Page 1

Number One

AirConditbninq

Maker

■: <•> > r.- :•:>■

•• ‘.V ••• V V

.■.‘.'.■.V ,■ V.' ■■ ■ .’.% ■■■.■

Division ot

Carrier Corporation

Carrier Parkway • Syracuse NY 13221

Open-Drive Centrifugal Liquid Chillers

SAFETY CONSIDERATIONS

Centrifugal liquid chillers are designed to provide safe

and reliable service when operated within design speci

fications. When operating this equipment, use good

judgment and safety precautions to avoid damage to

equipment and property or injury to personnel.

Be sure you understand and follow the procedures and

safety precautions contained in the machine instructions

as well as those listed in this guide.

A DANGER

DO NOT USE OXYGEN to purge lines or to pressurize a

machine for any purpose. Oxygen gas reacts violently

with oil, grease and other common substances.

NEVER EXCEED specified test pressures. VERIFY the

allowable test pressure by checking the instruction

literature and the design pressures on the equipment

nameplate.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly

installed and functioning before operating any machine.

A WARNING

DO NOT USE eyebolts or eyebolt holes to rig machine

sections or the entire assembly.

DO NOT woik on high voltage equipment unless you are

a qualified electrician

DO NOT WORK ON electrical components, including

control panels, switches, starters or oil heater until you

are sure ALL POWER IS OFF and no residual voltage

can leak from capacitors or solid-state components

LOCK OPEN AND TAG electrical circuits during servic

ing. IF WORK IS INTERRUPTED, confirm that all

circuits are de-energized before resuming work.

DO NOT syphon refrigerant by mouth.

AVOID SPILLING liquid refrigerant on skin or getting it

into the eyes USE SAFETY GOGGLES. Wash any spills

from the skin with soap and water. If any enters the

eyes, IMMEDIATELY FLUSH EYES with water and

consult a physician.

NEVER APPLY an open flame or live steam to a

refrigerant cylinder. Dangerous overpressure can result.

When necessary to heat refrigerant, use only warm

(llOF/43 C) water

DO NOT REUSE disposable (nonreturnable) cylinders

nor attempt to refill them. It is DANGEROUS AND

ILLEGAL. When cylinder is emptied, evacuate remain

ing gas pressure, loosen the collar and unscrew and

discard the valve stem. DO NOT INCINERATE.

CHECK THE REFRIGERANT TYPE before charging

machine. Higli pressure refrigerant in a low pressure

machine can cause vessels to rupture if the relief devices

cannot handle the refrigerant volume.

DO NOT ATTEMPT TO REMOVE fittings, covers, etc.

while machine is under pressure or while machine is

running. Be sure pressure is at zero psig before breaking

any refrigerant connection.

CAREFULLY INSPECT all relief valves, rupture discs

and other relief devices AT LEAST ONCE A YEAR. If

machine operates in a corrosive atmosphere, inspect the

devices at more frequent intervals.

DO NOT ATTEMPT TO REPAIR OR RECONDITION

any relief valve when corrosion or build-up of foreign

material (rust, dirt, scale, etc.) is found within the valve

body or mechanism. Replace the valve.

DO NOT VENT refrigerant relief valves within a

building, refer to ANSIB9.1. The accumulation of

refrigerant in an enclosed space can displace oxygen and

cause asphyxiation.

DO NOT install relief valves in series or backwards.

USE CARE when working near or in line with a

compressed spring. Sudden release of the spring can

cause it and objects in its path to act as projectiles.

A CAUTION

DO NOT STEP on refrigerant lines. Broken lines can

whip about and cause personal injury.

DO NOT climb over a machine. Use platform, catwalk or

staging. Follow safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc ) to

lift or move inspection covers or other heavy compo

nents. Even if components are light, use such equipment

when there is a risk of slipping or losing your balance.

DO NOT WELD OR FLAME CUT any refrigerant line or

vessel until all refrigerant has been transferred from the

vessel to storage.

BE AWARE that certain automatic start arrangements

CAN ENGAGE THE STARTER. Open the disconnect

ahead of the starter in addition to shutting off the

machine or pump

USE only lepair or replacement parts that meet the code

requirements of the original equipment

DO NOT VENT OR DRAIN water boxes containing

industrial brines, liquid, gases or semisolids without

permission of your Process Control Group.

DO NOT LOOSEN water box cover bolts until the water

box has been completely drained.

DOUBLE-CHECK that coupling nut wrenches, dial

indicators or other items have been removed before

rotating any shafts.

DO NOT LOOSEN a packing gland nut before checking

that the nut has a positive thread engagement.

PERIODICALLY INSPECT all valves, fittings and piping

for corrosion, rust, leaks or damage

PROVIDE A DRAIN connection in the vent line near

each pressure relief device to prevent a build-up of

condensate or rain water.

/Oi

___

:,

1 mn

P^rrrv

Page 2

CONTENTS

Page

SAFETY CONSIDERATIONS 1

INTRODUCTION 2

General 2

Job Data Required 2

Equipment Required 2

INITIAL PREPARATION 4

Machine Tightness 4

Check for Large Leaks 4

Check for Small Leaks 4

Check Leakage Rate 5

Machine Dehydration 5

Pumpout Procedures 5

Recheck Alignment 6

Check Grouting 6

Inspect Piping 6

Field Wiring 6

Lubrication 6

Refrigerant Charge 6

Drive 7

Purge 7

Air Supply (Pneumatic Control Only) 7

Check Safety Control Operation

(Electric Motor Drive) 7

Check Safety Control Operation

(Gas or Turbine Drive) 8

START-UP 10

Preliminary Checks 10

Compressor Rotation and Operation 10

Checking Safety Control Settings 10

Setting Operating Controls — Electronic 12

Setting Operating Controls — Pneumatic 13

Trimming Refrigerant Charge 14

Hot Alignment Check 14

Doweling 15

INSTRUCTING THE CUSTOMER

OPERATOR 15

INTRODUCTION

General — All persons involved in start-up and

operation of the 17CB machine should be familiar

with these instructions and all necessary job data

before initial start-up. Instructions are arranged in

the proper sequence for machine start-up.

MACHINES WITH SPECIAL COMPONENTS

AND/OR CONTROLS MAY REQUIRE SPECIAL

START-UP PROCEDURES OR ADJUSTMENTS.

CHECK YOUR INDIVIDUAL JOB

REQUIREMENTS.

Job Data Required

1. List of applicable design temperatures and

pressures

2. Machine assembly, wiring and piping prints

3. Prints and instructions for special controls

4. 17CB Installation Instructions

5. 17CB Operating and Maintenance Instructions

6. Manufacturer’s Installation and Start-Up In

structions for:

a. Drive

b. Gear (if applicable)

7. 5F,H Installation Instructions (Refrigerant 114

machines only)

