CARRE PENTASEM Series, PTS 3500, PTS 4000, PTS 6000, PTS 4800 Assembly & Use Instructions

...

PENTASEM

Assembly - Use

Ref. 38011901

Updated 10.11.10

CARRE sas • CONSTRUCTIONS MECANIQUES • Z.A Les Fours • BP 6

Tel. 02 51 07 82 35 • Fax 02 51 07 80 75 • http://www.carre.fr • Email: carre@carre.fr

85140 SAINT MARTIN DES NOYERS • FRANCE

CONTENTS

Page

1

2

3

INTRODUCTION ................................................................................. 3

SPECIFICATIONS .............................................................................. 3

SAFETY INSTRUCTIONS .................................................................. 5

3.1 Safety symbols ............................................................................................. 5

3.2 Usage as intended ....................................................................................... 6

3.3 General safety instructions........................................................................... 6

3.4 Safety in the public domain .......................................................................... 6

3.5 Accident prevention ..................................................................................... 7

3.6 Maintenance and repair ............................................................................... 7

4

5

OPERATOR CONTROLS ................................................................... 8

ASSEMBLY AND PUTTING INTO SERVICE ..................................... 8

5.1 Link on the tractor ........................................................................................ 8

5.2 Mounting the tines ........................................................................................ 8

5.3 Positioning the extensions ........................................................................... 9

5.4 Equipment .................................................................................................... 10

5.4.1 Front blade ................................................................................................... 10

5.4.2 Comb harrow Ø10 ........................................................................................ 10

5.4.3 Rubber tyre wheel ........................................................................................ 10

5.4.4 Blower .......................................................................................................... 11

5.5 Adjusting and using the sower before sowing .............................................. 12

5.5.1 Markers ........................................................................................................ 12

5.5.2 Pre-emergence markers ............................................................................. 12

5.5.3 Sowing depth adjustment ............................................................................ 13

5.5.4 Flow test ....................................................................................................... 14

5.5.5 Track marker adjustment ............................................................................ 18

5.5.6 Sower control ............................................................................................... 19

5.6 Using the sower during work ........................................................................ 20

5.7 Usage after work .......................................................................................... 21

5.7.1 Emptying the hopper and the dispenser ....................................................... 21

5.7.2 Sower storage .............................................................................................. 21

5.8 Using the case

6

MAINTENANCE .................................................................................. 38

.......................................................................................

22

6.1 Maintenance carried out by the user ............................................................ 38

6.2 Maintenance carried out by specialised personnel ...................................... 38

6.3 Troubleshooting ........................................................................................... 39

6.4 Tightening torque ......................................................................................... 40

7

8

DISPOSAL .......................................................................................... 41

CE DECLARATION OF CONFORMITY ............................................. 42

2

1 INTRODUCTION

Before using the PENTASEM sower, we recommend that you read this

manual carefully and that you scrupulously comply with the instructions. As such,

you will avoid putting yourself into a dangerous situation, you will reduce putting into

service time and the risk of undesirable incidents outside the warranty period.

Always keep this manual handy

Your CARRÉ reseller will provide you with advice so that you can obtain full

satisfaction from your machine.

Comply with the safety instructions

Warning symbol

CARRÉ cannot be held liable for any damage and operating incidents occurring

subsequent to usage that does comply with the instructions in this manual.

Warranty: Please fill out the warranty certificate enclosed with the machine

and return it as soon as possible to the indicated address in order to activate

your warranty.

2 SPECIFICATIONS (a)

Description of the PENTASEM

PENTASEM is used for planting a crop in simplified sowing at high speed.

Available in 5 widths, 3m50 as fixed, 4m00, 4m80, 5m60 and 6m00 as foldable.

Planting is accomplished with 45x12 right tines with seed diffuser.

Power required:

From 100 to 150 hp according to the widths.

Operating speed:

Up to 12 Km/h, varies according to method of use.

Static airborne noise:

None of the equipment produces when empty an equivalent A-weighted sound

pressure level exceeding 100 dB at a distance of 1m.

3

Technical characteristics (a):

Number of

Working

Transport

Power

Code

Weight

Code

Weight

Code

Weight

Options (b) (c)

Code

Weight

PENTASEM

Code PTS 3500 PTS 4000 PTS 4800 PTS 5600 PTS 6000

Weight

rows

Interline

width (m)

width (m)

required (hp)

Planting

1045 1670 1735 1790 1840

Specific characteristics

28 32 32 40 40

125 mm 125 mm 150 mm 140 mm 150 mm

3m50 4m00 4m80 5m60 6m00

3m50 3m20 / 3 parts 3m20 / 3 parts 3m20 / 3 parts 3m20 / 3 parts

100 120 150 150 150

45x12 right tines with seed diffuser

FRONT EQUIPMENT

FB – FLEXIBOARD front blade

FB35 00 FB40 00 FB48 00 FB56 00 FB60 00

145 184 198 206 210

REAR EQUIPMENT

HPS – Comb harrow Ø10 on one row with BF link

HPS35 00 HPS40 00 HPS48 00 HPS56 00 HPS60 00

57 96 100 105 117

BF – Rubber tyre wheel L=50 mm

BF35 00 BF40 00 BF48 00 BF56 00 BF60 00

140 202 238 246 250

- Hydraulic blower unit connected to tractor oil intake (for tractor

without flow adjustment)

- 300 litre hopper side board

- Distribution head cover 40/20

- Distribution head cover 32/16

- Descent seal cap

- Single disc pre-emergence marker

- Dual disc pre-emergence marker

- Electric track marker valve

- Set of 4 stands

-

Pair of fixed pneumatic depth gauge wheels on extensions

11916

11911

VN90048027

VN90048025

119005

11955

11954

VN90050044

11702

11925

18

17

5.3

2.8

30

60

0.5

30

130

(a) The technical characteristics, dimensions and weights are provided for the purposes of

information; these may change.

(b) Incomplete list.

(c) Regardless of the width of the device.

-

4

3 SAFETY INSTRUCTIONS

dangerous area.

dangerous area.

belt protective

cover in place

footstep while

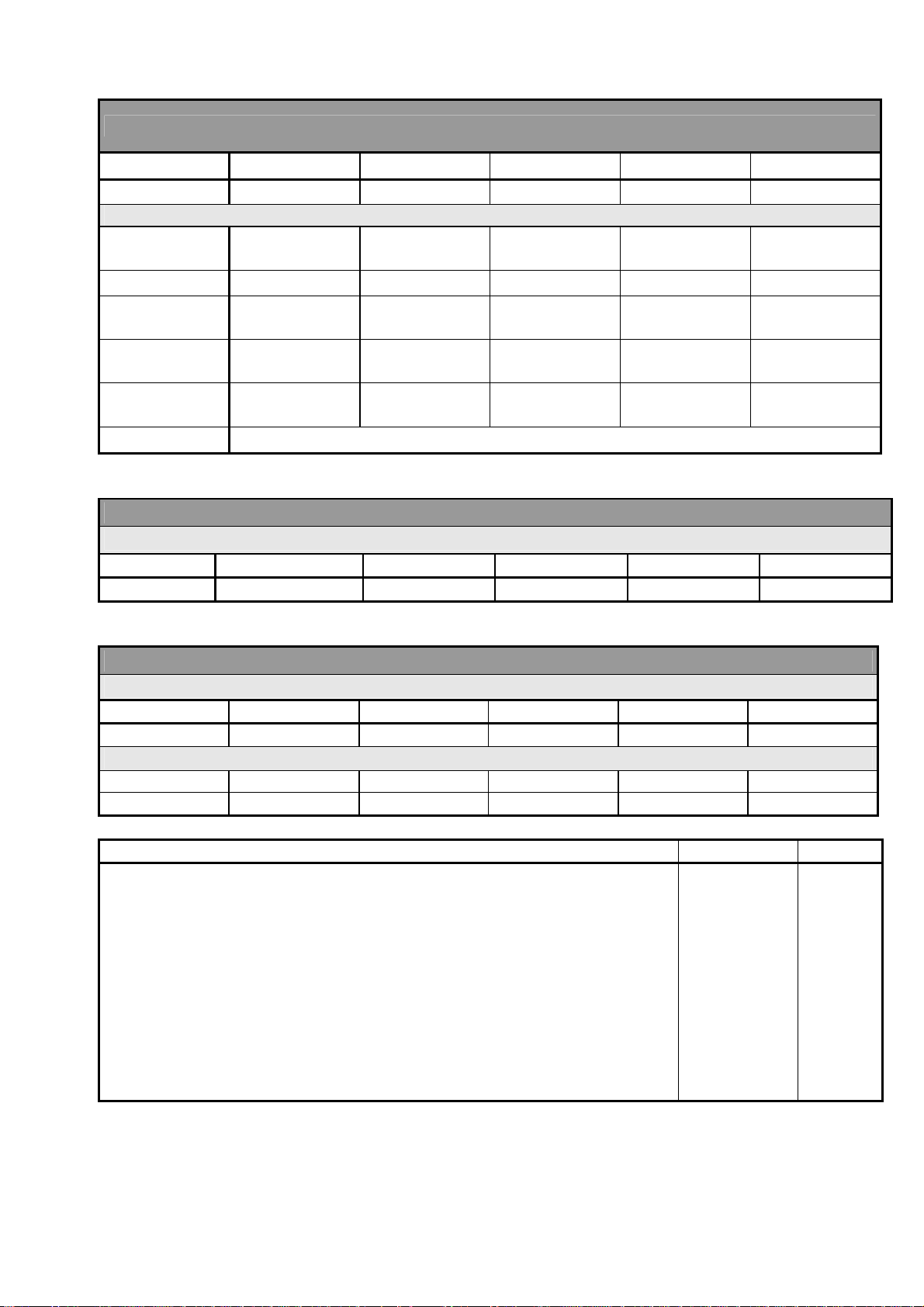

3.1 Safety symbols

On the machine

Make sure that the warnings and pictograms remain clean and visible at all times. If they

become deteriorated, ask your manufacturer (or distributor) for new stickers.

If repair work is done, ensure that the spare parts have the same stickers as the original

parts.

