Page 1

Carrier

Application Data

Application Detail

5qP£È.S<£ù£5 ¡sy

Hermetic Absorption Liquid Chillers

16JB

GENERAL

Application details in this publication cover

various methods of applying the 16JB absorption

machine to meet liquid chilling needs. Throughout

this publication, the chilled liquid will be water.

Subjects covered are chilled water temperature

control, condenser water temperature control,

system design for steam and hot water machines,

and general information.

CHILLED WATER TEMPERATURE CONTROL

The absorption machine is basically a water

chiller that can be connected to any conventional

open or closed system. However, circulation of

chilled water must be continuous during operation

of the machine and during the shutdown dilution

cycle. Chilled water flow may be restricted at

partial load.

For fine chilled water temperature control

within narrow limits, such as required in precision

control of industrial processes or maintenance of

laboratory conditions, the chilled water system

may require additional storage volume to allow the

machine to adjust slowly to changes in load.

Normal air-conditioning applications are not

subject to such requirements.

Systems having large storage volumes of chilled

water transmit load changes to the machine slowly,

allowing accurate chilled water temperature con

trol. Small storage systems transmit load changes

rapidly, making temperature control more diffi

cult. For fine temperature control, the chilled

water system volume should be at least ten times

the gpm flow through the cooler. If a tank is added

to the system for extra storage volume, it should

be located in the line from the load to the cooler.»

Two-Pipe Cooling-Heating Systems — When

machines are used in conjunction with a two-pipe

cooling-heating system, certain precautionary steps

should be taken during changeover from heating to

cooling.

Maximum water temperature permitted thru

the evaporator is 130 F because of the possibility

of tube stress. If system water temperature is above

80 F but less than 130F at changeover time,

evaporator flow should be throttled to prevent

machine overload.

It is recommended that hot water temperatures

be reset, based on outside air temperature. If a

reset-type control is used, the entering hot water

temperature at changeover will normally be lower

than 130 F.

STEAM MACHINES

Boilers — Generally, any boiler capable of modu

lating its input to maintain design operating steam

pressure within 1 psi under varying loads, is suit

able for application with the absorption machine.

This generally includes all gas- and oil-fired boilers.

Some oil-fired boilers are conversions from

coal-fired to oil-fired and may have control systems

which are too sluggish to give proper response to

machine load changes. Direct control of oil feed

rate normally ensures proper response.

Coal-fired boilers, due to slow buildup and

shutdown characteristics, should be used only

when the absorption machine represents less than

15% of boiler operating load. This generally limits

coal-fired boiler applications to large industrial jobs

where process steam is generated in large quantities

year-round.

BOILER CAPACITY — Minimum boiler capacity

for use with the absorption machine is equal to full

load steam consumption, plus sufficient capacity

to offset piping radiation losses. In the absence of a

detailed study of radiation and vent losses, a

minimum 10% safety factor should be used.

Pressure Reducing Valves — Maximum unit ratings

are based on 14 psig steam pressure at the

generator inlet. Operation at higher inlet pressures

or with more than 100 F superheat is not per

missible. Higher inlet pressures may lead to over

concentration.

Where steam supply pressures are above 15 psig

(14 psig + 1 psig for control) and below 20 psig,

the steam control valve can be used to reduce the

pressure. If steam supply is above 20 psig, a

pressure reducing valve must be provided between

the steam supply and the control valve inlet. A

safety relief valve should be provided between the

steam control valve and the generator inlet. This

valve must be set in accordance with paragraph

UG-133 (f) of the ASME code to relieve at a

pressure not exceeding 17 to 18 psig or the setting

determined by apphcable local codes.

Further specific details relative to pressure

reducing stations should follow accepted standards,

such as the ASHRAE Guide and manufacturer’s

recommendation. For applications on high-pressure

district heating, the steam utility should be con

sulted for local codes or standards.

Steam Piping should be sized to avoid excessive

pressure drop or excessive velocities. Recommenda

tions and pipe sizing tables are given in the Carrier

System Design Manual. It is recommended that

lines be sized on the basis of design system flow for

the machine plus a 10 to 20% safety factor to

allow for normal radiation losses.

© Carrier Corporation 1971

Form 16JB-2XA

Page 2

Start-Up Demand — Steam demand by the absorp

tion machine is greatest at start-up (see Table 1 for

values).

Table 1 — Maximum Condensate Flow (Ib/hr)

VALVE VALVE INLET STEAM PRESSURE

SIZE (in.)

2

2Y2

3

4

5

20 psig

2450 2025

4825 4000

8175 6760

14540 12025

21650

14 psig

17900

12 psig 10 psig

1880 1750

3710 3430

6285 5810

11190 10350

16655 15400

When boiler capacity is unable to keep up with

start-up demand, the steam pressure will fall off.

