Page 1

ti

Hermetic Absorption Liquid Chillers

Carrier

MACHINE OPERATION

MACHINE START-STOP SYSTEMS

General - The exact start-stop system for a given

machine is established by the customer. Systems

can vary from one installation to another. These

systems and procedures are meant for general

guidelines only.

The three most common types of systems are

given below. Review these systems and decide

which applies to your machine. Then follow the

start-stop procedure given.

NOTE: If machine has been shut down for more

than 2 days, follow procedures under Start-Up

After Limited Shutdown or Start-Up After

Extended Shutdown. In all cases below, when

machine starts, the white run light will en

ergize. When the machine stops, the light will

go out after automatic dilution.

Automatic Start-Stop System - Starting and stop

ping with this system is accomplished by an

automatic controller such as a thermostat or

time clock, etc. Also, an AUTO-MANUAL switch

is provided so the machine can be started bypressing machine START button with switch in

MANUAL position. All auxiliary equipment is

tied in with the machine control circuit and will

start when the machine starts. If automatic time

delay relays are provided, the machine will start

after a preselected time interval.

The operating engineer must make periodic

checks to ensure that the machine with auxiliary

equipment is operating satisfactorily.

PROCEDURES

1. Place AUTO-MANUAL switch in the AUTOpo-

sition for the machine to start or stop automat

ically. The automatic controller determines

when the machine starts or stops.

2. To start fully automatic machines after limited

or extended shutdown place the AUTO-MANUAL

switch in MANUAL and press the START

button. Then follow start-up procedures for

limited or extended shutdown. Only after man

ual start has been completed should the AUTO

MANUAL switch be placed in AUTO.

NOTE: When the machine shuts down either

automatically or manually, the refrigerant

and solution pumps will continue to run

until automatic dilution is completed.

Semiautomatic Start-Stop System - All auxiliary

equipment used with this system is tied directly

to the control circuit. It is necessary for the

operating engineer to press the START button

to start the condensing water pump, chilled water

pump, machine pumps, and cooling tower fan

(if used).

PROCEDURES

1. Press STOP button to stop machine.

START button to start machine.

NOTE: On shutdown the machine pumps will

continue to run until automatic dilution

is completed.

Semiautomatic Start-Stop System with Manual

Auxiliaries - All auxiliaries must be started

manually.

PROCEDURES

1. Start chilled water pump.

2. Start condensing water pump.

3. Start cooling tower fan (if used). (This depends

on outside temperature.)

4. Press START button to start machine.

5. To stop machine, press STOP button. Then

stop the following:

a. Cooling tower fan (if used).

b. Condenser water pump.

c. Chilled water pump.

NOTE: The refrigerant and solution

pumps will continue to run until auto

matic dilution is completed.

MACHINE START-UP PROCEDURES

General - Procedures for start-up differ depend

ing on how long the machine has been shut down.

There are two start-up procedures: Start-up

after limited shutdown (3 days to 3 weeks), and

start-up after extended shutdown (over 3 weeks).

Start-Up After Limited Shutdown

PROCEDURES

1. Start the machine as outlined for your system

under Machine Start-Stop Systems.

2. Check the leaving chilled water temperature.

If temperature drops to design, then steps 3

and 4 are not necessary. If the temperature

does not drop to design, noncondensables are

probably present in the machine. Proceed

with steps 3 and 4.

3. Determine the amount of noncondensables by

taking an absorber loss reading (the temper

ature difference between the refrigerant and

solution vapor). To determine absorber loss,

refer to Carrier Standard Service Techniques,

publication SM-16. A machine with absorber

loss of less than 6 F can normally be started

without the machine solution becoming solid

ified. If absorber loss is greater than 6 F,

auxiliary evacuation is recommended. A ma

chine fully evacuated will normally have an

absorber loss of 2 F or less. Instructions

for auxiliary evacuation are in Carrier Stand

ard Service Techniques, publication SM-16.

Press

Carrier Corporation 1968 Printed in U.S.A.

1-68

16JA-1SO

Page 2

To prevent solidification while purging:

a. Place reclaim switch to MANUAL.

b. Throttle back steam control valve.

(1) Electronic Control - Turn the control

point adjustor up approximately ten

degrees (ten divisions).

(2) Pneumatic Control - Turn the chilled

water thermostat set point up ten

degrees.

4. Evaluate machine tightness with a noncon

densable accumulation rate check. Refer to

Carrier Standard Service Techniques, publica

tion SM-16.