Read the maintenance

booklet and the safety

instructions before

turning on the

In order to prevent leaks

in the hydraulic circuit,

follow the instructions in

the maintenance booklet

machine.

Before any

intervention, turn off

the tractor engine and

remove the key.

Never place

hands in the

danger areas

when the parts

are in motion,

there is a risk of

pinching.

Have everyone

leave the

There is a risk

of crushing

Have everyone

leave the

There is a risk

of crushing

²

Keep the

sower's drive

in order to

protect the

hands

Do not step

on the

the machine

is moving

Electrical

installation

Triangle indicating DANGER each time that the risk of an accident is high or when

the equipment may be damaged.

This arrow indicates areas where advice is provided on facilitating the work.

5

3.2 Usage as intended

PENTASEM is designed to be used for planting a crop in simplified sowing at high speed.

Any use other than the latter shall be considered as non-compliant with the intended use

and shall release the manufacturer from any liability in the event of prejudice; the user

alone shall incur the risks that result from such use.

Comply with all of the installation, operating, adjusting, maintenance and repair instructions

contained in this notice.

Use only spare parts and accessories that comply with the manufacturer's

recommendations.

The use, maintenance and overhauling of the PENTASEM must be entrusted only to

people who are familiar with and who are informed of the possible dangers.

Do not modify or have your machine and its accessories modified by another person

(mechanical, electrical, hydraulic, pneumatic characteristics), without first obtaining

approval from your manufacturer.

Not complying with these rules can make your machine dangerous. In the event of damage

or injury, the manufacturer shall be released from any liability.

Moreover, the special instructions concerning the prevention of accidents must be complied

with, as well as the general rules in terms of technical safety, occupational medicine and

legislation concerning the use of roads.

The manufacturer declines all liability in the event of prejudice resulting from a modification

made to the PENTASEM without its approval.

3.3 General safety instructions

Only use the PENTASEM if all of the protective and safety devices are installed and are

operating correctly.

Check that the screws are tight on a regular basis and tighten them if necessary, especially

the clamping screws for the tines and the bearings on the equipment.

In the event of operating incidents, stop the machine immediately, then repair the

breakdown or have it repaired immediately.

3.4 Safety in the public domain

Before driving on a road, you must become familiar with the operation of all of the controls.

Comply with the rules of the road when you move into the public domain (roads, paths and

squares). Make sure beforehand that the condition of the PENTASEM is compliant with the

regulations set forth in the rules of the road.

Comply with authorised transport width limitations.

Adjust your speed and driving style to the land, roads and paths. Remain vigilant and

cautious!

At all times and in particular on sloped and broken land, operate the machine at slow

speed, especially when turning and do not change direction abruptly.

Do not brake or start abruptly while going up or down a slope.

Driving is influenced by the machine coupled to the tractor. Comply with the axle load limit

and the gross weight so that steering and braking precision are maintained and, when

turning, give particular attention to the overhang and the inertia mass of the PENTASEM.

Do not transport anyone on the PENTASEM.

6

3.5 Accident prevention

In addition to the recommendation in this manual, follow the instructions of the farming

mutual insurance companies.

During the hitching of the PENTASEM to the tractor:

- Ensure that the PENTASEM is resting on stable ground.

- Never remain between the tractor and the PENTASEM; there is a risk of an accident.

- Operate the 3-point hydraulic lift system slowly and with caution.

- Check that the 3-point hitching categories of the tractor and of the PENTASEM

correspond.

During use:

- Before turning on the machine, ensure that no one is within the vicinity of the machine.

Ensure that there is sufficient visibility.

- Do not transport anyone on the hoeing machine during work.

- None of the protective devices prescribed and delivered with the machine are to be

removed.

- Make sure that no one is in the pivoting area of the extensions that can be folded, the

markers and any pre-emergence markers.

- While operating and when in motion, the PENTASEM causes the projection of soil and

stones. Ensure that no one is within the vicinity of the machine.

During the operation of the power take-off of the sower:

- Comply with the instructions in the U-joint transmission manual.

- Use only U-joint transmission with their regulatory protectors (the tube and cone must

be mounted).

- Mount the U-joint transmission shaft only if the motor of the tractor is stopped and if the

power take-off is disconnected.

- Comply with the overlapping prescribed for the sliding shafts in transport and working

position.

- The U-joint transmission protectors must be immobilised in rotation.

- Do not turn on the power take-off until there is no one within in the vicinity of the sower.

- The rotating speed of the tractor's power take-off must correspond to the authorised

rotating speed of the sower.

- WARNING: Due to its inertia, the power take-off continues to rotate after it has been

disconnected. Stay away from the device during this lapse of time and do not intervene

on the latter until it has come to a complete stop.

- Put the protective sleeve back on tractor's power take-off, as soon as the U-joint shaft is

no longer connected to it.

3.6 Maintenance and repair

- Comply with the time frames that are recommended or indicated in this manual when

carrying out scheduled inspections and verifications.

- Before beginning any maintenance or repair work, make sure that the hydraulic

installation is not under pressure, and stop the tractor's power take-off and motor.

Uncouple the PENTASEM from the tractor.

- Carry out maintenance or repair work only if the PENTASEM is resting flat on stable

ground and where there is no risk of tipping.

- Do not carry out any maintenance work on a raised device without having installed the

appropriate supports for safety reasons.

7

- When assembling and disassembling, use appropriate means that do not compromise

your safety.

- Take advantage when cleaning the PENTASEM at the end of each crop year at least,

to check that the hydraulic lines are properly sealed, the connections are tight and that

there are no defects caused by friction. Replace anything that is deteriorated

immediately.

- When replacing wearing parts, use suitable tools and wear gloves.

- Spare parts must meet the manufacturer's technical requirements, which is always the

case with original parts.

- Before carrying out any electrical welding work on the PENTASEM, when it is hitched to

the tractor, disconnect the battery cables.

4 OPERATOR CONTROLS

With regards to hitching, and for safety reasons, the original pins must be used. In

order to prevent loss, the pins as well as their lynch pins are connected to the PENTASEM

by a chain.

5 ASSEMBLY AND PUTTING INTO SERVICE

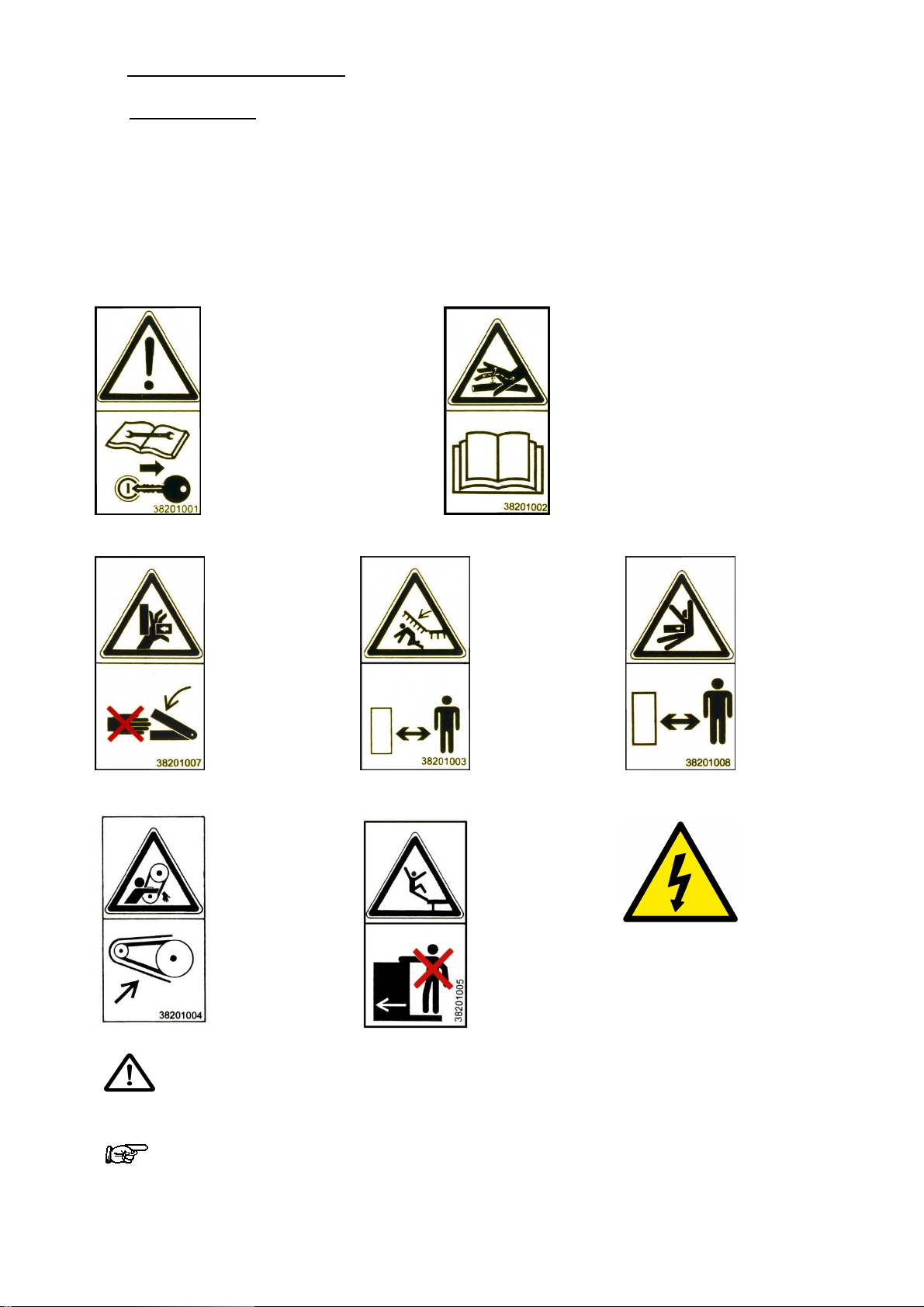

5.1 Link on the tractor

The PENTASEM is equipped with a 3-point pin coupling between yoke No. 3 and

reversible pin diameter No. 2 and No. 3, in accordance with standard NF U 14032.

WARNING: Never remain between the tractor and the PENTASEM; there is a risk

of an accident.