On boilers serving only the absorption machine,

this reduction in steam pressure will have no

adverse effect on the absorption machine other

than to lengthen start-up time. However, the

increased steam demand may have an adverse

effect on the boiler, causing it to run dry and fail.

As steam pressure is reduced, the steam control

valve pressure drop will eventually limit the de

mand on the boiler provided the steam control

valve is properly sized.

On boilers serving other loads simultaneously,

the start-up demand can reduce boiler pressure

sufficiently to cause adverse effects on other

steam-driven equipment. When a reduction in

boiler pressure cannot be tolerated without up

setting other equipment, the boiler capacity avail

able for absorption machine operation (with other

loads deducted) must equal or exceed the start-up

demands. If it does not, the start-up demand can

be reduced by using demand Hmit controls, or

installing a back-pressure regulator in the steam

line(s) between the boiler and the control valve(s).

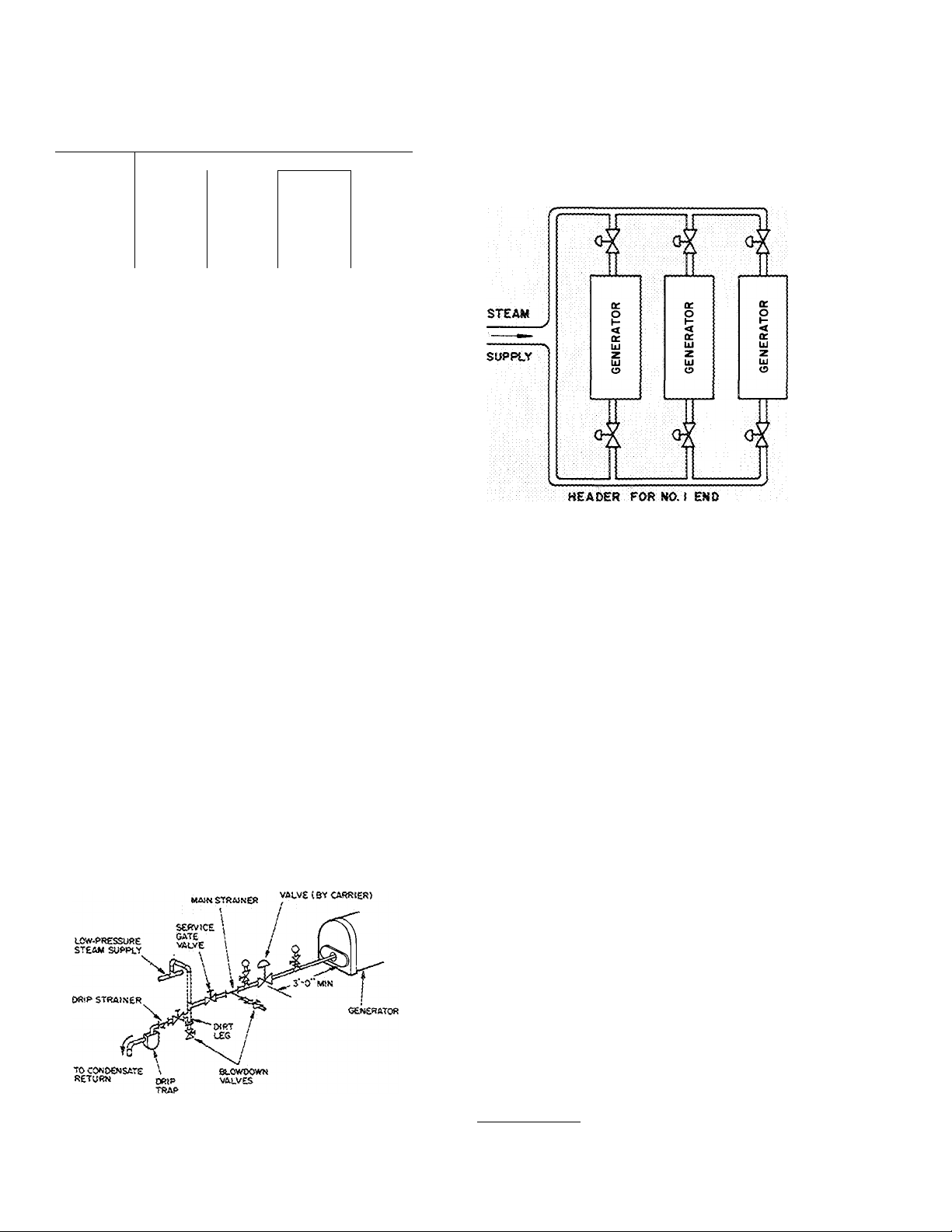

VALVE LOCATION AND PIPING - The steam

control valve should be located a minimum of 3 ft

away from the generator inlet. This is dictated by

good piping practice, to allow equal distribution of

steam in the generator tube bundle. Unequal

distribution of steam in the tube bundle may cause

a loss of capacity. Recommended steam supply

piping for low-pressure steam applications is

illustrated in Fig. 1.