Equipment Required

1. Mechanic’s tools

2. Volt-ohmmeter and clamp-on ammeter

3. Manometer, absolute pressure type

4. Leak detector, halide or electronic

5. Refrigerant drum charging valve (Fig. 5)

6. 5/8-in. SAE X 3/4-in. MPT adapter

7. Five to 10 ft of copper tubing or plastic hose to

fit 5/8-in. SAE connections

8. Portable vacuum pump, 5 to 7.5 cfm or larger

Page 3

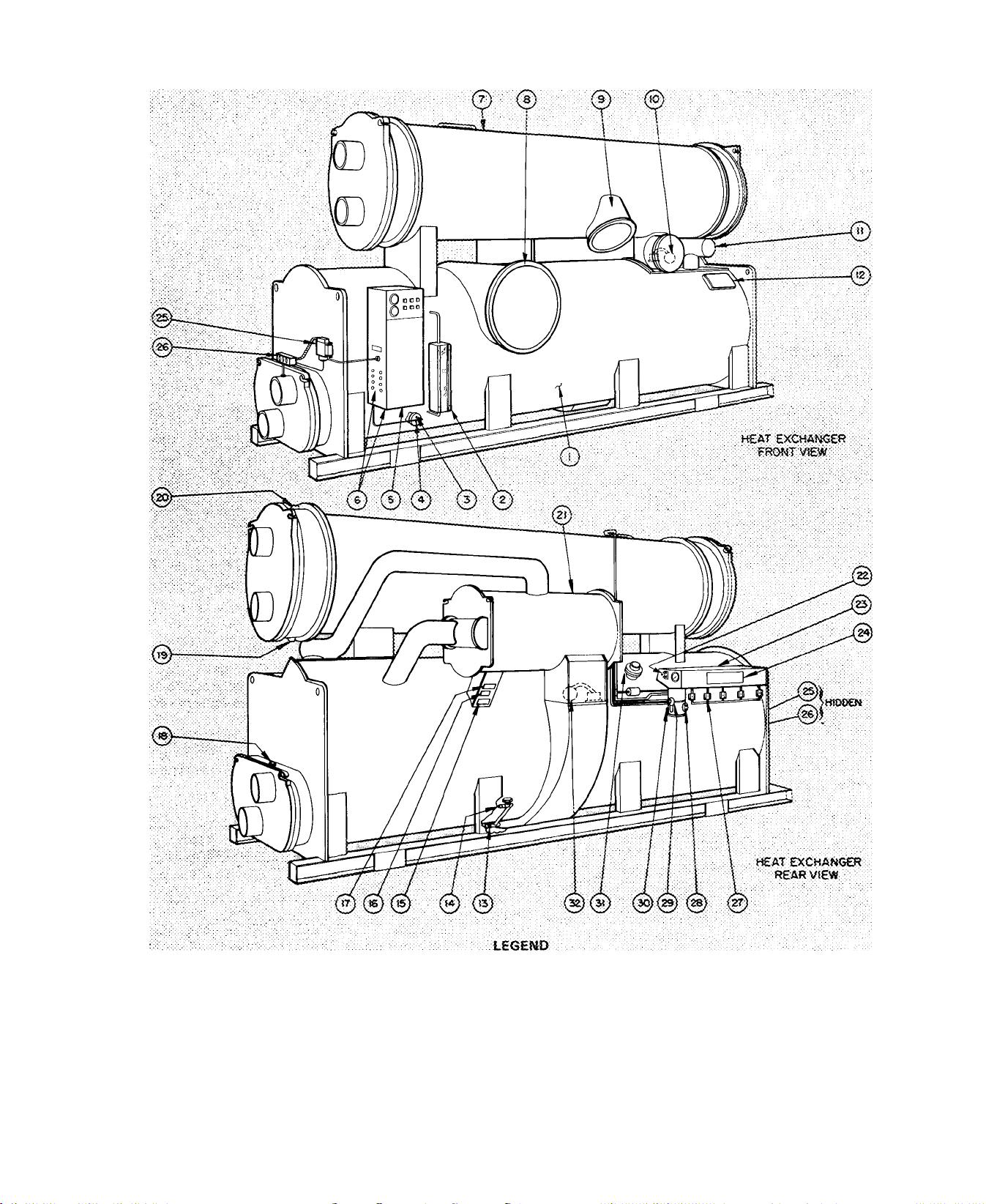

î, Cooier

2. Cooter Befngeranî Lev«} Sight Giass

3. tow Refrigerant Temoerature SiiJb

4. TheroKxneter Weii

5. îv/iachioe Controf Cerner {See P .g. 8 end 9,)

8. Knockouts for P ie!c! Wiring

7. Condenser

S. Cooler Suction Pipe

a. Coocte:Ker Discharge Pipe

■JO. CondenserPloat Veive

■J t. Ecottomizer P'lpe

Fig. 1 — 17CB Machine Components (R-11 Unit shown)

