Page 1

Installation Instructions

SAFETY CONSIDERATIONS

Centrifugal liquid chillers are designed to provide safe and

reliable service when operated within design specifications.

Whenoperatingthisequipment, usegood judgmentand safety

precautions to avoid damage to equipment and property or

injury to personnel.

Be sure you understand and follow the procedures andsafety

precautions contained in the machine instructions, as well

as those listed in this guide.

DO NOT VENT refrigerant relief devices within a building. Outlet from

rupture disc or relief valve must be vented outdoors in accordance with

the latest edition of ASHRAE (American Society of Heating, Refrigeration and Air Conditioning Engineers) 15. The accumulation of refrigerant in an enclosed space can displace oxygen and cause

asphyxiation.

PROVIDE adequate ventilation in accordance with ASHRAE 15, especially for enclosed and low overhead spaces. Inhalation of high

concentrations of vapor is harmful and may cause heart irregularities,

unconsciousness, or death. Intentional misuse can be fatal. Vapor is

heavier than air and reduces the amount of oxygen available for breathing. Product causes eye and skin irritation. Decomposition products are

hazardous.

DO NOT USE OXYGEN to purge lines or to pressurize a machine for

any purpose. Oxygen gas reacts violently with oil, grease, and other

common substances.

DO NOT USE air to leak test. Use only refrigerant or dry nitrogen.

NEVER EXCEED specified test pressures. VERIFY the allowable test

pressure by checking the instruction literature and the design pressures

on the equipment nameplate.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly installed and func-

tioning before operating any machine.

DO NOT WELD OR FLAMECUT any refrigerant line or vessel until

all refrigerant (liquid and vapor) has been removed from chiller. Traces

of vapor should be displaced with dry air or nitrogen and the work area

should be well ventilated. Refrigerant in contact with an open flame

produces toxic gases.

DO NOT USE eyebolts or eyebolt holes to rig machine sections or the

entire assembly.

DO NOT work on high-voltage equipment unless you are a qualified

electrician.

DO NOT WORK ON electrical components, including control panels,

switches, starters, or oil heater until you are sure ALL POWER IS OFF

and no residual voltage can leak from capacitors or solid-state

components.

LOCK OPEN AND TAGelectrical circuits during servicing. IF WORK

IS INTERRUPTED, confirm that all circuits are deenergized before

resuming work.

AVOID SPILLING liquid refrigerant on skin or getting it into the eyes.

USE SAFETY GOGGLES. Wash any spills from the skin with soap

and water. If liquid refrigerant enters the eyes, IMMEDIATELYFLUSH

EYES with water and consult a physician.

NEVER APPLY an open flame or live steam to a refrigerant cylinder.

Dangerous over pressure can result. When it is necessary to heat refrigerant, use only warm (110 F [43 C]) water.

17/19EX

50/60 Hz

Centrifugal Liquid Chillers

with HFC-134a

DO NOT REUSE disposable (nonreturnable) cylinders or attempt to

refill them. It is DANGEROUS AND ILLEGAL. When cylinder is emptied, evacuate remaining gas pressure, loosen the collar, and unscrew

and discard the valve stem. DO NOT INCINERATE.

CHECK THE REFRIGERANT TYPE before adding refrigerant to the

machine. The introduction of the wrong refrigerant can cause

machine damage or malfunction.

Operation of this equipment with refrigerants other than those cited

herein should comply with ASHRAE-15 (latest edition). Contact

Carrier for further information on use of this machine with other

refrigerants.

DO NOT ATTEMPT TO REMOVE fittings, covers, etc., while

machine is under pressure or while machine is running. Be sure pressure is at 0 psig (0 kPa) before breaking any refrigerant connection.

CAREFULLY INSPECT all relief valves, rupture discs, and other relief devices AT LEAST ONCE A YEAR. If machine operates in a corrosive atmosphere, inspect the devices at more frequent intervals.

DO NOT ATTEMPTTOREP AIROR RECONDITION any relief valve

when corrosion or build-up of foreign material (rust, dirt, scale, etc.) is

found within the valve body or mechanism. Replace the valve.

DO NOT install relief devices in series or backwards.

USE CARE when working near or in line with a compressed spring.

Sudden release of the spring can cause it and objects in its path to act

as projectiles.

DO NOT STEP on refrigerant lines. Broken lines can whip about, and

release refrigerant, causing personal injury.

DO NOT climb over a machine. Use platform, catwalk, or staging. Follow safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to lift or move

inspection covers or other heavy components. Even if components are

light, use mechanical equipment when there is a risk of slipping or

losing your balance.

BE AWARE that certain automatic start arrangements CAN ENGAGE

THE STAR TER,TOWERFANOR PUMPS. Open the disconnectahead

of the starter, tower fan, and pumps. Shut off the machine or pump

before servicing equipment.

USE only repaired or replacement parts that meet the code requirements of the original equipment.

DO NOT VENT OR DRAIN waterboxes containing industrial brines,

liquid, gases, or semisolids without the permission of your process control group.

DO NOT LOOSEN waterbox cover bolts until the waterbox has been

completely drained.

DOUBLE-CHECK that coupling nut wrenches, dial indicators, or other

items have been removed before rotating any shafts.

DO NOT LOOSEN a packing gland nut before checking that the nut

has a positive thread engagement.

PERIODICALLY INSPECT all valves, fittings, and piping for corrosion, rust, leaks, or damage.

PROVIDE A DRAIN connection in the vent line near each pressure

relief device to prevent a build-up of condensate or rain water.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2 2

Tab 5a 5d

PC 211 Catalog No. 531-749 Printed in U.S.A. Form 17/19EX-2SI Pg 1 3-96 Replaces: 17/19EX-1SI

Page 2

CONTENTS

Page

SAFETY CONSIDERATIONS ...................1

INTRODUCTION ..............................2

General ......................................2

Job Data ....................................2

Equipment Required .........................2

INSTALLATION .............................2-30

Receiving the Machine .......................2

• INSPECT SHIPMENT

• IDENTIFY MACHINE

• PROVIDE MACHINE PROTECTION

Rigging the Machine .........................2

• RIG MACHINE ASSEMBLY

• RIG MACHINE COMPONENTS

• COMPONENT DISASSEMBLY

Install Machine Supports ....................14

• INSTALL STANDARD ISOLATION

• INSTALL OPTIONAL ISOLATION

• INSTALL SPRING ISOLATION

Connect Piping .............................17

• INSTALL WATER PIPING TO HEAT

EXCHANGERS

• INSTALL WATER TO OIL COOLER ON FA

COMPRESSORS

• INSTALL VENT PIPING TO RELIEF DEVICES

Make Electrical Connections .................20

• CONNECT CONTROL INPUTS

• CONNECT CONTROL OUTPUTS

• CARRIER COMFORT NETWORK INTERFACE

Install Field Insulation .......................28

• FACTORY INSULATION (OPTIONAL)

INSTALLATION START-UP REQUEST

CHECKLIST .............................CL-1

INSTALLATION

Receiving the Machine

INSPECT SHIPMENT

Do not open any valves or loosen any connections. The

standard 17/19EX machine may be shipped with a nitrogen holding charge or with the refrigerant charge isolated within the utility vessel.

1. Inspect for shipping damage while machine is still on shipping conveyance. If machine appears to be damaged or

has been torn loose from its anchorage, have it examined

by transportation inspectors before removal. Forward claim

papers directly to transportation company. Manufacturer

is not responsible for any damage incurred in transit.

2. Check all items against shipping list. Immediately notify

the nearest Carrier representative if any item is missing.

3. Toprevent loss or damage, leave all parts in original packages until beginning installation. All openings are closed

with covers or plugs to prevent dirt and debris from entering the machine’s components during shipping. A full

operating oil charge is placed in the oil sump of the compressor before shipment.

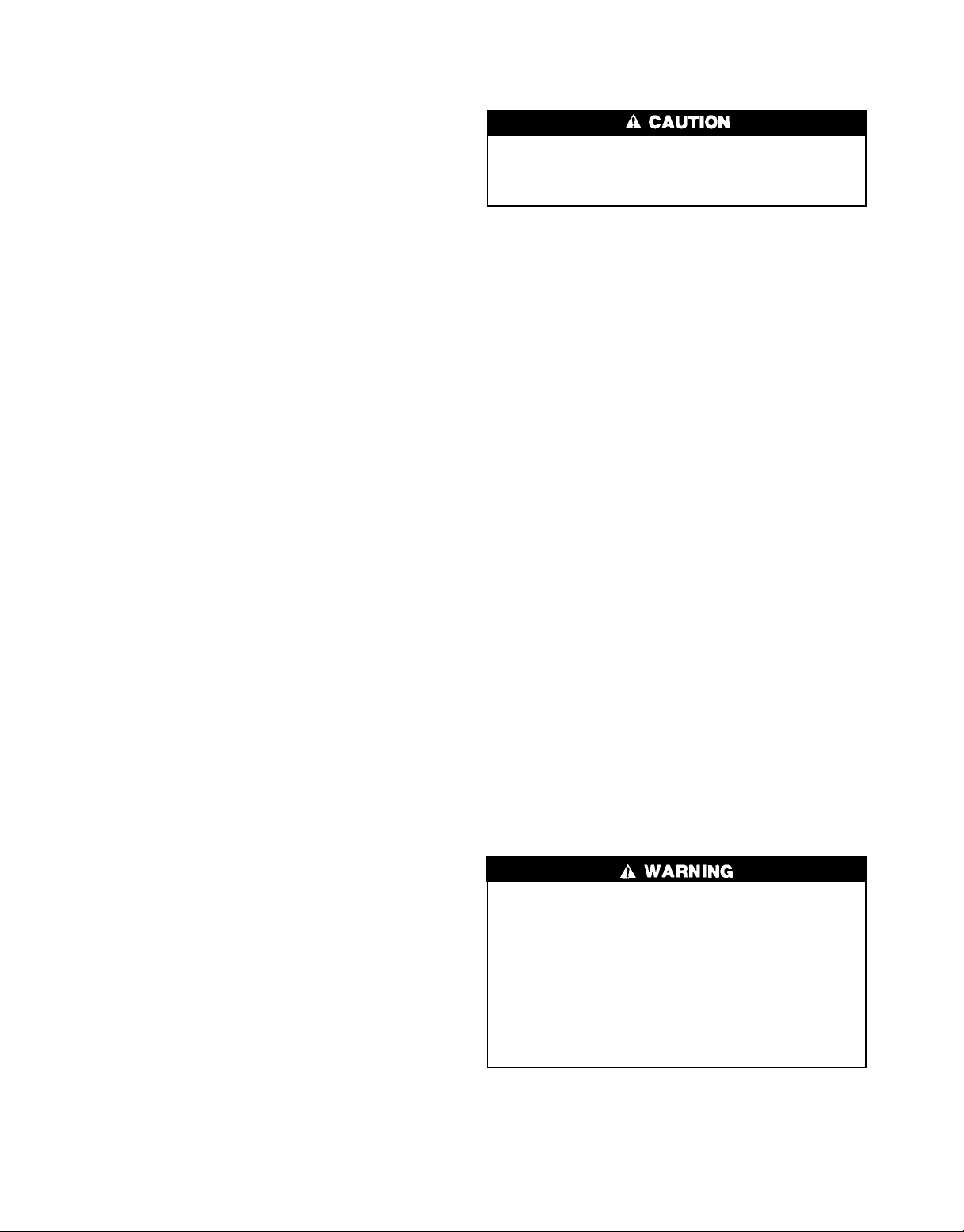

IDENTIFY MACHINE — The machine model number,

serial number, and heat exchanger sizes are stamped on

machine identification nameplate (Fig. 1). Check this information against shipping papers and job data.

PROVIDE MACHINE PROTECTION — Protect machine

and starter from construction dirt and moisture. Keep protective shipping covers in place until machine is ready for

installation.

If machine is exposed to freezing temperatures after water

circuits have been installed, open waterbox drains and remove all water from cooler and condenser.Leave drains open

until system is filled.

INTRODUCTION

General —

wired, and leak tested. Installation consists primarily of establishing water and electrical services to the machine. The

rigging, installation, field wiring, field piping and insulation

are the responsibility of the contractor and/or customer. See

Fig. 1 for model number information.