STEAM CONTROt

NOTE; Separate supoiy piping "for each end of machine sizes

16JB077 thro '24,

Fig. 1 — Low-Pressure Steam (2 to 15 psig)

Supply Piping

Machine sizes 16JB077 thru 16JB124 have

steam supply inlets on each end. These are to be

considered as two generators and should be piped

from a common steam header as in multiple

machine installations (see Fig. 2). Each inlet should

then be piped in accordance with Fig. 1.

HEADER FOR N0.2 END

NOTES:

1. Piping appiies to moitipie macbiries connected in paraiief

(3 shown).

2. Each end most be consdered as a separate generator.

3. The feed to each end of each generator should be piped as

shown in rig. 1.

Fig. 2 — Steam Piping For 16JB077 thru 124

Steam piping to the absorption machine should

be designed and supported to allow for thermal

expansion without imposing undue stresses on the

generator inlet. The machine is not designed for,

nor expected to act as, a piping support or anchor

for withstanding thermal stresses.

Condensate Systems — Satisfactory operation of

the absorption machine requires a condensate

handling system designed with the specific characteristics of the absorption machine in mind. The

following is intended to supplement available

reference data on condensate systems such as

Carrier System Design Manual, ASHRAE Guide

and individual manufacturer’s recommendations.

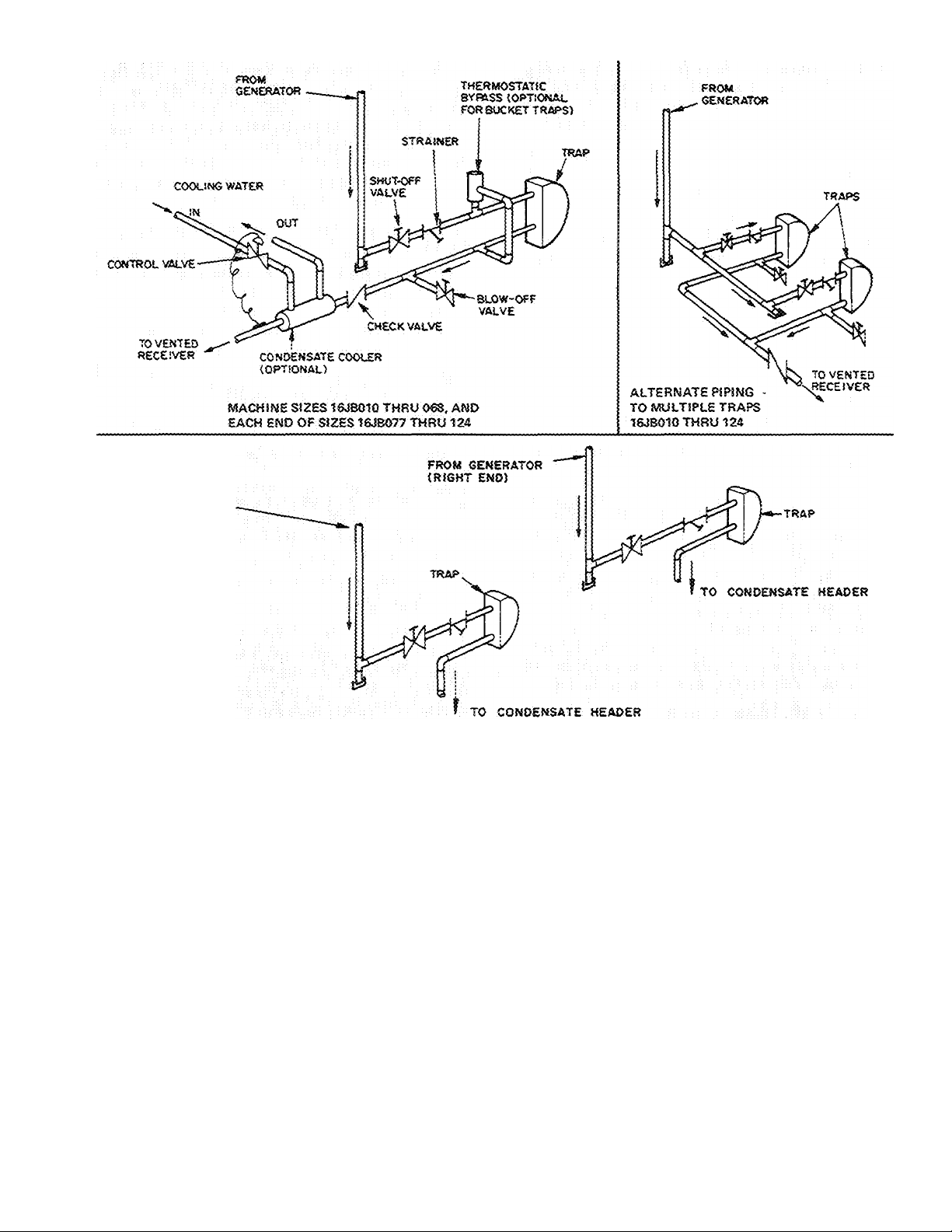

ATMOSPHERIC CONDENSATE RETURN

SYSTEMS (VENTED) - These systems usually

consist of steam traps, vented receiver, condensate

pump, and condensate cooler. Fig. 3 illustrates

typical atmospheric condensate return systems. On

larger machines, with dual steam generators, the

condensate outlet from each generator must be

piped thru separate steam traps.

