V3

Instruction Manual

Models

EP2020-000 EP4020-000

EP2040-000 EP4040-000

EP2060-000 EP4060-000

EP2075-000 EP4075-000

EP2100-000 EP4100-000

EP2125-000 EP4125-000

EP2150-000 EP4150-000

EP2200-000 EP4200-000

EP2250-000 EP4250-000

EP2300-000 EP4300-000

EP2400-000 EP4400-000

EP2500-000 EP4500-000

EP2600-000 EP4600-000

EP2700-000 EP4700-000

Table of Contents

1. General Description .......................................................................................................................................... 4

2. Specifications ....................................................................................................................................................4

2.1 Electrical.............................................................................................................................................4

2.2 Physical..............................................................................................................................................5

3. Installation .........................................................................................................................................................7

3.1 Control Installation .............................................................................................................................7

3.2 Wiring Guidelines ............................................................................................................................... 7

4. Terminal Connections & Functions ................................................................................................................... 7

4.1 AC Power Connections & Fusing.......................................................................................................7

4.2 Motor Connections ............................................................................................................................. 9

4.3 Signal Connections .......................................................................................................................... 11

5. Human Machine Interface (HMI) ..................................................................................................................... 14

5.1 Description of Interface .................................................................................................................... 14

5.2 Menu Structure.................................................................................................................................15

6. Start Up Procedure ......................................................................................................................................... 17

6.1 Pretest..............................................................................................................................................17

6.2 Adjustment Procedure: Velocity (Speed) Regulator.........................................................................17

6.3 Adjustment Procedure: Constant Horsepower................................................................................. 19

6.4 Adjustment Procedure: Torque (Current) Regulator........................................................................ 19

6.5 Calibration & Fine Tuning.................................................................................................................19

6.4 Password Protection ........................................................................................................................ 21

7. Programming & Adjustments .......................................................................................................................... 22

7.1 A: Options ........................................................................................................................................22

7.2 B: Digital Inputs ................................................................................................................................ 23

7.3 C: Analog Inputs...............................................................................................................................29

7.4 D: Digital Outputs ............................................................................................................................. 34

7.5 E: Analog Outputs ............................................................................................................................ 38

7.6 F: Motor Data ................................................................................................................................... 40

7.7 G: Control Loops .............................................................................................................................. 44

7.8 H: Start/Stop Logic ........................................................................................................................... 52

7.9 I: Setpoints ....................................................................................................................................... 56

7.10 J: Ramps ........................................................................................................................................ 58

7.11 K: Fault Logic ................................................................................................................................. 62

7.12 L: Applications................................................................................................................................68

7.13 M: Thresholds ................................................................................................................................78

7.14 N: Timers .......................................................................................................................................81

7.15 O: Logic Gates ............................................................................................................................... 83

7.16 P: Switches ....................................................................................................................................86

7.17 Q: Internal Links ............................................................................................................................. 87

7.18 R: Communications........................................................................................................................88

7.19 S: Zero Speed ................................................................................................................................ 91

7.20 T: System ....................................................................................................................................... 92

7.21 U: Auxiliary ..................................................................................................................................... 94

7.22 Parameter Table ............................................................................................................................95

8. Troubleshooting ............................................................................................................................................ 109

9. Serial Network Communications ...................................................................................................................113

9.1 Physical..........................................................................................................................................113

9.2 Modbus® Protocol..........................................................................................................................113

10. Spare Parts ................................................................................................................................................. 115

10.1 Printed Circuit Assemblies ........................................................................................................... 115

10.2 Fuses ...........................................................................................................................................115

10.3 Power Components......................................................................................................................117

11. Prints ...........................................................................................................................................................118

D14171 Control Board Assembly.........................................................................................................118

D14163 Trigger Board Assembly ......................................................................................................... 119

D14177 Regulator Board Assembly.....................................................................................................120

C14188 Snubber Board Assembly.......................................................................................................121

C14166 CT ID Board Assembly ........................................................................................................... 122

C14045 Processor Board Assembly .................................................................................................... 123

2

D14270 Assembly Drawing, 20-60HP Models .....................................................................................124

D14316 Assembly Drawing, 75-150HP Models ...................................................................................125

DXXXXX Assembly Drawing, 200-400HP Models...............................................................................126

D14356 Assembly Drawing, 500-700HP Models .................................................................................127

D14263 Assembly, Heatsink Chassis, 20-60HP Non-Regen Models ..................................................128

D14264 Assembly, Heatsink Chassis, 20-60HP Regen Models..........................................................129

D14347 Assembly, Heatsink Chassis, 75-150HP Non-Regen Models ................................................130

D14318 Assembly, Heatsink Chassis, 75-150HP Regen Models........................................................131

DXXXXX Assembly, Heatsink Chassis, 200-300HP Non-Regen Models............................................132

DXXXXX Assembly, Heatsink Chassis, 400HP Non-Regen Model.....................................................133

