!:$;<=<;0670$

!:$;<=<;0670$

ÉCONET

06$956:E0

06$956:E0$F

WWWCARREFR

WWWCARREFR

NOTICE

D’UTILISATION

A LIRE ATTENTIVEMENT AVANT

D’UTILISER LA MACHINE

INSTRUCTION

READ IT ATTENTIVELY BE-

FORE USING THE MACHINE

INSTRUCTION

READ IT ATTENTIVELY BE-

FORE USING THE MACHINE

Réf. 38010003 A

MAJ 04.2012

Type machine/ Type of machine: ÉCONET

Année de construction / Built in : 2012

Numéro de série / Serial Number :

Catalogues pièces/ Spare parts book :

Masse / Weight : ……….KG

Accessoires / Accessories :

SOMMAIRE - SUMMARY - SUMMARY

1. INTRODUCTION

2. SPECIFICATION

2.1 Description

2.2 Caractèristiques

techniques

3. CONSIGNES DE SECURITE

3.1 Symboles de sécurité

3.2 Utilisation conforme à

l’usage prévu

3.3 Prescription générale de

sécurité

3.4 Sécurité sur domaine

public

3.5 Prévention des accidents

3.6 Entretien et réparation

4. COMMANDES DE

L’OPERATEUR

5. MONTAGE ET MISE EN

SERVICE

5.1 Liaison sur le tracteur

5.2 Montage des éléments sur

le poutre

5.3 Elément large-élément

droit

5.4 Coutre circulaire

5.5 Repliage hydraulique

5.6 Repliage manuel

6. UTILISATION

7. AUTRES EQUIPEMENTS

7.1 Disques de chaussage et

déchaussage

7.2 Disques de buttage

7.3 Herses peignes

7.4 Etoiles à doigts NETLINE

7.5 Direction

8. MAINTENANCE

8.1 Entretien par l’utilisateur

8.2 Entretien par du personnel

spécialisé

8.3 Dépannage

9. ECONET GL

10. DECLARATION CE DE

CONFORMITE

1. INTRODUCTION

2. SPECIFICATION

2.1 Description

2.2 Technical caracteristics

3. SAFETY INSTRUCTIONS

3.1 Safety symbols

3.2 Use compliant with intended

use

3.3 General safety instructions

3.4 Safety on public land

3.5 Prevention of accidents

3.6 Maintenance and repair

4. OPERATOR CONTROLS

5. ASSEMBLY AND PUTTING

INTO SERVICE

5.1 Connection to the tractor

5.2 Assembly units on the beam

5.3 Wide unit – Narrow unit

5.4 Circular coulter

5.5 Hydraulic folding

5.6 Manual folding

6. USE

7. OTHER EQUIPMENTS

7.1 Earthing and unearthing

discs

7.2 Ridging discs

7.3 Comb harrow

7.4 NETLINEngerstars

7.5 Steering

8. MAINTENANCE

8.1 Maintenance by user

8.2 Maintenance by specialised

personnel

8.3 Corrective maintenance

9. ECONET GL

10. DECLARATION OF

CONFORMITY

1. INTRODUCTION

2. SPECIFICATION

2.1 Description

2.2 Technical caracteristics

3. SAFETY INSTRUCTIONS

3.1 Safety symbols

3.2 Use compliant with intended

use

3.3 General safety instructions

3.4 Safety on public land

3.5 Prevention of accidents

3.6 Maintenance and repair

4. OPERATOR CONTROLS

5. ASSEMBLY AND PUTTING

INTO SERVICE

5.1 Connection to the tractor

5.2 Assembly units on the beam

5.3 Wide unit – Narrow unit

5.4 Circular coulter

5.5 Hydraulic folding

5.6 Manual folding

6. USE

7. OTHER EQUIPMENTS

7.1 Earthing and unearthing

discs

7.2 Ridging discs

7.3 Comb harrow

7.4 NETLINEngerstars

7.5 Steering

8. MAINTENANCE

8.1 Maintenance by user

8.2 Maintenance by specialised

personnel

8.3 Corrective maintenance

9. ECONET GL

10. DECLARATION OF

CONFORMITY

Page 1

1. INTRODUCTION - INTRODUCTION - INTRODUCTION

Vous prenez possession d’un

matériel de notre production,

au nom de tous mes collaborateurs, je vous remercie de votre

conance.

Avant d’utiliser la bineuse

ECONET , nous recommandons

de lire attentivement le présent

manuel et d’en respecter

scrupuleusement les instructions.

Vous éviterez ainsi de vous

mettre en danger, vous réduirez

les temps de mise en service et

les risques d’incidents fâcheux.

Cette notice d’instructions contient

toutes les informations pratiques

pour faire fonctionner, manier,

régler et entretenir votre machine

correctement et en sécurité.

Conservez la notice d’instructions

pour consultation ultérieure à portée de la main en permanence ou

sur votre lieu de travail (ou d’exploitation).

Transmettez la à tout autre utilisateur, y compris en cas de revente

ou de prêt de votre machine.

Les symboles de mise en garde

ci-dessous identient les messages importants à respecter

pour votre sécurité. Lorsque vous

rencontrez ces symboles, lisez

attentivement le message qui suit

et informez les autres utilisateurs:

You are in possession of a material of our production, in the

name of all my colleagues, I’d

like to thank you for your trust.

Before using the ECONET hoeing

machine, we recommend that you

read this manual carefully and that

you comply with the instructions

scrupulously. By doing this, you will

avoid exposing yourself to danger,

you will reduce the time required

for putting the machine into

service and the risk of undesirable

incidents.

This instruction manual contains all

the practical information required

to operate, handle, adjust and

maintain your machine correctly

and safely.

Keep this instruction manual permanently at hand or at your place

of work (or farm).

Give it to any other user, or if your

machine is sold or lent to someone

else.

The warning symbols below

identify the important messages

that should be adhered to for

your safety. When you see these

symbols, read the message that

follows carefully and inform other

users.

You are in possession of a material of our production, in the

name of all my colleagues, I’d

like to thank you for your trust.

Before using the ECONET hoeing

machine, we recommend that you

read this manual carefully and that

you comply with the instructions

scrupulously. By doing this, you will

avoid exposing yourself to danger,

you will reduce the time required

for putting the machine into

service and the risk of undesirable

incidents.

This instruction manual contains all

the practical information required

to operate, handle, adjust and

maintain your machine correctly

and safely.

Keep this instruction manual

permanently at hand or at your

place of work (or farm).

Give it to any other user, or if your

machine is sold or lent to someone

else.

The warning symbols below

identify the important messages

that should be adhered to for

your safety. When you see these

symbols, read the message that

follows carefully and inform other

users.

Recommandation d’une

importance particulière

Symbole de mise en garde

Votre revendeur CARRÉ vous

conseillera pour que vous

puissiez en obtenir la meilleure

satisfaction. Ne pas ôter les

plaques du constructeur et

du marquage CE xées sur la

machine.

Recommendation of

particular importance

Warning symbol

Your CARRÉ retailer will advise

you on how to make the best use

of your machine. Do not remove

the manufacturer’s plates and the

CE marking afxed to the machine.

Page 2

Recommendation of

particular importance

Warning symbol

Your CARRÉ retailer will advise

you on how to make the best use

of your machine. Do not remove

the manufacturer’s plates and the

CE marking afxed to the machine.

Respectez les consignes de sécurité.

Comply with the safety instructions

Comply with the safety instructions

CARRÉ décline toutes responsabilités pour les dommages et

incidents de fonctionnement survenus à la suite d’utilisations non

conformes aux instructions du

présent manuel.

Garantie : Veuillez rapidement

compléter le certicat de garantie joint avec la machine, et

l’envoyer à l’adresse indiquée

pour qu’elle soit effective. Vous

pouvez également remplir ce

certicat de garantie directement sur notre site internet

www.carre.fr

CARRÉ cannot be held liable for

any damage and operating incidents occurring due to use that

does comply with the instructions

in this manual.

Warranty: Please complete the

warranty certicate enclosed

with the machine and return it

as soon as possible to the address indicated in order to activate your warranty.

You also can full in this war-

ranty certicate directly in our

website www.carre.fr

CARRÉ cannot be held liable for

any damage and operating incidents occurring due to use that

does comply with the instructions

in this manual.

Warranty: Please complete the

warranty certicate enclosed

with the machine and return it

as soon as possible to the address indicated in order to activate your warranty.

You also can full in this war-

ranty certicate directly in our

website www.carre.fr

Page 3

2. SPÉCIFICATIONS - SPECIFICATIONS - SPECIFICATIONS

2.1 Description - Description - Description

La bineuse ECONET est conçue

pour biner les cultures en lignes.

Les coutres installées à l’avant

stabilisent la machine. Chaque

élément est monté sur parallélogramme et suit les dénivellations

du terrain.

L’équipement standard pour une

bineuse de n rangs comprend :

1 poutre, 1 attelage à broches,

n-1 éléments (large ou étroit), 2

demi éléments pour les extrémités, n paires de disques protègeplants.

De nombreuses options sont

possibles : types de dents, direction, disques de déchaussage,

fertiliseur, pulvérisation, semoir

de ray-grass etc... La présente

notice donne des instructions en

vue de l’utilisation pour chacune

d’entre elles.

Puissance nécessaire = 2 à 3

chevaux par dent ( ou 1.5 kW).

Vitesse de travail = jusqu’à 15

Km/h

Bruit aérien en statique

Aucun équipement ne produit

à vide un niveau de pression

acoustique équivalent pondéré A

supérieur à 70 dB (A) à 1 m de

distance.

Aucun équipement ne produit une

valeur de la pression instantanée

pondérée C supérieure à 130

dB(C).

The ECONET hoeing machine is

designed for hoeing crops grown

in lines. The coulters installed in

the front stabilise the machine.

Each unit is mounted on a parallelogram and follows the differences in the level of the land.

The standard equipment for a

hoeing machine with n rows includes:

1 beam, 1 pin coupling, n-1 units

(wide or narrow), 2 half-units for

the ends, n pairs of plant-protection discs.

Many options are available: types

of tines, steering, unearthing

discs, fertiliser, spraying, raygrass sower, etc. This notice provides instructions for the use of

each of these options.

Power requirement = 2 to 3 horsepower per tine (or 1.5 kW).

Working speed = up to 15 Km/h

Static airborne noise

None of the equipment produces

when empty an equivalent Aweighted sound pressure level

exceeding 70 dB (A) at a distance

of 1 m.

No equipment produces a Cweighted instantaneous pressure

value exceeding 130 dB(C).