The 17/19EX machine is factory assembled,

Job Data

Necessary information consists of:

• job contract or specifications

• machine location prints

• rigging information

• piping prints and details

• field wiring drawings

• starter manufacturer’s installation details

• Carrier certified drawings

Equipment Required

• mechanic’s tools (refrigeration)

• volt-ohmmeter and clamp-on ammeter

• leak detector (halide or electronic)

• absolute pressure manometer or wet-bulb vacuum

indicator

• portable vacuum pumps

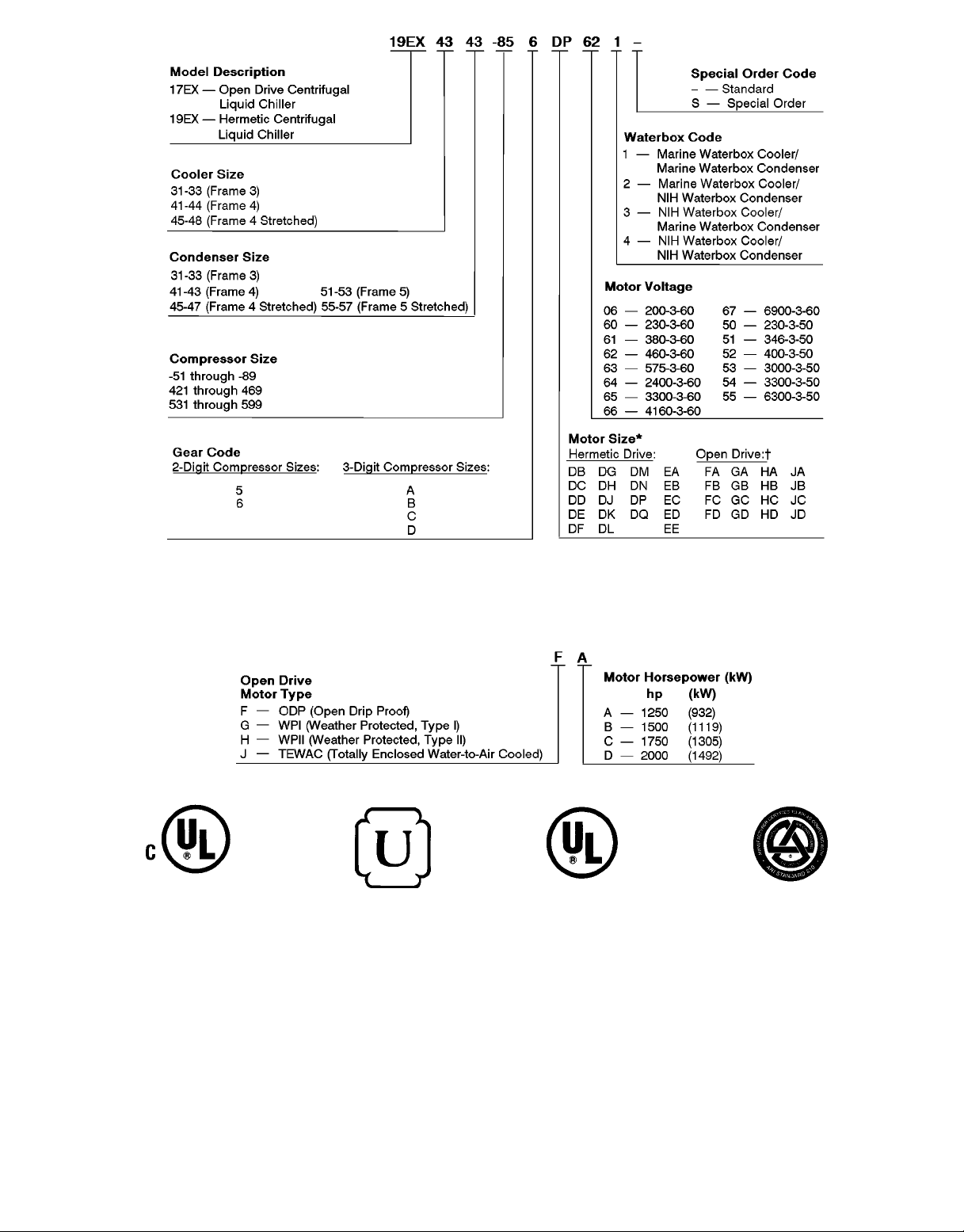

Rigging the Machine — The 17/19EX machine can

be rigged as an entire assembly. It also has flanged connections that allow the compressor, utility vessel, cooler, and

condenser sections to be separated for ease of installation.

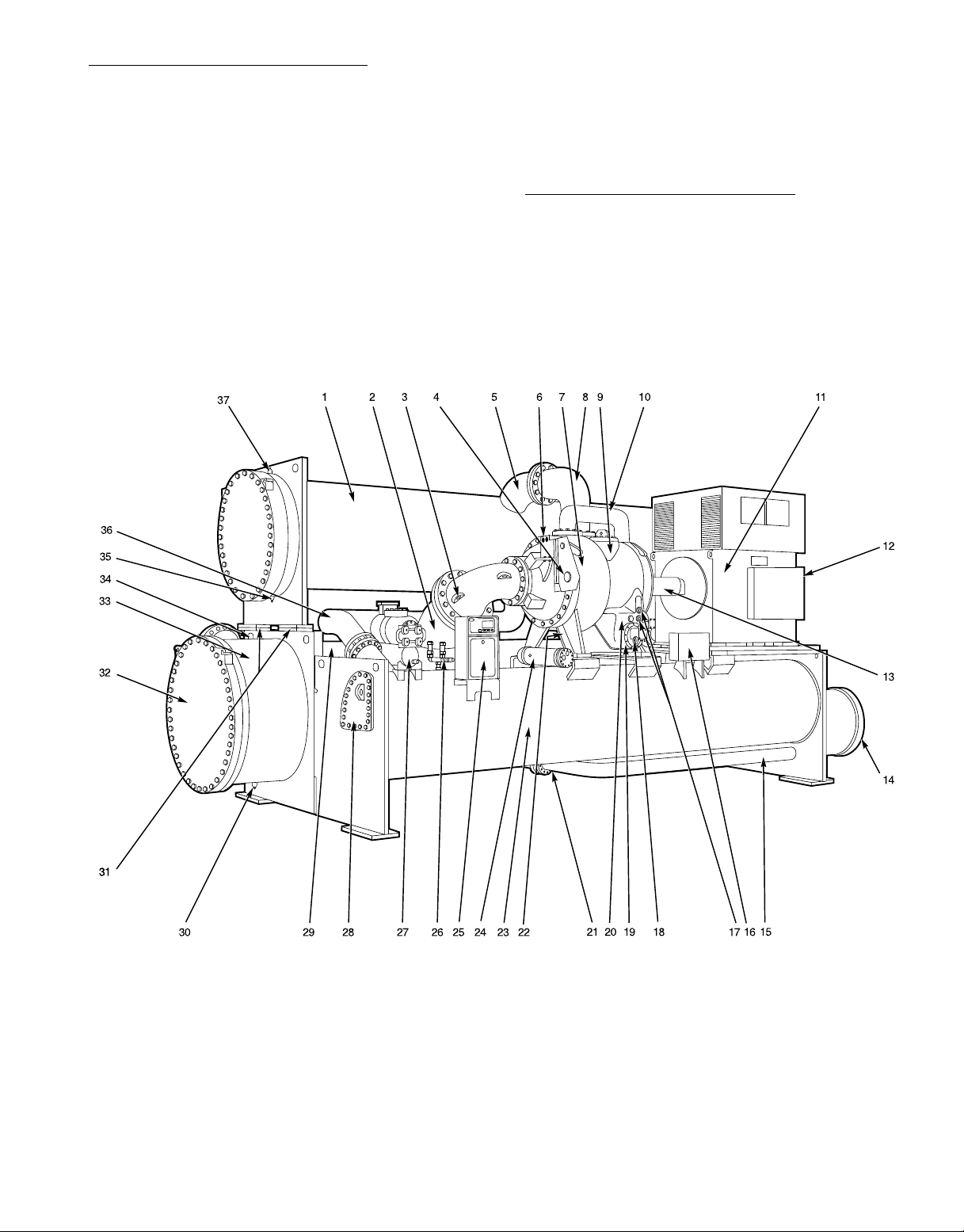

Figures 2 and 3 show 17/19EX components.

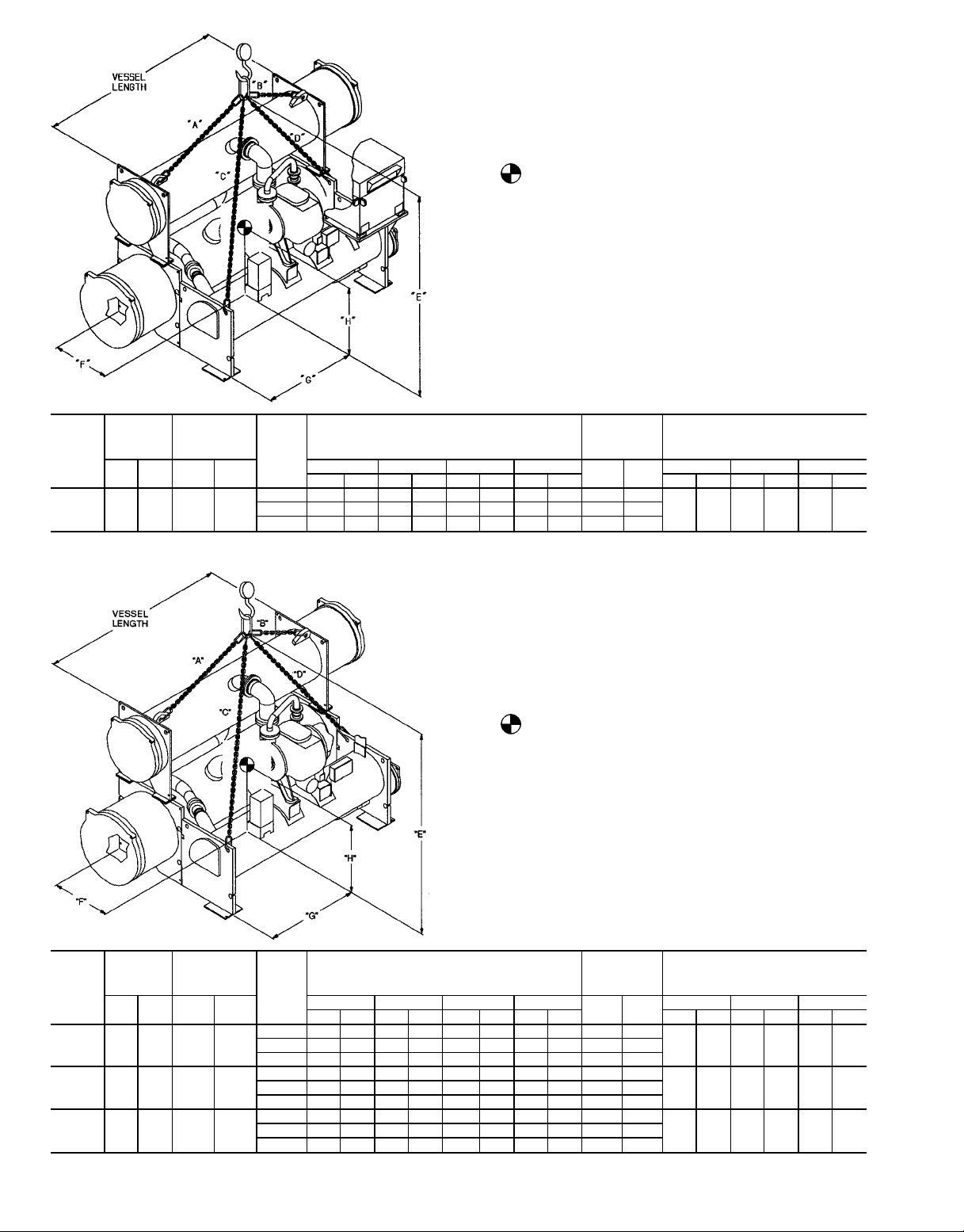

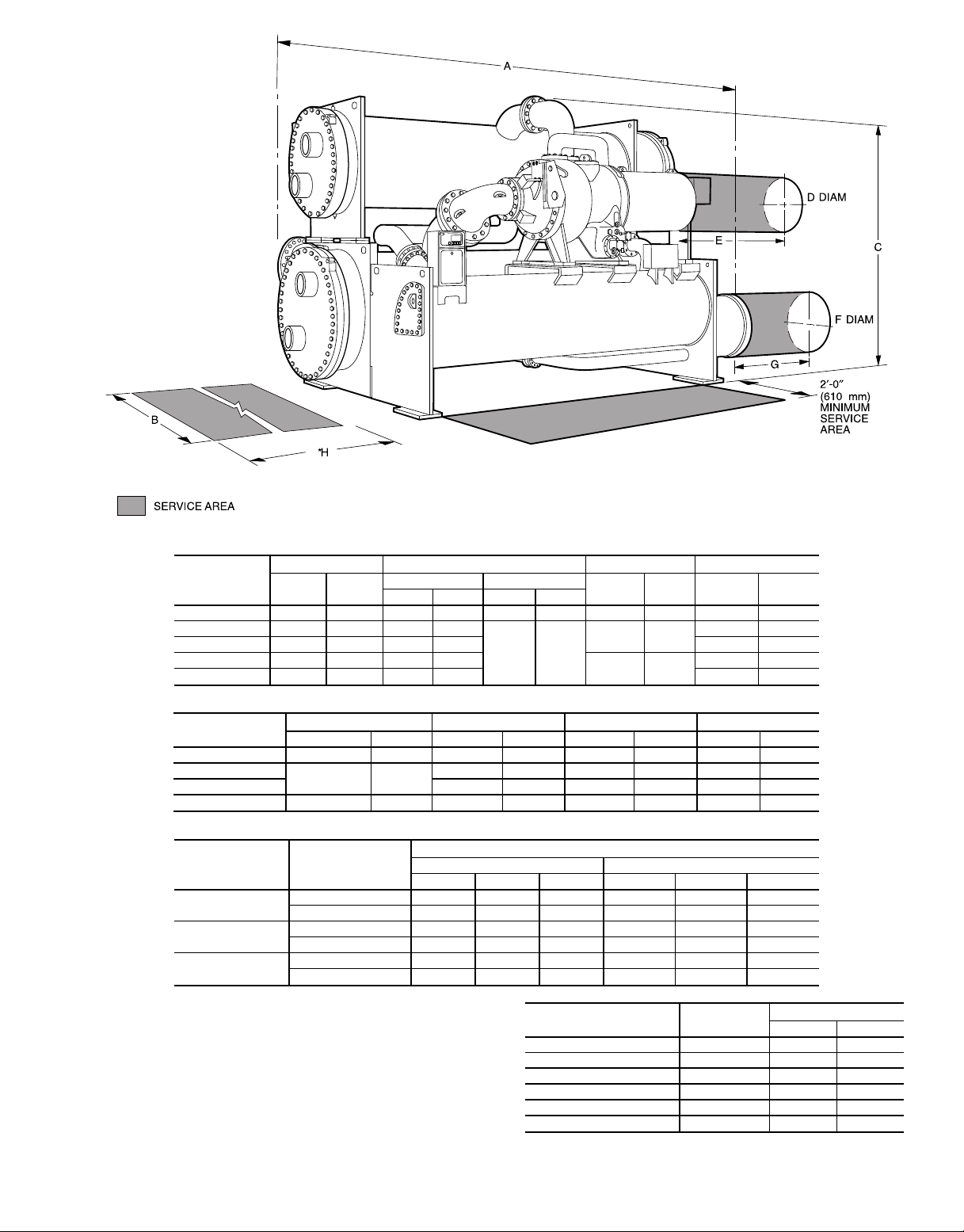

RIG MACHINEASSEMBLY— See rigging instructions on

label attached to machine. Also refer to the rigging information found in Fig. 4-9 and Tables 1-12. Lift machine only

fromthe 4 points indicated in rigging guide.Each lifting cable

or chain must be capable of supporting the entire weight of

the machine.

