosen

the collar and unscrew and discard the valve stem. DO NOT

INCINERATE.

CHECK THE REFRIGERANT TYPE before adding refrigerant to

the chiller.The introduction of the wrong refrigerant can cause damage or malfunction to this chiller.

Operation of this equipment with refrigerants other than those

cited herein should comply withASHRAE-15 (latest edition). Contact Carrier for further information on use of this chiller with other

refrigerants.

DO NOTATTEMPTTO REMOVE fittings, covers,etc., while chiller

is under pressure or while chiller is running. Be sure pressure is at

0 psig (0 kPa) before breaking any refrigerant connection.

CAREFULLY INSPECT all relief devices, rupture discs, and other

relief devices AT LEAST ONCE A YEAR. If chiller operates in a

corrosive atmosphere, inspect the devices at more frequent

intervals.

DO NOT ATTEMPT TO REPAIR OR RECONDITION any relief

device when corrosion or build-up of foreign material (rust, dirt,

scale, etc.) is found within the valve body or mechanism. Replace

the device.

DO NOT install relief devices in series or backwards.

USE CARE when working near or in line with a compressed spring.

Sudden release of the spring can cause it and objects in its path to

act as projectiles.

RUN WATERPUMPS when removing, transferring, or charging refrigerant.

DO NOT STEP on refrigerant lines. Broken lines can whip about

and cause personal injury.

DO NOT climb over a chiller. Use platform, catwalk, or staging.

Follow safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to lift or

move inspection covers or other heavy components. Even if components are light, use such equipment when there is a risk of slipping or losing your balance.

BE AWARE that certain automatic start arrangements CAN ENGAGE THE STARTER. Open the disconnect ahead of the starter

in addition to shutting off the machine or pump.

USE only repair or replacement parts that meet the code requirements of the original equipment.

DO NOTVENT OR DRAIN waterboxes containingindustrial brines,

liquid, gases, or semisolids without permission of your process control group.

DO NOT LOOSEN waterbox cover bolts until the waterbox has

been completely drained.

DOUBLE-CHECK that coupling nut wrenches, dial indicators, or

other items have been removed before rotating any shafts.

DO NOT LOOSEN a packing gland nut before checking that the

nut has a positive thread engagement.

PERIODICALLY INSPECT all valves, fittings, and piping for corrosion, rust, leaks, or damage.

PROVIDE A DRAIN connection in the vent line near each pressure relief device to prevent a build-up of condensate or rain

water.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab 5d

PC 211 Catalog No. 531-721 Printed in U.S.A. Form 17EX-1SS Pg 1 7-97 Replaces: New

Page 2

CONTENTS

Page

Page

SAFETY CONSIDERATIONS ......................1

INTRODUCTION

ABBREVIATIONS

17EX CHILLER FAMILIARIZATION

Chiller Identification Label

System Components

Cooler

Condenser

Compressor

Control Center

Motor Starter (Purchased Separately)

Economizer/Storage Vessel

REFRIGERATION CYCLE

OIL COOLING CYCLE

Compressor Oil Cooling

External Gear Oil Cooling

LUBRICATION CYCLE

Compressor Lubrication Cycle

External Gear Lubrication Cycle

STARTERS

CONTROLS

Definitions

........................................5

................................5

...............................5

.................5

.......................5

............................5

....................................5

...................................5

.................................5

..............5

......................5

.......................5-8

...........................8

.........................8

........................8

..........................8,9

...................8

..................9

....................................9

.................................11-43

....................................11

• ANALOG SIGNAL

• DIGITAL SIGNAL

• VOLATILE MEMORY

General

PIC System Components

......................................11

.......................12

• PROCESSOR/SENSOR INPUT/OUTPUT MODULE (PSIO)

• STARTER MANAGEMENT MODULE (SMM)

• LOCAL INTERFACE DEVICE (LID)

• SIX-PACK RELAY BOARD

• EIGHT-INPUT MODULES

• FOUR-IN/TWO-OUT (4-IN/2-OUT) MODULE

• OIL HEATER CONTACTOR (1C)

• COMPRESSOR OIL PUMP CONTACTOR (2C) AND GEAR

OIL PUMP CONTACTOR (5C)

• HOT GAS BYPASS CONTACTOR RELAY (3C) (Optional)

• OIL AUXILIARY RELAY (4C)

• CONTROL TRANSFORMERS (T1-T4)

• CONTROL AND OIL HEATER VOLTAGE

SELECTOR (S1)

• OIL DIFFERENTIAL PRESSURE/POWER SUPPLY

MODULE

LID Operation and Menus

.......................16

• GENERAL

• ALARMS AND ALERTS

• LID DEFAULT SCREEN MENU ITEMS

• MENU STRUCTURE

• TO VIEW OR CHANGE POINT STATUS

• OVERRIDE OPERATIONS

• TO VIEW OR CHANGE TIME SCHEDULE OPERATION

• TO VIEW AND CHANGE SET POINTS

• SERVICE OPERATION

PIC System Functions

..........................32

• CAPACITY CONTROL

• ENTERING CHILLED WATER CONTROL

• DEADBAND

• PROPORTIONAL BANDS AND GAIN

• DEMAND LIMITING

• CHILLER TIMERS

• OCCUPANCY SCHEDULE

Safety Controls

...............................33

• SHUNT TRIP

Default Screen Freeze .........................33

Auxiliary Compressor Oil Pump Control

Auxiliary Gear Oil Pump Control

Shaft Seal Oil Control

Ramp Loading Control

Capacity Override

High Discharge Temperature Control

Oil Sump Temperature Control

Oil Cooler

Remote Start/Stop Controls

Spare Safety Inputs

Spare Alarm Contacts

Condenser Pump Control

Condenser Freeze Prevention

Tower-Fan Relay

Auto. Restart After Power Failure

Water/Brine Reset

Demand Limit Control, Option (Requires Optional

8-Input Module)

Surge Prevention Algorithm

Surge Protection

Lead/Lag Control

....................................36

..........................33

.........................33

.............................35

..................35

.....................36

...........................36

.........................36

......................36

...................36

..............................36

.............................37

.............................37

....................37

..............................38

.............................38

..........33

................33

.............35

................36

• COMMON POINT SENSOR INSTALLATION

• CHILLER COMMUNICATION WIRING

• LEAD/LAG OPERATION

• FAULTED CHILLER OPERATION

• LOAD BALANCING

• AUTO. RESTART AFTER POWER FAILURE

Ice Build Control

..............................40

• ICE BUILD INITIATION

• START-UP/RECYCLE OPERATION

• TEMPERATURE CONTROL DURING ICE BUILD

• TERMINATION OF ICE BUILD

• RETURN TO NON-ICE BUILD OPERATIONS

Attach to Network Device Control

...............41

• ATTACHING TO OTHER CCN MODULES

Service Operation

.............................42

• TO ACCESS THE SERVICE SCREENS

• TO LOG OFF

• HOLIDAY SCHEDULING

START-UP/SHUTDOWN/RECYCLE SEQUENCE

Local Start-Up

Shutdown Sequence

Automatic Soft Stop Amps Threshold

Chilled Water Recycle Mode

Safety Shutdown

BEFORE INITIAL START-UP

Job Data Required

Equipment Required

Using the Economizer/Storage Vessel and Pumpout

System

Remove Shipping Packaging

................................43

...........................44

............44

....................44

..............................45

...................45-57

............................45

...........................45

....................................45

...................45

...43-45

• MOTOR

• EXTERNAL GEAR

Motor Electrical Connection

Motor Auxiliary Devices

Open Oil Circuit Valves

Tighten All Gasketed Joints and Guide Vane

Shaft Packing

Check Chiller Tightness

Refrigerant Tracer

Leak Test the Chiller

Standing Vacuum Test

Chiller Dehydration

...............................46

.............................46

...........................46

............................49

....................45

........................46

........................46

........................46

.........................49

2

Page 3

CONTENTS

Page

Page

Inspect Water Piping ..........................50

Check Optional Pumpout Compressor Water

Piping

Check Relief Devices

Inspect Wiring

....................................50

..........................50

................................50

• CHECK INSULATION RESISTANCE

Motor Pre-Start Checks

External Gear Pre-Start Checks

Carrier Comfort Network Interface

Check Starter

.................................53

........................51

.................51

...............53

• MECHANICAL STARTERS

• SOLID-STATE STARTERS

Compressor Oil Charge

Power Up the Controls and

Check the Compressor Oil Heater

........................54

.............54

• SOFTWARE VERSION

Set Up Chiller Control Configuration

Input the Design Set Points

Input the Local Occupied Schedule

(OCCPC01S)

Input Service Configurations

................................54

.....................54

....................54

.............54

• PASSWORD

• INPUT TIME AND DATE

• CHANGE LID CONFIGURATION IF NECESSARY

• MODIFY CONTROLLER IDENTIFICATION IF

NECESSARY

• INPUT EQUIPMENT SERVICE PARAMETERS IF

NECESSARY

• MODIFY EQUIPMENT CONFIGURATION IF

NECESSARY

• CHECK VOLTAGE SUPPLY

• PERFORM AN AUTOMATED CONTROL TEST

Check Pumpout System Controls and Optional

Pumpout Compressor

High Altitude Locations

Charge Refrigerant Into Chiller

........................56

........................57

..................57

• TRIMMING REFRIGERANT CHARGE

INITIAL START-UP

Preparation

Manual Operation of the Guide Vanes

Dry Run to Test Start-Up Sequence

Check Motor Rotation

...........................57-62

..................................57

............58

..............58

.........................58

• INITIAL MOTOR START-UP

Disc Coupling Installation and Alignment

.........59

• IMPORTANT INFORMATION

Check Oil Pressure and Compressor Stop

Calibrate Motor Current Demand Setting

To Prevent Accidental Start-Up

Hot Alignment Check

Doweling

Check Chiller Operating Condition

Instruct the Operator

....................................61

.........................61

..........................62

..................61

...............61

........61

..........61

• COOLER-CONDENSER

• ECONOMIZER/STORAGE VESSEL

• PUMPOUT SYSTEM

• COMPRESSOR ASSEMBLY

• COMPRESSOR LUBRICATION SYSTEM

EXTERNAL GEAR LUBRICATION SYSTEM

• CONTROL SYSTEM

• AUXILIARY EQUIPMENT

• CHILLER CYCLES

• MAINTENANCE

• SAFETY DEVICES AND PROCEDURES

• CHECK OPERATOR KNOWLEDGE

• THIS MANUAL

OPERATING INSTRUCTIONS

Operator Duties

...............................62

..................62,63

Prepare the Chiller for Start-Up .................62

Starting the Chiller

Check the Running System

Stopping the Chiller

After Limited Shutdown

Extended Shutdown

After Extended Shutdown

Cold Weather Operation

Manual Guide Vane Operation

Refrigeration Log

PUMPOUT AND REFRIGERANT TRANSFER

PROCEDURES

Preparation

Operating the Optional Pumpout

Compressor

..................................63

........................... 62

.....................62

...........................62

........................63

...........................63

......................63

........................63

...................63

.............................63

............................63-67

................................63

• READING REFRIGERANT PRESSURES

Transferring Refrigerant into the

Economizer/Storage Vessel

Transferring Refrigerant into

the Cooler/Condenser/Compressor Section

Return Chiller to Normal Operating

Conditions

GENERAL MAINTENANCE

Refrigerant Properties

Adding Refrigerant

Removing Refrigerant

Adjusting the Refrigerant Charge

Refrigerant Leak Testing

Leak Rate

Test After Service, Repair, or Major Leak

.................................67

............................67

....................................67

...................66

.....67

....................67-75

.........................67

.........................67

................67

.......................67

.........67

• REFRIGERANT TRACER

• TO PRESSURIZE WITH DRY NITROGEN

Repair the Leak, Retest, and Apply

Standing Vacuum Test

Checking Guide Vane Linkage

Contact Seal Maintenance

.......................68

..................68

......................68

• SEAL DISASSEMBLY

• SEAL REASSEMBLY

Chiller Alignment

.............................71

• ALIGNMENT METHODS

• PRELIMINARY ALIGNMENT

• NEAR FINAL ALIGNMENT

• FINAL ALIGNMENT

• HOT ALIGNMENT CHECK

• DOWELING

WEEKLY MAINTENANCE

Check the Lubrication System

SCHEDULED MAINTENANCE

Service Ontime

Inspect the Control Center

Check Safety and Operating Controls Monthly

Changing the Oil Filters

...............................76

.......................76

..................76

..................76-83

.....................76

.....76

........................76

• COMPRESSOR OIL FILTER

• EXTERNAL GEAR OIL FILTER

Oil Specifications

Oil Changes

.............................77

..................................77

• COMPRESSOR OIL

• EXTERNAL GEAR OIL

• MOTOR SLEEVE BEARING AND PUMPOUT

COMPRESSOR OIL

Inspect Refrigerant Float System

Inspect Relief Valves and Piping

Coupling Maintenance

Motor Maintenance

........................78

............................78

................78

................78

• CLEANLINESS

• SLEEVE BEARINGS

3

Page 4

CONTENTS (cont)

Page

Page

Motor Handling/Rigging ........................81

Motor Storage

External Gear Storage

................................81

.........................81

• SHORT-TERM STORAGE (Indoors)

• LONG-TERM STORAGE (Indoors)

• EXTENDED DOWNTIME

Compressor Bearing Maintenance

External Gear Maintenance

Inspect the Heat Exchanger Tubes

...............82

.....................82

...............82

• COOLER

• CONDENSER

Water Leaks

Water Treatment

Inspect the Starting Equipment

Check Pressure Transducers

Pumpout System Maintenance

..................................82

..............................82

.................83

...................83

..................83

• OPTIONAL PUMPOUT COMPRESSOR OIL CHARGE

• PUMPOUT SAFETY CONTROL SETTINGS

Ordering Replacement Chiller Parts

..............83

• MOTOR REPLACEMENT PARTS

• EXTERNAL GEAR REPLACEMENT PARTS

TROUBLESHOOTING GUIDE

Overview

Checking the Display Messages

Checking Temperature Sensors

....................................83

..................83-99

.................84

.................84

• RESISTANCE CHECK

• VOLTAGE DROP

• CHECK SENSOR ACCURACY

• DUAL TEMPERATURE SENSORS

Checking Pressure Transducers ................84

• OIL DIFFERENTIAL PRESSURE/POWER SUPPLY

MODULE CALIBRATION

• TROUBLESHOOTING TRANSDUCERS

• TRANSDUCER REPLACEMENT

Control Algorithms Checkout Procedure

Control Test

Control Modules

.................................85

..............................96

.........85

• RED LEDs

• GREEN LEDs

Notes on Module Operation

Processor/Sensor Input/Output Module (PSIO)

....................96

....97

• INPUTS

• OUTPUTS

Starter Management Module (SMM)

..............97

• INPUTS

• OUTPUTS

Options Modules (8-Input)

Four-In/Two-Out Module

.....................98

.......................98

• INPUTS

• OUTPUTS

Replacing Defective Processor Modules

.........98

• INSTALLATION OF NEW PSIO MODULE

PHYSICAL DATA AND WIRING SCHEMATICS

INDEX

INITIAL START-UP CHECKLIST FOR 17EX

....................................115-120

EXTERNALLY GEARED CENTRIFUGAL LIQUID

CHILLER

..........................CL-1 to CL-12

....99-114

4

Page 5

INTRODUCTION

Before initial start-up of the 17EX unit, those involved in

the start-up, operation, and maintenance should be thoroughly familiar with these instructions and other necessary

job data. This book is outlined so that you may become familiar with the control system before performing start-up procedures. Procedures in this manual are arranged in the sequence required for proper chiller start-up and

operation.

This unit uses a microprocessor controlled system. Do

not short or jumper between terminations on circuit boards

or modules; control or board failure may result.

Be aware of electrostatic discharge (static electricity) when

handling or making contact with circuit boards or module connections. Always touch a chassis (grounded) part

to dissipate body electrostatic charge before working inside the control center.

Use extreme care when handling tools near boards and

when connecting or disconnecting terminal plugs.

Circuit boards can easily be damaged. Always hold boards

by the edges and avoid touching components and

connections.

This equipment uses, and can radiate, radio frequency

energy. If not installed and used in accordance with

the instruction manual, it may cause interference to

radio communications. It has been tested and found to

comply with the limits for a Class A computing device

pursuant to Subpart J of Part 15 of FCC Rules, which

are designed to provide reasonable protection against such

interference when operated in a commercial environment. Operation of this equipment in a residential area

is likely to cause interference, in which case the user, at

his own expense, will be required to take whatever measures may be required to correct the interference.

Always store and transport replacement or defective boards

in anti-static shipping bag.

