CARRE PENTASEM Series, PTS 3500, PTS 4000, PTS 6000, PTS 4800 Assembly & Use Instructions

...

PENTASEM

Assembly - Use

Ref. 38011901

Updated 10.11.10

CARRE sas • CONSTRUCTIONS MECANIQUES • Z.A Les Fours • BP 6

Tel. 02 51 07 82 35 • Fax 02 51 07 80 75 • http://www.carre.fr • Email: carre@carre.fr

85140 SAINT MARTIN DES NOYERS • FRANCE

CONTENTS

Page

1

2

3

INTRODUCTION ................................................................................. 3

SPECIFICATIONS .............................................................................. 3

SAFETY INSTRUCTIONS .................................................................. 5

3.1 Safety symbols ............................................................................................. 5

3.2 Usage as intended ....................................................................................... 6

3.3 General safety instructions........................................................................... 6

3.4 Safety in the public domain .......................................................................... 6

3.5 Accident prevention ..................................................................................... 7

3.6 Maintenance and repair ............................................................................... 7

4

5

OPERATOR CONTROLS ................................................................... 8

ASSEMBLY AND PUTTING INTO SERVICE ..................................... 8

5.1 Link on the tractor ........................................................................................ 8

5.2 Mounting the tines ........................................................................................ 8

5.3 Positioning the extensions ........................................................................... 9

5.4 Equipment .................................................................................................... 10

5.4.1 Front blade ................................................................................................... 10

5.4.2 Comb harrow Ø10 ........................................................................................ 10

5.4.3 Rubber tyre wheel ........................................................................................ 10

5.4.4 Blower .......................................................................................................... 11

5.5 Adjusting and using the sower before sowing .............................................. 12

5.5.1 Markers ........................................................................................................ 12

5.5.2 Pre-emergence markers ............................................................................. 12

5.5.3 Sowing depth adjustment ............................................................................ 13

5.5.4 Flow test ....................................................................................................... 14

5.5.5 Track marker adjustment ............................................................................ 18

5.5.6 Sower control ............................................................................................... 19

5.6 Using the sower during work ........................................................................ 20

5.7 Usage after work .......................................................................................... 21

5.7.1 Emptying the hopper and the dispenser ....................................................... 21

5.7.2 Sower storage .............................................................................................. 21

5.8 Using the case

6

MAINTENANCE .................................................................................. 38

.......................................................................................

22

6.1 Maintenance carried out by the user ............................................................ 38

6.2 Maintenance carried out by specialised personnel ...................................... 38

6.3 Troubleshooting ........................................................................................... 39

6.4 Tightening torque ......................................................................................... 40

7

8

DISPOSAL .......................................................................................... 41

CE DECLARATION OF CONFORMITY ............................................. 42

2

1 INTRODUCTION

Before using the PENTASEM sower, we recommend that you read this

manual carefully and that you scrupulously comply with the instructions. As such,

you will avoid putting yourself into a dangerous situation, you will reduce putting into

service time and the risk of undesirable incidents outside the warranty period.

Always keep this manual handy

Your CARRÉ reseller will provide you with advice so that you can obtain full

satisfaction from your machine.

Comply with the safety instructions

Warning symbol

CARRÉ cannot be held liable for any damage and operating incidents occurring

subsequent to usage that does comply with the instructions in this manual.

Warranty: Please fill out the warranty certificate enclosed with the machine

and return it as soon as possible to the indicated address in order to activate

your warranty.

2 SPECIFICATIONS (a)

Description of the PENTASEM

PENTASEM is used for planting a crop in simplified sowing at high speed.

Available in 5 widths, 3m50 as fixed, 4m00, 4m80, 5m60 and 6m00 as foldable.

Planting is accomplished with 45x12 right tines with seed diffuser.

Power required:

From 100 to 150 hp according to the widths.

Operating speed:

Up to 12 Km/h, varies according to method of use.

Static airborne noise:

None of the equipment produces when empty an equivalent A-weighted sound

pressure level exceeding 100 dB at a distance of 1m.