DXXXXX Assembly, Heatsink Chassis, 200-300HP Regen Models....................................................134

DXXXXX Assembly, Heatsink Chassis, 400HP Regen Model.............................................................135

D14350 Assembly, Heatsink Chassis, 500-700HP Non-Regen Models ..............................................136

D14351 Assembly, Heatsink Chassis, 500-700HP Regen Models......................................................137

D14248 Wiring Diagram, 20-60HP Non-Regen Models ......................................................................138

D14249 Wiring Diagram, 20-60HP Regen Models .............................................................................. 139

D14322 Wiring Diagram, 75-150HP Non-Regen Models ....................................................................140

D14314 Wiring Diagram, 75-150HP Regen Models ............................................................................ 141

DXXXXX Wiring Diagram, 200-400HP Non-Regen Models ................................................................142

DXXXXX Wiring Diagram, 200-400HP Regen Models ........................................................................ 143

D14353 Wiring Diagram, 500-700HP Non-Regen Models ..................................................................144

D14354 Wiring Diagram, 500-700HP Regen Models .......................................................................... 145

D14308 General Connections..............................................................................................................146

D14306 RS422/485 Network Connections ..........................................................................................147

C14307 Sonic Transducer Option Connections...................................................................................148

D14309 Software Block Diagram .........................................................................................................150

12. Standard Terms & Conditions of Sale .........................................................................................................155

List of Tables

Table 1: Model Rating Data...................................................................................................................................9

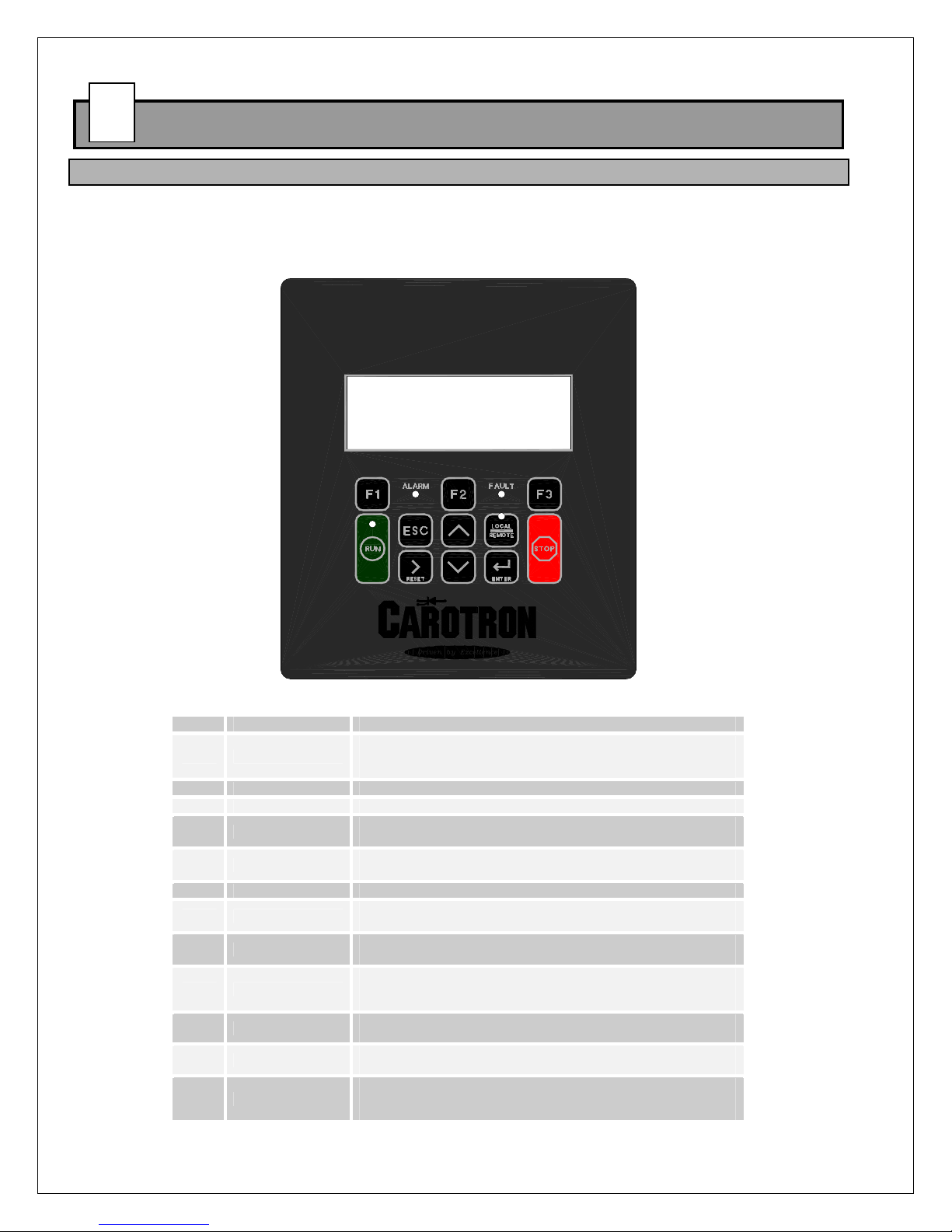

Table 2: HMI Description.....................................................................................................................................14