ABBREVIATIONS

Frequently used abbreviations in this manual include:

CCN — Carrier Comfort Network

CCW — Counterclockwise

CHW — Chilled Water

CHWR — Chilled Water Return

CHWS — Chilled Water Supply

CW — Clockwise

ECW — Entering Chilled Water

ECDW — Entering Condenser Water

EMS — Energy Management System

HGBP — Hot Gas Bypass

I/O — Input/Output

LCD — Liquid Crystal Display

LCDW — Leaving Condenser Water

LCW — Leaving Chilled Water

LED — Light-Emitting Diode

LID — Local Interface Device

OLTA — Overload Trip Amps

PIC — Product Integrated Control

PSIO — Processor Sensor Input/

Output Module

RLA — Rated Load Amps

SCR — Silicon Control Rectifier

SMM — Starter Management Module

TXV — Thermostatic Expansion Valve

17EX CHILLER FAMILIARIZATION

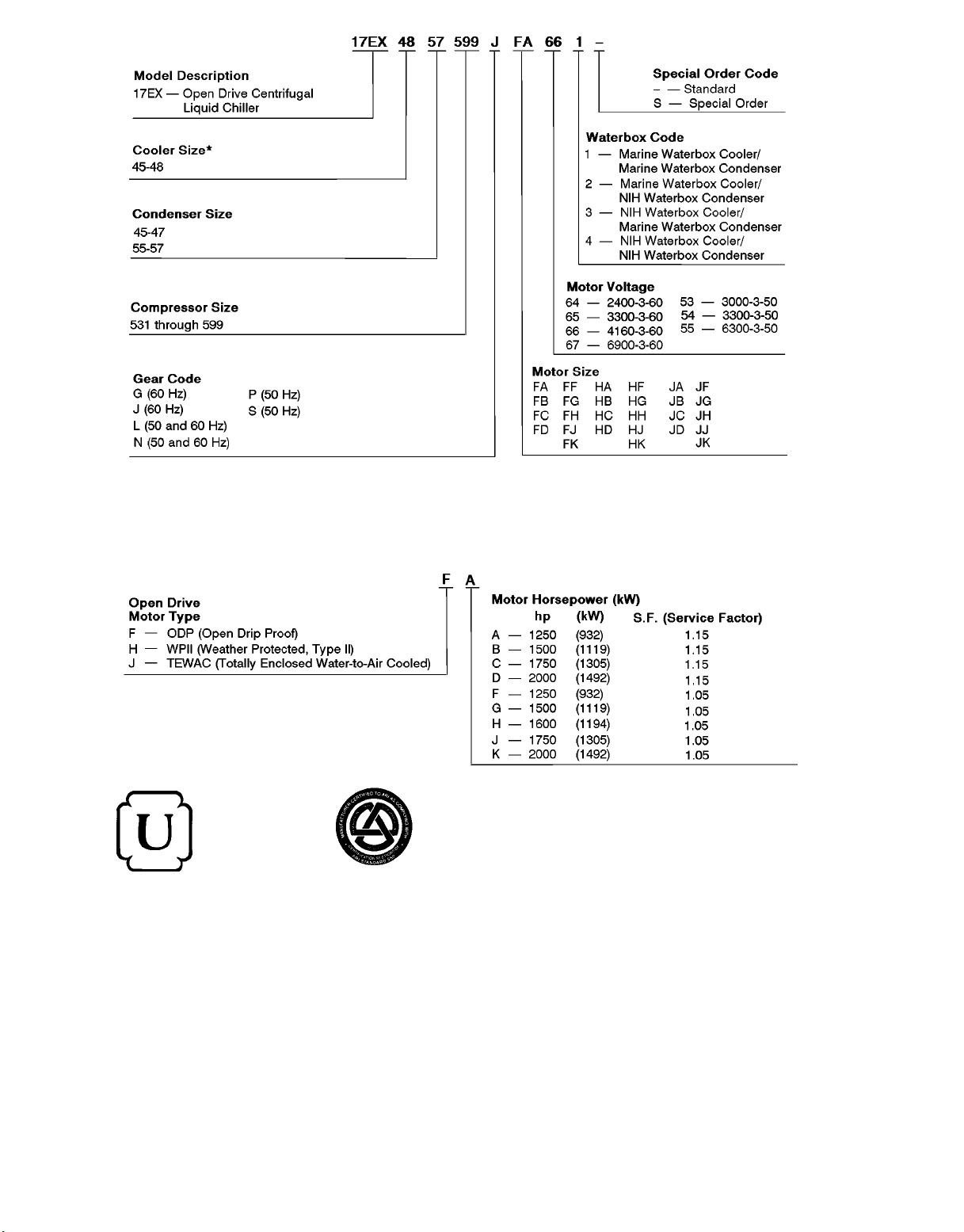

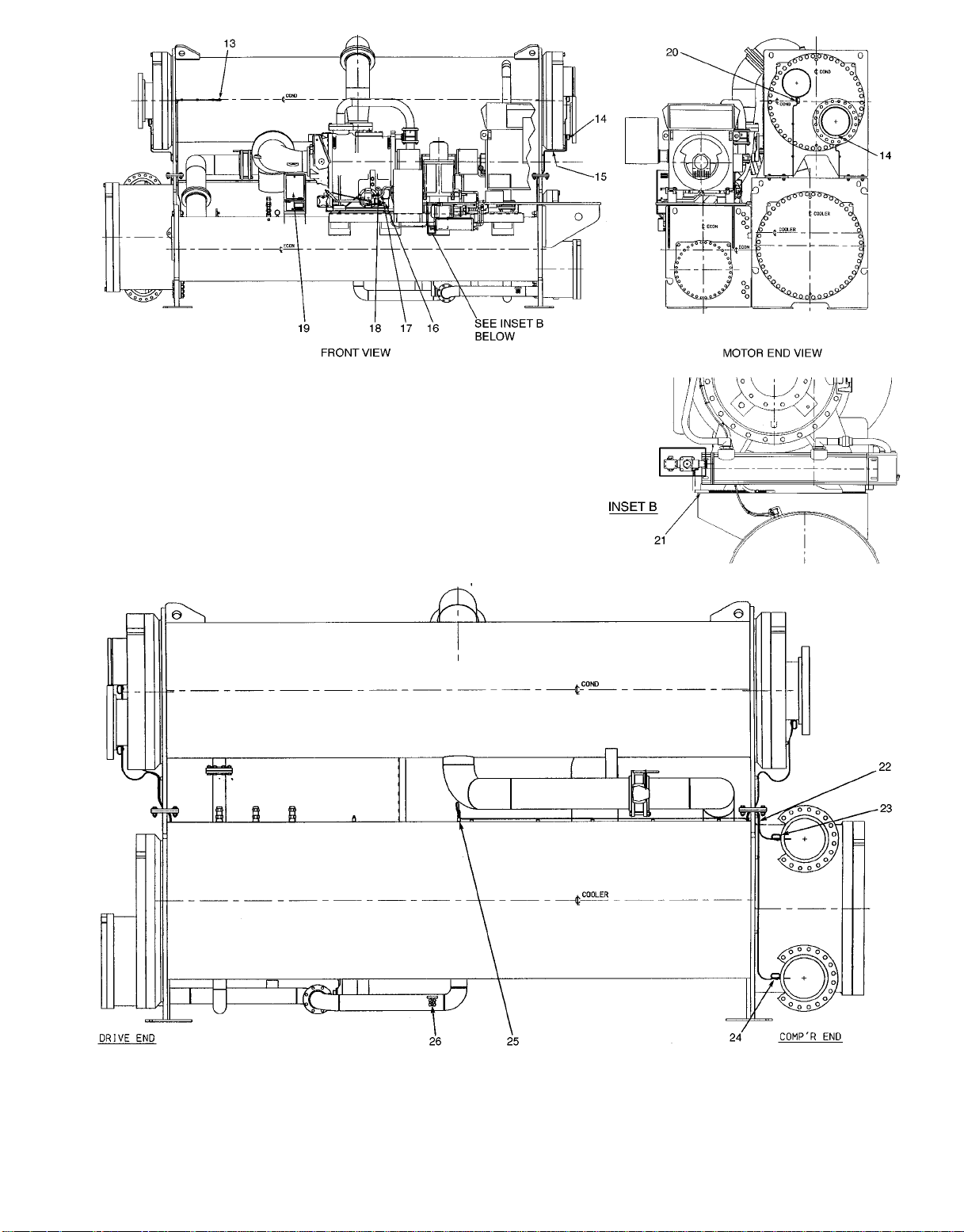

Chiller Identification Label (Fig. 1) —

tification label is located on the right side of the chiller control center panel. The label contains information on model

number, refrigerant charge, rated voltage, etc.

The iden-

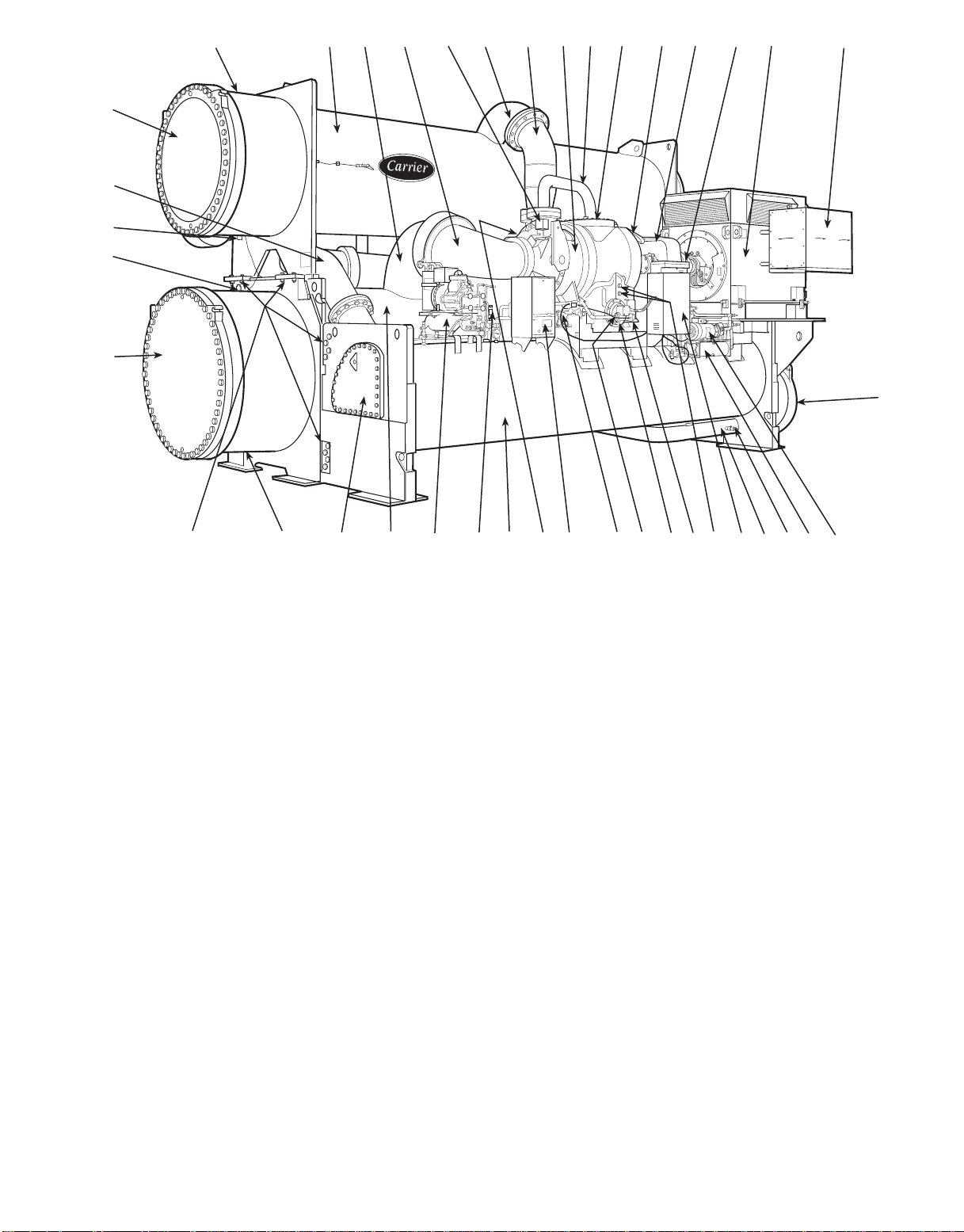

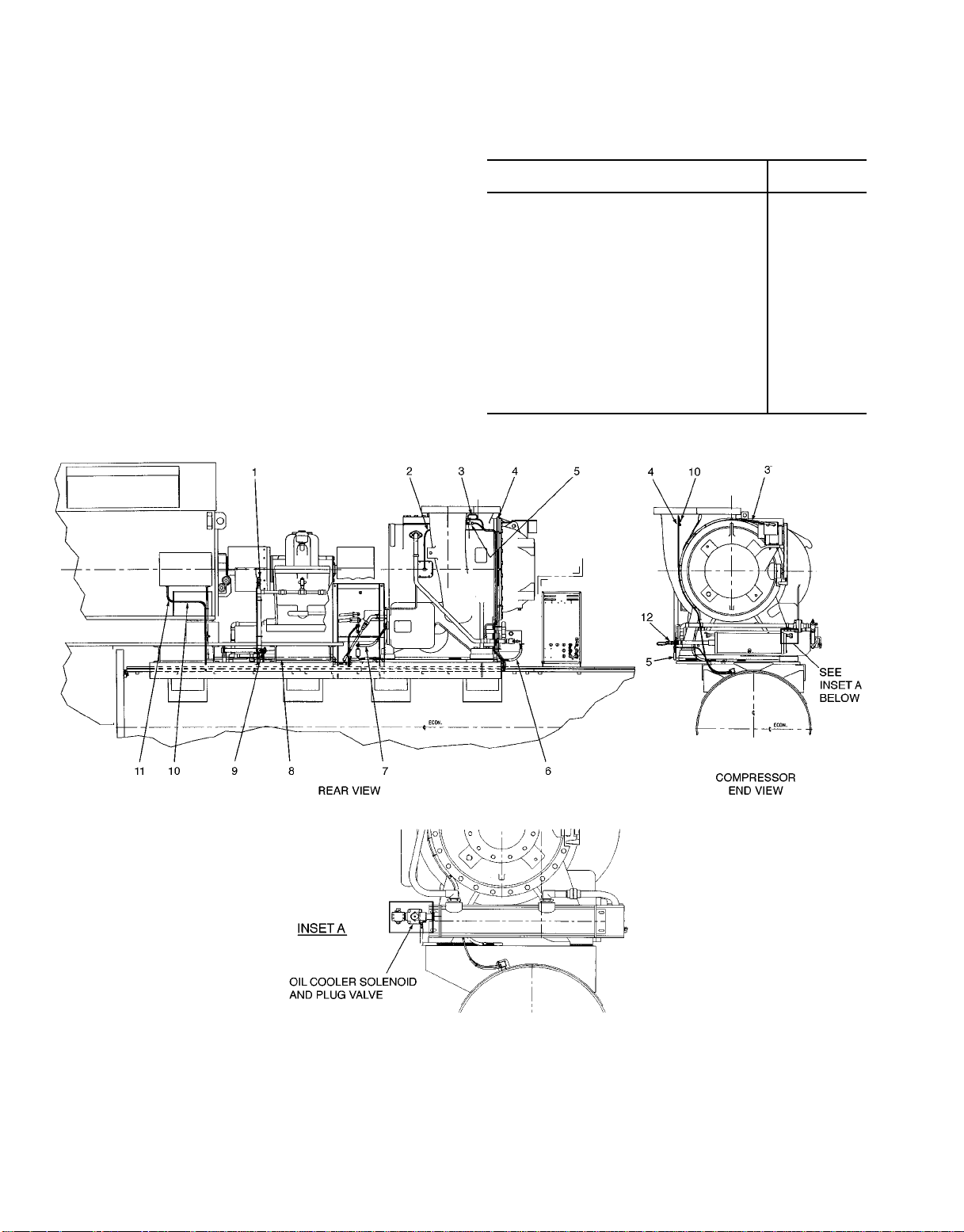

System Components (Fig. 2) — The components

include the cooler and condenser heat exchangers in separate vessels, compressor,compressorandgear lubrication packages, control center,speedincreasereconomizer/storage vessel,

motor, and starter. The compressor drive consists of an external gear (speed increaser) and an electric motor. All connections from pressure vessels have external threads to enable each component to be pressure tested with a threaded

pipe cap during factory assembly.

Cooler — This vessel (also known as the evaporator) is

located underneath the condenser, next to the economizer/

storage vessel. The cooler is maintained at lower temperature and pressure so that evaporating refrigerant can remove

heat from water flowing through its internal tubes.

Condenser — The condenser operates at a higher tem-

perature and pressure than the cooler and has water flowing

through its internal tubes in order to remove heat from the

refrigerant.

Compressor — This component maintains system tem-

perature and pressure differences and moves the heatcarrying refrigerant from the cooler to the condenser.

Control Center — The control center is the user inter-

face for controlling the chiller and regulates the chiller capacity as required to maintain proper leaving chilled

water temperature. The control center:

• registers cooler, condenser, and lubricating system

pressures

• shows chiller operating and alarm shutdown conditions

• records the total chiller operating hours and how many hours

the chiller has been running

• sequences chiller start, stop, and recycle under microprocessor control

• provides access to other CCN (Carrier Comfort Network)

devices

MotorStarter (Purchased Separately) — The starter

allows the proper start and disconnect of electrical energy

for the compressor-motor, oil pump, oil heater, and control

panels.

Economizer/Storage Vessel — During normal op-

eration, this vessel functions as an economizer,returning flash

gas to the second stage of the compressor and increasing the

efficiency of the refrigeration cycle. During periods of shutdown and service, the economizer/storage vessel can serve

as a storage tank for the refrigerant.

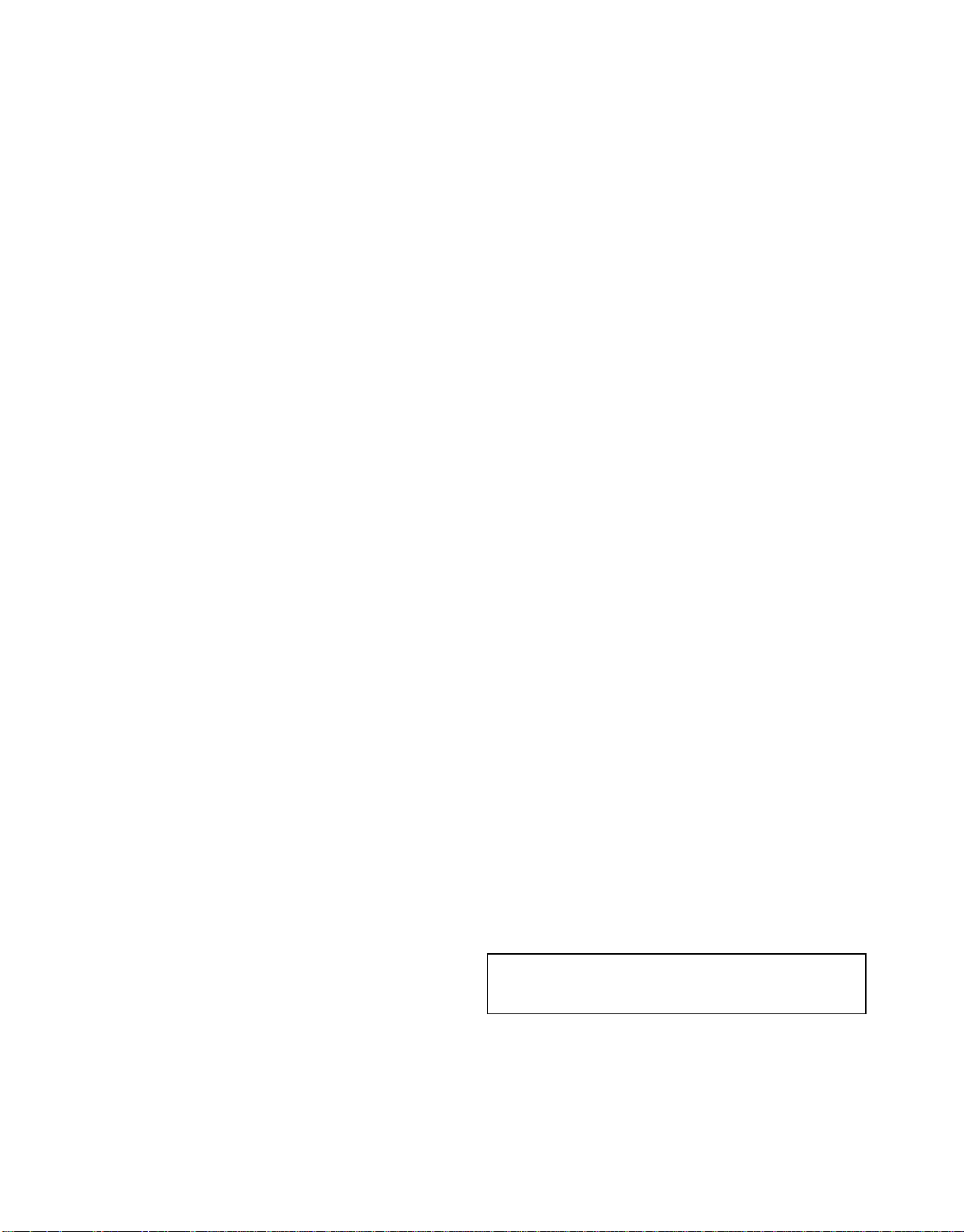

REFRIGERATION CYCLE (Fig. 3)

The 17EX chiller can be used to chill either water or brine.

The data in this book applies to either application. Applications using corrosive brines may require using special tubes,

tubesheet, and waterbox materials which are special order

items.

5

Page 6

LEGEND

NIH — Nozzle-In-Head

*Any available cooler size can be combined with any available condenser size.