Trap Selection — Steam traps should be located as

far below the generator outlet as possible. Actual

pressure drop available for trap selection will

depend on exact trap location below the generator

Page 3

FROM SEMERATOR

(LEFT END)

MACHINE Sizes 16J8077 THRU IZA

Fig. 3 — Typical Atmospheric (Vented) Condensate Return System

outlet, and trap outlet pressure. A vacuum breaker

is factory installed to ensure that operating steam

pressure in the generator does not fall below

atmospheric pressure. Use the following formulas

to determine available trap pressure drop:

Trap pressure drop = trap inlet ~ trap outlet

psig.

Trap inlet pressure = 0 psig + hydrostatic

head to trap inlet -- condensate leg pressure

drop.

Trap design outlet pressure receiver pres

sure + line pressure drop from trap outlet to

receiver.

In determining trap outlet pressure, discount

any liquid head drop to the receiver. This line may

not run full. If there is liquid lift from trap outlet

to the receiver, it must be added to trap outlet

pressure.

Either float-and-thermostat or inverted-bucket

traps may be used, provided the trap is recom

mended by the manufacturer for rapid handhng of

noncondensables. For fast start-up with invertedbucket traps, install an external thermostatic air

vent around the trap.

Traps should be sized for capacity to handle

more condensate than twice the design full-load

steam rate. See steam trap manufacturer’s recom

mendations. Maximum load on the trap will occur

during start-up when generator pressure falls to

atmospheric (0 psig) and steam condenses rapidly.

Page 4

At this time, pressure drop across the steam

control valve is maximum. If boiler capacity is

large enough, the control valve inlet pressure will

stay at design, then flow rate will be limited by

control valve capacity.

Table 1 gives maximum condensate flow for

different inlet steam pressures. Interpolate for

intermediate pressures.

If steam demand on start-up can be held within

a controlled limit, the trap(s) may be sized

accordingly.

When traps are undersized, condensate wiU

back up in the generator with loss in machine

capacity and may cause dangerous water hammer.

Depending on boiler size, the boiler water makeup

system could operate and add water to the boiler.

Sooner or later, excess water would return to the

boiler room and either overflow the hot well to

drain, or if it flows directly into the boiler, it may

shut the boiler down on high boiler water level

control.

Condensate Cooler is used on some atmospheric

condensate systems to reduce or eliminate loss of

flash steam from the open receiver vent. The

condensate cooler must be sized for handling and

condensing flash steam as well as cooHng the

condensate. Condensate is normally cooled to

about 180 F. Pressure drop thru the condensate

cooler should be very low, as it must be added to

trap outlet pressure. If there is a liquid leg down to

the condensate receiver, the condensate cooler and

trap should be located at the bottom of this leg.

When a condensate cooler is used, it is desirable

to use either cold boiler feed water or other cold

water source which can benefit by heat rejected

from hot condensate. Cooling tower bleed water

can be used, but it may be heavy with dissolved

solids and may rapidly foul the cooler. Tower

makeup water can be used when large cooling

towers are part of the system. Extra load to the

tower would be insignificant.

Receiver and Condensate Pumps — When open

receivers are used, the vent should be directed

outside the equipment space to eliminate fogging.

Be careful in using small receivers and closeconnected condensate pumps. Some commercially

available systems may work well on standard

heating systems but can present problems in

handling condensate from absorption machines.

The basic difference in absorption machine oper

ation lies in higher condensate temperatures and

greater amounts of flash vapor. Commercial

heating systems normally deliver condensate to the

receiver thru long return runs. This lowers con

densate temperature to 200 F or lower with

relatively little flash steam.

Absorption machines commonly located close

to the condensate receiver have little or no

condensate cooling. During full load, condensate

may be delivered to the trap at close to 12 psig and

240 F. This creates large amounts of flash steam at

the trap outlet and in the condensate receiver.

Very hot condensate drawn into the condensate

pump may cause cavitation.

To minimize these effects, the following guides

are offered:

1. If equipped with a vented receiver, the inlet line

to the receiver should enter above the receiver

water level. Flash steam can go directly out the

vent without creating turbulence or frothing.

2. Locate the condensate pump as far below

receiver water level as possible to give maxi

mum Net Positive Suction Head (NPSH) to the

pump.