12. Cooter-Êconcmizer Ecualiziitg Damper

Access Cover

13. Refrigerant Connection, 1-t/2:MPT

14. Cooter Charging Valve, 3/4 MPT

: 15. ASME Nameplate

16. Machine informative Plate

17. Safety Code Sticker

18. Cooier Waterixix Vent, 3/4 NPT

19. Condenser WaterOox Drain, 3.'4 NPT

20. Condenser Water'oox Vent, 3/4MPT

21. Economizer

22. Purge Operating Switch

23. Tnormal Purge

24. Purge Vaive Operation Plate

25. Chilled Water Low-TemperatureCutout

26. Chilled Water Temperature Probe

27. Purge Operatirig Valves

28. Purge Refrigerant Level Sight Giass

29. Pu:^ Water Level Sight Glass

30. Purge Water Drai n Vaive

31. Rupture Disc Assembl'y

32. Economizer float Vaive

Page 4

I

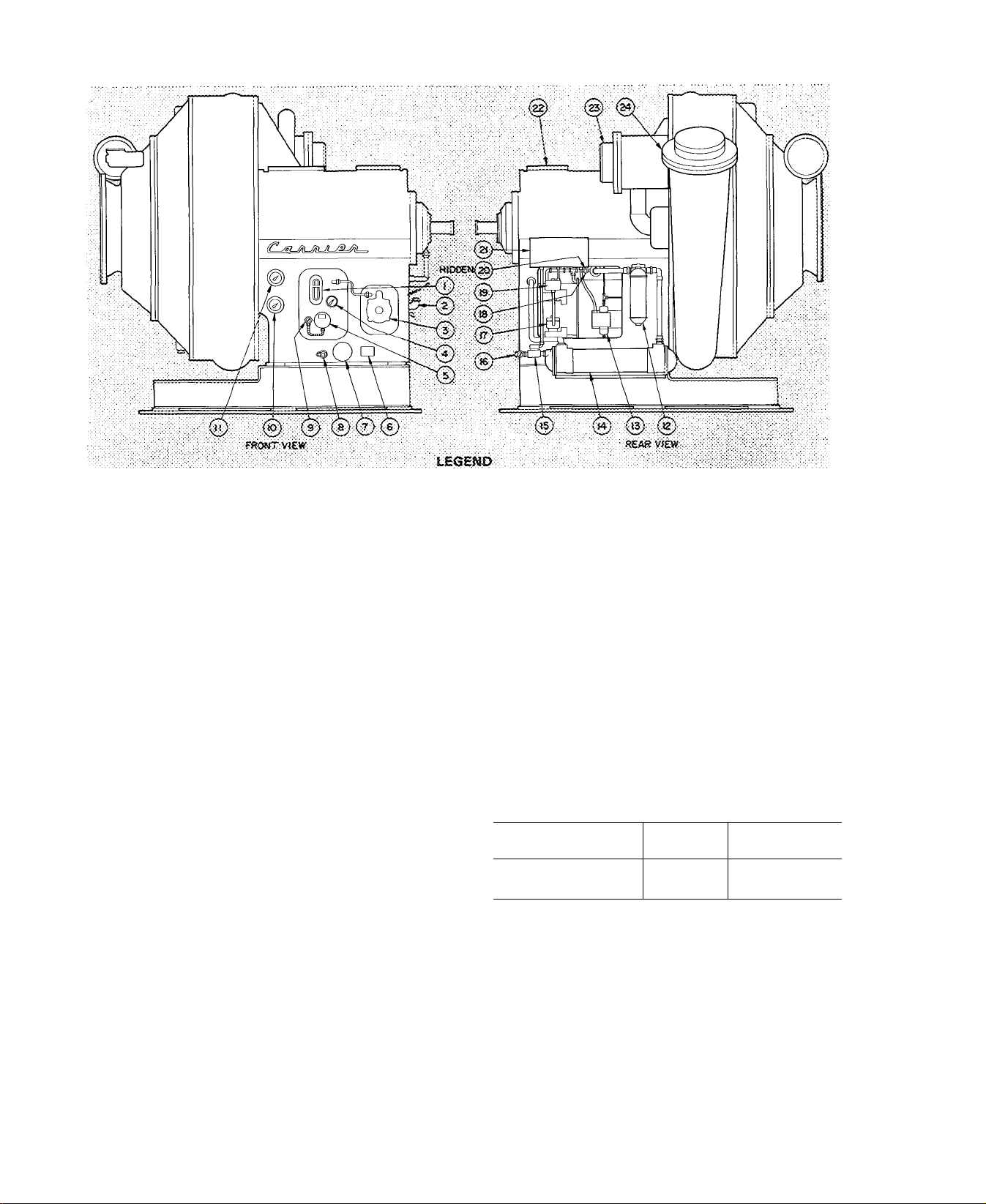

1, OS fieservoif S5g,fit:G:!ass-

2- Oii^C^iargjng EJdow,

Sc&i 01} Return

Sea! Cii Return Pomi>

a

Oil Reservoir Thermosneter

4.

5, Oii Beater Terrninaf Sox

6. Ot! Pump !\tamep!ate

INITIAL PREPARATION

7. 0:i Pomp Terminai Box

a Oii Ciwrging Vatve

■9. Oil Beater Thermostat

10. Oil Pressure Gege

tt. Main Searing Oi!

Thermometer

12. Git Pilte;

Fig. 2 — 17CB Centrifugal Compressor

C.AUTION: Do not start compressor or oil

purap, even for a rotation check, tmiess com

pressor is charged with oil and machine charged

with refri^rant.

Do not apply Yoitage of any kind while

machine is under dehydration vacuum.

Machine Tightness — If machine leak testing and

dehydration was not completed at installation,

check machine tightness (including pumpout sys

tem) as described below. Dehydration must be

repeated if machine has been idle for several weeks

or more after initial dehydration.

Check for Large Leaks — Using one of the methods

described below, pressurize the machine to the

level listed in Table 1. Do not exceed test pressure.

Listen for large leaks as the pressure builds up. If

test pressure holds for one hour, proceed with

Check for Small Leaks.

All 17CB machines may be pressurized with

cylinders of dry air or nitrogen thru the cooler

charging valve. Dry air or nitrogen charging is

preferable to purge or pumpout charging as it

ensures that moisture will not be introduced into the

machine. To pressurize with nitrogen (or dry air):

1. Connect a copper tube from charging valve to

pressure cylinder. Never apply full cylinder

pressure to the pressurizing hne. Follow steps 2

thru 5 in proper sequence.

15. Oii Pressure Oifferenirai

Switch

14. Oi! Cooler

: IS. Gii C>x>}er Solertoid Valve

16. Oil Cooler Plug Cock

T7. Porm "G" Solenoid Valve

15. Vai'te Speed Valve

2.

Open cooler charging valve fully.

3.

Open cylinder regulating valve slowly.

4.

Observe cooler or condenser pressure gage and

IS. form "W' SoiShoid Valve

20. pii PressureReguiating Valve

21. Compressor Controi Wiring

dunctiott 8ox

22. i nspection Cover

23. Economizer Stubout

24. Oischarge Stt:i50ut

close cylinder regulating valve when pressure

reaches test pressure listed in Table 1.

Do not exceed test pressure.!

5. Close cooler charging valve. Remove copper

tube.

Table 1 — Test Pressures

MACHINE SIZE

17CB1300 thru 1600 R-11

17CB1800 thru 2000 R-114

REFRIG

TEST

PRESSURE

8 to 10 psig

30 to 35 psig

Refrigerant 11 machines may be pressurized

with the purge pump. Ensure that electrical supply

to purge pump is 120 volts. Then follow operation

3 on the purge valve chart (item 24, Fig. 1).

Refrigerant 114 machines may be pressurized

with the pumpout unit. This method is detailed in

the section entitled Pumpout Procedures.

Check for Small Leaks

1. Pull a vacuum equal to 5 in. Hg (12.5 psia) by

using purge pump operation 2 (Refrigerant 11

machines), pumpout unit (Refrigerant 114

machines) or by applying a vacuum pump at

the cooler charging valve.

Page 5

r ^

2. Charge approximately 25 lb of the proper

refrigerant thru the cooler charging valve.

3. Pressurize machine to test pressure (Table 1)

using dry air or nitrogen, or purge or pumpout

unit. Do not exceed test pressure.

4. Test all joints, valves, fittings etc. with a halide

or electronic leak detector.

Check Leakage Rate

1. Install a mercury manometer (absolute pressure

type) on a tee at the cooler charging valve.

2. Pull 25 in. of vacuum on the machine.

3. Let machine stand with this vacuum for at least

8 hours.

4. If leakage rate is less than 0.1 in. Hg in 24 hours

(0.033 in. Hg in 8 hours), machine is suffi

ciently tight. Perform Machine Dehydration.

5. If leakage rate exceeds 0.1 in. Hg per 24 hours,

repeat Check for Small Leaks, repair leaks and

repeat this Leakage Rate Check.

6. Remove or valve off manometer before re

peating any pressure test.

Machine Dehydration

Before dehydration, drain shipping oil and flush oil

reservoir. Shipping oil vaporizes under vacuum and

can greatly inhibit dehydration.

6. Wait 2 hours and read manometer again. If

vacuum has not decreased, dehydration is com

plete. If vacuum has decreased, repeat steps 4, 5

and 6.

7. If vacuum fails to hold after several dehydra

tion attempts, check for machine leak by

repeating the refrigerant pressure test.

