CARR 210914 Rota Light Bar User Manual

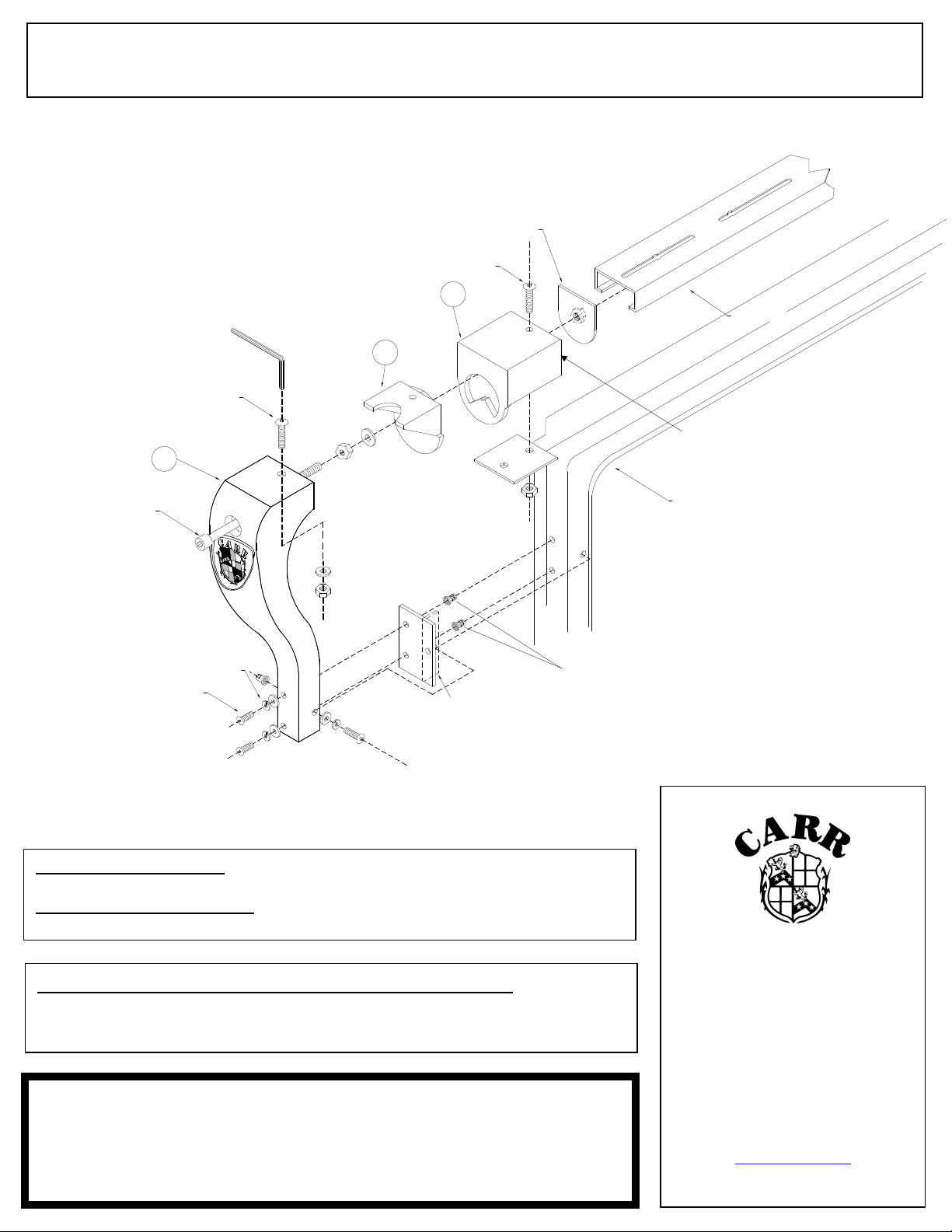

This is the open end of Casting

(1).

MATERIALS NEEDED:

ROTA LIGHT BAR MOUNTING INSTRUCTIONS

Part No’s: 210911, 210912 & 210914

Welded Nut

5/16" Bolt

Rota Hood Casting

Rota Angle Casting

1

Cross Bar

2

5/16" Bolt

Mounting End Castings

3

3/8" Bolt

Split Lock Washer

1/4" Bolt

Drill motor, 5/16” drill bit, hammer, center punch, ½”

drill bit, hacksaw.

MATERIALS FURNISHED: One hardware pack, two end castings, four Rota

castings, cross bar, instruction page.

Bend Rubber Gasket

THIS LIGHT BAR FITS THE FOLLOWING VEHICLES:

JEEP

‘76 – ‘95 Jeep CJ/YJ Wrangler

WARNING!

THIS CARR LIGHT BAR IS DESIGNED TO HANDLE A TOTAL

WEIGHT OF FOUR (4) LBS. ANY ADDITIONAL WEIGHT

BEYOND THIS CAPACITY, MAY RESULT IN SERIOUS

DAMAGE TO YOUR VEHICLE AND/OR ANOTHER VEHICLE.