Table 3: Drive Monitor Descriptions ....................................................................................................................16

Table 4: Common Digital Input Functions ...........................................................................................................23

Table 5: Common Analog & Freq Input Functions ..............................................................................................29

Table 6: Analog Input Status Readings...............................................................................................................30

Table 7: Common Relay & Digital Output Functions...........................................................................................34

Table 8: Common Analog & Freq Output Functions ...........................................................................................38

Table 9: Analog Output Status ............................................................................................................................39

Table 10: Drive Modes ........................................................................................................................................54

Table 11: Reference Select.................................................................................................................................56

Table 12: Faults 1................................................................................................................................................64

Table 13: Faults 2................................................................................................................................................64

Table 14: Alarms 1 ..............................................................................................................................................65

Table 15: Inertia Sensitivity .................................................................................................................................75

Table 16: Logic Gates Truth Table......................................................................................................................85

Table 17: Parameters..........................................................................................................................................95

Table 18: Faults.................................................................................................................................................109

Table 19: Supported Modbus® Functions.........................................................................................................114

Table 20: Field Fuses........................................................................................................................................115

Table 21: Recommended Line Fuses ...............................................................................................................116

Table 22: Armature Bridge Modules .................................................................................................................117

Table 23: Field Supply Modules ........................................................................................................................117

3

1111

General Description

The Elite Pro V3 Series is Carotron's 3rd generation of microprocessor based D.C. motor controls.

The series provides control of speed and torque control of 5-700HP D.C. motors rated for NEMA

type "C" power supplies. The EP2 (non-regenerative) series and the EP4 (regenerative) series are

offered in compact panel mounted assemblies.

2222

Specifications

2.1 Electrical

A.C. Input Voltage Range

•

3 phase, 230-460 VAC ± 10%, 50/60 Hz ± 2 Hz

•

1 phase, 115 VAC ± 10%, 50/60 Hz ± 2 Hz, 5A

A.C. Line Field Supply - 1 Phase (Optional)

•

230-460 VAC ± 10%, 50/60 Hz ± 2 Hz

Armature Output

•

0-240VDC @ 230 VAC input

•

0-415VDC @ 380 VAC input

•

0-500VDC @ 460 VAC input

Field Output

•

Voltage

0-200VDC @ 230 VAC input

0-330VDC @ 380 VAC input

0-400VDC @ 460 VAC input

•

Current

EPx020-000 thru EPx060-000: 8A max

EPx075-000 thru EPx150-000: 10A max

EPx200-000 thru EPx700-000: 12A max

Power Supplies

•

+24V (TB1-1): 50mA

•

+12V (TB1-17): 100mA

•

+10V (TB1-16): 50mA

•

-10V (TB1-46): 50mA

Digital Inputs (Qty: 7)

•

Sink Mode

Vih=20.0 VDC max

Vil=0.0 VDC min to 17.0 VDC max

•

Source Mode

Vih=8.0 VDC min to 30.0 VDC max

Analog Inputs (Qty: 5)

•

•

Max Input: ±20 mADC

•

Tachometer Feedback Input

•

Vil=5.0 VDC max

Voltage Mode

Max Input:±10 VDC

Input Impedance: 1MΩ

Current Mode

Input Impedance: 250Ω

Resolution: 12 bit

Max Input: ±200 V (AC or DC)

Encoder Feedback Input

•

Frequency: 200kHz max

•

Uni-directional (single channel) or Quadrature

•

Single ended or differential

•

Voltage: 12 VDC max

Frequency Input

•

Frequency: 40kHz max, square wave

•

Voltage: 12 VDC max

Vil=0.0 VDC to 1.5 VDC max

Relay Outputs (Qty: 3)

Form-C contact:

•

•

Armature Pilot Relay Output

•

•

Analog Outputs (Qty: 2)

•

•

Frequency/Digital Output

•

•

•

Speed Regulation

•

•

•

Torque Regulation

•

Speed Range

•

Temperature Range

•

•

Vih=2.5 VDC min to 12.0 VDC max

2 A @ 115 VAC (resistive)

2 A @ 60 VDC (resistive)

30 A @ 120 VAC (resistive)

30 A @ 28 VDC (resistive)

±10 VDC max, 20mADC max

Resolution: 12 bit + sign

Frequency: 10kHz max, square wave

Sink current: 100mA max

Voltage: 30VDC max

Armature Feedback: ±1%

Tachometer Feedback: ±0.01%

Encoder Feedback: ±0.01% (with 1024 min ppr)