The "Tractor + PENTASEM" unit has a substantial mass. In order to allow for

sufficient static stability, the load of the front axle of the tractor must not be less

than 20% of the empty weight of the tractor. For this, the most practical method consists in

weight the front of the tractor on a scale and comparing the result with the recommended

value in the tractor's user manual. Add weight to the front of the tractor if necessary.

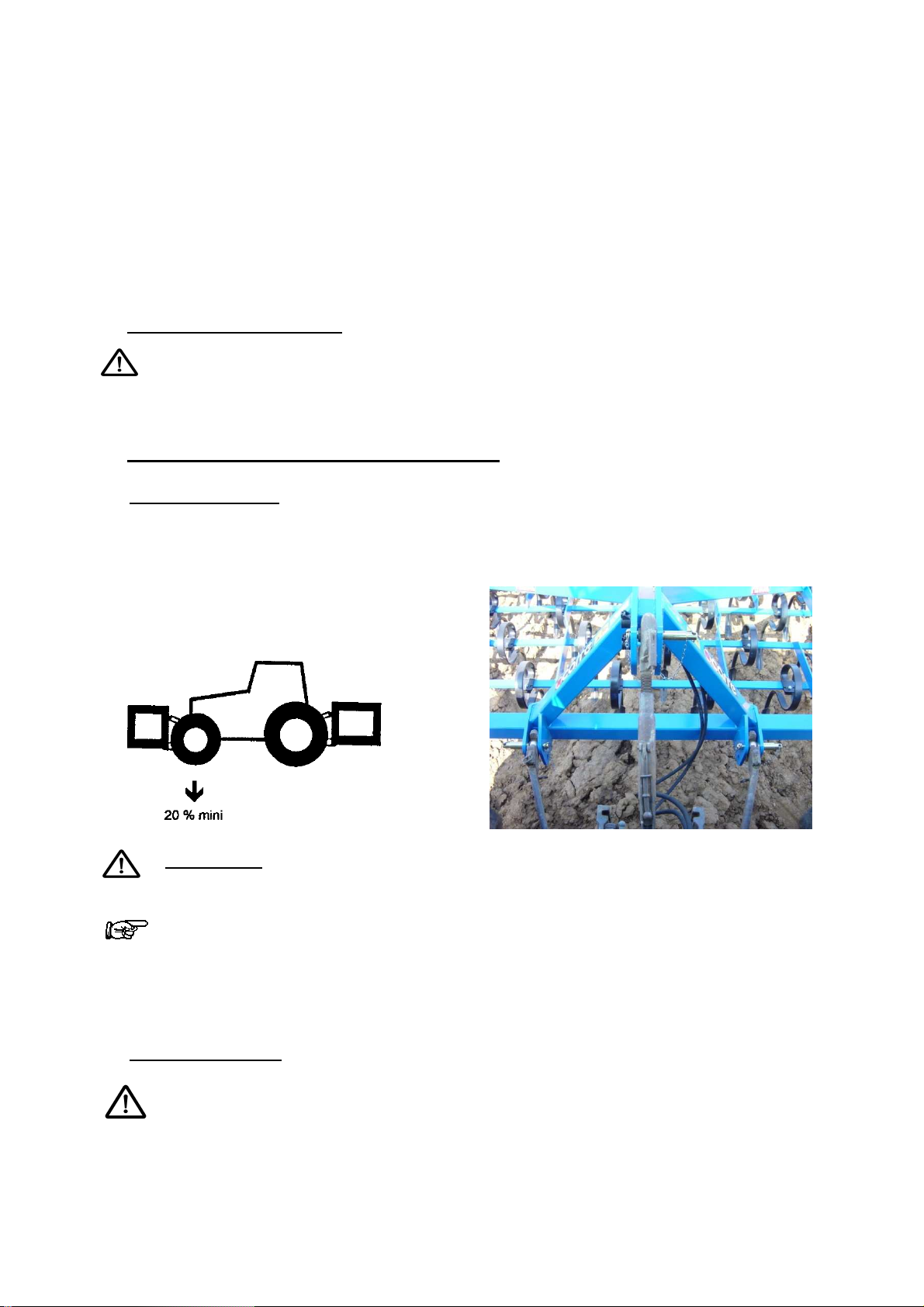

5.2 Mounting the tines

Planting seeds is accomplished with a 45x12 right tine with diffuser.

The tine pitch depends on the PENTASEM model (125 mm pitch for the 3m50 and

4m00 model; 140 mm pitch for the 5m60 et 150 mm pitch for the 4m80 and the 6m00).

8

Adjust the step screw in contact with

Retract the step screw to the maximum for

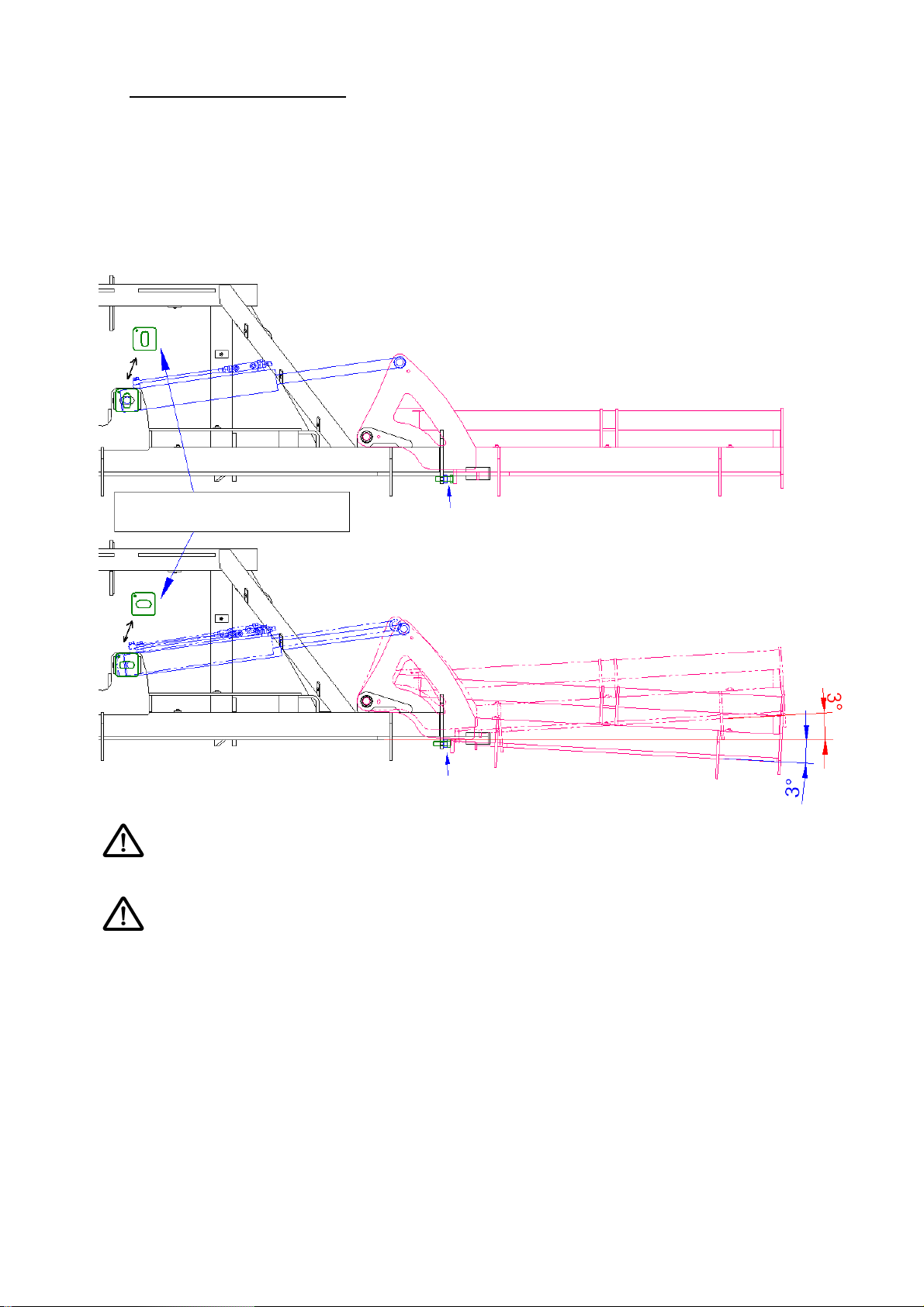

5.3 Positioning the extensions

The extensions can be in a fixed position or in a floating position. The floating position is

used to follow the differences in level of the ground in order to obtain even sowing in liaison

with the optional wheels on the extensions.

The PENTASEM must be placed on flat ground in unfolded position when switching from

the fixed position to the floating position. Remove the pin from the swivel cylinder of the

extensions and direct the shims (see drawing below).

Positioning the shims

the extension in horizontal position

the oscillation of the extension

Give attention to the adjusting of the lower stop according to the desired position of

the extensions.

