OCTOPUS

www.carre.fr

MANUAL

INSTRUCTIONS

• PNEUMATIC FERTILIZER SPREADER

• METERING UNIT

• COMPUTER

READ IT ATTENTIVELY BEFORE USING THE MACHINE

CARRE SAS – CONSTRUCTIONS MECANIQUES

2,ZA les Fours

85140 SAINT MARTIN DES NOYERS

Tel : +33 (0)2 51 07 82 35 Fax : +33 (0)2 51 07 80 75

e-mail : carre@carre.fr

Internet : http://www.carre.fr

Page 1

Réf. 38412121 A

MAJ 03.2016

SOMMAIRE

I. GENERAL INSTRUCTIONS........................................................................PAGE 1 À 16

II. PNEUMATIC FERTILIZER SPREADER......................................................PAGE 19 À 31

III. METERING UNIT......................................................................................... PAGE 32 À 41

IV. COMPUTER.................................................................................................PAGE 42 À 73

V. EC DECLARATION OF CONFORMITY........................................................PAGE 74

Page 2

GENERAL INSTRUCTIONS

1. INTRODUCTION

2. SUBJECT OF THE MANUAL INSTRUCTIONS

2.1 The use of the manual instructions ?

2.2 Warning symbols

2.3 Conservation

2.4 Direction of travel

3. INTENDED CONDITIONS OF USE

3.1 What is the use of the machine or equipment may be installed ont the machine ?

3.2 Operator qualications

3.3 Dénition workstation

3.4 Environmental conditions

3.5 Manufacturer & user responsibilities

4. GENERAL SAFETY RULES

4.1 Generalities

4.2 Warning & pictograms

4.3 Toxic products

4.4 Blockages

4.5 Fire

4.6 Overhead power lines

4.7 Hitch & towing

4.8 PTO / Transmitting cardan shaft

4.9 Maintenance & Repair

5. ENVIRONMENTAL PROTECTION

5.1 Storage and disposal of waste (pollutants)

5.2 Machines for the application of pesticides

6. COMMISSIONING AND OPERATION

6.1. Environmental conditions

7. SHIPPING AND TRAVEL

7.1 Trafc on roads open to the public

8. HANDLING

9. MAINTENANCE & REPAIR

9.1 Repair

10. CLEANING

10.1 Cleaning methods

10.2 Types of cleaning products

10.3 Control the condition of the equipment after cleaning

11. SPECIAL FEATURES OF THE MACHINES USED IN EXPLOSIVE ATMOSPHERES

Page 3

1. INTRODUCTION

Type of machine

Built in

Serial n°

Spare parts book

Weight

Accessories

Page 4

2. SUBJECT OF THE MANUAL INSTRUCTIONS

2.1 The use of the manual instructions

This instruction manual contains practical information to operate , handle, adjust and maintain your

machine correctly and safely.

Read it carefully and follow all instructions and any advice relating to your security.

2.2 Warning symbols

This warning symbol identies important messages to be respected for your safety.

When you see this symbol , be alert to the potential risk of injury , read the following

message and inform other users .

2.3 Conservation

Keep the instructions for future reference close at hand or permanently on your workplace (or operating ) .

Send it to any other user , including in the event of resale or loan of your machine.

Keep the instruction manual in the space provided for this purpose.

2.4 Direction of travel

The left side is the side located on the left of the user placed in the normal travel direction of the

machine forward.

The right side is the side on the right of the user placed in the normal direction of travel of the machine forward.

Direction of travel

Right sideLeft side

Page 5

3. INTENDED CONDITIONS OF USE

3.1 What is the use of the machine or equipment may be installed ont the

machine ?

This machine is intended to be used for routine farm work.

Any other use is considered contrary to the normal use and is therefore prohibited.

3.2 Operator qualications

The machine must be used, maintained and repaired by persons who are familiar with the particular

characteristics and who know the operational security modes correspondents.

Before using your machine , familiarize yourself with all the controls and use correct.

Ongoing work will be too late to do .

3.3 Dénition workstation

Never leave the driving position when the tractor (or the self-propelled machine ) is running.

No person shall be placed outside the dened workstations.

To access workstations , take the provision for access (ladder, step , etc.).

3.4 Environmental conditions

3.4.1 Working on slopes

Adapt your speed and driving style to land, roads and paths. Be vigilant and cautious !

In all circumstances , including in rough and steep terrain , driving at low speed machine especially

when cornering and avoid sudden changes of direction.

Do not stop or start suddenly up or down a slope.

3.4.2 Lighting , night work

Only operate your machine in daylight , otherwise use sufcient articial lighting ( contact your manufacturer or distributor) .

Page 6

3.5 Manufacturer & user responsibilities

Follow all installation instructions, operating settings,maintenance and repair in this manual .

Only use spare parts and accessories conform to the manufacturer ‘s recommendations.

Do not change yourself and do not change another person your machine and its accessories (

mechanical, electrical , hydraulic, pneumatic ) without

seek prior consent from the manufacturer.

Failure to comply with these rules can make your machine dangerous . In case of damage or

injury , product liability will be completely cleared.

4. GENERAL SAFETY RULES

4.1 Generalities

The other chapters of the instructions provide additional information that you also respect for your

safety.

Remember that vigilance and caution are the best assets of your safety.

Regulations and rules of prevention against accidents and safety related to occupational health,

protection of the environment and trafc must be observed at all times.

Make sure that no people, animals and no obstacle is not closed to the machine before starting and

during operation.

Keep children away permanently from the machine.

Never carry passengers on the machine OR Do not carry passengers by using seats provided for

this purpose, in accordance with current regulations.

Do not walk on the hoods or in any other place of the machine, except the areas provided for this

purpose (ladder, platform, means of access to the workstation)

Before working on the machine, ensure that it can not be started accidentally.

All remote commands (rope, cable, rod, exible, etc.) must be placed in designated areas so that

they may accidentally trigger a risk of generating operation of accident or damage.

Before use, check the tightening of screws, nuts and ttings. Tighten if necessary.

Before use, after each adjustment and maintenance, ensure that all devices protection are in place

and in good condition, and that their locks are engaged.

Make sure the plot (or lawn, etc.) has no unevenness and debris (wood, scrap metal, plastics, fence,

etc.) that can be thrown by the machine or damage it.

Do not wear loose clothing, long hair and jewelry and free that might be caught or trapped by elements of the machine in motion.

Never put hands, arms or feet moving parts, even at low speed. Keep your vis-à-vis animated elements distances.

When you hear a sound or feel unusual vibrations, stop the operation of the machine, look for and

eliminate the cause of the incident before returning to work. Call your dealer if necessary.

Page 7

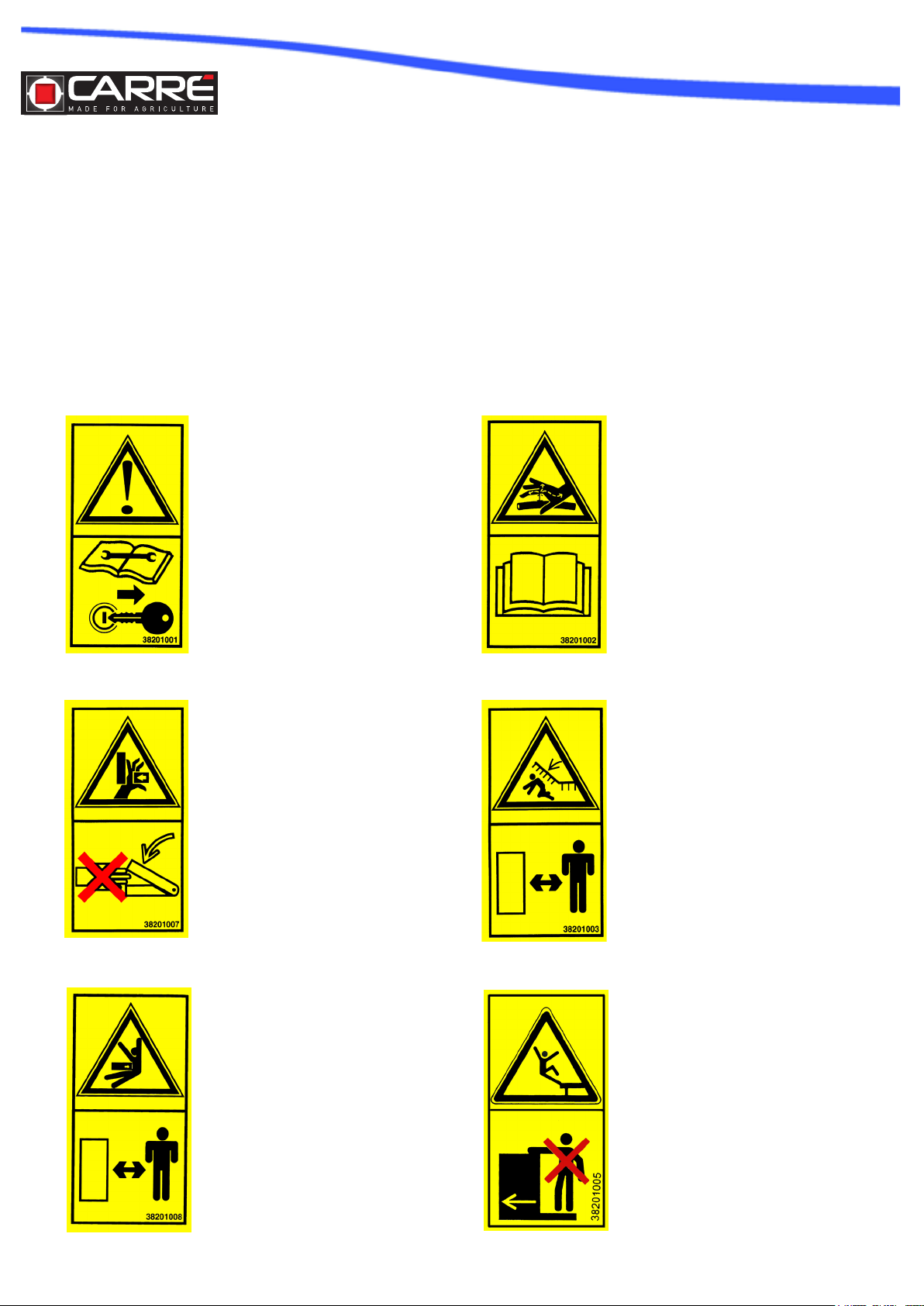

4.2 Warning & pictograms

Warnings and symbols afxed to the machine provide information on the security measures to

strictly observe and help prevent accidents.