±1% of Range Selected

100:1 typical when using tachometer or encoder

feedback. May be less depending upon motor

characteristics

Chassis: 0-55C

Enclosed: 0-40C

4

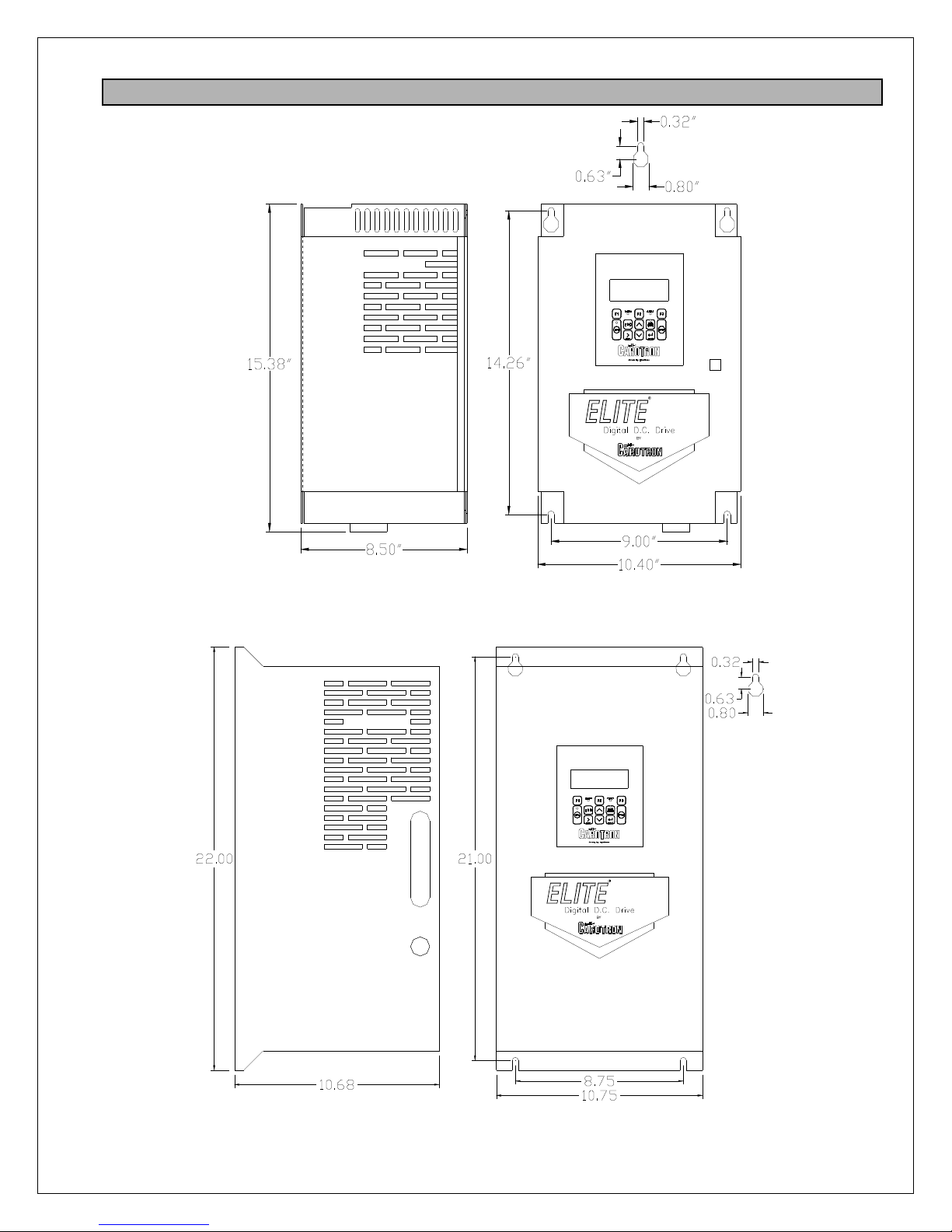

2.2 Physical

PRO

EPx020-000 thru EPx060-000

PRO

EPx075-000 thru EPx150-000

5

PRO

PRO

6

3333

Installation

3.1 Control Installation

Elite Pro motor controls require mounting in an upright position in an area that will permit adequate

airflow for cooling and ready access for making connections and for servicing. Because cooler air is

drawn in from the bottom and exhausted from the top, these areas should be kept clear for about a

six inch distance. Stacking of controls with one mounted above the other should be minimized so that

the upper control is not ventilated with hot exhaust air from the lower control.

Enclosures should be sized to provide adequate surface area for dissipating heat or provided with

forced ventilation with outside air from a duct system or enclosure fan. They should be mounted to a

cool surface not exposed to heat generated by nearby equipment.

Excess ambient temperatures within enclosures can reduce the life expectancy of electronic

components and can cause a heatsink over temperature fault on the Elite Pro control. Contact

Carotron for assistance in sizing enclosures for particular horsepower ratings.

3.2 Wiring Guidelines

To prevent electrical interference and to minimize start-up problems, adhere to the following

guidelines.

Make no connections to ground other than the designated terminal strip location.