Tinnerman Nuts

Measure from this point on each

Casting (1). (See step 22 on Light

Bar Mounting Instruction)

Windshield

Quality and Style that Endures

Follow the diagram and the written

directions carefully for a proper,

safe installation.

Should you encounter an unusual,

unforeseen problem, contact our

Technical Help Line

7:00 AM – 3:00 PM Pacific Time

(951) 719-1068

Visit our web-site at

www.CARR.com

Carr Pattern Co., Inc.

Screw the long 3/8" socket bolt into the washer with the welded nut all the way and lightly tighten. NOTE: Use the 5/16" Allen wrench through the large hole in Mounting

to the windshield frame, drill both 5/16" holes through the front of the windshield frame, using the holes in

ROTA LIGHT BAR MOUNTING INSTRUCTIONS

Part No’s:

210911, 210912 & 210914

Carr Pattern Co., Inc.

Do not over tighten the nuts and bolts or damage to the castings and or stripping of the threads could result.

FOR SAFE AND PROPER USAGE OF THIS PRODUCT, THE MOUNTING INSTRUCTIONS MUST BE FOLLOWED CAREFULLY AND COMPLETELY.

The manufacturer and distributor of this product are in no way responsible for the consumer’s failure to adhere to the warnings and directions of these instructions in the event of damage to the

consumer’s vehicle, other properties and or personal injury.

DO NOT REMOVE the PVC tape from the light bar until cutting is completed. When cutting black bar leave plastic bag on and wrap a rag around bar before putting into a vise so no scratching

WARNINGS!

1. Take the long 3/8" socket bolt and screw on to it the 3/8" jam nut all the way to the end of the threads and tighten down.

2. Put the long 3/8" socket bolt through the large hole in Mounting End Casting (3). Refer to the diagram provided.

3. Leave the head of the long socket bolt extending all the way out of Mounting End Casting (3).

4. Place Rota Angle Casting (2) inside of Mounting End Casting (3) and line up the two 5/16" holes.

5. Take the 5/16" Allen button head screw and put it through both Mounting End Casting (3) and Rota Angle Casting (2). Use the 5/16" washer and the 5/16" nylon lock nut

to securely tighten castings together. NOTE: The front face of casting (2) should be straight across the face of Mounting End Casting (3). When castings are securely

tightened together, Rota Angle Casting (2) should be protruding approximately 1/16" beyond Mounting End Casting (3).

6. Place a 3/8" flat washer on the long 3/8" socket bolt and now put the long socket bolt through the other hole in Rota Angle Casting (2).

7. Place Rota Hood Casting (1) on Rota Angle Casting (2).

8. With the welded nut facing away from Rota Angle Casting (2) place the large washer with the welded nut all the way to the inside of Rota Hood Casting (1).

9.

End Casting (3) to tighten and loosen the rotating motion. See diagram. (Beware of the CAUTION in step 37)

10. Repeat the same steps for the other side.

11. Take one Mounting End Casting assembly and measure from top of windshield frame hinge, 10 ½" to 11" up to bottom of end casting.

12. Line up the holes in the Mounting End Casting (3) and the rubber gasket, hold in position on the windshield frame, and mark the two side holes on the windshield frame

with a pencil. IMPORTANT: When positioning end casting (3) on the windshield frame, make sure it is up against a flat part of the frame, not a curved section. Also,

make sure the Mounting End Casting (3) will not interfere with opening and closing of the door or the removal of a soft top.

13. Follow the same procedure for the other side. IMPORTANT: To ensure that the light bar is level, measure up the exact same distance from both windshield frame hinges

to the bottom of both Mounting End Casting assemblies.

14. Center punch the two marked side holes on each side of the windshield frame from step 12.

15. Take a sharp 5/16" drill bit and drill out the four center punched holes. Then go back and enlarge the four holes to ½". WARNING: For best results the ½" holes should be

drilled to size. DO NOT drill the holes oversize and or oblong. A new ½" drill bit will make this task more accurate. AVOID drilling holes at an angle. Avoid forcing or

pushing too hard on the drill motor - this could result in an oblong or oversized hole. If you do not think you can drill these holes precisely, consider taking your vehicle

and light bar to a professional installer. This warning applies to steps 18 and 19 as well.

16. Take the Tinnerman nuts provided and tap them into the holes you have drilled, with the flange flat against the window frame metal.

17. Using the 1/4" tamper-proof Allen head bolts, 1/4" split-lock washers, and 1/4" flat washers, take one Mounting End Casting assembly with the rubber gasket, and mount

it to windshield frame. Securely tighten with the Allen wrench provided. Repeat for other side.

18. With both Mounting End Casting assemblies securely mounted

the castings as a guide. Then remove both Mounting End Casting assemblies.