Make sure that the warnings and pictograms remain clean and clearly visible. If damaged , have

new decals to your manufacturer (or distributor).

For repairs , ensure that spare parts have the same stickers as the original parts.

Read the maintenance manual and the

safety instructions before starting up.

Before any intervention, turn off the

tractor engine and remove the ignition

key.

Never put your hands in hazardous

areas while the parts are moving.

There is a danger of trapping your

hands.

To prevent leaks from the hydraulic

circuit, adhere to the instructions in

the maintenance manual.

People should be kept away from

the danger zone. There is a risk they

may be run over.

People should be kept away from

the danger zone. There is a risk they

may be run over.

Page 8

Do not go up on the step during the

moving of the machine.

Maintain in place the protection crankcase of the training belt of the seed

drill to protect your hands.

Be CAREFUL ! Risk of collision of

the wheels durng the folding against

hte tractor.

After the rst hour of work, tighten the

bolts.

Vibrations can loosen the bolt assembly.

To prevent eye injuries , do not look

directly into the area of service radar

sensor.

4.3 Toxic products

It is advisable to have at hand a rst aid kit .

Avoid contact with skin, eyes and mouth products such as fuels, oils ,

solvents, antifreeze and cleaning products . Most of them contain substances harmful to your health.

In case of incident , consult a doctor .

Please observe the indications on the safety labels containers of toxic products .

Batteries contain sulfuric acid. In case of skin contact , rinse

plenty of water and consult a doctor.

The pressurized hydraulic uid that escapes can have sufcient force to penetrate the skin and

cause serious injury . In case of contact with the body, see a doctor immediately .

4.4 Blockages

4.4.1 If the jam persists

Stop the engine, remove the ignition key or disconnect the battery (or the power outlet

electric).

Put the gear lever into neutral.

Apply the parking brake

Disengage the PTO .

Disengage the machine drive mechanism

Disconnect the hydraulic hoses.

Wait until all moving parts have completely stopped .

Lower / reassemble the machine

Fit the stabilization systems ( shims , stand, etc.).

Page 9

4.5 Fires

4.5.1 Preventive measures, warning against ammables

To avoid risk of re:

• make sure to keep the machine and its own accessories ;

• hold the (names of machine elements ) cleared of grass, leaves or excess grease .

Handle fuel with care. It is highly ammable, and its vapors are explosive .

Never store fuel container and the machine the tank still contains fuel in a building where fumes may

reach a ame or spark .

Never ll the fuel tank inside a building. Do not smoke while lling.

Never remove the fuel tank cap or add fuel in the tank when the engine is running ( or hot).

4.5.2 Fight against re

In any situation of re, use common sense and do the best to control it.

OR

Move away immediately from the machine and make sure that no one is near it.

4.6 Overhead power lines

Make sure that the clearance from the machine is sufcient in all cases of use of the machine ( eg

with open bonnets ) .

Consider also the radio antenna or other original accessory or retrotted and that changes the

height of the machine .

In case of contact of the machine with a power line , immediately stop the movement of the machine, its engine and engage the parking brake .

Check if you can leave your current position without touching the electric cables, then

jump your way that there is no position of simultaneous contact of your body with the machine and

the ground for your release .

Do not touch the machine until power lines are de-energized .

For anyone who approach the machine warn not to touch the machine and request that the power

line is switched off .

Page 10

4.7 Hitch / Tow

4.7.1 Generalities

The hitch of the tractor must be done on the hitch points provided for this purpose.

Ensure compatibility of the machine with the tractor (minimum motor power, hitch type, characteristics of the PTO of the tractor, etc.).

Do not stand between the tractor and the machine without turning the gear lever in neutral, close the

tractor parking brake and the machine disconnected PTO.

Do not stand between the tractor and the machine during a maneuver of the tractor, that it is controlled from the cab or from outside the tractor.

For maneuvers, select the forward speed of the tractor as small as possible.

When coupling, place the controls of the tractor so that it can not move during handling.

Once hitched machine, the towing device must be locked. Check the lock and the state of the hitch

before traveling.

Make sure the hitch of the machine causes neither overloaded nor bad weight distribution on the

tractor that could undermine stability:

• Do not exceed the maximum permissible load in tow points.

• Establish, if necessary, ballast weights on the supports provided for this purpose

according to the tractor manufacturer’s instructions.

When attaching or removing the machine, be sure to place all the support equipment and stability in

their respective places (on machines so equipped) to avoid imbalance of the machine.

4.7.2 Especially if towing a machine the lower lift arms : Hitch «two points»

Hitch the machine to a tractor whose lifting is equipped with lateral and vertical locking devices .

To travel on the road , observe the specied coupling height in the instructions for use and lock the

lift .

4.8 PTO / transmission Cardan shaft

4.8.1 Security linked to the tractor PTO and the machine shaft receiver

Check before operation that the speed and direction of rotation of the tractor PTO is compatible with

the intended use of the machine.

Check that power safety plugs are in place and in good condition. replace immediately if damaged .

Do not engage the PTO of the tractor when the engine is stopped.

Disengage the PTO when the angular limit of the transmission shaft may be achieved , eg by turning,

going up or down .

Any contact of the cardan shaft on the tractor or the machine can cause damage.

Page 11

4.8.2 Safety related to transmission shafts with universal joints

Only use the PTO shaft supplied with the machine or recommended by your manufacturer.

Ensure the proper collection tubes of the universal drive shafts , both in the working position in transport position .

Follow the safety instructions of the manufacturer of the transmission drive shaft .

Before connecting or disconnecting a transmission shaft PTO , disengage the PTO , stop the engine

and remove the ignition key.

Make sure before each use that the universal drive shaft is in good condition and is mounted and locked correctly.

Make sure the protector of the driveshaft is still in place and undamaged . Immediately replace if damaged .

After disconnecting the universal drive shaft to the PTO of the tractor , the latter must be covered with

a protective cap.