Start-Up After Extended Shutdown - This pro

cedure is critical since accumulated noncon

densables may allow the machine solution to

solidify if the following precautions are not taken,

PROCEDURES

1. Start the machine as outlined for your system

under Machine Start-Up Procedures. Make

sure steam valve is closed. If absorber solu

tion level is high (above 9 in.) and refrigerant

pump is noisy, open steam valve until absorber

level indicator shows approximately 9 in. of

solution, then close steam valve. Place refrig

erant pump switch in ON position.

2. Determine absorber loss by following proce

dures outlined in Carrier Standard Service

Techniques, publication SM-16.

a. If absorber loss is less than 6 F, open

steam valve and allow machine to go into

automatic operation.

b. If absorber loss is 6 F or greater, auxil

iary evacuation is required. Use instruc

tions for auxiliary evacuation provided in

Carrier Standard Service Techniques, pub

lication SM-16.

3. Continue auxiliary evacuation until absorber

loss is less than 6 F. Place machine in auto

matic operation.

4. After auxiliary evacuation, evaluate machine

tightness with a noncondensable accumulation

rate check.

WINTER CONDITIONS

General - At the end of each cooling season when

the machine is no longer required use one of the

following winter shutdown procedures. The choice

depends on whether the machine ambient tempera

ture will be kept above or below freezing.

Shutdown Procedures

BELOW FREEZING

1. Stop machine and wait until automatic dilution

completes and machine pumps stop.

2. Set dilution thermostat to its lowest possible

setting.

3. Connect a hose between solution and refrig

erant pump service valves. Open both valves.

4. Switch refrigerant pump ON-OFF switch to

OFF and solution pump switch to ON.

5. Press START button and allow solution pump

to run for approximately 5 minutes.

NOTE: This procedure contaminates the

refrigerant with lithium bromide solution

lowering the refrigerant freezing point.

6. Press STOP button and reset dilution thermo

stat to 140 F (refer to Checking Dilution Ther

mostat under Maintenance).

7. Drain water from all chilled water, condensing,

steam and condensate circuits. Flush all cir

cuits with ethylene glycol.

ABOVE FREEZING

1. Press STOP button.

2. Allow machine to go thru automatic dilution.

When dilution has completed, machine may

be left in this condition until spring start-up.

Start-Up Procedures

BELOW FREEZING

1. Refill all water circuits that were drained at

shutdown.

2. Follow Start-Up After Extended Shutdown pro

cedures.

3. Reclaim lithium bromide from refrigerant

circuit. Follow Reclaim Solution procedures

given under Maintenance.

4. Restart machine.

ABOVE FREEZING

1. If machine vacuum was broken for maintenance

work, etc., follow auxiliary evacuation pro

cedures outlined in Carrier Standard Service

Techniques, publication SM-16. Then follow

Start-Up After Extended Shutdown procedures.

2. If machine vacuum was not broken, follow

Start-Up After Extended Shutdown procedures.