NOTE: For details on motor size designations, see below.

ASME

‘U’ STAMP

ARI (Air Conditioning

and Refrigeration

Institute)

PERFORMANCE

CERTIFIED

(60 Hz Only)

Fig. 1 — Model Number Identification

6

Page 7

40

39

38

37

36

35

1 2 3 4 5 6 7 8 9 10 11 12 13 14

15

34

1—Condenser

2—Cooler Suction Pipe

3—Compressor Suction Elbow

4—Guide Vane Actuator

5—Condenser Discharge Pipe

6—Compressor Discharge Elbow

7—Two-Stage Compressor

8—Economizer Gas Line to Compressor

9—Compressor Housing Access Cover

10 — High-Speed Coupling (Hidden)

11 — External Gear (Speed Increaser)

12 — Low-Speed Coupling (Hidden)

13 — Open-Drive Compressor Motor

14 — Compressor Motor Terminal Box

15 — Low-Side Float Box Cover

16 — Gear Oil Pump

17 — Gear Oil Cooler/Filter

18 — Refrigerant Charging/Service Valve

19 — Refrigerant Liquid Line to Cooler

20 — Power Panel

21 — Oil Level Sight Glasses (2)

33

32

31

17EX WITH EXTERNAL GEAR (SPEED INCREASER)

Fig.2—Typical 17EX Chiller Components

30

LEGEND

29

26

22 — Oil Drain and Charging Valve

23 — Oil Heater (Hidden)

24 — Compressor Oil Pump

25 — Compressor Oil Cooler/Filter

26 — Local Interface Display Control Panel

27 — Cooler Relief Valves (Behind Compressor,

28 — Economizer Storage Vessel

29 — Economizer/Storage Vessel Relief Valves

30 — Pumpout Unit

31 — Cooler

32 — High Side Float Box Cover

33 — Cooler Waterbox Drain

34 — Take-Apart Connections

35 — Cooler Marine Waterbox

36 — Cooler Waterbox Vent

37 — Condenser Waterbox Drain

38 — Refrigerant Liquid Line to Economizer/

39 — Condenser Marine Waterbox

40 — Condenser Waterbox Vent

27

28

25

24

Hidden)

Storage Vessel

22

23

20

21

17

18

19

16

7

Page 8

The chiller compressor continuously draws large quantities of refrigerant vapor from the cooler at a rate determined

by the amount of guide vane opening. This compressor suction reduces the pressure within the cooler, allowing the liquid refrigerant to boil vigorously at a fairly low temperature

(typically 38 to 42 F [3 to 6 C]).

The liquid refrigerant obtains the energy needed to vaporize by removing heat from the water or brine in the cooler

tubes. The cold water or brine can then be used in air conditioning and/or other processes.

After removing heat from the water or brine, the refrigerant vapor enters the first stage of the compressor, is

compressed, and flows into the compressor second stage. Here

it is mixed with flash-economizer gas and is further

compressed.

Compression raises the refrigerant temperature above

that of the water flowing through the condenser tubes.

When the warm (typically 98 to 102 F [37 to 40 C]) refrigerant vapor comes into contact with the condenser tubes, the

relatively cool condensing water (typically 85 to 95 F

[29 to 35 C]) removes some of the heat, and the vapor condenses into a liquid.

The liquid refrigerant passes through an orifice into the

FLASC chamber.The coolest condenser water flows through

the FLASC and allows a lower saturated temperature and

pressure. Part of the entering liquid refrigerant will flash to

vapor once it has passed through the FLASC orifice, thereby

cooling the remaining liquid. The vapor is then recondensed

by the condenser water flowing through the FLASC

chamber.

The subcooled liquid refrigerant drains into a high-side

valve chamber that meters the refrigerant liquid into a flash

economizer chamber. Pressure in this chamber is intermediate between condenser and cooler pressures. At this lower

pressure, some of the liquid refrigerant flashes to gas, further cooling the remaining liquid. The flash gas, having absorbed heat, is returned directly to the compressor second

stage. Here it is mixed with discharge gas that is already compressed by the first-stage impeller. Since the flash gas has to

pass through only half the compression cycle to reach condenser pressure, there is a savings in power.

The cooled liquid refrigerant in the economizer is metered through the low-side valve chamber, reducing the refrigerant pressure. Pressure in the cooler is lower than in the

economizer. Some of the liquid flashes as it passes through

the low side float valve. The cycle is now complete.

OIL COOLING CYCLE

Compressor Oil Cooling —

water cooled. Water flow through the oil cooler is manually

adjusted by a plug valve to maintain an operating temperature at the reservoir of approximately 145 F (63 C). An oil

heater in the reservoir helps to prevent oil from being diluted by the refrigerant. The heater is controlled by the PIC

(Product Integrated Control) and is energized when the oil

temperature is outside the operating temperature range of 150

to 160 F (66 to 71 C).

The compressor oil is

External Gear Oil Cooling — The external gear oil

is also water cooled. Water flow through the gear oil cooler

is manually adjusted by a plug valve to maintain an operating temperature of approximately 130 F (54 C). If so equipped,

an oil heater in the reservoir helps to maintain the oil temperature under cold ambient operating conditions. The heater

is controlled by an internal thermostat.

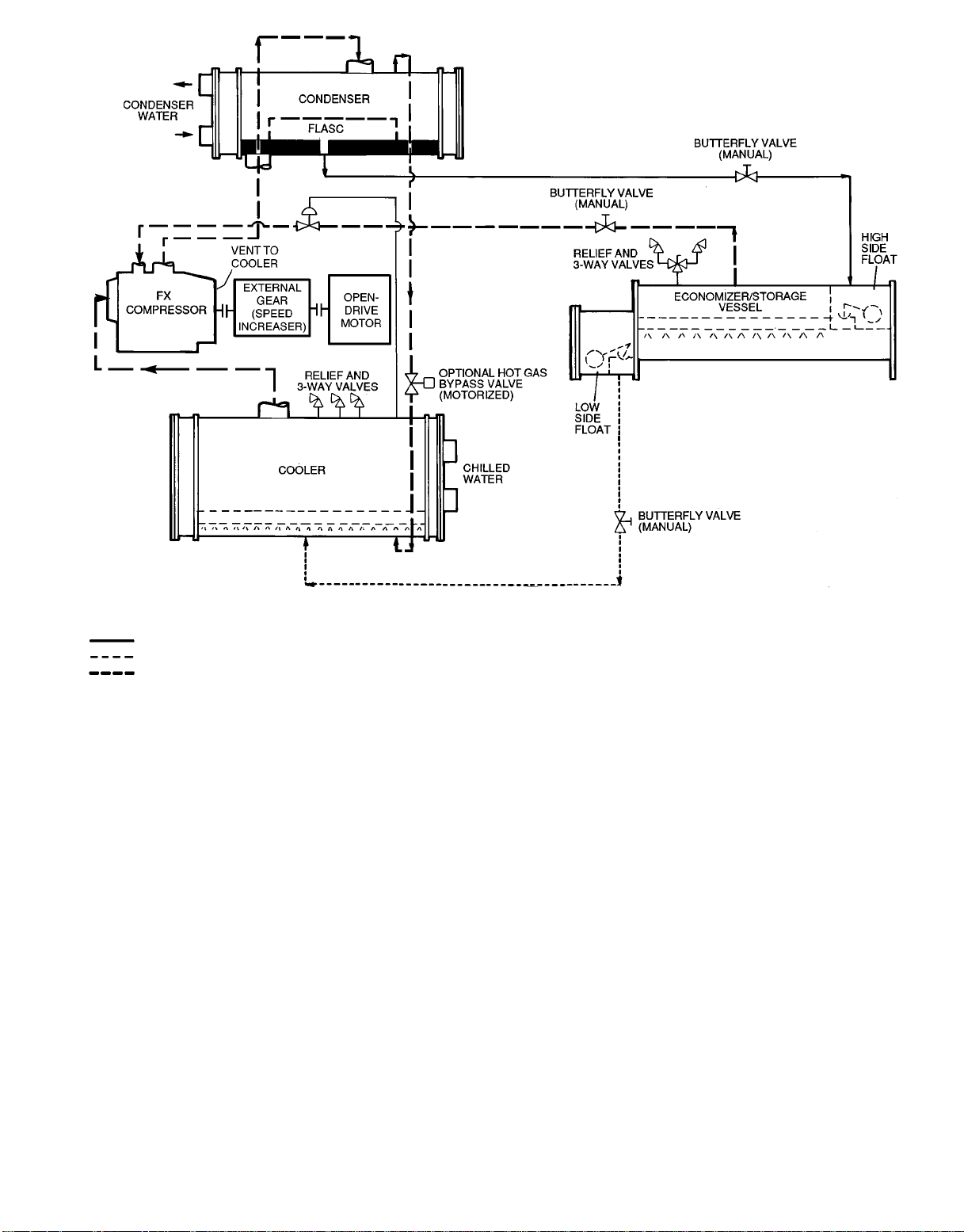

LUBRICATION CYCLE

Compressor Lubrication Cycle (Refer to item

numbers shown in Fig. 4) —

pump and oil reservoir are contained in the compressor base.

Oil is pumped through an oil cooler and filter to remove heat

and any foreign particles. A portion of the oil is then directed to the shaft-end bearing and the shaft seal. The balance of the oil lubricates the thrust and journal bearings and

the thrust end seal. The bearing and transmission oil returns

directly to the reservoir to complete the cycle. Contact-seal

oil leakage, however,iscollected in an atmospheric float chamber to be pumped back to the main reservoir as the oil

accumulates.

Oil may be charged into the compressor oil reservoir

(Item 8) through a charging valve (Item 6) which also functions as an oil drain. If there is refrigerant in the chiller, however, a hand pump will be required for charging at this

connection.

An oil-charging elbow (Item 3) on the seal-oil return chamber allows oil to be added without pumping. The seal-oil return pump (Item 4) automatically transfers the oil to the main

reservoir. Sight glasses (11) on the reservoir wall permit observation of the oil level.

Amotor-drivenoil pump (Item 10) discharges oil to an oil

cooler/filter (Item 16) at a rate and pressure controlled by an

oil regulator (Item 10). The differential oil pressure (bearing

supply versus oil reservoir) is registered on the control panel.

Water flow through the oil cooler is manually adjusted by

a plug valve (Item 17) to maintain the oil at an operating

temperature of approximately 145 F (63 C). During shutdown, the oil temperature is also maintained at 150 to

160 F (65 to 71 C) by an immersion heater (Item 7) in order

to minimize absorption of refrigerant by the oil.

Upon leaving the cooler section of the oil cooler/filter, the

oil is filtered (Item 15) and a portion is directed to the sealend bearing (Item 1) and the shaft seal (Item 2). The remainder lubricates thrust (Item 14) and journal bearings (Item 12).

Thrust bearing temperature is indicated on the PIC controls.

Oil from both circuits returns by gravity to the reservoir.

The shaft seal of the open compressor drive must be kept

full of lubrication oil, even when the chiller is not operating,

to prevent loss of refrigerant.

If the chiller is not operating and the oil pump has not

operated during the last 12 hours, the control system automatically runs the oil pump for one minute in order to keep

the contact seal filled with oil.

IMPORTANT: If the control power is to be deenergized for more than one day,the chiller refrigerant should

be pumped over to the economizer/storage vessel.

The compressor oil

8

Page 9

LEGEND

TXV — Thermostatic Expansion Valve

*The FX compressor and the gear have a water cooled oil cooler.

Liquid

Liquid/Vapor

Vapor

Fig. 3 — Refrigeration, Cycle

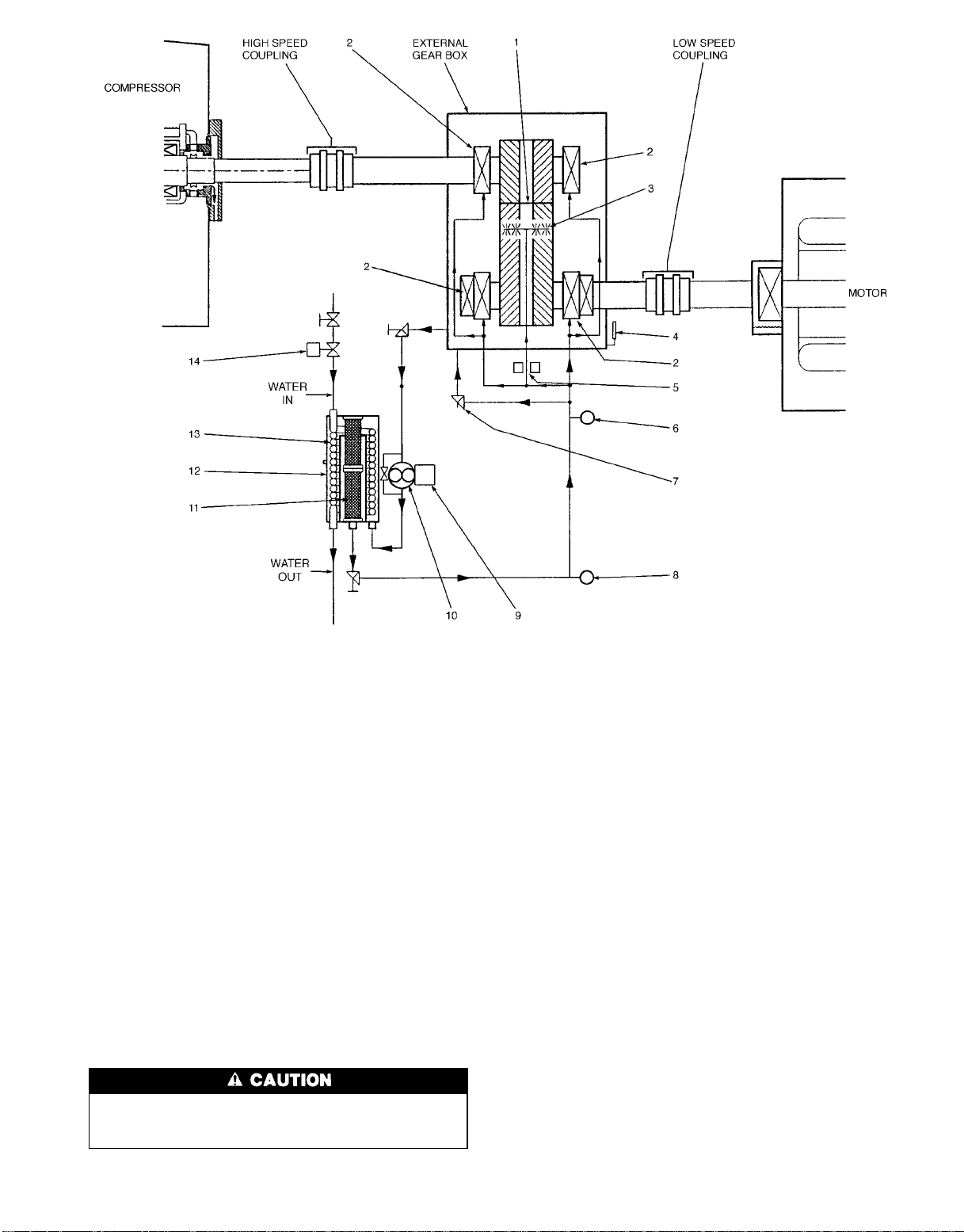

External Gear Lubrication Cycle (Refer to Item

numbers shown in Fig. 5) —

tained in the gear base.The external gear oil pump is mounted

below the gear with the cooler/filter. Oil is pumped through

an oil cooler/filter to remove heat and any foreign particles.

A portion of the oil is directed to the gear bearings and gear

mesh spray.The remainder is bypassed to the sump. The bearing and transmission oil returns directly to the reservoir to

complete the cycle.

Oil may be charged into the external gear oil reservoir as

described in the section, External Gear Pre-Start Checks,

page 51. Observe the oil level in the oil level glass (Item 4)

on the reservoir wall.

A motor driven oil pump (Item 10) discharges oil to the

oil cooler/filter (Item 12). The pump has an internal pressure

regulator to protect the pump in the event of an obstruction

downstream. Water flow through the oil cooler is manually

adjusted by a plug valve (Item 14) to maintain the oil at an

operating temperature of approximately 130 F (54 C).

Oil reservoir is con-

Upon leaving the cooler section (Item 13) of the oil cooler/

filter, the oil is filtered (Item 11) and is directed to the pressure control valve (Item 7). Before entering the pressure control

valve, the oil pressure (Item 16) and temperature (Item 8)

are monitored by the PIC.

A portion of the oil then lubricates the gear bearings

(Item 2). Another portion is directed through an orifice

(Item 5) to the gear mesh spray (Item 3) to lubricate the gear

mesh (Item 1) during operation. Oil from both circuits returns by gravity to the reservoir.

STARTERS

All starters, whether supplied by Carrier or the customer,

must meet Carrier Starter Specification Z-375. This specification can be obtained from a Carrier Sales Representative. The purpose of this specification is to ensure the compatibility of the starter and the chiller.Many styles of compatible

starters are available, including solid-state , auto-transformer,

full-voltage, and, in the case of low-voltage main power supply, wye-delta closed transition.

9

Page 10

13

COMPRESSOR OIL

PRESSURE LEAVING

FILTER LINE

12

JOURNAL

BEARING

CHECK VALVE

15

OIL FILTER

16

OIL COOLER/

FILTER

17

PLUG VALVE

SHAFT DISPLACEMENT

& BRG TEMP. CUTOUT

CONNECTIONS

TO PIC

CONTROLLER

8

MAIN OIL

RESERVOIR

14

THRUST

BEARING

COAST DOWN

RESERVOIRS

1

SEAL-END

BEARING

2

SHAFT

SEAL

3

OIL CHARGING

ELBOW

11

SIGHT

GLASSES

10

OIL PUMP

& PRESS. REGULATOR

TO POWER

PANEL

9

OIL

THERMISTOR

7

OIL

HEATER

6

DRAIN &

CHARGING VALVE

Fig. 4 — 17EX Compressor Lubrication Cycle

5

COMPRESSOR OIL

SUCTION PRESSURE

4

PUMP, SEAL

OIL RETURN

10

Page 11

1—Gear Mesh

2—Bearings

3—Gear Mesh Spray

4—Oil Level Glass

5—Orifice

6—Oil Supply Pressure

Transducer

7—Pressure Control Valve

NOTE: The oil reservoir is at the base of the gear box.

Fig. 5 — External Gear Oil Lubrication Cycle (Plan View)

8—Oil Supply Temperature Thermistor

9—Oil Pump Motor

10 — Oil Pump and Pressure Regulator

11 — Oil Filter

12 — Oil Cooler/Filter

13 — Oil Cooler

14 — Plug Valve

CONTROLS

Definitions

ANALOG SIGNAL — An analog signal varies in proportion to the monitored source. It quantifies values between

operating limits. (Example: A temperature sensor is an analog device because its resistance changes in proportion to

the temperature, generating many values.)

DIGIT ALSIGNAL— A digital (discrete) signal is a 2-position

representation of the value of a monitored source.

(Example: A switch is a digital device because it only indicates whether a value is above or below a set point or boundary by generating an on/off,high/low, or open/closed signal.)

VOLATILE MEMORY — Volatile memory is memory in-

capable of being sustained if power is lost and subsequently

restored.

The memories of the PSIO and LID modules are volatile. If the battery in a module is removed or damaged,

all programming will be lost.