4.9 Maintenance & repair

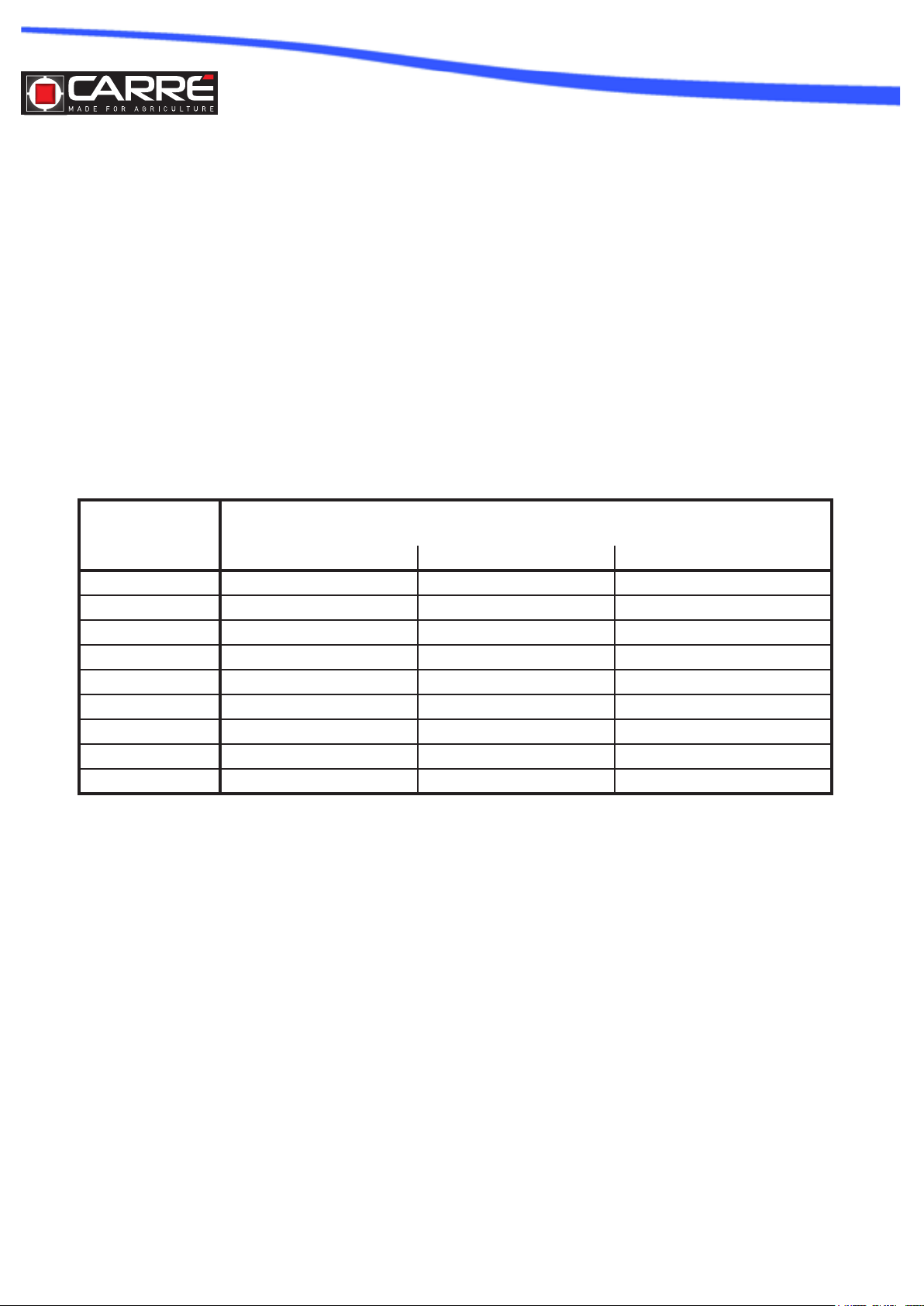

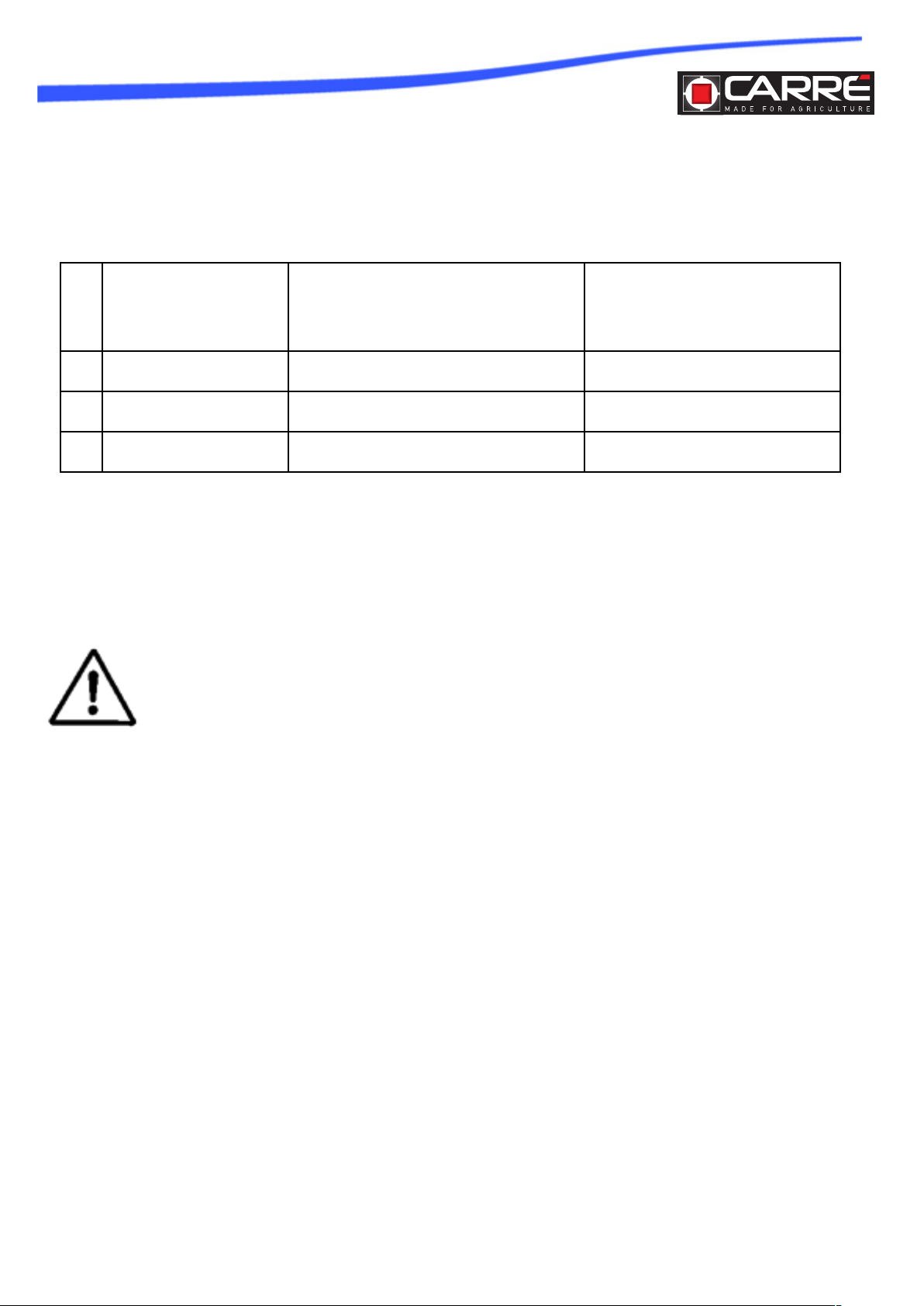

Torques depending on the class of quality screws and nuts

Thread -

8.8 10.9 12.9

M8 24 33 40

M10 47 65 79

M12 81 114 136

M14 128 181 217

M16 197 277 333

M18 275 386 463

M20 385 541 649

M22 518 728 874

M24 665 935 1120

4.9.1 Generalities

The maintenance and repairs must be performed by qualied persons.

Always keep the machine and its accessories in perfect condition.

Be sure to clean oil and fuel tanks .

Observe the maintenance intervals .

Before working :

Stop the engine, remove the ignition key or disconnect the battery (or the electrical outlet ) .

Put the gear lever into neutral.

Apply the parking brake .

Disengage the PTO .

Disengage the machine drive mechanism

Disconnect such hydraulic hoses.

Wait until all moving parts have completely stopped .

Lower / reassemble the machine.

Fit the stabilization systems ( shims , stand, etc.).

Let cool the engine, the transmission housing , the angle gear ... the machine.

Page 12

4.9.2 Welding operations

During welding operations on the machine ( or tractor) , disconnect the battery ( or the electrical outlet ) and protect the pipes (especially rubber ) to prevent them from being damaged by incandescent

projections that could cause loss of oil , hydraulic uid , coolant , etc.

4.9.3 Interventions on tires

Do not work on tires unless you have the special tools and the necessary experience. Incorrect ins-

tallation can seriously compromise your safety. When in doubt, call a qualied staff.

The tire assembly of characteristics different from those recommended by the manufacturer is prohibited.

4.9.4 Electrical work

Before starting work on the electrical system , disconnect the battery ( or the electrical outlet ) .

4.9.5 Hydraulic interventions

Before working on the hydraulic system , make sure that the installation is not under pressure. Eliminate the pressure before disconnecting hydraulic lines .

The hydropneumatic accumulator is a gas pressure apparatus. It is forbidden to change its appearance

by machining, welding, grinding, drilling or any other means.

The hydropneumatic accumulator and its attachment must be constantly maintained in good condition.

All precautions must be taken to never exceed the maximum allowable pressure for the accumulator

After checking or adjustment, it shall show no gas leak.

Before restoring pressure in the hydraulic lines , make sure all connections are tightened.

4.9.6 Repairs

Eliminate or to remove any failure that could compromise security.

Immediately repair any leak or incident of the hydraulic circuit and the cooling circuit of the machine.

Do not look for a hydraulic oil leak (under pressure) with the ngers.

Guards and defective or damaged locks must be replaced immediately. No protective originally xed

on the machine must be removed or modied.

The hoses must not come from pipes that have already been used in a circuit.

Gas tubes shall show no welding. When a exible or rigid pipe is damaged, it must be replaced

immediately.

Repairs affecting under pressure or tension (springs , accumulators , etc. ) use of procedures and

specic tools . They should only be performed by a qualied person .

Page 13

5. ENVIRONMENTAL PROTECTION

5.1Storage and disposal (pollutants )

5.1.1 Pollution of land

Be careful not to spill on the oor and not to throw waste into drains fats and substances such as

engine oil, hydraulic oil, coolant, brake uid, fuel, etc.

Do not mix fuel and oils.

The user’s attention should be drawn to the risk of serious pollution by disposal of waste oils. This

concerns in particular used engine oils and transmission systems, as well as lubricating oils, mineral

oils used for hydraulic systems used oil must be collected and stored by avoiding mixing with water

or any other waste not oily. They should be stored in airtight facilities until their collection or their

treatment.

Collect the draining of liquids in sealed containers, clean and provided for this purpose.

It is prohibited to store, to give up, to le in the natural environment or burning outdoors tires. Rapportez- them to a distributor or an authorized collector.

In the absence of specic EU directive, different arrangements may exist in other Member States.

5.1.2 Air pollution

Do not open an air conditioning circuit ( contains gases that should not be released into the atmosphere). Only your manufacturer (or distributor ) may empty , recharge an air conditioning system and

recover the polluting gases.

5.2 Machines for the application of pesticides

When mixing , keep the product manufacturer ‘s instructions

precisely determine the amount of product needed to avoid late boiled scraps of treatment.

When the product container is empty, rinse it thoroughly eg by rinsing device .

Intervene when weather conditions are favorable, early morning or late afternoon .

Select a slow forward speed and low pressure spray to avoid losses due to drift .

Page 14

6. COMMISSIONING AND OPERATION

6.1 Environmental conditions

If you must do when you start your machine in a room , make sure ventilation

sufcient local . ( The engine exhaust contains poisonous CO).

7. TRANSPORT / MOVING

7.1 Trafc on roads open to the public

Before embarking on the highway :

• Place the transport position wash according to the explanatory note ;

• check the correct operation of the brakes;

• ensure the proper implementation , cleanliness and proper functioning devices

signaling and lighting provided ( lights, reectors , etc.).

On public roads , observe the provisions of the Highway Code :

• Respect the maximum size (width, length ) allowed. If exceeded the maximum size , comply with

regulations for exceptional transport.

• Respect the speed limit

Page 15

• CALCULATION OF DISTRIBUTION OF EXPENSES

LOAD FRONT AXLE TRACTOR SHALL BE EQUAL AT LEAST 20% OF

WEIGHT EMPTY THE TRACTOR

To check these values , follow these steps to

perform the calculation:

tractor control

- To check :

• The total weight allowed.

• The loads permitted axle.

• The supported load the coupling point of the

tractor.

• The permissible load capacity of the tires

mounted on the tractor.

• Is it permissible coupling load enough?

All gures on the registration card or on the

rating plate and in the tractor manual .

Values to be aware :

P (Kg) empty weight of the tractor

P2 (Kg) load on the rear axle of the tractor empty

M2 (Kg ) Total weight behind machine

M1 (Kg) Total weight of ballast in the front

(M ) Distance between the ballast center of

a

front and center of the front axle

b (M ) Wheelbase of tractor

c

d

(M ) Distance between the axis and the lower

hitching center of the rear axle

(M ) Distance between the axis and the lower

hitching the machine center of gravity

gravity

Consult instructions for use or registration card

Consult the specications of the

Consult the technical characteristics of

tractor and the front ballast , or measure .

Consult instructions for use or registration card

tractor, or measure

Consult the specications of the

• M1 mini = Weighting calculation required up front to a minimum

• Pc= Calculation of the total weight of the unit ( tractor + Machine )

• P1c = Calculating the load on the front axle

• P2c = Calculating the load on the rear axle

tractor.P1 (Kg) load on the front axle of the tractor empty

machine.

machine.

Page 16

Complete the table below :

VALEURSCALCULEES

VALEURSAUTORISEESPARLE

VALEURSAUTORISESPARLES

PC

(Kg)

(Kg)

(Kg)

P1C

(Kg)

(Kg)

(Kg)

P2C

(Kg)

(Kg)

(Kg)

CALCULATED VALUES VALUE ALLOWED BY THE TRACTOR VALUES ALLOWED BY TIRES

TRACTEUR

FITTED TO THE TRACTOR

PNEUMATIQUESMONTESSURLE

TRACTEUR

- Check that:

• The calculated values must be <or = to the allowed values for the tractor and also by the tires

mounted on the tractor.