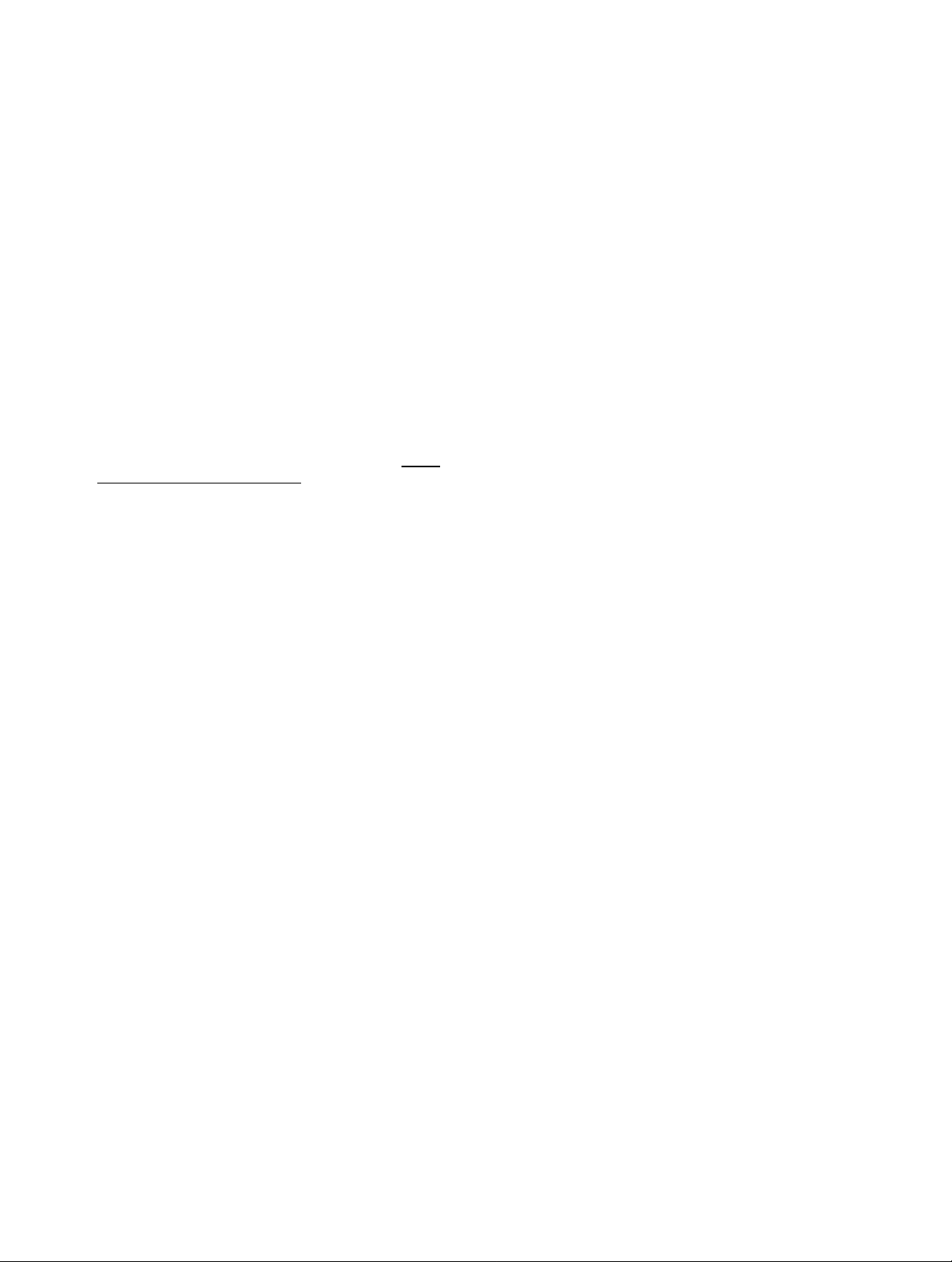

PURGE OPERATION

General - The 16JA purge unit automatically per

forms the following functions:

1. Removes noncondensables from the machine.

2. Accumulates these noncondensables in the

purge storage chamber where they will not

affect the machine performance.

3. Provides an indication of the degree of air

leakage into the machine.

The 16JA purge unit cannot be used as an auxil

iary evacuation device to evacuate the machine.

When the purge exhaust light (red) is energized

during machine operation, it indicates that the

purge must be manually exhausted. For instruc

tions refer to the instruction sticker located on the

separation chamber (Fig. 1) or use the following

procedure.

Page 3

CONDENSER PURGE

SUCTION LINE

PURGE EXHAUST

VALVE

INSTRUCTION

STICKER PURGE

PURGE RETURN VALVE

TO GENERATOR OVERFLOW TUBE

SEPARATION

CHAMBER

STORAGE CHAMBER

SUPPLY LINE

service valve. With correct pump rotation, the

gage will indicate a positive reading above at

mospheric pressure. If the pump is solidified,

the gage will indicate atmospheric pressure.

If the casing is partially desolidified and the

pump will not turn, the pressure gage will in

dicate a deep vacuum. Continue to heat the

casing until the pump is desolidified. Desolid

ification of the heat exchanger will take place

automatically once the pump starts functioning.

3. Refer to Troubleshooting Guide for possible

causes of solidification and their correction.

SOLUTION PUMP-

Fig. 1 - Purge Exhaust System

Manual Exhaust Procedures

1. Close purge return valve.

2. Wait 10 minutes for storage chamber to

pressurize.

3. Slowly open purge exhaust valve. If level in

container drops, shut valve and wait 2 minutes.

Reopen valve. If bubbles appear, keep valve

open until bubbles stop and level in container

rises, then close valve.

4. Collect lithium bromide solution to recharge

into machine. Recharging procedures are given

in Carrier Standard Service Techniques, pub

lication SM-16.

SOLUTION DESOLIDIFICATION

General - Should solidification occur, it will occur

usually in the shell side ofthe heat exchanger, pre

venting the strong solution in the generator from

returning to the absorber thru the strong solution

line. However, the strong solution will be returned

to the absorber thru the generator overflow tube

(Fig. 6) thereby desolidifying automatically.

If during a shutdown period solidification has

occurred to the extent that the solution pump will

not rotate and the motor overloads trip put, desolidify by using the following procedure.