3. If pump suction pipe is located at bottom of

the receiver, use a vortex breaker at the receiver

outlet.

4. Locate pump suction at opposite end of re

ceiver from the condensate inlet. This will

minimize agitation and frothing at pump inlet.

5. A properly selected condensate cooler, as

previously described, will eliminate problems

with flashing.

VACUUM PUMP CONDENSATE RETURN

SYSTEMS are sometimes used to return con

densate from space heating installations. The

vacuum pump maintains the condensate return

system at a subatmospheric pressure and permits

the heating system to operate with subatmospheric

pressure when the heating load is small.

It is generally impractical to use an existing

vacuum pump condensate return system. Con

densate from the absorption machine is far higher

in temperature than condensate from the original

heating system for which the vacuum return pump

■; was selected. Hot condensate forms excessive

quantities of flash vapor when released into the

vacuum return system and will usually cause vapor

lock in either the return piping or the vacuum

return pump, or both. When the existing

condensate return system is a vacuum pump type,

the recommended method of returning condensate

from the machine is a separate wet-return system,

if possible.

As an alternate choice, condensate can be

discharged thru a steam trap to an atmospheric

vent receiver. The receiver discharges flash-cooled

condensate thru a second trap into the vacuum-

return system.

If a condensate cooler is used, condensate may

be cooled to an acceptable level and discharged

Page 5

#

into the vacuum pump condensate return system.

If this method is used, it is desirable to use either

cold boiler feed water or any other cold water

source which will benefit by heat rejected from hot

condensate.

CLOSED CONDENSATE RETURN

SYSTEM

(PRESSURIZED)

16JB010-068 — Many manufacturers have hightemperature condensate units, generally suited for

use with most of the Carrier absorption machine

Une. Because the condensate units are usually quite

high, some of the smaller machines may not be

high enough to provide liquid head for gravity

flow. In these cases, the closed system should not

be used. A typical unit consists of a closed ASME

Code receiver and centrifugal pump for returning

hot condensate to the boiler. This system has the

advantage of complete condensate recovery with

out flash losses often experienced in atmospheric

return systems.

These systems require very careful application

to the absorption machine. There are two common

types of closed condensate systems :

1

CLOSED

CONDENSATE

RECEIVER 1

1 til TO

L-b^-eoa^

CLOSED

CONDENSATE

RECEIVER

TO lA S

NOTE' Each J5IKÌ 5s similar toOf) l&lóOliKSeS machìnes.

Fig. 4 — Closed Condensate Return System

П r~

1

-------------------------------------

(16JB077-124)

HOT WATER MACHINES

The 16JB hot water absorption machines are

furnished with pneumatic controls only. Fig. 5

schematically illustrates the capacity control

valves, controls and control panel. There are two

commonly used piping systems, depending on the

temperature of the supply hot water.

The first type will operate under pressurized

conditions. The pressure between the generator

and receiver is equalized and condensate flows by

gravity to the closed receiver located below the

generator outlet. It is essential that under these

conditions the vacuum breaker on the 16JB

generator should be blocked. This is to prevent air

from building up in the closed receiver. Also, the

closed receiver should be equipped with a device

that is capable of releasing the air that is in the

system after a shutdown period. A thermostatic

vent is usually suppUed for this purpose. In this

type of system, the pumps on the receiver can

pump under vacuum.

The second type of closed system consists of a

closed receiver with atmospheric condensate

pumps. Therefore, the receiver is usually equalized

with the steam chest. In this type of system, the

vacuum breaker and the generator must be left open

so that the receiver cannot go into the vacuum range.

A steam trap is usually recommended.

16JB077-124 — Because the 16JB077-124 units

have two steam inlets, these machines must be

considered as having two generators when applying

a closed condensate system. Each end of the

machine operates at a different steam pressure.

This could cause the condensate to back up into

the generator and cause dangerous water hammer if

the condensate system were not properly designed.

Each end of the machine should be considered

similar to the system on 16JB010-068 units (see

Fig. 4).

077 THRU 124 SIZES ONLY

EPS — Electric-Pneumatic Switch

PE — Pressure-Electric Switch

Fig. 5 — Pneumatic Control Schematic

Piping For Water Temperature of 300 F Or Below

— Fig. 6 gives suggested hot water piping when

supply hot water is 300 F or below. The capacity

of the machine is controlled by regulating the flow

of hot water through the generator. Either a

two-way or three-way capacity control valve (CV)

can be used. Machine sizes 16JB077-124 require

two capacity control valves if partial load effi

ciency of double generators is to be utilized.

Page 6

cw

ASR

ncfTmTSR

<5cJ«3RA70R

PlPtNS rOR MACHINE SiZES 16>® 077 THRO 124,

OR TWO St^íGt£-£^íO MACHINES fN PARAiXEL.