3

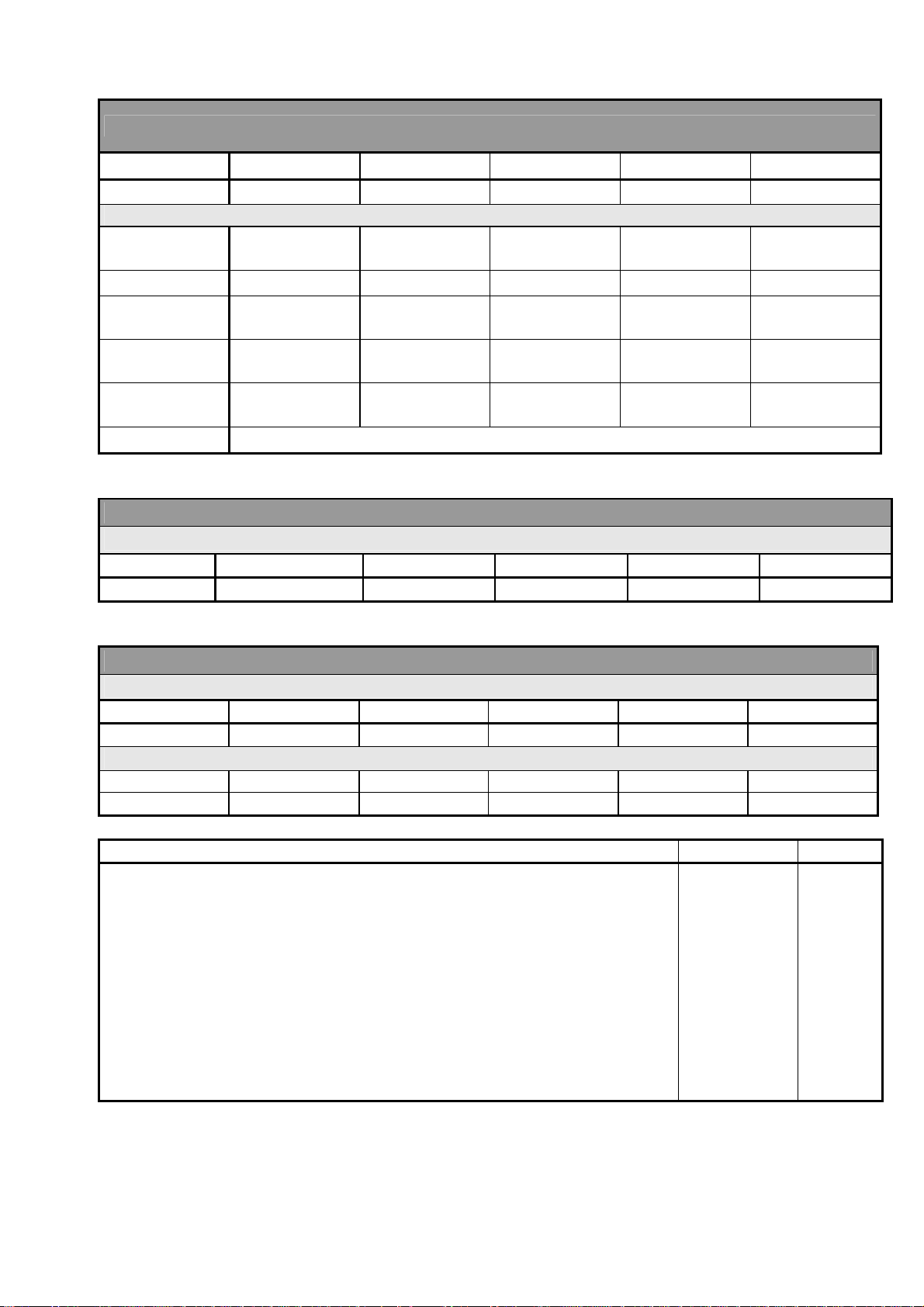

Technical characteristics (a):

Number of

Working

Transport

Power

Code

Weight

Code

Weight

Code

Weight

Options (b) (c)

Code

Weight

PENTASEM

Code PTS 3500 PTS 4000 PTS 4800 PTS 5600 PTS 6000

Weight

rows

Interline

width (m)

width (m)

required (hp)

Planting

1045 1670 1735 1790 1840

Specific characteristics

28 32 32 40 40

125 mm 125 mm 150 mm 140 mm 150 mm

3m50 4m00 4m80 5m60 6m00

3m50 3m20 / 3 parts 3m20 / 3 parts 3m20 / 3 parts 3m20 / 3 parts

100 120 150 150 150

45x12 right tines with seed diffuser

FRONT EQUIPMENT

FB – FLEXIBOARD front blade

FB35 00 FB40 00 FB48 00 FB56 00 FB60 00

145 184 198 206 210

REAR EQUIPMENT

HPS – Comb harrow Ø10 on one row with BF link

HPS35 00 HPS40 00 HPS48 00 HPS56 00 HPS60 00

57 96 100 105 117

BF – Rubber tyre wheel L=50 mm

BF35 00 BF40 00 BF48 00 BF56 00 BF60 00

140 202 238 246 250

- Hydraulic blower unit connected to tractor oil intake (for tractor

without flow adjustment)

- 300 litre hopper side board

- Distribution head cover 40/20

- Distribution head cover 32/16

- Descent seal cap

- Single disc pre-emergence marker

- Dual disc pre-emergence marker

- Electric track marker valve

- Set of 4 stands

-

Pair of fixed pneumatic depth gauge wheels on extensions

11916

11911

VN90048027

VN90048025

119005

11955

11954

VN90050044

11702

11925

18

17

5.3

2.8

30

60

0.5

30

130

(a) The technical characteristics, dimensions and weights are provided for the purposes of

information; these may change.

(b) Incomplete list.

(c) Regardless of the width of the device.

-

4

3 SAFETY INSTRUCTIONS

dangerous area.

dangerous area.

belt protective

cover in place

footstep while

3.1 Safety symbols

On the machine

Make sure that the warnings and pictograms remain clean and visible at all times. If they

become deteriorated, ask your manufacturer (or distributor) for new stickers.

If repair work is done, ensure that the spare parts have the same stickers as the original

parts.

Read the maintenance

booklet and the safety

instructions before

turning on the

In order to prevent leaks

in the hydraulic circuit,

follow the instructions in

the maintenance booklet

machine.

Before any

intervention, turn off

the tractor engine and

remove the key.

Never place

hands in the

danger areas

when the parts

are in motion,

there is a risk of

pinching.

Have everyone

leave the

There is a risk

of crushing

Have everyone

leave the

There is a risk

of crushing

²

Keep the

sower's drive

in order to

protect the

hands

Do not step

on the

the machine

is moving

Electrical

installation

Triangle indicating DANGER each time that the risk of an accident is high or when

the equipment may be damaged.

This arrow indicates areas where advice is provided on facilitating the work.

5

3.2 Usage as intended

PENTASEM is designed to be used for planting a crop in simplified sowing at high speed.