PROCEDURE

1. Heat the pump casing and adjacent lines with

steam until the pump will rotate. Be careful

not to allow steam and condensate to enter the

pump motor and controls.

jpr«ic3iCitK»3S miSt he

fi a beaîiïig torch 1& used, cadesr

lîcf hhaajà heat he

iÈC35eciÎ3f to âîiy ifeïige <M№iectiOîias3â!e’S'«ry

2. Confirm pump rotation. Rotation of the her

metic pump cannot be viewed directly. Install

a compound pressure gage on the solution pump

MAINTENANCE

INTRODUCTION

General - The following are routine steps nec

essary for normal preventive maintenance on

16JA Hermetic Absorption Liquid Chillers.

To ensure the continued satisfactory perform

ance of the machine, these schedules must be

closely adhered to.

We recommend the suggested steps be per

formed as often as indicated, and that an accurate

log be kept to aid in diagnosing any troubles.

Certain components and operations should be

checked on an individual basis as needed.

EACH MONTH

Reclaim Solution - During normal operation it is

possible that some lithium bromide might carry

over into the refrigerant circuit.

To determine if contamination exists, remove

a refrigerant sample from the machine using

refrigerant and solution sampling procedures out

lined in Carrier Standard Service Techniques,

publication SM-16. Measure the specific gravity

of the sample. If the value exceeds 1,02, the solu

tion must be reclaimed.

RECLAIM PROCEDURE FOR CONTINUOUS OP

ERATION

1. Place reclaim valve switch in MANUAL posi

tion. Wait for approximately 15 minutes. This

causes refrigerant to flow into the solution

circuit where the lithium bromide solution

is reclaimed.

2, Place reclaim switch in AUTO position, de

energizing the refrigerant solenoid valve,

thus stopping refrigerant flow.

RECLAIM PROCEDURE FOR FREQUENT SHUT

DOWN - When the machine is shut down, the re

claim valve will automatically reclaim the lithium

bromide salt solution.

NOTE: If the reclaim solenoid valve does not

energize during the reclaim procedure (aud

ible click, and typical rattling noise of refrig

erant passing thru the valve) contact your

nearest Carrier representative for assistance.

Page 4

Check Machine Tightness - The most important

maintenance item on the absorption machine is

maintaining vacuum tightness within acceptable

limits. Check machine tightness by determining

the noncondensable accumulation rate. Use pro

cedures given in Carrier Standard Service Tech

niques, publication SM-16.

condenser water temperature. Turn down control

point adjuster below design leaving chilled water

temperature setting. Repeat steps 1 thru 4.

Continual removal of water indicates leakage in

one of the tube bundles. Leak test by using proce

dures outlined in Carrier Standard Service Tech

niques, publication SM-16.

EVERY 2 MONTHS

Check Dilution Thermostat - The dilution thermo

stat should be open when the strong solution drops

to 140 F. If temperature cutout point is not 140 F,

insert screwdriver in slot on face of thermostat

(located on strong solution line) and turn adjust

ment dial until cutout occurs at 140 F.

Check Low-Temperature Cutout - Remove low-

temperature cutout sensing element from sep

arable well in the evaporator shell. Place it in

an ice bath. Low-temperature cutout should trip

at 5 F below design leaving chilled water tem

perature or a minimum of 36 F. The actual cutout

point is the dial setting less 3 F differential. When

the control trips, the machine will shut down

immediately without going thru a dilution cycle.

NOTE: The chilled water pump will continue

to run if hooked up in the standard wiring

arrangement.

EVERY 6 MONTHS

Check Evaporator Water Charge-Check the evap

orator water charge to determine if the reclaim

valve has energized. If valve has energized then

either tube leakage or excess refrigerant is

indicated.

Reclaim should start at full load (corresponds

to approximately 62 percent lithium bromide in

absorber for standard nominal conditions). Check

as follows:

1. Operate machine at full load with design en

tering condensing water and design leaving

chilled water.

2. Remove a sample of evaporator water from

refrigerant pump service valve and check the

specific gravity. If specific gravity is below

1.02 proceed with step 3. If specific gravity

is above 1.02 reclaim solution (see instruc

tions for Reclaim Solution, page 3) until specific

gravity is below this point, then proceed with

step 3.

3. Evaluate absorber loss. Should be 2 F or less.

If more, purge air from machine.

4. Check reclaim line by feel. Listen for refrig

erant flow (audible). If reclaim line is already

cold, with audible refrigerant flow, remove

refrigerant until reclaim valve closes (audible

click) and refrigerant flow ceases.

If machine is operating under light load, it will

be necessary to concentrate the absorber weak

solution to 62 percent. To do this, raise entering

Check Capacity Control Valve - Check to see if

leaving chilled water is being maintained at design

temperature. If not, adjust the electronic or

pneumatic control.