Lifting machine from points other than those specified

may result in serious damage to the unit and personal

injury. Rigging equipment and procedures must be adequate for machine weight. See Table 1 for machine

weights.

NOTE: These weights are broken down into component sections for use when installing the unit in

sections. For the complete machine weight, add all component sections and refrigerant charge together. Total

machine weight is also stenciled on the cooler and condenser sections.

2

Page 3

NIH — Nozzle-In-Head

*Motors beginning with ‘‘E’’ and open drive motors (FA-JD) cannot be used with size 51-89 or 421-469 compressors.

†Open-drive motor codes:

ASME

‘U’ STAMP

UNDERWRITERS’

LABORATORIES

Fig. 1 — Model Number Identification

3

ARI (Air Conditioning

and Refrigeration

Institute)

PERFORMANCE

CERTIFIED

(60 Hz Only)

Page 4

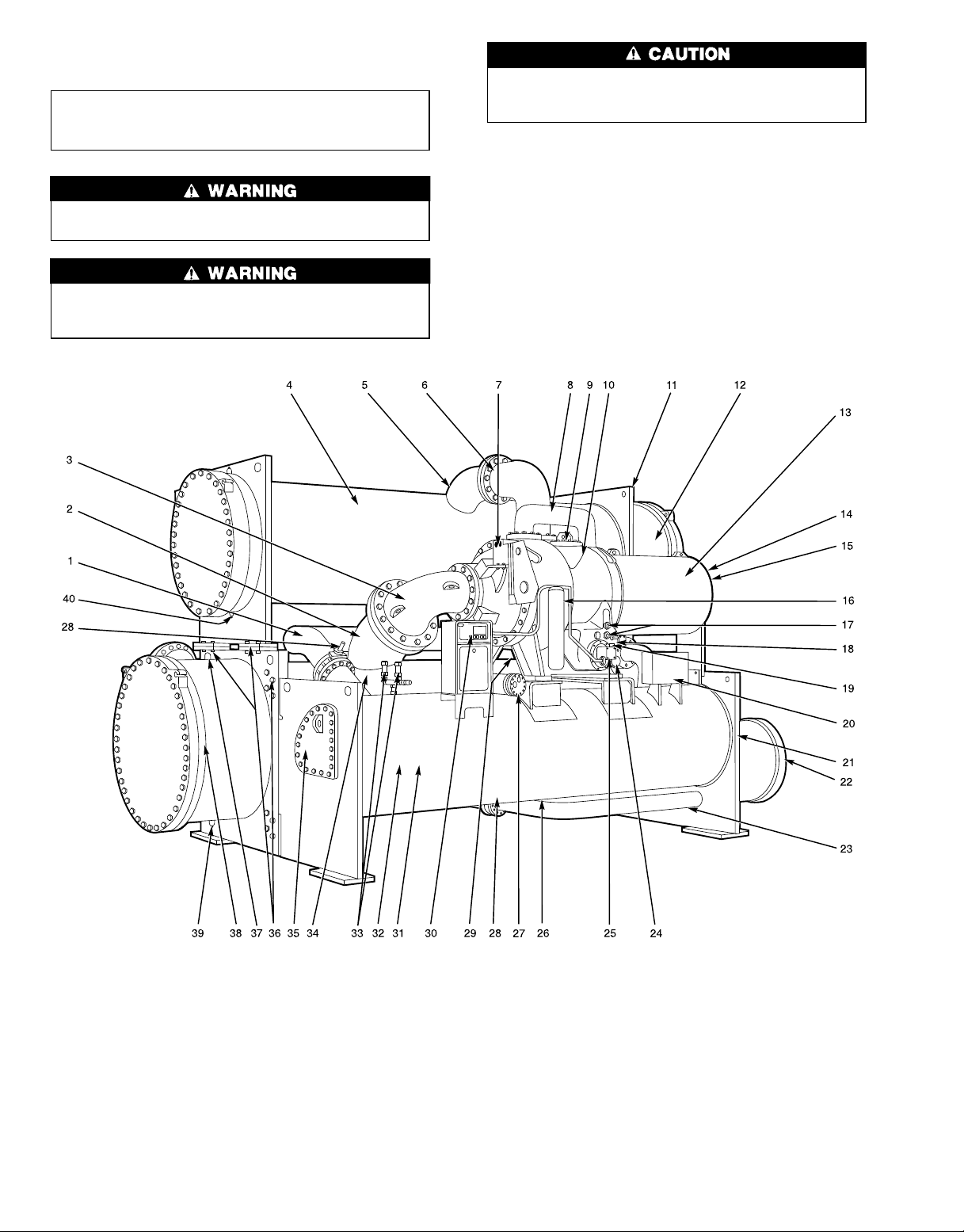

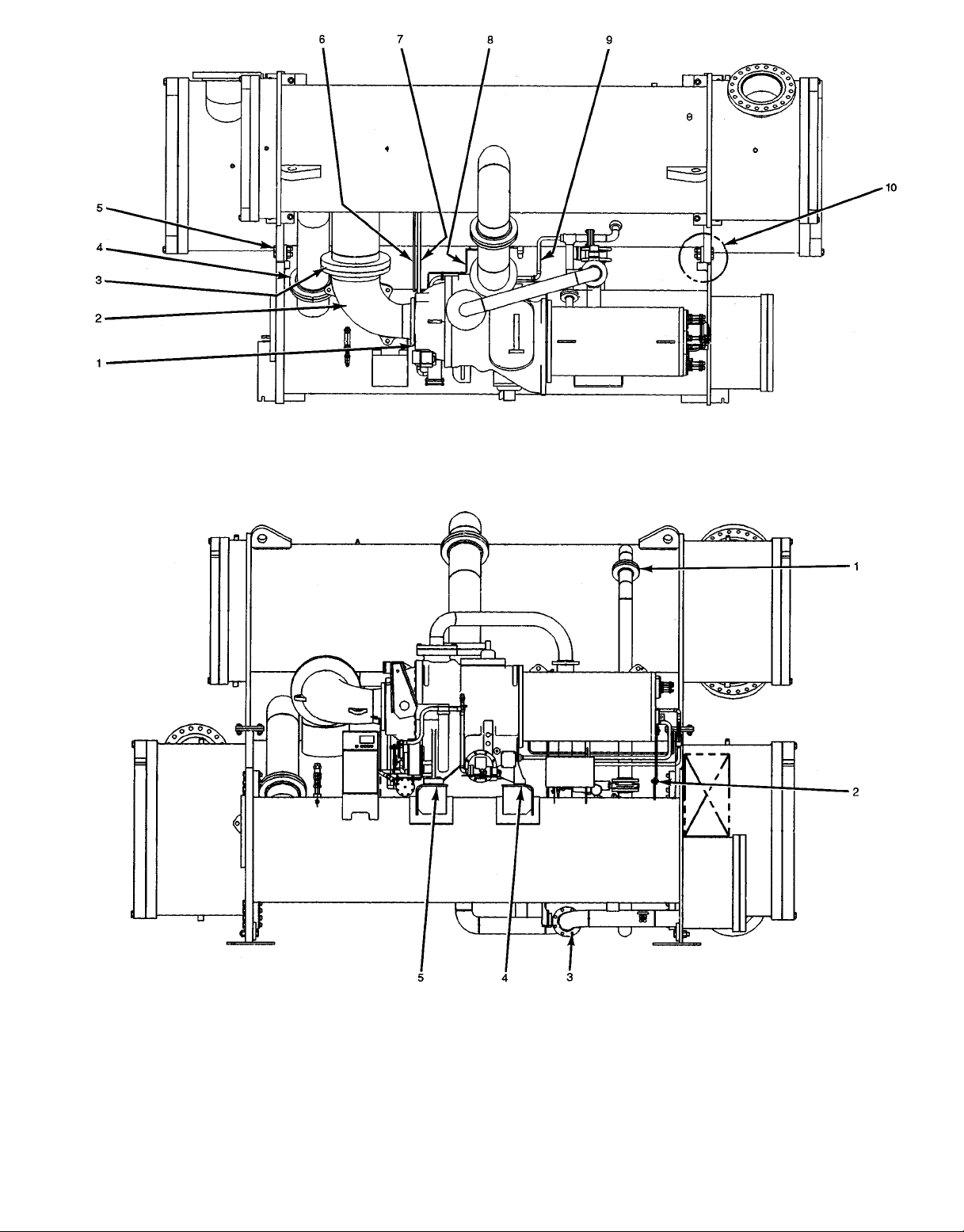

RIG MACHINE COMPONENTS — Refer to instructions

on page 5, Fig. 6-8, and Carrier certified drawings for machine component disassembly.

IMPORTANT: Onlya qualified servicetechnician should

disassemble and reassemble the machine. After reassembly,the machine must be dehydrated and leak tested.

When rigging components separately, the open drive

(17EX) motor must be removed to avoid overturning.

Do not attempt to disconnect flanges while the machine

is under pressure. Failure to relieve pressure can result

in personal injury or damage to the unit.

Before rigging the compressor, disconnect the wires

leading from the power panel to the control center at the

power panel.

NOTE: Wiring for sensors must be disconnected. Label each

wire before removal (see Carrier certified drawings).

Detach all transducer and sensor wires at the sensor, then

clip all wire ties necessary to remove the wires from the heat

exchangers.

1—Refrigerant Liquid Line to Economizer/

Storage Vessel

2—Cooler Suction Pipe

3—Compressor Suction Elbow

4—Condenser

5—Condenser Discharge Pipe

6—Compressor Discharge Elbow

7—Guide Vane Actuator

8—Economizer Gas Line to Compressor

9—Gear Inspection Cover

10 — 2-Stage Hermetic Compressor

11 — Condenser Waterbox Vent (Not Shown)

12 — Condenser Marine Waterbox

13 — Hermetic Compressor Motor

14 — Compressor Motor Terminal Box

(Not Shown)

19EX

LEGEND

15 — Motor Sight Glass (Not Shown)

16 — Oil Filter

17 — Oil Level Sight Glasses (2)

18 — Cooler Relief Valves (Not Shown)

19 — Oil Heater (Not Shown)

20 — Auxiliary Power Panel

(Field Wiring Terminals)

21 — Pumpdown Unit (Not Shown)

22 — Low-Side Float Box Cover

23 — Refrigerant Liquid Line to Cooler

24 — Oil Drain and Charging Valve

25 — Oil Pump

26 — Refrigerant Charging/Service

Valve 10 (Not Shown)

Fig.2—Typical 19EX Installation

4

27 — Oil Cooler

28 — Isolation Valves (Not Shown)

29 — Refrigerant Filter Drier

30 — Local Interface Display Control Panel

31 — Economizer/Storage Vessel

32 — Rigging Guide (Not Shown)

33 — Economizer/Storage Vessel

Relief Valves

34 — Cooler

35 — High-Side Float Box Cover

36 — Take-Apart Connections

37 — Cooler Waterbox Vent

38 — Cooler Marine Waterbox

39 — Cooler Waterbox Drain

40 — Condenser Waterbox Drain

Page 5

COMPONENT DISASSEMBLY

To Separate Compressor from the Machine

1. Make sure to check that the machine is at atmospheric

pressure before disassembly.

2. Since the center of gravity is high on 17EX machines,

the motor MUST be removed before rigging the

machine.

3. Suction elbow should be rigged separately (Fig. 6,

Item 2). Place slings around the elbow and attach to the

hoist. Remove bolting at flanges, (Fig. 6, Items 1 and 3).

Detach the elbow.

4. Unbolt discharge flange to the condenser at flange

(Fig. 8, Item 3). Cut copper lines (Fig. 6, Items 7, 8,

and 9).

5. Disconnect and detach the economizer vent line

(Fig. 8, Item 4). Unbolt the line at flange (Fig. 8,

Item 2).

6. On 19EX machines, disconnect the motor cooling drain

line at flange (Fig. 8, Item 5).

7. Disconnect wiring to the control center and power panel.

8. Connect rigging to the compressor.

9. Unbolt compressor from the utility vessel (Fig. 7,

Items 2, 4, and 5).

10. Hoist the compressor off of the unit.

11. If the compressor is to be transported or set down,

the base should be bolted to sections of 4 in.x6in.

lumber.