• It must be observed on the front axle of a tractor minimum load > or = 20 % of the load of the unladen tractor .

IT IS FORBIDDEN TO COUPLE THE MACHINE IS A TRACTOR:

• The calculated total load is > permissible value .

• The load on the front axle is < the minimum required.

Page 17

8. HANDLING

The handling of the machine will be done using the lifting eyes provided for this purpose , using a

hoist with a hook (crane, hoist , etc.).

Do not use the lifting eyes of the machine when lled .

When lifting the machine , be sure to keep away any other person and never be put under the lifted

machine .

9. HANDLING & REPAIR

9.1 Repair

Only use spare parts and accessories comply with the instructions in this document .

10. CLEANING

10.1 Cleaning Methods

Cover all openings to protect against the penetration of water, steam or cleaning products.

When using a high pressure hose , do not stand too close to the machine and avoid direct spray on

electronic organs, motor and electrical connections , hydraulic lines and hoses , seals, ller caps ,

etc.

10.2 Type cleaning products

Do not use harsh cleaning products ( chlorinated) .

Use rags that lint or soft brushes .

10.3 Controls the condition of the machine after cleaning

After cleaning, check the fuel lines , engine oil , brake and hydraulic oil and make sure they do not

leak , the connections are not loose and that show no deterioration.

Rectify immediately to deteriorations .

11. SPECIAL FEATURES OF THE MACHINES USED IN EXPLOSIVE

ATMOSPHERES

As part of an ATEX zone , the personnel must be aware of the risks

explosion and possibly have received specic ATEX training.

Page 18

FRONTAL HOPPER

Page 19

INDEX

1. TECHNICAL SPECIFICATIONS

1.1 Description

1.2 Implement components

1.3 Chart of technical data

1.4 Sound level

2. INSTALLATION

2.1 Transport

2.2 Lifting

2.3 Connecting the front hopper to the tractor

2.4 Radar installation

2.5 Connecting system between front hopper and rear distribution head

2.6 Check of the tractor stability and its lifting power

3. INSTRUCTIONS FOR USE

3.1 Operation of the blower

3.2 Distribution

3.3 Unhitching the front hopper

3.4 Unhitching the rear implement

4. MAINTENANCE

4.1 End of seasons operations

5. ACCESSORIES

5.1 Hopper extensions

Page 20

1. TECHNICAL SPECIFICATIONS

1.1 Description

• The seeder/fertilizer spreader mod. OCTOPUS must only be used for working agricultural lands.

Any other use differing from the one described in this manual can damage the machine and be dangerous for the operator.

• The seeder/fertilizer spreader mod. OCTOPUS can be used with other equipment for working the

soil, but only with the addition of a special assembly kit.

• The seeder/fertilizer spreader mod. OCTOPUS is ideal for sowing cereal: wheat, barley, rye, oats,

rice; ne seeds and fodder: rape, clover, alfalfa; and for big seeds: soya, peas.

• The seeder/fertilizer spreader mod. OCTOPUS is suited for the distribution of various types of fertilizers.

• The seeds are deposited in the soil by coulter organs, sock or discs, and are distributed continuously. A special

revolving metering unit driven by a wheel which adheres to the ground regulates the quantities to be

distributed.

• The seeds are distributed and transported to the coulters by compressed air that is produced by a

fan. The fan is

moved by the tractor power takeoff, or hydraulically as in the Plus version.

• The disc or sprint sock coulter is mounted on a super-elastic support that gives excellent depth and

pressure

control on the soil and regulates the height of the seed bar.

For the development and the construction of this implement the following guidelines of the Standard

98/37CE have been studied and applied:

UNI EN 14018

UNI EN 1553

UNI EN 982

ISO 11684

ISO 3757-2

The machine will work well if used correctly and if maintenance is carried out regularly. Users are

strongly advised to scrupulously observe the instructions given in this manual in order to prevent any

inconvenience that could impair good machine operation and its durability.

Users must follow the instructions given in this manual because the Manufacturer cannot be held

responsible for any damage or injury caused by negligence and the non-observance of such instructions.

The Manufacturer assures complete assistance with regard to immediate and accurate technical

service, a well as anything that may be necessary for a better operation and maximum performance

of the implement.