“Acid for 3-way vaive usaae. Pipe MC port (when 3-way valve

useO) to generator irvieris).

Fig. 6 — Suggested Piping For Hot Water Machines

Using Supply Hot Water 300 F or Below

A three-way valve is recommended to ensure a

constant system flow of hot water supply re

gardless of load. A two-way valve is suitable when

throttling of supply hot water at partial load does

not adversely affect the boiler or primary circu

lating pump.

Piping

Fig. 7

For Water Temperature Above 300 F —

gives suggested hot water piping when

supply High-Temperature Hot Water (HTHW) is

above 300 F. The three-way valve — CVl, diverts

HTHW and allows cooler recirculated hot water to

maintain design hot water temperature (300 F

max).

Machine capacity is controlled by regulating the

flow of hot water thru the generator. As machine

load decreases, the chilled water controller senses

the lower chilled water temperature and acts upon

the three-way diverting valve(s) CV2

(CV2 + CV3) to reduce the supply of hot water

to the generator. The recirculating pump, however,

is actually pumping a constant gpm.

The sensor for CVl should be located, if

possible, on the discharge side of the recirculating

pump. The recirculating pump should be sized for

design hot water at a head equal to the pressure

drop through the generator and recirculating loop

piping.

An alarm should be used to warn of excessive

entering hot water temperatures. Excessive tem

peratures could develop if control valve calibration

were lost.

P(PiN<3 FOR MftCHiNE SIZES 077 THRU t24

OR TWO SiNGL£-EN0 MACHINES iNRARALLEL

Fig. 7 — Suggested Piping For Hot Water Machines

Using Supply Hot Water Above 300 F

RECIRCULATING WATER CALCULATIONS Assume for example purposes;

Available supply hot water temp = 400 F

Design quantity of hot water needed = 243 gpm

Design entering hot water temp = 300 F

Design leaving hot water temp = 229 F

1. Determine the design hot water temperature

drop (ATi) thru the machine.

AT 1 = ent hot water (F) — Ivg hot water (F)

- 300 F - 229 F

= 71 F

2. Determine the temperature drop of 400 F

water (AT2) thru the machine.

AT2 = supply hot water (F) — Ivg hot water (F)

- 400 F^ 229 F

= 171 F

3. Determine the amount (gpm) of 400 F water

required.

Gpm of 400 F water

gpm of 300 F water

ATI

AT2

243 X-

71

171

= 101 gpm

Determine the amount (gpm) of recirculated

229 F water required to meet design quantity

of water needed:

Gpm of 229 F water - gpm of 300 F water

— gpm of 400 F water

= 243 - 101

- 142 gpm

Page 7

VALVE SIZING — The hot water capacity control

valve CV2, should be sized to handle full design

flow on machine sizes 010-068. Valves CV2 and

CVS on machine sizes 077-124 are each sized at

one-half design flow. The pressure drop and sizing

formula used in sizing the valve(s) should be

consistent with valve manufacturer’s recommenda

tions. The three-way diverting valve should be sized

to handle the design supply of high-temperature

hot water (HTHW) and must be suitable for high

temperature duty.

Methods Other Than Recirculation to lower supply

hot water temperature to acceptable levels (300 F

max) are:

1. A water-to-water heat exchanger

2. A hot water-to-steam converter

Rupture Disc — All 16JB hot water machines are

provided with a rupture disc on the generator shell

for safety reasons. A generator tube failure could

subject the shell to hot water supply working

pressure.

RELIEF PIPING — Some apphcations have relief

piping installed from the rupture disc discharge to

a location where high-temperature steam and

lithium bromide will not cause damage or injury.

Relief piping must include access to the rupture

disc, allowing replacement in case of failure. Piping

must be supported independent of the machine.

Hot Water Inlet Pressure — It is necessary to ensure

that generator hot water pressure is higher than

saturation pressure corresponding to the inlet hot

water temperature.

Minimum pressures are approximately equal to

10 psi plus the saturation pressure corresponding

to inlet water temperature. Using a recommended

minimum pressure will ensure that hot water inlet

pressure drops will not cause the pressure in the

lines to drop below saturation pressure. This could

cause flashing and water hammer.

3. Winter Operation — If the absorption machine

is to be applied under winter operating

conditions, an indoor cooling tower sump

should be provided to protect the cooling tower

water from freezing.

GENERAL INFORMATION

Insulation — Machine cold surfaces, subject to

sweating and corrosion, are factory insulated.