To Separate Condenser from the Machine

1. Unbolt flange (Fig. 6, Item 3).

2. Unbolt flange (Fig. 6, Item 4).

3. Cut copper pipe (Fig. 6, Item 7).

4. Unbolt hot flange (Fig. 7, Item 1).

5. Connect rigging to all corners of the condenser.

6. Unbolt condenser feet (Fig. 8, Items 1 and 6).

1—Condenser

2—Cooler Suction Pipe

3—Compressor Suction Elbow

4—Guide Vane Actuator

5—Condenser Discharge Pipe

6—Oil Filter (Hidden)

7—Two-Stage Compressor

8—Compressor Discharge Elbow

9—Gear Inspection Cover

10 — Economizer Gas Line to Compressor

11 — Open Drive Compressor Motor

12 — Compressor Motor Terminal Box

13 — Coupling Guard

14 — Low-Side Float Box Cover

LEGEND

15 — Refrigerant Liquid Line to Cooler

16 — Power Panel (Field Wiring Terminals)

17 — Oil Level Sight Glasses

18 — Oil Drain and Charging Valve

19 — Oil Heater (Hidden)

20 — Oil Pump

21 — Refrigerant Charging/Service Valve

10 (Not Shown)

22 — Cooler Relief Valves (Not Shown)

23 — Economizer/Storage Vessel

24 — Oil Cooler

25 — Control Center

26 — Economizer/Storage Vessel

Relief Valves

Fig.3—Typical 17EX Installation

5

27 — Pumpout Unit

28 — High Side Float Box Cover

29 — Cooler

30 — Cooler Waterbox Drain

31 — Take-Apart Connections (Typical)

32 — Cooler Marine Waterbox Cover

33 — Cooler Waterbox

34 — Cooler Waterbox Vent

35 — Condenser Waterbox Drain

36 — Refrigerant Liquid Line to

Economizer/Storage Vessel

37 — Condenser Waterbox Vent

Page 6

NOTES:

1. Each chain must be capable of supporting the maximum weight of the

machine.

2. = the approximate center of gravity.

3. Maximum possible weight is 88,500 lb (40 166 kg) which includes a maximum of 6,000 lb (2 721 kg) of HFC-134a refrigerant in the storage tank.

17EX FRONT VIEW

VESSEL

COOLER

SIZE

45-48 17-0 5182 88,550 40 166

LENGTH

ft-in. mm lb kg

MAXIMUM

WEIGHT

LIFTING

LIFTING

ANGLE

30° 10- 3 3124 9-0 2743 16-1 4902 13-6 4115 16-11 5156

60° 17-10 5436 17-1 5207 24-9 7544 22-8 6909 27- 3 8306

‘‘A’’ ‘‘B’’ ‘‘C’’ ‘‘D’’

ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm

CHAIN LENGTH

HEIGHT

FROM FLOOR

‘‘E’’

ft-in. mm

Fig. 4 — 17EX Machine Rigging Guide

NOTES:

1. Each chain must be capable of supporting the maximum weight of the

machine.

2. = the approximate center of gravity.

3. Maximum possible weight is 78,700 lb (35,698 kg) which includes a maximum of 6,000 lb (2,268 kg) of HFC-134a in the storage tank.

19EX FRONT VIEW

CENTER OF GRAVITY

APPROXIMATE LOCATION

‘‘F’’ ‘‘G’’ ‘‘H’’

4-1 1245 9-1 2769 4-9 144845° 12- 7 3835 11-7 3531 19-1 5817 16-9 5105 20- 8 6299

VESSEL

COOLER

SIZE

31-33 12-3 3734 55,000 24 948

41-44 12-3 3734 70,000 31 752

45-48 17-0 5182 78,700 35 698

LENGTH

ft-in. mm lb kg

MAXIMUM

WEIGHT

LIFTING

LIFTING

ANGLE

30° 7-2 1880 7-2 1880 11-11 3632 11-1 3378 13-7 4140

60° 12-5 3785 12-5 3785 18- 0 5486 17-6 5334 20-9 6325

30° 6-7 2007 6-9 2057 13- 0 3962 12-2 3708 15-1 4597

60° 11-4 3454 11-6 3505 18- 7 5664 18-0 5486 21-7 6579

30° 9-1 2769 9-6 2896 15- 1 4597 14-7 4445 16-4 4978

60° 15-9 4800 16-0 4877 22-10 6960 22-6 6858 25-5 7747

‘‘A’’ ‘‘B’’ ‘‘C’’ ‘‘D’’

ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm

CHAIN LENGTH

HEIGHT

FROM FLOOR

‘‘E’’

ft-in. mm

Fig. 5 — 19EX Machine Rigging Guide

6

CENTER OF GRAVITY

APPROXIMATE LOCATION

‘‘F’’ ‘‘G’’ ‘‘H’’

3-10 1168 6-1 1854 4-6 137245° 8-9 2667 8-9 2667 14- 0 4267 13-4 4064 16-2 4928

4- 0 1219 6-0 1829 4-8 142245° 8-0 2438 8-3 2515 14-11 4547 14-3 4343 17-5 5309

3-10 1168 8-3 2515 4-8 142245° 11-1 3378 11-6 3505 17- 9 5410 17-4 5283 19-8 5994

Page 7

NOTE: Item numbers are referenced in Rigging the Machine, Component Disassembly section.

Fig.6—Typical Top View (19EX Shown)

NOTE: Item numbers are referenced in Rigging the Machine, Component Disassembly section.

Fig.7—Typical Side View (19EX Shown)

7

Page 8

NOTE: Item numbers are referenced in Rigging the Machine, Component Disassembly section.

Fig.8—Typical Motor End View (19EX Shown)

To Separate Cooler From Utility Vessel

1. Remove condenser (see previous section).

2. Cut copper lines (Fig. 6, Items 6 and 8).

3. Unbolt liquid refrigerant line at flange (Fig. 7, Item 3).

4. Connect rigging to all four corners of the cooler before

lifting the unit.

5. Unbolt connections to the utility vessel (Fig. 6, Items 5

and 10).

To Assemble the Machine

1. Follow disassembly instructions (in reverse order) and bolt

all flanges back together using a gasket sealant. The following torque requirements are specified:

FIG. ITEM NO.

6

7

8

N-m — Newton Meters

*This torque is used to rig the entire machine. Once the machine

is in place, if no further rigging is anticipated, the bolt torque can

be reduced to 280 ft-lb (380 N-m).

3 580 786

1 or 4 170 230

5 and 10 840* 1139*

1 380 515

4 and 5 250 340

1 and 6 280 380

2 170 230

3 380 515

57196

TORQUE

ft-lb N-m

2. All gasketed or O-ring joints which have been disassembled must be assembled using new gaskets and O-rings.

These new gaskets and O-rings (along with gasket sealant, O-ring lubricant, and copper line couplings) are available through your Carrier representative.

3. Braze all copper lines back together using a suitable brazing material for copper. Carrier recommends an AWS

(American Welding Society) Classification BCuP-2.

Do not tilt the compressor; oil is contained in the oil

sump.

Additional Notes

1. Use silicon grease on new O-rings when refitting.

2. Use gasket sealant on new gaskets when refitting.

3. Cooler, utility, and condenser vessels may be rigged vertically, as separate components. Rigging should be fixed

to all four corners of the tube sheet.

4. New gaskets, grease for O-rings, and gasket sealant for a

complete take-apart operation are available in a kit. Contact your Carrier representative.

8

Page 9

NOTES:

1. Certified drawings available upon request.

2. Service accessshould be provided perAmerican Society of Heating,Refrigeration, and Air Conditioning Engineers (ASHRAE) 15, latest edition, National Fire Protection Association (NFPA)

70, and local safety codes.

DIMENSIONS

CONDENSER

SIZE

31-33 15-6 4724 N/A N/A 8-10 2692 10-8

41-43 15-6 4724 N/A N/A

45-47 20-3 6172 12-2 3708 17- 6 5334

51-53 15-6 4724 N/A N/A

55-57 20-3 6172 12-2 3708 17- 6 5334

A (LENGTH)† B (WIDTH) C (HEIGHT) H (TUBE PULL)

ft-in. mm

17EX** 19EX

ft-in. mm ft-in. mm

1

⁄22858

9-4

ft-in. mm ft-in. mm

1

⁄23264 12-10 3912

12-2 3708

12-5 3785

12-10 3912

12-10 3912

SERVICE CLEARANCES

COMPONENT

Motor DB - DQ 1-11

Motor EA - ED

Motor EE 4- 1

Low-Side Float — — — — 2-6

D (DIAMETER)†† E (LENGTH)†† F (DIAMETER) G (LENGTH)

ft-in. mm ft-in. mm ft-in. mm ft-in. mm

1

⁄

2- 2

4

3

⁄

4

591 3- 71⁄

679

3-10

2

1

1

1105 — — — —

⁄

4

1175 — — — —

⁄

4

1251 — — — —

1

⁄

2

775 1-0 305

NOZZLE SIZES

HEAT

EXCHANGER

31-33

41-48

51-57

NOZZLE TYPE

Cooler Passes Condenser Passes

123 1 2 3

Marine 12 10 10 12 10 10

NIH 12 10 10 — 10 10

Marine 20 14 12 20 14 12

NIH 18 14 10 18 12 10

Marine — — — — 16 —

NIH — — — 20 16 —

NOZZLE SIZES (in.)|

LEGEND

NIH — Nozzle-In-Head

*Distance required for tube removal may be either end.

†Based on 2-pass, nozzle-in-head (NIH) waterboxes with 150 psi (1038 kPa)

covers.

**Overall width of units with 17 Series compressors will vary greatly depend-

ing upon the application. See the appropriate certified drawings.

††For hermetic motors (19 Series) only.

\The table at right provides additional information on nozzle sizes. Victaulic

grooves are standard for these nozzles. Optional 150 psi (1034 kPa) and

300 psi (2068 kPa) flanges are available.

¶In conformance with ASA B36.10 (American Standards Association).

Fig.9—Typical Dimensions

NOMINAL PIPE SIZE (in.) SCHEDULE¶

10 40 .365 9.27

12 Std .375 9.53

14 30 .375 9.53

16 30 .375 9.53

18 Std .375 9.53

20 20 .375 9.53

9

WALL THICKNESS

in. mm

Page 10

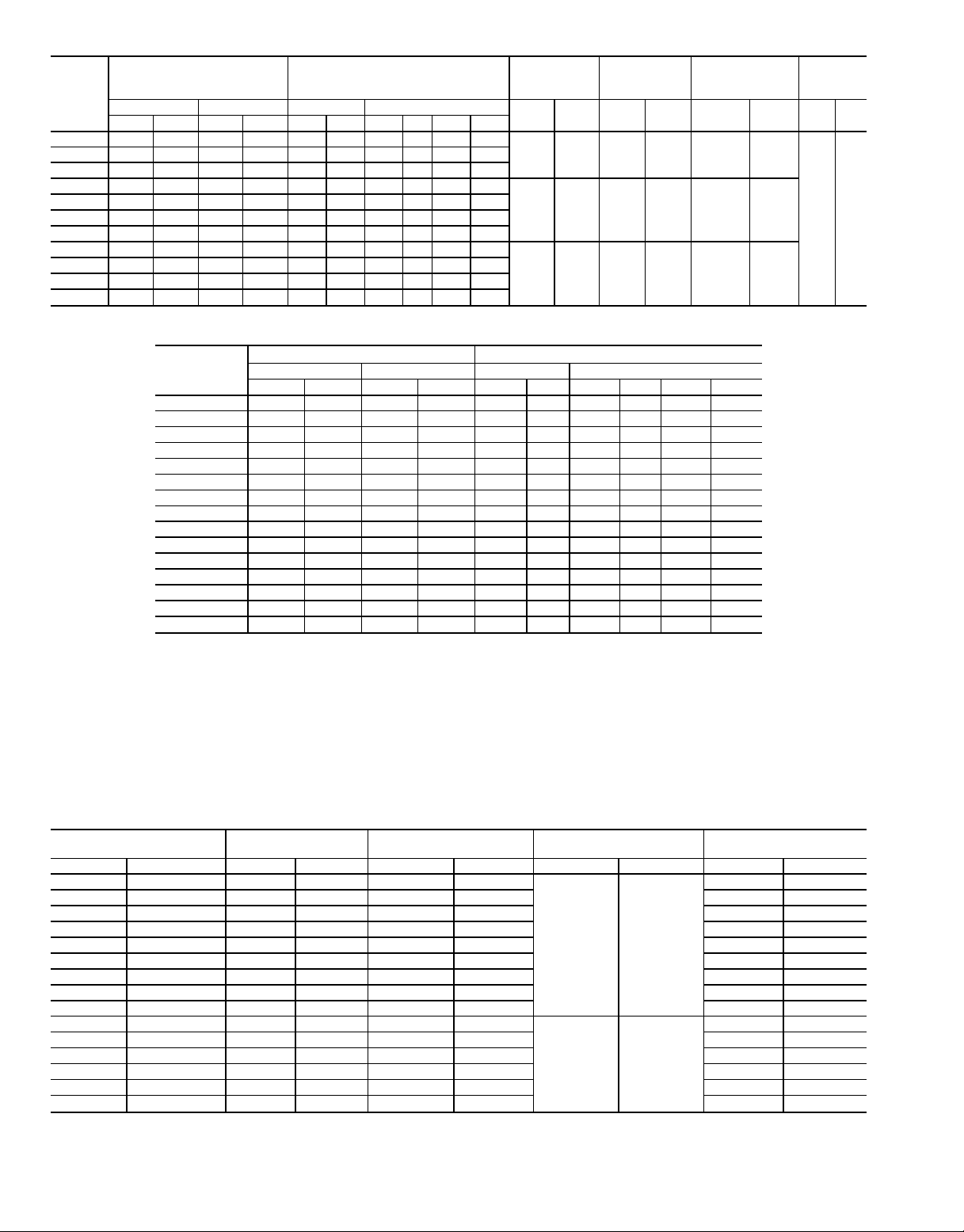

Table 1 — 17/19EX Heat Exchanger, Economizer/Storage Vessel, Piping, and Pumpout Unit Weights*