Use fully insulated and shielded cable for all signal wiring. The shield should be connected at one

end only to circuit common. The other end of the shield should be clipped and insulated to prevent

the possibility of accidental grounding.

Signal level wiring such as listed above should be routed separately from high level wiring such as

armature, field, and relay control wiring. When these two types of wire must cross, they should cross

at right angles to each other.

Any relays, contactors, starters, solenoids or electro-mechanical devices located in close proximity to

or on the same line supply as the motor control should have a transient suppression device such as

an MOV or R-C snubber connected in parallel with its coil (for AC coils). Diode suppression should

be used for DC coils. The suppressor should have short leads and should be connected as close to

the coil as possible.

4444

Terminal Connections & Functions

4.1 AC Power Connections & Fusing

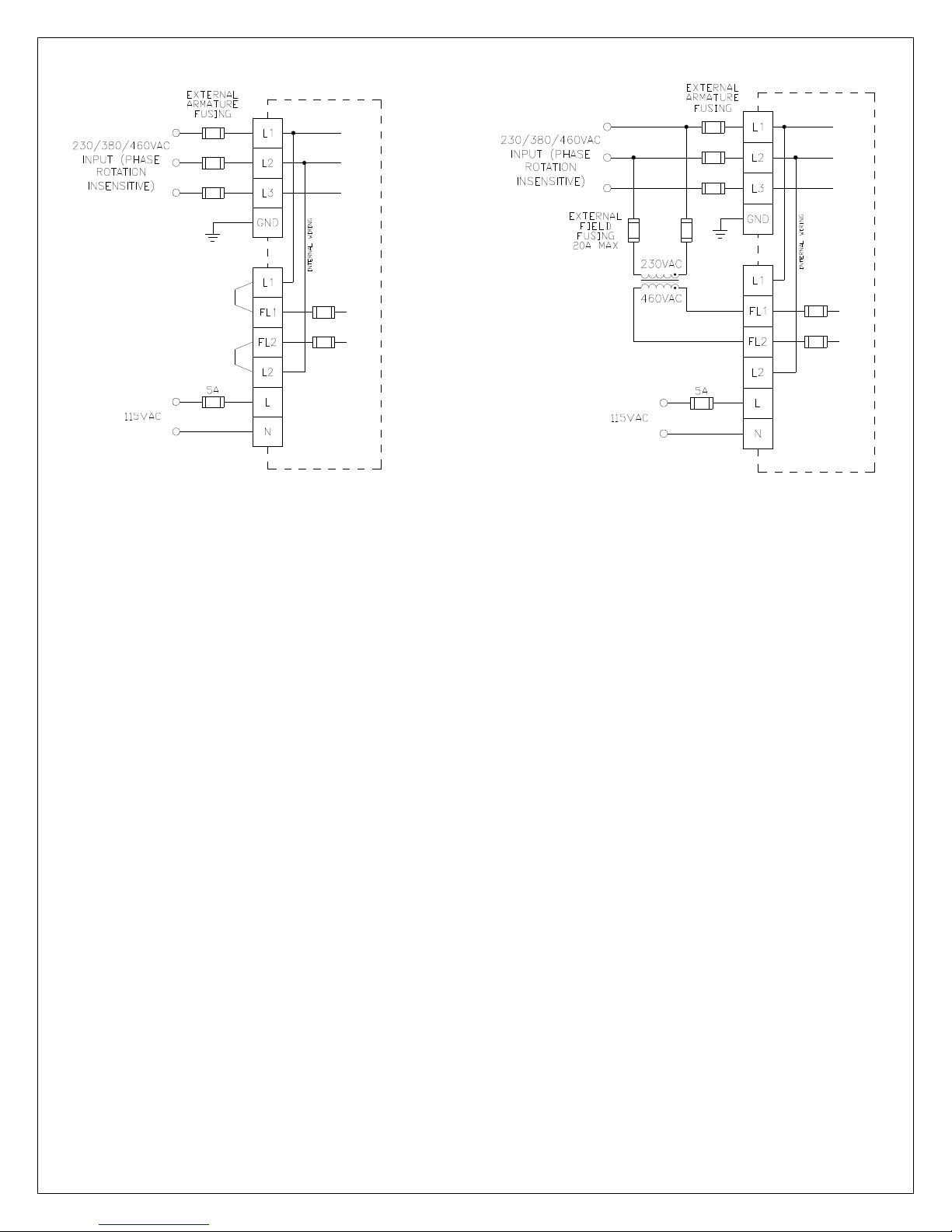

Terminals L1, L2, and L3 are the AC line inputs for the armature power bridge. High speed

semiconductor fuses must be provided externally. Refer to Figure 1 and Figure 2 on the next page

and Table 21 in the Spare Parts Section on page 116 for common manufacturers and part numbers.