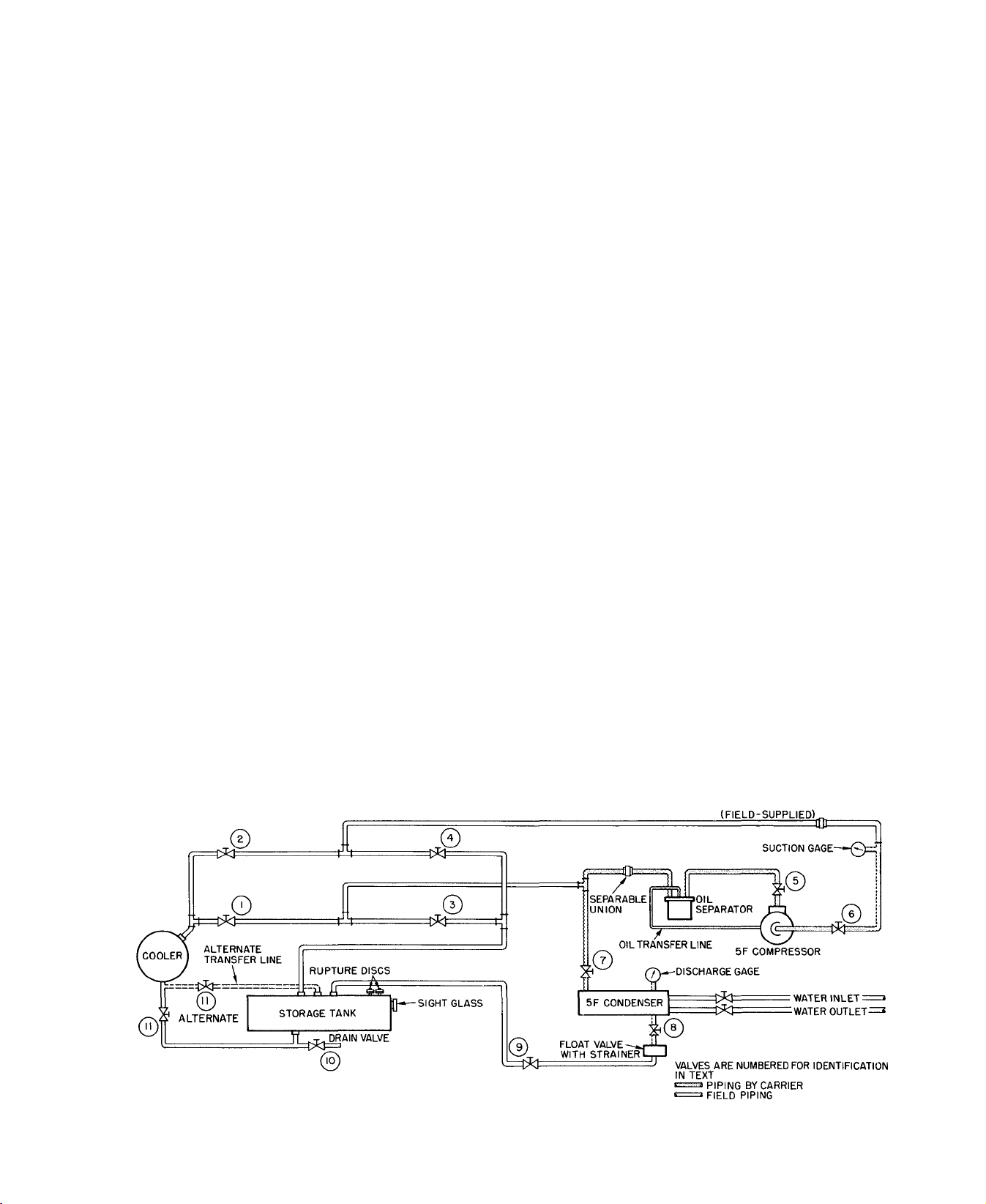

Pumpout Procedures, Refrig 114 Units (See Fig. 3)

MACHINE EVACUATION (No refrigerant in

system)

1. Set purge valves per operation 5 on purge valve

operation plate.

2. Jumper low-pressure cutout on pumpout

compressor.

3. Close valves 1,3,7 and 10.

4. Open valves 2, 4, 5, 6, 8, 9 and 11.

5. Disconnect separable union between pumpout

condenser and oil separator.

6. Run pumpout compressor until desired

machine vacuum is reached.

7. Close valve 5 and reassemble union.

8. Stop compressor.

9. Remove jumper.

CAUTION: Do not attempt to start oil pump

or purge motor even for a rotation check, nor

apply test voltage of any kind while machine is

under dehydration vacuum. Motor insulation

breakdown and serious damage may result,

1. Connect dehydration pump to cooler charging

valve.

2. Ensure that all valves on purge assembly are

closed.

3. Install mercury thermometer (absolute pressure

type) at charging valve tee.

4. Operate pump until manometer reads 29.80 in.

Hg vacuum (0.1 psia). Continue to operate

pump for 2 more hours.

5. Close cooler charging valve; stop pump; record

manometer reading.

PRESSURIZING THE MACHINE (No refrigerant

in system)

1. Set purge valves per operation 4 on purge valve

operation plate.

2.

Close valves 2, 4 and 10.

Open valves 1,3, 5, 6, 7, 8, 9 and 11.

3.

4.

Disconnect separable union in pumpout com

pressor suction line.

5.

Operate pumpout compressor until desired

pressure is reached. Do not exceed test pressure

listed in Table 1.

Shut off pumpout compressor.

6.

7.

Reassemble union.

Return purge valves to Normal-Auto condition

8.

when pressurizing is completed.

SEPARABLE UNION

Fig. 3 — Pumpout System Schematic (R-114 Units)

5

Page 6

I

Recheck Alignment — Angular and parallel align

ment must be within coupling manufacturer’s

specified tolerances before machine is operated.

Refer to Carrier Standard Service Techniques

Manual, Chapter 15, for checking methods.

Leave couplings disassembled until drive is

tested and operated.

Check Grouting — Make sure grouting was applied

during installation. Grouting should be completed

before machine is operated.

Inspect Piping — Refer to piping diagrams provided

in Job Data and inspect piping to cooler, condenser

and oil cooler.

Chilled water should enter the lower nozzle of

the cooler and leave at the upper nozzle. Chilled

water temperature probe should be installed in

leaving chilled water line.

Condenser water should enter the upper con

denser nozzle and leave at the lower.

Ensure that pipes are vented and properly

suspended, with no stress on nozzles or water box

covers.

Measure water pressure drop across cooler and

condenser or across the pumps. Check to see that

water flow agrees with design flow.

Oil cooler water must be clean, with 85 F

maximum temperature and 200 psi maximum inlet

pressure. Refer to tag attached to cooler inlet

connection for pressure drop and velocity limits.

Check that any drive piping is installed per

manufacturer’s instructions.

Field Wiring

Oil may also be added thru charging elbow

(item 2) in seal oil return chamber. The pump

(item 3) automatically transfers oil to the oil

reservoir.

IMPORT.ANT: After char^g oil, energize oil

heater (from its .separate l2D-voit source) to

minimize refrigerant absorption in the oiL Oil

heater indicating light comes on when heater is

energized. The thermostat should be set to

maintain a rhinimum temperature of 140 F at

shutdown. Adjust if required.

On pneumatic machines only, add a small

amount of oil to the vane seal chamber thru 1 /4-in.

pipe plug (Fig. 4) until level reaches bottom of

rack and gear as seen thru Plexiglas cover.

Fig. 4 — Pneumatic Vane Shaft Seal Chamber

WARNING: Do not attempt to check high

voltage supply without proper equipment and

procedure. Serious personal injury can result.

Check with power company for specific

instructions.

Refer to Job Data wiring diagrams and check

field wiring as follows:

1. Wiring, voltage, supply, and rotation of all

electrical equipment; brine pump, condenser

water pump, tower fan.

2. Overload settings on all motor starters.

3. Wiring on all electrical devices on drive; auxil

iary oil pumps, pump starters, etc.

4. Wiring between drive and control center and

compressor junction box.

5. Wiring to pumpout compressor.

6. Oil pump starter voltage against oil pump

nameplate voltage.

Lubrication

COMPRESSOR — Drain and flush out all shipping

oil; then charge oil shipped with machine. It

conforms to Carrier oil specifications for centrif

ugal compressors (listed in the Operating and

Maintenance Instructions). Charge thru oil reser

voir charging valve (item 8, Fig. 2) to middle of

reservoir sight glass. Machine vacuum draws oil

from container.

WARNING: Do not start oU pump^, even for a

rotation check, with madnne in dehydration

vacuum. Check rotation only after compressor

has been charged with oh and cooler has been

charged with refrigerant.

COUPLINGS — Lubricate couplings after they

have been reassembled. Follow manufacturer’s

recommendations for type of lubricant and

lubrication procedure.

NOTE. Do not reassemble couplings until drive has

been run separately.

SPEED INCREASING GEAR - Fill gear casing

with oil recommended by manufacturer. DO NOT

OVERFILL.

DRIVE — Refer to drive manufacturer’s instruc

tions for proper lubrication.

AUXILIARIES — Check all auxiliary pump motor

bearings for proper lubrication. Fill all oilers used

on shaft seals, bearings, etc.

Refrigerant Charge

1. Install a charging valve in the 3/4-in. drum

opening as shown in Fig. 5.

2. Connect a short length of plastic hose (R-11

only) or copper tubing from drum valve to

cooler charging valve.

3. Circulate chilled water during the charging

process.

Page 7

4.