Any use other than the latter shall be considered as non-compliant with the intended use

and shall release the manufacturer from any liability in the event of prejudice; the user

alone shall incur the risks that result from such use.

Comply with all of the installation, operating, adjusting, maintenance and repair instructions

contained in this notice.

Use only spare parts and accessories that comply with the manufacturer's

recommendations.

The use, maintenance and overhauling of the PENTASEM must be entrusted only to

people who are familiar with and who are informed of the possible dangers.

Do not modify or have your machine and its accessories modified by another person

(mechanical, electrical, hydraulic, pneumatic characteristics), without first obtaining

approval from your manufacturer.

Not complying with these rules can make your machine dangerous. In the event of damage

or injury, the manufacturer shall be released from any liability.

Moreover, the special instructions concerning the prevention of accidents must be complied

with, as well as the general rules in terms of technical safety, occupational medicine and

legislation concerning the use of roads.

The manufacturer declines all liability in the event of prejudice resulting from a modification

made to the PENTASEM without its approval.

3.3 General safety instructions

Only use the PENTASEM if all of the protective and safety devices are installed and are

operating correctly.

Check that the screws are tight on a regular basis and tighten them if necessary, especially

the clamping screws for the tines and the bearings on the equipment.

In the event of operating incidents, stop the machine immediately, then repair the

breakdown or have it repaired immediately.

3.4 Safety in the public domain

Before driving on a road, you must become familiar with the operation of all of the controls.

Comply with the rules of the road when you move into the public domain (roads, paths and

squares). Make sure beforehand that the condition of the PENTASEM is compliant with the

regulations set forth in the rules of the road.

Comply with authorised transport width limitations.

Adjust your speed and driving style to the land, roads and paths. Remain vigilant and

cautious!

At all times and in particular on sloped and broken land, operate the machine at slow

speed, especially when turning and do not change direction abruptly.

Do not brake or start abruptly while going up or down a slope.

Driving is influenced by the machine coupled to the tractor. Comply with the axle load limit

and the gross weight so that steering and braking precision are maintained and, when

turning, give particular attention to the overhang and the inertia mass of the PENTASEM.

Do not transport anyone on the PENTASEM.

6

3.5 Accident prevention

In addition to the recommendation in this manual, follow the instructions of the farming

mutual insurance companies.

During the hitching of the PENTASEM to the tractor:

- Ensure that the PENTASEM is resting on stable ground.

- Never remain between the tractor and the PENTASEM; there is a risk of an accident.

- Operate the 3-point hydraulic lift system slowly and with caution.

- Check that the 3-point hitching categories of the tractor and of the PENTASEM

correspond.

During use:

- Before turning on the machine, ensure that no one is within the vicinity of the machine.

Ensure that there is sufficient visibility.

- Do not transport anyone on the hoeing machine during work.

- None of the protective devices prescribed and delivered with the machine are to be

removed.

- Make sure that no one is in the pivoting area of the extensions that can be folded, the

markers and any pre-emergence markers.

- While operating and when in motion, the PENTASEM causes the projection of soil and

stones. Ensure that no one is within the vicinity of the machine.

During the operation of the power take-off of the sower:

- Comply with the instructions in the U-joint transmission manual.

- Use only U-joint transmission with their regulatory protectors (the tube and cone must

be mounted).

- Mount the U-joint transmission shaft only if the motor of the tractor is stopped and if the

power take-off is disconnected.

- Comply with the overlapping prescribed for the sliding shafts in transport and working

position.

- The U-joint transmission protectors must be immobilised in rotation.

- Do not turn on the power take-off until there is no one within in the vicinity of the sower.

- The rotating speed of the tractor's power take-off must correspond to the authorised

rotating speed of the sower.

- WARNING: Due to its inertia, the power take-off continues to rotate after it has been

disconnected. Stay away from the device during this lapse of time and do not intervene

on the latter until it has come to a complete stop.

- Put the protective sleeve back on tractor's power take-off, as soon as the U-joint shaft is

no longer connected to it.

3.6 Maintenance and repair

- Comply with the time frames that are recommended or indicated in this manual when

carrying out scheduled inspections and verifications.

- Before beginning any maintenance or repair work, make sure that the hydraulic

installation is not under pressure, and stop the tractor's power take-off and motor.

Uncouple the PENTASEM from the tractor.

- Carry out maintenance or repair work only if the PENTASEM is resting flat on stable

ground and where there is no risk of tipping.

- Do not carry out any maintenance work on a raised device without having installed the

appropriate supports for safety reasons.

7

- When assembling and disassembling, use appropriate means that do not compromise

your safety.

- Take advantage when cleaning the PENTASEM at the end of each crop year at least,

to check that the hydraulic lines are properly sealed, the connections are tight and that

there are no defects caused by friction. Replace anything that is deteriorated

immediately.

- When replacing wearing parts, use suitable tools and wear gloves.

- Spare parts must meet the manufacturer's technical requirements, which is always the

case with original parts.

- Before carrying out any electrical welding work on the PENTASEM, when it is hitched to

the tractor, disconnect the battery cables.

4 OPERATOR CONTROLS

With regards to hitching, and for safety reasons, the original pins must be used. In

order to prevent loss, the pins as well as their lynch pins are connected to the PENTASEM

by a chain.