General — The 17EX externally geared open-drive cen-

trifugal liquid chiller contains a microprocessor-based control center that monitors and controls all operations of the

chiller.The microprocessor control system matches the cooling capacity of the chiller to the cooling load while providing state-of-the-art chiller protection. The system controls

cooling load within the set point plus the deadband by sensing the leaving chilled water or brine temperature and regulating the inlet guide vane via a mechanically linked actuator motor.The guide vane is a variable flow prewhirl assembly

that controls the refrigeration effect in the cooler by regulating the amount of refrigerant vapor flow into the compressor.An increase in guide vane opening increases capacity.Adecrease in guide vane opening decreases capacity.Chiller

protection is provided by the processor which monitors the

digital and analog inputs and executes capacity overrides or

safety shutdowns, if required.

11

Page 12

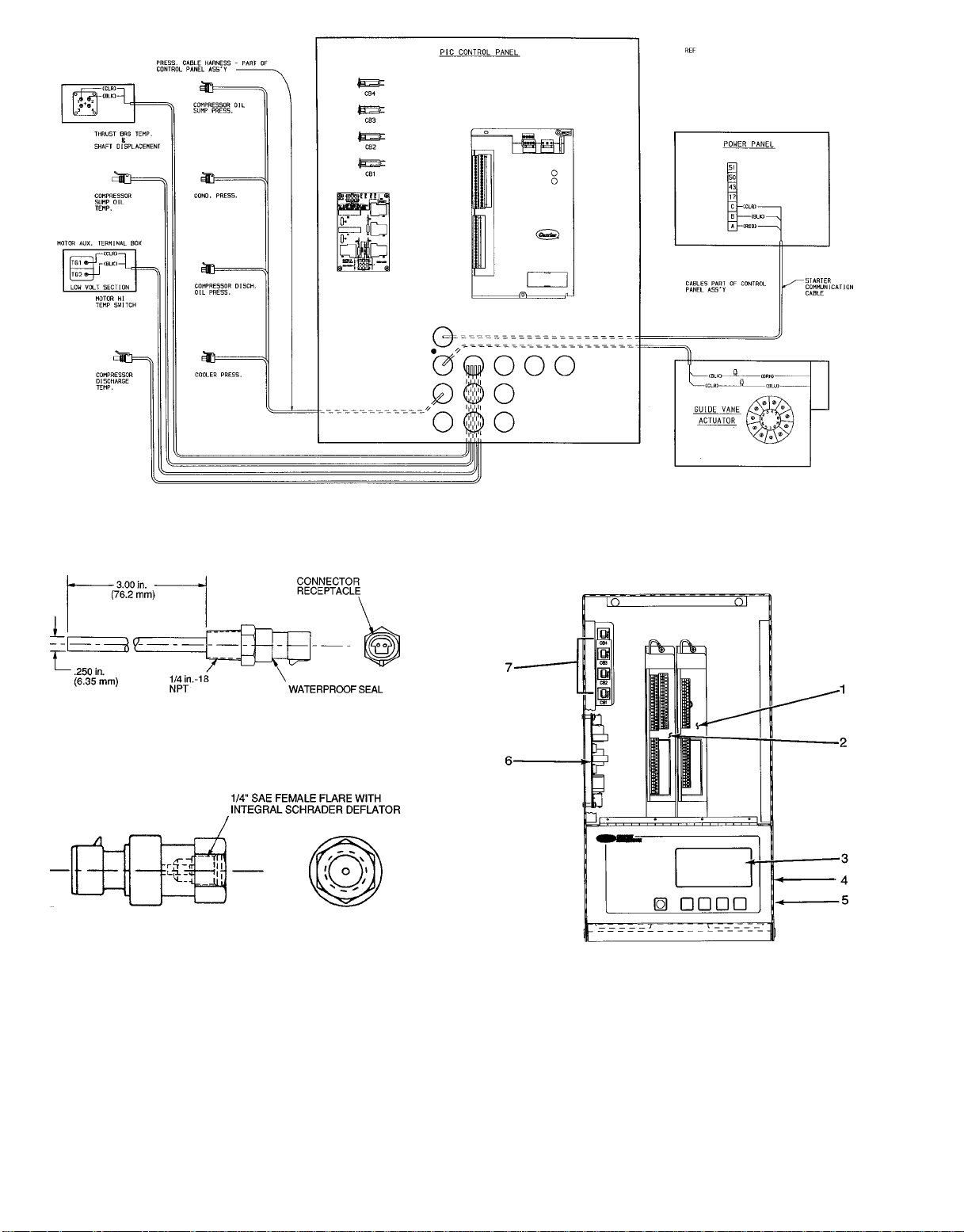

PIC System Components — The Product Integrated

Control (PIC) is the control system on the chiller. See

T able1. The PIC controls the operation of the chiller by monitoring all operating conditions. The PIC can diagnose a problem and let the operator know what the problem is and what

to check. It promptly positions the guide vanes to maintain

leaving chilled water temperature. It can interface with auxiliary equipment such as pumps and cooling tower fans to

turn them on only when required. It continually checks all

safeties to prevent any unsafe operating condition. It also

regulates the oil heater while the compressor is off and the

hot gas bypass valve, if installed. See Fig. 6-10 for the locations of sensors, transducers, and other devices controlled

and/or monitored by the PIC system.

The PIC can be interfaced with the Carrier Comfort

Network (CCN) if desired. It can communicate with other

PIC-equipped chillers and other CCN devices.

The PIC consists of 4 modules housed inside one of 3 locations: the control center, the power panel, or the starter

cabinet. The component names and the control voltage of

each location are listed below (also see Table 1):

• control center

— all extra low-voltage wiring (24 v or less)

REAR

• power panel

— 115 v control voltage

— up to 600 v for oil pump power

• starter cabinet

— chiller power wiring (per job requirement)

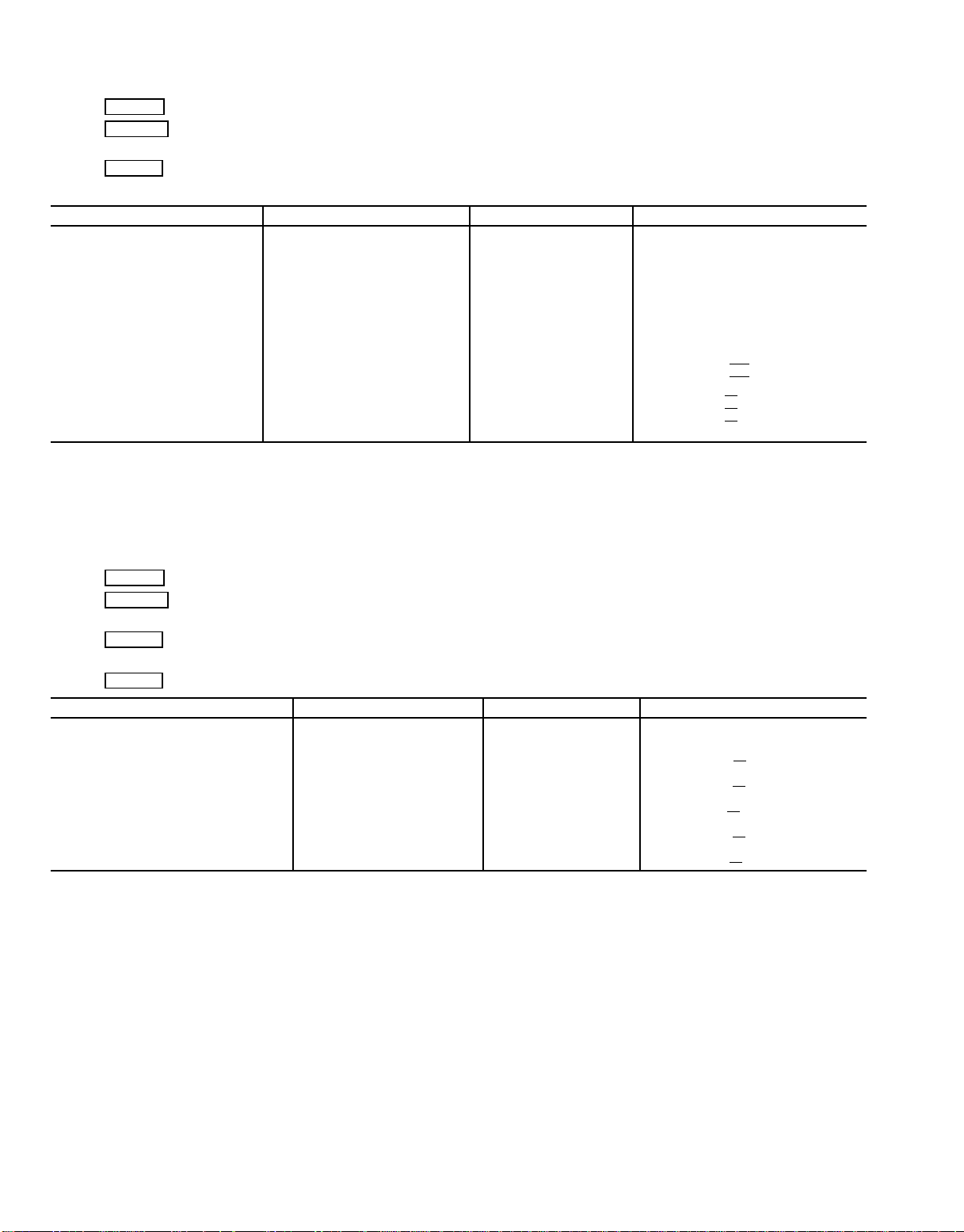

Table 1 — Major PIC Components and

Panel Locations*

PIC COMPONENT

Processor Sensor Input/Output Module

(PSIO)

Starter Management Module (SMM) Starter Cabinet

Local Interface Device (LID) Control Center

6-Pack Relay Board Control Center

8-Input Modules (Optional) Control Center

4-In/2-Out Module Power Panel

Oil Differential Pressure/Power Supply

Module

Oil Heater Contactor (1C) Power Panel

Compressor Oil Pump Contactor (2C) Power Panel

Gear Oil Pump Contactor (5C) Power Panel

Hot Gas Bypass Relay (3C) (Optional) Power Panel

Control Transformers (T1-T4) Power Panel

Control and Oil Heater Voltage Selector (S1) Power Panel

Temperature Sensors See Fig. 7

Pressure Transducers See Fig. 7

*See Fig. 6-10.

PANEL

LOCATION

Control Center

Control Center

1—Gear Oil Pressure Sensor

2—Thrust Bearing Temperature and

Impeller Displacement Cable

3—Discharge Temperature Sensor

4—Guide Vane Conduit and Cable

5—High Pressure Cutout Switch

LEGEND

6—Compressor Oil Cooler

Solenoid Conduit

7—Oil Heater Conduit

8—Motor Space Heater Conduit

9—Gear Oil Temperature Sensor

10 — Motor High Temperature Switch Cable

11 — Motor Water Cooling Leak Detector

12 — Discharge Oil Pressure Sensor

TEWAC — Totally Enclosed Water-to-Air Cooled

Fig. 6 — 17EX Controls and Sensor Locations

12

Cable (TEWAC Motor Only)

Page 13

LEGEND

13 — Condenser Pressure Transducer

14 — Condenser Entering Water

Temperature Sensor

15 — Condenser Entering and Leaving Water

Temperature Cable

16 — Oil Suction Pressure Sensor

17 — Oil Pump Conduit

18 — Oil Pump Sensor

19 — PIC Control Panel

20 — Condenser Leaving Water

Temperature Sensor

21 — Gear Oil Cooler Solenoid Conduit

LEGEND

22 — Cooler Temperature Cable

23 — Cooler Leaving Water Temperature Sensor

24 — Cooler Entering Water Temperature Sensor

25 — Cooler Pressure Sensor

26 — Refrigerant Charging Valve

Fig. 6 — 17EX Controls and Sensor Locations (cont)

13

Page 14

Fig. 6 — 17EX Controls and Sensor Locations (cont)

Fig. 7 — Control Sensors (Temperature)

Fig. 8 — Control Sensors

(Pressure Transducer, Typical)

LEGEND

LID — Local Interface Device

PIC — Product Integrated Controls

PSIO — Processor Sensor Input/Output Module

1—Optional 8-Input Module for Spare Inputs to Control

Interface (One of Two Available)

2—PSIO

3—LID Input/Output Interface Panel Display

4—Oil Differential Pressure/Power Supply Module (Hidden)

5—LID Light (Hidden)

6—6-Pack Relay Board

7—Circuit Breakers (4)

Fig. 9 — Control Center (Front View);

Shown with Options Module

14

Page 15

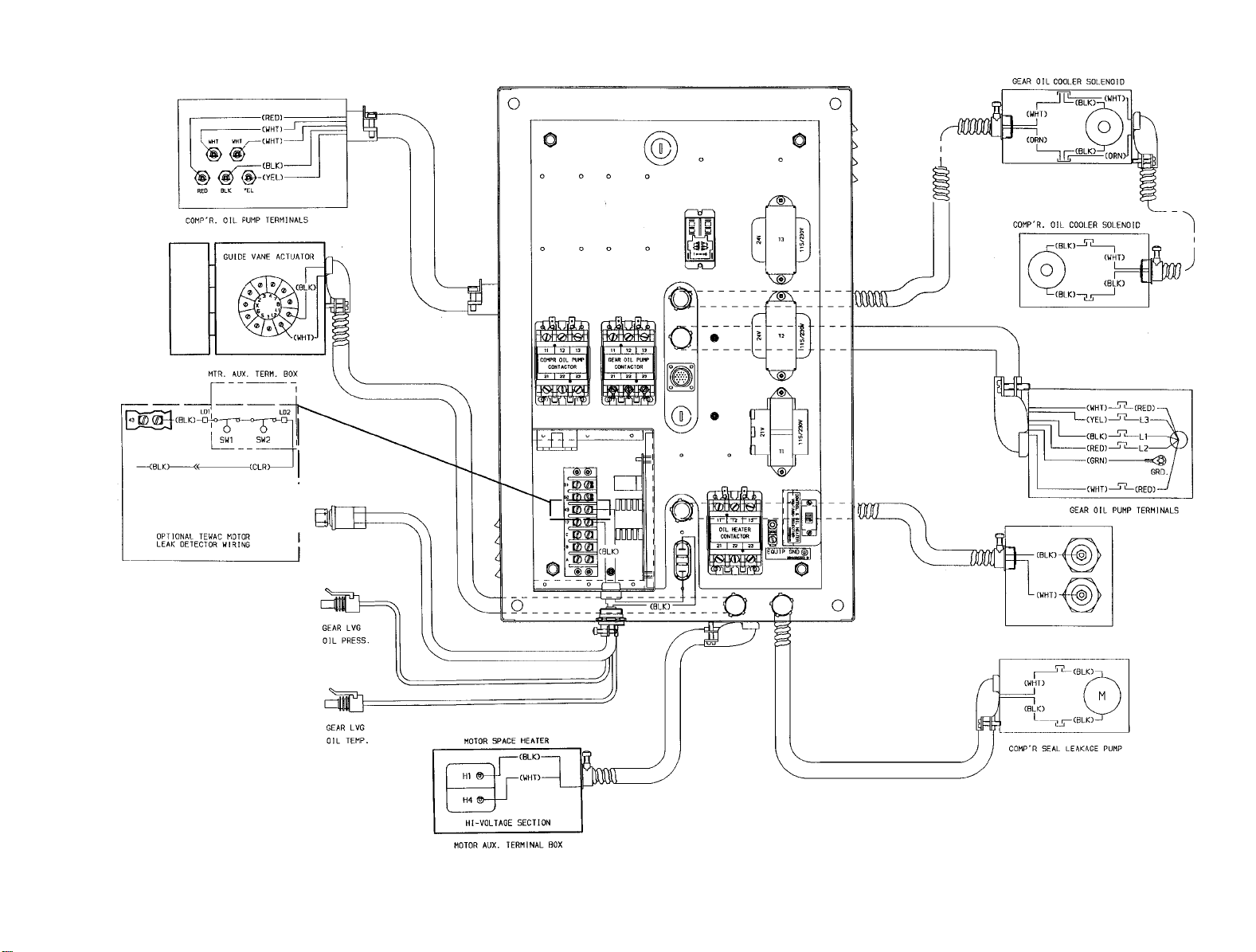

15

LEGEND

EQUIP GND — Equipment Ground

GRD — Ground

M—Motor

TEWAC — Totally Enclosed Water-to-

Air Cooled

Fig. 10 — 17EX Chiller Power Panel and Controls Connections

Page 16

PROCESSOR/SENSOR INPUT/OUTPUT MODULE (PSIO)

— This module contains all the operating software needed

to control the chiller. The 17EX uses 5 pressure transducers

and 8 thermistors to sense pressures and temperatures. These

inputs are connected to the PSIO module. The PSIO also

provides outputs to the guide vane actuator, compressor and

gear oil pumps, oil heater, hot gas bypass (optional), and alarm

contact. The PSIO communicates with the LID, the SMM,

and the optional 8-input modules for user interface and starter

management.

ST ARTER MANAGEMENT MODULE (SMM) — This module is located within the starter cabinet. This module initiates PSIO commands for starter functions such as start/

stop of the compressor; start/stop of the condenser and chilled

water pumps; start/stop of the tower fan, spare alarm contacts, and the shunt trip. The SMM monitors starter inputs

such as flow switches, line voltage, remote start contact, spare

safety, condenser high pressure, oil pump interlock, motor

current signal, starter 1M and run contacts, and the kW transducer input (optional). The SMM contains logic capable of

safely shutting down the chiller if communication with

the PSIO is lost.