At a vacuiun greater than that indicated in

Table 2, refrigerant will flash into gas and

may cause tube freeze-up. Keep refrigerant

drums upright and admit refrigerant as a gas

until cooler vacuum is less than that listed in

Table 2.

5.

The refrigerant supplied with the machine is in

excess of that required for initial charging.

Charge the amount shown in Table 3, less 200

pounds.

6.

After the machine has been started, it may be

necessary to adjust the charge for optimum

machine performance. For this adjustment, see

Trimming Refrigerant Charge.

Starting procedure of manually started drives may

be initiated after START button is pushed.

Purge — Place the purge operating valves (Fig. 1) in

“Normal-Automatic” position as indicated in

operation 1 on the purge valve operation plate

(item 24, Fig. 1). Operate the purge momentarily

by placing the purge switch in “Manual” position;

then place purge switch in “Auto” position.

Air Supply — Pneumatic Control Only — Check 25

psi air supply to pneumatic temperature controller

and pilot positioner.

Check Safety Control Operation (Electric Motor

Drive)

NOTE: Motor high temperature cutout is field

supplied only per customer’s request.

As the following checks are made, control panel

lights should appear as indicated in the diagrams.

Fig. 5 — Drum Charging Valve

Table 2 — Pressures Corresponding to

32 F Saturation Temperature

REFRIGERANT

n

114

PRESSURE

(in. Hg vacuum)

18.05

3 85

Table 3 — Refrigerant Shipping Charges

MACHINE SIZE REFRIG

17CB1300

17CB1400

17CB1500

17CB1600

17CB1800 114 4400

17CB2000 j 114 4400

11

1 1

11

11

SHIPPING

CHARGE (lb)

2800

3250

3250

3500

Drive — It is good practice to operate the drive

separately before operating compressor. Refer to

drive manufacturer’s instructions for drive pro

tection devices and settings. Check turbine over

speed at this time. Reassemble couplings after

operating drive separately.

If drive is wired for automatic starting, it will

start when compressor START button is pushed.

□ - OFF

1. Open main disconnect (all

power off to starter and

n

ON

STOP

ON

□ n

START OIL

controls). Disconnect main

motor leads in starter.

2. Provide

control circuit

power.

3. Press ON-STOP button

(light goes on). If

n □ □

POWER

SAFETY LOAD

CIRCUIT RECYCLE

n □ n

ON

START OIL

STOP

■ □ □ n

POWER SAFETY LOAD

CIRCUIT RECYCLE

■

ON

STOP

□ n

START

SAFETY CIRCUIT light

does not go on, check

resets on condenser high-

■ ■ ■

POWER

SAFETY LOAD

CIRCUIT RECYCLE

pressure safety, low refrig

erant safety, bearing and motor high tempera

ture circuit breakers and compressor overloads

in starter. Check 3-amp fuse in control center.

If SAFETY CIRCUIT Ught goes on but

LOAD RECYCLE light stays off, check the

chilled water recycle switch (auto-reset).

If both lights go on, manually trip and reset

motor and bearing high temperature circuit

breakers, compressor motor overloads and low

refrigerant temperature cutout to be sure they

cut off the safety Ught. Tripping the chilled

water recycle switch will cut off the LOAD

RECYCLE Ught only.

4. Press ON-STOP button

(Ught goes out). Remove

n □ n

ON

STOP

START

and tag gray striped wire

□ □

from control center ter

■

POWER SAFETY LOAD

CIRCUIT RECYCLE

minal [l^. Refer to ma

chine control schematic in the Operating and

Maintenance Instructions for terminal

location.

PUMP

n

PROGRAM

TIMER

PUMP

PROGRAM

TIMER

OIL

PUMP

n

PROGRAM

TIMER

PUMP

n

PROGRAM

TIMER

OIL

Page 8

5. Start chilled water and

condenser water pumps.

Press ON-STOP button

(Ught goes on).

6. Press OIL PUMP button

for several seconds. Pump

should raise pressure 25 to

27 psi above refrigerant

pressure at machine

shutdown condition.

SAFETY CIRCUIT and

lights should go on.

7. Release OIL PUMP

button. SAFETY CIR

CUIT light and LOAD

RECYCLE light should go

out.

■

ON

STOP

■ □ ■

STOP

START OIL

■

□ □

SAFETY LOAD

POWER

CIRCUIT RECYCLE

ON

START

■ ■ ■

POWER SAFETY LOAD

CIRCUIT RECYCLE

n

□

PUMP

n

PROGRAM

TIMER

PUMP

□

PROGRAM

TIMER

LOAD RECYCLE

■ □ n

ON

STOP

START OIL

■ □ □

POWER SAFETY LOAD

CIRCUIT RECYCLE

PUMP

n

PROGRAM

TIMER

12. Open oil pump main dis

connect. Starter must de

■ □ ■

ON

START OIL

STOP

PUMP

energize. OIL PUMP light

□ □

will remain on for approxi

mately 5 minutes.

OIL PUMP light goes out.

OIL

13. Close oil pump discon

nect. In approximately 10

minutes the program timer

will complete the anti

recycle portion of its cycle

■

POWER SAFETY LOAD

CIRCUIT RECYCLE

■ □ □

ON

STOP

■ □ □ ■

POWER SAFETY LOAD

CIRCUIT RECYCLE

■ □ n

ON

STOP

■

■ ■ n

POWER SAFETY LOAD

CIRCUIT RECYCLE

■

PROGRAM

TIMER

START OIL

STAffT OIL

PUMP

PROGRAM

TIMER

PUMP

PROGRAM

TIMER

and machine is ready to restart. (Total recycle

time is 15 minutes.)

14. Remove all power.

Reconnect motor leads.

Restore power.

8. With OIL PUMP button

depressed, alternately stop

■ □

ON

STOP

START

and restart chilled water

and condenser water

pumps. SAFETY CIR

■ □ □

SAFETY LOAD

POWER

CIRCUIT RECYCLE

CUIT and LOAD RE

CYCLE lights should go out as each pump

stops. (Continuous operation of oil pump is

unnecessary during these checks.)

9. Shut off water pumps. Re

lease OIL PUMP button.

n □ n

ON

STOP

START OIL

Press ON-STOP button

□ □ n

(light out). Replace tagged

■

POWER SAFETY LOAD

CIRCUIT RECYCLE

wire on terminal fl 7j.

10.

Press ON-STOP button

(light goes on).

11. Press machine START

button (motor leads

disconnected).

Oil pump starts within 30

seconds.

Compressor motor start

contacts will close 30

■

STOP

POWER

■ ■

STOP

POWER

STOP PUMP

□

ON

START

■

■ ■

SAFETY LOAD

CIRCUIT RECYCLE

START OIL

ON

■ ■

■

SAFETY LOAD

CIRCUIT RECYCLE

■ ■ ■

START

ON

■

■ ■

POWER

SAFETY LOAD PROGRAM

CIRCUIT RECYCLE TIMER

■ ■

ON

START

STOP

seconds later. Starter will

transfer to its run condi

tion 30 to 60 seconds

■ ■ ■

POWER SAFETY LOAD

CIRCUIT RECYCLE

after starter is energized.

■

OIL

PUMP

n

PROGRAM

TIMER

PUMP

PROGRAM

TIMER

n

OIL

PUMP

n

PROGRAM

TIMER

n

PUMP

■

PROGRAM

TIMER

■

■

PUMP

n

PROGRAM

TIMER

ELECTRONIC CONTROL PNEUMATIC CONTROL

Fig. 6 — Control Center Components

(Electric Motor Drive)

Check Safety Control Operation (Gas Engine or

Turbine Drive)

Refer to machine control schematic in the

Operating and Maintenance Instructions for loca

OIL

tion of electrical terminals listed.

