Page 1

Hermetic Absorption Liquid Chillers/Heaters

Start-Up, Operation, and

Maintenance Instructions

SAFETY CONSIDERATIONS

Absorption liquid chillers/heaters provide safe and reliable service

when operated within design specifications. When operating this

equipment, use good judgment and safety precautions to avoid

damage to equipment and property or injury to personnel.

Be sure you understand and follow the procedures and safety precautions contained in the machine instructions as well as those

listed in this guide.

DO NOT USE OXYGEN or air to purge lines, leak test, or pressurize

a machine. Use nitrogen.

NEVER EXCEED specifie d test pressures. For the 16DF machine,

the maximum pressure is 12 psig (83 kPa). For the chilled/hot water

and condensing water piping, the maximum pressure is stamped on

the machine.

WEAR goggles and suitable protective clothing when handling lithium bromide, octyl alcohol, inhibitor, lithium hydroxide, and hydrobromic acid. IMMEDIATELY wash any spills from the skin with

soap and water. IMMEDIATELY FLUSH EYES with water and consult a physician.

DO NOT USE eyebolts or eyebolt holes to rig machine sections or the

entire assembl y.

DO NOT work on high-voltage equipment unless you are a qualified

electrician.

DO NOT WORK ON electrical components, including control panels or switches, until you are sure ALL POWER IS OFF and no residual voltage can leak from capacitors or solid-state components.

LOCK OPEN AND TAG electrical circuits during servicing. IF

WORK IS INTERRUPTED, confirm that all circuits are deenergized

before resuming work.

NEVER DISCONNECT safety devices or bypass electric interlocks

and operate the machine. Also, never operate the machine when any

safety devices are not adjusted and functioning normally .

DO NOT REPEAT unsuccessful ignition attempts or restart after

flame failure without assurance that post-purge and prepurge have

eliminated combustible gas or all vapors from the combustion chamber. DO NOT EVER ATTEMPT IGNITION of a burner if there is

shutdown leakage of gas or oil through the fuel shutoff valves or from

the fuel lines.

DO NOT syphon lithium bromide or any other chemical by mouth.

BE SURE all hydrogen has been exhausted before cutting into purge

chambers. Hydrogen mixed with air can explode when ignited.

WHEN FLAMECUTTING OR WELDING on an absorption machine, some noxious fumes may be produced. Ventilate the area thoroughly to avoid breathing concentrated fumes.

DO NOT perform any welding or flamecutting to a machine while it

is under a vacuum or pressurized condition.

NEVER APPLY an open flame or live steam to a refrigerant cylinder. Dangerous overpressure can result. When necessary to heat a

cylinder, use only warm (1 10 F [43 C]) water.

DO NOT REUSE disposable (nonreturnable) cylinders or attempt to

refill them. It is DANG EROUS AND ILLEGAL. When c ylinder is

emptied, bleed off remaining gas pressure, loosen the collar and

unscrew and discard the valve stem. DO NOT INCINERATE.

DO NOT ATTEMPT TO REMOVE fittings, covers, etc., while machine is under pressure or while machine is running, and DO NOT

16DF013-050

OPERATE or pressurize a machine without all cover plates or bolts in

place.

→

CONNECT THE ABSORPTION CHILLER to a n em ergency power

source to ensure that a constant power supply is maintained to the unit

in the event that the main electrical power source is interrupted or

temporarily lost. Failure to provide an emergency power source to the

chiller could result in crystallization of the lithium bromide solution

inside the machine, rendering it temporarily inoperative. A potentially

lengthy decrystallization process might be required to return the

chiller to normal operation depending on the severity of the crystallization and/or the length of time the machine was without power.

→

PROVIDE AN EMERGENCY POWER SOURCE to the chilled

water and condenser water pumps to prevent the possibility of an

evaporator freeze-up. Failure to provide emergency power to these

pumps could result in machine operation with no flow of water

through the tubeside of the evaporator, absorber and condenser sections thereby allowing the water inside the evaporator tubes to freeze.

Further, a frozen evaporator tube can burst causing contamination of

the lithium bromide solution and the inside of the chiller. A freeze-up

in the evaporator will also result in a long period of chiller down time

due to the extensive repairs required to bring the chiller and the lithium bromide solution back to its original condition.

DO NOT climb over a machine. Use platform, catwalk, or staging.

Follow safe practices when using ladders.

DO NOT STEP ON machine piping. It might break or bend and cause

personal injury.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to lift or

move inspection covers or other heavy components. Even if components are light, use such equipment when there is a risk of slipping

or losing your balance.

VALVE OFF AND TAG steam, water, or brine lines before opening

them.

DO NOT LOOSEN water box cover bolts until the water box has

been completely drained.

DO NOT VENT OR DRAIN water boxes containing industrial

brines, liquid, gases, or semisolids without permission of your process

control group.

BE AWARE that certain automatic start arrangements can engage

starters. Open the disconnect s a head of th e st ar ters i n addition to shutting off the machine or pum p.

INVESTIGATE THE CAUSE of flame failure or any other safety

shutdown before attempting a restart.

KEEP EYES sufficiently away from sight tubes or burner openings,

and wear a protective shield or safety glasses when viewing a burner

flame.

USE only replacement parts that meet the code requirements of the

original equipment.

DO NOT ALLOW UNAUTHORIZED PERSONS to tamper with

burner equipment or machine safeties, or to make major repairs.

PERIODICALLY INSPECT all valves, fittings, piping, and relief

devices for corrosion, rust, leaks, or damage.

PROVIDE A DRAIN connection in the vent line near each pressure

relief device to prevent a build-up of condensate or rain water.

IMMEDIATELY wipe or flush the floor if lithium bromide or octyl

alcohol is spilled on it.

BE SURE combustion air inlets to the equipment room are open and

clear of any blockage.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Ta b 5 b

PC 211 Catalog No. 531-603 Printed in U.S.A. Form 16DF-1SS Pg 1 801 5-92 Replaces: New

Page 2

CONTENTS

Page

INTRODUCTION ..............................3

MACHINE DESCRIPTION ...................3-13

Basic Absorption Cooling Cycle ..............3

Double Effect Reconcentration ................3

Basic Heating Cycle ..........................3

Machine Construction ........................3

Cooling Cycle Flow Circuits ..................6

Heating Cycle Flow Circuits ..................6

Solution Cycle and Equilibrium Diagram ......9

• PLOTTING THE COOLING SOLUTION CYCLE

• PLOTTING THE HEATING SOLUTION CYCLE

Purge ......................................13

Operation Status Indicators ..................13

Burner .....................................13

MACHINE CONTROLS .....................14-32

General .....................................14

Start-Stop System ...........................14

• SEMIAUTOMATIC START-STOP

• FULL AUTOMATIC START-STOP

Machine Control Panel ......................14

Status Indicator Sticker .....................15

Adjustment Switches ........................15

• TOGGLE SWITCHES

• SET POINT AND DIP SWITCHES

Indicator LEDs ..............................16

Remaining Time Indication for

Dilution Cycle .............................19

Control Wiring ..............................19

Typical Control Sequence —

Normal Cooling Start ......................25

Typical Control Sequence —

Normal Heating Start ......................25

Typical Control Sequence —

Normal Cooling Stop ......................28

Typical Control Sequence —

Normal Heating Stop ......................28

Abnormal Shutdown ........................29

Operating Limit Controls ....................30

• HIGH-TEMPERATURE GENERATOR,

HIGH SOLUTION LEVEL

• HIGH-TEMPERATURE GENERATOR,

HIGH LEAVING SOLUTION TEMPERATURE

• HIGH-TEMPERATURE GENERATOR,

HIGH-SATURATION (VAPOR) TEMPERATURE

• CONCENTRATION CONTROL VALVE

• COOLING TOWER CONTROL

Automatic Capacity Control .................31

• TEMPERATURE CONTROL SETTINGS

• CHILLED/HOT WATER TEMPERATURE

DISPLAY

Burner Control ..............................32

• COMBUSTION CONTROL

• FIRING RATE CONTROL

BEFORE INITIAL START-UP ................32-36

Job Data and Tools Required ................32

Inspect Field Piping .........................33

Inspect Field Wiring .........................33

Inspect Machine Controls ...................34

• PREPARATION

• CHECK COOLING CYCLE START

• CHECK HERMETIC PUMP STARTERS

AND SHUTDOWN CYCLE

• CHECK HERMETIC PUMP MOTOR OVERLOADS

• CHECK BURNER INTERLOCKS

• CHECK LOW CHILLED WATER

TEMPERATURE CUTOUT

• CHECK HEATING CYCLE START AND STOP

• CHECK WATER FLOW SWITCHES

Page

• CHECK HIGH-STAGE GENERATOR

LOW SOLUTION LEVEL SWITCH

• CHECK HIGH COMBUSTION TEMPERATURE

SWITCHES

• CHECK HIGH-STAGE GENERATOR

TEMPERATURE SWITCH

• CHECK HIGH-STAGE GENERATOR

PRESSURE SWITCH

• RESTORATION

Burner System ..............................36

• GENERAL

• GAS FIRING

• OIL FIRING

Standing Vacuum Test ......................36

• LONG INTERVAL TEST

• SHORT INTERVAL TEST

Machine Evacuation .........................36

INITIAL START-UP .........................37-40

Job Data and Tools Required ................37

Noncondensable Evacuation .................37

Solution and Refrigerant Charging ...........37

• HANDLING LITHIUM BROMIDE SOLUTION

• CHARGING SOLUTION

• INITIAL REFRIGERANT CHARGING

Operational Controls Check and

Adjustment ...............................39

• PREPARATION

• WATER PUMP STARTERS

AND OVERLOADS

• HERMETIC PUMP ROTATION

Initial Combustion ..........................39

Add Octyl Alcohol ...........................40

Initial Start Operation .......................40

Capacity Control Adjustments ...............40

Refrigerant Charge Final Adjustment .........40

Check Machine Shutdown ...................40

OPERATING INSTRUCTIONS ...............40-45

Operator Duties .............................40

Before Starting Machine .....................43

Cooling/Heating Operation

Changeover ..............................43

• CHANGING FROM COOLING CYCLE

TO HEATING CYCLE

• CHANGING FROM HEATING CYCLE

TO COOLING CYCLE

Start Machine ...............................43

Heating Start-Up or Cooling Start-Up

After Limited Shutdown ...................43

Cooling Start-Up After

Extended Shutdown (More than 21 Days) ...43

Start-Up After Below-Freezing

Conditions ................................43

Operation Check ............................43

Normal Shutdown Procedure ................44

Shutdown Below Freezing Conditions ........45

Actions After Abnormal Shutdown ...........45

Actions After Power Interruption .............45

PERIODIC SCHEDULED MAINTENANCE ......46

Every Day of Operation ......................46

Every Month of Operation ...................46

Every 2 Months of Operation ................46

Every 6 Months of Operation or

Cooling/Heating Changeover ..............46

Every Year (At Changeover of Cooling/

Heating Cycle or Shutdown) ...............46

Every 2 Years ...............................46

Every 5 Years or 20,000 Hours

(Whichever is Shorter) ....................46

2

Page 3

CONTENTS (cont)

Page

MAINTENANCE PROCEDURES .............46-53

Log Sheets .................................46

Absorber Loss Determination ................46

Machine Leak Test ..........................46

Machine Evacuation .........................48

Purge Exhaust Procedure ...................48

Solution or Refrigerant Sampling ............48

• SOLUTION SAMPLE

• REFRIGERANT SAMPLE

Solution Analysis ...........................49

Inhibitor ....................................49

Adding Octyl Alcohol ........................49

Removing Lithium Bromide from Refrigerant .49

Refrigerant Charge Adjustment ..............49

Page

Capacity Control Adjustment ................49

Operating and Limit Controls ................49

Burner Checks and Adjustments .............50

Service Valve Diaphragm Replacement .......50

Hermetic Pump Inspection ...................50

• DISASSEMBLY

• INSPECTION

• REASSEMBLY

• COMPLETION

Condensing Water Tube Scale ...............53

Water Treatment ............................53

Solution Decrystallization ...................53

Internal Service .............................53

TROUBLESHOOTING GUIDE ...............54-56

INTRODUCTION

Everyone involved in the start-up, operation, and maintenance of the 16DF machine should be thoroughly familiar

with these instructions, the separate burner instructions, and

other necessary job data before initial start-up, and before

operating the machine or performing machine maintenance.

Procedures are arranged in the sequence required for proper

machine start-up and operation.

NOTE: In this manual, temperatures are shown in °C first,

with °F given in parentheses ( ), when a temperature display is in °C or a control set point scale is in °C values.