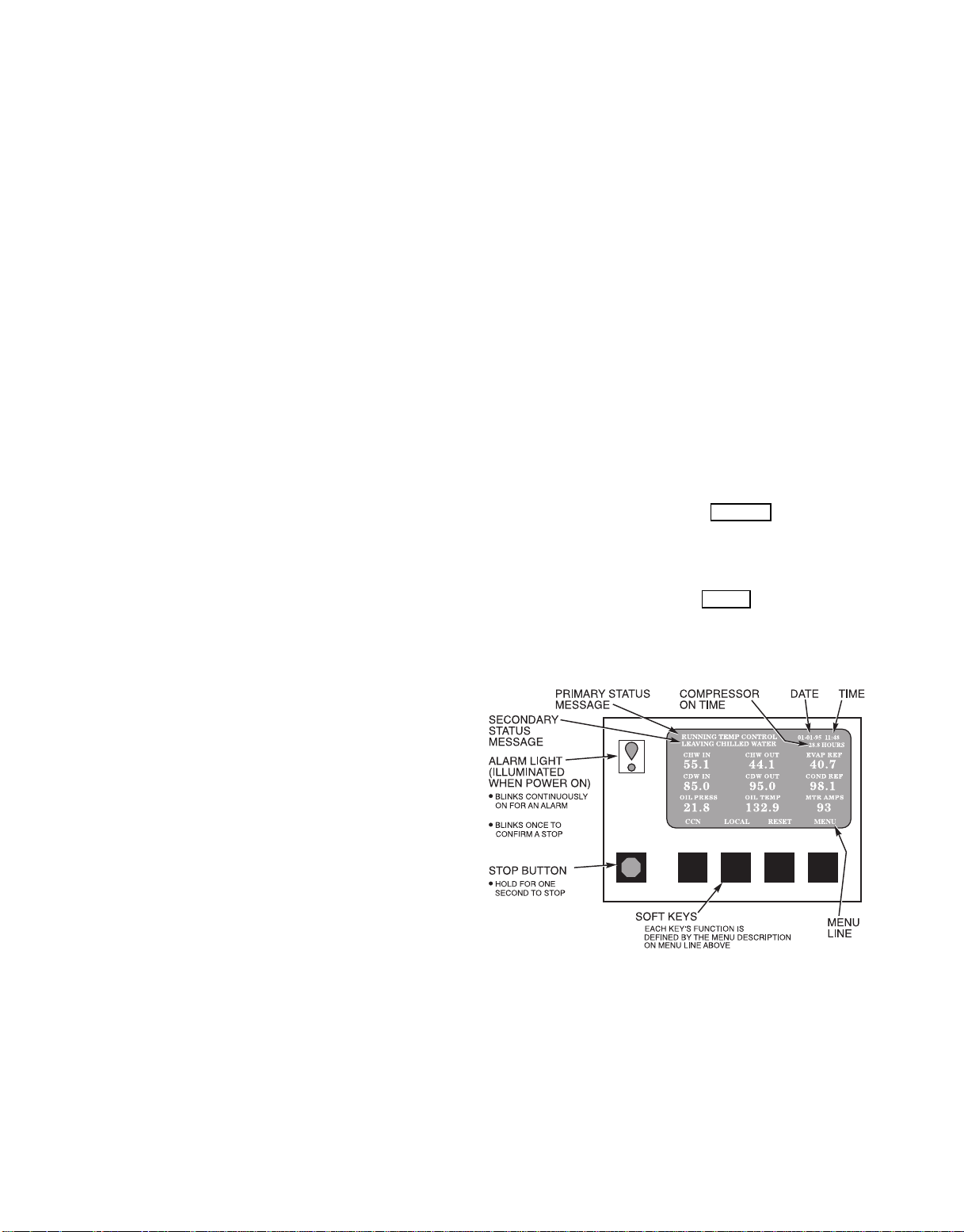

LOCALINTERFACE DEVICE (LID) — The LID is mounted

to the control center and allows the operator to interface with

the PSIO or other CCN devices. It is the input center for all

local chiller set points, schedules, set-up functions, and options. The LID has a STOP button, an alarm light, 4 buttons

for logic inputs, and a display. The function of the 4 buttons

or ‘‘softkeys’’ are menu driven and are shown on the display

directly above the key.

SIX-PACK RELAY BOARD (6-Pack Relay Board) — This

device is a cluster of 6 pilot relays located in the control

center. It is energized by the PSIO for the compressor oil

pump, oil heater, alarm, optional hot gas bypass relay, auxiliary oil pump.

EIGHT-INPUT (8-Input) MODULES — One optional module is factory installed in the control center panel when ordered. There can be up to 2 of these modules per chiller with

8 spare inputs each. They are used whenever chilled water

reset, demand reset, or reading a spare sensor is required.

The sensors or 4 to 20 mA signals are field-installed.

The spare temperature sensors must have the same

temperature/resistance curve as the other temperature sensors on this unit. These sensors are rated 5,000 ohm at 75 F

(25 C).

FOUR-IN/TWO-OUT(4-IN/2-OUT) MODULE —Thismodule monitors and controls the external gear lubrication system. It energizes the gear oil pump and is located in the power

panel.

OIL HEATER CONTACTOR (1C) — This contactor is located in the power panel and operates the heater at 115 v. It

is controlled by the PIC to maintain oil temperature during

chiller shutdown.

COMPRESSOR OILPUMP CONTACTOR(2C)ANDGEAR

OIL PUMP CONTACTOR (5C) — These contactors are located in the power panel. They operate all 200 to 575-v oil

pumps. The PIC energizes the contactor to turn on the oil

pumps as necessary.

HOT GAS BYPASS CONTACTOR RELAY (3C)

(Optional) — This relay, located in the power panel, controls the opening of the hot gas bypass valve. The PIC energizes the relay during low load, high lift conditions.

OIL AUXILIARY RELAY (4C) — This relay opens the oil

cooler solenoid valve and interlocks the oil pump with the

compressor (special order).

CONTROL TRANSFORMERS (T1-T4) — These transformers are located in the power panel and convert

incoming control voltage to either 21 vac power for the PSIO

module and options modules, or 24 vac power for 3 power

panel contactor relays and a control solenoid valve.

CONTROL AND OIL HEATER VOLTAGE SELECTOR

(S1) — It is necessary to use 115 v incoming control power

in the power panel. The switch must be set to the 115-v

position.

OIL DIFFERENTIAL PRESSURE/POWER SUPPLY

MODULE — This module, which is located in the control

center, provides 5 vdc power for the transducers and LID

backlight. This module outputs the difference between two

pressure transducer input signals. The module subtracts oil

supply pressure from transmission sump pressure and outputs the difference as an oil differentialpressure signal to the

PSIO. The PSIO converts this signal to differential oil pressure. To calibrate this reading, refer to the Troubleshooting,

Checking Pressure Transducers section on page 84.

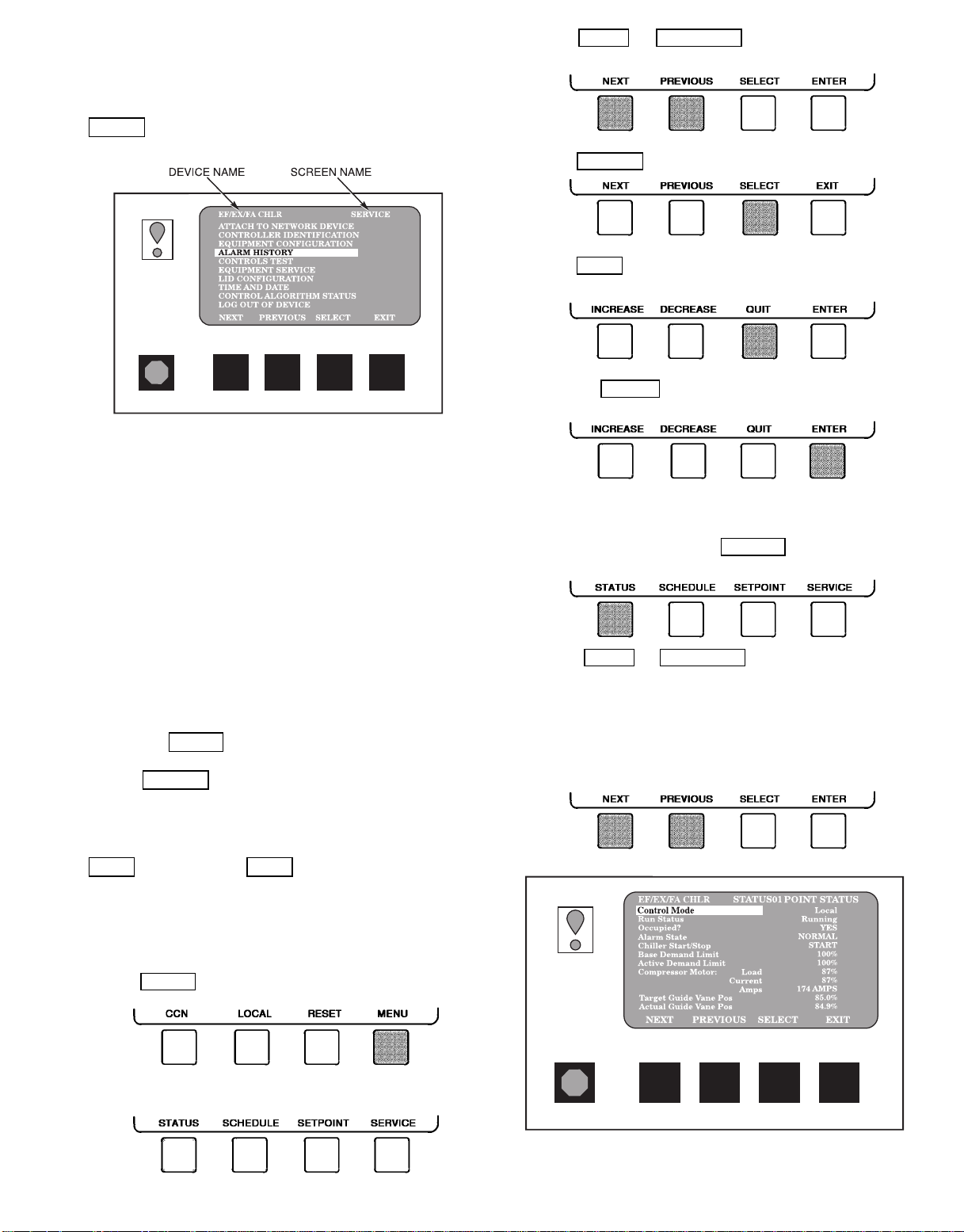

LID Operation and Menus (Fig. 11-17)

GENERAL

• The LID display automatically reverts to the default screen

(Fig. 11) after 15 minutes if no softkey activity takes place

and if the chiller is not in PUMPDOWN mode

• When not displaying the default screen, the upper righthand corner of the LID displays the name of the screen

that you have entered (Fig. 12).

• The LID may be configured in English or SI units, through

the LID configuration screen.

• Local Operation — Pressing the LOCAL

the PIC in LOCAL operation mode, and the control ac-

cepts modification to programming from the LID only. The

PIC uses the Local Time Schedule to determine chiller start

and stop times.

• CCN Operation — Pressing the CCN softkey places the

PIC in the CCN operation mode, and the control accepts

modifications from any CCN interface or module (with the

proper authority), as well as the LID. The PIC uses the

CCN time schedule to determine start and stop times.

Fig. 11 — LID Default Screen

ALARMS AND ALERTS — An alarm (*) or alert (!) status

is indicated on the default screen and the status tables. An

alarm (*) shuts down the compressor. An alert (!) notifies

the operator that an unusual condition has occurred. The chiller

continues to operate when an alert is shown.

Alarms are indicated when the control center alarm light

(!) flashes. The primary alarm message is viewed on the default screen and an additional, secondary, message and

troubleshooting information are sent to the ALARM HISTORY table.

softkey places

16

Page 17

NOTE: When an alarm is detected, the LID default screen

freezes (stops updating) at the time of alarm. The freeze enables the operator to view the chiller conditions at the time

of the alarm. The status tables show the updated informa-

tion. Once all alarms have been cleared (by pressing the

RESET

softkey), the default LID screen returns to normal

operation.

Fig. 12 — LID Service Screen

LID DEFAULT SCREEN MENU ITEMS — To perform

any of the operations described below, the PIC must be powered up and have successfully completed its self test.

The default screen menu selection offers four options

(STATUS, SCHEDULE, SETPOINT, and SERVICE). The

STATUS menu allows viewing and limited calibration/

modification of control points and sensors, relays and contacts, and the options board. The SCHEDULE menu allows

viewing and modification of the Local Control, CCN Control, and Ice Build time schedules. Numerous set points including Base Demand Limit, LCW, ECW, and Ice Build can

be adjusted under the SETPOINT menu. The SERVICE menu

can be used to revise alarm history, control test, control algorithm status, equipment configuration, equipment service,

time and date, attach to network, log out of device, controller identification, and LID configurations. Figures 15 and 16

provide additional information on the menu structure.

Press the MENU

softkey to select from the 4 options.

To view or change parameters within any menu structure,

use the SELECT

softkey to choose the desired table or

item. The softkey modification choices displayed will depend on whether the selected item is a discrete point, analog point, or an override point. Press the softkey that corresponds to your configuration selection or press the

QUIT softkey. If the QUIT softkey is depressed, the

configuration will not be modified. Use the following softkeys to access and select the desired section.

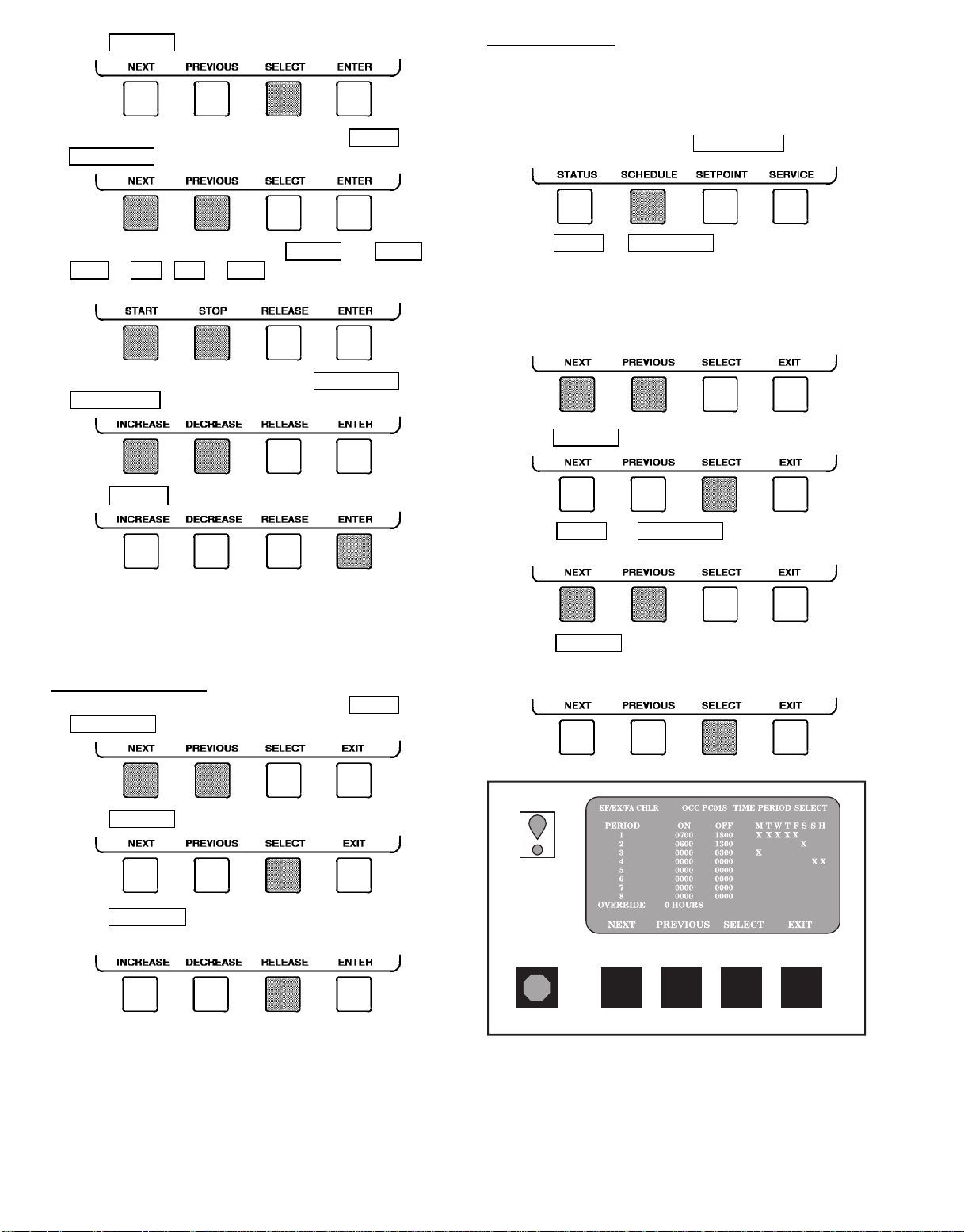

MENU STRUCTURE — To perform any of the operations

described below, the PIC must be powered up and have successfully completed its self test.

• Press MENU

to select from the four available options.

• Press NEXT or PREVIOUS to highlight the desired

entry.

• Press SELECT to access the highlighted point.

• Press QUIT to leave the selected decision or field without saving any changes.

• Or, press ENTER to leave the selected decision or field

and save changes.

TOVIEWOR CHANGE POINT STATUS (Fig. 13) — Point

Status is the actual value of all of the temperatures, pressures, relays, and actuators sensed and controlled by the PIC.

1. On the Menu screen, press STATUS

to view the list of

Point Status tables.

2. Press NEXT or PREVIOUS to highlight the desired

status table. The list of tables is:

• STATUS01 — Status of control points and sensors

• STATUS02 — Status of relays and contacts

• STATUS03 — Status of both optional 8-input modules

and sensors

• STATUS04 — Gear oil temperature and pressure

• Press the softkey that corresponds to the desired menu

structure.

Fig. 13 — Example of Point Status Screen

(Status01)

17

Page 18

3. Press SELECT to view the desired Point Status table.

4. On the Point Status table press NEXT or

PREVIOUS

until desired point is displayed on the screen.

Override Indication — An override value is indicated by

‘ ‘SUPVSR,’’‘‘SERVC,’’or ‘‘BEST’’ flashing next to the point

value on the Status table.

TO VIEW OR CHANGE TIME SCHEDULE OPERATION

(Fig. 14)

1. On the Menu screen, press SCHEDULE

.

For Discrete Points — Press START or STOP ,

or NO ,ONor OFF , etc. to select the desired

YES

state.

For Analog Points — Press INCREASE or

DECREASE

to select the desired value.

5. Press ENTER to register new value.

OVERRIDE OPERATIONS

NOTE: When overriding or changing metric values, it is nec-

essary to hold the softkey down for a few seconds in order

to see a value change, especially on kilopascal values.

To Remove an Override

1. On the Point Status table press NEXT or

PREVIOUS

to highlight the desired point.

2. Press NEXT or PREVIOUS to highlight one of the

following schedules.

OCCPC01S — LOCAL Time Schedule

OCCPC02S — ICE BUILD Time Schedule

OCCPC03-99S — CCN Time Schedule (Actual

number is defined in CONFIG table.)

3. Press SELECT to access and view the time schedule.

4. Press NEXT or PREVIOUS to highlight the desired period or override that you wish to change.

5. Press SELECT to access the highlighted period or

override.

2. Press SELECT to access the highlighted point.

3. Press RELEASE to remove the override and return the

point to the PIC’s automatic control.