COOLER

COOLER

SIZE†

31 14,173 6 429 17,518 7 946 1,540 699 1,810 217 821 821

32 14,538 6 594 18,117 8 218 1,640 744 1,944 233 882 882

33 14,904 6 760 18,722 8 492 1,740 789 2,078 249 943 943

41 21,674 9 831 26,120 11 848 1,900 862 2,441 293 1 107 1 107

42 22,019 9 988 26,736 12 127 2,000 907 2,575 309 1 168 1 168

43 22,364 10 144 27,322 12393 2,100 953 2,709 325 1 229 1 229

44 23,841 10 814 29,836 13533 2,190 993 3,285 394 1 490 1 490

45 25,032 11 354 30,790 13966 2,260 1 025 3,006 361 1363 1 363

46 25,529 11 580 31,658 14360 2,360 1 070 3,192 383 1448 1 448

47 26,025 11 805 32,496 14740 2,460 1116 3,378 405 1 532 1 532

48 28,153 12 770 36,053 16353 2,540 1 152 4,173 500 1893 1 893

lb kg lb kg lb kg lb gal kg L

TOTAL

WEIGHT

Dry Operating†† Refrigerant Water

COOLER

CHARGE

ECONOMIZER/

STORAGE

VESSEL**

lb kg lb kg lb kg lb kg

7,169 3252 610 277 820 372

7,169 3 252 610 277 1,095 497

7,900 3 583 840 381 1,149 521

ECONOMIZER

REFRIGERANT

MISCELLANEOUS

PIPING

PUMPOUT

UNIT

210 95

CONDENSER

SIZE†

31 10,454 4 742 13,022 5 907 950 431 1,613 193 732 732

32 10,809 4 903 13,514 6 130 950 431 1,750 210 794 794

33 11,164 5 064 14,000 6 350 950 431 1,886 226 855 855

41 13,768 6 245 16,999 7711 1,090 494 2,146 257 973 973

42 14,118 6 404 17,498 7 937 1,090 494 2,282 274 1 035 1 035

43 14,468 6 563 17,978 8 155 1,090 494 2,419 290 1 097 1 097

45 16,676 7 564 20,800 9 435 1,400 635 2,720 326 1 234 1 234

46 17,172 7 789 21,489 9 747 1,400 635 2,908 348 1 319 1 319

47 17,669 8 015 22,178 10 060 1,400 635 3,096 371 1 404 1 404

51 17,188 7 796 20,993 9 522 1,100 499 2,707 325 1 228 1 228

52 17,848 8 096 21,923 9 944 1,100 499 2,964 355 1 344 1 344

53 18,400 8 346 22,682 10 288 1,100 499 3,178 381 1 442 1 442

55 20,725 9 401 25,598 11 611 1,420 644 3,453 412 1 566 1 566

56 21,663 9 826 26,896 12 199 1,420 644 3,808 457 1 727 1 727

57 22,446 10 181 27,980 12 691 1,420 644 4,105 492 1 862 1 862

*If a machine configuration other than 2-pass, 150 psig (1034 kPa), NIH waterbox configuration is used, refer to Tables 3

and 4 to obtain the additional dry and water weights that must be added to the values shown in this table.

†Cooler and condenser weights shown are based upon 2-pass, nozzle-in-head (NIH) waterboxes with 150 psig (1034 kPa)

covers. Includes components attached to cooler, but does not include suction/discharge, elbow, or other interconnecting

piping.

**Dry weight includes all components attached to economizer: Covers, float valves, brackets, control center (31 lb [14 kg]),

and power panel (20 lb [9 kg]). Dry weight does not include compressor weight, motor weight, or pumpout condensing unit

weight. The pumpout condensing unit weight is 210 lb (95 kg). For compressor and motor weights, refer to Tables 6, 7, 8,

10A, and 10B.

††Operating weight includes the sum of the dry weight, refrigerant weight, and water weight.

CONDENSER TOTAL WEIGHT CONDENSER CHARGE

Dry Operating†† Refrigerant Water

lb kg lb kg lb kg lb gal kg L

Table 2 — Refrigerant Charge

HEAT EXCHANGER SIZE COOLER CHARGE CONDENSER CHARGE ECONOMIZER CHARGE

Cooler Condenser lb kg lb kg lb kg lb kg

31 31 1540 699 950 431

32 32 1640 744 950 431 3200 1 452

33 33 1740 789 950 431 3300 1 497

41 41 1900 862 1090 494 3600 1 633

42 42 2000 907 1090 494 3700 1 678

43 43 2100 953 1090 494 3800 1 724

44 51 2190 993 1100 499 3900 1 769

44 52 2190 993 1100 499 3900 1 769

44 53 2190 993 1100 499 3900 1 769

45 45 2260 1 025 1400 635

46 46 2360 1 070 1400 635 4600 2 087

47 47 2460 1 116 1400 635 4700 2 132

48 55 2540 1 152 1420 644 4800 2 177

48 56 2540 1 152 1420 644 4800 2 177

48 57 2540 1 152 1420 644 4800 2 177

*Total machine refrigerant charge includes the cooler, condenser, and economizer.

NOTE: Regulations mandate that machine shipping charge is limited to 7500 lb (3402 kg).

610 277

844 381

TOTAL REFRIGERANT

CHARGE*

3100 1 406

4500 2 041

10

Page 11

Table 3 — Additional Cooler Weights*

COOLER

FRAME

3

4

NIH — Nozzle-In-Head

*When using a machine configuration other than 2-pass, NIH waterboxes with 150 psig (1038 kPa) covers, add the weights listed in this table to the appropriate weights

in Table 1 to obtain the correct cooler weight.

WATERBOX

TYPE

NIH 1, 3 150 1034 655 297 — — — —

NIH 1, 3 300 2068 2226 1010 — — — —

NIH 2 300 2068 1406 638 — — — —

Marine 1, 3 150 1034 780 354 3192 383 1448 1448

Marine 2 150 1034 390 177 1596 191 724 724

Marine 1, 3 300 2068 3412 1548 3192 383 1448 1448

Marine 2 300 2068 1706 774 1596 191 724 724

NIH 1, 3 150 1034 515 234 — — — —

NIH 1, 3 300 2068 2941 1334 — — — —

NIH 2 300 2068 2085 946 — — — —

Marine 1, 3 150 1034 2100 953 5102 612 2314 2314

Marine 2 150 1034 792 359 2551 306 1157 1157

Marine 1, 3 300 2068 3844 1744 5102 612 2314 2314

Marine 2 300 2068 2536 1150 2551 306 1157 1157

NUMBER

OF PASSES

DESIGN MAXIMUM

WATER PRESSURE

psig kPa lb kg lb gal kg L

ADDITIONAL

DRY WEIGHT

ADDITIONAL

WATER WEIGHT

Table 4 — Additional Condenser Weights*

COMPONENT

CONDENSER

NIH — Nozzle-In-Head

*When using a machine configuration other than 2-pass, NIH waterboxes with 150 psig (1034 kPa) covers, add the weights listed in this table to the appropriate weights

in Table 1 to obtain the correct condenser weight.

†Subtract 228 lb (103 kg) from the weight shown in Table 1.

HEAT EXCHANGER

SIZE

31-33

41-43

45-47

51-53

55-57

WATERBOX TYPE

NIH 3 150 1034 262 119 — — — —

NIH 3 300 2068 1328 602 — — — —

NIH 2 300 2068 872 396 — — — —

Marine 3 150 1034 842 382 2276 273 1032 1032

Marine 2 150 1034 421 191 1138 136 516 516

Marine 3 300 2068 1520 689 2276 273 1032 1032

Marine 2 300 2068 1099 498 1138 136 516 516

NIH 1, 3 150 1034 344 156 — — — —

NIH 1, 3 300 2068 1652 749 — — — —

NIH 2 300 2068 1132 513 — — — —

Marine 1, 3 150 1034 1692 767 3400 408 1542 1542

Marine 2 150 1034 674 306 1700 204 771 771

Marine 1, 3 300 2068 2651 1202 3400 408 1542 1542

Marine 2 300 2068 1630 739 1700 204 771 771

NIH 1 150 1034 † † — — — —

NIH 1 300 2068 1588 720 — — — —

NIH 2 300 2068 1591 721 — — — —

Marine 2 150 1034 25 11 1734 208 787 787

Marine 2 300 2068 1225 555 1734 208 787 787

NUMBER OF

PASSES

DESIGN MAXIMUM

WATER PRESSURE

psig kPa lb kg lb gal kg L

ADDITIONAL

DRY WEIGHT

ADDITIONAL

WATER WEIGHT

Table 5 — Auxiliary Connection Sizes

SIZE AND STYLE USAGE

3

⁄8in. Male Flare

1

⁄2in. FPT

1

⁄2in. NPT Conduit Power Panel Oil Pump Power Connection

1 in. NPT

1

⁄4in. FPT

1

Pumpout Condenser Refrigerant Vapor Connection

(Rupture Disc)

Pumpout Water Inlet Connection

Pumpout Water Outlet Connection

Waterbox Vent Connection

Waterbox Drain Connection

Cooler Relief Valve Connection

Economizer/Storage Vessel Connection

11

Page 12

Table6—Total 19EX Motor Weights (60 Hz)

MOTOR SIZE

DB 1484 673 1420 644 NA NA

DC 1496 678 1478 670 NA NA

DD 1514 687 1503 682 2097 951

DE 1620 728 1536 696 2152 976

DF 1657 752 1635 742 2656 1205

DG 1662 754 1677 761 2741 1243

DH 1749 793 1715 778 2806 1273

DJ 1790 812 1758 797 2876 1305

DK 1823 827 2267 1028 3054 1385

DL 2262 1026 2374 1077 3162 1434

DM 2337 1060 2501 1134 3222 1461

DN 2415 1095 2558 1160 3277 1486

DP 2456 1114 2688 1219 3402 1543

DQ NA NA 2721 1234 3467 1573

EA 1968 893 2031 921 2377 1078

EB 2128 965 2233 1013 2427 1101

EC 2241 1017 2358 1070 2602 1180

ED 2366 1073 2514 1140 2827 1282

EE 2664 1208 2989 1356 3258 1478

NA — Not Available

NOTE:Low-voltage motors are ratedbelow 600 v,medium-voltage motors range

from 600 v to 6,000 v, and high-voltage motors are rated above 6,000 v.

LOW VOLTAGE MEDIUM VOLTAGE HIGH VOLTAGE

lb kg lb kg lb kg

Table7—Total 19EX Motor Weights (50 Hz)

MOTOR SIZE

DB 1662 754 1568 711 NA NA

DC 1677 760 1628 740 NA NA

DD 1696 769 1662 754 2312 1049

DE 1710 776 1707 775 2332 1058

DF 1792 813 1807 820 2386 1082

DG 1863 845 2212 1003 2947 1337

DH 1921 871 2283 1036 3022 1371

DJ 2222 1008 2340 1061 3097 1405

DK 2331 1057 2472 1121 3187 1446

DL 2373 1076 2624 1190 3257 1477

DM 2481 1125 2692 1221 3317 1505

DN 2555 1159 2864 1299 3407 1545

DP 2597 1178 2924 1326 3502 1588

DQ NA NA 3014 1367 3612 1638

EA 2232 1012 2392 1085 2682 1217

EB 2443 1108 2380 1080 2887 1310

EC 2646 1200 2747 1246 3257 1477

ED 2760 1252 2952 1339 3442 1561

EE 3009 1365 3161 1434 3533 1603

NA — Not Available

NOTE:Low-voltage motors are ratedbelow 600 v,medium-voltage motors range

from 600 v to 6,000 v, and high-voltage motors are rated above 6,000 v.

LOW VOLTAGE MEDIUM VOLTAGE HIGH VOLTAGE

lb kg lb kg lb kg

Table 8 — Compressor Weights

COMPONENT

Compressor

Weight*

Suction

Elbow

*Weight does not include motor.

NOTES:

1. 19EX compressors include sizes −51 through −89.

2. 17/19FA5 compressors include sizes 531 through 599.

3. 19FA4 compressors include sizes 421 through 469.