MACHINE DESCRIPTION

Basic Absorption Cooling Cycle —

sorption chiller uses water as the refrigerant in vessels maintained under a deep vacuum. The chiller operates on the simple

principle that under low absolute pressure (vacuum), water

takes up heat and vaporizes (boils) at a low temperature. For

example, at the very deep vacuum of 0.25 in. (6.4 mm) of

mercury absolute pressure, water boils at the relatively cool

temperature of only 40 F (4 C). To obtain the energy required for this boiling, it takes heat from, and therefore chills,

another fluid (usually water). The chilled fluid then can be

used for cooling purposes.

To make the cooling process continuous, the refrigerant

vapor must be removed as it is produced. For this, a solution

of lithium bromide salt in water is used to absorb the water

vapor. Lithium bromide has a high affinity for water, and

will absorb it in large quantities under the right conditions.

The removal of the refrigerant vapor by absorption keeps

the machine pressure low enough for the cooling vaporization to continue. However, this process dilutes the solution

and reduces its absorption capacity. Therefore, the diluted

lithium bromide solution is pumped to separate vessels where

it is heated to release (boil off) the previously absorbed water. Relatively cool condensing water from a cooling tower

or other source removes enough heat from this vapor to condense it again into liquid for reuse in the cooling cycle. The

reconcentrated lithium bromide solution is returned to the

original vessel to continue the absorption process.

The 16DF ab-

Double Effect Reconcentration — With this chiller,

reconcentration of the solution is done in 2 stages to improve the operating efficiency. Approximately half of the

diluted solution is pumped to a high-temperature vessel (high

stage) where it is heated for reconcentration directly from

the combustion of gas or light oil. The rest of the solution is

pumped to a low-temperature vessel (low stage) where it is

heated by the hotwatervaporgeneratedinthehigh-temperature

vessel. The low stage acts as the condenser for the high stage,

so the heat energy first applied in the high-stage vessel is

used again in the low-stage vessel. This cuts the heat input

to almost half of that required for an absorption chiller with

a single-stage reconcentrator.

Basic Heating Cycle — The heating cycle uses a dif-

ferent vapor flow path than that used for cooling, and does

not use the absorption process. The high-temperature water

vapor produced in the direct fired high-stage vessel is passed

directly to the heating tubes where it condenses and transfers its heat into the circulating hot water. The condensed

water then flows by gravity to mix with the concentrated solution which had returned from the high-stage vessel. This

diluted solution then is pumped back to the high-stage vessel to repeat the vapor generation for the heating function.

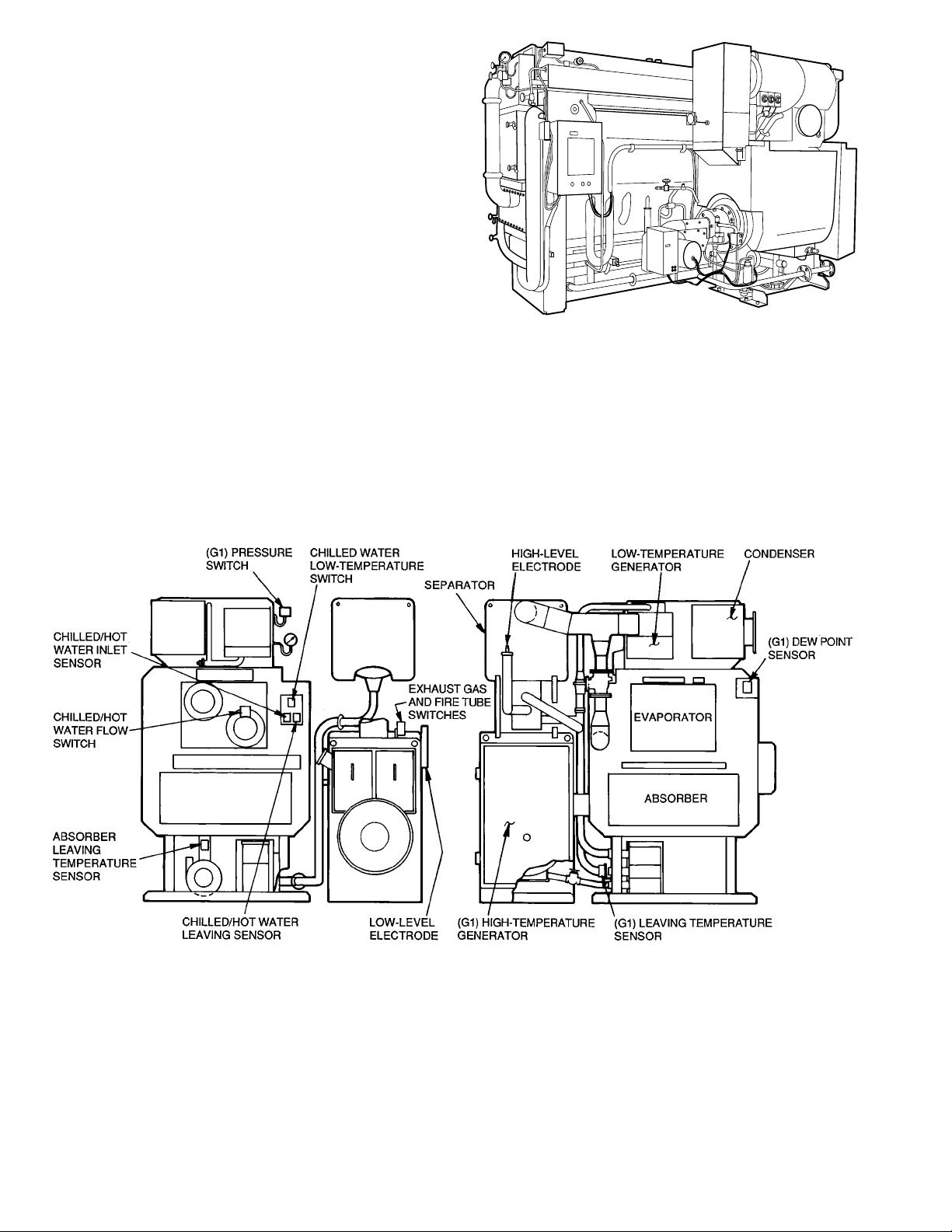

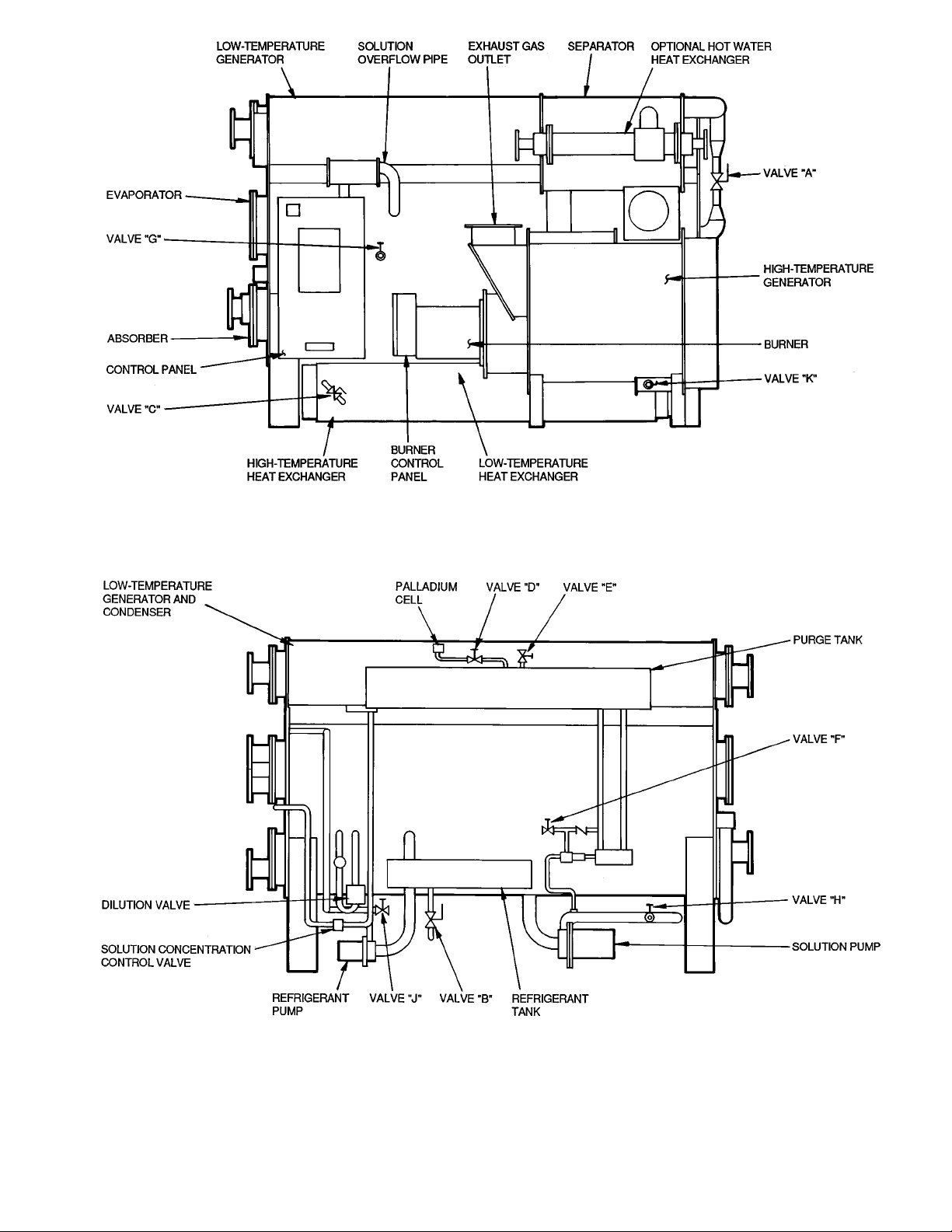

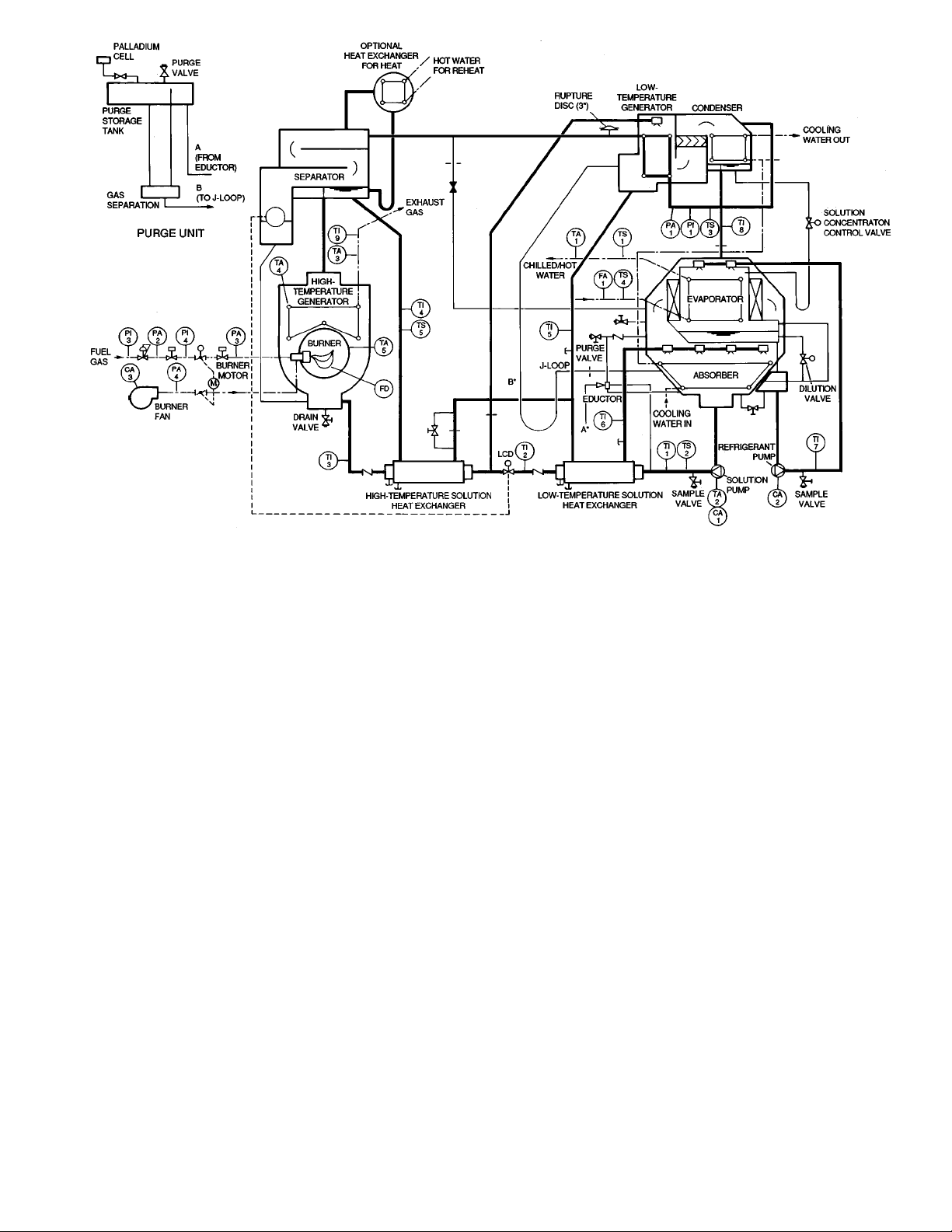

Machine Construction — The major sections of

the machine are contained in several vessels (Fig. 1- 4,

Table 1).