In most cases, the drive will use the internal field supply wiring scheme (Figure 1). The field bridge

is powered from the auxiliary L1 and L2 output terminals via factory installed jumpers. However, in

some cases, the field voltage required by a motor exceeds the maximum obtainable field voltage that

can be produced using the required AC line voltage for the motor armature. In these cases, an

external single phase AC supply for the field bridge must be used. The factory supplied terminal

jumpers should be removed and the external supply connects to FL1 and FL2 (Figure 2). Note the

external supply must be in phase with the L1 and L2 armature supply terminals.

7

Figure 1: Internal Field Supply Wiring

For example, consider the motor that has a rated armature voltage of 240VDC and a rated field of

240VDC. The rated armature voltage requires that an input supply of 230VAC be connected to L1,

L2, and L3. However, the maximum field voltage attainable from the field bridge using the internal

supply would be 200VDC. In order to obtain the required 240VDC field, an external single phase

460VAC supply (obtained via a transformer) can be connected to FL1 and FL2.

The drive also requires a fused single phase 115VAC control power on terminals L and N.

Carotron recommends the use of three phase DIT, drive isolation type transformers. While Elite Pro

controls do not require these transformers for proper operation, they can be helpful in reducing the

effects of line transients on this control and generated by this control on other products and can

provide fault current limiting in the event of severe motor or control failure. Refer to Table 1 as a

general guide in sizing line supply transformers and wiring.

Figure 2: External Field Supply Wiring

8

Drive

Model

EPx020-000

EPx040-000

EPx060-000

EPx075-000

EPx100-000

EPx125-000

EPx150-000

EPx200-000

EPx250-000

EPx300-000

EPx400-000

EPx500-000

EPx600-000

EPx700-000

x=2 for non-regenerative models

x=4 for regenerative models

Arm

Volts

240

500

240

500

240

500

240

500

240

500

240

500

240

500

240

500

240

500

240

500

240 200 220

500 400

240 250 275

500 500

240 300 330

500 600

240 350 385

500 700

Motor

HP

5 18 7.5 18 10Ω, 300W

7.5 26 11 28.1 5Ω, 600W

10 34 14 36

5 9 7.5 8.5 40Ω, 375W

7.5 14 11 13.2 20Ω, 750W

10 18 14 17.2 20Ω, 750W

15 25 20 25.2 14Ω, 1000W

20 34 27 36

15 50 20 55 3Ω, 1000W

20 65 27 71

25 40 34 43 7Ω, 2000W

30 47 40 51 6Ω, 2000W

40 63 51 71

25 84 34 91.1

30 98 40 107

50 78 63 83.7

60 93 75 107

40 118 51

75 106 93

50 148 63

100 141 118

60 174 75

125 177 145

75 93

150

100 118 360 Amps 0.47Ω, 4700W

200

125 145 535 Amps 0.37Ω, 5300W

250

150 175 535 Amps 0.31Ω, 7000W

300

Approx. Full Load

Line Amps

213

283

354

426

555

694

832

950

3 Phase DIT

KVA Rating

175

220

275

330

440

550

660

770

Table 1: Model Rating Data

Arm

Amps

140

174

206

256

340

425

510

688

850

1020

1165

Contactor

Rating

40 Amps

40 Amps

75 Amps

75 Amps

110 Amps

110 Amps

180 Amps

180 Amps

180 Amps

180 Amps

260 Amps

260 Amps

260 Amps

260 Amps 1.24Ω, 4464W

360 Amps 1.02Ω, 6500W

535 Amps 0.82Ω, 11000W

535 Amps 0.65Ω, 14600W

Consult

Factory

Consult

Factory

Consult

Factory

Consult

Factory

D.B. Resistor

Rating

4.4Ω, 750W

10Ω, 1500W

2.2Ω, 1500W

5Ω, 3000W

1.7Ω, 2000W

3.4Ω, 4000W

1.3Ω, 2080W

2.6Ω, 4160W

0.62Ω, 2232W

1.24Ω, 4464W

0.62Ω, 2232W

1.24Ω, 4464W

0.62Ω, 2232W

Consult

Factory

Consult

Factory

Consult

Factory

Consult

Factory

4.2 Motor Connections

Field

Most motor fields consist of two windings that are connected in parallel for low voltage operation and

in series for high voltage operation. Refer to Figure 3. The winding leads are individually marked

and have a polarity that must be observed for proper and safe operation. Since direction of rotation is

controlled by field polarity as well as armature polarity, it is sometimes more convenient to swap the

smaller field leads when making corrections to the direction of rotation during initial installation. An

energized field should never be switched by relay, contactor, switch or any other manual or electromechanical device.

In most cases, when the Elite Pro is supplied with 230VAC, the field should be wired for low voltage

operation. When supplied with 460VAC, the motor field is typically wired for high voltage operation.

The F1 and F3 leads should always have the same polarity regardless of the mode used.

9

Figure 3

Armature

The armature leads are usually the highest current wires associated with the drive and warrant

special attention to sizing based on current rating as well as length of run. Extra care should be used

where terminations and splices are made. Refer to Table 1 for typical armature voltage, current,

contactor and dynamic braking resistor ratings. Figure 4 shows a typical armature wiring scheme

using a contactor. An optional dynamic breaking resistor is also shown.