Page 21

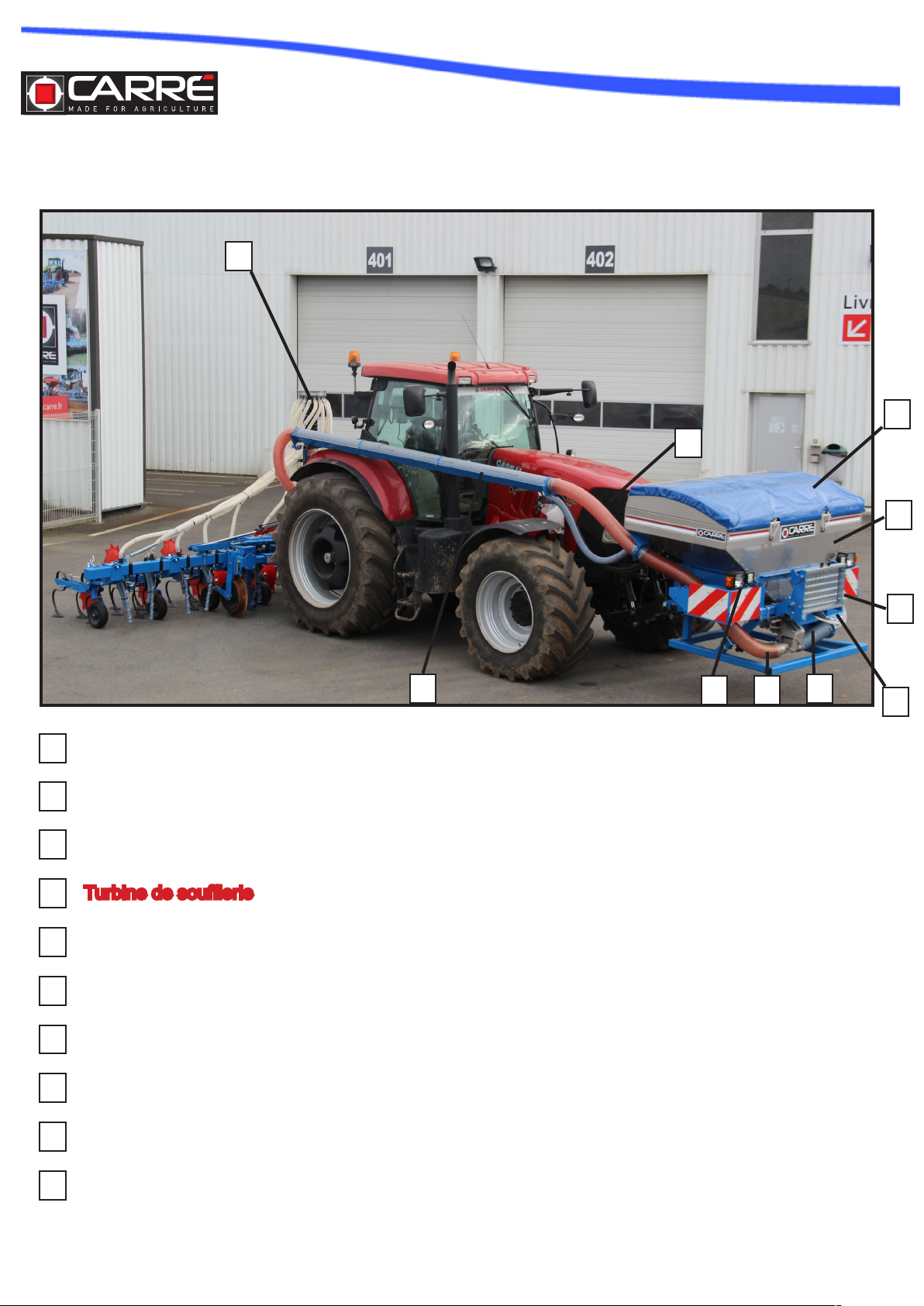

1.2 Implement component

10

7

8

1

2

Hopper

1

Ladder for lling lader

2

Front lights

3

Turbine de souferie

4

Metering unit

5

Radar

6

Closing cover

7

Seed conveying pipe

8

Seed conveying pipe

9

9

3

6

5

4

Distribution head

10

Page 22

1.3. Chart of technical data

MOD

6

OCTOPUS

250 cm

45-50 cm

70-80 cm

1400 ou 1800

L

600 ou 650 kg8

12

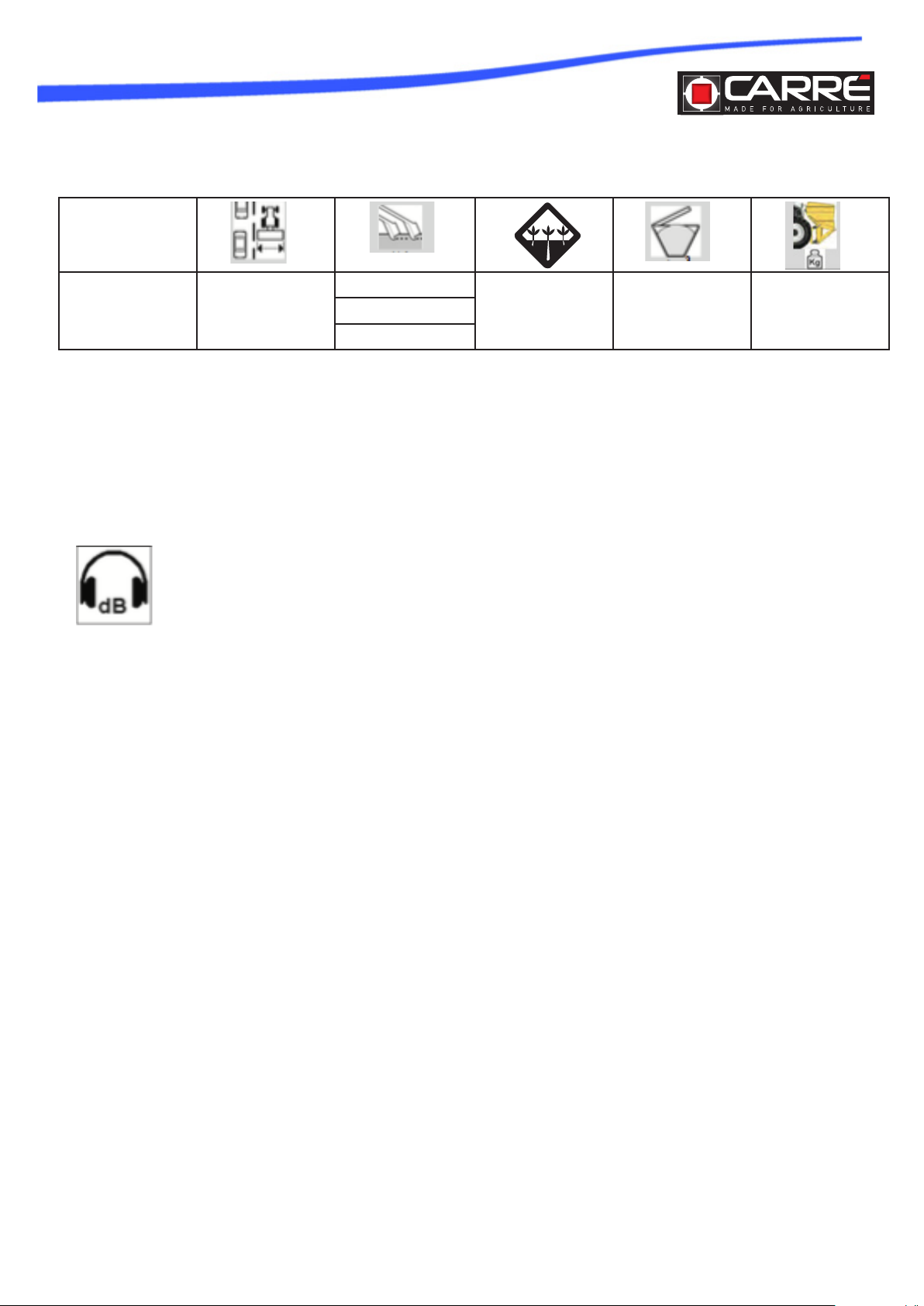

1.4. Sound level

If the tractor is equipped with a cabin, the sound level will depend on the soundproo-

ng level of the cabin itself. If the tractor does not have a cabin or is used with the

windows open, the noise level emitted by the machine while working and measured

at a distance of 200 mm. from the rear window exceeds 85 dBa. It is therefore advisable to use protective earmuffs as indicated in the regulations of different countries.

Page 23

2. INSTALLATION

2.1 Transport

The machine can easily be transported even over long distance with suitable means of transportation:

lorries, trailers, train cars etc.

The loading and unloading of the machine can be rather dangerous operations, unless they

are performed with the utmost care: have all unauthorized personnel leave the area; clear

and circumscribe the loading area; check that the available means of transportation are in

good working order and strong enough for the job at hand.

It is also necessary to make sure that the area of operation is free and that there is enough

escape space, i.e. a free and safe area where it is possible to move quickly should the machine fall down. Said operations are to be performed exclusively by personnel trained to perform this type

of work.

Before beginning the loading operation make sure that the available means is certied for this type of

transportation and that it is strong enough to support the weight of the machine. To this end see CHART

OF TECHNICAL DATA (see Par. 2.3) for the weight of the machine.

This chart is also useful to check the possibility of transit of the machine through narrow passages.

2.2 Lifting

The Lifting and moving operations must be performer with means

strong enough to carry the weight of the machine and by personnel trained in this type of work. If it becomes necessary to lift the

machine, hook the machine

as shown in the picture and move it: during this operation the

machine should not be lifted by more than 200 mm. from the ground. In order to

avoid damages to the hopper metal plates, use approved lifting belts

2.3 Connecting the front hopper to the tractor

This operation must be carried out on a horizontal surface, with the seed-drill in a stable

position on its support legs

The front hopper is supplied STANDARD with a cat. 2 hitch for tractors with front lifter.

When the hopper has been connected solidly to the tractor, make sure that the equipment

is perpendicular to the ground. If necessary, you can use the upper arm to correct the position of the

equipment.

Support the hopper with the tractor lift and lift the legs toward the tractor. Block them into position by

inserting the pin into the corresponding bushing (see pct. below)

Page 24

2.4 Radar installation

The radar is to be positioned as follows on the frame supporting the hopper:

1. Attach the support A to the lower frame of the hopper by means of the U-bolts clamps C

2. Attach the radar B to the support A.

There is only one possible position of the radar on its support, while the latter can be displaced along the slanted pipe of the frame, so as to guarantee, in the working position, a

height from the ground which can vary between 0.4 and 1m.

In order for the radar to work at its ideal position of ± 37° the hopper must be parallel to the grou nd

while it is working.

2.5 Connecting system between front hopper and rear distribution head

The seeder/fertilizer spreader OCTOPUS is

complete with a connecting system between the

front hopper(A) and the distribution head (B).

Such connection can be adjustable and must be

rmly attached to the tractor, so as to avoid loops

and to guarantee the correct performance of the

power or disc harrow when working up or downhill.

2.5.1 Main components

The connecting system consists of:

A. 2m long rigid PVC pipes

B. Supporting plates

C. Blocking rings

D. Connecting anges between the rigid and the

exible pipes

E. Different tightening elements

F. Connecting electric wires

B

A

Page 25

2.5.2 Installation of the connecting system on the tractor

When the seeder/fertilizer spreader is delivered, the system for connecting it to the tractor is not

assembled.

Its assembly is a task to be performed by the end user, who must perform said assembly depending

on his tractor and following the steps below:

1. Determine the length (L) from the possible ones: 3860, 3660, 3460 ,3260, 3060, 2860, 2660, 2460

2. Assemble the plates (B) on the length (L) and attach them rmly to the tractor

3. Insert in the receptacle (S) the wire extensions and keep the connection protruding by 10/15 cm

from their seats (M)

4. Pull out from their seats (U) the wires which will be connected with the tractor (es: monitor, battery)

calculating their necessary length

5. Coil possible exceeding lenghts of cables inside their receptacle (S)

6. Secure all the wires with plastic strips

7. Insert the pipes into each other (A) and cut a piece off the end to adjust to the length (L)

8. Place the pipes over the plates, assemble the anges (D) at the ends and secure them with the

fastening metal rings (C)

Page 26

2.5.3 Connecting the hopper with the implement

The operation is to be performed on a level surface, with the seeder/fertilizer spreader and the

implement rmly supported by their supporting stands.

The newly assembled connecting system can be left permanently attached to the tractor. It pres-

ents at its ends two quick hitching anges for the front hopper and the rear implement.

Once the hopper and the implement have been hitched to the tractor, connect them pneumatically and

electrically, following the steps illustrated below:

1. Connect the Ø130 mm seed-conveying pipe (A), already atta-

ched to the hopper with the front hitching ange of the connecting

system and secure it with an metal clamps.

2. Insert the Ø 60 mm pipe containing the electric wires (B), already attached to the hopper, into the lower hole of the front quick-

hitching ange and secure it with a metal clamp.

3. Connect the electric wires coming from the hopper with the respective extensions previously installed on the connecting system

(C)

4. Hitch the implement to the tractor.

5. Connect the seed-conveying Ø130 mm hose (D), coming from

the distribution head with the rear quick-hitching ange of the

connecting system and secure it with a metal clamp.

6. Connect the electric extensions of the connecting system with

the relevant wires of the electronic components installed on the

implement (E) and seure them with a plastic strip.

In order to use the tractor with other implements it is possible to unhitch the hopper and the implement,

from the tractor without removing the system for the connection with the tractor.

Page 27

2.6 Check of the tractor stability and its lifting power

When an implement is hitched to a tractor and, as far as circulating on public roads is concerned, it

becomes an integral part of it, it can alter its stability and make it difcult to drive it and to work.

When you add a machine to the tractor, you will change the weight distribution over the axles. It is therefore recommended to add suitable ballast to the front of the tractor, so as to distribute adequately the

weight over the axles.

Calculate the ballast to be used with the following formula:

CALCULATING TRACTOR STABILITY.

were:

i = inter-axle (m) of the tractor wheel

d = distance between the front axle and the front

ballast (m) s = projection of the implement from the

rear axle (m)

T = tractor mass (kg)

Z = ballast mass + hopper with seeds (Kg)

M = implement mass (Kg)

At least 20% of the total tractor-implement mass must

weigh on the front bridge of the tractor. It should be

remembered, however, that stability can be improved

with the right choice of tractorimplement combination

and with the application of ballast to the front, in the

limits and methods indicated by the tractor manufacturer. Moreover, when the tractor is stopped, the machine must be lowered to the ground, thereby improving stability.

Page 28

3. INSTRUCTIONS FOR USE

3.1 Operation of the blower

The implement is suited only for the use described. Any other use deferring from the

one described in this owner’s manual can damage the machine and be a hazard to the

user.

The good performance of the implement depends on its proper use and an adequate maintenance. It

is, therefore, advisable to follow closely the directions contained herein, so as to prevent any inconvenience which may impair the good performance and the life span of the machine. It is also important

to follow the directions contained in this owner’s manual, because the Manufacturer cannot be held

responsible for damages caused by negligence or the non-observance of the directions. The hydraulic system driving the air-pump must be used, serviced and repaired by personnel having a perfect

knowledge of the unit itself and of the hazards it may present. Check the correct plugging of the quick

couplings: unless they are correct, damages may occur to the components of the system. Only disconnect hydraulic connections after they have been de-pressurized.

The leaking of oil under pressure may cause skin wounds and severe infections.

Should this happen, consult a doctor immediately. It is absolutely forbidden to install

hydraulic components inside the tractor cab.

3.1.1Hydraulic connection with the tractor

Check in the Owner’s Manual of the tractor its hydraulic features, which must be as follows:

• Hydraulic system of the “CLOSED CENTER” (also called LOAD SENSING )type

• Pump with variable displacement

• Oil delivery exceeding 50l/min. the hydraulic operation requires 24 l/min.

• Working pressure: 100 ÷ 130 Bar Max 150 Bar (fan speed 4200÷4500 rpm, max 4600 rpm)

• Oil cooling: should the tractor not be equipped with an adequate cooling system it is necessary to install one

• The tractor must be suited to receive a free-return ow connector (NO COUNTERPRESSURE).