5 ASSEMBLY AND PUTTING INTO SERVICE

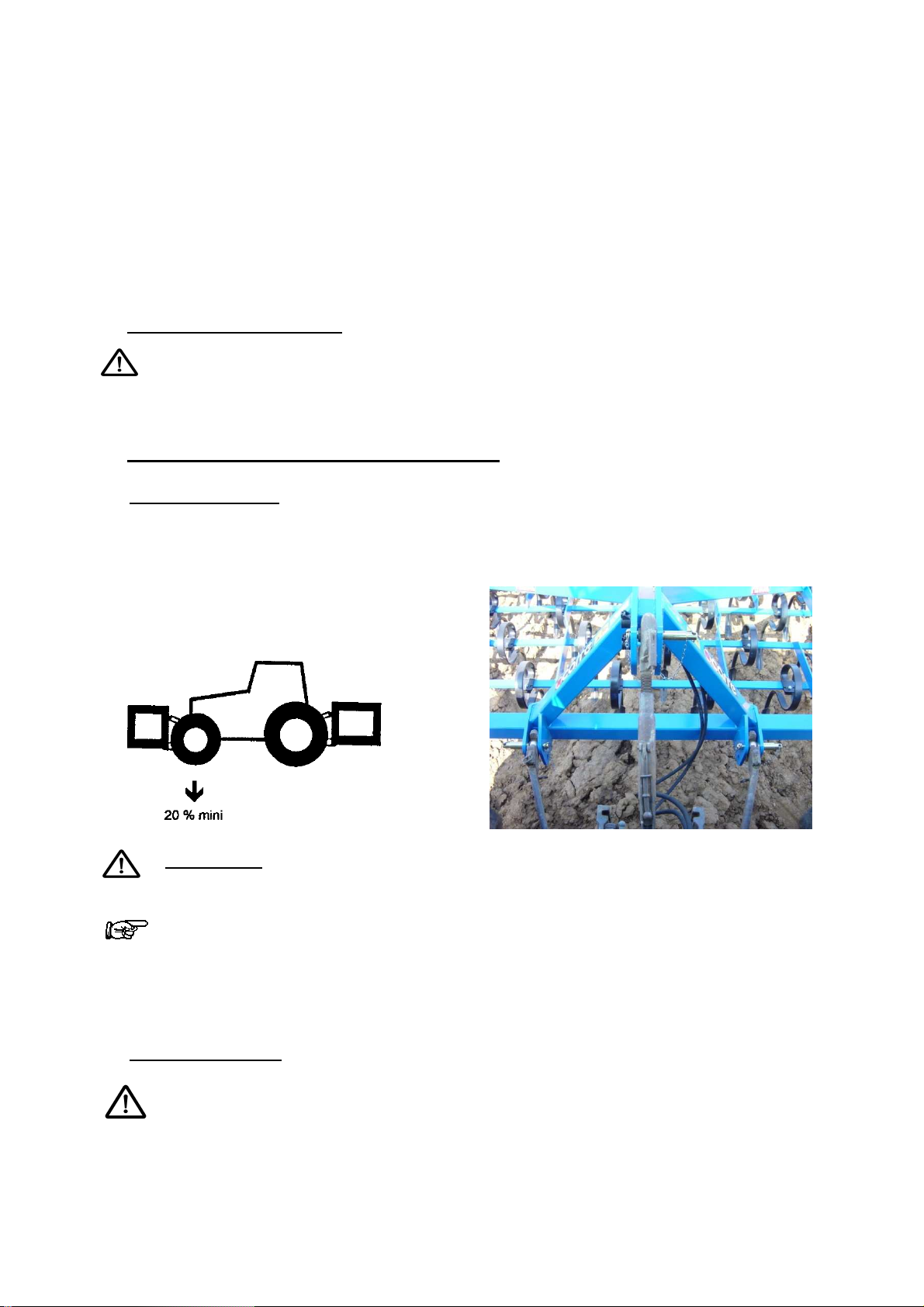

5.1 Link on the tractor

The PENTASEM is equipped with a 3-point pin coupling between yoke No. 3 and

reversible pin diameter No. 2 and No. 3, in accordance with standard NF U 14032.

WARNING: Never remain between the tractor and the PENTASEM; there is a risk

of an accident.

The "Tractor + PENTASEM" unit has a substantial mass. In order to allow for

sufficient static stability, the load of the front axle of the tractor must not be less

than 20% of the empty weight of the tractor. For this, the most practical method consists in

weight the front of the tractor on a scale and comparing the result with the recommended

value in the tractor's user manual. Add weight to the front of the tractor if necessary.

5.2 Mounting the tines

Planting seeds is accomplished with a 45x12 right tine with diffuser.

The tine pitch depends on the PENTASEM model (125 mm pitch for the 3m50 and

4m00 model; 140 mm pitch for the 5m60 et 150 mm pitch for the 4m80 and the 6m00).