As checks are made, control panel lights

should appear as indicated in the diagrams.

1. Turn off main steam or

gas supply to prevent

OIL

drive from starting. Place

jumpers across oil switch

□ □ □

POWER ON

STOP

(g)

□

OIL

PUMP

oTp

START

□

SAFETY

CIRCUIT

terminals (67} and

and flow switch terminals [69j and [70] inside

the control center.

Page 9

circuit

power.

■ □ □

ON

POWER

STOP

oT, (g)

□

OIL

PUMP

3. Press ON-STOP button

(light on). If SAFETY

CIRCUIT light does not ^

go on, check resets on ^

□

condenser high-pressure

safety, cooler low refrig

erant safety, bearing high temperature circuit

breaker, chilled water low temperature switch

and driver overload in starter. Check 3-amp

fuse in control center.

Manually trip and reset the bearing high

temperature circuit breaker, driver overload,

low refrigerant safety and chilled water switch

to be sure they cut off the safety light.

4. Press ON-STOP button

(light goes out). Remove

jumpers across terminals

(6^ and [0], [6^ and

■ □ □

POWER

ON

STOP

oTp (|1

□

OIL

PUMP

START

□

SAFETY

CIRCUIT

□

START

□

SAFETY

CIRCUIT

9. With OIL PUMP and

ON-STOP switches on,

and water pumps oper

ating, press machine

START button (gas or

steam supply turned ofO

10. Turn off OIL PUMP

switch. Oil pump must

continue operating.

11. Open oil pump main disconnect. Driver circuit

control must de-energize.

Oil pump will remain on

for 3 minutes.

12. OIL PUMP light goes out.

13. Press ON-STOP switch

(light goes off).

(g

■

POWER

oTp (g)

■

POWER ON

oTp (g)

■

POWER ON

gl

■ □

ON

STOP

■

SAFETY

OIL

PUMP

CIRCUIT

■ □

STOP

□

OIL

SAFETY

PUMP

CIRCUIT

□

STOP

□

SAFETY

OIL

PUMP

CIRCUIT

START

□

START

□

□

START

□

5. Start chilled water and

condenser water pumps.

Press ON-STOP button

(light goes on).

■ ■ □

POWER ON

STOP

□

OIL

PUMP

Turn on OIL-PUMP

switch for several seconds.

Pump should raise oil

pressure 25 to 27 psi

(g)

above refrigerant pressure

at machine shutdown con

dition. SAFETY CIRCUIT light should go on.

If oil pump operates but SAFETY CIRCUIT

light is out, check water flow switches.

7. Turn off OIL PUMP

switch. SAFETY CIRCUIT light should go off.

■ ■ □

POWER ON START

□

OIL

PUMP

START

□

SAFETY

CIRCUIT

□

SAFETY

CIRCUIT

□

SAFETY

CIRCUIT

14. Remove all power. Restore gas or steam supply

to drive. Restore power.

CONDENSER

/

COOLER

REFRIG

TEMP

CUT-OUT

TIT“

□ □ □

POWER ON START

STOP

□

OFF^

OIL PUMP CIRCUIT

= K8

Z CAPACITY

SAFETY

o

CONDENSER

PRESSURE

CUT-OUT

ELAPSED

TIME

INDICATOR

CONTROL

MODULE

\

CONDENSER

REFRIG

TEMP

CUT-OUT

OFF

□ □

POWER ON

STOP

OIL PUMP

□

START

□

SAFETY

CIRCUIT

ELAPSED

TIME

INDICATOR

8.

With OIL PUMP switch

on, manually trip and

reset water pump switches.

SAFETY CIRCUIT light

should go off as each

switch is tripped. (Continuous operation of oil

pump is unnecessary during these checks.)

□

START

□

SAFETY

CIRCUIT

RELAY MODULE

I I I I I I i~Tn

ELECTRONIC CONTROL PNEUMATIC CONTROL

RELAY MODULE

I I I I I I I T-|

Fig. 7 — Control Center Components

(Gas Engine or Turbine Drive)

Page 10

START-UP

Preliminary Checks

1. Power on to circuit breakers, water pumps,

cooling tower fans

2. Cooling tower water level

3. Refrigerant level

4. Oil reservoir level

5. Oil reservoir temperature 140 F or warmer

6. Oil cooler plug cock (item 16, Fig. 2) partially

open, and any other valves in oil cooler line

fully open

7. Valves in chilled water and condenser water

circuits open and water circulating properly. Do

not permit water over 100 F to flow thru

cooler.

8. Air supply to pneumatic controls

9. Purge valves and switches in “NormalAutomatic” position. (Refer to chart attached

to purge cover.)

Compressor Rotation and Operation

Electronic Control: Set capacity control switch to

“Hold.”

Pneumatic Control; Turn off supply air to chilled

water thermostat and vane positioner.

Turn on OIL PUMP switch if gas engine or

turbine drive. Press machine ON-STOP and START

buttons (lights go on). As soon as the compressor

shaft begins to turn, note direction of rotation. If

not counterclockwise as viewed from drive end,

stop compressor by pressing ON-STOP button

(light goes out) and correct condition.

If rotation is counterclockwise, let compressor

come up to speed and press ON-STOP button (light

goes out). Listen for any unusual sounds as

compressor coasts to a stop.

The program timer on electric drive units will

allow compressor restart 15 minutes after stop.

Checking Safety Control Settings

While performing these checks, carefully moni

tor chilled water temperature to prevent

freeze-up. Protection by safety controls cannot

be assumed until all settings have been con

firmed as follows.

Shut off gas or steam supply to engine or

turbine. Open main disconnect (all power off to

starter and controls).

Electronic Capacity Control: Set capacity control

switch on “Hold.”

Pneumatic Capacity Control: Ensure that pilot

positioner operates as described in Setting Oper

ating Controls — Pneumatic. If compressor has

electric motor drive, set percent load knob on

demand limit control at 100% and turn calibration

screw fully clockwise.

Install jumpers across low refrigerant and low

chilled water cutouts as follows:

Electric Motor Drive — ^ to (4^ ; (0) to

Gas Engine or Turbine Drive

[TT|.

611 to [621; [71

to

Close disconnects, start compressor and check oil

pressure and temperature. With compressor run

ning, operate the guide vanes with the capacity

control switch or the pneumatic thermostat. Do

not exceed full load condition.

1. Check controls 1 and 2 as indicated in Table 4.

2. Stop machine; open disconnects; remove

jumpers; and check controls 3, 4 and 5 as

indicated.

Table 4 — Setting Safety Controls

SAFETY OR CONTROL DEVICE SAFETY OR CONTROL DEVICE

1. Chilled Water Low-Temperature Cutout and Recycle Switch

(Fig. 1).

-TEMPERATURE ADJUSTMENT

Set this switch to break at approximately 5 F below design

chilled water temperature, or at 36 F whichever is higher

Set the differential at 10 ± 1 F so that when the machine shuts

down automatically at approximately 5 F below the design

chilled water temperature it will restart at approximately 5 F

above the design water temperature

This control must break ahead of the refrigerant lowtemperature cutout switch or the machine will not recycle

automatically

2. Refrigerant Low-Temperature Cutout (Fig. 6 and 7)

ADJUSTMENT

Set refrigerant low-temperature cutout at 33 F or one degree below

design refrigerant temperature, whichever is lower, while checking

temperature at thermowell near control center

10

CUTOUT

Page 11

Table 4 — Setting Safety Controls (cont)

SAFETY OR CONTROL DEVICE

STOP MACHINE, REMOVE JUMPERS AND PERFORM RE

MAINING CHECKS.