The oil ow necessary to drive the blower is taken from the tractor

hydraulic distributor, through a delivery hose 1⁄2 A.

The rotational speed of the hydraulic motor and, as a consequence, of

the suction unit depends on the ow pressure, which is shown on the

manometer.

The system is complete with a safety valve which makes it possible for

the device to keep on turning by inertia even after the system has been

shut off or a sudden break down of the system has occurred.

For a correct performance it is important to connect the ow discharge

hose 3⁄4 G of the hydraulic motor to a free ow discharge plug of the

tractor; this free discharge cannot present any counter-pressure exceeding 3 Bar.

This connection is of basic importance above all to protect the hydraulic

seals of the motor, which, if damaged, would allow very dangerous oil

leaks.

A) Quick coupling on the delivery side 1⁄2 B) Three-way electro-valve

C) Manometer

D) Motor

E) Free-ow discharge

F) Safety valve

G) Quick coupling on free-ow discharge 3⁄4 H) Flow-adjusting device

(option)

Page 29

3.1.2 Adjustment of the oil ow without a varaible displacement pump

If the tractor does not have a variable displacement pump, there is a special kit

for this purpose which is supplied on demand.

3.2 Distribution

The metering unit is the main element that makes the seed- drill work. It is

positioned under the seed hopper and

it is driven by the driving wheel through a mechanical chain transmission and

a universal joint.

The metering unit, which consists of a cylinder containing longitudinal hollow

sections A, distributes a certain quantity of seed - depending on the calibratio

The air ow generated by the fan blower D and regulated by the buttery

throttle E transports the seeds to the distributor head that can be found at

the end of the “Venturi” tube. From here, the seeds are taken to the coulters

and then sown.

The metering unit can work with seeds of between 1 and 10 mm. The main

seeds are:

• Cereal: wheat, barley, oats, rye, triticale, sorghum, rice

• Large seeds: corn, peas, beans, soya

• Small seeds: grass, clover, rape

3.3 Unhitching the front hopper

The unhitching of the hopper from the tractor can be a very hazardous operation. Use

estreme caution while performing the entire operation and follow directions strictly.

To unhitch the seed-drill correctly, you must work on a horizontal surface as follows:

• Lower to the ground the supporting stands and secure them rmly with the appropriate pins.

• Disconnect all hydraulic and electric connectors supplying the seeder/fertilizer spreader

• Remove the conveying corrugated hose from the connecting system

• Unhitch the hopper from the tractor and make sure it remains in a stable position

3.4 Unhitching the rear implement

The unhitching of the disc or power harrow from the tractor can be a very hazardous

operation. Use estreme caution while performing the entire operation and follow

directions strictly.

To unhitch disc or power harrow correctly, you must work on a horizontal surface as follows:

• Lower to the ground the supporting stands and secure them rmly with the appropriate pins.

• Disconnect all hydraulic and electric connectors supplying the seeder/fertilizer spreader

• Remove the conveying corrugated hose from the connecting system

• Unhitch the hopper from the tractor and make sure it remains in a stable position

Page 30

4. END OF SEASON OPERATIONS

4.1 Remisage

At the end of the season, or if you believe that you will not use the machine for a long period of

time, the following operations should be carried out in order to maintain its integrity:

Carefully remove all the seeds from the hopper and the distribution organs.

Wash the machine with plenty of water, especially the hoppers, then dry it. While doing this keep

ap B open (gure above) and remove the connection bend to the Venturi. Do not use a water

cleaner.

Leave ap B open (gure above) to protect against mice that can damage the machine.

Carefully check and, if necessary, replace any worn or damaged parts

Tighten all screws and bolts

Protect all unpainted parts with lubricant

Cover the machine to protect it

5. ACCESSORIES

5.1 Hopper extension

The hopper extension increases the hopper capacity from a basic 1400 litres to 1800 litres (+400

lit).

Page 31

DOSEUR

Page 32

INDEX

1. TECHNICAL SPECIFICATIONS

1.1 Description

2. SETTINGS FOR SEED DRILLING

2.1 Seeding chart

2.2 Reading the chart

2.3 Adjustment of the metering unit

3. CALIBRATION TEST

3.1 Electrical calibration test

4. CLEANING

4.1 Discharging the seeds

Page 33

1. TECHNICAL SPECIFICATIONS

1.1. Description

The metering unit, the main element for the performance of the seed-drill, is positioned under the

seed hopper and it can work with seeds

measuring from 1 to 10 mm.

The main elements which constitute it

are:

1. Gears for the selection of normal to

ne seeds

2. Lever for the adjustment of the seed

quantity

3. Sticker with graduated scale

4. Indicator of seed quantity

5. Brush for cleaning the alveolar rotor

6. Lever controlling the shutter to

quickly empty the metering unit/hopper

7. Knobs for the quick removal of the

bottom wall

8. Snap pin for normal/ne seeds

9. Slide for calibration test

10. Venturi element

11. Lever for calibration test

12. Flap for discharging seeds out of

the Venturi element

2.SETTINGS FOR SEED-DRILLING

For each type of seed to be drilled it is necessary to adjust the metering unit very precisely

following the indications concerning the main seed types listed in the SEEDING CHART

Depending on whether you need to drill ne or normal seeds the metering unit needs to be

adjusted as indicated in the seeding chart

It is obvious that the F position is meant for Fine seeds, while the N position is meant for Normal

seeds.

Page 34

2.1 Tableau de semis

Page 35

2.2 Reading the chart

When reading the chart, follow the procedure described below:

1. In the chart identify the type of seed you want to drill

2. Set the metering unit on the normal seed N position or on the ne seed F (see chap.3.4).

The position is indicated in the chart and it relates to the type of seed

3. Choose the quantity of seed you want to drill (Kg/ha)

4. By matching the line of the quantity to be drilled with the column of the position (normal or

ne seeds) you will identify the degree of opening of the alveolar rotor of the metering unit

5. Adjust the metering unit on the resulting datum (see chap. 3.4)

Page 36

2.3 Adjustment of the metering unit

In order to dispense all types of seeds, the metering unit must undergo three different adjustments :

A. By properly moving the highlighted gear you can

obtain two different rotation speeds of the alveolar

rotor (chap. 3.4.1)

B. Through the highlighted handle, which is complete

with a blocking pin, you obtain the proper volume of

seeds to be distributed directly in the alveolar rotor

(chap. 3.4.2).

C. With the snap pin you change the position in the

metering unit: either NORMAL or FINE seeds (chap.

In order to prevent damages to the metering unit, decrease the quantity of seed

only when it is rotating or when the hopper is empty

2.3.1 Rotation speed

The rotation speed is chosen by moving the 2

gears along the shaft:

RED = Fine seeds BLACK= Medium seeds

In order to do this, it is necessary to overcome

a small resistance to bring them to the desired

position: a click will signal that this position has

been reached.

Before you perform this movement, make sure

that the cogs of the gears are aligned by rotating

one of the two shafts.

2.3.2 Seed quantity

The index on the graduated sticker can be made to slide by turning the crank handle and it determines the quantity of seed to be distributed.

The sticker is divided into two sections:

- from 0 to 30 for ne seeds F

- from 0 to 130 for normal seeds N

Page 37

2.3.3 Normal seed/Fine seed positions

The heart of the metering unit consists of the alveolar rotor which is

divided into 2 sections: ne seeds F and normal seeds N.

To obtain the setting for normal or for ne seeds it is necessary to

bring the index to the “0” position on the graduated sticker. This must

be done with the metering unit empty and clean. Then insert the snap

pin in the correct position

f you set the metering unit for normal seeds, remove the revolving cleaning brush,

because it is only necessary to clean and empty the alveolar rotor from ne seeds

To assemble or remove the revolving brush, all you need to

do is to loosen the knobs for the quick removal and remove

the bottom plate of the metering unit.

This will make the inside of the metering unit accessible to

perform this operation

Page 38

3.CALIBRATION TEST

Before lling the hopper for the rst time, open ap A in order to remove possible foreign

bodies which may be present. When lling the hopper always make sure that foreign objects

(nylon, paper, strings etc.) do no enter.

Once the metering unit has been properly set, it is necessary to perform a calibration test, since the data in the chart are

merely indicative, due to the differences in size, humidity content

and specic weight of the seeds.

With the empty hopper completely empty, shut the alveolar rotor

with the C crank handle.

Introduce a small quantity of seeds (at least for 2/10th of an hectare) into the hopper.

From the chart calculate the opening degree of the alveolar rotor

based on the type and quantity of seed to be distributed, by turning

the crank handle C and making it coincide with the number in the

graduated sticker D.

Through the lever E on the Venturi element open the shutter, then

place a container under the slide B to collect the seeds

Depending on the composition of your seed-drill, there are 2

methods for performing the calibration test

- mechanical calibration test - electrical calibration test

Bulkhead F allows for a precise sawing test.

Remove Bulkhead F and perform the sawing test under the Venturi by opening only the G door in case of large quantities To be

sawn as avoiding to doing so might provide wrong results.

Page 39

3.1 Electrical calibration test

With your monitor ON press the push button for the calibration test and hold it down for the period of

time necessary to sufciently ll the container. Weigh the collected seeds and store the net weight in the

monitor.

Do not shut the alveolar rotor with seeds inside the metering unit; these would damage the metering

elements.

The data in the chart are indicative, since the specic weight, the humidity content and the size of the

seeds often vary. Therefore, it is advisable to perform yet another calibration test, just to be sure: the

quantity measured with this latter test will then be the constant weight distributed.

4.CLEANING

At the end of the season or whenever you foresee that the seed drill will be idle for a long period of time,

it is mandatory to discharge all the residual seeds from the hopper and the distribution elements and to

4.1 Discharging the seeds

The discharge of the seeds is done in 2 steps:

- Emptying the hopper

- Completely emptying the metering unit

- Emptying of the Venturi element

4.1.1 Emptying the hopper

To discharge the seeds from the hopper open the ap

at the bottom of the metering unit and place a container underneath to collect the seeds.

Page 40

4.1.2 Completely emptying the metering unit

When emptying the hopper, some residual seeds will remain inside the metering unit. It is highly advisable to remove them, since they may sprout and damage the metering components.

In order to perform a thorough cleaning, remove the knobs A and remove plate B. Now the inside of

the metering unit is accessible. Turn the alveolar rotor to remove possible residues from the cells C.