The ECONET hoeing machine is

designed for hoeing crops grown

in lines. The coulters installed in

the front stabilise the machine.

Each unit is mounted on a parallelogram and follows the differences in the level of the land.

The standard equipment for a

hoeing machine with n rows includes:

1 beam, 1 pin coupling, n-1 units

(wide or narrow), 2 half-units for

the ends, n pairs of plant-protection discs.

Many options are available: types

of tines, steering, unearthing

discs, fertiliser, spraying, raygrass sower, etc. This notice provides instructions for the use of

each of these options.

Power requirement = 2 to 3 horsepower per tine (or 1.5 kW).

Working speed = up to 15 Km/h

Static airborne noise

None of the equipment produces

when empty an equivalent Aweighted sound pressure level

exceeding 70 dB (A) at a distance

of 1 m.

No equipment produces a Cweighted instantaneous pressure

value exceeding 130 dB(C).

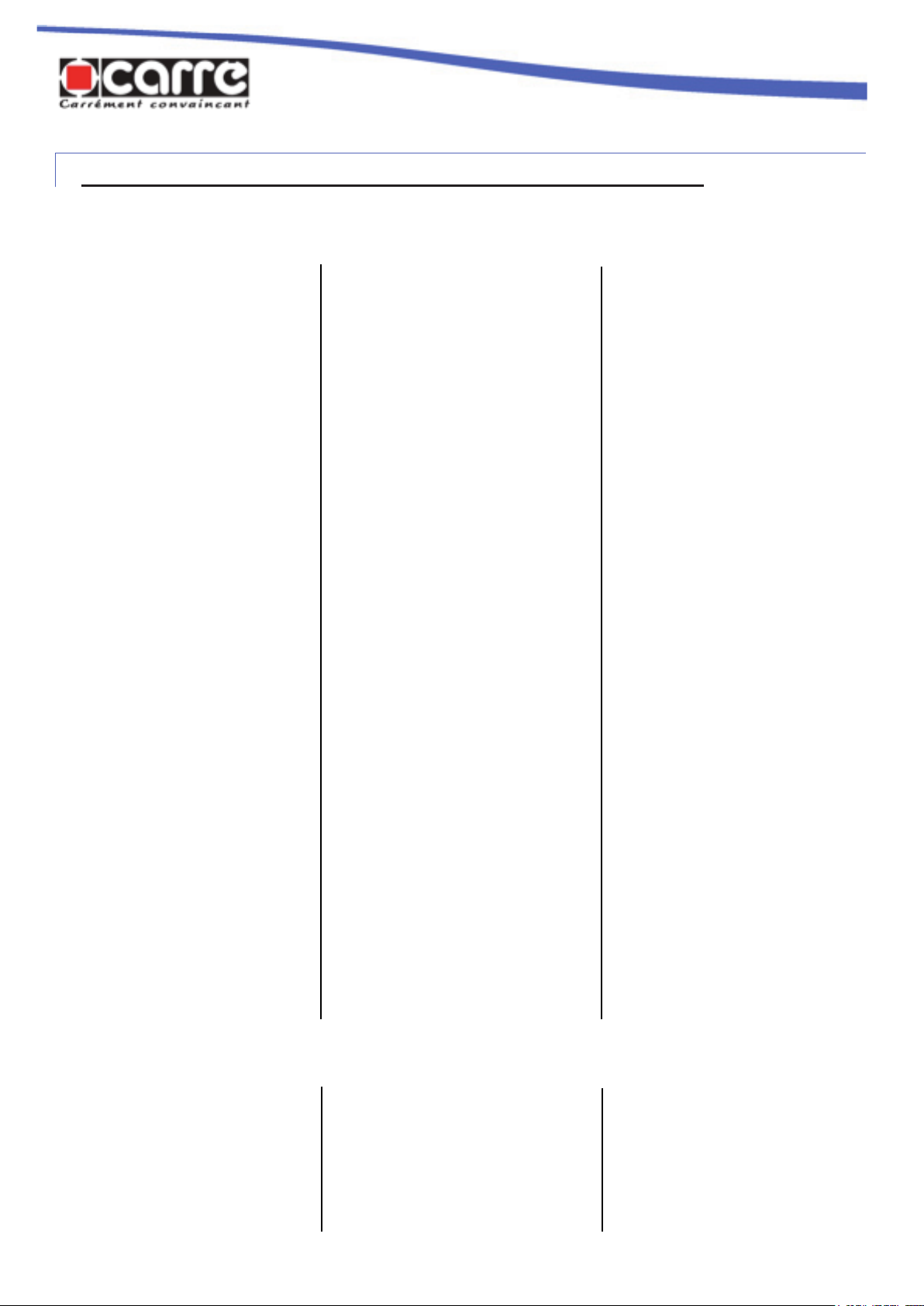

2.2 Caractéristiques techniques - Technical caracteristics - Technical caracteristics

Les caractéristiques techniques,

dimensions et masse sont données à titre indicatif, elles peuvent

être modiées sans préavis et varier suivant les équipements et le

type de montage de la bineuse.

The technical characteristics,

dimensions and weight are provided for the purposes of information; these can be changed

without notice and vary according

to the equipment and the type of

assembly of the hoeing machine.

The technical characteristics,

dimensions and weight are provided for the purposes of information; these can be changed

without notice and vary according

to the equipment and the type of

assembly of the hoeing machine.

Page 4

ECONET FIXE / FIXED ECONET

Rangs de 0m60 à

0m80 / rows from

0m60 to 0m80

L4BA

L6BA

L8BA

L12BA

Rangs de 0m45 à

0m60 / rows from

0m45 to 0m60

E5BA

E6BA

E7BA

E8BA

E12BA

ECONET REPLIABLE / FOLDING ECONET

Rangs de 0m70 à

1m05 / rows from

0m70 to 1m05

Nombre de rangs /

Number of rows

4 3,48 582

6 5,08 780

8 6,68 1210

12 9.88 1606

5 3,28 605

6 3,88 691

7 4,48 778

8 5,08 864

12 7,48 1442

Nombre de rangs /

Number of rows

Largeur hors tout

/ Overall width

Largeur hors tout

/ Overall width

Masse (kg)/

Weight (kg)

Masse (kg)/

Weight (kg)

L4LR

L6BLR

Rangs de 0m60 à

0m80 / rows from

0m60 to 0m80

L6BAR 6 3,48 950

L8BAR 8 3,48 1255

Rangs de 0m45 à

0m60 / rows from

0m45 to 0m6

E6BAR 6 2,54 845

E7BAR 7 3,03 921

E8BAR 8 2,54 1007

E12BAR 12 3 1478

ECONET REPLIABLE MONOPOUTRE / SINGLE BEAM FOLDING ECONET

Rangs de 0m70 à

0m80 / rows from

0m70 to 0m80

0

Nombre de rangs /

Number of rows

4 2,7 797

6 2,7 1108

Largeur hors tout

/ Overall width

Masse (kg)/

Weight (kg)

L4MPR 4 2,5 689

L6MPR 6 2,5 901

L8MPR 8 2,5 1099

Page 5

3. CONSIGNES DE SÉCURITÉ - SAFETY INSTRUCTIONS - SAFETY

INSTRUCTIONS

3.1 Symboles de sécurité - Safety symbols - Safety symbols

Veillez à ce que les avertissements et pictogrammes restent

propres et visibles en permanence. En cas de détérioration,

demandez des autocollants neufs

à votre fabricant (ou distributeur).

En cas de réparation, veillez à

ce que les pièces de rechange

portent les mêmes autocollants

que les pièces d’origine.

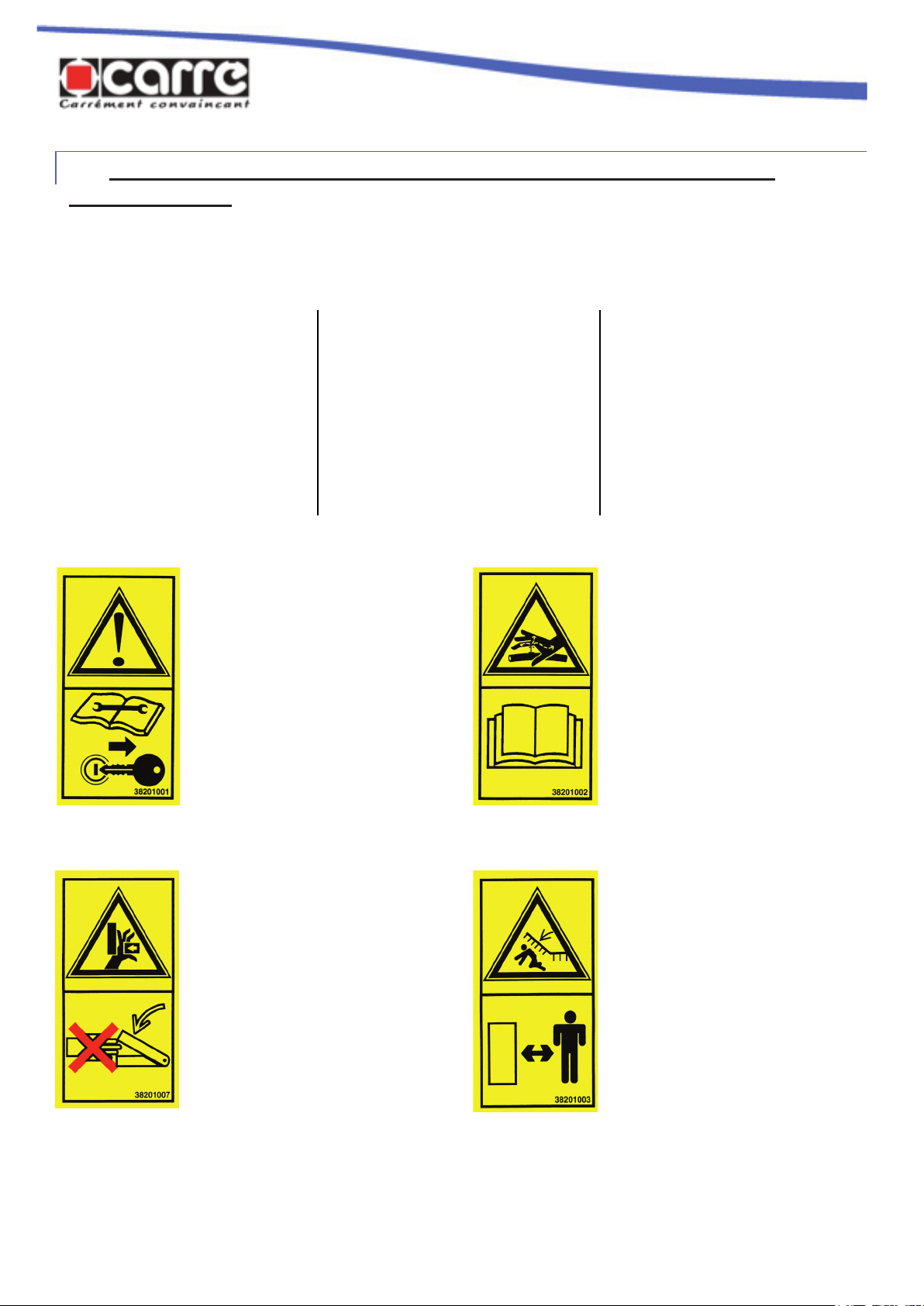

Lire le livret d’entretien et les

consignes de sécurité avant la mise

en marche. Avant toute intervention,

éteindre le moteur du tracteur et retirer

la clé de contact.