Fig. 14 — Example of Time Schedule

Operation Screen

18

Page 19

CCN

Start Chiller In CCN Control

Start Chiller In Local Control

DEFAULT SCREEN

LOCAL RESET

MENU

(SOFTKEYS)

Clear Alarms

NEXT

NEXT

START

INCREASE

ENABLE

STATUS

List the

Status Tables

STATUS

STATUS

STATUS

STATUS

PREVIOUS

PREVIOUS

STOP RELEASE

DECREASE

DISABLE

SCHEDULE SETPOINT

01

02

03

04

SELECT

SELECT

RELEASE

RELEASE

Access Main Menu

SERVICE

EXIT

EXIT

ENTER

ENTER

ENTER

(SELECT A T ABLE)

(SELECT A POINT

ON THE TABLE)

(MODIFY A

DISCRETE POINT) or

(MODIFY AN

ANALOG POINT) or

(MODIFY CONTROL

OPTIONS)

Select a Schedule

NEXT

Select a Time Period/Override

NEXT

Modify a Schedule Time

INCREASE

Add/Eliminate a Day

ENABLE

123

List the Schedules

OCCPC01S - Local Time Schedule

OCCPC02S - Ice Build Time Schedule

OCCPC03S-99S - CCN Time Schedule

(ENTER A 4-DIGIT PASSWORD)

4

Select the Setpoint

Modify the Setpoint

1

2

3

4

5

6

7

8

Override

SELECT

SELECT

ENTER

ENTER

PREVIOUS

PREVIOUS

DECREASE

DISABLE

Display the Setpoint Table

NEXT

INCREASE

•

Base Demand Limit

•

LCW Setpoint

•

ECW Setpoint

•

Ice Build Setpoint

PREVIOUS

DECREASE

EXIT

EXIT

EXIT

EXIT

(ANALOG VALUES)

(DISCRETE VALUES)

List the Service Tables

SELECT

QUIT

EXIT

ENTER

Select a Service Table

NEXT

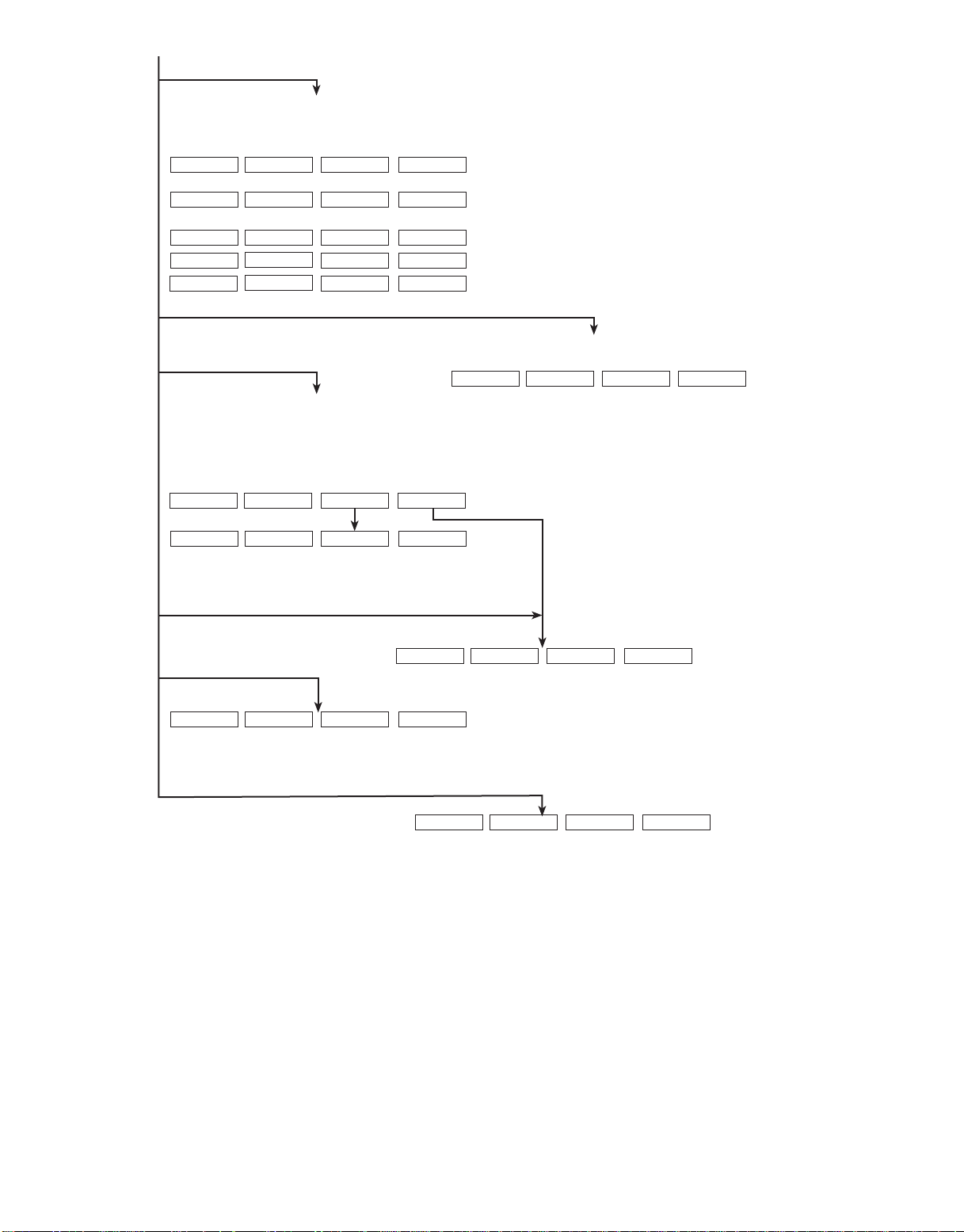

Fig. 15 — 17EX LID Menu Structure

19

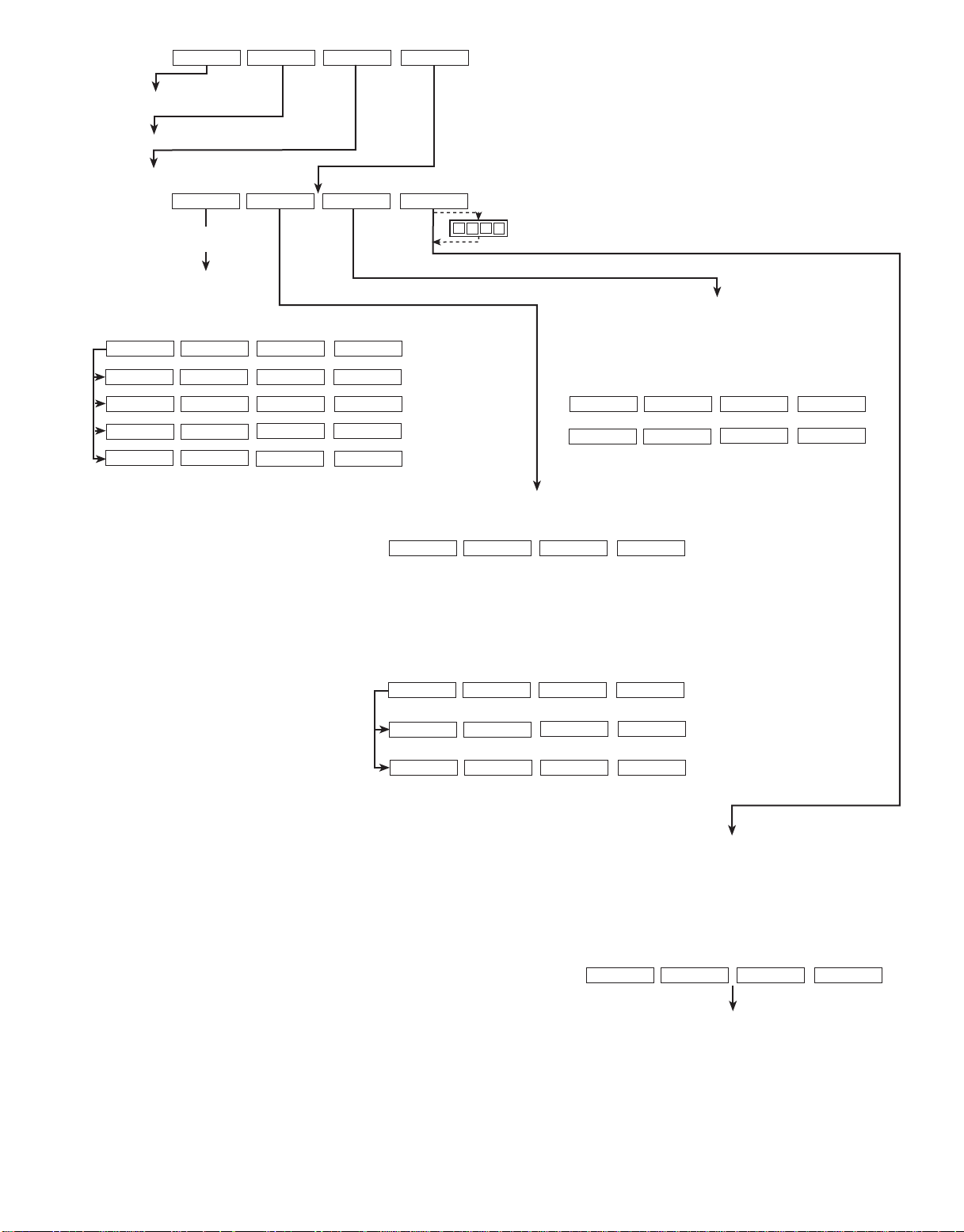

• ALARM HISTORY

• CONTROL TEST

• CONTROL ALGORITHM STATUS

• EQUIPMENT CONFIGURATION

• EQUIPMENT SERVICE

• TIME AND DATE

• ATTACH TO NETWORK DEVICE

• LOG OUT OF DEVICE

• CONTROLLER IDENTIFICATION

• LID CONFIGURATION

PREVIOUS

SEE FIGURE 16

SELECT

EXIT

Page 20

SERVICE TABLE

NEXT

PREVIOUS

ALARM HISTORY

CONTROL TEST

CONTROL ALGORITHM STA TUS

List the Control Algorithm Status Tables

MAINT01 (Capacity Control)

MAINT02 (Override Status)

MAINT03 (Surge/HGBP Status)

MAINT04 (Lead/Lag Status)

WSMDEFME (Water System Manager Control Status)

OCCDEFM (Time Schedule Status)

SELECT

Display Alarm History

(The table holds up to 25 alarms

and alerts with the last alarm at

the top of the screen.)

EXIT

List the Control Tests

Select a Test

NEXT

• Automated T est

• PSIO Thermistors

• Options Thermistor

• Transducers

• Guide Vane Actuator

• Pumps

• Discrete Outputs

• Pumpdown Lockout

• Terminated Lockout

• FX Gear Oil Pump I/O

PREVIOUS

SELECT

EXIT

Select a Table:

NEXT

OCCDEFM (Time Schedule Status)

Data Select Table

NEXT

EQUIPMENT CONFIGURATION List the Equipment Configuration Tables

PREVIOUS

PREVIOUS

OCCPC01S (Local Status)

OCCPC02S (CCN, ICE BUILD Status)

OCCPC03S (CCN Status)

SELECT

SELECT

EXIT

MAINT01 (Capacity Control Algorithm)

MAINT02 (Override Status)\

MAINT03 (Surge/HGBP Status)

MAINT04 (LEAD/LAG Status)

WSMDEFM2 (Water System Manager Control Status)

EXIT

Maintenance T able Data

• CONFIG

• LEAD/LAG

• OCCDEFCS

• HOLIDEF

• BRODEF

• WSMALMDF

• ALARMDEF

• CONS_DEF

• RUNT_DEF

Select a Table

NEXT

PREVIOUS

SELECT

EXIT

CONTINUED

ON NEXT PAGE

Select a Parameter

NEXT

Modify a Parameter

INCREASE

ENABLE

YES

PREVIOUS

DECREASE

DISABLE

NO

Fig. 16 — 17EX Service Menu Structure

20

SELECT

QUIT

QUIT

QUIT

EXIT

ENTER

ENTER

ENTER

(ANALOG

VALUES)

(DISCRETE

VALUES)

(DISCRETE

VALUES)

Page 21

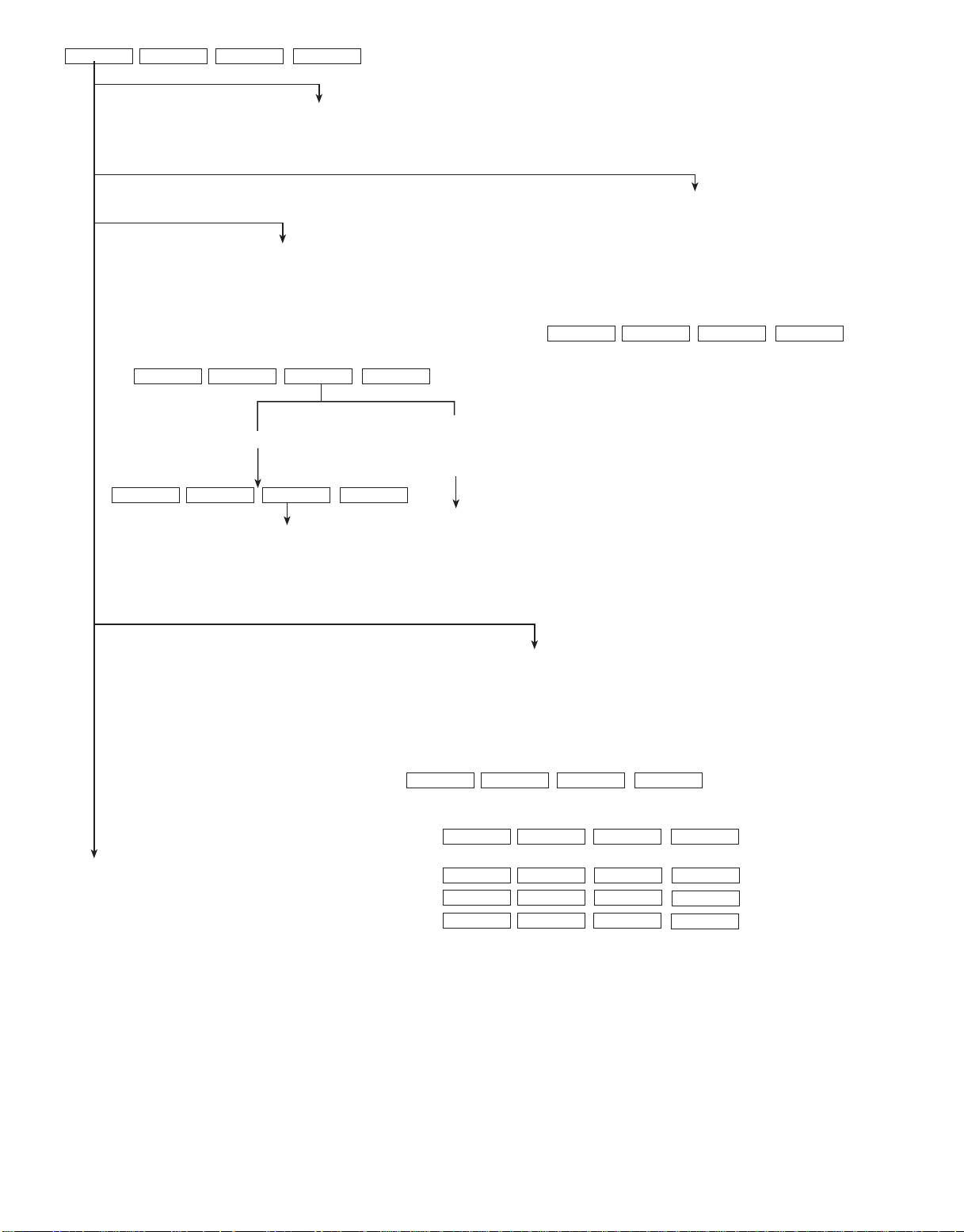

SERVICE MENU CONTINUED

FROM PREVIOUS PAGE

EQUIPMENT SERVICE (See Table 2, Examples 8, 9, and 10)

Service Tables: (See Note)

• SERVICE1

• SERVICE2

• SERVICE3

Select a Service Table

NEXT

Select a Service Table Parameter

NEXT

Modify a Service Table Parameter

INCREASE

ENABLE

NO

TIME AND DATE

ATTACH TO NETWORK DEVICE

Select a Device

NEXT

Modify Device Address

INCREASE

• Use to attach LID to another CCN network or device

• Attach to "LOCAL" to enter this machine

• To upload new tables

PREVIOUS

PREVIOUS

DECREASE

DISABLE

YES

List Network Devices

• Local

• Device 1

• Device 2

• Device 3

• Device 4

• Device 5

PREVIOUS

DECREASE

SELECT

SELECT

QUIT

QUIT

QUIT

• Device 6

• Device 7

• Device 8

• Device 9

SELECT

ENTER

EXIT

EXIT

ENTER

ENTER

ENTER

ATTACH

EXIT

(ANALOG VALUES)

(DISCRETE VALUES)

(DISCRETE VALUES)

Display Time and Date Table:

• To Modify — Time — Day of Week

INCREASE

DECREASE

— Date — Holiday Today

ENTER

EXIT

LOG OUT OF DEVICE

CONTROLLER IDENTIFICATION

PSIO Controller

Identification Table

INCREASE

• To modify — PSIO CCN Address • To View — PSIO Software Version

LID CONFIGURATION

DECREASE

LEGEND

CCN — Carrier Comfort Network

HGBP — Hot Gas Bypass

LID — Local Interface Device

NOTE: SERVICE TABLES:

SERVICE1: — Capacity Override

— Type of Chilled Medium

— Alert Temperature

— Flow Verification

— Deadband

— Recycle Restart Time

— Surge/HGBP Operation

— Motor Voltage, RLA, and Frequency

— Starter Type

— Condenser Freeze Safety

— Soft Stop Configuration

— Start to Stop Timer

— Gear Oil Pump Configuration

ENTER

Default Screen

CCN

EXIT

(last 2 digits on part number indicate software version)

LID Configuration Table

INCREASE

• To Modify — LID CCN Address

LOCAL

DECREASE

— English or S.I. Metric Units

— Password

RESET

ENTER

SERVICE2: — 8-input Modules

SERVICE3: — Proportional Inc each Band

MENU

— 20 mA Power Source

— Proportional Dec each Band

— Proportional ECW Gain

— Maximum Guide Vane Opening

EXIT

• To View — LID Software Version

(last 2 digits of part number

indicate software version)

Fig. 16 — 17EX Service Menu Structure (cont)

21

Page 22

6. a. Press INCREASE or DECREASE to change the

time values. Override values are in one-hour incre-

ments, up to 4 hours.

b. Press ENABLE to select days in the day-of-week

fields. Press DISABLE

to eliminate days from the

period.

7. Press ENTER to register the values and to move

horizontally (left to right) within a period.

8. Press EXIT to leave the period or override.

9. Either return to Step 4 to select another period or

override, or press EXIT

again to leave the cur-

rent time schedule screen and save the changes.

4. Press SELECT to modify the highlighted set point.

5. Press INCREASE or DECREASE to change the selected set point value.

6. Press ENTER to save the changes and return to the

previous screen.

10. Holiday Designation (HOLIDEF table) may be found in

the Service Operation section, page 42.You must assign

the month, day, and duration for the holiday.The Broadcast function in the BRODEF table also must be enabled for holiday periods to function.

TO VIEW AND CHANGE SET POINTS (Fig. 17)

1. To view the Set Point table, at the Menu screen press

SETPOINT

.

2. There are 4 set points on this screen: Base Demand Limit;

LCW Set Point (leaving chilled water set point); ECW

Set Point (entering chilled water set point); and ICE BUILD

set point. Only one of the chilled water set points can be

active at one time, and the type of set point is activated

in the Service menu. ICE BUILD is also activated and

configured in the Service menu.

3. Press NEXT or PREVIOUS to highlight the desired

set point entry.

Fig. 17 — Example of Set Point Screen

SERVICE OPERATION — To view the menu-driven programs available for Service Operation, see the Service Operation section, page 42. For examples of LID display screens,

see Table 2.