Never switch from the floating or fixed position with the machine folded

9

setting

setting

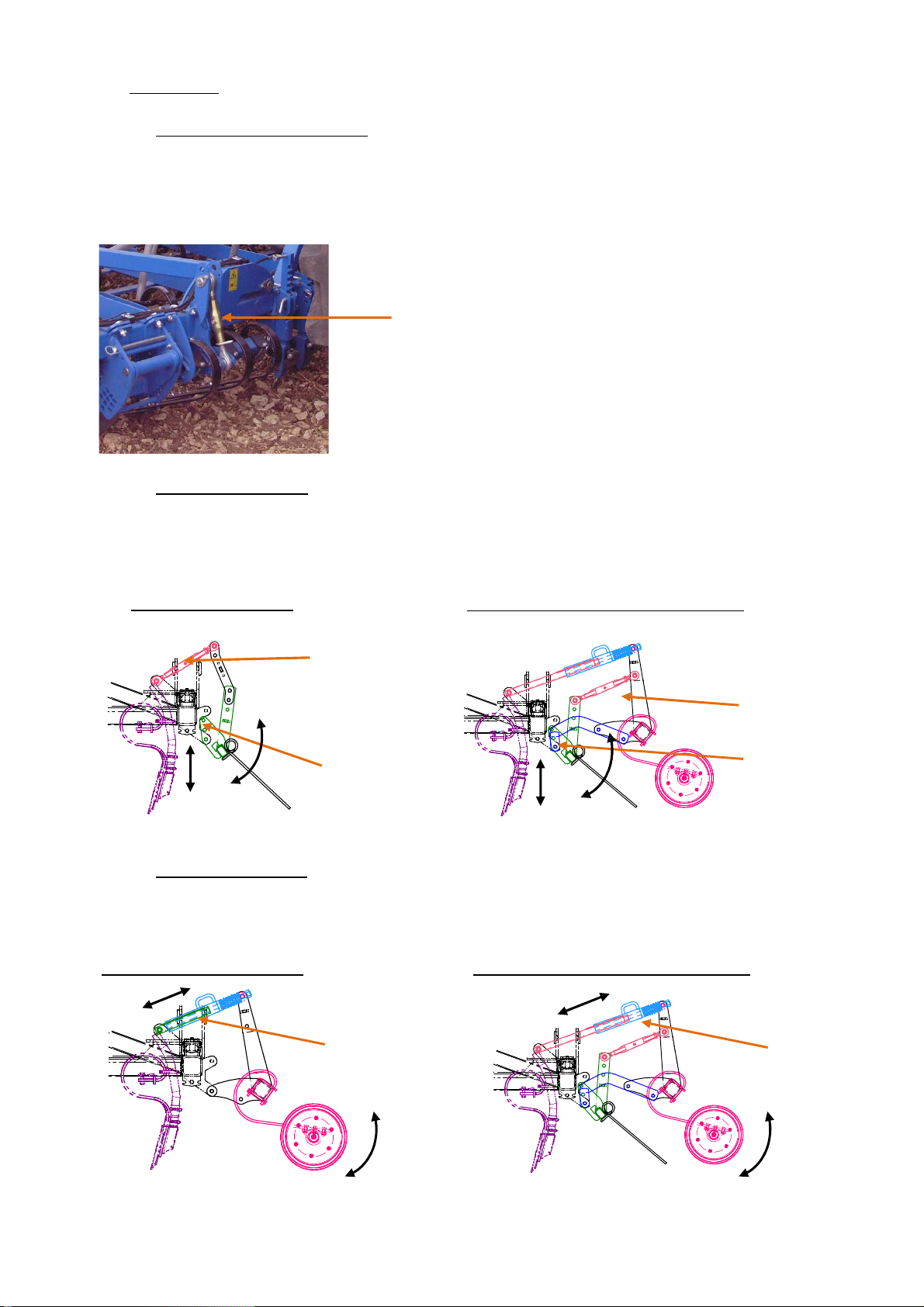

5.4 Equipment

5.4.1 FLEXIBOARD front blade

The front blade is mounted on the front beam of the PENTASEM. It is provided with several

spring blades, and participates in levelling the ground before the sowing tine passes.

Adjustments are made by the push bars and can be turned off.

Blade adjustment

5.4.2 Comb harrow Ø10

The comb harrow is mounted behind the sowing tines, and allows the sowing to be finished

by closing up the furrows evenly.

It is used alone or along with the rubber tyre wheels.

Comb harrow alone

Comb harrow + rubber tyre wheel

Harrow

inclination

Harrow

inclination

Harrow height

setting

Harrow height

setting

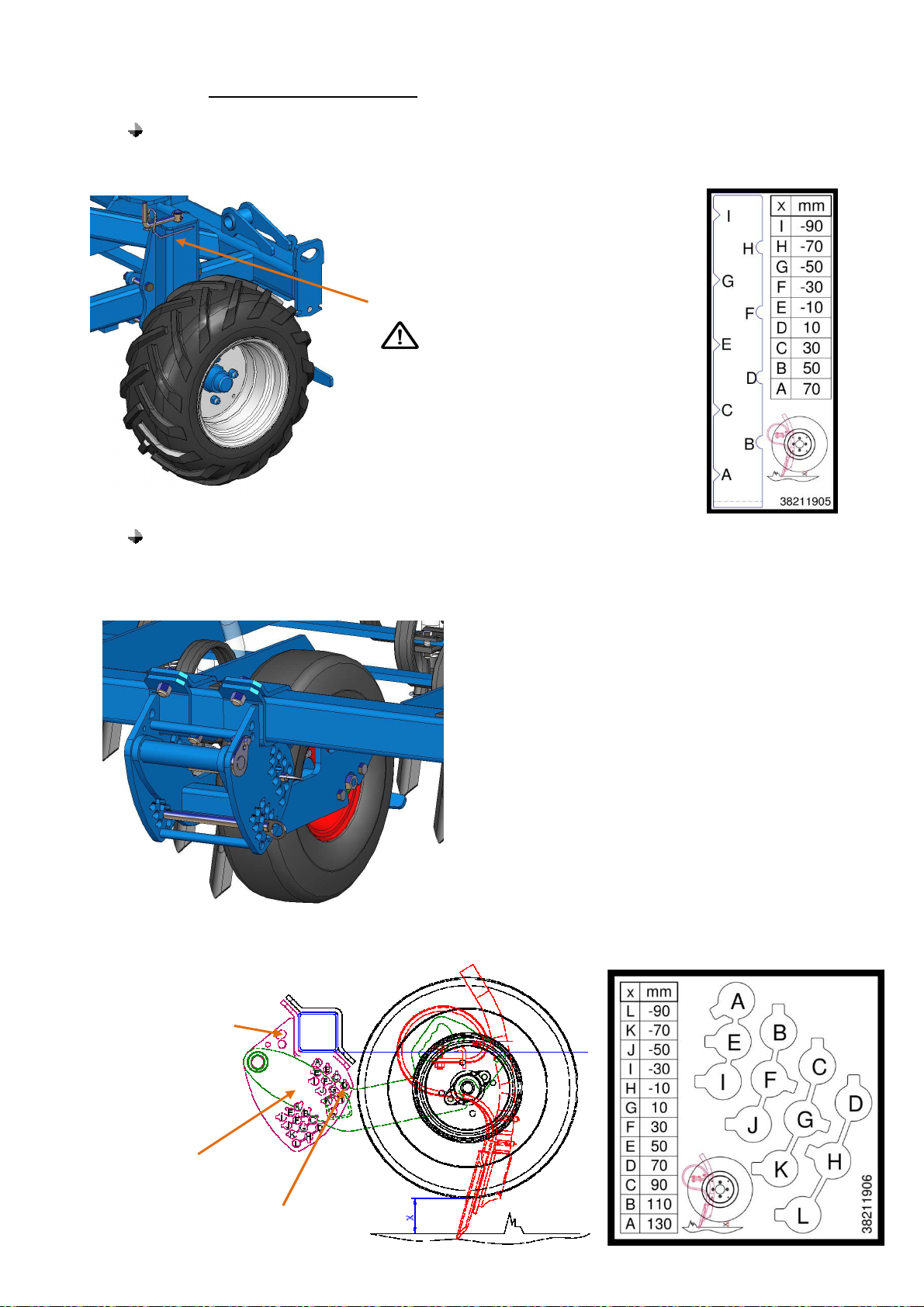

5.4.3 Rubber tyre wheel

The rubber tyre wheels are mounted behind the sowing tines. They allow for regular and

individual consolidation of the sowing coulter.

Depth

adjustment

Comb harrow + rubber tyre wheel Rubber tyre wheel alone

Depth

adjustment

10

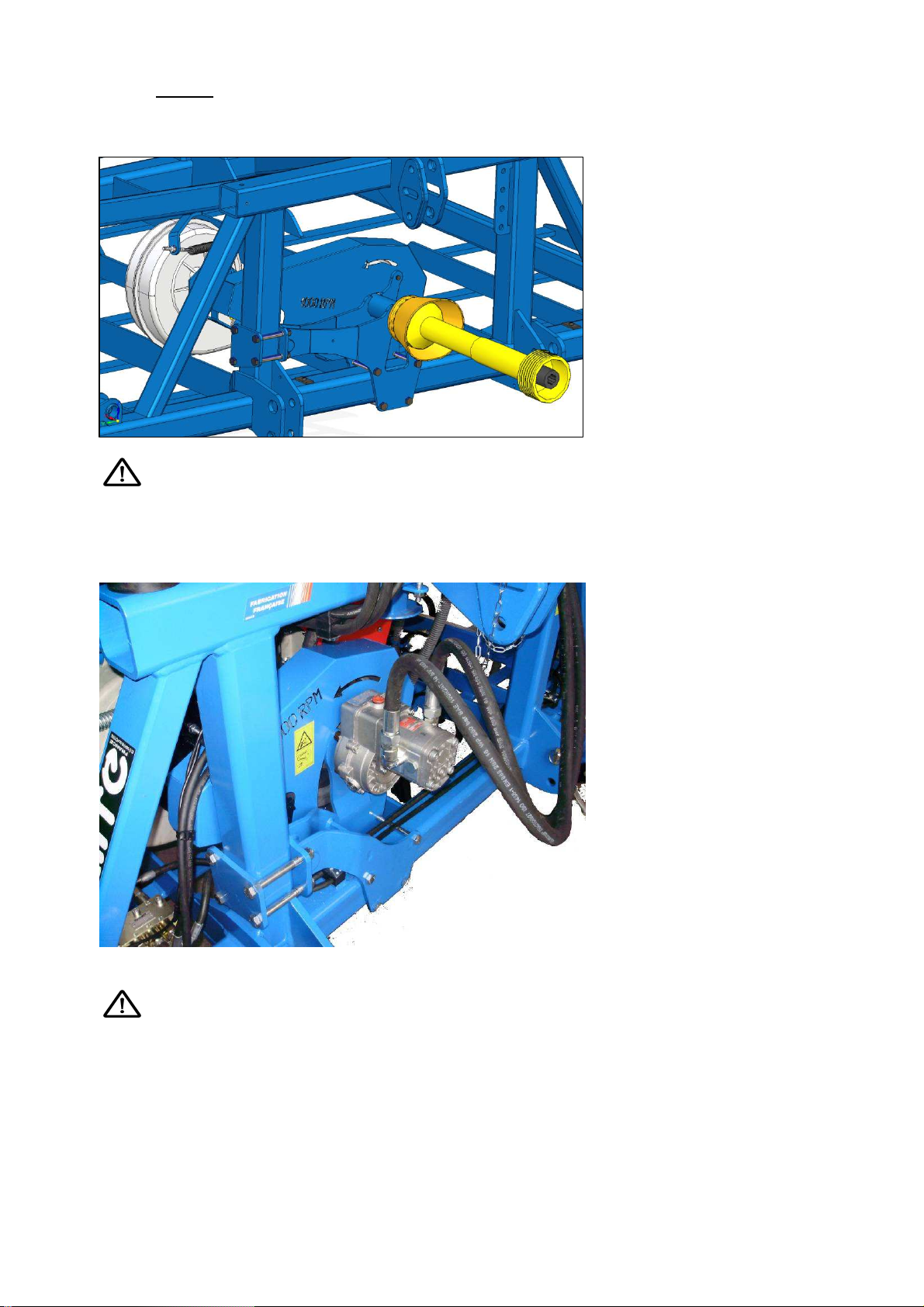

5.4.4 Blower

Mechanical blower

Required nominal speed is 1000 rpm PTO which is a blower rotation of 4300 rpm.