Read the maintenance manual and the

safety instructions before starting up.

Before any intervention, turn off the

tractor engine and remove the ignition

key.

Vor Inbetriebnahme Wartungsbuch und

Sicherheitshinweise lesen.

Vor Eingriffen an der Maschine Schlepper-motor abschalten und Zündschlüssel ziehen.

Make sure that the warnings and

pictograms remain clean and

visible at all times. If they deteriorate, ask your manufacturer

(or distributor) for new stickers. If

repairs are made, ensure that the

spare parts have the same stickers as the original parts.

Make sure that the warnings and

pictograms remain clean and

visible at all times. If they deteriorate, ask your manufacturer

(or distributor) for new stickers. If

repairs are made, ensure that the

spare parts have the same stickers as the original parts.

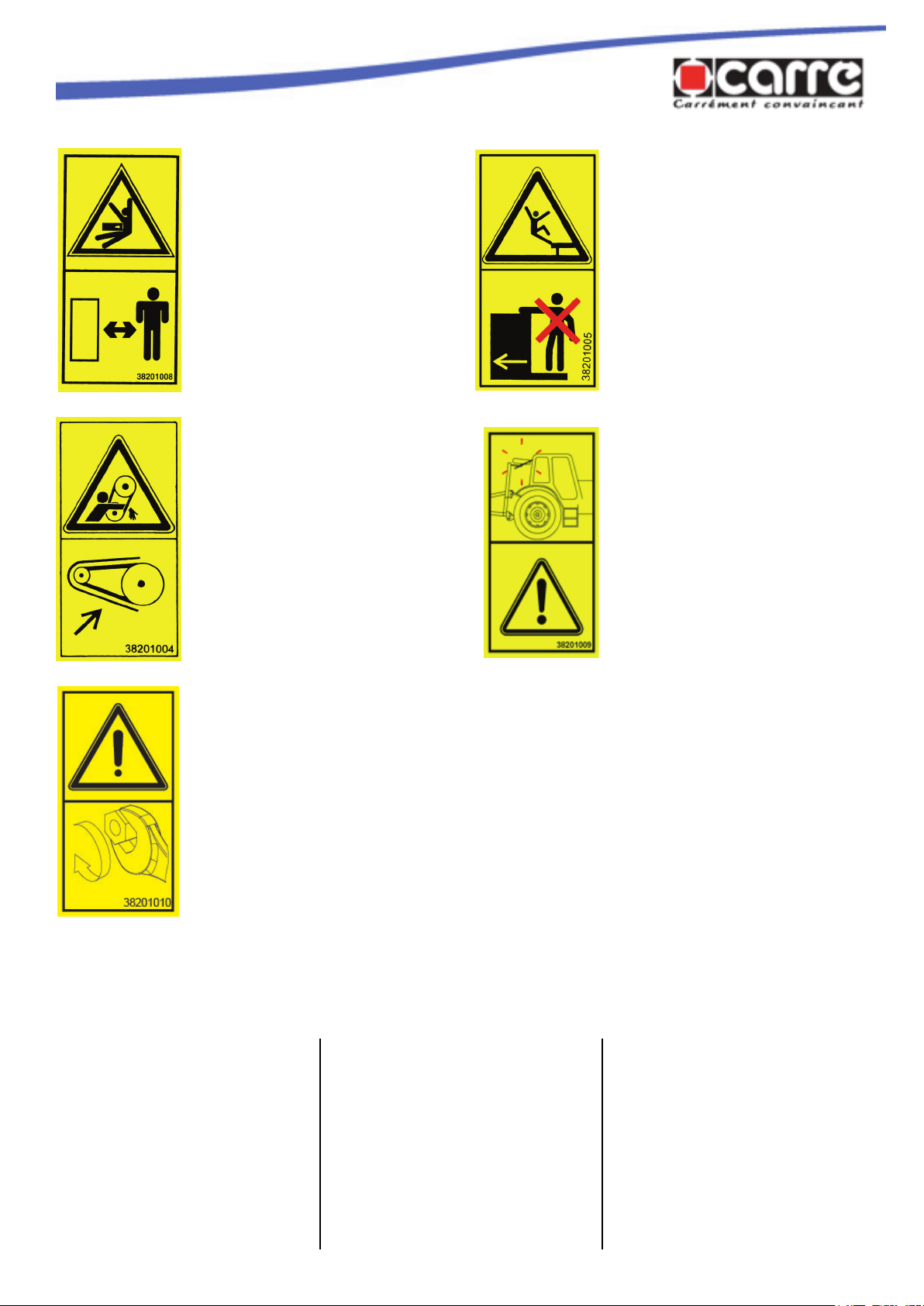

Pour prévenir les fuites dans le circuit

hydraulique, respecter les consignes

du livret d’entretien.

To prevent leaks from the hydraulic

circuit, adhere to the instructions in

the maintenance manual.

Um Undichtigkeiten an den Hydraulikleitungen vorzubeugen, Wartungshinweise befolgen.

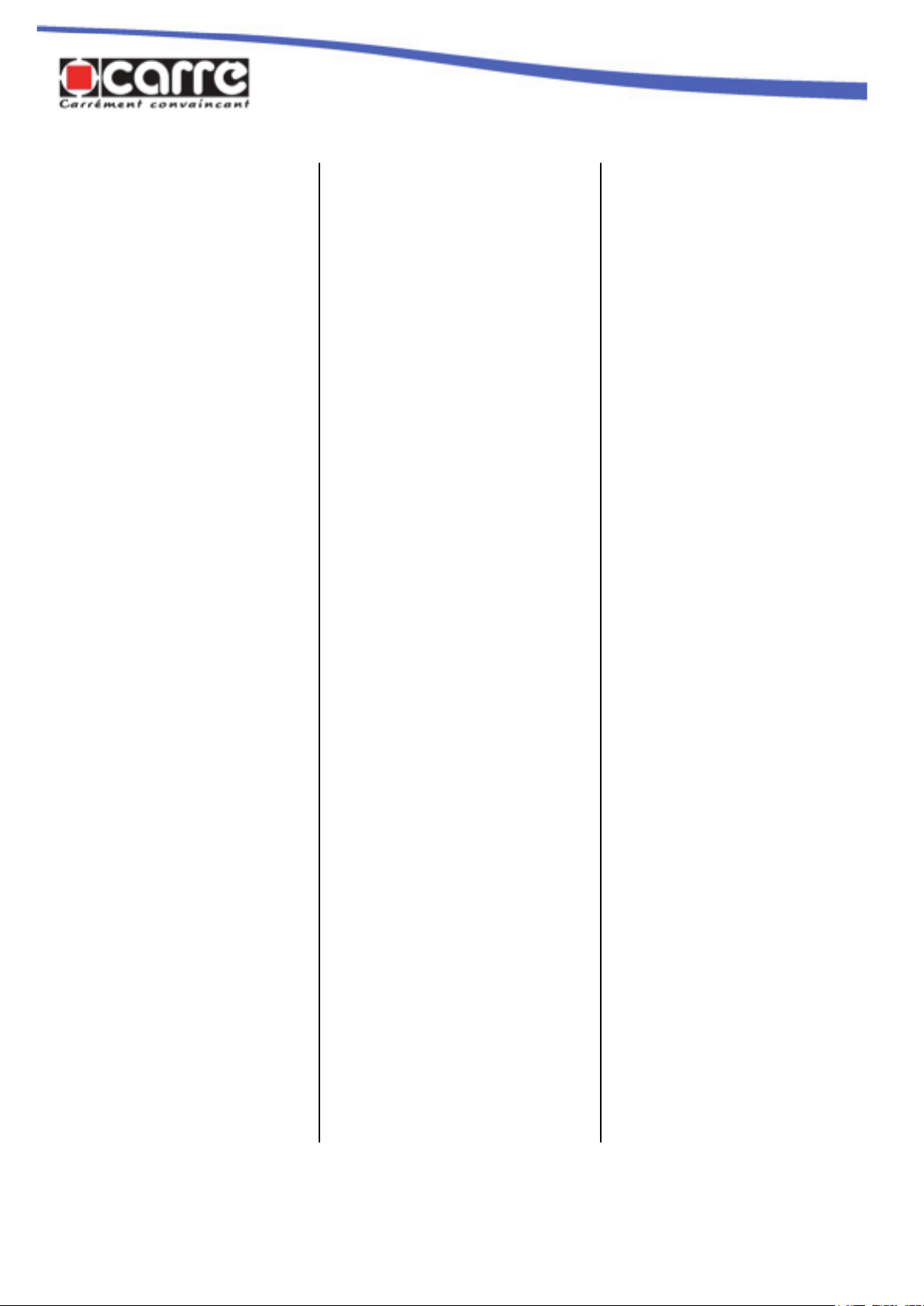

Ne jamais mettre les mains dans les

zones de danger tant que des pièces

sont en mouvement, il y a risque de

pincement.

Never put your hands in hazardous

areas while the parts are moving.

There is a danger of trapping your

hands.

Hände bei drehenden Teilen nicht in

die Gefahrenbereiche halten, es besteht Einklemmgefahr.