Figure 4

Series Field

When present, the S1 and S2 for the SERIES field winding is placed in series with the armature

leads on non-regenerative models only! They should NOT be used with the EP4 Series

regenerative models. On regenerative models, the leads should not be connected and should be

individually insulated. On non-regenerative models the series field winding polarity must be kept at

the same polarity as the shunt field winding, i.e. F1 and S1 the same, F2 (or F4) and S2 the same. If

during startup the field windings are reversed to change direction of the motor, the series windings

should also be reversed to maintain the proper polarity. Figure 5 shows a typical wiring scheme

using the series field with a non-regenerative drive. Note the polarity of the shunt field and series

field windings (S1 is positive with respect to S2, F1 is positive with respect to F2).

10

Figure 5

Motor Thermostat

Most motors include "J" or "P" leads that connect to an internal normally closed thermostat.

Connecting the thermostat to TB1-38 & 39 as shown in Figure 6 will allow a motor over-temperature

condition to shut down the control as in an Emergency Stop condition. If the motor does not provide

a thermostat or the thermostat wiring is not used, a jumper must be placed across terminals 38 & 39.

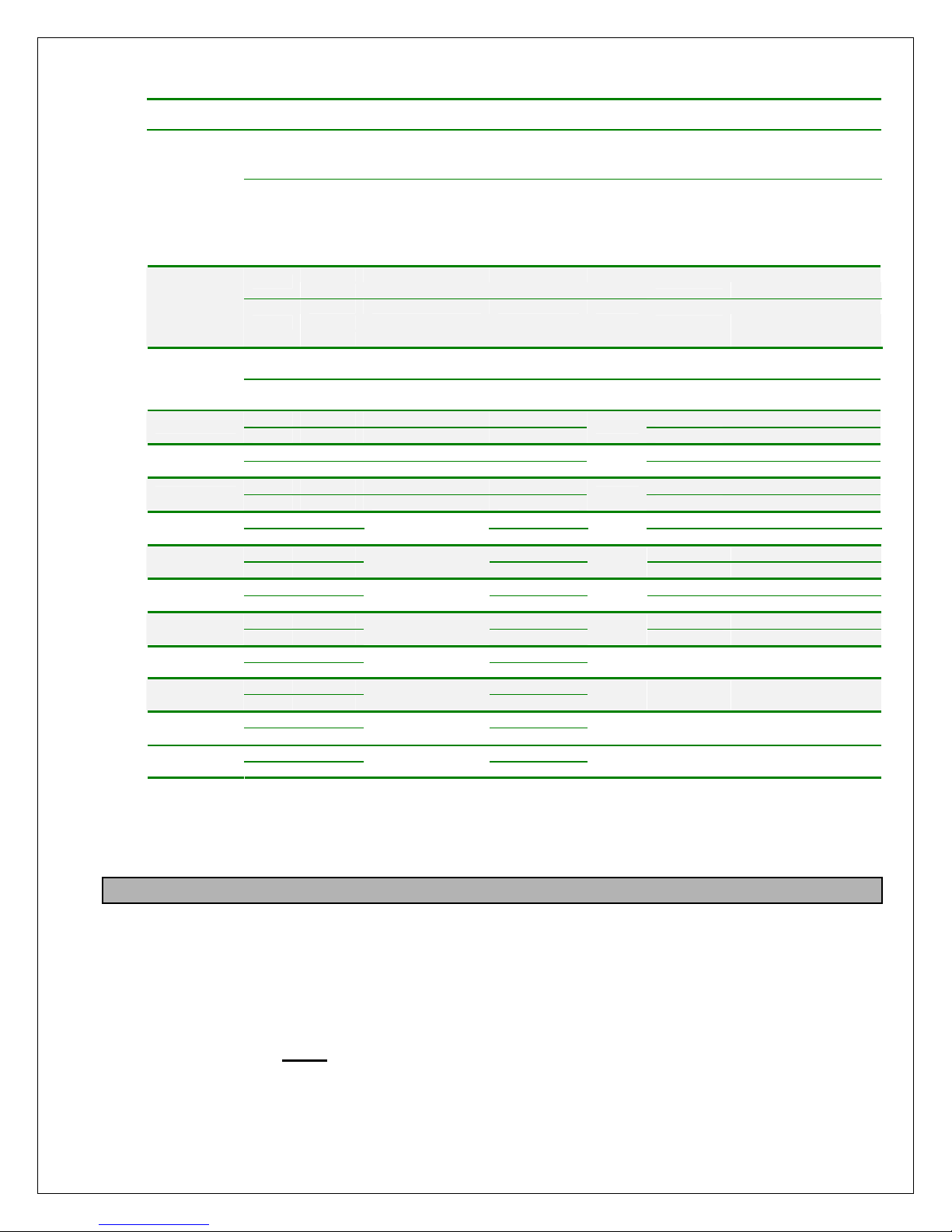

4.3 Signal Connections

Figure 6 shows the typical signal connections to an Elite Pro drive. When operated, the Emergency

Stop contacts at terminals 6 and 7 will immediately clamp all control signals. The armature contactor

will also de-energize to disconnect the armature from the bridge output. Motor stopping time is

determined by inertia and friction characteristics of the load and can be decreased by use of a brake

resistor. Refer to Table 1 for recommended resistor values. If a maintained Emergency Stop pushbutton is used, the E-Stop Reset contacts at TB1-8 & 9 can be jumpered. Otherwise, a momentary

push-button can be used to reset the E-Stop condition.