The large lower shell contains the evaporator section in

its upper part and the absorber section at the bottom. In the

evaporator,therefrigerantwatervaporizesinthe cooling cycle

and cools the chilled water for the air conditioning or cooling process. In the heating cycle, hot water vapor flows into

the evaporator section where it condenses and heats the hot

water for the heating process. The heat transfer tube bundle

in the evaporator is used for both cooling and heating. In the

absorber, vaporized refrigerant water is absorbed by lithium

bromide solution in the cooling cycle. In the heating cycle,

condensed refrigerant water from the evaporator drains into

the absorber where it is mixed with the strong solution.

The short vessel with the burner, located next to the

evaporator/absorber assembly,is the high-stage generator.The

vessel above it is the separator. In both the cooling and heating cycles, approximately half of the diluted lithium bromide solution is heated directly from the combustion of gas

or oil. The water vapor created in this process is released

from the reconcentrated solution in the separator vessel.

3

Page 4

The smaller shell above the evaporator/absorber assembly contains the low-stage generator and condenser. In the

cooling cycle, about half of the diluted lithium bromide

solution is heated and reconcentrated in the low-stage

generator by high-temperature vapor from the high-stage generator. The water vapor released from the solution in this

process is condensed to liquid in the condenser section. This

vessel is not used in the heating cycle, although about half

of the diluted solution does flow through the generator.

This chiller also has: 2 solution heat exchangers to improve operating economy; an external purge system to maintain machine vacuum by the continuous removal of noncondensables; 2 hermetic pumps to circulate the solution and

refrigerant; various operation, capacity, and safety devices

to provide automatic, reliable machine performance; and the

ability to manually switch between cooling and heating

operation.

Fig. 1 — 16DF Machine, Front View

Fig. 2 — Machine Controls and Components, Schematic

4

Page 5

Fig.3—Valve and Component Locations, Front View

Fig.4—Valve and Component Locations, Rear View

5

Page 6

Table1—Valve Descriptions

VALV E US E

A Heating/Cooling Vapor

B Heating/Cooling Liquid

C Heat Exchanger Service

D Palladium Cell Isolation

E Purge Storage Tank Evacuation

F Auxiliary Evacuation

G Vacuum/Pressure Gage

H Solution Pump Service

J Refrigerant Pump Service

K High-Stage Generator Service

Cooling Cycle Flow Circuits — Figure 5 illustrates

the basic flow circuits of the 16DF absorption chiller during

the cooling cycle.

The liquid to be chilled is passed through the evaporator

tube bundle and is cooled by the evaporation of refrigerant

water sprayed over the outer surface of the tubes by the recirculating refrigerant pump. The refrigerant vapors are drawn

into the absorber section and are absorbed by the lithium

bromide-water solution sprayed over the absorber tubes. The

heat picked up from the chilled liquid is transferred from the

absorbed vapor to cooling water flowing through the absorber tubes.

The solution in the absorber becomes diluted as it absorbs

water, and loses its ability to continue the absorption. It is

then transferred by the solution pump to the generator sections to be reconcentrated. Approximately half of the weak

(diluted) solution goes to the high-stage generator where it

is heated directly by the combustion of gas or oil to boil out

the absorbed water. The mixture of reconcentrated solution

and vapor rises to the separator, where the vapor is released

and is then passed to the low-stage generator tubes. In the

low-stage generator, the rest of the weak solution is heated

by the high-temperature vapor from the high-stage separator, to boil out the remaining absorbed water.

The resulting water vapor from the low-stage generator

solution passes into the condenser section and condenses on

tubes containing cooling water.This is the same cooling water which had just flowed through the absorber tubes. The

condensed high-temperature water from the low-stage generator tubes is also passed over the condenser tubes where it

is cooled to the condenser temperature. The combined condensed refrigerant liquid, from the 2 generators, now flows

back to the evaporator to begin a new refrigerant cycle.

The strong (reconcentrated) solution flows from the 2 generators back to the absorber spray headers to begin a new

solution cycle. On the way, it passes through solution heat

exchangers where heat is transferred from the hot, strong solution to the cooler, weak solution being pumped to the generators. Solution to and from the high-stage generator passes

through both a high-temperature heat exchanger and a lowtemperature heat exchanger. Solution to and from the lowstage generator passes through only the low-temperature heat

exchanger,mixedwiththe high-stage generator solution. This

heat transfer improves solution cycle efficiency by preheating the relatively cool, weak solution before it enters the generators, and precooling the hotter, strong solution before it

enters the absorber.

During high-load cooling operation, some abnormal conditions can cause the lithium bromide concentration to increase above normal. When this happens, a small amount of

refrigerant is transferred by an evaporator overflow pipe into

the absorber solution to limit the concentration. This is necessary to keep the strong solution concentration away from

crystallization (see Solution Cycle and Equilibrium Diagram section, page 9).

The evaporator refrigerant level is directly related to machine solution concentration. As the concentration increases

(has less water), so does the refrigerant level. As the solution

concentration increases beyond a safe limit, the refrigerant

level rises to the level of the overflow pipe and some spills

over to flow into the absorber. The concentration at which

the refrigerant overflows is determined by the amount of refrigerant (water) which is charged into the machine.

If, for some reason, the machine controls and evaporator

overflow do not prevent strong solution crystallization during abnormal operating conditions, and flow blockage occurs, the strong solution overflow pipe will reverse or limit

the crystallization until the cause can be corrected. The overflow pipe is located between the low-temperature generator discharge box and the absorber, bypassing the heat

exchangers.

If crystallization occurs, it generally takes place in the shell

side of the low-temperature heat exchanger, blocking the flow

of strong solution from the generators. The strong solution

then backs up in the discharge box and spills over into the

overflow pipe, which returns it directly to the absorber sump.

The solution pump then returns this hot solution through the

heat exchanger tubes, automatically heating and decrystallizing the shell side.

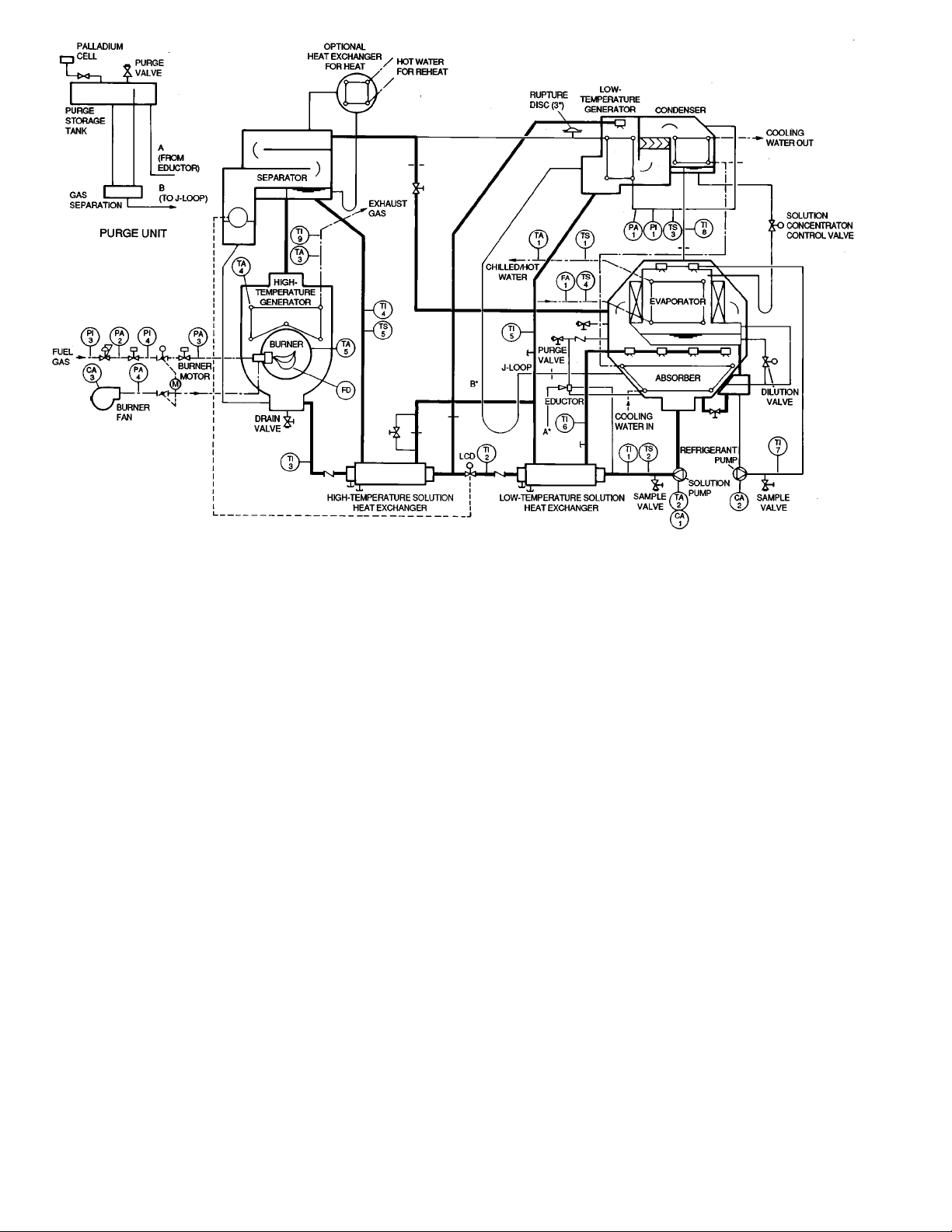

Heating Cycle Flow Circuits — Figure 6 illustrates

the basic flow circuits of the 16DF absorption chiller during

the heating cycle.

The liquid to be heated is passed through the evaporator

tube bundle and is heated by condensation of hot water vapor from the high-stage generator. The solution flowing from

the absorber, through the heat exchangers to the generators

via the solution pump, and then back through the heat exchangers to the absorber sprays is basically the same as in

the cooling cycle. However, the solution is heated and reconcentrated only in the high-stage generator. The heating

refrigerant water cycle is quite different from that of the cooling cycle. The cooling water flow is turned off, as is the refrigerant recirculating pump.Thehigh-temperaturewatervapor

from the high-stage generator is diverted to the evaporator,

and the condensed vapor in the evaporator is drained directly to the absorber solution.

6

Page 7

A,B — Connecting Piping from Purge

CA1 — Solution Pump Motor Overload

CA2 — Refrigerant Pump Motor Overload

CA3 — Burner Blower Motor Overload

FA1 — Chilled/Hot Water Flow Switch

FD — Burner Flame Detector

LCD — Level Control Device

M—Burner Firing Rate Positioning

PA1 — High-Temperature Generator High-

PA2 — Low Gas Pressure Switch

PA3 — High Gas Pressure Switch

PA4 — Low Combustion Air Pressure

*See Purge Unit insert.

NOTE: Service valve connections are

Unit Diagram to Machine Cycle

Diagram

Motor

Pressure Switch

Switch

1

⁄2-in. NPT.