Refer to Fig. 8 and Table 2 for details.

d> 6 é

¡S3 FACTORY INSULATION

LEGEND

1 — Refrigeract Pump Housing

2 — EvaporaTor Shell

3 — Refrigerant Suction Piping

Fig. 8 — Machine Cold Surfaces

CONDENSING WATER TEMP CONTROL

If the absorption machine is to be applied

under conditions where the condensing water

temperature can fall below 55 F, condensing water

temperature control is required. This can be

accomplished by:

1. Fan Cycling — On a single-cell coohng tower,

the tower fan can be shut off when the

temperature of the water reaches 55 F. This

allows the temperature of the tower water to

warm up using the heat rejected from the

machine. In order to ensure against rapid fan

cycling, which can cause fan motor problems, it

is recommended that the cooling tower water

temperature be allowed to rise to design

temperature before fan operation is resumed.

2. Multiple-Cell Tower — The temperature of a

multiple-cell tower can be controlled by

shutting off the number of operating cells. This

creates an effect similar to shutting the fan off

in a single-cell tower. The controls should be

adjusted to shut off in stages to 55 F and come

on again in predetermined stages.

Table 2 — Insulation For Cold Surfaces

EVAP

UNIT

SHELL

16JB

TTlff“

012

014

018

021

024

028

032

036

041

047

“054~

057

061

068

w

084

097

107

115

124

^Quantity of insulation specified is adequate to cover cooler water

boxes and covers on both ends of machine

REFRIG

PUMP(S)

(ft2)

75 3 6 10 ft

96 3 6 11 ft 12

114

147

177

188

216

275 8 16

328

360 8

(ft 2)

REFRIG

Suction

(ft2)

3 6 12 ft 15

3

4 6 12 ft

4 9 15 ft 21

4 10

8 17 60 ft

LINES

2 in.

Disch

6 12 ft 17

13 ft

48 ft 21

19

60 ft

COOLER

WATER BOXES

AND COVERS*

(ft2)

9

20

24

24

27

Page 8

The generator shell and some of the machine

piping will become hot during operation. If insula

tion is to be used as a safety precaution, or to

reduce ambient temperature in the machine room,

we recommend insulating the surfaces shown in

Fig. 9. Hot-surface dimensions are given in Table 3.

Generator insulation can be either blanket-type

or low-pressure boiler insulation. Insulation used

for piping is generally standard low-pressure steam

pipe insulation.

Table 3 — Insulation For Hot Surfaces*

GENt

UNIT

SHELL

16JB

010

012

014

018

021

024

028

032

036

041

047

054

057

061

068

077

084

097

107

115

124

•Refer to Fig. 10 for location of hot surfaces.

fl nciudes outiet box and ends

EXCH

(ft 2)

(ft 2)

62

67 45

72

77 55

82

98

98 60

152

184 no 18 4

184

GEN —Generator

HT EXCH — Heat Exchanger

STRONG

HT

SOL LINE

Lgth

Size

(in.)

(ft)

40 7 3 20

7 3 21 2 12

50 8

60

55 8 4

102

1 18

4 22

9 4

10 4

10 4

16 4 44 2 3 4

20 4 49

WEAK

SOL LINE

Lgth

Size

(in.)

(ft)

V/2

2

23

2'/2

24

3 16 4

22 3 10 4

24 3

3

47

3

GEN

OVERFLOW

(GO) TUBE

Lgth

(ft)

1 1

13 4

15 4

12

4

4

Size

(in.)

3

4

4

4

4

HOT SURFACES THAT

CAN BE INSULATED

LEGEND

1 — Generator Shell (refer to Table 4 for sq ft surface area)

2 — Steam Supply Line

3 — Condensate Line

4 — Weak Solution Line (to generator)

5 — Strong Solution Line (from generator)

6 — Generator Overfiow Tube (only hot during abnormal

conditions)

7 — Heat Exchanger

Fig. 9 — Machine Hot Surfaces

isolation — 16JB machines are not in themselves a

major source of vibration ; and isolation equipment

is not supplied with the machine unless requested

on the order. It is possible, however, for a machine

to receive and transmit vibrations from

other

sources that are imperfectly isolated such as

condensing water pumps, chilled water pumps, or

other piping. Isolation packages are available from

a number of manufacturers. Specifications for

Carrier machines are given in Table 4.

Table 4 — Isolation Pad and Soleplate

Specifications

UNIT

16JB

010

012

014

018

021

024

028

032

036

041

047

054

057

061

068

077

084

097

107

115

124

NOTE:

Higher isolation efficiencies may be obtained with double-layer

pads. Double-layer pads, factory-fused together, are available from

various manufacturers. If two single-layer pads are used, a metal

divider equal to pad dimensions should be inserted between iayers.

NO. (EACH)

OF PADS AND

SOLEPLATES

4 9 X 6 X %

4 9 X 10 X %

4

4

4

4

4

6

6

6

PAD

DIMENSIONS

(in.)

9 X 12 X Vs

9 X 14 X %

9 X 18 X %

12 X 18 X Vs

14 X 18 X %

12 X 18 X %

15 X 18 X Vs

16 X 18 X % 17 X 19 X

SOLEPLATE

DIMENSIONS

(in.)