TO ADJUST ELECTRONIC CONTROL

1. Move control point adjuster clockwise to in

crease temperature, or counterclockwise to

decrease temperature. If this fails to bring

leaving chilled water within design temper

ature, perform step 2.

2. Replace vacuum tubes in control motor. Make

sure that new tubes are installed in correct

plugs. If this fails to bring leaving chilled

water within design temperature, proceed

with step 3,

3. Clean relay contacts with stiff paper. If this

fails to correct problem, contact Carrier

immediately.

TO ADJUST PNEUMATIC CONTROL

1. Reset control point setting to design.

2. If above fails to correct problem, contact

Carrier immediately.

Check Cooling Tower Bypass Control - If control

is not maintaining design entering condensing

water temperature, recalibrate the control ther

mostat. For information, contact the valve (or

control) manufacturer.

EVERY YEAR

Check for Absorber and Condenser Scale - Check

absorber and condenser tubes to see if cleaning

is required. Soft scale may be removed with tube

cleaning brushes. When hard scale has formed,

it may be necessary to chemically clean the tubes.

If a scale problem occurs, contact a water treat

ment representative. Annual tube cleaning may

not be required if adequate water treatment is

maintained.

Recharge Lithiunn Bromide - Recharge lithium

bromide when the purge exhaust bottle becomes

filled.

PROCEDURES

1. Open the exhaust valve and allow solution to

be forced back into the purge,

2. Close the exhaust valve when the level nears

the end of the tube. Do not allow air to be

drawn into the tube.

Page 5

EVERY 2 YEARS

Replace Service Valve Diaphragms - Require

ment to replace valve diaphragms is determined

by valve usage or number of machine operating

hours. Less frequent usage of valves and lower

number of machine operating hours results in

longer life span for valve diaphragms. With min

imum usage the requirement to replace dia

phragms might be 3 years. With maximum usage

they will need to be replaced in approximately

2 years.

PROCEDURES

1. Remove all solution and refrigerant from the

machine.

2. Break vacuum with nitrogen unless performed

previously. Refer to Carrier Standard Service

Techniques, publication SM-16,

3. Remove solution and refrigerant from machine

unless performed previously.

NOTE: Store solution in clean containers

for recharging.

4. Remove old valve diaphragms.

5. Install new valve diaphragms. Torque bolts

to 3 ft lb.

6. Leak test all affected joints to make sure

that all valves are leak tight.

7. Replace solution and refrigerant in machine.

NOTE: The same quantity of solution and

refrigerant removed from the machine must

be charged back into the machine.

3, Pull stator and adapter flange straight back

from pump casing. If paint has frozen flange

to casing, gently pry between adapter flange

and pump discharge pipe (item 4) until paint

seal is broken.

4, Remove and discard gasket (item 5),

5. Remove impeller (item 6) by straightening

locking tabs on impeller lock washer (item 7).

Prevent impeller from rotating while removing

locking bolt (item 8). Remove impeller key in

the shaft.

6. Remove bearing and wearing ring housing:

a. F-8 Frame Pumps (Fig. 2) - Unbolt cap

screws (item 9). Remove bearing and wear

ing ring housing (item 10).

OAiliiWi Do. safe afc bearii® to

or 0300 XEOOr. AiSO oo ca. _

fel ucc lo Jos£i retaimfag clip iitom 18>

b. F-66 Frame Pumps (Fig. 3) - Remove stud

nuts (item 9). Use jacking screws to loosen

bearing and wearing ring housing (item 10),

Insert jacking screws in tapped holes pro

vided in wearing ring housing.

7, Slide out rotor (item 11) carefully, so as not

to damage the stator can (item 12), rotor can

(item 13), or motor end bearing (item 14).

8. Remove motor end bearing, retaining clip (item

15) and spring (item 16). Remove spring bear

ing plate (item 17) used on Frame F-8 only.

8. Re-evacuate the machine after service work

is completed. See auxiliary evacuation pro

cedures in Carrier Standard Service Tech

niques, publication SM-16.

EVERY 5 YEARS

Inspect Hermetic Pumps - Pumps used on Carrier

Absorption Machines are hermetic and do not re

quire seals. Pump motors are cooled by the fluid

being pumped and are thermally protected with

high-temperature cutouts (Klixons).

Inspect hermetic pumps and motors every

5 years or 20,000 hours, whichever comes first,

DISASSEMBLY PROCEDURES - Refer to Fig, 2

and Fig. 3.

1. Disconnect motor power leads at junction box

on stator. Mark leads for ease in reassembly.

2, Remove bolts (item 1) holding motor adapter

flange (item 2) to pump casing (item 3),

NOTE: Use blocking to support weight of

motor stator when removing bolts.