LEGEND

PI1 — High-Temperature Generator

Pressure Gage

PI3 — Supply Gas Pressure Gage

PI4 — Regulated Gas Pressure Gage

TA1 — Chilled/Hot WaterTemperature Limit

TA2 — Solution Pump Motor High-

Temperature Limit

TA3 — Exhaust Gas High-Temperature

Limit

TA4 — Fire Tube High-Temperature Limit

TA5 — Return End Refractory

High-Temperature Limit

TI1-3 — Weak Solution Temperature

Measurement Wells

TI4-6 — Strong Solution Temperature

Measurement Wells

Fig. 5 — Cooling Cycle with Data Points

TI7 — Refrigerant Temperature

Measurement Well

TI8 — Refrigerant Condensate Tempera-

ture Measurement Well

TI9 — Exhaust Gas Temperature

Measurement Gage

TS1 — Leaving Chilled/Hot Water

Temperature Sensor

TS2 — Weak Solution Temperature

Sensor

TS3 — High-Temperature Generator

Vapor Temperature Sensor

TS4 — Entering Chilled/Hot Water

Temperature Sensor

TS5 — High-Temperature Generator

Strong Solution Temperature

Sensor

7

Page 8

A,B — Connecting Piping from Purge

CA1 — Solution Pump Motor Overload

CA2 — Refrigerant Pump Motor Overload

CA3 — Burner Blower Motor Overload

FA1 — Chilled/Hot Water Flow Switch

FD — Burner Flame Detector

LCD — Level Control Device

M—Burner Firing Rate Positioning

PA1 — High-Temperature Generator High-

PA2 — Low Gas Pressure Switch

PA3 — High Gas Pressure Switch

PA4 — Low Combustion Air Pressure

*See Purge Unit insert.

NOTE: Service valve connections are

Unit Diagram to Machine Cycle

Diagram

Motor

Pressure Switch

Switch

1

⁄2-in. NPT.

LEGEND

PI1 — High-Temperature Generator

Pressure Gage

PI3 — Supply Gas Pressure Gage

PI4 — Regulated Gas Pressure Gage

TA1 — Chilled/Hot WaterTemperature Limit

TA2 — Solution Pump Motor High-

Temperature Limit

TA3 — Exhaust Gas High-Temperature

Limit

TA4 — Fire Tube High-Temperature Limit

TA5 — Return End Refractory

High-Temperature Limit

TI1-3 — Weak Solution Temperature

Measurement Wells

TI4-6 — Strong Solution Temperature

Measurement Wells

Fig. 6 — Heating Cycle with Data Points

TI7 — Refrigerant Temperature

Measurement Well

TI8 — Refrigerant Condensate Tempera-

ture Measurement Well

TI9 — Exhaust Gas Temperature

Measurement Gage

TS1 — Leaving Chilled/Hot Water

Temperature Sensor

TS2 — Weak Solution Temperature

Sensor

TS3 — High-Temperature Generator

Vapor Temperature Sensor

TS4 — Entering Chilled/Hot Water

Temperature Sensor

TS5 — High-Temperature Generator

Strong Solution Temperature

Sensor

8

Page 9

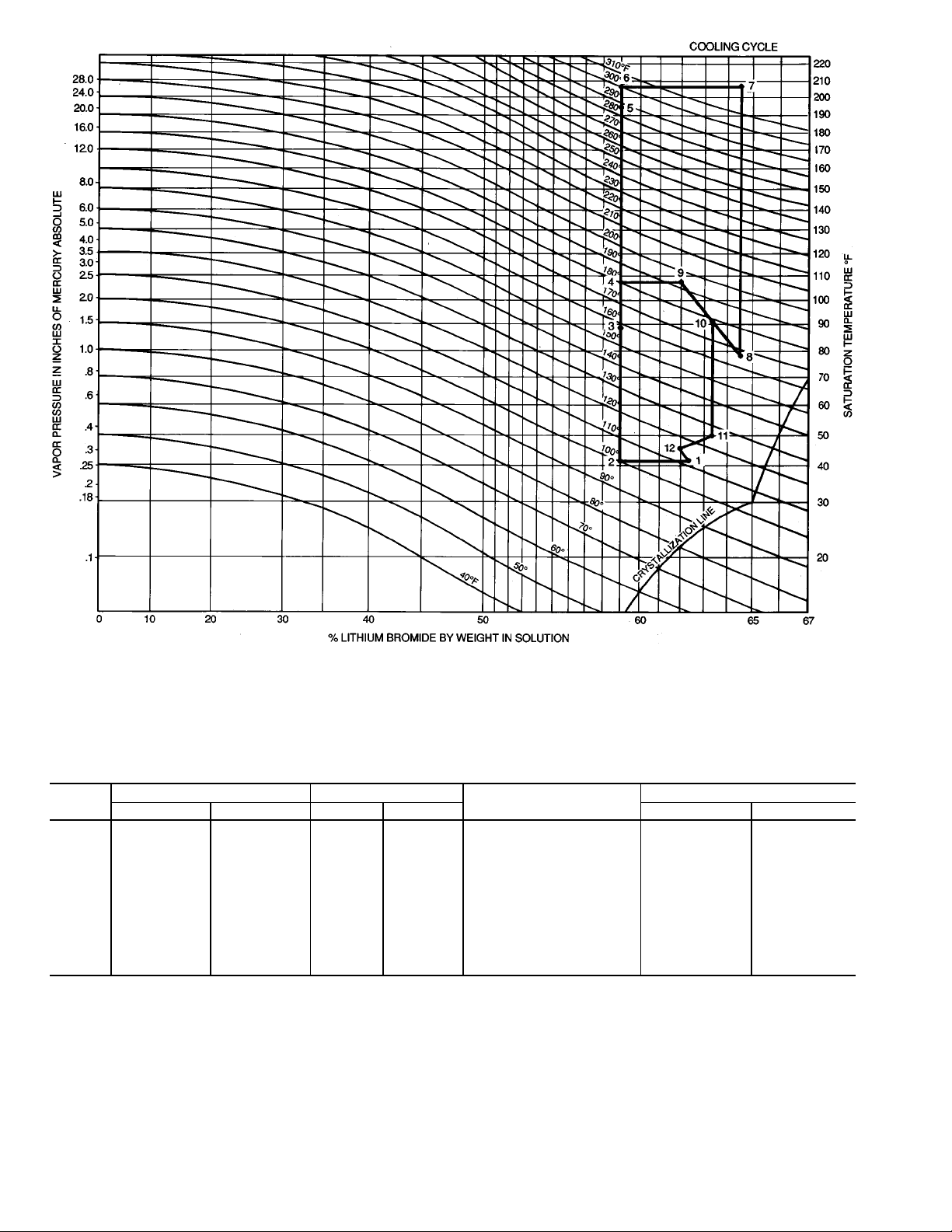

Solution Cycle and Equilibrium Diagram — The

solution cycles for cooling and heating operation can be illustrated by plotting them on a basic equilibrium diagram

for lithium bromide in solution with water (Fig. 7 and 8).

The diagram is also used for performance analyses and

troubleshooting.

The left scale on the diagram indicates solution and water

vapor pressures at equilibrium conditions. The right scale

indicates the corresponding saturation (boiling or condensing) temperatures of the refrigerant (water).

The bottom scale represents solution concentration, expressed as percentage of lithium bromide by weight in solution with water. For example, a lithium bromide concentration of 60% means 60% lithium bromide and 40% water

by weight.

The curved lines running diagonally left to right are solution temperature lines (not to be confused with the horizontal saturation temperature lines). The single curved line

beginning at the lower right represents the crystallization line.

The solution becomes saturated at any combination of temperature and concentration to the right of this line, and it

will begin to crystallize (solidify) and restrict flow.

The slightly sloped lines extending from the bottom of the

diagram are solution-specific gravity lines. The concentration of a lithium bromide solution sample can be determined

by measuring its specific gravity with a hydrometer and reading its solution temperature. Then, plot the intersection point

for these 2 values and read straight down to the percent lithium

bromide scale. The corresponding vapor pressure can also

be determined by reading the scale straight to the left of the

point, and its saturation temperature can be read on the scale

to the right.

PLOTTING THE COOLING SOLUTION CYCLE — An

absorption solution cycle at typical full load conditions is

plotted in Fig. 7 from Points 1 through 12. The corresponding values for these typical points are listed in Table 2. Note

that these values will vary with different loads and operating

conditions.

Point 1 represents the strong solution in the absorber, as it

begins to absorb water vapor after being sprayed from the

absorber nozzles. This condition is internal and cannot be

measured.

Point 2 represents the diluted (weak) solution after it leaves

the absorber and before it enters the low-temperature heat

exchanger.Thisincludes its flow through the solution pump.

This point can be measured with a solution sample from the

pump discharge.

Point 3 represents the weak solution leaving the lowtemperature heat exchanger. It is at the same concentration

as Point 2 but at a higher temperature after gaining heat from

the strong solution. This temperature can be measured. At

this point, the weak solution is split, with approximately half

of it going to the low-stage generator,and the rest of it going

on to the high-temperature heat exchanger.

Point 4 represents the weak solution in the low-stage generator after being preheated to the boiling temperature. The

solution will boil at temperatures and concentrations corresponding to a saturation temperature established by the vapor condensing temperature in the condenser. This condition

is internal and cannot be measured.

Point 5 represents the weak solution leaving the hightemperature heat exchanger and entering the high-stage generator. It is at the same concentration as Points 2 and 3, but

at a higher temperature after gaining heat from the strong

solution. This temperature can be measured.

Point 6 represents the weak solution in the high-stage generator after being preheated to the boiling temperature. The

solution will boil at temperatures and concentrations corresponding to a saturation temperature established by the vapor condensing temperature in the low-stage generator tubes.

This condition is internal and cannot be measured.

Point 7 represents the strong solution leaving the high-stage

generator and entering the high-temperature heat exchanger

after being reconcentrated by boiling out refrigerant. It can

be plotted approximately by measuring the temperatures of

the leaving strong solution and the condensed vapor leaving

the low-stage generator tubes (saturation temperature). This

condition cannot be measured accurately.

Point 8 represents the strong solution from thehigh-temperature

heat exchanger as it flows between the 2 heat exchangers. It

is the same concentration as Point 7, but at a cooler temperature after giving up heat to the weak solution. It is an

internal condition and cannot be measured.

Point 9 represents the strong solution leaving the low-stage

generator and entering the low-temperature heat exchanger.

It is at a weaker concentration than the solution from the

high-stage generator, and can be plotted approximately by

measuring the temperatures of the leaving strong solution

and vapor condensate (saturation temperature). This condition cannot be measured accurately.

Point 10 represents the mixture of strong solution from the

high-temperature heat exchanger and strong solution from

the low-stage generator after they both enter the lowtemperature heat exchanger. It is an internal condition and

cannot be measured.

Point 11 represents the combined strong solution before it

leaves the low-temperature heat exchanger after giving up

heat to the weak solution. This condition is internal and cannot be measured.

Point 12 represents the strong solution leaving the lowtemperature heat exchanger and entering the absorber spray

nozzles, after being mixed with some weak solution in the

heat exchanger. The temperature can be measured but the

concentration cannot be sampled. After leaving the spray

nozzles, the solution is somewhat cooled and concentrated

as it flashes to the lower pressure of the absorber.

9

Page 10

Fig. 7 — Equilibrium Diagram, Cooling Cycle

Table2—Typical Full Load Cooling Cycle Equilibrium Data

POINT

1 111 44 0.26 6.6 62.2 41 5

2 100 38 0.26 6.6 59.0 41 5

3 158 70 1.20 30.0 59.0 84 29

4 181 83 2.20 56.0 59.0 104 40

5 289 143 23.00 584.0 59.0 198 92

6 300 149 27.00 686.0 59.0 208 98

7 332 167 27.00 686.0 64.5 208 98

8 167 75 0.80 20.3 64.5 72 22

9 194 90 2.20 56.0 62.0 104 40

10 178 81 1.30 33.0 63.4 86 30

11 126 52 0.39 9.9 63.4 51 11

12 117 47 0.30 7.6 62.0 45 7

SOLUTION TEMPERATURE VAPOR PRESSURE

°F °C in. Hg mm Hg °F °C

SOLUTION PERCENTAGE

LITHIUM BROMIDE

SATURATION TEMPERATURE

10

Page 11

PLOTTING THE HEATING SOLUTION CYCLE —Aheating solution cycle at typical full load conditions is plotted in

Fig. 8 from Points 1 through 11. The corresponding values

for these typical points are listed in Table3.Theheating cycle

operates with lower (more dilute) solution concentrations than

used with the cooling cycle because most of the refrigerant

water is drained from the evaporator into the solution. Note

that these values will vary with different loads and operating

conditions.

Point 1 represents the strong solution in the absorber after

being sprayed from the absorber nozzles, before it begins to

mix with condensed water vapor draining from the evaporator. The temperature of the solution to the spray nozzles

can be measured, but the concentration cannot be sampled.