4.1.3 Emptying the venturi element

After the removal of the seeds from the metering unit, open

the ap B at the bottom of the Venturi element by acting on

the shutting catch A, then remove possible seed residue from

the bottom of the element

At the end of these operations wash the hopper and the transmission organs with water. Dry thoroughly. Check that no part is damaged: should there be any damaged part, replace it and protect the

unvarnished metal parts with lubricants.

It will be in your best interest to nd the machine ready to be used the next time you need it.

Page 41

COMPUTER

Page 42

INDEX

1. GENERAL INFORMATION

1.1 Purpose of the owner’s manual

1.2 Warranty

2. TECHNICAL SPECIFICATIONS

2.1 General description

2.2 Installation of the computer

3. INSTALLATION

3.1 Electric wiring

3.2 Installation of the sensor of the distribution fan «t»

3.3 Instalaltion of the sensor of the product level indicator «n°1»

3.4 Installation of the «x» lifting position sensor

4. FUNCTION

4.1 Description of the control panel

4.2 Status indicator

4.3 Use of the monitor keys

4.4 List of screen shots

4.5 Description of the main screen shot («main»)

5. PROGRAMMING

5.1 Menu for tramline programming

5.2 Programming menu for the forward speed sensor

5.3 Radar automatic calibration

5.4 Set simulated forward speed

5.5 Programming menu for the seed drill width

5.6 Programming menu for the manual adjustment of the calibration rate

5.7 Programming menu for the calibration test from the monitor

5.8 Programming menu of fan/seed level alarms

5.9 Menu for the operator’s conguration

5.10 Calibration test through the switch on the machine

6. DIAGNOSTIC

6.1. Diagnostic instrument

6.2 Diagnostic - metering unit

6.3 DIagnostic hystory

7. MAINTENANCE

7.1 Normal maintenance

Page 43

1. GENERAL INFORMATIONS

1.1. But de la notice d’utilisation

This Owner’s Manual has been written by the manufacturer of the machine and it is an integral

part of the documents accompanying the machine.

This Owner’s Manual denes the purposes for which the machine has been manufactured, specifying its correct

use and the limits of the same.

The punctual application of the data contained in the present Owner’s Manual guarantees the safety of the persons using the machine, economy of operation and a longer lifespan of the machine.

The present Owner’s Manual has been divided into different paragraphs in order to make the

search for the various items and the consultation of the initial index easier.

The pictures included in this Owner’s Manual are supplied by way of information only. Even if they

greatly differ from your machine, the safety rules and the information are always guaranteed at any

rate.

1.2. Warranty

At the time of delivery, check whether the machine has been damaged in transit and if all the

accessories are present.

Possible claims must be made in writing within 6 days.

INVALIDATION OF THE WARRANTY

The warranty becomes immediately void:

-if damage is caused by an incorrect maneuver

-in case the instructions given in this manual have not been strictly followed

-if non-original parts have been used

-if modications have been made to the machine without the consent of the Manufacturer.

-if a damage has been caused accidentally

-if the damage has been caused by events of force majeure (lightening, oods, re or other independent causes)

Page 44

2.TECNICAL SPECIFICATIONS

2.1.General description

The multi-function electronic computer of the “ALPETRONIC Super Plus” series has been designed for agricultural, pneumatic row-seeding seed-drills

Alpetronic Super Plus has been designed to automatically and continuously monitor the quantity

of seed distributed by the seed-drill. With the machine in operation and depending on the soil

conditions, it is possible to increase or decrease the normally pre-set seed ow

This computer can manage and monitor the following functions:

• Tramline : it automatically shuts off some of the rows to obtain a non-seeded track to be used as

a “road” for

the subsequent operation with a sprayer.

• Pre-start : it allows the start of the seed metering unit while the machine is idle, in order to guarantee a

precise drilling when the seed-drill work is resumed. It displays and checks the following data:

• Driving speed recorded by radar (Km/h).

• Number of hectares seeded, through two independent totalizators (partial and total)

• Quantity in kg of seed distributed through two independent totalizators (partial and total)

• Total number of hours worked (cannot be reset)

• Number of hectares seeded (cannot be reset)

• Seed-level in rear hopper

• RPM of distributor fan

2.2.Installation of the computer

To install the computer proceed as follows:

• On a at surface inside the cabin of the tractor bore two holes (D. 8 mm) at the same distance as

the holes which are present in the holding bracket (ref. A), then attach the bracket to the frame of

the tractor through

We suggest that you install the computer right in front of the operator in order to Make its use

easier during the working cycle.

Page 45

3.INSTALLATION

3.1 Electric wiring

Connect cable A directly with the tractor battery. Be careful to connect the poles correctly (brown +

/ blue -) and wire the cable correctly to the tractor.

From time to time check the voltage of the tractor battery, since the electric part

of this instrument requires a constant 12 volt supply. If the power is lower it may

cause malfunctions. (go to the page “Diagnostic) and select “Instrument”: this will

show the voltage of the battery

• Connect the connectors of cable A to the connector of cable B

• Fix the monitor inside the cabin

• Connect cable C with cable D and fasten the 2 connectors tightly.

Page 46

3.2. Installation of the sensor of the distribution fan “T”

3.2.1. Hydraulic version

The sensor for the reading of the fan “T” RPM must be installed on the

proper bracket (A), which, in turn, must be attached to the fan support

(B) perpendicular to the rotating shaft, at a distance of 2 /3 mm. from

the magnetic reference (C). The sensor will read the passage of insert

C.

Page 47

3.3. Installation of the sensor of the product-level indicator “N1”

The capacitive sensor recording the product level must be positioned so as to record the level of the

product in the hopper when it drops below the reserve limit; it is positioned inside the hopper and

mounted on the frame. It is important for the head of the capacitive sensor to be directly in touch with

the product: thus, when the sensor is covered by the product it issues no alarm signal, but when the

seed drill is in operation and the sensor head is uncovered, the relevant alarm signal is activated.

3.4. Installation of the “X” lifting position sensor

This sensor must be installed with its relevant elements and must be

adjusted so as to record the changing position of the implement from

its working to its lifted position.

For the assembly details see the special manual concerning the

component S31155 (cod.D13007).

Page 48

4.FUNCTION

4.1 Description of the control panel

All the functions of the instrument are accessible through FIVE menu keys below the LCD computer

screen. Picture 1

A few seconds after pressing the ON / OFF key (Ref A) the main screen shot “MAIN” will appear, then,

by pressing again the key you will have access to the screen shots: “RATE” “INFO” and programming

menu.

The key in the middle (Ref B) makes it possible to:

1. Activate the manual Pre-start (see par..4.5.4)

2. Increase the percentage of the seed quantity (see par. 4.6)

3. Scroll the various Menus and enter the values and the parameters

The three keys under the LCD screen Ref C control various functions in the main screen ( for instance:

blocking the rotation of the electric motor , blocking the Tramline) and in the programming menus they

are used to select and enter several parameters. The texts and the icons are displayed at the side of the

keys to indicate their functions

To turn off the instrument press for more than 5 seconds

4.2 Status indicator

On the upper section of the display and in all the screen shots there is a bar showing the time but also

all the icons. Said icons indicate:

MARCHE

ARRÊT

Page 49

4.3 Use of the monitor keys

Page 50

4.4 List of the sreen shots

Once the monitor has been turned on, each time you press the key, you will enter a different page

Indicator of the screen shot

number

Page 51

Page 52

4.5 Description of the main screen shot (“MAIN”)

Whenever the computer is switched on the main screen shot (“MAIN”) will be accessed directly. This

screen shot is divided into 5 sections which display the following functions

Screen shot with the machine not in operation

Page 53

4.5.1 Forwards speed & alarms

With the exception of sudden speed variations, the forward speed displayed at any given moment will

be the average speed calculated every 3 seconds.

The instrument is programmed to set off a «low speed» & a «high speed» alarm

If the seed drill is working at

a forward speed of less than

0.5 Km/h an alarm will blink

on the main screen shot (see

picture at the right), at the

same time an acoustic alarm

will be set off. At any rate the

minimum speed value can be

altered at the discretion of the

end-user. (see par. 4.3)

If the seed drill is working at

a speed exceeding the speed

calculated and permitted by

the computer (indicated in the

main screen shot “RATE”) an

alarm will blink on the main

screen shot (see picture at

the right), at the same time an

acoustic alarm will be set off.

Page 54

When a new seed quantity to be distributed is inserted in the RATE screen

shot, the instrument will re-calculate and display the maximum speed at which

the new quantity can be maintained.

Said calculation takes the following data into consideration :

- New quantity of seed to be distributed

- Working width

- Calibration rate (calculated by the instrument with the calibration routine)

- Reduction rate of the electric motor

Maximum RPM of the electric motor

Press key to go back to the “RATE” screen shot .

N.B: If the forward speed is too low, the operator must modify (increase)

the opening of the metering unit and perform the calibration routine again to

increase the calibration rate.

4.5.2 Tramline status / Functions

The main screen shot “MAIN” will display the tramline “status”

TRAMLINE RHYTHM

INCREASE OF NUMBER OF BOUTS

The tramline rhythm does not always begin at bout “1”; check programming carefully (see par. 5.1) The increase of the number of bouts is

determined by the lifting of the machine until the tie-rod of the upper arm

of the tractor lift activates a micro-switch which is present on the top link

of the 3-point hitch of the machine.

The pin of the micro-switch must always be positioned below the

top link of the 3-point hitch.

Page 55

The bracket must be adjusted (see picture at the right) so that while in the working position - the pin of the micro-switch never

comes in touch with the top link of the 3-point hitch and when

the machine is lifted the pin is tilted.

Pay special attention to and take particular care of this micro- switch. NEVER

TEMPER WITH IT FOR ANY REASON,

since it would jeopardize the function of

the metering system control.

If necessary press key +1 to change & obtain the correct number of the bout: for instance, if while

working it becomes necessary to lift the machine in order to avoid an obstacle, the +1 key is used to

go back to the initial working bout.

HOLDING THE TRAMLINE BOUT NUMBER

Press key in order to hold the current tramline bout number. This is a very useful function

when it becomes necessary to perform unforeseen maneuvers during the working process.

The icon indicates that the bout number is being held. Press the key under this icon to activate the relevant tramline bout number again

4.5.3. Manual control of the metering unit rotation

With the fan in full operation/ and after the forward speed has been registered by pressing the key

under the con it is possible to stop the rotation of the metering unit.