INSPECTION PROCEDURES

1. Check for bearing wear by measuring depth

from large end to start of cone (Fig. 4). If

wear exceeds 3/16 in,, replace the bearing.

Use standard parts lists for ordering new

bearing.

Instructions for bearing replacement are fur

nished with new bearing.

2. Check recirculation passages (item 20). Clean

as required.

3. Check impeller stator can, rotor can and

wearing rings for wear. Clean or replace

if necessary.

NOTE: If wearing rings require replace

ment, break the old ring with a chisel.

These rings were staked in place. Do not

restake new wearing ring.

4. Check spring loaded bearings for free move

ment within the bearing housing.

Page 6

note: item numbers are referenced in

DISASSEMBLY AND REASSEMBLY

PROCEDURES.

Fig. 2 - F-8 Frame Pumps

NOTE: ITEM NUMBERS ARE REFERENCED IN

DISASSEMBLY AND REASSEMBLY

PROCEDURES

Fig. 3 - F-66 Frame Pumps

Page 7

J."

MAX

16

REASSEMBLY PROCEDURES

Refer to Fig. 2

and 3.

1. Clean all parts.

2. Replace wearing rings. Use hand pressure

to position new rings.

3. Insert motor end spring and bearing plate

(F-8 Frame Pump only).

4. Install retaining clip and spring in bear

ing housing.

5. Insert motor end bearing into housing. Should

be a free sliding fit without excessive ra

dial play.

6. Guide the rotor into position.

7. Install end bearing in bearing and wearing

ring housing:

a. Frame F-8 Pumps - Be sure bearing re

tainer pin is in the retainer slot.

b. Frame F-66 Pumps - Be sure bearing re

tainer pin is in the bearing retainer hole.

8. Install bearing and wearing ring housing.

Tighten cap screws (Frame F-8 pumps), or

stud nuts (Frame F-66 pumps).

9. Install impeller with impeller key, lock

washer and locking bolt. Bend tabs of washers

over flats of locking bolt heads.

10. Install new 1/32 in. thick EPR gasket by

removing transfer tape from adhesive side

of gasket and positioning gasket on adapter

flange periphery.

11. Assemble motor stator housing and adapter

flange assembly by sliding the housing and

adapter flange assembly into pump casing.

Refer to step 2 of Disassembly Procedures

as to blocking. Install and tighten bolts and

washers. Remove blocking.

12. Connect power supply to stator junction box.

AS NEEDED

Adding Octyl Alcohol - Octyl alcohol is usually

required when the leaving chilled water tempera

ture starts to rise above design providing the

control set point has not been altered. Since a

rise in leaving chilled water temperature is also

an indication of fouled condensing water tubes,

use the following procedure to determine if

alcohol is required.

PROCEDURE

1. Remove a sample of solution from solution

pump service valve. If solution has no odor

of alcohol (very pungent), then octyl alcohol

should be added.

2. Add alcohol using the procedure outlined in

Carrier Standard Service Techniques, pub

lication SM-16.

3. If alcohol is not required, refer to Trouble

shooting Guide for symptoms of fouled tubes.

Log Sheets - We recommend that log sheets be

obtained from your Garrier representative and

that readings be taken periodically. They are

used to:

1. Familiarize operator with machine operation.

2. Be of assistance when planning maintenance.

3. Diagnose machine troubles.

Ordering Spare Parts - Order spare parts from

your nearest Carrier office. To speed up the

process of filling part orders, the following in

formation must accompany the order:

1. Delivery address.

2. Machine size.

3. Machine serial number.

4. Part name, part number and quantity required.

5. Orders for pump parts must show the motor

serial number found on the motor nameplate.

TROUBLESHOOTING

The remedies listed do not represent a series

of corrective procedures. They are merely check

points and possible individual remedies to machine

problems. When the troubleshooting remedies fail

to pinpoint a problem, contact your nearest

Carrier representative for assistance.

Page 8

TROUBLESHOOTING GUIDE

SYMPTOM OR DIFFICULTY

A. Lithium bromide

solidifies at start-up.

B. Lithium bromide

solidifies during

operation.

POSSIBLE CAUSE

REMEDY

1. Condenser water too cold. 1. a. Reset cooling tower bypass

valve to design conditions.

b. Check cooling tower fan con

trol setting.

2. Air in machine. 2. Purge the machine. Use Carrier

Standard Service Techniques,

publication SM-16.

3. Improper purging. 3. a. Check to see that all valves

are in correct position.

b. Check machine leak rate with

purge.

1. Condensing water too cold. 1. a. Reset cooling tower bypass

valve to design conditions.

b. Check cooling tower fan con

trol setting.