LEGEND FOR TABLE 2 — LID DISPLAY DATA

CCN — Carrier Comfort Network

CHWR — Chilled Water Return

CHWS — Chilled Water Supply

Compr — Compressor

Dec — Decrease

Ecw — Entering Chilled Water

HGBP — Hot Gas Bypass

Inc — Increase

LCW — Leaving Chilled Water

mA — Milliamps

P—Pressure

PIC — Product Integrated Controls

Refrig — Refrigerant

T—Temperature

Temp — Temperature

22

Page 23

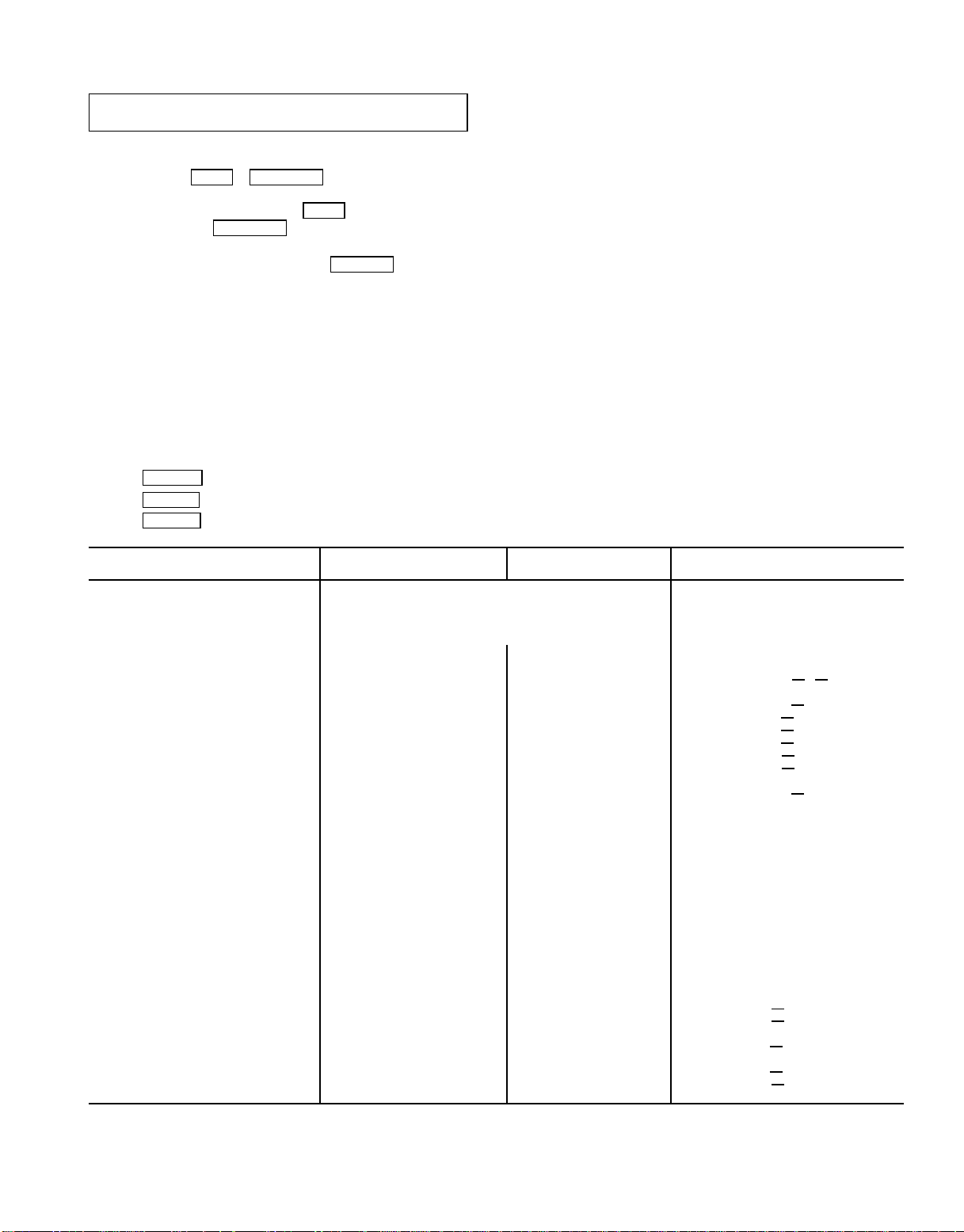

Table 2 — LID Display Data

NOTES:

IMPORTANT: The following notes apply to all Table 2

examples.

1. Only 12 lines of information appear on the LID screen at any one

time. Pressthe NEXT

or to view items below or above the current screen. If you have a

chiller with a backlit LID, press the NEXT

forward; press the PREVIOUS

2. Toaccess the information shown in Examples 6 through 14, enter

your 4-digit password after pressing the SERVICE

softkeys arepressed for 15 minutes, the LIDautomatically logs off

(to prevent unrestricted access to PIC controls) and reverts to the

default screen. If this happens, you must reenter your password

to access the tables shown in Examples 6 through 14.

3. Termsin the Description column of these tables are listed as they

appear on the LID screen.

4. The LID may be configured in English or Metric (SI) units using

theLIDCONFIGURATIONscreen. See the ServiceOperation section, page 42, for instructions on making this change.

To access this display from the LID default screen:

1. Press MENU

2. Press STATUS

3. Press SELECT

or PREVIOUS softkey to highlightapoint

softkey twice to page

softkey twice to page back.

softkey.If no

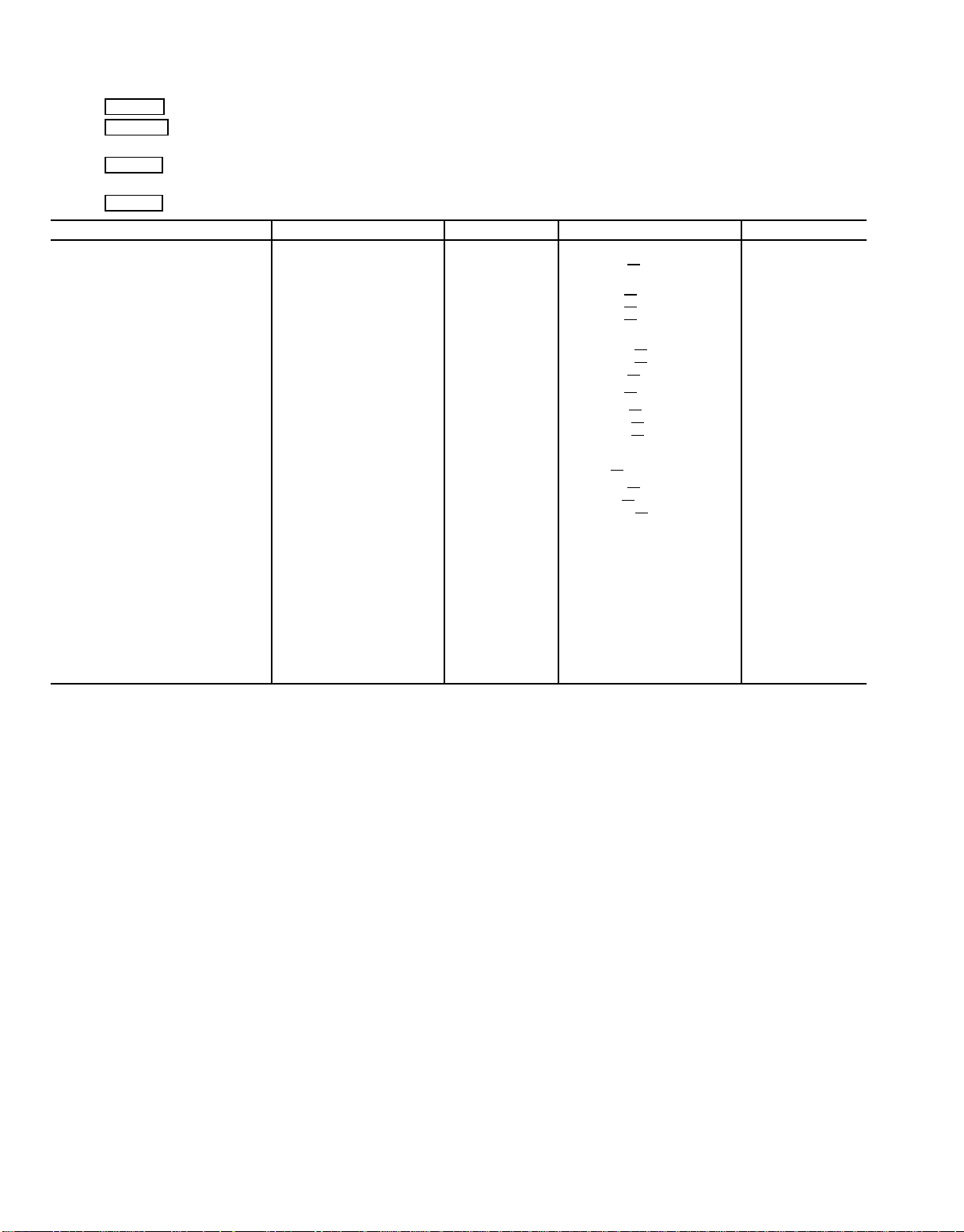

EXAMPLE1—STATUS01 DISPLAY SCREEN

.

(STATUS01 will be highlighted).

.

5. The items in the Reference Point Name column

the LID screen

Building Supervisor software. They are listed in these tables as a

convenience to the operator if it is necessary to cross reference

CCN/BS documentation or use CCN/BS programs. For more information, see the 17EX CCN literature.

6. Reference Point Names shown in these tables in all capital letters

can be read by CCN and Building Supervisor software. Of these

capitalized names, those preceded by an asterisk can also be

changed (that is, written to) by the CCN, Building Supervisor software and the LID. Capitalized Reference Point Names preceded

by two asterisks can be changed only from the LID. Reference

Point Names in lower case type can be viewed by CCN or Building Supervisor software only by viewing the whole table.

7. Alarms and Alerts: An asterisk

screen

tion point in the far right field of the LID screen indicates an alert

state. The asterisk (or exclamation point) indicates that the value

on that line has exceeded (or is approaching) a limit. For more

information on alarms and alerts, see the Alarms and Alerts section, page 16.

. They are data or variable names used in CCN or

in the far right field of a LID status

indicates that the chiller is in an alarm state; an exclama-

do not appear on

DESCRIPTION RANGE UNITS

Control Mode Reset.Off. Local. CCN MODE

Run Status Timeout. Recycle. Startup. STATUS

Occupied ? No/Yes OCC

Alarm State Normal/Alarm ALM

*Chiller Start/Stop Stop/Start CHIL S S

Base Demand Limit 40-100 % DLM

*Active Demand Limit 40-100 % DEM LIM

Compressor Motor Load 0-999 % CA L

Current 0-999 % CA P

Amps 0-9999 AMPS CA A

*Target Guide Vane Pos 0-100 % GV TRG

Actual Guide Vane Pos 0-100 % GV ACT

Water/Brine: Setpoint 10-120 (–12.2-48.9) DEG F (DEG C) SP

* Control Point 10-120 (–12.2-48.9) DEG F (DEG C) LCW STPT

Entering Chilled Water –40-245 (–40-118) DEG F (DEG C) ECW

Leaving Chilled Water –40-245 (–40-118) DEG F (DEG C) LCW

Entering Condenser Water –40-245 (–40-118) DEG F (DEG C) ECDW

Leaving Condenser Water –40-245 (–40-118) DEG F (DEG C) LCDW

Evaporator Refrig Temp –40-245 (–40-118) DEG F (DEG C) ERT

Evaporator Pressure –6.7-420 (–46-2896) PSI (kPa) ERP

Condenser Refrig Temp –40-245 (–40-118) DEG F (DEG C) CRT

Condenser Pressure –6.7-420 (–46-2896) PSI (kPa) CRP

Discharge Temperature –40-245 (–40-118) DEG F (DEG C) CMPD

Bearing Temperature –40-245 (–40-118) DEG F (DEG C) MTRB

Motor Winding Temp† –40-245 (–40-118) DEG F (DEG C) MTRW

Motor Winding Hi

Temp Cutout

Oil Sump Temperature –40-245 (–40-118) DEG F (DEG C) OILT

Oil Pressure Transducer† –6.7-420 (–46-2896) PSI (kPa) OILP

Oil Pressure** –6.7-420 (–46-2896) PSID (kPad) OILPD

Line Voltage: Percent 0-999 % V P

*Remote Contacts Input Off/On REMCON

Total Compressor Starts 0-65535 c starts

Starts in 12 Hours 0-8 STARTS

Compressor Ontime 0-500000.0 HOURS c hrs

*Service Ontime 0-32767 HOURS S HRS

*Compressor Motor kW 0-9999 kW CKW

†Information is applicable to hermetic chillers (19EX) only.

**Oil pressure is read directly from a differential pressure module on 17EX chillers.

NOTE: values preceded by an asterisk (*) can be forced (changed by an operator) from the LID screen

or from another control device (such as a Carrier Comfort Network [CCN] terminal).

Actual 0-9999 VOLTS V A

Ramping. Running. Demand.

Override. Shutdown. Abnormal.

Pumpdown

Normal/Alarm MTRW

REFERENCE POINT NAME

(ALARM HISTORY)

23

Page 24

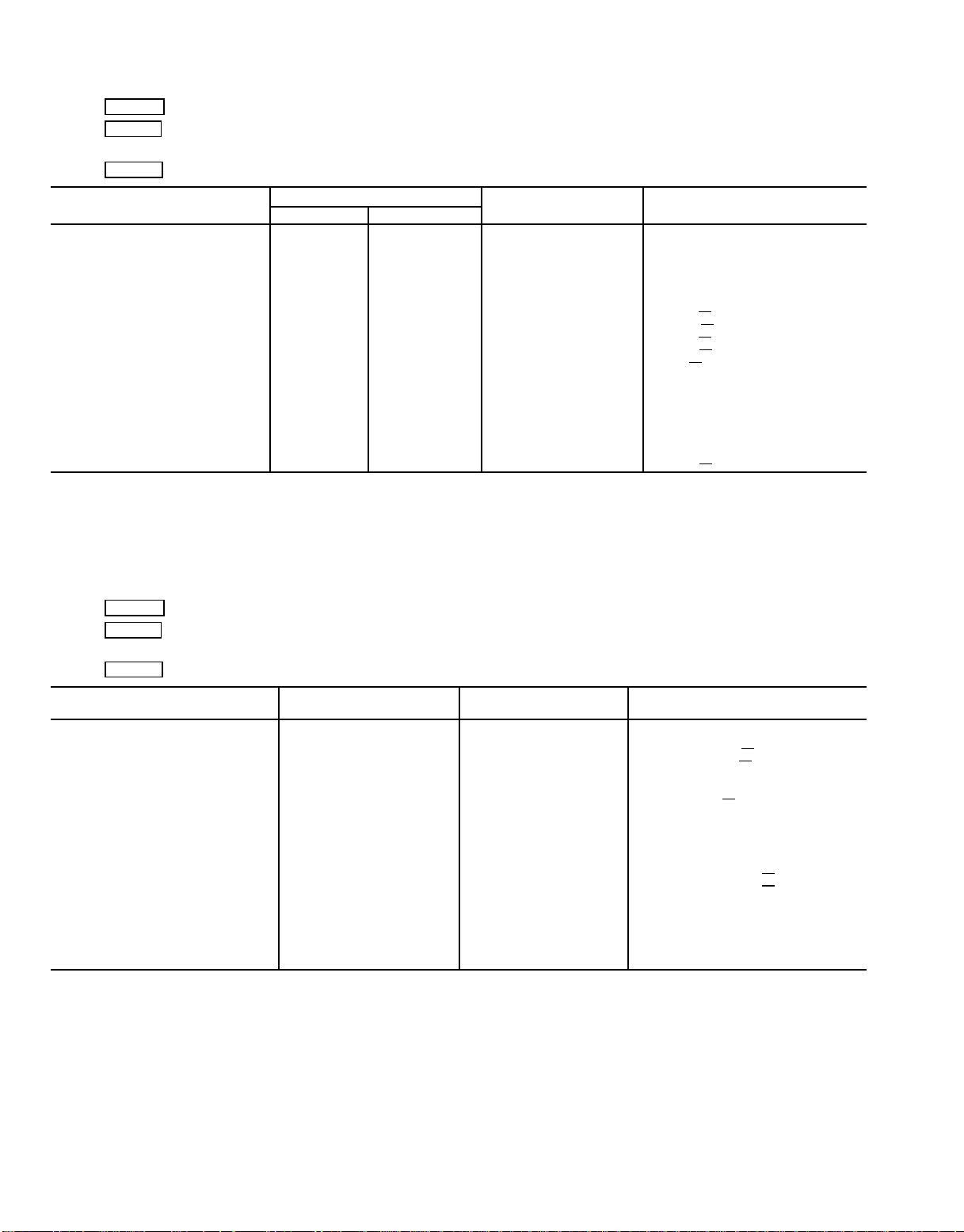

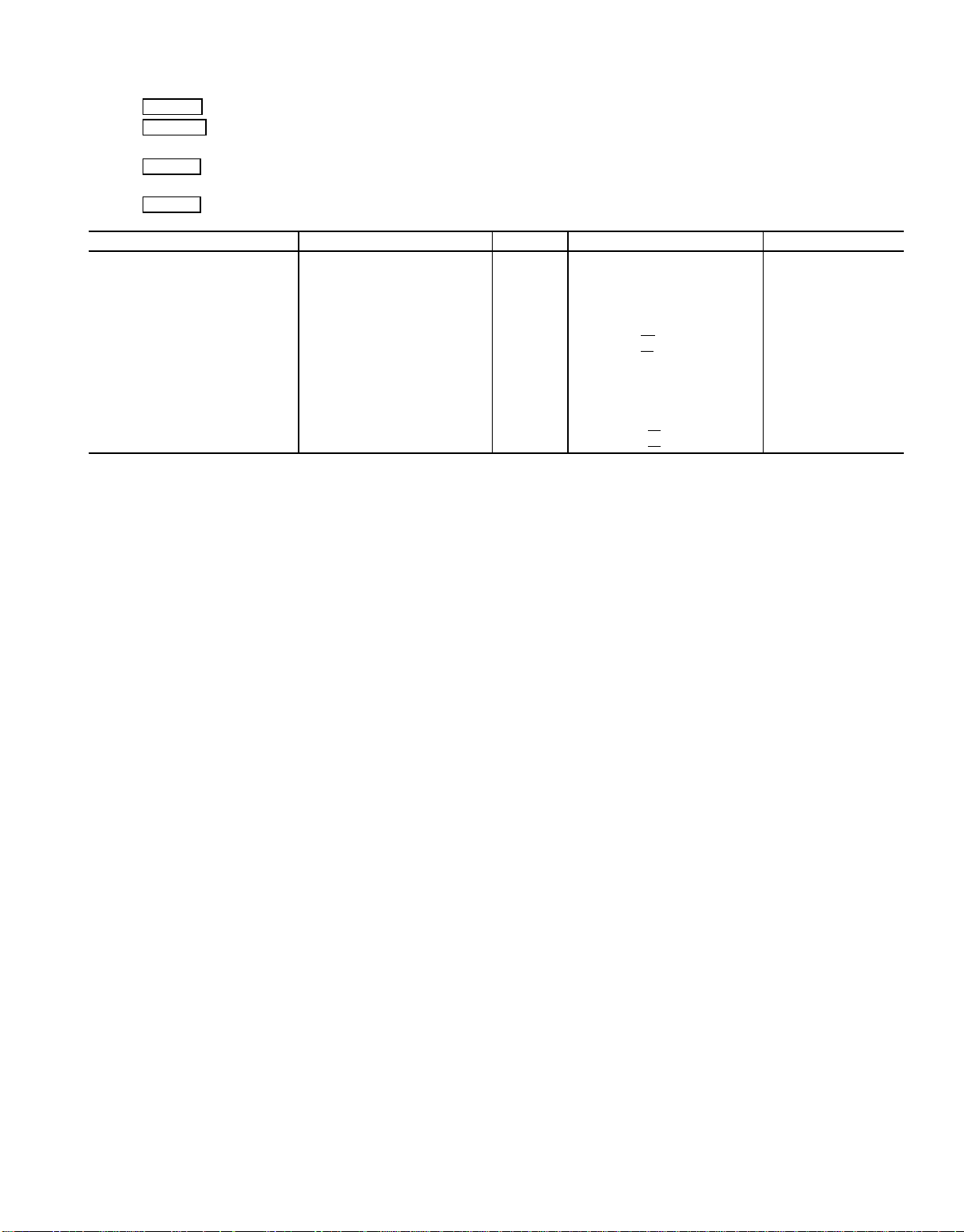

EXAMPLE2—STATUS02 DISPLAY SCREEN

To access this display from the LID default screen:

1. Press MENU

2. Press STATUS

3. Scroll down to highlight STATUS02.

4. Press SELECT

.