Point 2 represents the diluted (weak) solution, with the condensed water, leaving the absorber and entering the lowtemperature heat exchanger.Thispoint can be measured with

a solution sample from the pump discharge.

Point 3 represents the weak solution as it leaves the lowtemperature heat exchanger. It is at the same concentration

as Point 2 but at a slightly warmer temperature after gaining

some heat from the strong solution. This temperature can be

measured. At this point, the weak solution is split, with approximately half of it going to the low-stage generator, and

the rest of it going to the high-temperature heat exchanger.

Although the solution sent to the low-stage generator is not

used in the heating function, the solution distribution and

flow rates are maintained approximately the same as in the

cooling cycle to minimize piping and control differences.

Point 4 represents the weak solution as it leaves the hightemperature heat exchanger and enters the high-stage generator. It is at the same concentration as Points 2 and 3, but

at a higher temperature after gaining heat from the strong

solution. This temperature can be measured.

Point 5 represents the weak solution in the high-stage generator after being preheated to the boiling temperature. The

solution will boil at temperatures and concentrations corresponding to a saturated temperature established by the vapor

condensing temperature in the evaporator. This condition is

internal and cannot be measured.

Point 6 represents the strong solution leaving the high-stage

generator and entering the high-temperature heat exchanger

after being reconcentrated by boiling out refrigerant water.

The heat energy in the vapor produced in this process is used

directly for heating the circulating hot water in the evaporator. The leaving strong solution temperature can be measured but the saturation temperature cannot be measured accurately to plot the point.

Point 7 represents the strong solution from thehigh-temperature

heat exchanger as it flows between the two heat exchangers.

It is the same concentration as Point 6, but at a cooler temperature after giving up heat to the weak solution. It is an

internal condition and cannot be measured.

Point 8 represents the weak solution leaving the low-stage

generator and entering the low-temperature heat exchanger.

It is at a slightly higher concentration than the entering solution because it has picked up some heat from the hot vapor

in the generator tubes, as an incidental occurrence in the flow

process.

Point 9 represents the mixture of strong solution from the

high-temperature heat exchanger and the weak solution from

the low-stage generator after they both enter the lowtemperature heat exchanger. It is an internal condition and

cannot be measured.

Point 10 represents the combined strong solution before it

leaves the low-temperature heat exchanger, after giving up

heat to the weak solution. This is an internal condition and

cannot be measured.

Point 11 represents the strong solution leaving the lowtemperature heat exchanger and entering the absorber spray

nozzles, after being mixed with some weak solution in the

heat exchanger. The temperature can be measured, but the

concentration cannot be sampled. After leaving the spray

nozzles, the solution is somewhat cooled and concentrated

as it flashes to the lower pressure of the absorber.

11

Page 12

Fig. 8 — Equilibrium Diagram, Heating Cycle

Table3—Typical Full Load Heating Cycle Equilibrium Data

POINT

1 188 87 4.1 104 54.4 127 53

2 188 87 6.4 163 50.5 142 61

3 199 93 8.0 203 50.5 152 67

4 248 120 21.0 533 50.5 199 93

5 255 124 24.0 610 50.5 207 97

6 307 153 24.0 610 60.6 207 97

7 195 91 2.8 71 60.6 113 45

8 202 94 8.0 203 51.5 152 67

9 198 92 4.7 119 56.0 130 54

10 190 88 4.0 102 56.0 125 52

11 190 88 4.9 124 54.0 131 55

SOLUTION TEMPERATURE VAPOR PRESSURE

°F °C in. Hg mm Hg °F °C

SOLUTION PERCENTAGE

LITHIUM BROMIDE

SATURATION TEMPERATURE

12

Page 13

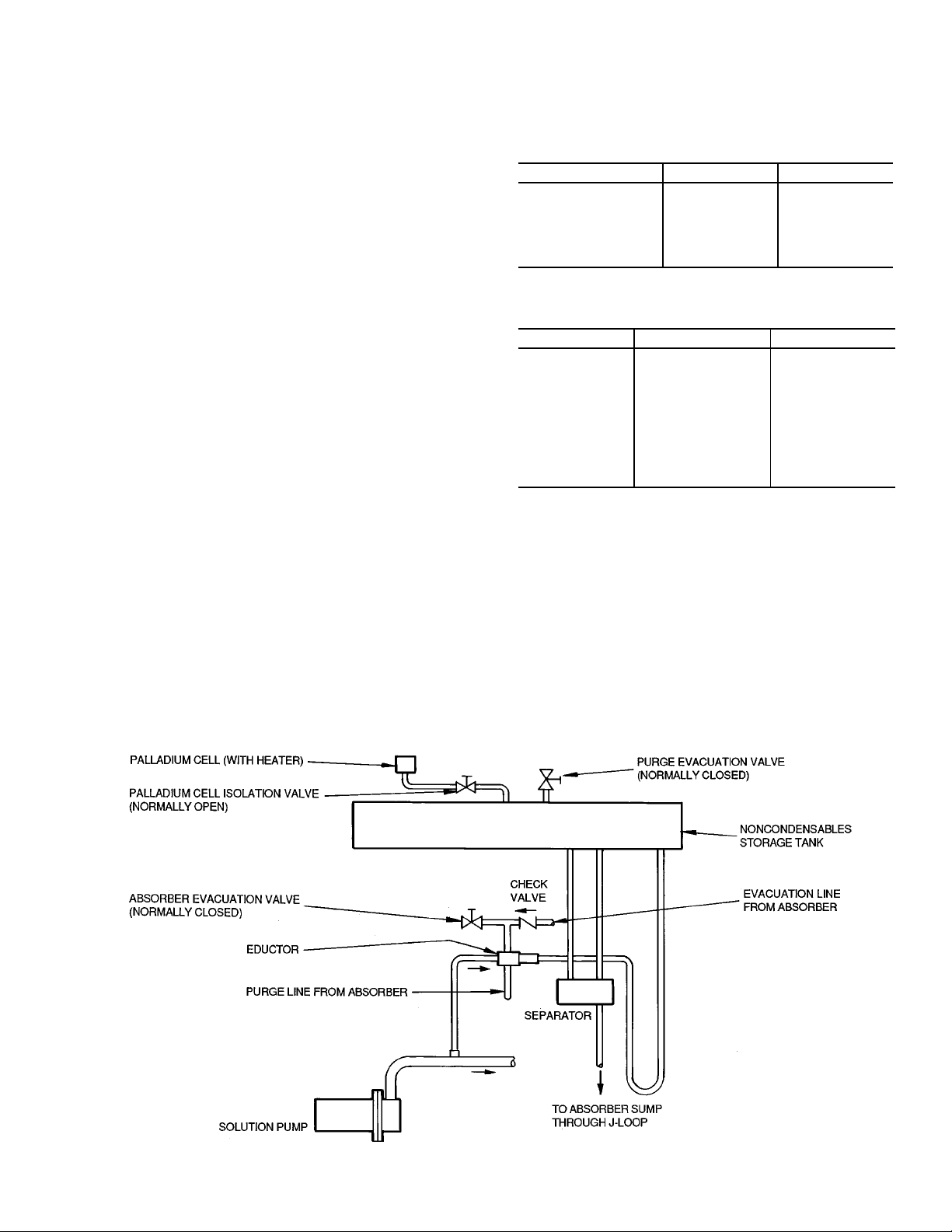

Purge — The basic components and flow circuits of the

motorless purge are shown in Fig. 9.

The purge system automatically removes noncondensables from the machine and transfers them to a storage chamber where they cannot affect machine operation.

Noncondensables are gases which will not condense at the

normal chiller operating temperatures and pressures (N

, etc.) and, because they reduce the machine vacuum, they

H

2

would also reduce the machine capacity.

Hydrogen (H

normal operation, and its rate of generation is controlled by

) gas is liberated within the machine during

2

the solution inhibitor. The presence of most other gases in

the machine would occur either through a leak (the machine

is under a deep vacuum) or during service activities.

While the machine is operating, any noncondensables accumulate in the absorber which is the lowest pressure area

of the machine.

For purging, noncondensables are continuously drawn from

the absorber into the lower pressure of an eductor, where

they are entrained in solution flowing from the solution pump.

The mixture then continues on to the purge storage tank. The

noncondensables are released in a separator and the solution

flows back to the absorber by way of the generator overflow

pipe. Typicallymost of the noncondensable gas is hydrogen,

which is automatically passed out to the atmosphere through

a heated palladium membrane cell.

Any other gas accumulates in the purge storage tank where

it is isolated from the rest of the machine. It is then removed

from the storage tank, when necessary, by a vacuum pump

connected to the tank exhaust valve. If the machine is maintained in a leak-tight condition, as it should be, the storage

tank is normally exhausted once or twice a year, during a

normal shutdown period or seasonal changeover. When it is

necessary to remove noncondensables directly from the machine, such as after service work, a vacuum pump can be

connected to the auxiliary evacuation valve, which is connected directly to the absorber through an isolation check

valve.

2,O2

Operation Status Indicators — The 16DF absorp-

tion chiller/heater is equipped with several instruments and

sight glasses for direct observation of its operation in addition to a digital display of the temperature sensed for machine control and for codes (Tables 4 and 5).

,

DESCRIPTION LOCATION FUNCTION

High-Temperature

Generator Compound

Gage

Exhaust Gas

Thermometer

Table 4 — 16DF Instruments

Low-Temperature

Generator

Steam Chamber

High-Temperature

Generator

Exhaust Stack

High-Temperature

Generator

Vessel Pressure

Exhaust Gas

Discharge

Temperature

Table 5 — 16DF Sight Glass

DESCRIPTION LOCATION FUNCTION

Absorber Sight

Glass

High-Temperature

Generator

Sight Glass

Combustion

Chamber

Sight Glass

Evaporator Refrigerant

Overflow Pipe

High-Temperature

Generator Level

Control Device Box

High-Temperature

Generator

Combustion Chamber

Return End

Absorber

Liquid Level

Refrigerant Overflow

High-Temperature

Generator

Liquid Level

Combustion and

Refractory

Insulation

Status

Burner — The burner is a packaged, forced-draft type,

with modulating firing rate control. It is supplied with components selected for operation with either gas, light oil, or

both fuels, and with appropriate safety and control components to comply with specified code, insurance, and jurisdictional agency requirements.

Specific information is contained in the burner manual ac-

companying each burner.

Fig. 9 — Purge System

13

Page 14

MACHINE CONTROLS

This machine uses a microprocessor control system. Do

not short or jumper between terminations on printed circuit boards. Control or board failure may result. Also,

when performing welding, wiring, or an insulation resistance test on the machine, disconnect wiring to the

CPU (Control Processing Unit) board to avoid risk of

voltage damage to the board components.

Be aware of electrostatic discharge (static electricity)

when handling or making contact with the printed circuit boards. Always touch a grounded chassis part to

dissipate body electrostatic charge before working inside the control center.

Use extreme care when handling tools near boards

and when connecting or disconnecting terminal plugs.

Circuit boards can easily be damaged. Always holdboards

by edges and avoid touching components and pin connections. Always store and transport replacement or defective boards in anti-static bags.

General — The 16DF machine uses a microprocessor-

based control center which monitors and controls all operations of the machine. It also has a separate burner control

center, under direction of the machine control center, to provide burner sequence control and combustion supervision.

The integrated control system matches the cooling and heating capacities of the machine to the respective cooling and

heating loads, while providing state-of-the-art machine

protection.

The system controls the machine output temperatures within

the set point deadband by sensing the leaving chilled and hot

water temperatures and regulating the burner heat input accordingly. Machine protection is provided by continuously

monitoring critical conditions and performing control overrides or safety shutdowns, if required.

Start-Stop System — The type of start-stop system is

selected by the customer. The most commonly used systems

are described below. Review the descriptions and determine

which system applies to your job.

SEMIAUTOMATIC START-STOP — In this basic system,

auxiliary equipment is wired into the machine control circuit and machine is started and stopped manually with the

machine Start and Stop switches. Two variations are used:

With Pilot Relays — The coils for the chilled/hot water and

condensing water pump starters (or other auxiliary equipment) are wired into the machine control circuit so that the

auxiliary equipment operates whenever machine operates. The

starter contacts and starter overloads remain in the external

pump circuits. The pump flow switch(es) and auxiliary starter

circuits are also wired into the machine control circuit and

must be closed for the machine to operate.

WithManualAuxiliaries — With this system, the auxiliaries

must be started manually and independently from the machine start, and they must be operating before the machine

can start. As with the pilot relay system above, the flow

switch(es) and auxiliary starter contacts are in the machine

control circuit and must be closed for the machine to

operate.