At the end of the plot, reduce the PTO to a minimum in order to avoid a power loss

in blower speed.

Hydraulic blower

Hydraulic supply to be connected as single-acting of the tractor.

Connect the return to the free return of the tractor, with pressure less than 5 bars,

otherwise the shaft seal will be destroyed.

Oil flow: 40l/min which is a blower rotation of 4300 rpm.

11

Adjusting screw

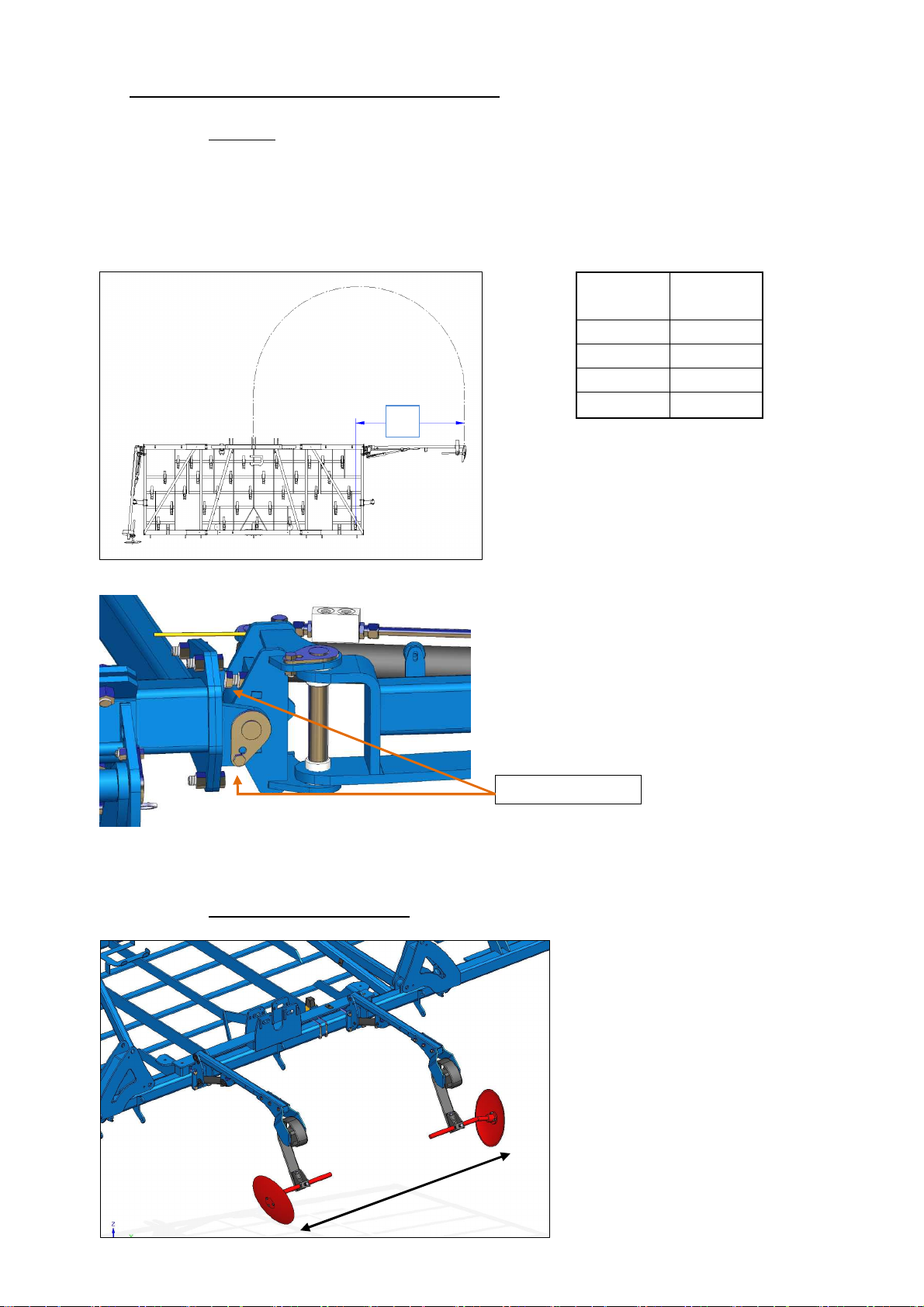

5.5 Adjusting and using the sower before sowing

5.5.1 Markers

Adjusting the markers

Disc markers can be adjusted in the middle of the tractor. They mark a line on the

ground to follow during the return. The middle of the tractor as such passes along

this line on the ground

X

Adjusting marker inclination

The inclination is adjusted using 2 adjusting

screws. It can be placed in a fixed position

or in a floating position.

Sower

width

4m00 206.2

4m80 247.5

5m60 287

6m00 307.5

X (cm)

The marker disc is adjusted on the ground;

measure the distance X between the

middle of the last tine and the middle of

the disc (see the table according to the

width of the sower).

The marker sequence is done at the end of the field using the control of a single dualaction distributor.

5.5.2 Pre-emergence markers

The single- or dual-disc pre-

emergence markers are lowered

simultaneously with the track

marker valve control in order to

create lines for the treatment

machines.

They are activated at the same

time as the track marker valves of

the sprayer track.

12

5.5.3 Sowing depth adjustment

Depth gauge wheel on fixed chassis.

The depth adjustment wheels allow the working depth to be controlled reliably.

Adjusting the depth is carried out

using the crank screw.

The wheels must be set

identically on each side of the

sower.

Depth gauge wheel on extensions

The depth gauge wheels on the extensions allows the working depth to be controlled when

the extensions are in floating position, in order to follow the differences in level of the land.

Depth adjustment is carried out using 2 pins

Position of the pin

if work as

floating

Lower

stop

Upper

stop

13

5.5.4 Flow test

1

2

3

4

5

6 9

8

7

Determining the setting value

For a correct adjustment, it must be determined whether you are dealing with a common

seed or fine seeds.

-

Common seed: between 4 and 10 mm

- Fine seed: between 1.5 and 4 mm

Following the handling instructions in the order listed and the adjustment table in order

to control the flow. Use the microdosage for sowing fine seeds and small quantities.

Distribution + blower details

1- Case

2- Graduation sector

3- Inverter

4- Drain trapdoor

5- Threaded rod

6- Microdosage sprocket

7- Gear reducer

8- Elbow

9- Spring clamp for the blower air adjustment flap

Table of settings

The values shown in this table of settings are provided solely for the purposes of

information, as the specific weight and the calibre of the seed are often very different. The

correct value is determined by carrying out a flow inspection at a fixed station. The volume

determined as such will always correspond the the seed flow (for the same seed).

14

(seed value between 4 and 10mm)

*:

Fine seed

(seed value between 1.5 and 4mm

)

Common seed

TYPES OF SEED

In case of a low flow (for example: cell width < 25mm) more regular sowing may possibly be obtained by activating micro dosage even in a normal sowing range

15

During the fixed station flow inspection, proceed as follows:

B

1- Do you want to perform a flow control for common seed or with fine seed?

2- Types of seed

a-

For common seed, place the inverter C on the dispenser and the spring clamp of the

blower adjustment flap to open position [ 1 ] (in the axis of the pipe) and place

sprocket A in sprocket B.

2

A

b- Adjust smaller doses only if the dispenser is running or if the hopper is empty.

Otherwise, you run the risk of deteriorating the dispenser by pressing on the seed.

For fine seed, turn the threaded rod until the value 0 is shown in the graduated

sector. Then turn the inverter C to the right, until it snaps into the groove of the hex

shaft.

Also position the spring clamp of the blower air adjustment flap to position [ 2 ] and

take out sprocket A so that it drives sprocket C.

2

C

A

B

C

3- Use the settings table to locate the value that corresponds to the quantity to sow.

4- The graduated sector indicates values from 0 to 110 (only up to 25 for small seeds).

Turn the threaded rod until the value of the setting appears against the notch of the

case.

1

16

5- Close the drain trapdoor

6- Pour the seed into the hopper

7- Remove the elbow located under the injector after loosening the wing nut

8- Place the basin (fixed under the hopper) under the opening of the injector to collect

the seed from the flow test.

9- Perform the weighings (see procedure on page 30).

10- Then attach the elbow between the injector and the blower.

The flow inspection test is complete.

Flow test with microdosage.

With microdosage, it is possible to sow small seeds and very small quantities per hectare.

The advantage with microdosing compared to a normal rotating speed for small seeds

resides in the fact that the opening of the cells is twice as large for the same flow. This

results is better self-cleaning of the cells.

Pull the red sprocket towards the exterior until it snaps in. The microdosage is connected.

The value of the setting must be read from the table for small seeds.

A cell cleaning brush, for sowing small seeds, is fixed to the inside of the case of the

dispenser. This prevents the grooves from becoming clogged when treated seed is used,

for example. It is located under the steel sheet that covers the injector behind the

sprockets. Check that it is in good condition before beginning to sow.