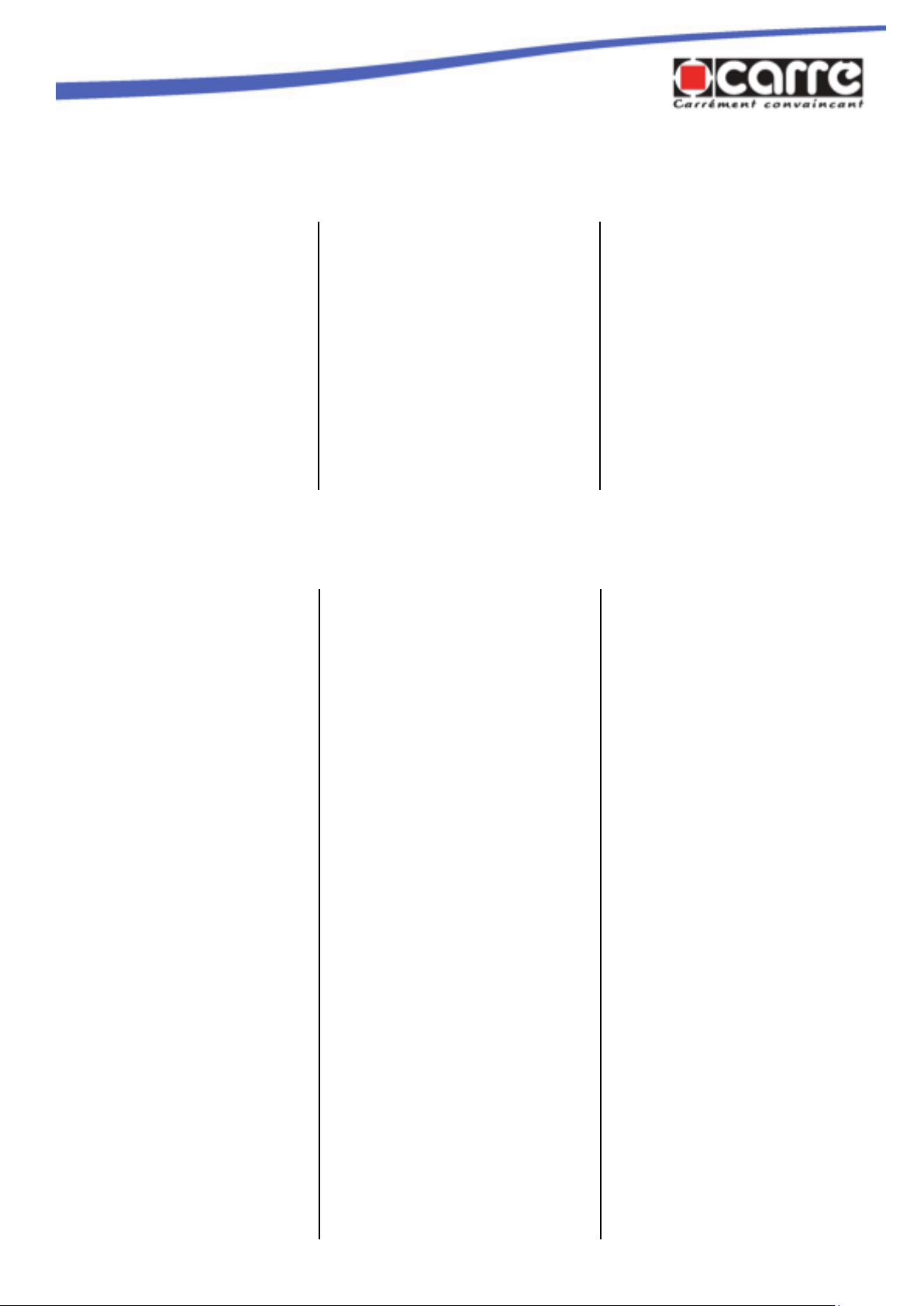

Eloigner toute personne de la zone

dangereuse, Il y a risque d’écrasement.

People should be kept away from

the danger zone. There is a risk they

may be run over.

Darauf achten, dass sich niemand im

gefahrenbereich bendet, es besteht

Quetschgefahr.

Page 6

Eloigner toute personne de la zone

dangereuse, Il y a risque d’écrasement.

Ne pas monter sur le marche pieds

pendant le déplacement de la

machine

People should be kept away from

the danger zone. There is a risk they

may be run over.

Alle Person von der Gefahrzone entfernen, es gibt Überfahrungsgefahr.

Maintenir en place le carter de protection de la courroie d’entrainement

du semoir pour protéger les mains

Maintain in place the protection crankcase of the training belt of the seed

drill to protect your hands.

Die Schutzhaube des Antriebsriemens

der Sämaschine anstehend erhalten,

um Hände zu schützen.

Do not go up on the step during the

moving of the machine.

Nicht des Trittbrett besteigen wegen

der Maschinebewegung.

ATTENTION ! Risque de collision

des roues au repliage contre la

cabine du tracteur.

Be CAREFUL ! Risk of collision of

the wheels durng the folding against

hte tractor.

ACHTUNG! Kolisionsrisiko der Räde

an Klappung gegen des Schlepperkabine.

Après la 1ère heure de travail, resserrer tous les boulons.

Les vibrations peuvent desserrer les

assemblages boulonnés.

After the rst hour of work, tighten

the bolts.

Vibrations can loosen the bolt

assembly.

Nach der ersten Arbeitsstunde,

anziehen Sie bitte die Schrauben.

Schwingungen können die

Schrauben lösen.

3.2 Utilisation conforme à l’usage prévu - Usage as intended - Usage as intended

La bineuse ECONET est prévue

pour biner les cultures en ligne,

le fertiliseur qui lui est associé

permet d’apporter de l’engrais en

même temps que le binage, le

pulvérisateur permet de désherber sur le rang ou de pratiquer un

traitement insecticide, le semoir

est utilisé pour implanter un couvert végétal dans l’inter rang.

The ECONET hoeing machine

is designed for hoeing crops

grown in lines; the fertiliser

associated with it allows fertiliser

to be supplied while hoeing, the

sprayer makes it possible to weed

on the row or apply an insecticide

treatment, the sower is used to

plant vegetational coverage in the

row spacing.

The ECONET hoeing machine

is designed for hoeing crops

grown in lines; the fertiliser

associated with it allows fertiliser

to be supplied while hoeing, the

sprayer makes it possible to weed

on the row or apply an insecticide

treatment, the sower is used to

plant vegetational coverage in the

row spacing.

Page 7

Toute utilisation autre que celleci sera considérée comme non

conforme à l’usage prévu et dégagera le constructeur de toute

responsabilité en cas de préjudice, l’utilisateur supportera seul

les risques résultant d’une telle

utilisation.

Respectez l’ensemble des prescriptions d’installation, de fonctionnement, de réglages, de

maintenance et de réparation

contenues dans cette notice.

Utilisez exclusivement des pièces

de rechange et des accessoires

conformes aux préconisations du

fabricant. L’utilisation, l’entretien

et la remise en état de la bineuse

ECONET ne devront être conés

qu’à des personnes familiarisées

et informées des dangers éventuels.

Ne modiez pas vous-même et

ne faites pas modier par une

autre personne votre machine et

ses accessoires (caractéristiques

mécaniques, électriques, hydrauliques, pneumatiques), sans

demander au préalable l’accord

écrit de votre fabricant.

Le non-respect de ces règles

peut rendre votre machine dangereuse. En cas de dégâts ou de

blessures, la responsabilité du

fabricant sera entièrement dégagée.

Il convient en outre de respecter

les consignes particulières de

prévention des accidents, ainsi

que les règles générales en matière de sécurité technique, de

médecine de travail et de législation routière.

Le constructeur décline toute

responsabilité en cas de préju-

dice résultant d’une modication

apportée à la bineuse ECONET

sans son agrément.

Any use other than the latter shall

be considered as non-compliant

with the intended use and shall

release the manufacturer from any

liability in the event of prejudice;

the user alone shall incur the risks

that result from such use.

Comply with all of the installation,

operating, adjusting, maintenance

and repair instructions contained

in this notice

Use only spare parts and

accessories that comply

with the manufacturer’s

recommendations. The use,

maintenance and overhauling

of the ECONET hoeing machine

must be entrusted only to people

who are familiar with and who are

informed of the possible dangers.

Do not modify or have your

machine and its accessories

modied by another person

(mechanical, electrical, hydraulic,

pneumatic characteristics),

without rst obtaining approval

from your manufacturer.

Not complying with these rules can

make your machine dangerous. In

the event of damage or injury, the

manufacturer shall be released

from any liability.

Moreover, the special instructions

concerning the prevention of

accidents must be complied

with, as well as the general

rules in terms of technical safety,

occupational medicine and

legislation concerning the use of

roads.

The manufacturer declines all

liability in the event of prejudice

resulting from a modication

made to the ECONET hoeing

machine without its approval.

Any use other than the latter shall

be considered as non-compliant

with the intended use and shall

release the manufacturer from any

liability in the event of prejudice;

the user alone shall incur the risks

that result from such use.

Comply with all of the installation,

operating, adjusting, maintenance

and repair instructions contained

in this notice

Use only spare parts and

accessories that comply

with the manufacturer’s

recommendations. The use,

maintenance and overhauling

of the ECONET hoeing machine

must be entrusted only to people

who are familiar with and who are

informed of the possible dangers.

Do not modify or have your

machine and its accessories

modied by another person

(mechanical, electrical, hydraulic,

pneumatic characteristics),

without rst obtaining approval

from your manufacturer.

Not complying with these rules can

make your machine dangerous. In

the event of damage or injury, the

manufacturer shall be released

from any liability.

Moreover, the special instructions

concerning the prevention of

accidents must be complied

with, as well as the general

rules in terms of technical safety,

occupational medicine and

legislation concerning the use of

roads.

The manufacturer declines all

liability in the event of prejudice

resulting from a modication

made to the ECONET hoeing

machine without its approval.

Page 8

3.3 Prescription générale de sécurité - General safety instructions - General safety

instructions

N’utiliser la bineuse ECONET

que si tous les dispositifs de

protection et de sécurité sont

en place et fonctionnent bien.

Contrôler régulièrement le bon

serrage des boulons et les resserrer si nécessaire, en particulier

les boulons de serrage des dents.

En cas d’incidents de fonctionnement, arrêter tout de suite

la machine, puis procéder ou

faire procéder immédiatement

à la réparation de la panne.

3.4 Sécurité sur le domaine public - Safety in the public domain - Safety in the public

domain

Avant d’aller sur une route, il faut

se familiariser avec le fonctionnement de toutes les commandes

ainsi que leurs fonctions.

Respectez les règles du code de

la route lorsque vous vous engagez sur le domaine public (routes,

chemins et places). Assurez-vous

préalablement que l’état de la bineuse ECONET est conforme aux

réglementations prescrites par le

code de la route. Respectez la

largeur de transport admise.

Only use the ECONET hoeing

machine if all of the protective

and safety devices are installed and are operating correctly.