19EX COMPRESSOR 17/19FA5 COMPRESSOR 19FA4

lb kg lb kg lbs kg

4886 2216 5150 2336 2625 1191

500 227 500 227 325 147

Table9—Total 17EX Drive Component Weights

MOTOR

HORSEPOWER (kW)

CODE

A 1200 544 75 34 25 11

B 1200 544 75 34 25 11

C 1200 544 75 34 25 11

D 1100 499 75 34 25 11

BASE WEIGHT COUPLING WEIGHT GUARD WEIGHT

lb kg lb kg lb kg

12

Page 13

ENCLOSURE

TYPE

Open-Drip Proof

(ODP)

Weather Protected

Type I (WPI)

Weater Protected

Type II (WPII)

Totally Enclosed

Water-To-Air Cooled

(TEWAC)

Table 10A — 17EX Motors — Total Weight, Lbs (English)

HERTZ VOLTAGE SIZE (HP)

FA (1250) FB (1500) FC (1750) FD (2000)

GA (1350) GB (1500) GC (1750) GD (2000)

HA (1250) HB (1500) HC (1750) HD (2000)

JA (1250) JB (1500) JC (1750) JD (2000)

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50Hz

60 Hz

50 Hz

2400 4836 5721 5900 7160

3300 4824 5832 5832 7127

4160 4836 5721 5900 7160

6900 5596 6577 8776 8990

3000 5518 5878 7148 9048

3300 5518 5878 7148 9073

6300 5596 6577 8875 8976

2400 5046 5871 6050 7270

3300 5034 5982 5982 7237

4160 5046 5871 6050 7270

6900 5806 6727 8926 9100

3000 5728 6028 7298 9158

3300 5728 6028 7298 9183

6300 5806 6727 9025 9086

2400 5146 6151 6330 7600

3300 5134 6262 6262 7567

4160 5146 6151 6330 7600

6900 5906 7007 9206 9430

3000 5828 6308 7578 9488

3300 5828 6308 7578 9513

6300 5906 7007 9305 9416

2400 5707 6746 6925 8290

3300 5694 6857 6857 8257

4160 5707 6746 6925 8290

6900 6466 7602 9801 10,120

3000 6388 6903 8173 10,178

3300 6388 6903 8173 10,203

6300 6466 7602 9900 10,106

ENCLOSURE

TYPE

Open-Drip Proof

(ODP)

Weather Protected

Type I (WPI)

Weather Protected

Type II (WPII)

Totally Enclosed

Water-To-Air Cooled

(TEWAC)

Table 10B — 17EX Motors — Total Weight, Kg (SI)

FREQ VOLTAGE SIZE (kW)

FA (932) FB (1119) FC (1305) FD (1492)

GA (932) GB (1119) GC (1305) GD (1492)

HA (932) HB (1119) HC (1305) HD (1492)

JA (932) JB (1119) JC (1305) JD (1492)

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

2400 2194 2595 2676 3248

3300 2188 2645 2645 3233

4160 2194 2595 2676 3248

6900 2538 2983 3981 4033

3000 2503 2666 3242 4104

3300 2503 2666 3242 4116

6300 2538 2983 4026 4072

2400 2289 2663 2744 3298

3300 2283 2713 2713 3283

4160 2289 2663 2744 3298

6900 2634 3051 4049 4128

3000 2598 2734 3310 4154

3300 2598 2734 3310 4165

6300 2634 3051 4094 4121

2400 2334 2790 2871 3447

3300 2329 2840 2840 3432

4160 2334 2790 2871 3447

6900 2679 3178 4126 4277

3000 2644 2861 3437 4304

3300 2644 2861 3437 4315

6300 2679 3178 4221 4271

2400 2587 3060 3141 3760

3300 2583 3110 3110 3745

4160 2587 3060 3141 3760

6900 2933 3448 4446 4590

3000 2898 3131 3707 4617

3300 2898 3131 3707 4628

6300 2933 3448 4490 4584

13

Page 14

Table 11 — Marine Waterbox Cover Weights*

HEAT EXCHANGER

SIZE

31-33

41-48

51-57

*Heat exchangers with marine waterboxes have heavier dry and operating weights than heat exchangers with nozzle-

in-head waterboxes.

DESIGN MAXIMUM WATER PRESSURE COOLER CONDENSER

psi kPa lb kg lb kg

150 1034 1667 756 1092 495

300 2068 2280 1034 1436 651

150 1034 2236 1015 1275 579

300 2068 3060 1389 1660 754

150 1034 — — 1643 746

300 2068 — — 2243 1018

Table 12 — NIH Waterbox Cover Weights*

HEAT EXCHANGER

SIZE

31-33

41-48

51-57

NIH — Nozzle-in-Head

*The 150 psig (1034 kPa) 2-pass waterbox cover weights are included in the dry weight shown in Table 1.

†Twodifferent waterbox covers are present on 2-pass machines. The weight shown in this table represents the weight

of the waterbox cover that contains the nozzles. A blank waterbox cover is also present on 2-pass units. The weight

of the blank waterbox cover is identical to the weight of the same size marine waterbox cover. Refer to Table 11.

PASSES

DESIGN MAXIMUM WATER PRESSURE COOLER CONDENSER

psi kPa lb kg lb kg

1

2

3

1

2†

3

1

2†

3

150 1034 1880 853 — —

300 2068 2748 1247 — —

150 1034 2168 983 1356 615

300 2068 3107 1409 1959 889

150 1034 2105 955 1283 582

300 2068 2991 1357 1828 829

150 1034 2997 1361 1735 788

300 2068 4225 1918 2510 1140

150 1034 2984 1355 1885 856

300 2068 4188 1901 2590 1176

150 1034 3035 1378 1777 807

300 2068 4244 1927 2539 1153

150 1034 — — 2032 923

300 2068 — — 2940 1335

150 1034 — — 2649 1203

300 2068 — — 3640 1653

150 1034 — — — —

300 2068 — — — —

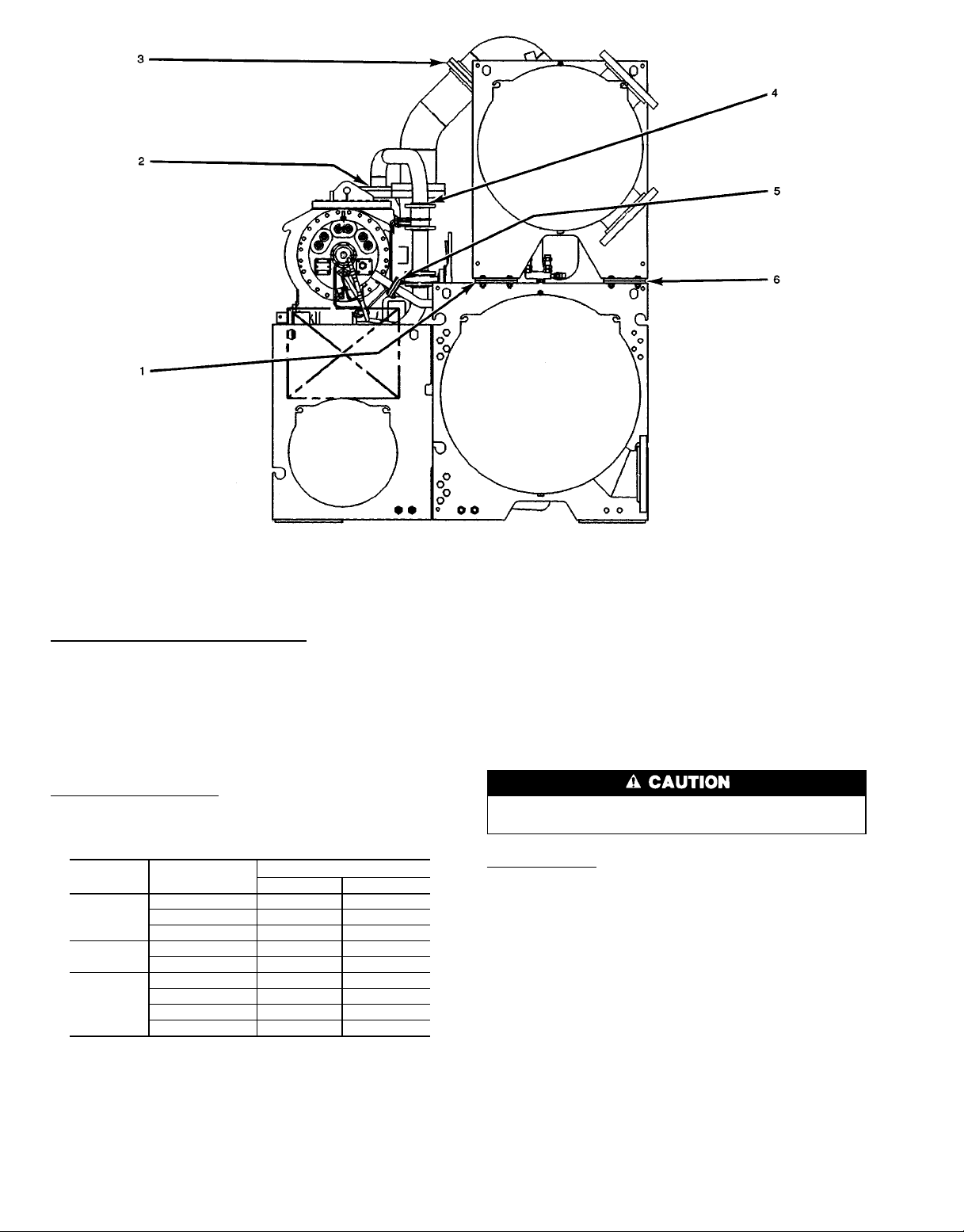

Install Machine Supports

INSTALL STANDARD ISOLATION — Figures 10 and 11

show the position of support plates and shear flex pads, which

together form the standard machine support system.

INSTALL OPTIONAL ISOLATION (if required) — Uneven floors or other considerations may dictate the use of

soleplates and leveling pads. Refer to Fig. 10 and 11.

Level machine by using jacking screws in isolation sole-

plates. Use a level at least 24 in. (600 mm) long.

For adequate and long lasting machine support, proper grout

selection and placement is essential. Carrier recommends that

only pre-mixed, epoxy-type, non-shrinking grout be used for

machine installation. Follow manufacturer’s instructions in

applying grout.

1. Check machine location prints for required grout

thickness.

2. Carefully wax jacking screws for easy removal from grout.

3. Grout must extend above the base of the soleplate and

there must be no voids in grout beneath the plates.

4. Allow grout to set and harden, per manufacturer’s instructions, before starting machine.

5. Remove jacking screws from leveling pads after grout has

hardened.

INSTALL SPRING ISOLATION — Field-supplied spring

isolators may be placed directly under machine support plates

or be located under machine soleplates. Consult job data for

specific arrangement. Low profile spring isolation assemblies are recommended so that the machine is kept at a convenient working height inside of the tube sheet.

Obtain specific details on spring mounting and machine

weight distribution from job data. Also, check job data for

methods for supporting and isolating pipes that are attached

to the spring-isolated machines.

14

Page 15

COOLER SIZES 31-33 AND 41-44

COOLER SIZES

AB C

ft-in. mm ft-in. mm ft-in. mm

31-33 8-8

2

2654 8-10 2692 4- 8 1422

1

⁄

41-44 9-3 2819 9- 4

COOLER SIZES 45-48

DIMENSIONS

1

⁄

2

2858 4-111⁄

4

1505

NOTES:

1. Dimensions in ( ) are in mm.

2. 1 inch = 25.4 mm.

3. All dimensions approximately ±

1

⁄2inch.

Fig. 10 — Machine Contact Surfaces

15

Page 16

SOLEPLATE ISOLATION TYPICAL ISOLATION

ACCESSORY ISOLATION

SOLEPLATE DETAIL

SECTION A-A

NOTES:

1. Dimensions in ( ) are in millimeters.

2. Accessory soleplate package includes 4 soleplates, 16 jacking screws and leveling pads. Requires

isolation package.

3. Jacking screws to be removed after grout has set.

4. Thickness of grout will vary,depending on the amount necessary to level chiller. Use only pre-mixed

non-shrinking grout, Celcote HT-648 or Master Builders 636, 08-1

1

⁄29 (38.1) to 08-21⁄49 (57) thick.

STANDARD ISOLATION

VIEW B-B

ISOLATION WITH ISOLATION PACKAGE ONLY

(STANDARD)

NOTE: Isolation package includes 4 shear flex pads.

Fig. 11 — Machine Vibration Isolation

16

Page 17

Connect Piping

INSTALL WATER PIPING TO HEAT EXCHANGERS —

Install piping using job data, piping drawings, and procedure outlined below. A typical piping installation is shown

in Fig. 12.

Factory-supplied insulation is not flammable but can be

damaged by welding sparks and open flame. Protect insulation with a wet canvas cover.

Remove chilled and condenser water sensors before

welding connecting piping to water nozzles. Refer to

Fig. 2 and 3. Replace sensors after welding is complete.

1. If the machine is a nozzle-in-head (NIH) arrangement,

offset pipe flanges to permit removal of waterbox cover

for maintenance and to provide clearance for pipe cleaning. See Tables 11 and 12 for waterbox cover weights.

No flanges are necessary with marine waterboxes; however, water piping should not cross in front of the waterbox or access will be blocked off.

2. Provide openings in water piping for required pressure

gages and thermometers. Openings should be at least 6 to

10 pipe diameters from the waterbox nozzle. For thorough mixing and temperature stabilization, wells in the

leaving water pipe should extend inside pipe at least

2 in. (50 mm).

3. Install air vents at all high points in piping to remove air

and prevent water hammer.

4. Install pipe hangers where needed. Make sure no weight

or stress is placed on waterbox nozzles or flanges.

5. Water flow direction must be as specified in Fig. 13.

NOTE: Entering water is always the lower of the 2 nozzles.

Leaving water is always the upper nozzle for cooler or

condenser.

6. Water flow switches must be of vapor-tight construction

and must be installed on top of pipe in a horizontal run

and at least 5 pipe diameters from any bend.

Differential pressure type flow switches may be connected at the nozzle of the waterbox.

7. Install waterbox vent and drain piping in accordance with

individual job data. All connections are3⁄4-in. FPT.

8. Install waterbox drain plugs in the unused waterbox drains

and vent openings.

9. Install water piping to the optional pumpout system condenser storage tank as shown in Fig. 14.

LEGEND

COM — Common

N.O. — Normally Open

*Donot locate pressure connections past the machineisolation valve.

Fig. 12 — Typical Nozzle Piping

17

Page 18

NOZZLE-IN-HEAD WATERBOXES

FRAME 3 AND 5 MARINE WATERBOXES

COOLER WATERBOX

Pass In Out

1

2

3

Pass In Out

1

2

3

NOTES:

1. Frame 5 condenser available in 1 and 2

pass only. Frame 3 in 2 and 3 pass only.

2. The vents for these waterboxes, located

in the covers are 1 in. FPT at the top of

each box, and the drains are 1 in. FPT,at

the bottom.

3. Victaulic connections are standard.

4. Flanged waterbox connections are

optional.

85 A

58 B

79 C

46 D

76 E

49 F

CONDENSER WATERBOX

11 2 P

211 Q

10 12 R

13 S

10 3 T

112 U

Arr.