2. Steam pressure above design. 2. Reset to design conditions.

3. Vapor condensate temperature

3. Reduce condensing water flow.

too low. (Temperature should

never be below 114 F at full

load.)

4. Machine requires octyl alcohol. 4. Add octyl alcohol. Use Carrier

Standard Service Techniques,

publication SM-16.

5. Improper purging.

5. See Remedy in A-3 above.

6. Air leakage. 6. Leak test machine.

C. Low capacity

1. Air in machine. 1. Find and repair leak. Purge the

machine.

2. Condenser tubes dirty. Noted by

continually rising vapor con

densate temperature (above 114

F) at full load.

2. Clean the tubes and take cor

rective action in water treat

ment methods. Use the Carrier

Standard Service Techniques,

publication SM-16.

3. Improper purging. 3. See Remedy in A-3.

4. Machine needs octyl alcohol.

4. Add octyl alcohol. Refer to

Carrier Standard Service Tech

niques, publication SM-16.

5. Improper setting of capacity

control valve.

5. Reset capacity control valve to

design temperature by turning

control point adjuster down.

6. Insufficient condensing water

flow, or temperature too high.

6, a. Reset cooling tower bypass

valve to design temperature,

b. Check operation of tower fan.

c. Check the condenser water

strainer.

7. Solution temperature generator

below design at full load. Note

correct temperature at full load.

7. a. Raise steam press, to design.

b. Unplug the steam strainer

or trap.

Page 9

TROUBLESHOOTING GUIDE (CONT)

SYMPTOM OR DIFFICULTY

D. Machine shuts down on

safety control.

E. Solidification during

shutdown.

POSSIBLE CAUSE

1. Motor overloads.

1. Reset all motor overloads and

REMEDY

check reason for failure.

2, Hermetic pump overload has

tripped.

2. a. If pump is out of liquid, add

solution or water.

b. If pump is solidified, de-

solidify. (Refer to Solution

Desolidification.)

3. Shutdown on low-temperature

cutout.

3. a. Check low-temperature cut

out setting.

b. Control point adjuster set

ting too low. Turn up chilled

water controller to design.

c. Check condensing water tem

perature control.

1, Dilution cycle not long enough. 1. Check setting of dilution ther

mostat, Should be 140F. If still

solidifies reset to lower cutout

temperature.

2. Improper closing of capacity

2. Check valve closure, Desolidify,

control valve.

3. Machine is shut down, but con

densing water pump is still

3. Manually shut down condensing

water pump.

running.

F, Suspect air leakage. Leakage into vacuum side of

machine.

G. Loss of vacuum at

shutdown.

H, Failure to keep ma

chine purged.

Leakage into vacuum side of

machine.

1, Leakage above the pumping rate

of purge.

2. Purge not performing properly.

Determine noncondensable ac

cumulation rate. Refer to the

Carrier Standard Service Tech

niques, publication SM-16.

Leak test machine.

1. a. Perform leak rate check,

b. Leak test machine.

2. a. Valves not opened properly.

Check to see that all valves

are in correct position,

b. Purge solidified. Desolidify.

c. Lack of solution flow to purge

from solution pump. Con

tact your Carrier repre

sentative.

Page 10

GENERAL INFORMATION

EQUILIBRIUM DIAGRAM

The Equilibrium Diagram (Fig. 5) is used to

determine solution concentration in your machine.

It is important to maintain solution concentration

within certain limits in order to maintain equilib

rium conditions.

Refer to the typical machine absorption cycle

plotted on Fig. 5, Points 1 thru 7 represent a

complete cycle. Specific point values are given

in Table 1. An explanation of each point and the

lines drawn between is as follows:

Point 1 - The strong solution as it sprays out of

the absorber spray nozzle and starts to

absorb refrigerant.

The following explains the equilibrium diagram

and how to determine solution concentration:

The curved line in the lower right-hand corner

is the crystallization line. This line indicates the

point at which the solution will begin to change

from a liquid to a solid. This sets the limits of

the cycle. Crystallization of a solution is quite

different from the freezing of a single substance

such as water. When water is subjected to a

temperature even slightly below 32 F, all of it

will eventually freeze. In contrast, when the

lithium bromide solution temperature is reduced

below the solidification point for that particular

concentration, only a portion of the salt will

crystallize or freeze. The remainder of the solu

tion will become more dilute or less concentrated

and will remain in a liquid state. Crossing of the

crystallization line does not necessarily result in

solidification provided the subcooling does not

progress too far. Solidification of solution will

not harm the absorption machine but it will

interrupt service. Satisfactory design requires

that operation take place above the crystalliza

tion line.