Check that the bolts are tight

on a regular basis, and tighten them if necessary, especially the tine clamping bolts.

In the event of operating incidents, stop the machine immediately, then repair the breakdown

or have it repaired immediately.

Before driving on a road, you

must become familiar with the

operation of all of the controls as

well as their functions.

Comply with the rules of the road

when you move into the public domain (roads, paths and squares).

Make sure beforehand that the

condition of the ECONET hoeing

machine is compliant with the regulations set forth in the rules of

the road. Comply with authorised

transport width limitations.

Only use the ECONET hoeing

machine if all of the protective

and safety devices are installed and are operating correctly.

Check that the bolts are tight

on a regular basis, and tighten them if necessary, especially the tine clamping bolts.

In the event of operating incidents, stop the machine immediately, then repair the breakdown

or have it repaired immediately.

Before driving on a road, you

must become familiar with the

operation of all of the controls as

well as their functions.

Comply with the rules of the road

when you move into the public domain (roads, paths and squares).

Make sure beforehand that the

condition of the ECONET hoeing

machine is compliant with the regulations set forth in the rules of

the road. Comply with authorised

transport width limitations.

Adaptez votre vitesse et votre

mode de conduite aux terrains,

routes et chemins. Soyez vigilants et prudents !

En toute circonstance et notamment sur les terrains accidentés

et pentus, conduisez la machine

à faible vitesse, surtout dans les

virages et évitez les brusques

changements de direction.

Ne pas freiner ou démarrer brutalement en montant ou descendant une pente.

La conduite est inuencée par la

machine attelée sur le tracteur :

respecter la limite de charge d’es-

Adjust your speed and driving

style to the land, roads and paths.

Remain vigilant and cautious!

At all times and in particular on

sloped and broken land, operate

the machine at slow speed, especially when turning and do not

change direction abruptly.

Do not brake or start abruptly

while going up or down a slope.

Driving is inuenced by the machine coupled to the tractor: comply with the axle load limit and the

gross weight so that steering and

braking precision are maintained.

Page 9

Adjust your speed and driving

style to the land, roads and paths.

Remain vigilant and cautious!

At all times and in particular on

sloped and broken land, operate

the machine at slow speed, especially when turning and do not

change direction abruptly.

Do not brake or start abruptly

while going up or down a slope.

Driving is inuenced by the machine coupled to the tractor: comply with the axle load limit and the

gross weight so that steering and

braking precision are maintained.

sieu et le poids total admis an

que la précision de direction et de

freinage soit maintenue.

Ne transporter aucune personne

sur la bineuse.

3.5 Prévention des accidents - Accidents prevention - Accidents prevention

Do not transport anyone on the

hoeing machine.

Do not transport anyone on the

hoeing machine.

En complément aux recommandations faites dans ce manuel,

respectez les prescriptions des

assurances mutuelles agricoles.

Pendant l’opération d’attelage

de la bineuse ECONET sur le

tracteur :

- Veiller à ce qu’elle repose sur

un sol stable.

- Ne jamais rester entre le tracteur et la bineuse, il y a risque

d’accident.

- Manoeuvrer le relevage trois

points hydraulique lentement et

avec précaution.

- Vérier que les catégories de

l’attelage trois points du tracteur

et de la bineuse correspondent.

Système hydraulique :

- Ne brancher les conduites hydrauliques au système hydraulique du tracteur que s’il n’y a

aucune pression côté tracteur et

côté machine.

- Le système hydraulique fonctionne avec de la haute pression,

vérier régulièrement si toutes

les conduites, les tuyaux et les

raccords n’ont pas de fuite ou de

détériorations visibles. Si c’est le

cas, le remplacement doit être

immédiat.

- L’huile s’échappant sous pression peut causer des blessures

et des infections : consulter un

médecin.

- Avant de travailler sur le circuit

hydraulique, enlever la pression

et couper le moteur.

In addition to the recommendation in this manual, follow the instructions of the farming mutual

insurance companies.

During the hitching of the ECONET hoeing machine to the

tractor:

- Ensure that it is resting on stable

ground.

- Never remain between the tractor and the hoeing machine; there

is a risk of an accident.

- Operate the 3-point hydraulic lift

system slowly and with caution.

- Check that the 3-point hitching

categories of the tractor and of

the hoeing machine correspond.

Hydraulic system:

- Connect the hydraulic lines to

the tractor’s hydraulic system only

if there is no pressure on the tractor side and on the machine side.

- The hydraulic system operates

under high pressure, check on a

regular basis that all of the lines,

pipes and connectors do not show

any leaks or visible deterioration.

If so, they must be replaced immediately.

- Oil released under pressure can

cause injury and infections: see a

doctor.

- Before working with the hydraulic circuit, release the pressure

and turn off the motor.

During use:

- Before turning on the machine,

ensure that no one is within the vicinity of the machine. Ensure that

In addition to the recommendation in this manual, follow the instructions of the farming mutual

insurance companies.

During the hitching of the ECONET hoeing machine to the

tractor:

- Ensure that it is resting on stable

ground.

- Never remain between the tractor and the hoeing machine; there

is a risk of an accident.

- Operate the 3-point hydraulic lift

system slowly and with caution.

- Check that the 3-point hitching

categories of the tractor and of

the hoeing machine correspond.

Hydraulic system:

- Connect the hydraulic lines to

the tractor’s hydraulic system only

if there is no pressure on the tractor side and on the machine side.

- The hydraulic system operates

under high pressure, check on a

regular basis that all of the lines,

pipes and connectors do not show

any leaks or visible deterioration.

If so, they must be replaced immediately.

- Oil released under pressure can

cause injury and infections: see a

doctor.

- Before working with the hydraulic circuit, release the pressure

and turn off the motor.

During use:

- Before turning on the machine,

ensure that no one is within the vicinity of the machine. Ensure that

Page 10

Pendant l’utilisation :

- Avant la mise en route, s’assurer que personne ne se trouve à

proximité de la machine. Veiller à

avoir une visibilité sufsante.

- Ne transporter aucune personne

sur la machine pendant le travail.

- Aucun dispositif de protection

prescrit et livré avec la machine

ne doit être enlevé.

- Eloigner toute personne se trouvant dans la zone de pivotement

des rallonges repliables par hydraulique.

- La bineuse entraîne au cours du

travail et lors du déplacement de

nombreuses projections de terre

et de cailloux. Eloigner toute personne se situant à proximité de la

machine.

3.6

Entretien et réparation - Maintenance and repair - Maintenance and repair

there is sufcient visibility.

- Do not transport anyone on the

hoeing machine during work.

- None of the protective devices

prescribed and delivered with the

machine are to be removed.

- Make sure that no one is in the

pivoting area of the extension that

can be folded hydraulically.

- While operating and when in mo-

tion, the hoeing machine causes

the projection of soil and stones.

Ensure that no one is within the

vicinity of the machine.

there is sufcient visibility.

- Do not transport anyone on the

hoeing machine during work.

- None of the protective devices

prescribed and delivered with the

machine are to be removed.

- Make sure that no one is in the

pivoting area of the extension that

can be folded hydraulically.

- While operating and when in motion, the hoeing machine causes

the projection of soil and stones.

Ensure that no one is within the

vicinity of the machine.

- Respecter les délais prescrits

ou indiqués dans ce manuel pour

procéder aux vérications et

inspections prévues.

- Avant de faire des travaux

d’entretien et de réparation,

s’assurer que l’installation

hydraulique n’est pas sous

pression. Dételer la bineuse du

tracteur.

- Ne procéder à des travaux

d’entretien ou de réparation que

si la bineuse repose à plat sur

un sol bien stable et ne risque

pas de se renverser (béquilles

optionnelles sur certain modèle).

- Ne pas effectuer des travaux

d’entretien sur l’appareil relevé

sans avoir mis par mesure de

sécurité des supports appropriés.

- Pour le montage et le démontage,

utiliser des moyens appropriés

qui ne mettent pas votre sécurité

en danger.

- Proter du nettoyage de la bineuse

à la n de chaque campagne au minimum - pour vérier si les

conduites hydrauliques sont bien

étanches, si les raccords sont

- Comply with the time frames that

are recommended or indicated

in this manual when carrying

out scheduled inspections and

verications.

- Before beginning any

maintenance or repair work, make

sure that the hydraulic installation

is not under pressure. Uncouple

the hoeing machine from the

tractor.

- Carry out maintenance or repair

work only if the hoeing machine

is resting at on stable ground

and where there is no risk of

tipping (optional stands on certain

models).

- Do not carry out any maintenance

work on a raised device without

having installed the appropriate

supports for safety reasons.

- When assembling and

disassembling, use appropriate

means that do not compromise

your safety.

- Take advantage when cleaning

the hoeing machine at the end

of each crop year – at least

– to check that the hydraulic

- Comply with the time frames that

are recommended or indicated

in this manual when carrying

out scheduled inspections and

verications.

- Before beginning any

maintenance or repair work, make

sure that the hydraulic installation

is not under pressure. Uncouple

the hoeing machine from the

tractor.

- Carry out maintenance or repair

work only if the hoeing machine

is resting at on stable ground

and where there is no risk of

tipping (optional stands on certain

models).

- Do not carry out any maintenance

work on a raised device without

having installed the appropriate

supports for safety reasons.

- When assembling and

disassembling, use appropriate

means that do not compromise

your safety.

- Take advantage when cleaning

the hoeing machine at the end

of each crop year – at least

– to check that the hydraulic

Page 11

desserrés ou s’il y a des défauts

dus au frottement. Remplacer

immédiatement ce qui est

détérioré.

- Pour le remplacement des

pièces d’usure, utiliser des outils

appropriés et porter des gants.

- Les pièces détachées doivent

correspondre aux exigences

techniques du constructeur, ce

qui est toujours le cas avec des

pièces d’origine.

- Avant d’effectuer des travaux de

soudure électrique sur la bineuse,

lorsqu’elle est attelée sur le

tracteur, déconnecter les câbles

de l’alternateur et de la batterie.

lines are properly sealed, the

connections are tight and that

there are no defects caused by

friction. Replace anything that is

deteriorated immediately.

- When replacing wearing parts,

use suitable tools and wear

gloves.

- Spare parts must meet the

manufacturer’s technical

requirements, which is always the

case with original parts.

- Before carrying out any electrical

welding work on the hoeing

machine, when it is hitched to the

tractor, disconnect the battery and

alternator cables.

lines are properly sealed, the

connections are tight and that

there are no defects caused by

friction. Replace anything that is

deteriorated immediately.