For common seed, remove the brush

17

Sower

Sprayer (M)

Cleaning brush

5.5.5 Track marker adjustment

Passage marks can be marked out automatically with the device that electronically shuts

off ploughshare power.

In order to mark out the lines, ploughshare power must be cut off by closing the

corresponding electric valves. The track of the tractor that will be used later for spreading

fertiliser or for spraying is determinant in choosing the ploughshares that have to be closed.

The power must be cut off for several ploughshares located next to each other (2 on the

right and 2 on the left as standard, with a possibility of 3 on the right and 3 on the left for

wider wheels).

A rate determine the moment when the track marking operation is carried out.

Working width of the treatment machine

--------------------------------------------------------------- = Track marking rate

Sower working width

Example: With a 4m80 sower and a sprayer with a working width of 24m:

24

---- = 5 = Track marking rate

4.8

The following table shows the most common combinations for marking out lines.

8 9 12 15 18 20 21 24 27 28 30 32 33 36 38 40 42

4m00 2 3 5 6 7 8 9 10

4m80 5

5m60 5

6m00 2 3 4 5 6 8

The even rates are for tracking marking with two passes. Lines for passes that are marked

out in a single pass are however more accurate than in they are marked out in two passes.

For this reason, lines can also be marked out in a single pass by using the even rates.

18

In this case, sowing must be carried out during the first pass with only half the working

width of the sower, or distribution must be disconnected for the corresponding portion of

the sprayer or fertiliser distributor.

Fertilisation or

treatment

machine track

Even rate

Odd rate

The odd rates (i.e. 3, 5, 7, etc.) mark out lines in a single pass.

Before using for the first time, check that the lines are marked out with a spacing

that complies with what you are looking for! The sowing tines in the line must not

leave seed.

5.5.6 Sower control

Before leaving the farm to go to the place of use, you are advised to check the following:

• The sower is compliant with the instructions concerning transport on roads.

• The hitching of the sower to the tractor.

• The setting of the track marking (rate)

• The opening and closing of the electric valves by the track marking device.

• The track marking and the electronic control of the sower when changing tractors.

• All of the sowing tines sow. (Turn on the blower and allow the distribution to operate,

by passing in front of the radar, seed should then be on the ground under each tine).

• The elbow is positioned, as instructed, under the injector.

• The beige inverter on the dispenser and the air flap on the blower are in the desired

position.

• The divider cover in the distribution head, all the rows or 1 out of 2.

• The closing of the drain trapdoor.

• The filtering sieve in the hopper.

19

5.6 Using the sower during work

Adapt the sower to the work in the field.

In the field, the sower must be switched from the transport position to the working position

in order to operate.

Before using the PENTASEM, follow these instructions:

1. Couple the PENTASEM to the tractor.

2. Adjust the sower's plumb line via the angle indicator / hopper side

3. Connect the sower's hydraulic couplers to that of the tractor

4. Connect the electronic case to the tractor's 12-volt power supply

5. Connect the lighting to the tractor

6. Install the mechanical drive for the PTO 1000 rpm or connect the hydraulic unit (free

return)

7. Adjust the radar stop sensor to the 3rd point of the tractor

8.

Position the blower flap to microdosage (fine seed: colza, etc.) or normal dosage

(common seed: wheat, etc.)

9. Position the dispenser inverter to micro dosage or normal dosage

10. Adjust the sower value according to the table of settings

11. Adjust the gearing to micro dosage or normal dosage

12. Install the cleaning brush for fine seed or remove it for common seed

13. Install the simple cover or divider / distribution head

14. Adjust the hopper level sensor

15. Fill the seed hopper (make sure the drain trapdoor is closed)

16. Carry out a flow test at a fixed station, and refer to the instructions for use for the

RDS "Artemis" case

17. Adjust the sowing depth on the central portion with the depth gauge wheels

(pressure = 2.25 bars)

18. Install the fixed or floating position on the extensions

19. Adjust the sowing depth on the extensions with the depth gauge wheels (pressure =

7 bars)

20. Adjust the working depth of the marker erasers

21. Adjust the depth and the inclination of the comb harrow

22. Adjust the depth of the rubber tyre wheel (working free spring)

23. Adjust the depth and the inclination of the "flexiboard" levelling blade

Once all of these operations have been verified or carried out, turn on the sower's

blower to 1000 rpm, with the unit unfolded and set on the ground in the plot:

Make sure that after a brief manual pass in front of the radar, all of the descents are

distributing seed (except for alternating row sowing)

Make sure that the track marker cycle is operating correctly

Sow over a few meters to check sowing depth then adjust the settings more finely if

necessary.

20

Sowing control

Sowing perfection primarily depends on how it is controlled. Sowing must be checked after

having progressed a few meters and also from time to time on large plots.

• Are the sowing depth and the seed covering sufficient (compare the sowing tine

rows)?

• Are the tines sowing a volume that is identical to that of the tests (especially with

small seed)?

• Is the seed flowing perfectly through the electric valves?

• Are the tines clogged?

• Are the tines hindered by plant debris?

• Are the markers correctly adjusted?

• Are the electric valves operating perfectly?

• Are the electric valves correctly adjusted at the distribution head?

• Does the speed of the power take-off or of the hydraulic blower remain constant

during sowing?

• Are there any bridges formed in the hopper (especially with bearded seed)?

If you interrupt working because of a clog, the machine must be raised and backed up

about one meter before resuming in order to avoid missing areas.

How to make a U-turn with the sower

Just before reaching the end of the field or before initiating a U-turn, reduce engine speed

and raise the sower while moving. After completing the U-turn, set the sower back down

and resume service, at the required engine speed and power take-off, at about one meter

before the line starting where you want to sow. A short amount of time is needed for the

seed to be carried from the dispenser to the sowing tines, and as such the pre-start

function must be used (§5.8 - B6).

5.7 Usage after work

5.7.1 Emptying the hopper and the dispenser

Place the sower on firm and very flat land.

After sowing, the hopper and the dispenser must be completely emptied.

If the hopper is almost empty, place a container under the drain trapdoor and open the

latter.

Press the white push-button, which will remove the remaining seed. Where applicable, any

clogging and deposits must be removed with a brush. Leave the dispenser open. As such,

you will prevent rodents from causing any damage.

5.7.2 Sower storage

The sower must be placed horizontally on very firm ground. The PENTASEM must be in

folded position. Raise the marker erasers where applicable. The hydraulic and electric

connectors and the U-joint transmission shaft if there is one must then be disassembled.

21

5.8 USING THE CASE

A. GENERAL PRESENTATION ............................................................................ 23

A.1 The Artémis system .................................................................................... 23

A.2 Main functions ........................................................................................... 24

A.3 Data Regulation and Recording Modes ................................................... 25

Automatic Regulation Mode ......................................................................... 25

Regulation Mode with Dose Modulation....................................................... 25

A.4 Psi console buttons ................................................................................... 25

B. OPERATION ...................................................................................................... 25

B.1 Status icons ............................................................................................... 26

B.2 'MAIN' screen ............................................................................................. 26

B.2.1 Forward speed display and alarm functions ............................................ 27

B.2.2 Marking Functions/Statuses .................................................................... 28

B.2.3 Manually increasing the pass number ..................................................... 28

B.2.4 Freezing the pass number ....................................................................... 28

B.3 'RATE' sowing dose screen ...................................................................... 28

2.3.1 Adjusting / forcing the target dose ........................................................... 29

B.4 'INFO' screen .............................................................................................. 30

B.5 Marking

B.6 Pre-start function ....................................................................................... 31

B.7 Electric motor – manual forcing/sowing a half-width ............................. 32

B.8 Product CALIBRATION .............................................................................. 32

2.8.1 Initial CALIBRATION of the product ........................................................ 32

2.8.2 ‘CALIBRATION NUDGE’ – Adjusts the calibration factor ........................ 34

B.9 Setting the turbine speed and hopper empty alarms ............................. 35

B.10 Simulating forward speed ......................................................................... 35

B.11 Selecting the units / ‘Pitch’ for the % dose .............................................. 36

C. RECORDING DATA AND MODULATING DOSES ........................................... 36

22

(Radar)

Track marker

A. GENERAL PRESENTATION

A.1

The Artémis system

Figure 1

Manual

Calibration

Button

power

Motor

‘MCM’

A/N Module

(Motor)

Marking

Switch

PSi Console Electrical

Distribution

sensor

Turbine

speed

sensor

Speed

Sensor

valve

Hopper

empty

sensor

Marker

sensors

‘HBM’

A/N Module

23

Figure 1 shows the various components of an Artémis installation with single or

dual motors. All sowing configurations are possible (one or two motors with one or

two dispensers) and the Psi Artémis console can be configured as desired.

PRODUCT

SEED

SEED

+

FERTILISER

CONSOLE SETTING

DISPENSER/MOTOR

CONFIGURATION

SINGLE MOTOR/

CONSOLE

SETTING

DISPENSER

SINGLE MOTOR/

DUAL DISPENSER

2 MOTORS /

SINGLE DISPENSER

SINGLE MOTOR/

DISPENSER (SEED)

+

SINGLE MOTOR/

DISPENSER

(FERTILISER)

SINGLE MOTOR/

DUAL DISPENSER

(SEED)

+

SINGLE MOTOR/

DUAL DISPENSER

(FERTILISER)

A few of the screen pages are slightly different, according to the sower

configuration selected. Look for the symbols above next to the text.

A.2 Main functions

Artémis is designed to allow for automatic adjustment at a variable dose for any

sower using an Accord dispenser. At any time, you can manually modulate the

preset dose in order to adapt it to areas in the plot.

The basic functions are:

• Variable dose regulation

• Marking

• Forward speed alarms

• Hopper empty alarm

• Turbine speed alarm

• Information on totals (surface area, quantities)

24

The console has a special mode in order to easily CALIBRATE the dispenser.

In this CALIBRATION mode, each dispenser is controlled by the "manual calibration

button" to distribute the product (figure 1).

During normal operation, the system is automatically started and stopped by a

magnetic sensor when the sower is raised and lowered for work. According to the

type of installation, this sensor is actuated either by the movement of a wheel or by

the markers.