Code

Arr.

Code

Fig. 13 — Nozzle Arrangements

COOLER WATERBOX

Pass In Out

1

2

3

Pass In Out

2

3

NOTES:

1. Frame 3 condenser available in 2 and 3

pass only.Frame 5 condenser available in

2 pass only.

2. The vents for these waterboxes are

1 in. FPT at the top of each box, and the

drains are 1 in. FPT, at the bottom.

3. Victaulic connections are standard.

4. Flanged waterbox connections are

optional.

85 A

58 B

79 C

46 D

16 17 G

76 E

49 F

CONDENSER WATERBOX

10 12 R

13 S

13 15 Y

10 3 T

112 U

Arr.

Code

Arr.

Code

18

Page 19

FRAME 4 MARINE WATERBOXES

NOTES:

1. The vents for these waterboxes are 1 in. FPT at the top of each box. The

drains are 1 in. FPT, at the bottom.

2. Victaulic connections are standard.

3. Flanged connections are optional.

COOLER WATERBOX

Pass In Out

1

2

3

Pass In Out

1

2

3

85 A

58 B

79 C

46 D

16 17 G

76 E

49 F

CONDENSER WATERBOX

11 2 P

211 Q

10 12 R

13 S

13 15 Y

10 3 T

112 U

Arr.

Code

Arr.

Code

Fig. 13 — Nozzle Arrangements (cont)

Fig. 14 — Pumpout Unit

INSTALL WATER TO OIL COOLER ON FA COMPRESORS — On FAcompressors, water must be piped to the oil

cooler heat exchanger (located under the suction pipe to the

compressor). The water supply may be either city water or

chilled water. Pipe city water to an open sight drain. Chilled

water enters via the cooling entering water intake (Fig. 15).

City water must be clean and noncorrosive. Water side

erosion or corrosion of the oil cooler coil may lead to

extensive machine damage not covered by the standard

warranty.

If water from the machine chilled water circuit is used for

oil cooling, it should enter the oil cooler from the entering

water line of the machine cooler. Water leaving the oil cooler

should connect to the leaving water line of the machine cooler

at a point downstream from the chilled water sensor, so that

oil cooler leaving water temperature does not affect the sensor readings.

Locate the oil cooler leaving water connection at some

distance from any water temperature indicators. On singlepass machines, water leaving the oil cooler should be connected into the suction side of the chilled water pump so that

adequate pressure drop is assured for oil cooling.

The nominal conditions for oil cooler water flow are:

Flow rate .......................30gpm(1.9 L/s)

Leaving temperature ........85to100F(29to38C)

Pressure drop at oil cooler .......7.25 psid (50 kPad)

Max differential pressure across closed

solenoid valve ..............150psid (1034 kPad)

1

The oil cooler connections are 1

⁄4in. FPT.

19

Page 20

Fig. 15 — Water Piping, Oil Cooler to

Chilled Water Circuit (Typical)

INSTALL VENT PIPING TO RELIEF DEVICES — The

17/19EX chiller is factory equipped with relief devices on

the cooler and utility vessels. Refer to Fig. 2 and 3, and

Table 13 for size and location of relief devices, as well as

information that will help determine pipe size. Vent relief

devices to the outdoors in accordance with ASHRAE 15

(latest edition) Safety Code for Mechanical Refrigeration and

all other applicable codes. Toensure relief valve serviceability, and as required in ASHRAE 15, latest edition, 3-way

dual shutoff valves and redundant relief valves are installed

on the economizer/storage vessel, refer to Fig. 16.

NOTE: The 3-way dual shutoff valve should be either front

seated or back seated. Running the refrigeration system with

the valve stem in the center position can reduce total relief

capacity and cause valve chattering.

Refrigerant discharged into confined spaces can displace oxygen and cause asphyxiation.

1. If relief device piping is manifolded, the cross-sectional

area of the relief pipe must at least equal the sum of the

areas required for individual relief pipes.

2. Provide a pipe plug near outlet side of each relief device

for leak testing. Provide pipe fittings that allow vent piping to be disconnected periodically for inspection of valve

mechanism.

3. Piping to relief devices must not apply stress to the

device. Adequately support piping. A length of flexible

tubing or piping near the device is essential on springisolated machines.

4. Cover the outdoor vent with a rain cap and place a condensation drain at the low point in the vent piping to prevent water build-up on the atmospheric side of the relief

device.

Make Electrical Connections — Field wiring must

be installed in accordance with job wiring diagrams and all

applicable electrical codes.

Fig. 16 — Typical 17/19EX Utility Vessel

Relief Valve Tee

Do not run 120-v wiring into the control center. The

control center should only be used for additional extra

low-voltage wiring (50 v maximum).

Wiring diagrams in this publication (Fig. 17-23) are for

reference only and are not intended for use during actual installation; follow job specific wiring diagrams.

Specific electrical ratings for individual components are

shown in Table 14.

Do not attempt to start compressor or oil pump — even

for a rotation check — or apply test voltage of any kind

while machine is under dehydration vacuum. Motor insulation breakdown and serious damage may result.

CONNECT CONTROL INPUTS — Connect the control input wiring from the chilled and condenser water flow switches

to the starter terminal strip. Wiring may also be specified for

a spare safety switch, and a remote start/stop contact can be

wired to the starter terminal strip, as shown in Fig. 17 and

18. Additional spare sensors and Carrier Comfort Network

modules may be specified as well. These are wired to the

machine control center as indicated in Fig. 22 and 23.

CONNECT CONTROL OUTPUTS — Connect auxiliary

equipment, chilled and condenser water pumps, and spare

alarms as required and indicated on job wiring drawings.

Connect Starter — Assemble and install compressor terminal box in desired orientation, and cut necessary conduit openings in conduit support plates. Attach power leads to compressor terminals in accordance with job wiring drawings,

observing caution label in terminal box. Use only copper conductors. The motor must be grounded in accordance with

NEC (National Electrical Code), applicable local codes, and

job wiring diagrams.

IMPORTANT: Do not insulate terminals until wiring

arrangement has been checked and approved by

Carrier start-up personnel.Also, make sure correct phasing is followed for proper motor rotation.

20

Page 21

Insulate Motor Terminals and Lead Wire Ends — Insulate

compressor motor terminals, lead wire ends, and electrical

wires to prevent moisture condensation and electrical arcing. For low-voltage units (up to 600 v), insulate the electrical terminals as follows:

1. Insulate each terminal by wrapping with one layer of

insulation putty.

2. Overwrap putty with 4 layers of vinyl tape.

High-voltage units require special terminal preparation. The

vinyl tape is not acceptable; a high voltage tape must be used.

Installer is responsible for any damage caused by improper

wiring between starter and compressor motor.

Connect Power Wiresto Oil Pump Contactor — Connect power

wires to oil pump contactor mounted in machine power panel.

(See Fig. 19.) Use the electrical disconnect located in the

machine starter (if supplied), or a separate fused disconnect

as shown on job wiring diagrams. Check that power supply

voltage agrees with oil pump voltage. Follow correct phasing for proper motor rotation.

Do notwire into the top surface of the power panel. Knockouts are provided on the underside of the panel.

Table 13 — Relief Valve Locations and Data

Connect Power Wires to Oil Heater Contactor — Connect

control power wiring between the oil heater contactor terminals (Fig. 17 and 18) and terminals LL1 and LL2 on the

field wiring strip in the compressor motor starter. Refer to

Fig. 21 and wiring label on the chiller power panel.

Voltage to terminals LL1 and LL2 comes from a control transformer in a starter built to Carrier specifications. Do not connect an outside source of control power

to the compressor motor starter (terminals LL1 and LL2).

An outside power source will produce dangerous voltage at the line side of the starter, because supplying voltage at the transformer secondary terminals produces input level voltage at the transformer primary terminals.

Connect Communication and Control Wiring from Starter to

Power Panel — Connect control wiring from main motor starter

to the chiller power panel. All control wiring must use shielded

cable. Also connect the communications cable. Make sure

the control circuit is grounded in accordance with applicable

electrical codes and instructions on chiller control wiring

label.

RELIEF VALVE

LOCATION

Cooler

Economizer/Storage

Pumpout Unit Condenser ALL ALL 1.5 0.01

*To ensure relief valve serviceability, and as required in ASHRAE 15,

latest edition, three-way valves and redundant relief valves are installed on the storage vessel. Only one half of the ‘‘No. of Valves’’

listed are in service at any time.

NOTES:

1. Thecooler relief C-factor is forboth cooler and condenser vented

through the cooler in accordance with ASHRAE (American

Society of Heating, Refrigeration, and Air Conditioning Engineers) 15, latest edition.

Vessel

HEAT EXCHANGER

SIZE

Cooler Condenser lb air/min. kg air/sec. psig kPa

31-33 31-33 139.7 1.06 1

41-43 41-43 158.8 1.20 1

44 51-53 164.6 1.24 1

45-47 45-47 216.3 1.64 1

48 55-57 228.5 1.73 1

41-44 ALL 64.2 0.49 1

45-48 ALL 84.3 0.64 1

REQUIRED C FACTOR

NOMINAL OUTLET

PIPE SIZE (in.)

1

⁄4FPT 2 225 1551

1

⁄4FPT 2 225 1551

1

⁄4FPT 2 225 1551

1

⁄4FPT 3 225 1551

1

⁄4NPT 3 225 1551

1

⁄4NPT 2* 225 1551

1

3

2. Relief valve discharge pipe sizing is to be calculated per latest

version of ASHRAE 15, using the tabulated C-factors and nominal pipe size listed above. Cooler and economizer/storage vessel rated relief valve pressure is 225 psig (1551 kPa).

3. The pumpout unit condenser contains less than 110lb (50 kg) of

HFC-134a,which isa GroupA1 refrigerant.TheASHRAE15 standard exempts small-volume vessels from the requirement to vent

outside. However, Carrier recommends that the pumpout condenser be connected to the rest of the vent system.

⁄4FPT 2* 225 1551

⁄8in. Male Flare MPT 1 385 2655

NUMBER OF

VALVES

RATED RELIEF

PRESSURE

21

Page 22

Table 14 — Individual Component Ratings

POWER SOURCE ITEM AVERAGE kW

Seal Leakage

1*

(17EX Only)

1†

2† Oil Pump

1**

3**

(Optional)

LEGEND

FLA — Full Load Amps

LRA — Locked Rotor Amps

*Available for 17EX machines only.

†Available for 17/19EX machines.

**Available as an option on 17/19EX machines.

Pump

Motor Space

Heater

Control Module

and Actuator

Oil Sump Heater 1.00 115

Hot Gas

Bypass

Pumpout

Compressor

0.23 115 115-1-50/60 4.78 21.7

0.50 115 115-1-50/60 4.35 4.35

0.40 115

1.35 220 200/240-3-60 4.32 24.5

1.30 430 380/480-3-60 2.15 12.2

1.37 563 507/619-3-60 2.13 25.0

1.49 230 220/240-3-50 4.83 28.0

1.49 393 346/440-3-50 2.59 12.2

0.20 115 115-1-50/60 2.00 4.75

3.41

DESIGN CENTER

VOLTAGE

204 200/208-3-60 10.90 63.5

230 220/240-3-60 9.50 57.5

460 440/480-3-60 4.70 28.8

575 550/600-3-60 3.80 23.0

400 380/415-3-50 4.70 28.8

NOTE: The oil pump is powered through a field wiring terminal into

the power panel. Power to the controls and oil heater via the power

panel must be on circuits that can provide continuous service when

the compressor starter is disconnected.

SUPPLY

V-PH-HZ

115-1-60

115-1-50

115-1-60

115-1-50

FLA LRA

3.50 —

8.70 —

22

Page 23

*Indicates chilled water pump control contacts or run status contacts.

†Indicates condenser water pump control contacts.

**Indicates tower fan relay contacts.

††Indicates circuit breaker shunt trip contacts.

\ Indicates remote alarm contacts.

NOTES:

I. GENERAL

1.0 Starters shall be designed and manufactured in accordance with Carrier Engineering Requirement Z-375.

1.1 All field-supplied conductors, devices, field-installation wiring, and termination ofconductors and devices, must be in compliance with all applicable codes and job specifications.

1.2 The routing of field-installed conduit and conductors and the location of fieldinstalled devices must not interfere with equipment access or the reading, adjusting,

or servicing of any component.

1.3 Equipment, installation, and all starting and control devices must comply with details in equipment submittal drawings and literature.

1.4 Contacts and switches are shown in the position they would assume with the circuit

deenergized and the chiller shut down.

1.5 WARNING — Do not use aluminum conductors.

1.6 Installer is responsible for any damage caused by improper wiring between starter

and machine.

II. POWER WIRING TO STARTER

2.0 Power conductor rating must meet minimum unit nameplate voltage and compressor motor RLA.

When (3) conductors are used:

Minimum ampacity per conductor = 1.25 x compressor RLA

When (6) conductors are used for Wye-Delta starting:

Minimum ampacity per conductor = 0.721 x compressor RLA

2.1 Lug adapters may be required if installation conditions dictate that conductors be

sized beyond the minimum ampacity required. Contact starter supplier for lug

information.

2.2 Compressor motor and controls must be grounded by using equipment grounding

lugs provided inside starter enclosure.

III. CONTROL WIRING

3.0 Field supplied control conductors to be at least 18 AWG or larger.

3.1 Chilled water and condenser water flow switch contacts, optional remote start device contacts and optional spare safety device contacts must have 24 vdc rating.

Max current is 60 ma, nominal current is 10 ma. Switches with gold plated bifurcated contacts are recommended.