.

.

Table 2 — LID Display Data (cont)

DESCRIPTION

Hot Gas Bypass Relay X OFF/ON HGBR

*Chilled Water Pump X OFF/ON CHWP

Chilled Water Flow X NO/YES EVFL

*Condenser Water Pump X OFF/ON CDP

Condenser Water Flow X NO/YES CDFL

Compressor Start Relay X OFF/ON CMPR

Compressor Start Contact X OPEN/CLOSED 1CR AUX

Compressor Run Contact X OPEN/CLOSED RUN AUX

Starter Fault Contact X OPEN/CLOSED STR FLT

Pressure Trip Contact X OPEN/CLOSED PRS TRIP

Single Cycle Dropout X NORMAL/ALARM V1 CYCLE

Oil Pump Relay X OFF/ON OILR

Oil Heater Relay X OFF/ON OILH

Motor Cooling Relay† X OFF/ON MTRC

Auxiliary Oil Pump Relay X OFF/ON AUXOILR

*Tower Fan Relay X OFF/ON TFR

Compr. Shunt Trip Relay X OFF/ON TRIPR

Alarm Relay X NORMAL/ALARM ALM

Spare Prot Limit Input X ALARM/NORMAL SPR PL

†Information is applicable to hermetic machines only.

NOTE: values preceded by an asterisk (*) can be forced (changed by an operator) from the LID screen

or from another control device (such as a Carrier Comfort Network [CCN] terminal).

To access this display from the LID default screen:

1. Press MENU

2. Press STATUS

3. Scroll down to highlight STATUS03.

4. Press SELECT

.

.

.

POINT TYPE

INPUT OUTPUT

EXAMPLE3—STATUS03 DISPLAY SCREEN

UNITS

REFERENCE POINT NAME

(ALARM HISTORY)

DESCRIPTION RANGE UNITS

OPTIONS BOARD 1

*Demand Limit 4-20 mA 4-20 mA DEM OPT

*Temp Reset 4-20 mA 4-20 mA RES OPT

*Common CHWS Sensor –40-245 (–40-118) DEG F (DEG C) CHWS

*Common CHWR Sensor –40-245 (–40-118) DEG F (DEG C) CHWR

*Remote Reset Sensor –40-245 (–40-118) DEG F (DEG C) R RESET

*Temp Sensor — Spare 1 –40-245 (–40-118) DEG F (DEG C) SPARE1

*Temp Sensor — Spare 2 –40-245 (–40-118) DEG F (DEG C) SPARE2

*Temp Sensor — Spare 3 –40-245 (–40-118) DEG F (DEG C) SPARE3

OPTIONS BOARD 2

*4-20 mA — Spare 1 4-20 mA SPARE1 M

*4-20 mA — Spare 2 4-20 mA SPARE2 M

*Temp Sensor — Spare 4 –40-245 (–40-118) DEG F (DEG C) SPARE4

*Temp Sensor — Spare 5 –40-245 (–40-118) DEG F (DEG C) SPARE5

*Temp Sensor — Spare 6 –40-245 (–40-118) DEG F (DEG C) SPARE6

*Temp Sensor — Spare 7 –40-245 (–40-118) DEG F (DEG C) SPARE7

*Temp Sensor — Spare 8 –40-245 (–40-118) DEG F (DEG C) SPARE8

*Temp Sensor — Spare 9 –40-245 (–40-118) DEG F (DEG C) SPARE9

NOTE: values preceded by an asterisk (*) can be forced (changed by an operator) from the LID screen

or from another control device (such as a Carrier Comfort Network [CCN] terminal).

REFERENCE POINT NAME

(ALARM HISTORY)

24

Page 25

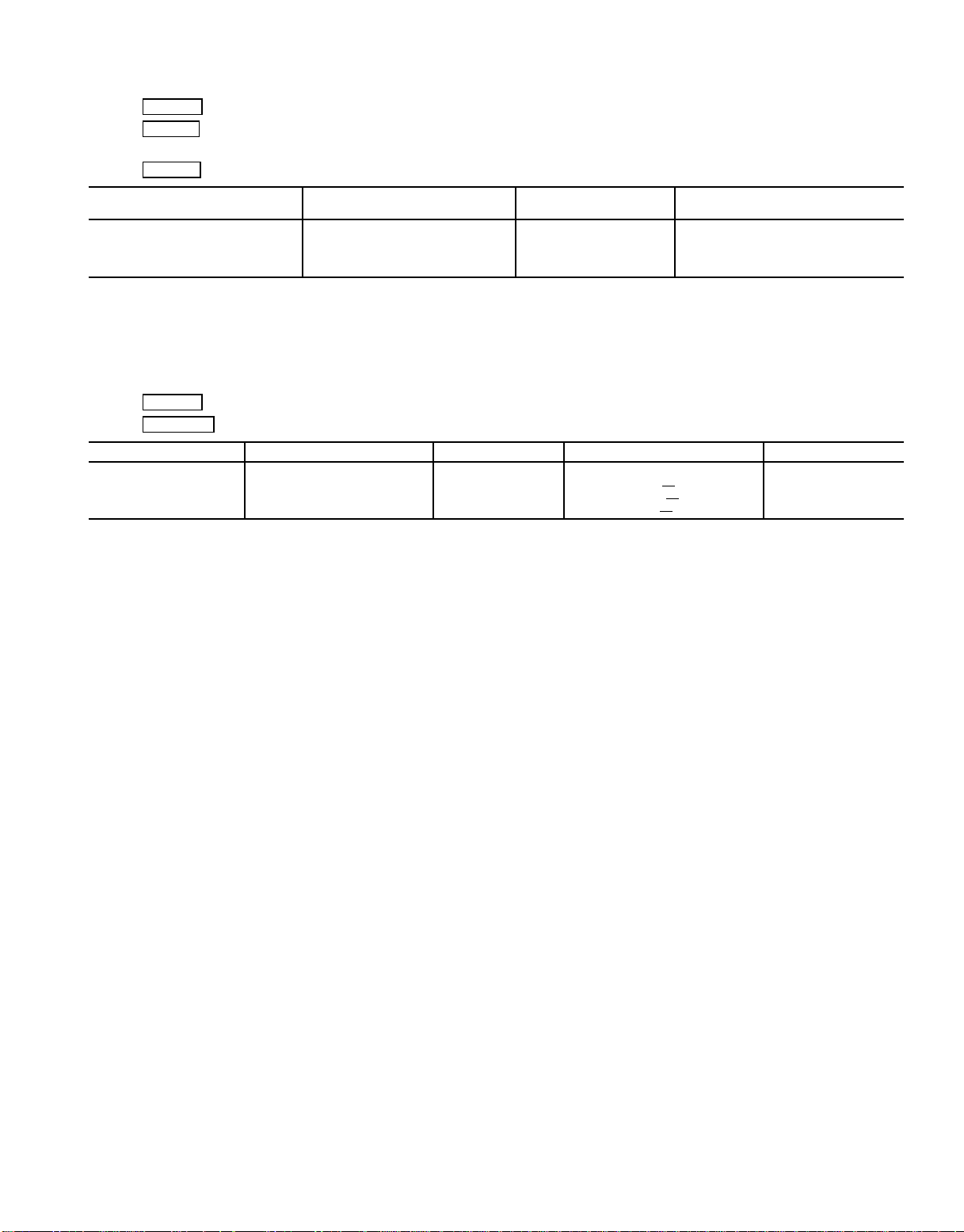

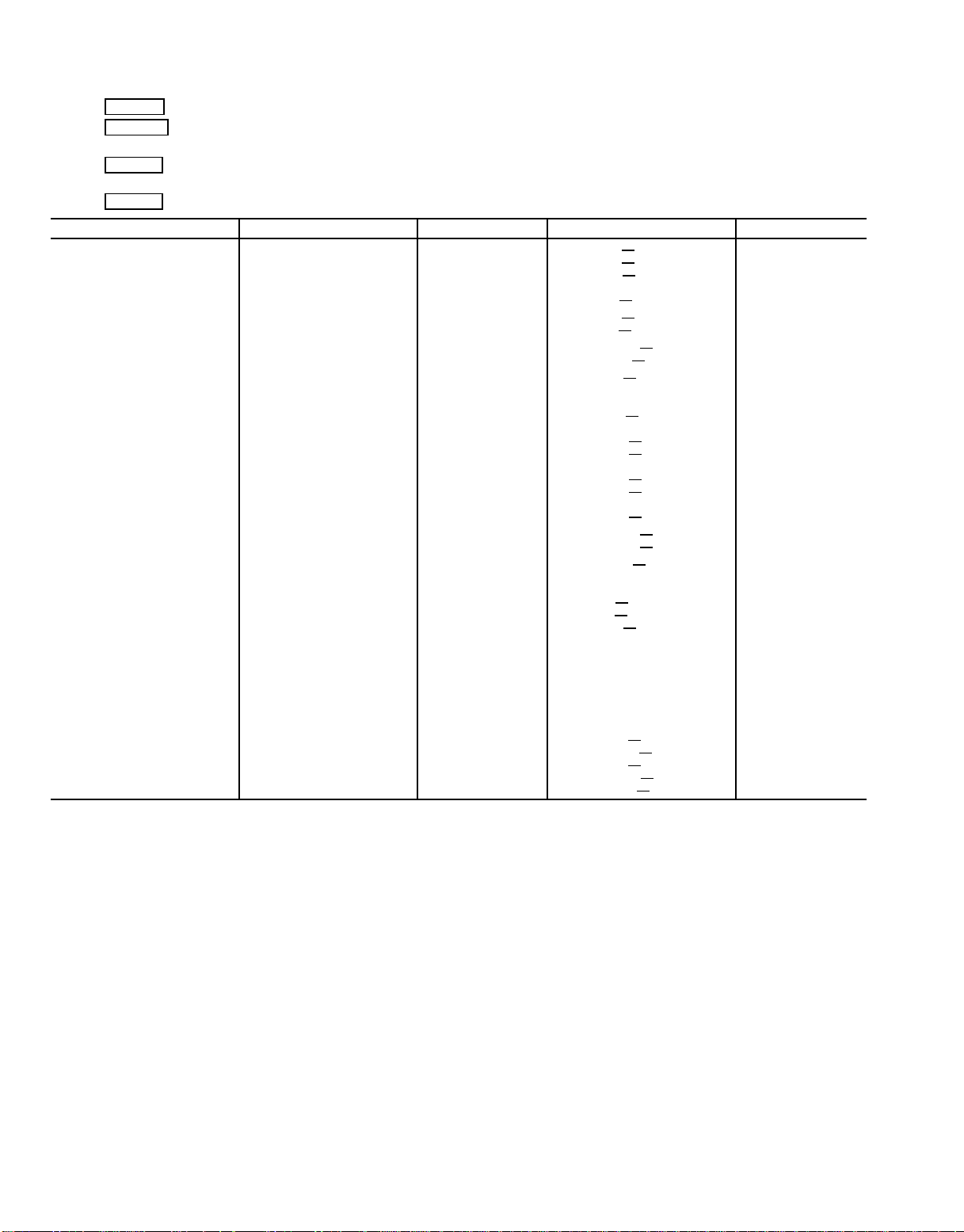

EXAMPLE4—STATUS04 DISPLAY SCREEN

To access this display from the LID default screen:

1. Press MENU

2. Press STATUS

3. Scroll down to highlight STATUS04.

4. Press SELECT

.

.

.

Table 2 — LID Display Data (cont)

DESCRIPTION RANGE UNITS

Main Gear Oil Pump OFF/ON MAINPMP1

Auxiliary Gear Oil Pump OFF/ON AUXPMP2

Gear Oil Pressure −6.7 to 420 (−46 to 2896) psi (kPa) GEAROILP

Gear Oil Temperature −40 to 245 (−40 to 118) DEG F (DEG C) GEAROILT

EXAMPLE 5 — SETPOINT DISPLAY SCREEN

To access this display from the LID default screen:

1. Press MENU

2. Press SETPOINT

DESCRIPTION CONFIGURABLE RANGE UNITS REFERENCE POINT NAME DEFAULT VALUE

Base Demand Limit 40-100 % DLM 100

LCW Setpoint 20-120 (–6.7-48.9) DEG F (DEG C) lcw sp

ECW Setpoint 20-120 (–6.7-48.9) DEG F (DEG C) ecw sp 60.0 (15.6)

ICE BUILD Setpoint 20- 60 (–6.7-15.6) DEG F (DEG C) ice sp

.

.

REFERENCE POINT NAME

(ALARM HISTORY)

50.0 (10.0)

40.0 ( 4.4)

25

Page 26

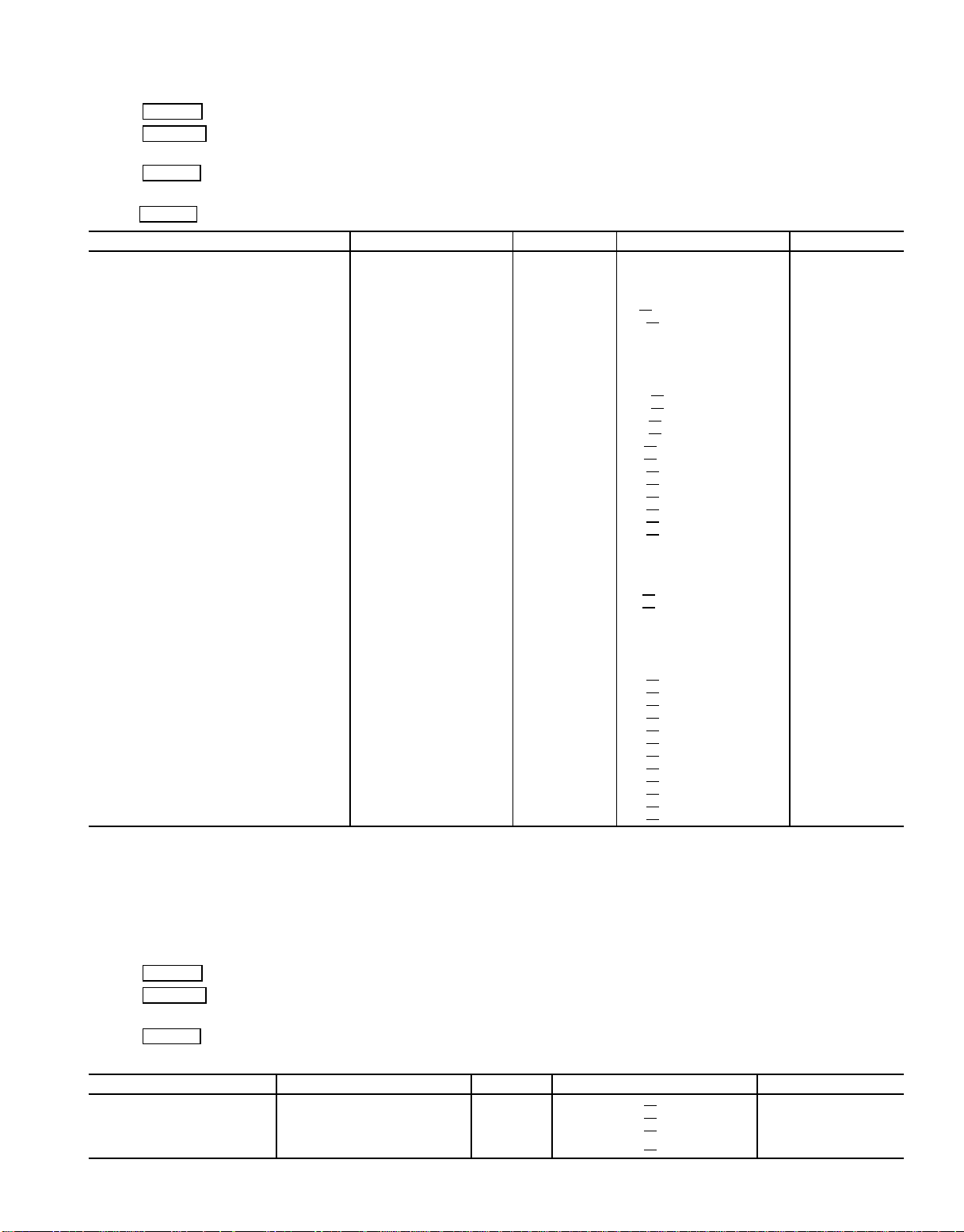

Table 2 — LID Display Data (cont)

EXAMPLE 6 — CONFIGURATION (CONFIG) DISPLAY SCREEN

To access this display from the LID default screen:

1. Press MENU

2. Press SERVICE

3. Scroll down to highlight EQUIPMENT CONFIGURATION.

4. Press SELECT

5. Scroll down to highlight CONFIG.

6. Press SELECT

DESCRIPTION CONFIGURABLE RANGE UNITS REFERENCE POINT NAME DEFAULT VALUE

RESET TYPE 1

Degrees Reset at 20 mA –30-30 (–17-17) DEG F (DEG C) deg 20ma

RESET TYPE 2

Remote Temp (No Reset) –40-245 (–40-118) DEG F (DEG C) res rt1

Remote Temp (Full Reset) –40-245 (–40-118) DEG F (DEG C) res rt2 65 (18)

Degrees Reset –30-30 (–17-17) DEG F (DEG C) res rt 10D(6D)

RESET TYPE 3

CHW Delta T (No Reset) 0-15 (0-8) DEG F (DEG C) restd 1

CHW Delta T (Full Reset) 0-15 (0-8) DEG F (DEG C) restd 2 0D(0D)

Degrees Reset –30-30 (–17-17) DEG F (DEG C) deg chw 5D(3D)

Select/Enable Reset Type 0-3 res sel

ECW CONTROL OPTION DISABLE/ENABLE ecw opt

Demand Limit At 20 mA 40-100 % dem 20ma 40

20 mA Demand Limit Option DISABLE/ENABLE dem sel DISABLE

Auto Restart Option DISABLE/ENABLE astart DISABLE

Remote Contacts Option DISABLE/ENABLE r contact

Temp Pulldown Deg/Min 2-10 tmp ramp

Load Pulldown %/Min 5-20 kw ramp 10