A.3 Data Regulation and Recording Modes

Automatic Regulation Mode

The sowing dose is automatically adjusted according to the forward speed, in

order to ensure that the current sowing dose constantly corresponds to the preset

target dose. The sowing dose can be increased or decreased manually in relation

to the preset target dose.

Parcel plan data ("work summary") can be recorded and stored in the console's

internal memory. Up to 75 summaries can be stored. With a GPS receiver and an

SD memory card, you can also record the vehicle's travel and the application data

in a "Dynamic record" file on the SD card. The work summary is also created in this

file.

Regulation Mode with Dose Modulation

This allows the system to be controlled by preset cards (prepared using highprecision farming software and the position provided by the DGPS). In order to

carry out automatic dose modulation, the PS 8000i requires a DGPS receiver and an

SD memory card in order to load the preset plans generated with high-precision

farming software.

A work record file is automatically created in the card for recording the data

which confirms the current application. The work summary is also created in this

file, and it can be opened in high-precision farming software.

A.4 Psi console buttons

All of the console functions are available through 9 buttons located at the edge

of the LCD screen.

Figure 1

Menu Buttons

On-Off Button

Sub-menu Buttons

Confirm

Delete

SD card reader

25

The 4 menu buttons located to the right of the screen (figure 1) display the

Forward speed

(Section 2.2.1)

Target

(Section 2.3)

Dispenser status

(Section

2.9)

S

urface

cut

DGPS

Signal

common screen pages (those that are used during normal operation). There are 3

basic screens: MAIN, RATE (dose) and INFO for the normal operating functions,

and a SETTINGS screen for the CALIBRATION functions.

The 5 sub-menu buttons below the screen control various display functions and the

setting for each basic screen page. Text or icons are displayed above each button

to indicate their function.

B. OPERATION

B.1 Status icons

All of the operation screens have a status bar at the top of the screen which

displays the time and a number of different icons. These icons indicate:

Working

Not working

NOTE: The memory card and GPS icons are displayed only when these functions

have been activated in the settings.

B.2 'MAIN' screen

The console always displays the MAIN screen when it is started up. The MAIN

screen is divided into 5 parts which display the following functions.

Figure 2: MAIN screen (single product / single dispenser)

Memory card

Inserted

Not inserted

No signal

Signal – no differential

Signal - differential OK

(Section 2.7)

‘Pre-start’ function

(Section 2.6)

Dipenser On-Off

(Manual forcing)

Marking status

(Section 2.5)

26

Turbine Speed

sowing dose

Marking – manual

increment

Stop automatic

incrementing of

marking

(Manual forcing)

NOTE: The status of the dispenser will be displayed differently according to the configuration of the

If the sower is working and

the forward speed is less

/h, this warning

logo will blink on the

screen with an audible

If the sower is working and

the forward speed is above

the maximum speed that

can be accepted by the

Artémis system, (indicated

on the RATE sowing dose

screen), this warning logo

will b

link on the screen with

sower (see figures 3 and 4).

Figure 3: MAIN screen (dual product / single dispenser)

Portion of the display that changes

Figure 4: MAIN screen (single product / dual dispenser)

Portion of the display that changes

B.2.1 Forward speed display and alarm functions

Smoothing of the displayed speed

Except in cases of quick changes in speed, the forward speed displayed at any

time will be the average speed calculated over 3 seconds.

Speed alarms on the MAIN screen

The console is programmed with high and low forward speed alarms.

than 0.5 km

alarm.

an audible alarm.

27

06.PCX

Maximum forward speed

When you set a new target dose in the RATE sowing dose screen, the console

recalculates and displays the maximum forward speed at which the dose can be

maintained (fig. 5). This is calculated using the sowing dose, the width of the

sower, the current CALIBRATION factor, the transmission ratio of the gearbox and

the maximum rotating speed of the motor.

Figure 5

UK566-

Press to go back to the RATE sowing dose screen.

NOTE: If the speed is too low, the operator has to open the dispenser and re-

calibrate in order to increase the calibration factor (see the 'CALIBRATION'

manual).

B.2.2 Marking Functions/Statuses

The MAIN screen shows the current marking status.

Marking mode: Symmetrical Asymmetric Left Asymmetric Right

Deployed status

( = ON)

Current pass

Target number

of passes

B.2.3 Manually increasing the pass number

When the console is turned on, the marking sequence always starts at '1'.

If necessary, press to select the correct pass number, for example to start

a parcel with a pass number other than ‘1’.

B.2.4 Freezing the pass number

Press to freeze the pass number displayed (for example, when sowing

around a pole where the sower needs to be raised and lowered several times).

The icon indicates that the pass number is frozen. Press to go back

to normal operation.

NOTE: The marking sequence is set in the SETTINGS screen (see section 2.5).

28

Current target dose

05.PCX

B.3 'RATE' sowing dose screen

This screen allows the sowing dose to be adjusted. Each of the kg/ha or

seeds/m2 units can be adjusted in the SETTINGS screen.

Figure 6: 'RATE' sowing dose screen - single product

% off target

‘Pitch’ of the dose

Target dose forced

manually by ‘pitch’ %

('pitch' % in the SETTINGS

screen)

Figure 7: RATE screen – dual product

Maximum forward

speed at which the

sowing dose can be

maintained

UK566-

Reset to the basic

target dose

NOTE: The maximum forward speed displayed is lower for the two products.

B.3.1. Adjusting / forcing the target dose

To adjust the target dose, simply enter the value and press the CONFIRM

button to confirm.

To set the target dose or manually adjust the dose for each product, first press

the CONFIRM button to select the SEED or FERTILISER product.

The application dose displayed in the MAIN screen is the

same as that displayed in the RATE sowing dose screen. If the

target dose is modified manually + or - in the RATE sowing dose screen,

this dose modification % will blink in the main screen.

When the system is operating with a preset card, this dose

modification % will blink only if the target dose was modified

using the ‘+’ or ‘–‘ buttons in the RATE sowing dose screen.

% off target

29

To force the target dose, use the

l

counter

)

SETTINGS screen.

To return to the target dose, use the button.

Both products are returned to their respective target dose

B.4 'INFO' screen

buttons. The 'pitch" % is set in the

Figure 8

Surface counter

Seed counter

Fertiliser counter

Displays the partial/tota

counters

Displays the grand total

There is a partial and a total counter for each

product (seed/product).

Resets the selected

(Not used)

(Not used

30

B.5 Marking

To set the marking mode, select the SETTINGS screen and press

Figure 9

The sprayer width

calculation is based

on the width of the

sower, the number

of target passes and

the marking mode.

Increase/decrease the

number of target passes

Mode select

The target number of passes can range up to 10, with symmetrical,

asymmetrical left or asymmetrical right marking modes.

Symmetric Symmetric left Symmetric right

The console displays the sower/sprayer width combination for the target

number of passes.

B.6 Pre-start function

This function is used especially with a front dosing hopper. The pre-start

function assists in avoiding unsowed areas especially in field corners. This starts

the dispenser at the CALIBRATION speed while the sower is still stopped, and as

such starts the primes the sower until the seed arrives at the sowing units just

before the sower starts to work.

The settings for this function are carried out through tests and error tests when

the system is turned on for the first time, and are then adjusted in the SETTINGS

menu.

To use the pre-start function, press in the MAIN screen before moving.

The motor will start at the CALIBRATION speed for a preset period of time, or

until the forward speed exceeds 2km/H, and then the automatic regulation takes

over.

31

B.7 Electric motor – manual forcing/sowing a half-width

Press the desired button .

The electric motor can be stopped manually as desired, for example:

(a) A portion of the plot needs another preparation of the land before sowing.

(b) With a front dosing hopper, the electric motor is stopped just before the end

of the pass in order to sow all of the seed in the pipes (the opposite of the

'pre-start' function).

(c) You want to sow a half-width.

B.8 Product CALIBRATION

B.8.1 Initial CALIBRATION of the product

Prepare the sower as normal for calibration with a bucket.

1. In the SETTINGS screen, press .

2a. If the console is configured for two products, select the product to calibrate

(fig. 10).

Figure 10: Dual product/single dispenser

2b. Or if configured for two dispensers, select the dispenser to calibrate (fig. 11).

Figure 11: Single product/dual dispenser

3. Otherwise, select the desired weight unit (kg or g), and then enter the weight

required for the calibration (fig. 12) and press CONFIRM. The dispenser starts

32

and runs at the programmed CALIBRATION speed to distribute the correct

quantity of product, and then stops.

NOTE: If a manual calibration button is used for the CALIBRATION, the calibration

procedure will start (fig. 13).

4. Weight the product obtained in the bucket, and enter this value (fig. 14). Then

press CONFIRM to confirm.

Figure 12

5. Press CONFIRM again, and the console recalculates and displays the new

CALIBRATION factor in kg/rev, the error %, and the maximum forward speed

allowed calculated according to the application dose that is set for the product

(fig.15).

Figure 15

6. Press CONFIRM again to confirm and store the new calibration factor, or press

ESC to go back to the SETTINGS screen.

The PARTIAL counter should be reset before starting to sow. This will allow you,

after having sowed a portion of the plot, to quantify any error in the calibration

factor by comparing the theoretical quantity of product sowed with the actual

quantity sowed that is known (an entire big bag for example).

You can then accurately adjust the calibration factor, is needed (see section

2.5.2).

NOTE: Systems mounted on an 'Accord' type dispenser.

33

When you switch from a low sowing dose to a high dose, for example from

3kg/ha to 100kg/ha, use the following procedure:

1. Open the dispenser to a raised position.

2. Start the calibration procedure, distribute a suitable quantity of product and

enter the weight obtained. The error will be substantial but press ENTER to

correct the calibration factor and continue (see Fig. 15).

3. The programme now needs the application dose (see Section 2.3).

4. Repeat the calibration procedure again, and this time the error should be low.

Accept the error and begin to sow.

When you switch from a high sowing dose to a low dose, for example from

100kg/ha to 3kg/ha, use the following procedure:

1. Open the dispenser to a lowered position.

2.