3.2 Remove jumper wire between 12A and 12B before connecting auxiliary safeties between these terminals.

3.3 Pilot relays can control cooler and condenser pump and tower fan motor contactor

coil loads rated 10 amps at 115vacupto 3 amps at 600 vac. Control wiring required

for Carrier to start pumps and tower fan motors must be provided to assure

machine protection. If primary pump and tower fan motor are controlled by other

means, also provide a parallel means for control by Carrier. Do not use starter control transformer as the power source for pilot relay loads.

Fig. 17 — Typical Field Wiring (Low-Voltage Motors) with Free-Standing Starter

LEGEND

Required Power Wiring

Required Control Wiring

SMM — Starter Management Module

IV. POWER WIRING BETWEEN STARTERAND COMPRESSOR MOTOR

Options Wiring

3.4 Do not route control wiring carrying 30 v or less within a conduit which has wires

carrying 50 v or higher or along side wires carrying 50 v or higher.

3.5 Voltage selector switch in machine power panel isfactorysetfor 115vcontrolpower

source. Do not use the 230 v position. If this switch is set to 230 v position, the oil

heater will not operate.

3.6 Control wiring cables between starter and power panel must be shielded with minimum rating of 600 v, 80 C ground shield at starter. Wires A,B, and C are communication wires and must be run in a separate cable.

3.7 If optional oil pump circuit breaker is not supplied within the starter enclosure as

shown, it must be located within sight of the machine with wiring routed to suit.

3.8 Voltage to terminals LL1 and LL2 comes from a control transformer in a starter built

to Carrier specifications. Do not connect an outside source of control power to the

compressor motor starter (terminals LL1 and LL2). An outside power source will

produce dangerous voltage at the line sideof the starter,because supplying voltage

at the transformer secondary terminals produces input level voltage at the transformer primary terminals.

4.0 Low voltage (600 v or less) compressor motors have (6),5⁄8in. terminal studs (lead

connectors not supplied by Carrier). Either 3 or 6 leads must be run between compressor motor and starter, depending on type of motor starter employed. If only 3

leads are required, jumper motor terminals as follows: 1 to 6, 2 to 4, 3 to 5. Center

tocenter distance between terminals is 2

have nameplate stamped as to conforming with Carrier requirement Z-375. Medium

voltage (over 600 v) compressor motors have (3) terminals. Connections out of terminals are 3 in. long stranded wire pigtails, #4 AWG, strand wire for all medium

voltage motor sizes. Distance between terminal is 7

connectorsandinsulationforhighvoltagealternatingcurrentcableterminations(these

items are not supplied by Carrier). Compressor motor starter must have nameplate

stamped as to conforming with Carrier requirement Z-375.

4.1 When more than one conduit is used to run conductors from starter to compressor

motor terminal box, one conductor from each phase must be in each conduit to

prevent excessive heating. (e.g., conductors to motor terminals 1, 2 and 3 in one

conduit, and those to 4, 5 and 6 in another.)

4.2 Compressor motor power connections can be made through top, top rear or sides

of compressor motor terminal box using holes cut bycontractor to suit conduit. Flexible conduit should be used for the last few feet to the terminal box for unit vibration

isolation. Use of stress cones or 12 conductors larger than 500 MCM may require

an oversize (special) motor terminal box (not supplied by Carrier). Lead connections between 3-phase motors and their starters must not be insulated until Carrier

personnel have checked compressor and oil pump rotations.

4.3 Compressor motor frame to be grounded in accordance with the National Electrical

Code (NFPA-70) and applicable codes. Means for grounding compressor motor is

a pressure connector for #4 to 500 MCM wire, supplied and located in the back

lower left side corner of the compressor motor terminal box.

4.4 Do not allow motor terminals to support weight of wire cables. Use cable supports

and strain reliefs as required.

4.5 Use backup wrench when tightening lead connectors to motorterminalstuds.Torque

to 45 lb-ft max.

15

⁄16inches.Compressor motor starter must

9

⁄16inches. Use suitable splice

23

Page 24

Notes on following page.

LEGEND

PIC — Product Integrated Control

SMM — Starter Management Module

Required Power Wiring

Required Control Wiring

Options Wiring

Fig. 18 — Field Wiring (High Voltage Motors) with Optional Free-Standing Starter

24

Page 25

NOTES:

I GENERAL

1.0 Starters shall be designed and manufactured in accordance with

Carrier Engineering requirement Z-375.

1.1 All field-supplied conductors, devices and the field-installation wiring,

termination of conductors and devices, must be in compliance with all

applicable codes and job specifications.

1.2 The routing of field-installed conduit and conductors and the location of

field-installed devices, must not interfere with equipment access of the

reading, adjusting, or servicing of any component.

1.3 Equipment installation and all starting and control devices must comply

with details in equipment submittal drawings and literature.

1.4 Contacts and switches are shown in the position they would assume

with the circuit deenergized and the chiller shut down.

1.5 WARNING: Do not use aluminum conductors.

1.6 Installer is responsible for any damage caused by improper wiring between starter and machine.

II POWER WIRING TO STARTER

2.0 Power conductor rating must meet minimum unit nameplate voltage

and compressor motor RLA (rated load amps). When (3) conductors

are used:

Minimum ampacity per conductor =1.25 x compressor RLA

When (6) conductors are used:

Minimum ampacity per conductor =0.721 x compressor RLA.

2.1 Lug adaptersmay be required if installation conditions dictate thatconductorsbe sized beyond the minimumampacity required. Contact starter

supplier for lug information.

2.2 Compressor motor and controls must be grounded by using equipment grounding lugs provided inside starter enclosure.

III CONTROL WIRING

3.0 Field supplied control conductors to be at least 18AWG(AmericanWire

Gage), or larger.

3.1 Chilled water and condenser water flow switch contacts, optional remote start device contacts, and optional spare safety device contacts

must have 24 vdc rating. Maximum current is 60 ma, nominal current

is 10 ma. Switches with gold plated bifurcated contacts are

recommended.

3.2 Remove jumper wire between 12A and 12B before connecting auxiliary

safeties between these terminals.

3.3 Maximum loadon pilot relays is 10amps. Pilot relays can control cooler

and condenser pump and tower fan motor contactor coil loads rated up

to 10 amps at 115 vac or up to 3 amps at 600 vac. Control wiring required for Carrier to start pumps and tower fan motors must be provided to assure machine protection. If primary pump and tower motor

control is by other means, also provide a parallel means for control by

Carrier. Do not use starter control transformer as the power source for

pilot relay loads.

3.4 Do not route control wiring carrying 30 v or less within a conduit which

has wires carrying 50 v or higher or along side wires carrying 50 v or

higher.

3.5 Voltage selector switch in machine power panel is factory set for

115 v control and oil heater power source. The 230 v position is not

used. If switch is set to 230 v position, oil heater will not operate.

3.6 Control wiring cablesbetween starter and powerpanel must be shielded

with minimum rating of 600 v, 80 C. Ground shield at starter. Wires A,

B, and C arecommunication wires and must be run ina separate cable.

3.7 If optional oil pump circuit breaker is not supplied within the starter enclosure as shown, it must be located within sight of the machine with

wiring routed to suit.

3.8 Voltage to terminals LL1 and LL2 comes from a control transformer in

astarter built to Carrierspecifications. Do not connectan outside source

of control power to the compressor motor starter (terminals LL1 and

LL2). An outside power source will produce dangerous voltage at the

line side of the starter, because supplying voltage at the transformer

secondary terminals produces inputlevel voltage at the transformer primary terminals.

IV POWER WIRING BETWEEN STARTER AND COMPRESSOR MOTOR

4.0 Medium voltage (over 600 volts) hermetic compressor motors have

3 terminals. Use no. 4 AWG strand wires for all medium and high voltage hermetic motors. Distance between terminal is 7

suitable splice connectors and insulation for high-voltage alternating

current cable terminations (these items are not supplied by Carrier).

Compressor motor starter must have nameplate stamped as to conforming with Carrier requirement Z-375. Medium voltage open motors

have lug terminations (see certified drawings for size).

4.1 When more than one conduit is used to run conductors from starter to

compressor motor terminal box, one conductor from each phase must

be in each conduit, to prevent excessive heating, (e.g., conductors to

motor terminals 1, 2, and 3 in one conduit, and those to 1, 2, and 3 in

another).

4.2 Compressor motor power connections can be made through top, top

rear, or sides of compressor motor terminal box by using holes cut by

contractor to suit conduit. Flexible conduit should be used for the last

few feet to the terminal box for unit vibration isolation. Use of stress

cones may require an oversize (special) motor terminal box (not supplied by Carrier).

4.3 Compressor motor frame to be grounded in accordance with the NationalElectrical Code (NFPA-70)andapplicablecodes. Means for grounding compressor motor is a no. 4 AWG, 500 MCM pressure connector,

supplied and located in the lower left side corner of the compressor

motor terminal box.

4.4 Do not allow motor terminals to support weight of wire cables, use

cable supports and strain reliefs as required.

9

⁄16inches. Use

Fig. 18 — Field Wiring (High Voltage Motors) with Optional Free-Standing Starter (cont)

25

Page 26

LEGEND

Factory Wiring

Field Wiring

Oil Pump Terminal

Power Panel Component Terminal

Fig. 19 — Oil Pump Wiring

LEGEND

1—Chilled Water Pump Starter

2—Condenser Water Pump Starter

3—Cooling Tower Fan Starter

4—Condenser Water Pump

5—Chilled Water Pump

6—Disconnect

7—Oil Pump Disconnect (See Note 5)

8—Free-Standing Compressor Motor Starter

9—Chiller Auxiliary Power Panel

Piping

Control Wiring

Power Wiring

Fig. 20 — 17/19EX with Free-Standing Starter

19EX SHOWN

NOTES:

1. Wiring and piping shown are for general point-of-connection only

2. All wiring must comply with applicable codes.

3. Refer to Carrier System Design Manual for details regarding pip-

4. Wiring not shown for optional devices such as:

5. Oil pump disconnect may be located within the enclosure of Item

6. Water piping to the oil cooler is required on FA compressors.

26

and are not intended to show details fora specific installation. Certified field wiring and dimensional diagrams are available on request.

ing techniques.

• Remote Start-Stop

• Remote Alarms

• Optional Safety Device

• 4 to 20 mA Resets

• Optional Remote Sensors

8 — Free-Standing Compressor Motor Starter.

Page 27

LEGEND

Field Wiring

Power Panel Component Terminal

Fig. 21 — Oil Heater and Control Power Wiring

temperature range of −4 F to 140 F (−20 C to 60 C) is

required. See table below for cables that meet the

requirements.

MANUFACTURER CABLE NO.

Alpha 2413 or 5463

American A22503

Belden 8772

Columbia 02525

When connecting the CCN communication bus to a system element, a color code system for the entire network is

recommended to simplify installation and checkout. The following color code is recommended:

Fig. 22 — Carrier Comfort Network

Communication Bus Wiring

CARRIER COMFORT NETWORK INTERFACE — The

Carrier Comfort Network (CCN) communication bus wiring

is supplied and installed by the electrical contractor (if required by jobsite prints). It consists of shielded, 3-conductor

cable with drain wire.

The system elements are connected to the communication

bus in a daisy chain arrangement. The positive pin of each

system element communication connector must be wired to

the positive pins of the system element on either side of it.

The negative pins must be wired to the negative pins. The

signal ground pins must be wired to the signal ground pins.

See Fig. 23 for location of the CCN network connector

(COMM1) on the processor module.

NOTE: Conductors and drain wire must be 20 AWG

(American WireGage) minimum stranded, tinned copper. Individual conductors must be insulated with PVC, PVC/

nylon, vinyl, Teflon, or polyethylene. An aluminum/ polyester 100% foil shield and an outer jacket of PVC, PVC/

nylon, chrome vinyl, or Teflon with a minimum operating

SIGNAL TYPE

+ Red 1

Ground White 2

− Black 3

CCN BUS CONDUCTOR

INSULATION COLOR

COMM1 PLUG

PIN NO.

If a cable with a different color scheme is selected, a

similar color code should be adopted for the entire network.

At each system element, the shields of its communication

bus cables must be tied together. If the communication bus

is entirely within one building, the resulting continuous shield

must be connected to ground at only one single point. See

Fig. 23. If the communication bus cable exits from one building and enters another, the shields must be connected to ground

at the lightning suppressor in each building where the cable

enters or exits the building (one point only).

To connect the 17/19EX chiller to the network, proceed

as follows (Fig. 23):

1. Cut power to the PIC (Product Integrated Control) panel.

2. Remove the COMM1 plug from the processor module.

3. Cut a CCN wire and strip the ends of the RED, WHITE,

and BLACK conductors.

4. Using a wirenut, connect the drain wires together.

5. Insert and secure the RED wire to Terminal 1 of the

COMM1 plug.

6. Insert and secure the WHITE wire to Terminal 2 of the

COMM1 plug.

7. Insert and secure the BLACK wire to Terminal 3 of the

COMM1 plug.

8. Attach the COMM1 plug back onto the processor

module.

9. Mount a terminal strip in a convenient location.

10. Connect the opposite ends of each conductor to separate

terminals on the terminal strip.

11. Attach the CCN Network wiring:

a. Connect the RED wire to the matching location on

the terminal strip.

b. Connect the WHITE wire to the matching location

on the terminal strip.

c. Connect the BLACK wire to the matching location

on the terminal strip.

27

Page 28

Install Field Insulation

Protect insulation from weld heat damage and weld splatter. Cover with wet canvas cover during water piping

installation.

When installing insulation at the job site, insulate the fol-

lowing components (see Fig. 24 and Table 15):

• compressor motor

• cooler shell

• cooler tube sheets

• suction piping

• motor cooling drain