CARR 501030 Work Truck Step User Manual

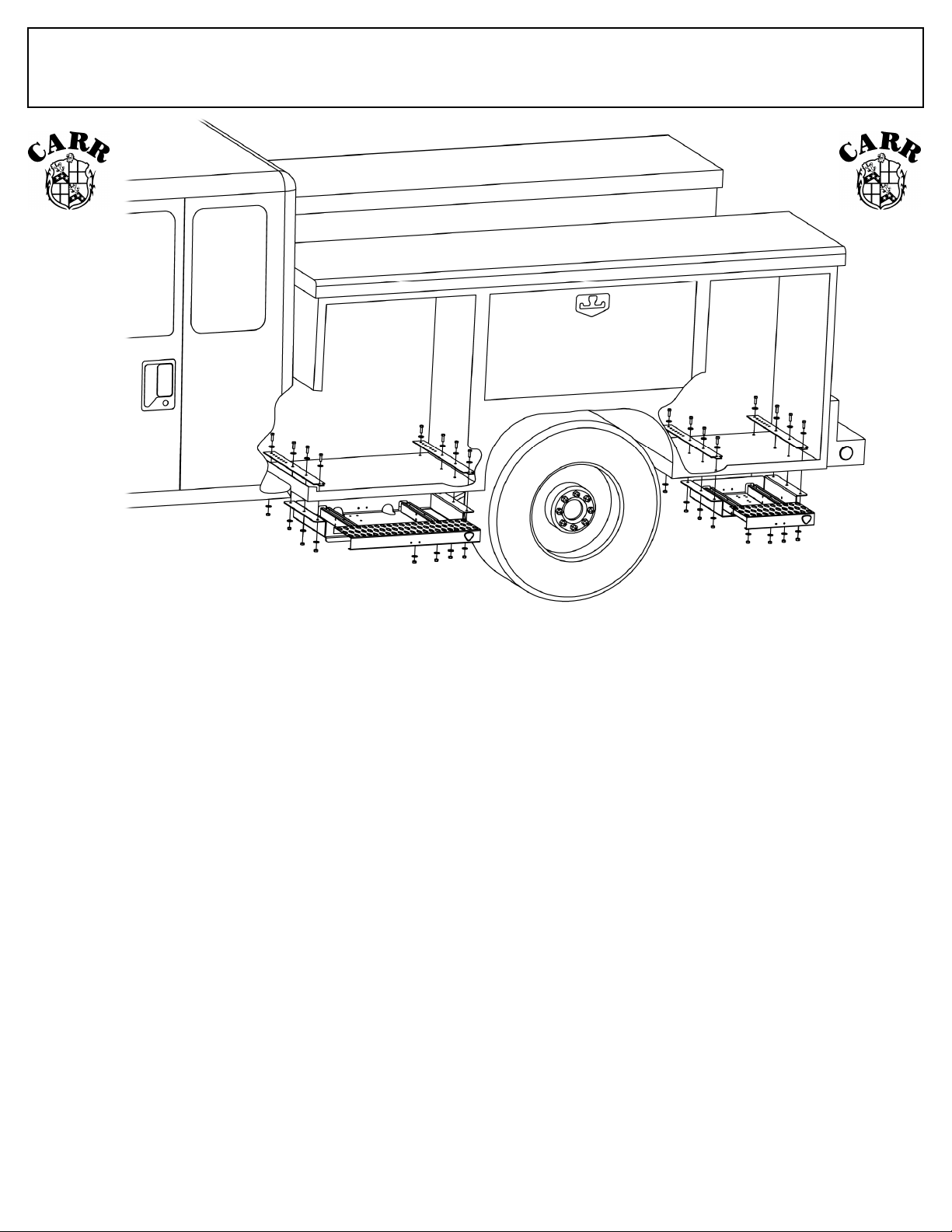

Work Truck Step Installation Instructions

Part No’s: 501010, 501020, 501030

1.

WARNING: Rear passenger side tool box on some trucks may have an exhaust pipe. The Step assembly may have to be moved

forward for proper installation. Some exhaust pipes are flexible and will move some, which may be enough to get the step assembly

installed properly.

2.

Make sure this step assembly will be mounted to a flat service where access to both sides of the mounting area is available.

3.

From underneath the mounting area, position the step assembly in its desired position. Line up the front edge of the step assembly

with the edge of the mounting area to insure step assembly is straight.

4.

Set the front edge of the step pan back ¼” from the front edge of the mounting area. This will insure that the support straps will fit

properly inside.

5.

From underneath take a pencil and mark the two front holes in the step pan. Set the step assembly aside.

6.

Drill out the marked holes with a 5/16 drill bit and remove any burrs.

7.

Place the step assembly back into position and with the 5/16 hardware provided tighten the drilled areas to the step assembly.

8.

For boxes that are less than 13” in depth follow these instructions. With the step in position you now can drill out the other two

holes using the holes in the step pan as a guide. Since your box is not as deep, you will not use the back two holes in the step pan.

Drill out the two other holes. Remove the step assembly and remove all burrs. Measure the inside of the mounting area and cut the

support straps to that dimension. Cut the ends of the support straps that have the holes that are spaced closer to each other. The

closer you cut this end to the inside corner of the mounting area, the stronger this installation will be. After cutting, apply some black

primer paint on the area that was just cut. Now place the support straps back inside the mounting area and line up the four holes

you drilled in the pervious step with the four holes that are in the support straps. Take the 5/16 hardware and mount the step

assembly to the mounting area with the support straps inside. See diagram for exploded view of this. Securely tighten the

hardware. Go to step 10.