Start the calibration procedure, distribute a suitable quantity of product and

enter the weight obtained. If a manual calibration button is used, distribute a

small quantity of product and enter the weight. The error will be substantial

but press ENTER to correct the calibration factor and continue (see Fig. 15).

3. The programme now needs the application dose (see Section 2.3).

4. Repeat the calibration procedure again, and this time the error should be low.

Accept the error and begin to sow.

B.8.2 ‘CALIBRATION NUDGE’ – Adjusts the calibration factor

The ‘CALIBRATION nudge’ procedure allows you to adjust the existing

calibration factor without having to rerun the test with the bucket.

1. First, note the quantity of product displayed in the PARTIAL counter on the

INFO screen. This is the theoretical quantity that the instrument has calculated.

From the SETTINGS screen, either press

(Calibration Verification), or

(Sower SETTINGS).

If the console is configured for two products, select the product to calibrate (fig.

10).

Likewise, if the console is configured for two dispensers, select the right or left

side (fig. 11).

2. On each screen, press to select the ‘CALIBRATION Nudge’ screen (fig.

16).

Figure 16

34

3. Enter the theoretical weight that was noted from the INFO screen in step 1 and

press CONFIRM twice.

4. Enter the weight actually sowed and press CONFIRM twice.

5. The calibration factor is recalculated, and the error % and the maximum

forward speed (fig. 18) are also displayed. Press CONFIRM again to confirm

the new factor.

B.9 Setting the turbine speed and hopper empty alarms

To see the alarm thresholds (fig. 19), from the SETTINGS screen, press .

Figure 19

Low turbine speed alarm

High turbine speed alarm

Hopper empty alarm (ON/OFF)

To adjust the thresholds, enter the value and press CONFIRM.

B.10 Simulating forward speed

If the forward speed sensor (radar, encoder on a wheel, etc.) is no longer

working, you can continue sowing by simulating a forward speed. What is important

is to remember what your forward speed was before the breakdown, in order to

type the right simulation speed, otherwise the sowing density will not be correct. If

you sow at a speed that is higher than the simulation speed, you will under-dose

and vice-versa.

To set the simulated forward speed, from the SETTINGS screen, select ‘1

Operator Config’ then ‘2. Speed sensor factor’.

Press (fig. 20), then enter the value of the simulation speed (fig. 21).

Press the CONFIRM button to start the speed simulation.

Figure 20

During the speed simulation, the forward speed on the MAIN screen blinks (fig. 22)

35

NOTE: The pre-start function also works with speed simulation.

Functions that can

B.11 Selecting the units / ‘Pitch’ for the % dose

In the SETTINGS screen, select ‘1 Operator Config’ then ‘3. Adapt’.

Figure 23

If the console is configured for two products, first select the product with the

LEFT/RIGHT arrows (fig. 23).

Use the UP/DOWN arrows to select the parameter.

Use the LEFT/RIGHT arrows to select the units (kg/ha or seeds/m2).

Use the LEFT/RIGHT arrows to adjust the “pitch”, or enter the value with the

numeric keypad and press CONFIRM to confirm.

C. RECORDING DATA AND MODULATING DOSES

The data recording and dose modulation functions are available via the SETTINGS

screen.

1. Press to select the recording screen (fig. 24).

The console then detects the presence of a memory card.

2. Press the START button to go to the 'Start task' page (fig. 25).

Figure 24

Figure 25

be used with

Artémis

There are several functions possible. Only functions 1, 2 and 3 can be used with

Artémis.

36

1. Apply the plan (Dose modulation)

Several configurations are possible:

(a) The PS 8000i receives the dose from a preset plan located on the SD memory card

and controls the system according to this dose via the RDS regulation system. A

complete recording of the application carried out is generated and saved to the

memory card.

(b) The PS 8000i receives the dose from a preset plan located on the SD memory card

and sends this dose to another regulation case, which will carry out regulating the

system of another manufacturer. In this case, the PS 8000i is used as the controller.

(c) The PS 8000i receives the dose from another case (case which is used as a

controller) and controls the system via the RDS regulation system. The PS 8000i

can in return send back the current application dose to the other case.

All of these configurations allow the operator to modulate the doses.

For configurations (a) and (b), a complete recording of the application carried out is

generated and saved to the memory card. The record file for the work can be

opened in mapping software. The work summary is also created in this file.

2. Treatment recording (Dynamic data recording)

A compete record of the application carried out is generated, recording the dose

and other parameters ("tags", for example) in real time, combining this data with the

georeferenced position. The associated "Dynamic Recording" file can be opened in

mapping software. A large quantity of data is generated by dynamic recording and

must be saved to the SD memory card. The work summary is also created in this

file.

3. Summary recording (Internal data recording)

For simple recording for the purposes of traceability, you can record a summary of

each work in the internal memory, then download it directly to a computer, a

memory card or print it. The quantity of data in the summaries for each work is

small, and is stored in the console's internal memory. The console can store up to

75 summaries.

37

6 MAINTENANCE

6.1 Maintenance carried out by the user

AFTER THE FIRST HOUR OF USE

•

Check the tightness of the tines and ploughshares.

BEFORE EACH DAY OF WORK

IMPORTANT: Check the wear of the tine ploughshares, invert or change

those as required.

• The wheel roller bearings are maintenance free, just check their condition.

•

IMPORTANT: Check the recommended tyre pressure at 2.25 bars for the

wheels on the central portion and 7 bars for the wheels on the

extensions.

ONCE A YEAR, AFTER EACH SEASON

• Replace worn ploughshares, as well as the tines which are showing signs of

fatigue (lengthening, cracks, etc.)

• The bearings on the depth adjustment wheels are lubricated for life, check the

set of hubs by hand.

•

Inspect the articulation rings on the equipment. They must be replaced if worn.

• Inspect the articulation rings on the Chisel tines.

• Check for the good condition of the rubber tyre wheel bearings, the absence of

excessive play and the proper tightening of the rings.

•

Spare parts as requested. Consult the corresponding nomenclatures. Spare

parts must meet the manufacturer's technical requirements, which is always the

case with original parts.

• Check belt tension.

• Clean the cells on the dispenser.

• Remove the distribution head cover then blow air on the descents.

STORAGE BETWEEN 2 CROP YEARS

• After cleaning with a spray of water or high-pressure hose, all of the points that

can be removed should be oiled or greased.

• Store the device on stable ground.

6.2 Maintenance carried out by specialised personnel

The PENTASEM does not require the use of any special tools for maintenance. This

can therefore be accomplished entirely by the user.

Do not clean the electrical box with a high-pressure hose.

38

6.3 Troubleshooting

Defect

Solution

Advice

The turbine speed is too low with

the hydraulic unit

The hydraulic motor heats up

The turbine speed is too low with

PTO

The blower does not produce any

air

Speed is slowing

-

The seeds are clogging the pipes

Too much straw and plant debris

are retained

Consolidation of the sowing lines

is too weak

- Check the hydraulic flow

Speed ≈ 4300 rpm

-

Check the direct return to the

tractor's tank

-

Check belt tension

-

Check the free wheel on the drive

pulley

The trapezoidal belt is worn

-

Ensure that the blower flap is

correctly positioned

-

Change the angle of inclination of

the combs

-

Increase the pressure on the

ground of the tyre wheels

The markers are deployed at the

same time

The turbine revolution counter only

indicates half of the speed

The revolution counter does not

show any speed.

No trace of the pass is created

The sowing line for the creation of

the track pass remains locked on

each trip

The pre-emergence marker does

not move

The sowing rate is too high or too

low

-

Check the synchronisation valve

of the markers

- A single magnet is triggering the

pulse

- The electrical power is cut off.

- No pulse is detected.

The sensor is defective.

-

The track marker valve is not

activated.

- The track marker valve is stuck.

-

There are foreign bodies in the

main distributor.

-

The track marker valve is not

powered electrically.

- Incorrect setting value.

- Check for proper operating

condition of the scale.

- Use an accurate scale.

-

Do not count the weight of the

basin.

39

Defect

The sowing rate is too low

The ploughshare pipe is

obstructed with seed

Solution

-

Common seed: Microdosage is

activated

-

Fine seed: The cells are dirty

-

The cleaning brush is defective

Advice

- The turbine adjustment flap is set

to fixed seed for common seed.

- The diffusers are obstructed with

soil

-

The turbine speed is too low

The sowing is too deep

-

The comb harrow is working too

deeply

The comb harrow is clogged

6.4 Screw tightening torque

Tightening torque according to the quality rating of

Threading

8.8 10.9 12.9

M8 24 33 40

M10 47 65 79

M12 81 114 136

Lower the depth gauge wheels

- The pressure is too high.

-

The depth was incorrectly set.

-

The angle of the comb harrow

was set too steep

the screws and nuts (in Nm)

M14 128 181 217

M16 197 277 333

M18 275 386 463

M20 385 541 649

M22 518 728 874

M24 665 935 1120

40

7 DISPOSAL

At the end of the machine's life, it must be disposed of in accordance with the

environment. Comply with the instructions concerning this when the machine is

disposed of.

Be careful not spill onto the ground or discard into the drains used grease and

substances such as motor oil, hydraulic oil, coolant, brake fluid, fuel, etc.

All of the metal items can be given to scrap iron recovery centre.

All of the metal items can be given to scrap iron recovery centre.

Collect the hydraulic oil in clean and sealed containers that are intended for this

purpose. Do not use containers for food or bottles for beverages.

Take the hydraulic oil and the hoses to a suitable recovery centre.

Electronic components can be removed to a suitable industrial waste reception

centre.

41

CE Declaration of conformity

The manufacturer: ETS CARRÉ S.A.S.

B.P. 6

Z.A. Les Fours

85140 SAINT MARTIN DES NOYERS

Declares that: The PENTASEM of the CARRÉ brand PTS type

Serial number 38011901 - 2010

Complies with the provisions of the amended "machines"

directive (Directive 89/392/EC) and with the transpositions

into national law

And also complies with the provisions of the following

harmonised European standards:

- EN 292-1 and EN 292-2

- EN 294

- EN 349

And also complies with the following national standards and

technical measures:

- NF U 14-032

Established in St Martin des Noyers

10 November 2010

Benoît CARRÉ

President

42

Notes:

43

Loading...

Loading...