FULL AUTOMATIC START-STOP — This system is basically the same as the semiautomatic system with pilot relays described above. Machine and auxiliary start and stop,

however are controlled by a field-supplied thermostat, timer,

or other automatic device when the TS6 Local/Remote switch

is in the REMOTE position, and the machine Start switch

has been depressed.

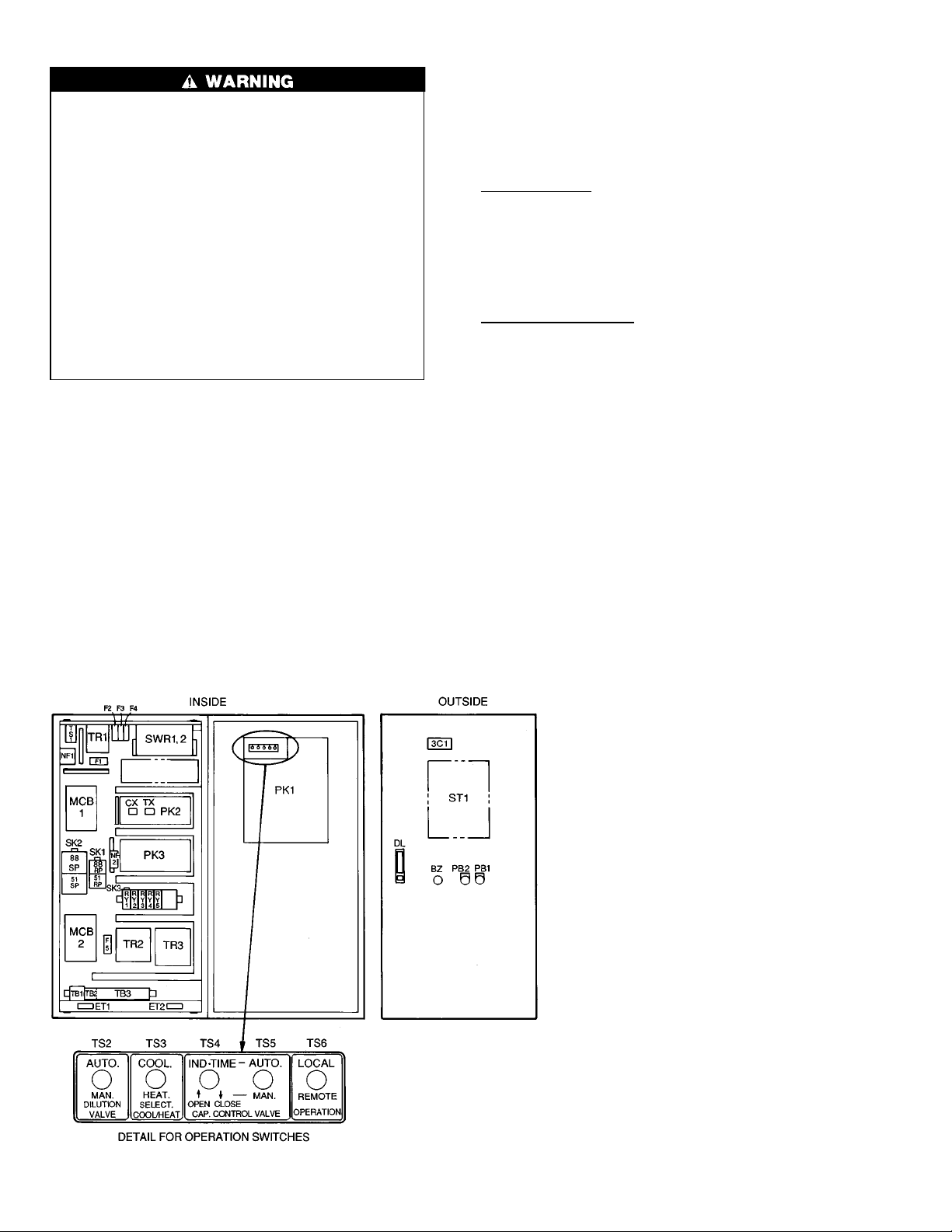

Machine Control Panel — The 16DF standard con-

trol panel is shown in Fig. 10.

LEGEND

3CI — Three-Character Indicator

51RP — Refrigerant Pump Overcurrent Relay

51SP — Solution Pump Overcurrent Relay

88RP — Refrigerant Pump Electromagnetic

88SP — Solution Pump Electromagnetic

BZ — Alarm Buzzer

CX — Remote Control Auxiliary Relay*

DL — Door Latch

ET1,2 — Grounds

F0 — End-Contact Fuse

F1-5 — Enclosed Fuses

MCB1,2 — Main Circuit Breakers

NF1,2 — Line Noise Filters

PB1 — Start Pushbutton Switch

PB2 — Stop Pushbutton Switch

PK1 — Central Processing Unit (CPU) Board

PK2 — Input Terminal Module

PK3 — Output Terminal Module

RY1 — External Emergency Stop Auxiliary Relay

RY2-5 — Burner Safety Shutdown Auxiliary Relays

SK1-3 — Surge Suppressors

ST1 — Display Code Identification Sticker

SWR1,2 — Switching Regulators

T1 — Burner Safety Shutdown (‘‘Off’’ Delay Timer)

TB1-3 — Terminal Boards

TR1 — Transformer

TR2 — Direct Current Control Circuit

TR3 — Alternating Current Control Circuit Transformer

TS2-6 — Operation Switches

TS1 — Direct Current Power Supply (On/Off)

TX — Remote Control Circuit Auxiliary Relay*

*CX,TX auxiliary relays for remote operation are

optionally installed signals.

Contactor

Contactor

(see also Fig. 11)

Transformer

Fig. 10 — Control Panel

14

Page 15

Status Indicator Sticker — The sticker shown in

Fig. 11 is located on the front of the control panel. It identifies the basic codes for machine operating status and safety

shutdown, as displayed by the 3-character indicator on the

front of the control panel.

NOTE: See Digital Temperature Display, page 16, and Adjustment Switches, below, for switch selections that display

temperatures being measured by the machine sensors as well

as the machine cumulative run time.

Adjustment Switches — These are located on the cir-

cuit board on the inside panel door.

TOGGLE SWITCHES (Fig. 12) — These are summarized

in Table 6 and discussed in greater detail in various sections

throughout this manual.

Table 6 — Control Panel Toggle Switches

SYMBOL TOGGLE SWITCH DESCRIPTION

TS1 On-Off Direct Current Power Supply

TS2 Auto.-Manual Dilution Valve

TS3 Cool-Heat Select Cool/Heat

TS4 Open-Close Capacity Control Valve

TS5 Auto.-Manual Capacity Control Valve

TS6 Remote-Local Operation

NOTES:

1. Time display selection shows thecumulative machine operating time inhours

on the panel door operating status indicator. With the capacity control valve

selection in the AUTO. position, momentarily depressing the switch to OPEN

displays the first 3 digits of the time, and depressing the switch to CLOSE

displays the last 2 digits and decimal. Example:

OPEN position indicates = 012

CLOSE position indicates = 345

Cumulative run time = 01234.5 hours

2. With capacity control valve selection in the MANUAL position, momentarily

depressing the switch to OPEN or CLOSE will move the burner fuel control

valve and air damper proportionally open or closed.