10 X 7 X V2

10 X 11 X V2

10

X 13 X %

10 X 1 5 X

10 X 19 X %

13 X 19 X %

15 X 19 X h

13 X 19 X %

16 X 19 X %

(4

‘/ 2

Page 9

The integral shipping skids, or base rails, are

normally left on the machine. However, the base

rails may be removed, if desired, but not until the

machine is in final position. When isolation pads

are used, they should be located under the corners

of the machine, atop soleplates with 1/2-in. min

imum thickness (see Fig. 10). The soleplate ensures

machine contact on the floor only at the corners

when base rails are left on. Shims may be inserted

under the soleplates for leveling the machine.

Grouting is optional.

Outdoor Installation — Outdoor installation of the

16JB absorption machine creates a number of

special problems which must be resolved. Such

applications should be considered only when the

customer has qualified operating personnel,

familiar with the maintenance of mechanical equip

ment located outdoors. Standard machines require

protection from weather. A simple, heated

structure is preferred. If this is not possible,

protection from the weather must be provided by

machine modifications.

WEATHERPROOFING -- Pneumatic control sys

tems are recommended for outdoor installations.

Controls can be factory furnished to meet NEMA

No. 4 Waterproofing Specifications.

FREEZE PROTECTION — When the machine area

may be subjected to temperatures below 40 F and

if the machine is to be shut down for an extended

time during these low-temperature periods, all

water circuits and tube bundles should be drained,

then filled with ethylene glycol. Table 5 lists

storage volumes of 16JB header and tube bundles.

This data can be used when calculating the

quantity of ethylene glycol needed to provide

adequate freeze protection.

Fig. 10 — Typical isolation Assembly

Explosionproof Machines — 16JB standard absorp

tion machines can be factory equipped with

explosionproof electric motors and controls

suitable for Class 1, Group D hazardous locations

specified by the National Electrical Code. Modi

fications to the standard control system are

described in the controls application publications.

Table 5 Header and Tube Bundle Storage

Volumes (gal.)

UNIT

EVAPORATOR ABSORBER CONDENSER

16JB

010

012

014

018

021

024

028

032

036

041

047

054

057

061

068

077 ^

084

097

107

115

124

GEN — Generator

106

108

129 179 68

158

198 271

228

25 27

28

30 35 17 17

43 46

48 51

57

64 69

76

83

96

30 16 16

62

83

90

104

117 59

150 57 74

215 129

310 186 150

14

24

26

32

36

42

46 43

52 49

163 138

HOT

WATER

GEN

14

23

25

30

34

39

56

87

106

Page 10

Tube Removal — Clearance for tube removal

should be considered when planning a piping

system. The 16JB machines are designed so all

tubes are accessible for cleaning or servicing should

the need arise. Refer to Fig. 11 for tube pulling

clearance dimensions and data. Evaporator,

absorber and condenser tubes may be pulled from

either end.

UNIT

16J8

010,0i2.0U

0t8,02t

024,028

032,036

041,047

i 16-lOli

i

1 17- Oii

i 16-U’4

£’.7- 2\

054,057 r 6- 3%

061,068

i 21- Sy, ; 7- 3ii

077,084 i 32- 2 i 6- 314

097,107

} 32- 2

115,124 ; 2 /—SO /<

'Weights given are for each cover.

NOTE: Minimym space for tube removai !Din>er;sion O) may be tocated on either end.

CLEARANCE DIMENSIONS (ft

A 8 c

: 3-

7- sy. ; 14-2

\ 4- 4Vi 7- 914

; 5- Oti

i 6- 3

s 6- n

8- 9y ' 14-2

10- H4 ; 14-2

;i- 6‘/*

■•-10

13- 214

1:- 4

> 7— 1 ^

12-tOy

13- 9y

Certified dimension drawings are available on request.

Fig. 11 — Tube Pulling Clearance Data

— in.)

i D

E

4- S

; 14-2

.5- 1

5-10 ; 4- 0 < 88

6-10 ; 5- 0

: 14-2 8- 6 ; 5- 3

i 19-3

: 19-3

: 29-1

8- 7 i 5- 0

9- 3

8- .5

i 29-1 9" 5 j 6— 6 193

• 29—^ 9- 9

COVER PLATE WEIGHTS* (lb)

F

; 2- 8

i 3- 6

Comlertser(G)

45

50

; Absorber(H) Evaporator{J)

: 100 ;

177 ; 177

275 ; 275

87

t

>

>

!07

169 i 318 ;

; 5-11 ¡69

; 325 :

i 460 ;

; 389 i

i 5— 0 153 1 310 i

“T ssT" r

I 6- G

•93

1 438 t

'•■DO

32.5

460

384

471

384

471

566

10

Page 11

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 15

Form 16JB-2XA New

Printed in U.S.A. 6-71 Codes MA and ML Catalog No. 511-602

Loading...

Loading...