3. Condenser High-Pressure Cutout (Fig. 6 and 7).

CUTOUT ADJUSTM^T

COVER

CUTOUT SCALE

RESET

BUTTON

REFRIG

11

114

SETTING

15 psig

45 psig

The condenser high-pressure cutout is factory set to shut the

machine down when condenser pressure reaches setting listed.

Isolate the switch and check setting with a metered supply of air.

4. Oil Heater Thermostat (Fig. 2).

SAFETY OR CONTROL DEVICE

6. Oil Pressure Regulating Valve (Item 20, Fig. 2).

R^FiyC

11

114

SETTING*

15 psid

1 5-20 psid

*Settings given are above

reservoir pressure

SEALING

GASKET

Remove cap and washer and loosen locknut Turn adjusting screw

clockwise to raise oil pressure.

7. Vane Speed Valve (Electronic Machine Only)

Angle valve is located between oil line to main bearing and "F" and

“G" solenoid valves (items 17 and 19, Fig. 2) Set valve at full open

position

8. Chilled Water Flow Switch

Field supplied and installed. Follow switch manufacturer's instruc

tions for adjustment and maintenance

9. Main Bearing Oil Temperature (item 11, Fig. 2)

During machine operation, gauge should read 150 to 165 F. Adjust

water flow thru oil cooler with plug cock (item 16, Fig 2). Do not

exceed 7 gpm or pressure drop of 5 psig. Do not exceed 100 psi

working pressure

SCREW

Set the oil heater thermostat to maintain a minimum oil reservoir

temperature of 140 F at shutdown

5. Low Oil Pressure Cutout (Fig. 2).

RANGE

DIAL ADJUSTMENTTî:

REMOVE METAL

COVER

DIFFERENTIAL

Low oil differential pressure switch is factory set to open at 11 ± 1

psi and close at 15 ± 1 psi differential pressure Operate oil pump

manually Remove cap and gasket from regulating valve and loosen

locknut. Turn adjusting screw counterclockwise to lower oil

pressure to 11 psi differential If safety does not trip, turn range dial

clockwise until cutout occurs

10. Dual Pressurestat for R-114 Pump-Down Compressor

LOW-PRESSURE

SWITCH

COMPRESSOR.

CONNECTIONS

COVER

CUTOUT AND

CUT-IN PRESSURE

. ADJUSTMENT

\jp PRESSURE

l-ADJUSTMENT ONLY

CUTOUT PRESSURE

ADJUSTMENT ONLY

High-pressure switch to open on rise at 45 psig Low-pressure switch

to open on fall at 2 0 in. Hg vacuum.

Set high-pressure switch by operating compressor and throttling

pump-down condenser water while watching pressure gauge.

Set low-pressure switch by operating compressor and gradually

shutting suction valve while watching pressure gauge.

11. Oil Safety Switch for R-114 Pump-Down Compressor

MANUAL

RESET BUTTON

CONNECT IN

SERIES WITH

HIGH PRESSURE

CONN TO

OIL PUMP DISCHARGE

CONTROL CIRCUIT

(SEE WIRING

CONNECT TO

II50R 230V SOURCE

(SEE WIRING DIAGRAM)

DIAGRAM)

Contacts open on drop in oil pressure. Cutout 11-14 psi; cut-in

16-19 psi differential between pump discharge and compressor

suction

Preset switch with an external air source

11

Page 12

Setting Operating Controls — Electronic

MOTOR CURRENT CALIBRATION (Electronic

Capacity Control/Motor Drive)

1. Establish a steady motor current value for this

calibration. Open guide vanes manually

(capacity control to “Inc”) until full load

current is reached. Motor current calibration

(Fig. 8) may need to be turned counter

clockwise to permit vanes to open further. Do

not exceed 105% of nameplate full load

amperes.

If system load is sufficient to maintain full

load current for a period of time, caUbrate at

this condition. With small loads, pull down to

and maintain design leaving chilled water

temperature (capacity control at “Hold”) and

calibrate at this condition.

Fig. 8 — Capacity Control Module

(Electric Motor Drive)

2. Measure motor current at selected condition.

Determine its percentage of full load motor

current.

3. Use this percentage figure to set the electrical

demand adjustment (Fig. 8) per the following

table:

Percent of Full

Load Motor Current

105

85 or above

65 to 84

45 to 64

below 45

Electrical Demand

Adjustment Setting

100 percent

80 percent

60 percent

40 percent

Control cannot be

calibrated

4. Turn the motor current calibration adjustment

fully clockwise. The guide vanes will close part

way.

5. Turn the thermostat adjustment (Fig. 8) to

COOLER (fully counterclockwise).

6. Set capacity control at “Inc” position.

7. Slowly turn the motor current calibration

counterclockwise. Allow the guide vanes to

open until motor current reaches 5% above the

electrical demand setting.

NOTE; There is a time lag of several seconds

due to feedback capacitance in the motor

current circuit. When the motor current cali

bration setting is adjusted, allow for this time

lag.

8. Check the foregoing motor current calibrations

with machine under “Auto” control as

follows:

a. Close vanes manually (capacity control to

DEC).

b. Turn capacity control to AUTO. Vanes

should stop opening at electrical demand

setting.

9. If control was calibrated at less than 100%

load, turn electrical demand adjustment setting

to 100%. Control is now automatically cali

brated for 100% full load current.

10. If control cannot be calibrated with above

procedure, check voltage signal from signal

resistor in starter. At 100% full load current,

voltage between terminals 23 and 24 inside

control center must be 0.5 ± 0.1 volts. If not

in this range, check sizing of resistor in starter.

Both excess motor current and chilled

water temperatures below the thermostat set point

(Fig. 8) will override the capacity control setting.

If the capacity control knob is in the “Inc”

position, the guide vanes will stop opening. With

the knob in any of the other positions, the vanes

will close as needed.

The motor current limiting circuit operates in

two steps.

At 100% full load motor current, the vanes

will stop opening further. If the motor current

should increase to 105% due to some change in

load conditions, the vanes will close until the

motor current is reduced to about 102%.

If the motor current is reduced to 98% or

below, control again operates in response to chilled

water temperature.

The electrical demand adjustment permits the

operator to set the maximum current drawn by the

motor and thus minimize the electrical demand

rate during off-season operation.

CHILLED WATER CALIBRATION (Electronic

Controls)

1. Turn throttle range adjustment (Fig. 8 and 9)

fully clockwise.

A

i.

12

Page 13

\<%A—

max

iol

\<%4-. ^

^Oi ir«&S5“

\o\

Fig. 9 — Capacity Control Module

(Gas Engine or Turbine Drive)

2. Turn chilled water thermostat until design

chilled water temperature is maintained. Mark

thermostat at this position. If capacity control

vanes hunt, turn throttle range adjustment

counterclockwise in small increments until

hunting ceases. Chilled water thermostat may

require resetting.

Setting Operating Controls — Pneumatic

“»<*

\

--

MUtM. fft

i mm «Nft

^ 9mi.y%

i V \ , WOlM«t

. \ sosogn

i -------* m^Si

Preparation:

1. Place jumper between terminals (L^ and

2. Open 25 lb air supply valve.

3. Remove cover from pilot positioner.

Calibration:

Rotate dial on chilled water thermostat to vary

pilot pressure. Observe pressure gage in pilot

supply line near pilot positioner and adjust starting

point nut (2) until piston operator (Fig. 4) begins

to move at 5 psi pilot pressure. Place follower

spring (4) in proper hole in level arm so that piston

operator opens 100% at 15 psi pilot pressure.