Fig. 12 — Control Panel Toggle Switches

Fig. 11 — Control Panel Status Indicator Sticker

15

Page 16

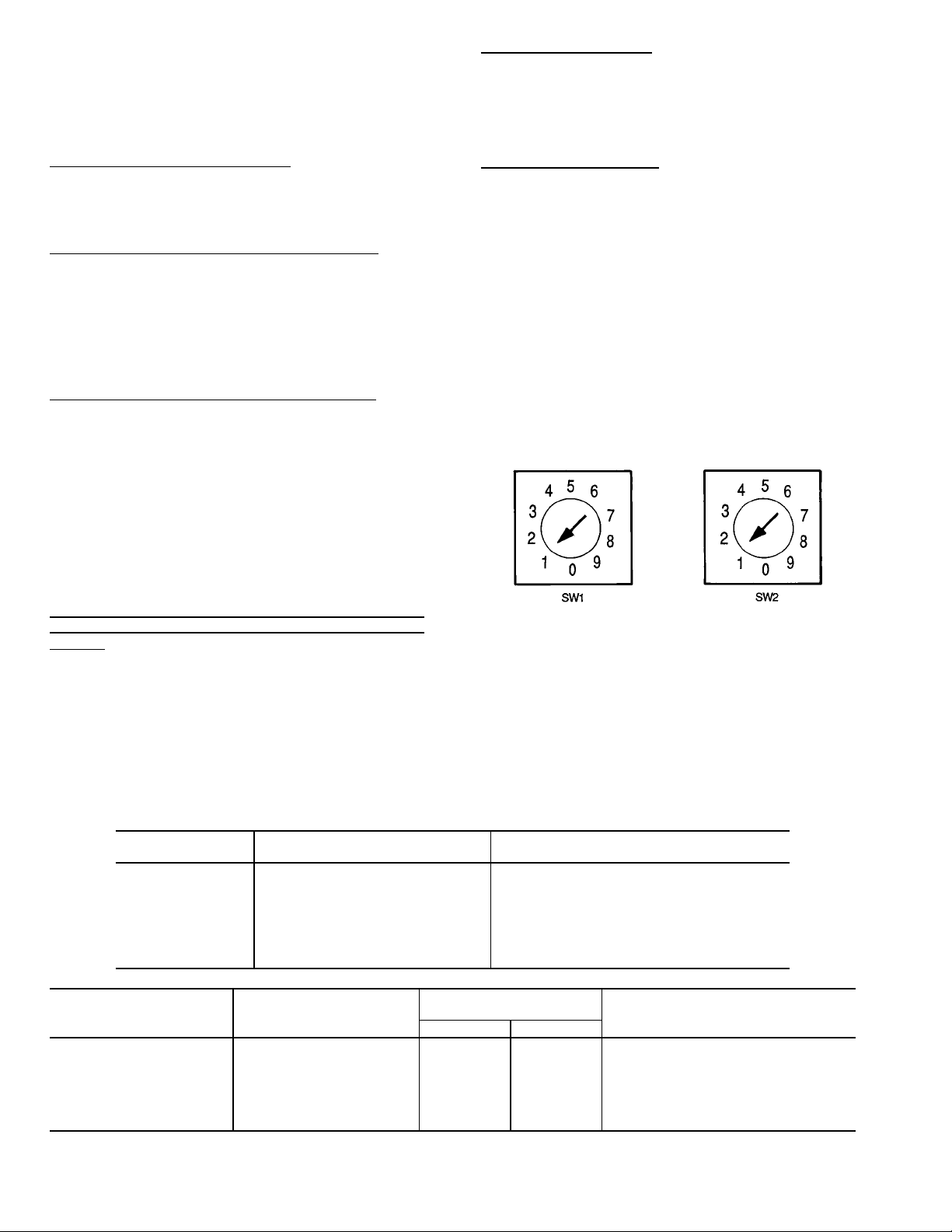

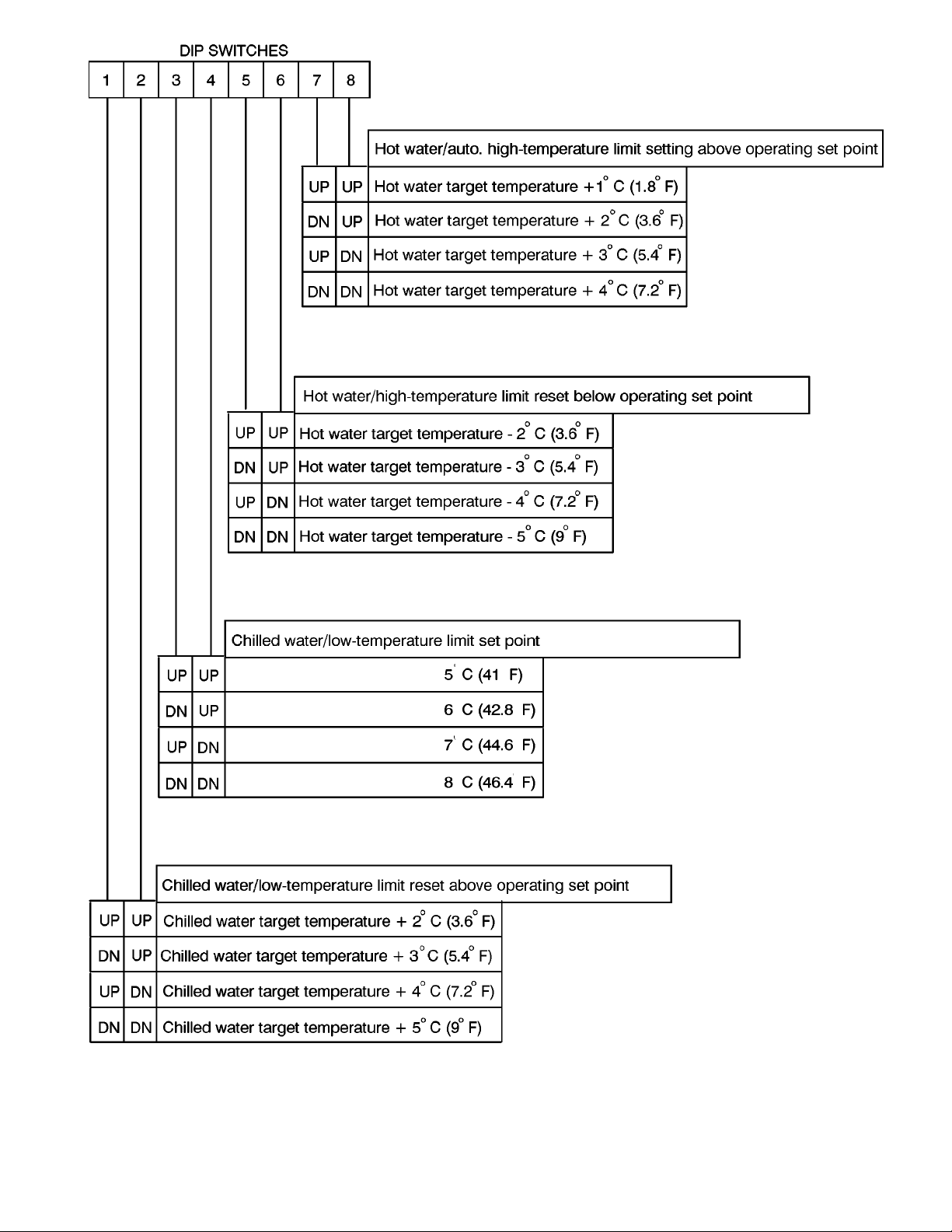

SET POINT AND DIP (Dual In-Line Package) SWITCHES

(Fig. 13-16) — These switches are used to adjust chilled water and hot water capacity control temperature set points (also

see Automatic Capacity Control section, page 31); to select

the type of remote control signal; to display temperatures of

the various machine temperature control sensors; and for service selections.

Chilled/Hot Water Control Location — SW11 switch 2

(Fig. 16) determines whether the capacity controller will use

the chilled/hot water inlet nozzle sensor (UP position), or

the outlet nozzle sensor (DOWN position).

NOTE: DOWN is the typical selection.

Chilled Water Capacity Control TemperatureSetPoint — The

chilled water control temperature is determined by the setting on SW2 (Fig. 13, right side). The settings are increments of 1° C (1.8° F) from 0° to 9° C (0° to 16° F), and the

control temperature is the SW2 setting above a base temperature of 5 C (41 F), for an adjustable range of 5 to 14 C

(41 to 57 F). For example, a selection of 2 on SW2 would

be a setting of 2° C plus5C(7Ctotal) (3.6° F plus 41 F =

44.6 F total).

Hot Water Capacity Control Temperature Set Point — The

hot water control temperature is determined by the settings

on SW1 (Fig. 13, left side) and on SW10 switches 1 and 2

(Fig. 15). The SW1 settings are increments of 1° C (1.8° F)

from 0° C to 9° C (0° to 16° F). The SW10 1 and 2 selections are for a base temperature of either 40 C (104 F),

50 C (122 F), 60 C (140 F), or 70 C (158 F). The control

temperature is the SW2 setting above the selected base

temperature, for an adjustable range of 40 to 79 C (104 to

174 F). For example, a selection of 2 on SW1 and placing

both SW10 switches in the UP position would be a setting

of 2° C plus 70 C (72 C total) (3.6 F plus 158 F =

161.6 F total).

Remote ON/OFF Signal — When the Local/Remote Operation toggle switch (Fig. 12) is in the REMOTE position, SW11

switch 1 (Fig. 16) will determine whether the remote signal

is to be a remotely powered on/off voltage signal to the machine control circuit (UP position), or is from machine control circuit power through remote dry contacts (DOWN

position).

Digital Temperature Display — The temperatures being measured by the machine’s analog sensors will be displayed in

°C by the 3-character indicator on the front of the control

panel when DIP switch 6 on SW11 (Fig. 16) is placed in the

UPposition.OtherwisethisswitchshouldbeleftintheDOWN

position for normal operating status indication. The temperatures will be shown in 8 sequential displays, with the

first of the 3 characters indicating the channel (sensor) and

the second and third characters showing the temperature. The

first 6 channels indicate temperatures of 0° to 99 C (32 to

210 F) directly, and the seventh indicates, by code, 0° to 200

C (32 to 392 F). See Table 7.

Indicator LEDs — Fig. 17 shows the status of the ma-

chine’s light-emitting diode (LED) indicator lights for DIP

switch 5 of SW11 (Fig. 16).

Chilled and Hot Water Temperature Limit Settings on SW9

(Fig. 14) and Capacity Control Response Speed on SW10

(Fig. 15) — The purpose and selection of these settings are

SW1 — Hot Water Temperature Setting

SW2 — Chilled Water Temperature Setting

explained in the Automatic Capacity Control section.

Table 7 — Digital Temperature Display Codes

FIRST CHARACTER SECOND AND THIRD CHARACTERS

CHANNEL NUMBER (TEMPERATURE IN °C)

0 00 to 99 Chilled/hot water leaving temperature

1 00 to 99 Weak solution leaving absorber temperature

2 00 to 99 High-stage generator vapor temperature

3 00 to 99 Chilled/hot water entering temperature

4 — Not used at this time

5 — Not used at this time

6 — Not used at this time

7 Code display High-stage generator leaving solution temperature

CHANNEL 7

TEMPERATURE CODE

7

*Example: A display showing 7C3 means channel 7 measures 123 C (253.4 F).

SECOND CHARACTER

CODE

A 100 212

B 110 230

C 120 248

D 130 266

E 140 284

F 150 302

H 160 320

TEMPERATURE

CF

Fig. 13 — Load Water Temperature

Adjustment Switches

CONDITION SENSED

BASE

THIRD CHARACTER

This is the unit of temperature

in 1° C increments (1.8° F) added to

the base temperature*

16

Page 17

Fig. 14 — Switch SW9

17

Page 18

Fig. 15 — Switch SW10

LEGEND

DN — Down

Indicates typical setting

*—Priority over error number

Fig. 16 — Switch SW11

18

Page 19

Fig. 17 — LED Indicator Lights Status

Remaining Time Indication for Dilution Cycle

To view remaining time in minutes on the control panel

—

indicator, depress the Stop button (PB2) during the shutdown dilution cycle operation. It will be displayed only while

the button is depressed.

The following example indicates 12 minutes still remain

before dilution cycle is completed:

Dilution Cycle Indication — dPP

Depress Stop Button (PB2)

Remaining Time Indication — d12

Control Wiring — Figures 18-23 represent typical ma-

chine wiring schematics and component identification. See

machine control panel diagram (Fig. 10) for component location. Refer to burner manufacturer’s manual for burner control wiring diagram and component identification.

19

Page 20

LEGEND FOR WIRING DIAGRAMS (Fig. 18 - 23), Pages 20 - 25

3CI — Three-Character Indicator

20CCV — Concentration Control Valve Positioner

21CV — Burner Capacity Control Positioner

20DV — Dilution Valve

26CA — Fire Tube High-Temperature Switch

26EH — Burner Exhaust Gas High-Temperature Switch

26SP — Solution Pump High Motor Temperature Switch

51BF — Burner Blower Motor Overload Relay

51RP — Refrigerant Pump Overload Relay

51SP — Solution Pump Overload Relay

69CW 1,2 — Chilled Water and Cooling Water Flow Switches

86X — Burner Safety Auxiliary Relay

88BF — Burner Blower Motor Starter

88CP — Cooling Water Pump Starter

88EP — Chilled/Hot Water Pump Starter

88CT — Cooling Tower Fan Starter

88RP — Refrigerant Pump Starter

88SP — Solution Pump Starter

AR1-8 — Machine Control Relays

BCB — Burner Control Box

BZ — Alarm Buzzer

C/H — Chiller/Heater

CX — Remote Control Auxiliary Relay*

CN1-10 — Wiring Cable Connectors

ET1,2 — Grounds

F0 — End-Contact Fuse

F1-5 — Enclosed Fuses

G1 — High-Stage Generator

GH — High-Stage Generator, High-Solution Level Switch

M1-3 — Three-Phase Motors

MCB1,2 — Main Circuit Breakers

MCP — Machine Control Panel

NF1,2 — Line Noise Filters

PB1 — Start Pushbutton

PB2 — Stop Pushbutton

PK1 — Main Circuit Board

PK2 — Input Terminal Circuit Board

PK3 — Output Terminal Circuit Board

RY1 — External Emergency Stop Auxiliary Relay

RY2-5 — Burner Safety Shutdown Auxiliary Relays

SK1-3 — Surge Suppressors

ST1 — Display Code Identification Sticker

SWR1,2 — Switching Regulators

T1 — Burner Safety Shutdown (‘‘Off’’ Delay Timer)

T3H, T4H — Temperature Sensors

TB — Terminal Boards

TR1 — Transformer

TR2 — Direct Current Control Circuit Transformer

TR3 — Alternating Current Control Circuit Transformer

TS1 — Direct Current Power Supply (On/Off)

TS2-6 — Operation Switches

TX — Remote Control Circuit Auxiliary Relay*

Factory Wiring

Field Wiring

Optional Wiring

*CX, TX auxiliary relays for remote operation are optionally installed

signals.

NOTES:

1. BCB — installed in burner control box.

2. F — installed on chiller/heater.

Fig. 18 — Control Panel Power Wiring Schematic

20

Page 21

Fig. 19 — Terminal Strip, External Wiring Connections

21

Page 22

Fig. 20 — Circuit Board Wiring Locations

22

Page 23

NOTES:

1. PK3 — mounted on output terminal module in control panel.

2. Legend on page 20.

Fig. 21 — PK3 Circuit Board Output Wiring Connections

23

Page 24

Fig. 22 — PK2 Circuit Board Input Wiring Connections

24

Page 25

NOTES:

1. When the contacts of external emergency stop signals are connected, remove the jumper wire between terminal R2 and X4 and

connect external contacts to these terminals.

2. BCB — installed in burner control box.

3. F — Positioning motor.

4. PK2 — input terminal module in control panel.

5. PK3 — output terminal module in control panel.

Fig. 23 — PK2 and PK3 Partial Wiring Connections

REMOTE OPERATION CIRCUIT

Typical Control Sequence — Normal Cooling

Start (Fig. 24)

1. When power is supplied to the chiller control panel and

the machine is not in operation, the status indicator will

display ‘‘000’’.

2. For starting, the machine and burner switches should be

positioned as shown in Table 8, and the manual cooling/

heating valves positioned for cooling (Table 9).

NOTE: The Cool switch selection must be made before

the Start button is depressed.

3. When the Start button is depressed, the microprocessor

will initiate the timed starting and system checks sequence. The chilled water pump will be started, if not already running.After20seconds, the pump run interlock(s)

will be checked to verify if the pump is running. If it is,

the status indicator will display ‘‘CPO’’. If not, the sequence will be halted until the interlocks show the pump

is running.

4. The capacity controller then will be queried to see if there

is a need for cooling. If not, the sequence will be halted.

If cooling isrequired,thecoolingwaterpumpwill be started,

if not already running. After 20 seconds, the pump run

interlock(s) will be checked to verify it is running. If it is,

the start sequence will proceed. If not, the sequence will

be halted until the interlocks show the pump is running.

When the pump is running, the status indicator will display ‘‘CPP’’.

5. The cooling water temperature will be checked and, if it

is not too low,the cooling tower fan will be started, if not

already running. The status indicator will now display

‘‘CPP’’. At the same time, the solution pump and burner

will be started. The refrigerant pump will be started after

a short time delay. The chiller is now in normal

operation. The control system will continuously monitor

the capacity controller for load requirements, the safety

interlocks for abnormal conditions, and operating limits

for override control when necessary.

Typical Control Sequence — Normal Heating

Start (Fig. 24)

1. When power is supplied to the chiller control panel and

the machine is not in operation, the status indicator will

display ‘‘000’’.