- When replacing wearing parts,

use suitable tools and wear

gloves.

- Spare parts must meet the

manufacturer’s technical

requirements, which is always the

case with original parts.

- Before carrying out any electrical

welding work on the hoeing

machine, when it is hitched to the

tractor, disconnect the battery and

alternator cables.

Page 12

4. COMMANDES DE L’OPÉRATEUR - OPERATOR CONTROLS - OPERATOR

CONTROLS

En matière d’attelage, et

pour une raison de sécurité, il

est impératif d’utiliser les broches

d’origine. An de ne pas les égarer, les broches ainsi que leurs

goupilles clips sont liées à la bineuse par des chaînettes, et les

2 goupilles de la barre d’attelage

sont attachées par une chaînette.

Dans le cas d’une ECONET à repliage hydraulique des

rallonges, la commande du circuit

hydraulique doit être à «action

maintenue», c’est à dire que le

distributeur du tracteur, lorsqu’il

n’est pas maintenu, revient en

position neutre et le mouvement

est arrêté.

With regards to hitching,

and for safety reasons, the origi-

nal pins must be used. In order

to prevent loss, the pins as well

as their lynch pins are connected

to the hoeing machine by chains,

and the 2 pins on the hitching bar

are attached with a chain.

With an ECONET with hy-

draulic folding of the extensions,

control of the hydraulic circuit is

through «maintained action», i.e.

the distributor of the tractor, when

it is not maintained, return to neu-

tral position and movement stops.

With regards to hitching,

and for safety reasons, the original pins must be used. In order

to prevent loss, the pins as well

as their lynch pins are connected

to the hoeing machine by chains,

and the 2 pins on the hitching bar

are attached with a chain.

With an ECONET with hydraulic folding of the extensions,

control of the hydraulic circuit is

through «maintained action», i.e.

the distributor of the tractor, when

it is not maintained, return to neutral position and movement stops.

Page 13

5. MONTAGE ET MISE EN SERVICE - ASSEMBLY AND PUTTING INTO SER-

VICE - ASSEMBLY AND PUTTING INTO SERVICE

5.1 Liaison sur le tracteur - Link on the tractor - Link on the tractor

Les bineuses ECONET xes

(jusqu’à 5m08) sont équipées

d’un attelage à broches catégorie

n°1 et n°2. La distance à respecter entre les chapes sur la poutre

est 825mm (voir g.1), toutefois,

pour certains écartements de

rangs, il n’est pas possible de

respecter cette distance car les

éléments se trouvent placés sur

la poutre au même endroit. Dans

ce cas, on met la cote qui se rapproche le plus de 825mm tout en

vériant les possibilités d’attelage

du tracteur ou bien il faut monter

un attelage avancé. Pour tous les

autres modèles de bineuses (xe

à partir de 6m68 et repliable) l’attelage à broches catégorie n°2 et

n°3 est soudé sur la poutre.

ATTENTION : Ne jamais rester

entre le tracteur et la bineuse, il y

a risque d’accident.

Fixed ECONET hoeing machines

(up to 5m08) are equipped with

a category 1 and 2 pin coupling.

The distance to be maintained

between the yokes on the beam is

825mm (see g. 1), however, for

some row spacing, this distance

cannot be maintained as the units

are placed on the beam in the

same location. In this case, the

distance that is closest to 825mm

is used, while still checking for

coupling possibilities for the tractor or otherwise a front hitch must

be mounted. For the other hoeing

machine models (xed starting

from 6m68 and foldable) the

category 2 and 3 pin coupling is

welded onto the beam.

WARNING: Never remain

between the tractor and the

hoeing machine; there is a risk of

an accident.

Fixed ECONET hoeing machines

(up to 5m08) are equipped with

a category 1 and 2 pin coupling.

The distance to be maintained

between the yokes on the beam is

825mm (see g. 1), however, for

some row spacing, this distance

cannot be maintained as the units

are placed on the beam in the

same location. In this case, the

distance that is closest to 825mm

is used, while still checking for

coupling possibilities for the tractor or otherwise a front hitch must

be mounted. For the other hoeing

machine models (xed starting

from 6m68 and foldable) the

category 2 and 3 pin coupling is

welded onto the beam.

WARNING: Never remain

between the tractor and the

hoeing machine; there is a risk of

an accident.

a La conduite est inuen-

cée par la machine attelée sur

le tracteur. En vue de permettre

une stabilité statique sufsante,

il faut s’assurer que la charge sur

l’essieu avant du tracteur n’est

pas inférieure à 20% du poids à

vide du tracteur. Pour cela la méthode la plus pratique consiste à

peser l’avant du tracteur sur une

bascule et comparer le résultat

avec la valeur conseillée dans

la notice du tracteur. Ajouter des

masses à l’avant du tracteur si

nécessaire.

a Driving is inuenced by the

machine coupled to the tractor. In

order to allow for sufcient static

stability, the load of the front axle

of the tractor must not be less than

20% of the empty weight of the

tractor. For this, the most practical method consists in weight the

front of the tractor on a scale and

comparing the result with the recommended value in the tractor’s

user manual. Add weight to the

front of the tractor if necessary.

Page 14

a Driving is inuenced by the

machine coupled to the tractor. In

order to allow for sufcient static

stability, the load of the front axle

of the tractor must not be less than

20% of the empty weight of the

tractor. For this, the most practical method consists in weight the

front of the tractor on a scale and

comparing the result with the recommended value in the tractor’s

user manual. Add weight to the

front of the tractor if necessary.

5.2 Montage des éléments sur la poutre - Assembly units on the beam -Assembly

units on the beam

La g.1 indique le principe pour

positionner les éléments sur la

poutre.

Dans le cas d’un nombre pair de

rangs (4, 6, 8, 12), il y a un élément au milieu.

Dans le cas d’un nombre impair

de rangs (5, 7, 9, 11), il n’y a pas

d’élément au milieu.

Fig. 1 shows the principle for positioning units on the beam.

If there is an even number of rows

(4, 6, 8, 12), there is a unit in the

middle.

If there is an odd number of rows

(5, 7, 9, 11), there is no unit in the

middle.

Fig. 1 shows the principle for positioning units on the beam.

If there is an even number of rows

(4, 6, 8, 12), there is a unit in the

middle.

If there is an odd number of rows

(5, 7, 9, 11), there is no unit in the

middle.

Fig. 1

Page 15

5.3 Élément large/élément étroit - Wide unit/narrow unit - Wide unit/narrow unit

Suivant les écartements de rang

il y a 2 manières de monter les

éléments :

- équipement étroit, soit 3 dents

par élément pour des rangs de

0m45 à 0m60,

- équipement large, soit 5 dents

par élément pour des rangs de

0m60 à 0m80.

Il est possible de transformer

rapidement un équipement large

en équipement étroit en suivant

la méthode préconisée voir g.2

:

1° - Enlever la dent gauche

avant (A).

2° - Desserrer la manivelle centrale (B) puis enlever l’ensemble

de droite (C) sans démonter ni la

dent ni le disque protège plants.

3° - Desserrer la manivelle avant

(D) et enlever l’ensemble (E)

sans démonter la dent qui peut

rester sur son support.

4° - Mettre la traverse (C) à

l’avant.

5° - Effectuer les réglages suivant l’écartement des rangs désiré, au moyen des manivelles

(D) et (F).

6° - Mettre les éléments sur la

poutre aux emplacements désirés, voir §5.1

According to the row spacings

there are 2 ways to assemble the

units:

- narrow equipment, which is 3

tines per unit for rows from 0m45

to 0m60,

- wide equipment, which is 5 tines

per unit for rows from 0m60 to

0m80,

It is possible to quickly transform wide equipment into narrow equipment by following the

recommended method, see g. 2:

1 – Remove the front left tine (A).

2 – Loosen the central crank

screw (B) then remove the right

unit (C) without removing the tine

or the plant-protection disc.

3 – Loosen the front crank screw

(D) then remove the unit (E) without removing the tine which can

remain on its support.

4 – Place the strut (C) in the front.

5 – Make the adjustments according to the row spacing desired,

using the crank screws (D) and

(F).

6 – Place the units on the beam

at the desired locations, see §5.1

And reciprocally in order to transform narrow equipment into wide

equipment.

According to the row spacings

there are 2 ways to assemble the

units:

- narrow equipment, which is 3

tines per unit for rows from 0m45

to 0m60,

- wide equipment, which is 5 tines

per unit for rows from 0m60 to

0m80,

It is possible to quickly transform wide equipment into narrow equipment by following the

recommended method, see g. 2:

1 – Remove the front left tine (A).

2 – Loosen the central crank

screw (B) then remove the right

unit (C) without removing the tine

or the plant-protection disc.

3 – Loosen the front crank screw

(D) then remove the unit (E) without removing the tine which can

remain on its support.

4 – Place the strut (C) in the front.

5 – Make the adjustments according to the row spacing desired,

using the crank screws (D) and

(F).

6 – Place the units on the beam

at the desired locations, see §5.1

And reciprocally in order to transform narrow equipment into wide

equipment.

Et réciproquement pour transformer un équipement étroit en

équipement large.

Page 16

5.4 Coutre circulaire - Circular coulter - Circular coulter

La bineuse ECONET est équipée en standard d’une paire de

coutre de guidage an d’assurer

un suivi correct du rang biné.

Le coutre se monte, sauf cas

particulier, en face de l’élément

bineur. Les 2 vis sans tête E permettent de régler l’orientation du

coutre par rapport à la machine.

Le ressort amortisseur (R) monté sur le coutre est précontraint

de 5mm ce qui le ramène à une

longueur de 120mm environ.

The ECONET hoeing machine

is provided with a pair of guide

coulters as standard equipment in

order to provide correct following

of the hoed row. The coulter is

mounted, except in special cases,

across from the hoeing unit. The

2 headless screws E allow the

orientation of the coulter to be adjusted in relation to the machine.

The buffer spring (R) mounted

on the coulter is pre-stressed by

5mm which returns it to a length

of about 120mm.

The ECONET hoeing machine

is provided with a pair of guide

coulters as standard equipment in

order to provide correct following

of the hoed row. The coulter is

mounted, except in special cases,

across from the hoeing unit. The

2 headless screws E allow the

orientation of the coulter to be adjusted in relation to the machine.

The buffer spring (R) mounted

on the coulter is pre-stressed by

5mm which returns it to a length

of about 120mm.

5.5 Repliage hydraulique - Hydraulic folding- Hydraulic folding

Les bineuses ECONET bipoutre

repliable pour écartement de

0m60 à 0m80 ont une largeur

de transport de 3m48 une fois

repliée an de favoriser la polyvalence de l’appareil. Ainsi une

bineuse repliable 6 rangs peut

biner 4 rangs une fois repliée.