9.

For boxes that are deeper than 13” in depth follow these instructions. With the step in position you now can drill out the other

four holes using the holes in the step pan as a guide. Take the two support straps and place them inside the mounting area and line

up the six holes you just drilled with the six holes that are spaced farther apart. (NOTE: if the support straps are to long, measure

the inside of the mounting area and cut the ends of the support straps that have the holes that are spaced closer to each other. The

closer you cut this end to the inside corner of the mounting area, the stronger this installation will be. After cutting, apply some black

primer paint on the area that was just cut. Now place the support straps back inside the mounting area and line up the six holes you

drilled in the pervious step with the six holes that are spaced farther apart in the support straps.) Take the 5/16 hardware and

mount the step assembly to the mounting area with the support straps inside. See diagram for exploded view of this. Securely

tighten the hardware. From inside the cabinet take a 5/16 drill bit and using the holes at the end of the support straps as a guide,

drill out the metal of the mounting area. Remove all burrs. Use the remaining 5/16 hardware and securely tighten the end of the

support strap to the mounting area.

10.

All moving parts ride on Delrin plastic which will give you smooth, efficient and long lasting functionality.

11.

Cut the zip ties from the back of each rail. Now your step is ready to go!

12.

To deploy your step out, just push the step in with you foot. To lock it in, do the same thing except push the step in until it locks.

Work Truck Step Installation Instructions

Part No’s: 501010, 501020, 501030

WARNINGS!

FOR SAFE AND PROPER USAGE OF THIS PRODUCT, THE MOUNTING INSTRUCTIONS MUST BE

FOLLOWED CAREFULLY AND COMPLETELY.

The manufacturer and distributor of this product are in no way responsible for the consumer’s failure to adhere

to the warnings and directions of these instructions in the event of damage to the consumer’s vehicle, other

properties and or personal injury.

Vehicle Application:

All commercial, industrial, utility, fire prevention and service trucks that

have tool boxes or a flat platform area that has access to both sides.

Quality and Style that Endures

Follow the diagram and the

written directions carefully for a

proper, safe installation.

Should you encounter an

unusual, unforeseen problem,

contact our Technical Help Line

7:00 AM – 3:00 PM Pacific

Time

(951) 719-1068

Visit our web-site at

www.CARR.com

Carr Pattern Co., Inc.

MATERIALS NEEDED:

* Drill motor

* 5/16 drill bit

* Pencil

* 2 – ½” wrenches or sockets

* Possibly a metal cutting device (hacksaw, band saw, grinder, etc)

* Cutters to cut zip ties

* Black primer paint (if support straps are cut)

MATERIAL FURNISHED:

* Step Assembly

* 2 – Support Straps

* Hardware installation pack

* Instruction sheet

Installation time for one step assembly – ½ hour

Carr Pattern Co., Inc.

Finishes: Limited Lifetime

Structural Warranty: Limited Lifetime

Warranty Conditions:

a. All warranties start from consumer’s date of purchase.

b. A new product will be sent out immediately to replace a warranty claim.

c. The above guidelines apply only to the Original Purchaser.

d. Original proof of purchase must be submitted for all warranty and returns issues.

Warranty Limitations:

a. Warranty coverage extends ONLY to repair or replacement of the CARR product. This warranty does not cover the cost of labor, transportation, installation or removal of the product.

b. Warranty coverage does not extend to damage caused by: collision, fire, theft, freezing, vandalism, riot, explosion or object striking the product, or misuse of the product and/or the vehicle on

which the product is being installed.

c. Warranty coverage does not extend to damage caused by: airborne fallout (chemicals, tree sap, etc.), stones, hail, earthquake, water or flood, windstorm, lightning, the application of chemicals or

sealants subsequent to manufacture.

d. Warranty coverage does not extend to damages caused by: normal wear and tear, abuse, modification or improper installation of the product.

e. Warranty coverage does not extend to any economic loss or extra expense including (without limitation), payment for the loss of time or pay, inconvenience, storage, loss of vehicle use, vehicle

rental expense, equipment rental expense, lodging, meals, or other travel costs.

Other Terms:

This warranty gives you specific legal rights and you may also have other rights that vary from state to state. CARR does not authorize any person to create for it any other obligation or liability in

connection with its products. ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE APPLICABLE TO THIS PRODUCT IS LIMITED IN

DURATION TO THE DURATION OF THIS WRITTEN WARRANTY. PERFORMANCE OF REPAIRS AND NEEDED ADJUSTMENTS IS THE EXCULSIVE REMEDY UNDER THIS

WRITTEN WARRANTY OR ANY IMPLIED WARRANTY. CARR SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM BREACH OF

THIS WRITTEN WARRANTY.*

*Some states do not allow limitations on how long an implied warranty will last or the exclusion or limitation of incidental or consequential damages, so that above limitations or exclusions may not

apply to you.

Guarantee: Every attempt has been made to manufacture and distribute the finest quality products available. Our manufactured products are guaranteed to be free of defects due to workmanship or

materials. Distributed products are subject to manufacturer’s warranty only.

CARR ● 27447 Bostik Court ● Temecula CA 92590

Warranty Policy

Loading...

Loading...