This function is useful when the soil needs to be cultivated further, without, however, being seeded .

By pressing the key under the icon or the second

time the rotation of the metering unit controlled by the radar

and by the micro-switch which is on the top link of the machine is resumed

Whenever the seed drill is lifted off the ground the rota-

tion of the metering unit is stopped thanks to the action

of the micro-switch which is located on the top link of

the 3-point hitch.

Page 56

4.5.4. Fonction pré-start (manuelle)

La fonction de pré-démarrage aide à éviter les zones non semées notamment dans les coins de

champs. Cela démarre le doseur à la vitesse de calibrage pendant que le semoir est toujours à l’arrêt,

et ainsi amorce le semoir jusqu’à ce que la semence arrive aux éléments semeurs juste avant que le

semoir commence à travailler.

Pour utiliser cette fonction, il est nécessaire de :

1) Faire tourner la turbine de distribution à son régime nominal

2) Appuyer sur la touche sous l’icône de l’écran principal MAIN.

3) Le semoir à l’arrêt, le moteur démarre à la vitesse de calibrage pendant un temps maximum de 5 seconde (programmé d’usine) qui laisse de temps à l’opérateur d’atteindre

2km/h, vitesse d’avancement à laquelle la régulation automatique par le radar prend le relais.

A chaque départ, veuillez à nouveau appuyer sur la touche

pré-start pour l’activer.

4.5.5. Fonction pré-start (automatique)

An d’utiliser cette fonction, il est nécessaire de:

1. Allez sur l’écran 4 (voir par 3.4)

2. Sélectionnez Cong Operateur / Pre-Start (Ecran 4.1.7)

3. Programmez le temps utile pour dépasser 2Km/h

4. Appuyez sur la touche sous l’icone pour faire varier la

fonction puis OK POUR VALIDER

Pre Start Manuel ACTIF

Pre Start Automatique ACTIF

5. Revenez à l’écran principal (1)

6. Enclenchez la turbine au régime nominal

7. Sur l’écran principal (MAIN) appuyez sur la touche sous

l’icône

8. Machine arrêtée, le moteur électrique va faire tourner le

doseur à la vitesse simulée de travail pendant un temps paramétré dans le menu Cong. Opérateur / Pré-Start. Sur l’écran principal apparaît alors le compte à rebours du temps programmé.

Ce temps permettra de :

- Arriver à une vitesse supérieure à 2 Km/h, vitesse limite qui

déconnecte automatiquement la fonction vitesse simulée. A partir

de cette vitesse la rotation du doseur est à nouveau gérée par le

radar.

A chaque fois que la machine est abaissée et que l’interrupteur de

3eme point est en position travail, le Pré-Start s’active de manière

automatique sans avoir à appuyer sur la touche sous l’icône

Page 57

4.5.6. Description de l’écran «RATE»

La dose d’application afchée sur l’écran MAIN est la même que celle afchée dans

l’écran dose de semis RATE. Si dans l’écran de dose de semis RATE, la dose cible est

manuellement modiée en + ou en-, ce % de modulation de dose clignotera sur l’écran

principal.

Page 58

4.5.7. Half width function (Manual)

4.5.8. Description of the “info” screen shot

Go to screen shot 3 (see par. 3.4)

Page 59

5.PROGRAMMING

5.1. Menu for tramline programming

Go to screen shot 4C (see par. 3.4)

Page 60

Page 61

5.2. Programming menu for the forward speed sensors

Go to screen shot 4.B.1 (see par. 4.4)

Through the middle key move the cursor to:

Signal : It mentions the device by which the speed is recorded (cannot be

modied)

SSF 0.008 m / imp : Speed rate devoted to the registration of the speed

by the radar (can be modied through the middle key) 0.008 is the standard radar value, however, IT IS ADVISABLE to perform an AUTOMATIC

CALIBRATION TEST in the eld, as described in paragraph 5.3.1, to

obtain a more precise value of the forward speed, and, therefore, of the

number of hectares worked by the machine.

Autocalib : Automatic calculation of the speed rate through 100 m test run

in the eld

Vitesse : Minimum speed below which the speed alarm will be activated

(this value can be modied through the middle key).

Press ESC to go back to the previous page.

5.3. Radar automatic calibration

Go to screen shot 4.B.2 (see par. 4.4)

1. Mark and measure a straight path of 100 meters with an instrument suited to verify the measurement.

2. Start working with the machine during the test and press the key

under the “OK” icon

3. Drive the 100 meters at the desired working speed and maintain the

speed as constant as possible

4. Start working with the machine during the test and press the key

under the “OK” icon

5. The new speed rate will be stored in the instrument.

Page 62

5.4. Set simulated forward speed

Go to screen shot 4.B.3 (see par. 4.4)

Should a malfunction occur in the radar, it is possible to simulate the

desired forward speed; by pressing the middle key in the direction of

the arrows, as shown in the icon, the speed rate will be modied

• Lift the machine, so as to lower the pin of the micro-switch

• Press the key under the “OK” icon to activate the simulated speed.

For each modication remember to press “OK” to conrm the new data.

In the MAIN screen shot the section of the forward speed will be modi-

ed as shown in the screen shot at the left.

Whenever the machine is lowered to the ground in its working position,

even when the tractor is not moving, the rotational speed of the metering unit is proportional to the simulated speed; in the example, the

speed of the metering unit is already 8 Km/h, even though the machine

is “idle”.

The pre-start function cannot be used.

In order to disable the simulated speed, go back to screen shot 4 and

press the key under the icon.

Check the simulated forward speed; the calibration test will be performed at this speed.

5.5. Programming menu for the seed drill width

Go to screen shot 4.B (see par. 4.4)

In this screen shot it is possible to set / modify the width of the seed

drill. Through the middle key move the cursor to “Width”, press the

key under the “OK” icon and, always using the middle key, change

the width and enter by pressing the key under the “OK” icon.

Page 63

5.6. Programming menu for the MANUAL ADJUSTMENT OF THE CALIBRATION

RATE

Go to screen shot 4.B (see par. 4.4)

In this screen shot it is possible to manually modify

the calibration rate.

Usually this rate is calculated through the calibration

test by the computer or through the relevant switch.

However, the operator may record:

- The type of seed

- The quantity of seed (value entered into the RATE

screen shot )

- The opening position of the metering unit

- The value of the calibration rate obtained from the

calibration test,

so that, by entering these data, the calibration test

can be dispensed with in future drilling operations

5.7. Programming menu for the calibration test from the monitor

Go to screen shot 4.B.3 (see par. 4.4)

N.B: BEFORE DOING THIS, MAKE SURE YOU HAVE

ENTERED THE DESIRED QUANTITY OF SEED IN

THE “RATE” SCREEN-SHOT (SEE PAR. 4.6)

While the hopper is empty shut off completely the alveolar rotor with the crank (see Owner’s Manual of the seed

– drill).

From the seed chart attached to the seed drill calculate,

depending on the type and quantity of seed to be distributed, the opening rate of the alveolar rotor and, using

the crank, make it coincide with the value marked on the

indexed tag. (see Owner’s Manual of the seed–drill).

Do not shut the alveolar rotor with seed inside the metering unit: it would cause the breaking of the metering

elements.

Remember to weigh the (empty) container before performing the calibration test.

-Place the container under the opening for the calibration test of the metering unit (see Owner’s Manual of the

seed –drill).

Page 64

Enter the seed quantity (through the keyboard) which you wish to

obtain from the calibration test and press the key under the “OK”

icon to conrm the value.

Wait for the metering unit to ll up the container for the calibration

test.

As soon as the metering unit stops rotating, a screen shot like this

one will appear.

Weigh the container and enter into this screen shot the Net weight

obtained through the use of the middle key

Once you have entered the weight press the key under the “OK”

icon to conrm the value.

After the weight has been entered and conrmed, the following

screen shot will appear. It will display the following data:

- The value of the calibration rate Kg /revolution of the preceding

calibration test

- The value of the calibration rate Kg /revolution of the calibration

test you have just performed

- The error between the two preceding tests

- The max. speed at which the metering unit guarantees a constant

distribution of the seed

It is of the utmost importance for the values to be conrmed by

pressing the key under the “OK” icon for the values to be actually

stored.

Page 65

5.8. Programming menu of fan / seed level alarm

Go to screen shot 4.D (see par.4.4)

5.9. Menu for the operator’s conguration

Go to screen shot 4.1 (see par. 4.4)

By pressing the middle key in the direction of the arrows as shown

in the icon (of the key) the cursor is moved to the various titles of the

menu and by pressing the key under the “OK” icon the following screen

shots are accessed:

Press ESC to go back to the previous page.

Select title 1 (Display)

By pressing the keys under the arrows you can adjust the contrast and

the brightness of the screen

Press ESC to go back

Select title 2 (Customise)

Measuring unit = It is possible to change the calibration measuring unit

in the RATE screen shot : Kg/ha or Seeds/m^2

Interval = It is possible to enter the percentage increase or decrease

steps in the Rate display

Whenever you modify a datum, remember to press “OK” in order to

conrm the new data.

Select the title 3 (time /date)

By pressing the middle key in the direction of the arrows as shown in

the icon you can enter the hour / minutes / day / month / year..

Whenever you modify a datum, remember to press “OK” in order to

conrm the new data.

Page 66

Page 67

5.10. Calibration test through the switch on the machine

While the hopper is empty shut off completely the alveolar rotor with the crank (see Owner’s Manual of

the seed – drill).

From the seed chart attached to the seed drill calculate, depending on the type and quantity of seed

to be distributed, the opening rate of the alveolar rotor and, using the crank, make it coincide with the

value marked on the indexed tag. (see Owner’s Manual of the seed –drill).

Do not shut the alveolar rotor with seed inside the metering unit: it would cause the breaking of the

metering elements.

Remember to weigh the (empty) container before performing the calibration test.

-Place the container under the opening for the calibration test of the metering unit (see Owner’s Manual

of the seed –drill).

- Turn on the monitor

Go to screen shot “RATE” and enter the quantity of seed to be distribu-

ted, then press the key under the “OK” icon to conrm the value.

Press push-button A and keep it depressed (see picture) for as long as

it takes to ll the container sufciently

A screen shot like this one will appear and the value of the weight will

begin to increase as the seeds drop into the calibration test container

Release the push button A and a screen shot like the one at the left will

appear.