Toutefois il est possible de diminuer la largeur de transport à

3m28 si nécessaire en repliant

un élément supplémentaire par

rallonge.

ECONET dual beam foldable

hoeing machines for a spacing

from 0m60 to 0m80 have a transport width of 3m48 once folded

back in order to favour versatility

for the device. As such, a 6-row

foldable hoeing machine can hoe

4 rows once folded. However, the

transport width can be reduced to

3m28 if necessary by folding back

an additional unit per extension.

Page 17

ECONET dual beam foldable

hoeing machines for a spacing

from 0m60 to 0m80 have a transport width of 3m48 once folded

back in order to favour versatility

for the device. As such, a 6-row

foldable hoeing machine can hoe

4 rows once folded. However, the

transport width can be reduced to

3m28 if necessary by folding back

an additional unit per extension.

Les bineuses ECONET monopoutre repliable pour écartement de 0m60 à 0m80 ont une largeur de transport de 2m50 une fois repliée.

ECONET single beam foldable hoeing machines for a spacing from 0m60 to 0m80 have a transport width

of 2m50 once folded back.

ECONET single beam foldable hoeing machines for a spacing from 0m60 to 0m80 have a transport width

of 2m50 once folded back.

Page 18

5.6 Repliage manuel - Manual folding - Manual folding

Les bineuses ECONET à repliage manuel permettent de replier 1 élément bineur à chaque

extrémité. Elles sont équipées

de ressorts an d’aider l’opérateur lors de la manipulation des

rallonges.

Une broche permet de verrouiller la rallonge en position travail

ou transport.

ECONET hoeing machines with

manual folding allow 1 hoeing unit

at each end to be folded back.

They are equipped with springs in

order to assist the operator when

manipulating extensions.

A pin allows the extension to be

locked into the working or transport position.

ECONET hoeing machines with

manual folding allow 1 hoeing unit

at each end to be folded back.

They are equipped with springs in

order to assist the operator when

manipulating extensions.

A pin allows the extension to be

locked into the working or transport position.

ATTENTION : avant de manipuler les rallonges, il faut impérativement verrouiller l’élément en position

haute à l’aide du crochet de verrouillage situé au niveau de la manivelle de terrage de l’élément primeur.

WARNING: before manipulating extensions, the unit must be locked into the upper position using the locking hook located on the depth control crank screw of the priming unit.

WARNING: before manipulating extensions, the unit must be locked into the upper position using the locking hook located on the depth control crank screw of the priming unit.

Page 19

6. UTILISATION - USE - BETRIEB

Le réglage du 3° point détermine

l’aplomb de la machine, et permet

d’obtenir une bonne régularité du

terrage entre l’avant et l’arrière

des éléments.

Les bras de relevage doivent être

stabilisés en bonne position an

que les coutres ne s’enfoncent

pas exagérément surtout en terre

très meuble. Il faut limiter la descente des bras de façon à pouvoir contrôler la pénétration des

coutres.

De plus, en position travail, les

biellettes des éléments bineurs

doivent être horizontales an de

permettre une oscillation vers le

haut ou vers le bas en fonction

des dénivellations du terrain et

des obstacles rencontrés.

The setting of the 3rd point determines the machine’s plumb line,

and allows for good regularity in

the depth gauge between the

front and the rear of the units.

The lift arms must be stabilised

in the correct position so that the

coulters do not sink excessively,

especially on very loose ground.

The descent of the arms must be

limited in such a way as to be able

to control coulter penetration.

In addition, in working position,

the tie-rods of the hoeing units

must be horizontal in order to

allow for oscillation upwards or

downwards according to the differences in level of the ground and

any obstacles encountered.

The setting of the 3rd point determines the machine’s plumb line,

and allows for good regularity in

the depth gauge between the

front and the rear of the units.

The lift arms must be stabilised

in the correct position so that the

coulters do not sink excessively,

especially on very loose ground.

The descent of the arms must be

limited in such a way as to be able

to control coulter penetration.

In addition, in working position,

the tie-rods of the hoeing units

must be horizontal in order to

allow for oscillation upwards or

downwards according to the differences in level of the ground and

any obstacles encountered.

Le terrage de chaque élément

est indépendant, à chaque tour

de manivelle, la roue monte ou

descend de 5mm. Pour un meilleur contrôle, utiliser la réglette

graduée collée sur le fourreau de

la roue.

Au travail, si la bineuse a ten-

dance à tirer d’un coté, vérier

l’équerrage des coutres par rapport à la poutre et, si nécessaire,

afner en jouant sur les vis (E)

g.3 qui règlent le parallélisme

des axes de coutre.

The depth control for each unit is

independent; the wheel is raised

or lowered 5mm at each turn

of the crank screw. For better

control, use the graduated guide

strip afxed to the wheel shaft.

When working, if the hoeing machine tends to pull to one side,

check the squareness of the

coulters in relation to the beam

and, if needed, rene the setting

by adjusting the screws (E) g. 3

which adjust the parallelism of the

coulter axes.

Page 20

The depth control for each unit is

independent; the wheel is raised

or lowered 5mm at each turn

of the crank screw. For better

control, use the graduated guide

strip afxed to the wheel shaft.

When working, if the hoeing machine tends to pull to one side,

check the squareness of the

coulters in relation to the beam

and, if needed, rene the setting

by adjusting the screws (E) g. 3

which adjust the parallelism of the

coulter axes.

Lorsque l’emploi des disques protège-plants n’est pas souhaitable,

il est possible de les maintenir en

position relevée (Fig.4). Le plat

soudé sur la bague (A), solidaire

de l’axe de rotation du bras, vient

en appui sur le buttoir (B).

When the use of plant-protection

discs is not desired, they can be

maintained in a raised position

(Fig. 4). The at welded onto ring

(A), integral with the axis of rotation of the arm, presses against

the ridger (B)..

When the use of plant-protection

discs is not desired, they can be

maintained in a raised position

(Fig. 4). The at welded onto ring

(A), integral with the axis of rotation of the arm, presses against

the ridger (B).

Page 21

7. AUTRES EQUIPEMENTS - OTHER EQUIPMENT - OTHER EQUIPMENT

7.1 Disque de chaussage/déchaussage - Earthing/unearthing disc - Earthing/

unearthing disc

Ces disques s’installent à l’arrière

de la machine et leur support se

xe dans les 4 trous prévus sur

chaque élément. Le support peut

se mettre dans 3 positions : on

choisira de préférence la plus

rapprochée de l’élément mais,

dans certains cas de chaussage

et en écartement plus étroit (60

cm mini) on devra l’éloigner pour

dégager la dent.

Pour chausser, les disques sont

positionnés bombé vers l’intérieur

dans ce cas c’est la vis position

(A) qui vient serrer dans la rainure

du montant de disque.

These discs are installed at the

rear of the machine and their support is attached in the 4 holes provided on each unit. The support

can be installed in 3 positions: the

position that is the closest to the

unit is the preferred position but,

in certain earthing cases and with

more narrow spacing (min. 60 cm)

this must be separated in order to

release the tine.

For earthing, the discs are positioned bulging towards the inside;

in this case it is screw position

(A) which which tightens in the

groove of the disc riser.

These discs are installed at the

rear of the machine and their support is attached in the 4 holes provided on each unit. The support

can be installed in 3 positions: the

position that is the closest to the

unit is the preferred position but,

in certain earthing cases and with

more narrow spacing (min. 60 cm)

this must be separated in order to

release the tine.

For earthing, the discs are positioned bulging towards the inside;

in this case it is screw position

(A) which which tightens in the

groove of the disc riser.

Pour déchausser, le bombé est

vers l’extérieur, c’est la vis position (B) qui serre. Il y a 3 angles

de travail des disques réglables

avec le boulon (C), vérier que

les disques sont tous réglés avec

le même angle.

For unearthing, the bulging is towards the outside; this is screw

position (B) which tightens. There

are 3 disc working angles which

can be set with bolt (C); check

that all of the discs are set to the

same angle.

Page 22

For unearthing, the bulging is towards the outside; this is screw

position (B) which tightens. There

are 3 disc working angles which

can be set with bolt (C); check

that all of the discs are set to the

same angle.

7.2 Disque de buttage - Ridging disc - Ridging disc

Ces disques s’installent à l’arrière de l’élément. L’inclinaison

des disques dénit la forme de la

butte, et elle est aussi fonction de

l’écartement des rangs (utilisable

uniquement de 0m60 à 1m00).

Cette inclinaison se règle au

moyen de la chape (A) qui possède plusieurs trous.

These discs are installed at the

rear of the unit. The inclination of

the discs denes the form of the

hill, and it also depends on the

row spacing (which can be used

only from 0m60 to 1m00). This

inclination is adjusted using yoke

(A) which has several holes.

These discs are installed at the

rear of the unit. The inclination of

the discs denes the form of the

hill, and it also depends on the

row spacing (which can be used

only from 0m60 to 1m00). This

inclination is adjusted using yoke

(A) which has several holes.

7.3 Herse peigne - Comb harrow - Comb harrow

La herse constituée de 4 peignes

s’installe à l’arrière de l’élément

bineur et permet d’améliorer la

nition du travail effectuer par les

dents. Les peignes émottent les

adventices et les ramènent à la

surface du sol facilitant ainsi leur

dessèchement.

Des oeillères, au niveau des 4

trous de xation permettent de

régler l’effort d’appui des dents

sur sol.

The harrow with its 4 combs is

installed at the rear of the hoeing

unit and allows the nishing of

the work done by the tines to be

improved. The combs break up

propagating clods and bring them

to the surface of the ground which

facilitates drying.

Side shields, on the 4 fastening

holes allow the pressing force

of the tines on the ground to be

adjusted.

The harrow with its 4 combs is

installed at the rear of the hoeing

unit and allows the nishing of

the work done by the tines to be

improved. The combs break up

propagating clods and bring them

to the surface of the ground which

facilitates drying.

Side shields, on the 4 fastening

holes allow the pressing force

of the tines on the ground to be

adjusted.

Page 23

7.4 Étoile à doigts NETLINE - Finger stars NETLINE - Finger stars NETLINE

Ce système s’installe à l’arrière

de l’élément bineur et permet de

travailler sur le rang en détruisant

les jeunes adventices et d’écroûter la zone située au pied de la

culture. Le NETLINE s’utilise sur

des cultures résistantes et bien

implantées en terrain nivelé,

souple et avec peu de cailloux.