The scale on the left represents the straight

horizontal lines and indicates the vapor pressure

of the solution or evaporator water at equilib

rium conditions.

On the right-hand side is the saturation temper

ature scale for pure water corresponding to the

vapor pressures on the left-hand scale. This

scale also represents the horizontal lines and

is located on the right side to avoid confusion in

reading the chart.

The scale at the bottom is for the vertical

lines. They represent solution concentration in

percent by weight. For example, a solution of

60% is 60% lithium bromide and 40% water

by weight.

Point 2 - The weak solution as it leaves the ab

sorber and enters the heat exchanger.

Line 1-2 represents absorption of the

refrigerant thereby diluting solution.

Point 3 - The weak solution after it has passed

thru the heat exchanger. Line 1-3 rep

resents the amount of heat gained by

the solution in the heat exchanger.

Point 4 - The weak solution entering the genera

tor and being heated. Line 3-4 repre

sents the amount of heat required to

start the weak solution to boil.

Point 5 - Maximum solution concentration in the

generator after much of the refrigerant

has boiled out. Line 4-5 represents the

amount of heat required to boil off the

refrigerant.

Point 6 - The strong solution as it leaves the heat

exchanger on its way to spray nozzles.

Point 7 - The strong solution entering the spray

nozzles.

Table 1 - Cycle Data

POINT

1

SOLUTION

TEMP

(F)

115 0 25

2

3

4

5

6

7

101

165

192 3.20 59.5 115

215

134 0.45 64 0

119

VAPOR

PRESS.

(in Hg)

0 25

1 65

3 20

0.30 63 0

PERCENT

LITHIUM

BROMIDE SOL

63.3

59 5 42

59 5

64 0 115

SATURATED

TEMP

(F)

42

95

55

45

The curved lines running from left to right

are solution temperature lines. These should not

be confused with the saturation temperatures.

The curved lines which extend upward from the

bottom of the diagram are specific gravity lines.

These are used to determine solution concentra

tion. By measuring the specific gravity with a

hydrometer and finding the temperature, the per

cent of concentration can be determined by plot

ting these two points on the diagram.

10

Page 11

“n

<p*

in

m

Si

E.

5"

c*

3

VAPOR PRESSURE IN INCHES OF MERCURY ABSOLUTE

® fv> cr w

ro ts> UJ OJ ^ Ol cn

o Ü» o o> o o o

Q

(Q

2

3

SATURATION TEMPERATURE (F)

Page 12

16JA ABSORPTION CYCLE

Figure 6 illustrates the basic absorption flow

diagram. The evaporator-absorber section oper

ates at an absolute pressure of 0.25 in. Hg. As

the cooling load passes thru the cooler, the re

frigerant picks up heat and is vaporized (boiled)

at 40 F because of the low absolute pressure. The

vaporized refrigerant migrates to the absorber

section due to the strong affinity for water of the

lithium bromide solution.

As more refrigerant is absorbed by the solution

the absorption rate decreases necessitating re

generation of the lithium bromide solution to a

more concentrated form to maintain machine ca

pacity, To accomplish this, diluted solution in the

absorber is pumped thru the tube side of a shell

and tube heat exchanger where it picks up some

heat from the hot strong solution returning from

the generator. On leaving the heat exchanger the

now warmer weak solution enters the generator,

is heated to boiling and the refrigerant is boiled

out, becoming a strong solution again. This strong

solution leaves the generator and passes thru the

shell side of the heat exchanger losing some heat

to the weak solution passing thru the tube side.

Usage of the heat exchanger reduces total heat

quantity required.

The strong solution returns to the absorber

sprays and is then sprayed over the absorber tube

bundle where absorption of refrigerant com

mences again.

NOTE: Solution flow from generator to ab

sorber is the result of gravity and pressure

difference and not by a pump.

Refrigerant boiled out of solution in the gen

erator condenses on the condenser water coils and

returns to the evaporator via the vapor condensate

line. Refrigerant flows into the evaporator sump,

where it is pumped to sprays over the evaporator

coils and the cycle is repeated.

Capacity Control - A steam control valve is used

to control capacity. This valve operates by a con

troller which senses the temperature of the leav

ing chilled water. When the temperature is at or

above the design point, the machine will beat full

load. At this condition the steam control valve is

wide open to reconcentrate the solution in the gen

erator. As the chilled water temperature drops be

low the design point, the steam will be throttled. At

no load conditions the steam valve will be closed.

Manufacturer reserves the right to change any product specifications without notice

Tab 15 16JA-1SO New 1-68 Code MA Catalog No. 531-642

Loading...

Loading...