8

Adjust the step screw in contact with

Retract the step screw to the maximum for

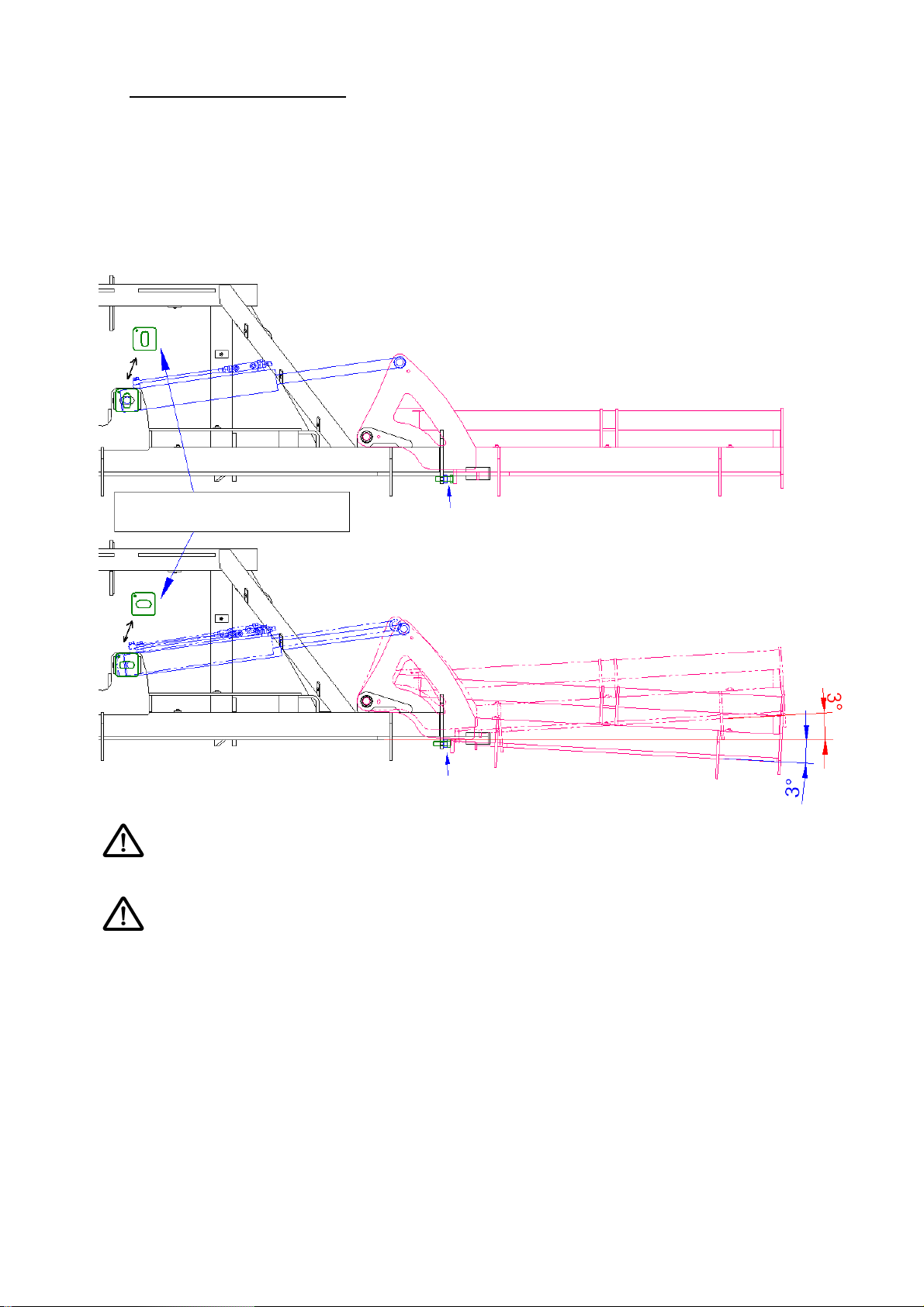

5.3 Positioning the extensions

The extensions can be in a fixed position or in a floating position. The floating position is

used to follow the differences in level of the ground in order to obtain even sowing in liaison

with the optional wheels on the extensions.

The PENTASEM must be placed on flat ground in unfolded position when switching from

the fixed position to the floating position. Remove the pin from the swivel cylinder of the

extensions and direct the shims (see drawing below).

Positioning the shims

the extension in horizontal position

the oscillation of the extension

Give attention to the adjusting of the lower stop according to the desired position of

the extensions.