2. For starting, the machine and burner switches should be

positioned as shown in Table 8, and the manual cooling/

heating valves positioned for heating (Table 9).

NOTE: The Heat switch selection must be made before

the Start button is depressed.

3. When the Start button is depressed, the microprocessor

will initiate the timed starting and system checks sequence. The hot water pump will be started, if not already running.After20seconds, the pump run interlock(s)

will be checked to verify it is running. If it is, the status

indicator will display ‘‘HPO’’. If not, the sequence will

be halted until the interlocks show the pump is running.

4. The capacity controller then will be queried to see if there

is a need for heating. If not, the sequence will be halted.

If there is, the start sequence will proceed.

5. The solution pump and the burner will be started. The

status indicator will display ‘‘HPO’’. The heater is now

in normal operation. The control system will continuously monitor the capacity controller for load requirements, the safety interlocks for abnormal conditions, and

operating limits for override control when necessary.

25

Page 26

NOTE: ‘‘XXX‘‘ represents letters for indicator on control panel.

Fig. 24 — Normal ‘‘Start’’ Flow Chart

26

Page 27

Table 8 — Switch Positions for Start-Up

MACHINE CONTROL PANEL

SYMBOL DESCRIPTION TOGGLE SWITCH SETTING

TS1 Direct Current Power Supply On-Off ON

TS2 Dilution Valve Auto.-Manual AUTO.

TS3 Select Cool/Heat Cool-Heat COOL OR HEAT

TS4 Capacity Control Valve Open-Close (NEUTRAL)

TS5 Capacity Control Valve Auto.-Manual AUTO.

TS6 Operation Remote-Local REMOTE OR LOCAL

BURNER CONTROL PANEL

DESCRIPTION TOGGLE SWITCH SETTING

Burner Control On-Off ON

Firing Rate Selector Auto.-Manual AUTO.

Firing Position Open-Stop-Close STOP

Fuel Selection (if used) Gas-Oil GAS OR OIL

Table 9 — 16DF Valves

MANUAL VALVES

NO. SYMBOL DESCRIPTION LOCATION OPERATION*

1 A Heating/Cooling Vapor Valves High-Temperature Vapor Discharge Pipe

2 B Heating/Cooling Liquid Valve Underside Refrigerant Tank

3 C Heat Exchanger Bypass Solution Heat Exchanger

4 D Palladium Cell Isolation Palladium Cell Connection Pipe

5 E Purge Storage Tank Evacuation Purge Tank

6 F Auxiliary Evacuation Purge Pipe

7 G Vacuum/Pressure Gage Connection Absorber Shell

8 H Solution Pump Service Solution Pump Discharge

9 J Refrigerant Pump Service Refrigerant Pump Discharge

10 K High-Stage Generator Service Underside High Temperature Generator

*Valve positions—O=FULLY OPEN; C = FULLY CLOSED.

Cooling Cycle C

Heating Cycle O

Cooling Cycle C

Heating Cycle O

Normal Operation C

Service O

Normal Operation O

Service C

Normal Operation C

Purge Discharge O

Normal Operation C

Machine Evacuation O

Normal Operation C

Vacuum/Pressure Check O

Normal Operation C

Service O

Normal Operation C

Service O

Normal Operation C

Service O

AUTOMATIC VALVES

NO. SYMBOL DESCRIPTION LOCATION OPERATION*

1 21CV Capacity Control Valves Burner Fuel Line and Air Damper Proportional between high fire and low fire

2 — Fuel Valves Burner Fuel Line

3 20DC Dilution Valve Evaporator Refrigerant Overflow Pipe

4 20CCV Concentration Control Valve Condenser Refrigerant Return Pipe

5 LCD Solution Flow Control Weak Solution Pipe

*Valve positions—O=FULLY OPEN; C = FULLY CLOSED.

Burner On O

Burner Off C

Dilution Cycle O

Normal Operation C

Concentration Control Cycle O

Normal Operation C

Reduces flow for low loads and low cooling water

temperature.

27

Page 28

Typical Control Sequence — Normal Cooling

Stop (Fig. 25)

1. The timed shutdown sequence begins when the Stop button is depressed or the capacity controller senses there is

insufficient load for continued operation. The status indicator will display ‘‘dPP’’.

2. The burner control is given a signal to move to the lowfire position, and, after 30 seconds, combustion is stopped

and the burner goes through its post-purge shutdown

sequence.

3. The refrigerant pump is stopped, and the dilution valve is

opened to drain refrigerant from the evaporator into the

absorber solution. The valve remains open until the shutdown is complete, and the refrigerant flow continues until the evaporator level reaches the level of the drain pipe.

4. Five minutes after the stop sequence is initiated, the solution temperature is checked to be sure it is cool enough

to stop the cooling water flow. When it is, the cooling

tower fan and cooling water pump are stopped if

they are connected to the control circuit for automatic

operation.

5. Fifteen minutes after the stop sequence is initiated, the

solution pump is stopped, and the machine shutdown is

completed. The pump remains in operation during the dilution period to mix refrigerant through the solution.

6. If the chilled water pump is connected to the control circuit for automatic operation, and the shutdown was initiated by the capacity controller, the chilled water pump

will continue running to be ready for a restart, and the

status indicator will display ‘‘APO’’. With a manual stop,

the chilled water pump will be stopped and the status indicator will display ‘‘000’’.

IMPORTANT :With manual pump control,thechilled

water pump must not be stopped until the shutdown cycle has been completed.

Typical Control Sequence — Normal Heating

Stop (Fig. 25)

1. The timed shutdown sequence begins when the Stop button is depressed or the capacity controller senses there is

insufficient load for continued operation. The status indicator will display ‘‘dPO’’.

2. The burner control is given a signal to move to the lowfire position, and, after 30 seconds, combustion is stopped

and the burner goes through its post-purge shutdown

sequence.

3. Fifteen minutes after the stop sequence is initiated, the

solution pump is stopped, and the machine shutdown is

completed. The pump remains in operation during the shutdown period to cool the solution and machine.

4. If the hot water pump is connected to the control circuit

for automatic operation, and the shutdown was initiated

by the capacity controller, the hot water pump will continue running to be ready for a restart, and the status indicator will display ‘‘APO’’. With a manual stop, the hot

water pump will be stopped and the status indicator will

display ‘‘000’’.

IMPORTANT: With manual pump control, the hot

water pump must not be stopped until the shutdown cycle has been completed.

Fig. 25 — Normal ‘‘Stop’’ Flow Chart

28

Page 29

Abnormal Shutdown (Fig. 26 and Table 10)

— During operation, various conditions are monitored by

the control system to protect the machine and to ensure safe

operation. When any of these conditions exceed their normal safe operating limit, the machine will be shut down automatically and the audible alarm on the front of the control

panel will buzz.

The cause of the limit shutdown will be displayed in code

by the 3-character indicator on the front of the control panel.

These are listed in Table 7. The alarm can be silenced by

depressing the Stop button, after the cause of the shutdown

has been noted. This will reset the control circuit for a restart

after the shutdown sequence has been completed and the cause

of the shutdown has been corrected. Combustion failures are

also indicated by an alarm light on the burner panel. Acombustion failure can be reset by pressing the reset button on

the burner combustion controller in the burner control panel.

Some conditions will allow the burner to first modulate to

the minimum firing position for a normal low-fire shutdown.

Others will close the fuel valve immediately. Most of the

conditions will allow a normal dilution period before shutdown, but several will stop the machine immediately without dilution.Thelatterconditionsshouldbe corrected as quickly

as possible to allow a restart or manual dilution before solution crystallization occurs.

The shutdown follows the typical cooling or heating stop

sequence, with the immediate combustion stop or lack of dilution exceptions as listed. Also with low chilled water temperature or flow, the dilution cycle is delayed until after the

cooling tower fan and cooling water pump are stopped.

Fig. 26 — Abnormal ‘‘Stop’’ Flow Chart

29

Page 30

Table 10 — Abnormal Shutdown Conditions

AUTO. LIMIT LIMIT CONTROL STOP LOW

CONDITION SETTING SYMBOL CODE FIRE

Low leaving chilled water temperature cutout (cooling only) 4 C (39 F) 26CW E01 No Yes

High-temperature generator high-solution temperature

switch

High-temperature generator high-pressure switch -20 mm Hg (-.8 in.) 63GE E05 No Yes

Exhaust gas high-temperature switch 300 C (572 F) 26EH E06 No Yes

Fire tube high-temperature switch 300 C (572 F) 26TH E06 No Yes

Burner combustion failure/limit

• Within 3 minutes of machine start

• After 3 minutes of machine start

External emergency limit switch Per device SE E10 No Yes

Refractory high-temperature switch 150 C (302 F) 26CA E06 No Yes

Solution pump motor overloads Rated amp 51SP E04 Yes No

Solution pump motor high-temperature switch 135 C (275 F) 26SP E04 Yes No

Refrigerant pump motor overloads (cooling only) Rated amp 51RP E04 Yes Yes

Refrigerant pump motor high-temperature switch

(larger size chillers, cooling only)

High-absorber; weak solution temperature sensor

(cooling only)

Chilled/hot water low flow 50% design 69CW1 E02 Yes Yes

Cooling water low flow (optional) (cooling only) 50% design 69CW2 E03 Yes Yes

Chilled/hot water pump interlock Open circuit 88EP E02 Yes Yes

Cooling water pump interlock (cooling only) Open circuit 88CP E03 Yes Yes

Sensor error (7 conditions) Out of range — E13-34 Yes Yes

Operating Limit Controls — Several special fea-

tures allow the machine to continue to run in limited operation with certain abnormal conditions, until those conditions

either are corrected to resume normal operation or deteriorate to a point where the machine is automatically shut down:

HIGH-TEMPERATURE GENERATOR, HIGH SOLUTION LEVEL — An immersion electrode with a switched

output continuously monitors the high-stage generator solution level. If a problem causes a high level and the condition continues for 5 minutes, the solution pump is turned

off to stop solution supply to the generators. If the temperature of the solution leaving the high-stage generator is below

212 F (100 C) the solution pump is restarted after 60 seconds. If the solution temperature is 212 F (100 C) or higher,

the pump is restarted after 30 seconds.

If the high level continues for 10 minutes, meaning it was

not corrected by stopping the pump, the alarm buzzer will

sound, the status indicator will display safety shutdown code

E13 for ‘‘electrode fault’’, and the machine will shut down

with the normal dilution cycle. The solution pump will continue operating through the shutdown sequence.

HIGH-TEMPERATURE GENERATOR, HIGH LEAVING

SOLUTION TEMPERATURE — When this temperature

reaches 311F(155C),thecapacitycontrol signal to the burner

is limited to prevent an increase in the heat input. If the temperature continues to rise, a ‘‘close’’ signal is given to the

burner control for 2 or 3 seconds for each incremental increase of 0.5° F (0.3° C).

If this temperature rises above 329 F (165 C), the close

signal is given in increments for 5 seconds. If the temperature continues to rise to 338 F (170 C), the burner will be

stopped immediately, the alarm buzzer will sound, the status

indicator will display safety shutdown code E05 for ‘‘high

170 C (338 F) T4H E05 No Yes

Per device 86X

• E08

• E09

135 C (275 F) 26RP E04 Yes Yes

45 C (113 F) T2 E07 Yes Yes

No Yes

HIGH-TEMPERATURE GENERATOR, HIGHSATURATION (VAPOR) TEMPERATURE — When this

temperature reaches 199 F (93 C), the capacity control signal to the burner is limited to prevent an increase in the heat

input. If the temperature continues to rise, a ‘‘close’’ signal

is given to the burner control for 2 or 3 seconds for each

incremental increase of 0.4° F (0.3° C). If this temperature

rises above 203 F (95 C), the close signal is given in increments for 5 seconds.

CONCENTRATION CONTROL VALVE — When the temperature of the solution leaving the absorber drops below 91

F (33 C) during cooling operation, because of low cooling

water temperatures, the concentration control valve is opened.

This valve is located in a condensate line between the bottom of the condenser and the evaporator and, when open,

drains extra refrigerant into the evaporator. This is to prevent possible refrigerant pump cavitation and damage due to

loss of refrigerant with the low solution concentrations which

can occur with cooling water temperatures below design. The

valve closes when the solution temperature rises above 95 F

(35 C).

The concentration control valve is also opened during the

shutdown dilution cycle and during heating operation.

COOLING TOWER CONTROL — When the temperature

of the solution leaving the absorber drops below 77 F

(25 C) during cooling operation, because of low cooling water temperatures, the tower fan is turned off. When the solution warms to 86 F (30 C), the fan is turned back on.