This system is installed at the rear

of the hoeing unit and allows you

to work on the row by destroying

young propagations and to turn

the soil of the area located at the

foot of the crop. NETLINE is used

on resistant crops which are well

planted on levelled ground and

with few stones.

This system is installed at the rear

of the hoeing unit and allows you

to work on the row by destroying

young propagations and to turn

the soil of the area located at the

foot of the crop. NETLINE is used

on resistant crops which are well

planted on levelled ground and

with few stones.

Page 24

7.5 Direction - Steering - Steering

Pour pouvoir biner encore plus

près du rang, on installe sur la

poutre de la bineuse une direction

manoeuvrée par un assistant, qui

prend place sur un siège. Il agit au

moyen du manche de direction,

sur les roues à collerette, Fig.7

qui pivotent autour d’un axe vertical. Il est possible de remonter ou

d’abaisser de 25mm les roues par

rapport à la poutre en déplaçant

les bagues de réglage du pivot.

In order to hoe even closer to the

row, steering manoeuvred by an

assistant is installed on the beam

of the hoeing machine, who sits

on a seat. The assistant interacts

by means of the steering handle,

on the skirted wheels, Fig. 7 which

pivot around a vertical axis. The

wheels can be raised or lowered

25mm in relation to the beam by

displacing the adjusting rings of

the pivot.

In order to hoe even closer to the

row, steering manoeuvred by an

assistant is installed on the beam

of the hoeing machine, who sits

on a seat. The assistant interacts

by means of the steering handle,

on the skirted wheels, Fig. 7 which

pivot around a vertical axis. The

wheels can be raised or lowered

25mm in relation to the beam by

displacing the adjusting rings of

the pivot.

Les roues a collerettes peuvent

être remplacées par les coutres

circulaires de la bineuse autoguidée. A ce moment là, il est indispensable de limiter la descente

des bras du relevage du tracteur

an de diminuer la profondeur de

pénétration des coutres car plus

ils seront en terre, plus il sera

difcile de les faire pivoter. La

bineuse peut s’utiliser de manière

classique en bloquant la direction

soit en agissant sur le verrou du

manche, soit en empêchant la

pivotement des roues en utilisant

les butées.

The skirted wheels can be replaced with the circular coulters

on the self-guided hoeing machine. In this case, the tractor’s lift

arms must be limited in descent

in order to reduce coulter penetration depth, because the more

they are in the ground, the more

difcult it will be to pivot them.

The hoeing machine can be used

conventionally by blocking the

steering either by acting on the

lock on the handle, or by preventing the wheels from pivoting by

using the stops.

Page 25

The skirted wheels can be replaced with the circular coulters

on the self-guided hoeing machine. In this case, the tractor’s lift

arms must be limited in descent

in order to reduce coulter penetration depth, because the more

they are in the ground, the more

difcult it will be to pivot them.

The hoeing machine can be used

conventionally by blocking the

steering either by acting on the

lock on the handle, or by preventing the wheels from pivoting by

using the stops.

8. MAINTENANCE - MAINTENANCE - MAINTENANCE

8.1 Entretien par l’utilisateur - Maintenance by the user - Maintenance by the user

a APRES LA PREMIERE

HEURE D’UTILISATION -

* Vérier le serrage des dents

vibrantes.

* Contrôler l’absence de fuites

dans le circuit hydraulique du repliage.

a APRES CHAQUE JOURNEE

DE TRAVAIL -

* IMPORTANT : Vérier l’état

d’usure des socs de dents, inverser ou changer ceux qui le nécessite.

* Contrôler l’absence de fuites

dans le circuit hydraulique. Si besoin, faire appel à du personnel

spécialisé.

• FERTILISEUR : Nettoyage des

tré-mies. L’engrais très corrosif

attaque les parties métalliques.

• PULVERISATION : A la n de

chaque traitement, ne jamais laisser de produit séjourner dans la

cuve, ni dans le circuit. A chaque

change-ment de produit, nettoyer

en utili-sant un détergent et rin-

cer abon-damment. Dès la n du

traitement, rincer le circuit à l’eau

claire. Après le rinçage du cir-

cuit, nettoyer les ltres, démonter

et nettoyer les buses en cas de

bouchage (ne pas utiliser de l de

fer qui pourrait abî-mer la buse et

proscrire le soufage à la bouche

car les produits sont toxiques).

• SEMOIR RAY GRASS : A la suite

de fort dégagement de poussière

lors du semis, la souferie sera

nettoyée à l’air comprimé. L’axe

de la roue d’entraînement du semoir devra être regraissé après

chaque utilisation.

a UNE FOIS PAR AN, APRES

CHAQUE SAISON -

aAFTER THE FIRST HOUR

OF USE * Check the tightness of the vibrating tines.

* Make sure there are no leaks in

the hydraulic folding circuit.

a AFTER EACH DAY OF

WORK:

* IMPORTANT: Check the wear

of the tine ploughshares, invert or

change those as required.

* Make sure there are no leaks in

the hydraulic circuit. If required,

call upon specialised personnel.

• FERTILISER: Hopper cleaning.

Highly corrosive fertilisers attack

the metal parts.

• SPRAYING: At the end of each

treatment, do not allow the product to remain in the tank, or in the

circuit. Each time the product is

changed, clean with a detergent

and rinse with plenty of water. As

soon as treatment is complete,

rinse the circuit with clean water.

After the circuit has been rinsed,

clean the lters, remove and

clean the nozzles if they are clogged (do not use a piece of wire as

this could damage the nozzle and

do not blow with your mouth as

the prod-ucts are toxic).

• RAY GRASS SOWER: When

a lot of dust has been released

dur-ing sowing, the blower will

be cleaned with compressed air.

The axis of the sower drive wheel

must be greased again after each

use.

a ONCE A YEAR, AFTER

EACH SEASON * Replace worn ploughshares,

as well as the tines which are

showing signs of fatigue (lengthening, cracks, etc.)

aAFTER THE FIRST HOUR

OF USE * Check the tightness of the vibrating tines.

* Make sure there are no leaks in

the hydraulic folding circuit.

a AFTER EACH DAY OF

WORK:

* IMPORTANT: Check the wear

of the tine ploughshares, invert or

change those as required.

* Make sure there are no leaks in

the hydraulic circuit. If required,

call upon specialised personnel.

• FERTILISER: Hopper cleaning.

Highly corrosive fertilisers attack

the metal parts.

• SPRAYING: At the end of each

treatment, do not allow the product to remain in the tank, or in the

circuit. Each time the product is

changed, clean with a detergent

and rinse with plenty of water. As

soon as treatment is complete,

rinse the circuit with clean water.

After the circuit has been rinsed,

clean the lters, remove and

clean the nozzles if they are clogged (do not use a piece of wire as

this could damage the nozzle and

do not blow with your mouth as

the prod-ucts are toxic).

• RAY GRASS SOWER: When

a lot of dust has been released

dur-ing sowing, the blower will

be cleaned with compressed air.

The axis of the sower drive wheel

must be greased again after each

use.

a ONCE A YEAR, AFTER

EACH SEASON * Replace worn ploughshares,

as well as the tines which are

showing signs of fatigue (lengthening, cracks, etc.)

Page 26

* Remplacer les socs usagés,

ainsi que les dents qui donnent

des signes de fatigue (allonge-

ment, ssures...)

* Remplacer les coutres de guidage s’ils sont usés.

* Vérier le bon état des roulements des coutres de guidage

et des protèges plants. Ils sont

graissés à vie.

* Si le jeu dans les axes de parallélogramme de chaque élément

est anormal, il faut remplacer les

bagues d’usure.

* Vérier si les conduites hydrauliques de la bineuse repliable sont

bien étanches, si les raccords

sont desserrés ou s’il y a des

défauts dus au frottement. Remplacer ce qui est détérioré. ATTENTION, avant de travailler sur

le circuit hydraulique, enlever la

pression et couper le moteur. Au

besoin faire appel à du personnel

spécialisé.

* Après un nettoyage au jet d’eau

ou au nettoyeur haute pression,

il est bon d’huiler ou de graisser

tous les points susceptibles d’être

démontés.

a REMISAGE ENTRE 2 CAM-

PAGNES * Stocker l’appareil de préférence

déplié, et sur un sol stable. Utiliser les béquilles de maintien.

* Protéger les tiges des vérins

hydrauliques des rallonges re-

pliables en y appliquant un lm

anticorrosif (graisse).

* Remplir le circuit de pulvérisation avec de l’antigel.

a Pièces détachées sur de-

mande. Voir les nomenclatures

correspondantes. Les pièces

détachées doivent correspondre

aux exigences techniques du

constructeur, ce qui est toujours

le cas avec des pièces d’origine.

* Replace the guide coulters if

they are worn.

* Check that the bearings of the

guide coulters and the plant pro-

tectors are in good condition.

These are lubricated for life.

* If the space in the parallelogram

axes of each unit is not normal, the

wearing rings must be replaced.

- Check that the hydraulic lines on

the folding hoeing machine are

properly sealed, the connections

are tight and that there are no de-

fects caused by friction. Replace

anything that is deteriorated.

WARNING, before working with

the hydraulic circuit, release the

pressure and turn off the motor.

Call upon specialised personnel

when necessary.

* After cleaning with a spray of

water or high-pressure hose, all

of the points that can be removed

should be oiled or greased.

a STORAGE BETWEEN 2

CROP YEARS * Store the device on stable

ground, preferably unfolded. Use

the maintaining stands.

* Protect the rods of the hydraulic

cylinders on the foldable extensions by applying an anti-corro-

sive lm (grease).

* Fill the spray circuit with antifreeze.

a Spare parts as requested.

Consult the corresponding nomenclatures. Spare parts must

meet the manufacturer’s technical

requirements, which is always the

case with original parts.

* Replace the guide coulters if

they are worn.

* Check that the bearings of the

guide coulters and the plant protectors are in good condition.

These are lubricated for life.

* If the space in the parallelogram

axes of each unit is not normal, the

wearing rings must be replaced.

- Check that the hydraulic lines on

the folding hoeing machine are

properly sealed, the connections

are tight and that there are no defects caused by friction. Replace

anything that is deteriorated.

WARNING, before working with

the hydraulic circuit, release the

pressure and turn off the motor.

Call upon specialised personnel

when necessary.

* After cleaning with a spray of

water or high-pressure hose, all

of the points that can be removed

should be oiled or greased.

a STORAGE BETWEEN 2

CROP YEARS * Store the device on stable

ground, preferably unfolded. Use

the maintaining stands.