Never switch from the floating or fixed position with the machine folded

9

setting

setting

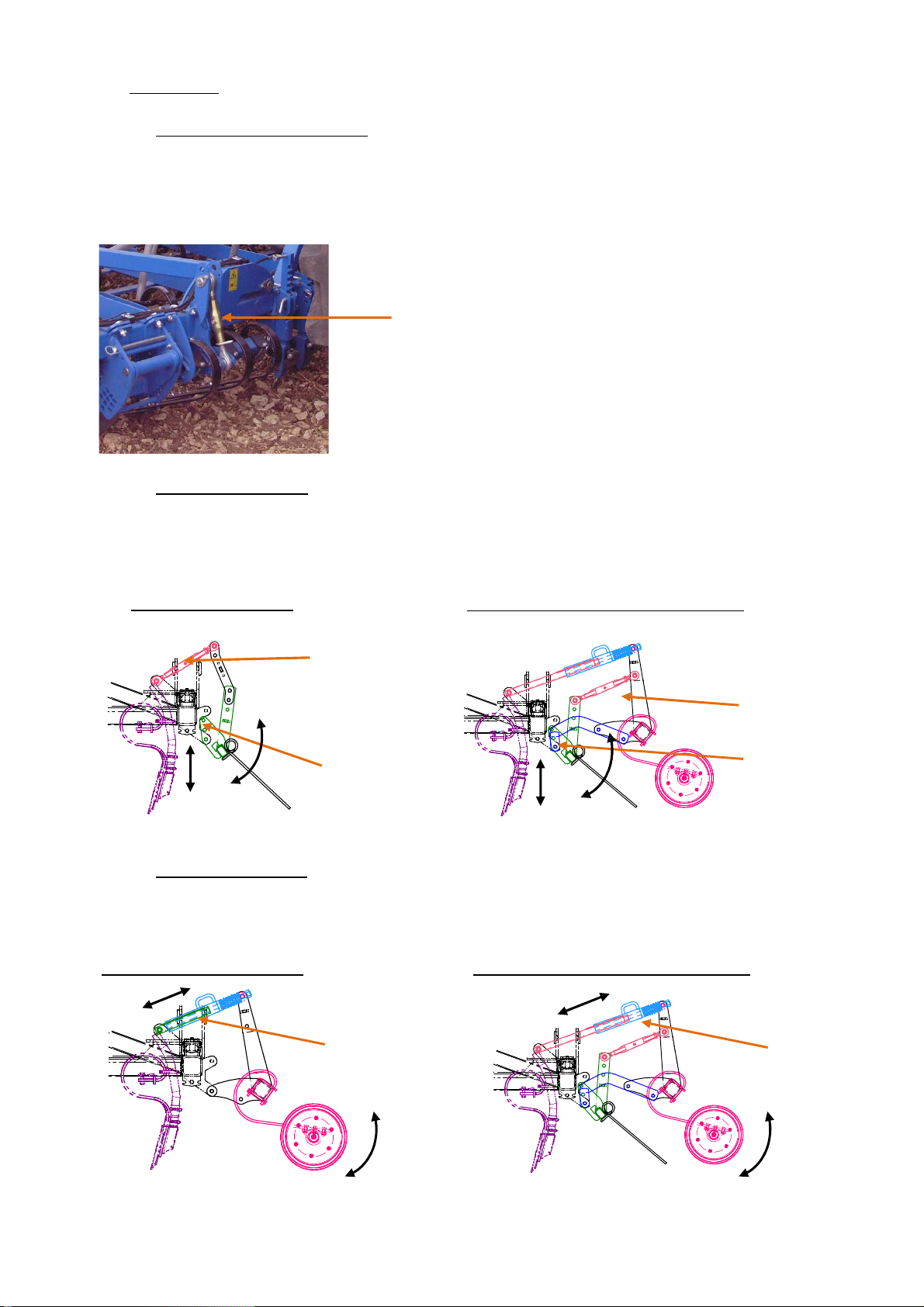

5.4 Equipment

5.4.1 FLEXIBOARD front blade

The front blade is mounted on the front beam of the PENTASEM. It is provided with several

spring blades, and participates in levelling the ground before the sowing tine passes.

Adjustments are made by the push bars and can be turned off.

Blade adjustment

5.4.2 Comb harrow Ø10

The comb harrow is mounted behind the sowing tines, and allows the sowing to be finished

by closing up the furrows evenly.

It is used alone or along with the rubber tyre wheels.