19. Drill out the two 5/16" holes to ½". Tap in a Tinnerman nut in each front drilled hole.

20. Re-mount both Mounting End Casting assemblies with the hardware provided. Mount the two sets of outside bolts and securely tighten them first. Then securely tighten

the two front bolts.

21. Remove any excess rubber gasket for a cleaner appearance.

22. With both Mounting End Casting assemblies installed, take a tape measure and measure the distance between each open end (refer to diagram) of each Rota Hood

Casting (1), and than add 2 inches to that dimension.

23. Subtract that total from the total length of the bar, which is 56".

24. Take the difference and divide it by two.

25. The amount divided by two is the amount you will cut off each end of your bar. CAUTION: Do not cut from one end, this will make lights off-center.

26. Measure and mark a line on both ends of the steel bar using the dimensions from steps 22-25.

27. Clamp the end of the bar into a vise (be careful not to scar the light bar). Using a hack saw, cut carefully along the lines you have marked. If a vise is not available, put the

bar on a table or bench, securely tighten, and cut. IMPORTANT: For black and silver-titanium finished bars, paint the cut surfaces of the bar with rust-resistant paint.

28. Remove PVC tape or plastic bag from light bar. Place bar underneath Mounting End Castings and push into place. Be sure bar is centered.

29. Put a 5/16" Allen head bolt through top of each Rota Hood Casting (1) from the top down.

30. Place large rectangular washers inside of bar. Push the light bar up inside of each Rota Hood Casting (1). IMPORTANT: be sure that the rectangular washers are

completely underneath Rota Hood Casting (1)

31. With rectangular washers in place, take nylon lock nuts and Allen wrench provided, and securely tighten the light bar to the Rota Hood Castings.

32. The light bar mounting bolts that attach to the windshield frame should be checked periodically and tightened if necessary.

33. Check again and securely tighten ALL hardware

34. After one month of use, go back and give all hardware a final tightening.

35. To maintain luster of polished areas use an aluminum polish on a regular basis.

36. CAUTION: WHEN LIGHTS ARE INSTALLED ON YOUR BAR AND YOU WANT TO LOOSEN THE BAR TO ROTATE THE BAR DOWN, BE CAREFUL NOT

TO LOOSEN TOO MUCH BECAUSE LIGHTS COULD CRASH AGAINST THE VEHICLE AND CAUSE DAMAGE TO THE VEHICLE AND THE LIGHTS.

ALSO, DO NOT LOSE YOUR ALLEN WRENCHES.

Finishes: Limited Lifetime

Structural Warranty: Limited Lifetime

Warranty Conditions:

a. All warranties start from consumer’s date of purchase.

b. A new product will be sent out immediately to replace a warranty claim.

c. The above guidelines apply only to the Original Purchaser.

d. Original proof of purchase must be submitted for all warranty and returns issues.

Warranty Limitations:

a. Warranty coverage extends ONLY to repair or replacement of the CARR product. This warranty does not cover the cost of labor, transportation, installation or removal of the product.

b. Warranty coverage does not extend to damage caused by: collision, fire, theft, freezing, vandalism, riot, explosion or object striking the product, or misuse of the product and/or the vehicle on which the product is being installed.

c. Warranty coverage does not extend to damage caused by: airborne fallout (chemicals, tree sap, etc.), stones, hail, earthquake, water or flood, windstorm, lightning, the application of chemicals or sealants subsequent to

manufacture.

d. Warranty coverage does not extend to damages caused by: normal wear and tear, abuse, modification or improper installation of the product.

e. Warranty coverage does not extend to any economic loss or extra expense including (without limitation), payment for the loss of time or pay, inconvenience, storage, loss of vehicle use, vehicle rental expense, equipment rental

expense, lodging, meals, or other travel costs.

Other Terms:

This warranty gives you specific legal rights and you may also have other rights that vary from state to state. CARR does not authorize any person to create for it any other obligation or liability in connection with its products. ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE APPLICABLE TO THIS PRODUCT IS LIMITED IN DURATION TO THE DURATION OF THIS WRITTEN

WARRANTY. PERFORMANCE OF REPAIRS AND NEEDED ADJUSTMENTS IS THE EXCULSIVE REMEDY UNDER THIS WRITTEN WARRANTY OR ANY IMPLIED WARRANTY. CARR SHALL NOT BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM BREACH OF THIS WRITTEN WARRANTY.*

*Some states do not allow limitations on how long an implied warranty will last or the exclusion or limitation of incidental or consequential damages, so that above limitations or exclusions may not apply to you.

Guarantee: Every attempt has been made to manufacture and distribute the finest quality products available. Our manufactured products are guaranteed to be free of defects due to workmanship or materials. Distributed products are

subject to manufacturer’s warranty only.

CARR ● 27447 Bostik Court ● Temecula CA 92590

Warranty Policy

Loading...

Loading...