Completion:

1. Remove jumper from terminals [L^ and

2. Replace positioner cover.

ELECTRO-PNEUMATIC RELAY (Electric Motor

Drive Only)

LOCKNUTS,

COVER

SENSITIVITY SCREW

SET POINT SCREW

CONTROL AIR

(OUTPUT)

NOTE; if raachiiie has special pne^iipaiic con

trols, follow the instructions supplied in the job

data for their setting and adjustment.

PILOT POSITIONER

MAIN AIR CONNECTION (25 PSIG)

STARTING POINT ADJUSTMENT NUT

LEVER ARM

FOLLOWER SPRING

PILOT AIR CONNECTION

(FROM CONTROL CENTER)

This control is factory calibrated to provide a

linear output signal of 3 psi at 6 volts d-c to 18 psi

at 15 volts d-c. Field recalibration should not be

necessary.

If calibration is required:

1. Establish 15 volt d-c input with 25 psi supply

air.

2. Turn sensitivity screw to obtain 18 psi or higher

output.

3. Adjust setpoint screw, if required, to set output

at 18 ± 1/4 psi.

4. Reduce input to 6 volts. Output should be 3 ±

1/4 psi. If low, turn sensitivity screw carefully

clockwise. If high, turn screw counterclockwise.

5. Re-check output at 15 volts. Repeat steps 3 and

4 if necessary.

1 3

Page 14

DEMAND LIMIT CONTROL

CALIBRATION

ADJUSTMENT

% LOAD DIAL

COVER

BANDWIDTH

DIAL

1. Set percent load dial at 100%.

2. Set Band Width dial at 3.

3. Turn Calibration Adjustment screw fully

clockwise.

4. Run machine at 100% LLA by adjusting dial on

chilled water thermostat.

5. Turn Cahbration Adjustment screw counter

clockwise until guide vanes just begin to close.

6. If hunting occurs, increase band width and

repeat steps 4 and 5.

7. If control cannot be calibrated with above

procedure, check voltage signal from resistor in

starter. At 100% full load, voltage between

terminals 23 and 24 inside control center must

be 3.0 ± 0.1 volts. If not in this range, check

sizing of resistor in starter.

CHILLED WATER THERMOSTAT (PNEUMATIC)

Preparation;

1. Ensure 25 psi supply air to thermostat.

2. Loosen Allen setscrew in sensitivity slider and

move slider halfway between midpoint and DA.

Re tighten screw.

Cahbration:

1. Turn thermostat dial until control air registers

15 psi.

2. Operate machine to reach design chilled water

temperature at design load. Maintain 15 psi

control air during pulldown by adjusting ther

mostat dial as required.

3. On reaching design chilled water temperature,

turn dial until control air pressure holds

machine at design conditions.

4. Hold setpoint adjusting screw stationary within

the dial post and set the thermostat dial at

design chilled water temperature.

^ Completion:

If vane hunting occurs, move sensitivity slider

away from DA. Sensitivity decreases as slider is

moved from 5 psi/F to the lower limit of 0.1 psi/F.

Trimming Refrigerant Charge — After machine is

placed in operation, it may be necessary to adjust

the refrigerant charge to obtain optimum machine

performance.

When machine full load is available, slowly add

a sufficient amount of the remaining 200 lb of

refrigerant until the difference between leaving

chilled water temperature and cooler temperatures

reaches design conditions or becomes a minimum.

Shut down machine. Mark maximum refrigerant

level. Maintain refrigerant at this level.

ITEM DESCRIPTION

1 SET POINT ADJUSTING SCREW

2 THERMOSTAT DIAL

3 SENSITIVITY SLIDER

4 SUPPLY AIR PRESSURE GAGE

5 SUPPLY AIR CONNECTIONS

6 CONTROL AIR PRESSURE GAGE

7 CONTROL AIR CONNECTIONS

8 DIAL RETAINING SCREW (2)

Hot Alignment Check — When all machine com

ponents have reached operating temperature (after

running near full load for approximately two

hours), a hot alignment check must be made.

1. Shut down machine.

2. Quickly disassemble couplings between com

pressor and drive (and gear, if used).

3. Check angular and parallel alignment in plan and

elevation. Indicators may be mounted as in Fig.

10. Refer to coupling manufacturer’s instruc

tions and to Carrier Standard Service Tech

niques, Chapter 15, for applicable procedures.

4. After making adjustments, reassemble the

couplings and run the machine until it reaches

operating temperature.

5. Repeat steps 1 thru 3 until angular and parallel

alignment is within coupling manufacturer’s

specified tolerances.

14

Page 15

1

£

\

Fig. 10 — Checking Alignment with Dial Indicator

TO CHHCK ANGOi-AR AtJGNMSXT

A second method of checking hot alignment

can be used if there is room on the shafts between

equipment and coupling to clamp a sturdy bracket.

Clamping tool, Part No. TS-170, is available for

this purpose thru Carrier Service Parts Department.

Check with your local Carrier Office. Dial indicator

must be obtained separately. Clamps must have

space to rotate with the shaft. This method is

quicker because couplings do not have to be

disassembled. Mount brackets and dial indicators as

in Fig. 11. Since both shafts are rotating together,

concentricity and condition of the faces are not

problems. The diameter used in the angular

alignment formula is the circle thru which dial

indicator rotates. This method is more accurate

since the diameter is larger.

Doweling — After hot alignment is completed, the

compressor, gear and drive must be doweled to

their soleplates. This permits repositioning of

components if they have to be moved. Compressor

has four 3/4-in. holes for doweling.

1. Drill thru these holes into the soleplates Ream

holes with a tapered reamer with straight flutes.

2. Coat dowels with white lead or other lubricant

to prevent rusting.

3. Tap dowels lightly into position with a small

hammer. A ringing sound indicates the proper

seating.

TO CHECK PARALLSL AUGNMSiT

Fig. 11 — Alignment Check — Assembled Coupling

Repeat these steps with gear and drive, keeping

dowels as vertical as possible. Dowel thru the four

3/4-in. holes on suction end of compressor base,

the two feet on high speed end of gear, and the

drive feet adjacent to gear. Refer to drive man

ufacturer’s instructions for additional details on

doweling this equipment.

Page 16

INSTRUCTING THE CUSTOMER OPERATOR

Be sure the operator carefully reads and under

stands the 17CB Operating and Maintenance In

structions and any instructions on drive operation

and maintenance.

Point out the following machine components,

explain their function and that of the system in

which they are used.

1. Compressor-Motor Assembly

a. Guide Vanes, Vane Motor and Linkage

2. Cooler-Condenser-Economizer

a. Float Chamber, Sight Glasses

b. Thermowells

c. Rupture Disc

d. Refrigerant Charging Valve

3. Purge System

a. Importance of Proper Operation

b. Valves and System Operation

c. Sight Glasses, Gage

4. Lubrication System

a. Oil Pump, Cooler, Filter

b. Solenoid Valve, Plug Cock

c. Heater, Thermostat, Temperature Gage

d. Pressure Regulating Valve

e. Oil Level, Temperature

5. Control System

a. Manual Switches (ON-STOP, START,

OIL-PUMP)

b. Gages and Lights

c. Safety Controls

d. Operating Controls

e. Auxiliary and Special Controls

6. Auxiliary Equipment

a. Starter(s)

b. Pumps

c. Cooling Tower

d. Pumpout System (if supplied)

Describe Refrigeration Cycle

Review Maintenance

1. Scheduled

2. Extended Shutdown

3. Importance of Log Sheet

4. Importance of Water Treatment

Check Operator Knowledge

1. Start-Stop Procedure

2. Safety and Operating Controls

Discuss Carrier Service

1. Availability

2. Method of Ordering Parts

Review Operating and Maintenance Instructions

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab

5d

Form17CB-2SS Supersedes 17CB-1SS Printed in U.S.A.

3-79

PC 211

Catalog No 531—740

Loading...

Loading...