Comb harrow alone

Comb harrow + rubber tyre wheel

Harrow

inclination

Harrow

inclination

Harrow height

setting

Harrow height

setting

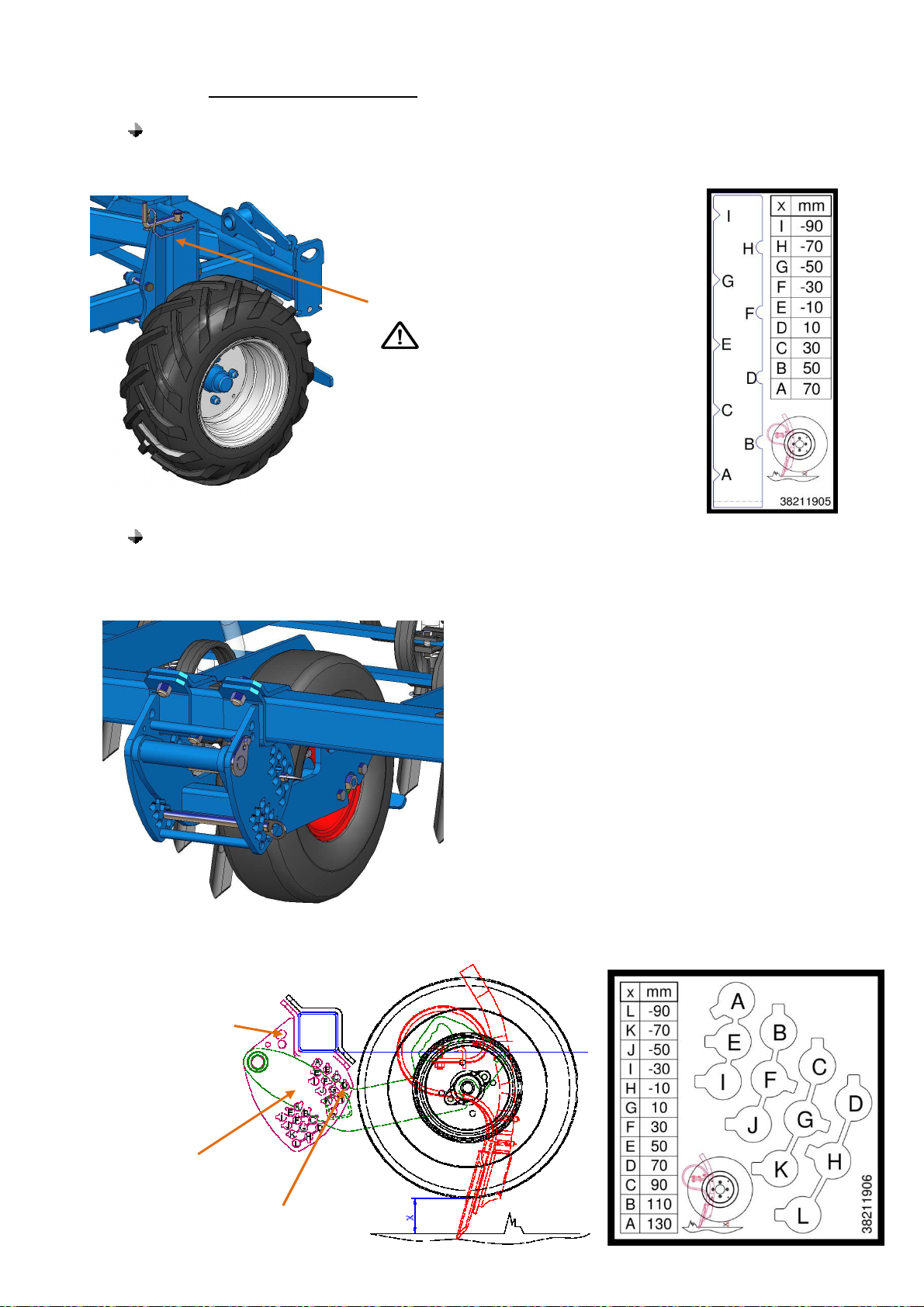

5.4.3 Rubber tyre wheel

The rubber tyre wheels are mounted behind the sowing tines. They allow for regular and

individual consolidation of the sowing coulter.

Depth

adjustment

Comb harrow + rubber tyre wheel Rubber tyre wheel alone

Depth

adjustment

10

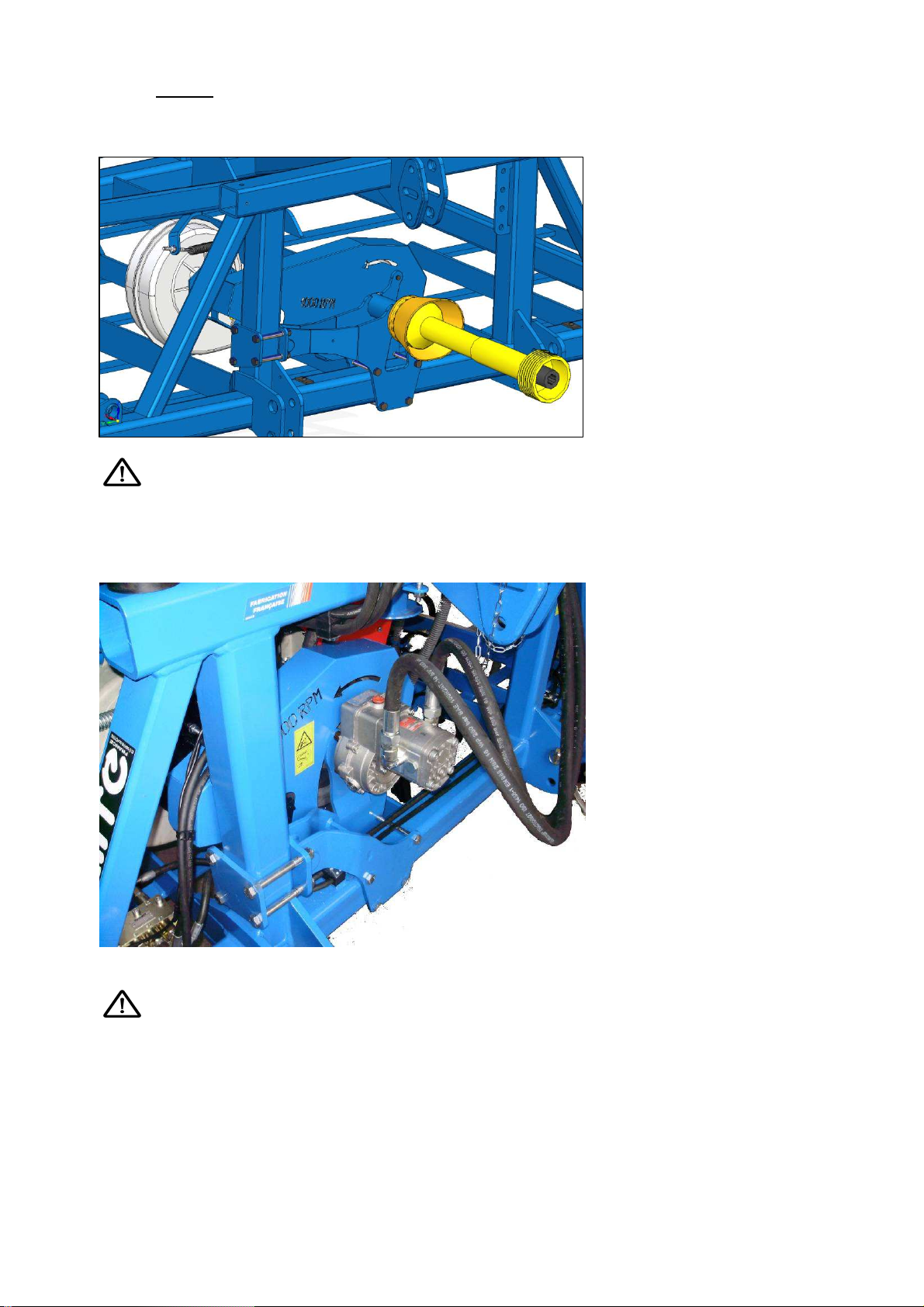

5.4.4 Blower

Mechanical blower

Required nominal speed is 1000 rpm PTO which is a blower rotation of 4300 rpm.

At the end of the plot, reduce the PTO to a minimum in order to avoid a power loss

in blower speed.

Hydraulic blower

Hydraulic supply to be connected as single-acting of the tractor.

Connect the return to the free return of the tractor, with pressure less than 5 bars,

otherwise the shaft seal will be destroyed.

Oil flow: 40l/min which is a blower rotation of 4300 rpm.

11

Adjusting screw

5.5 Adjusting and using the sower before sowing

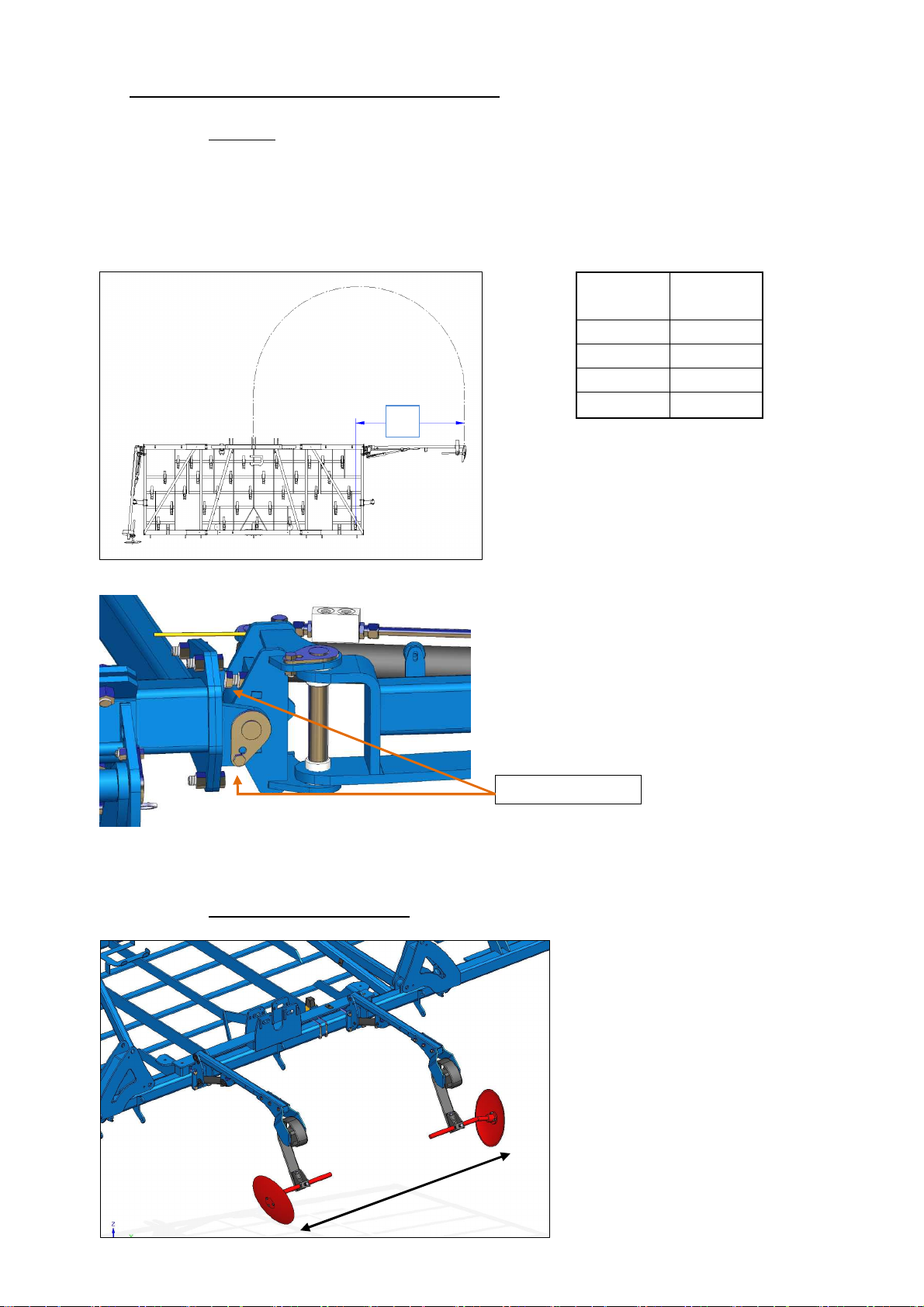

5.5.1 Markers

Adjusting the markers

Disc markers can be adjusted in the middle of the tractor. They mark a line on the

ground to follow during the return. The middle of the tractor as such passes along

this line on the ground

X

Adjusting marker inclination

The inclination is adjusted using 2 adjusting

screws. It can be placed in a fixed position

or in a floating position.

Sower

width

4m00 206.2

4m80 247.5

5m60 287

6m00 307.5

X (cm)

The marker disc is adjusted on the ground;

measure the distance X between the

middle of the last tine and the middle of

the disc (see the table according to the

width of the sower).

The marker sequence is done at the end of the field using the control of a single dualaction distributor.

5.5.2 Pre-emergence markers

The single- or dual-disc pre-

emergence markers are lowered

simultaneously with the track

marker valve control in order to

create lines for the treatment

machines.

They are activated at the same

time as the track marker valves of

the sprayer track.

12

5.5.3 Sowing depth adjustment

Depth gauge wheel on fixed chassis.

The depth adjustment wheels allow the working depth to be controlled reliably.

Adjusting the depth is carried out

using the crank screw.

The wheels must be set

identically on each side of the

sower.

Depth gauge wheel on extensions

The depth gauge wheels on the extensions allows the working depth to be controlled when

the extensions are in floating position, in order to follow the differences in level of the land.

Depth adjustment is carried out using 2 pins

Position of the pin

if work as

floating

Lower

stop

Upper

stop

13

Loading...

Loading...