11

12

Figure 6: Signal Connections

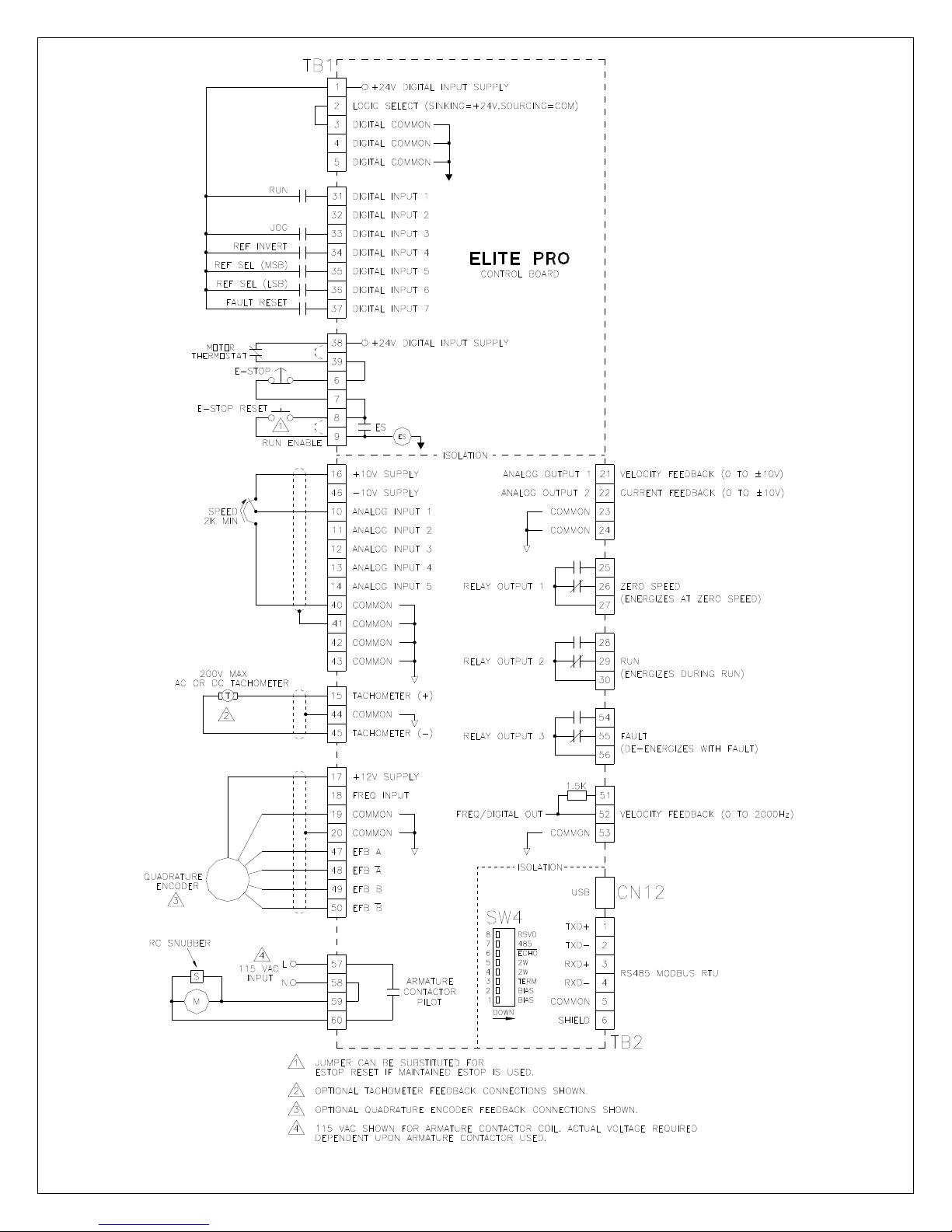

The Elite Pro V3 supports three different start/stop logic schemes (four including the local mode).

Refer to Figure 7 below. The momentary scheme (often called 3 wire) uses momentary pushbuttons

to control the starting and stopping of the drive. A selector switch or a contact controls the direction.

The other two schemes use maintained contacts (often called 2 wire mode). In the Run/Direction

scheme, a single contact starts and stops the drive. Another contact selects direction. In the final

scheme, each contact starts the drive and selects the direction. Parameter H1.01 needs to be set

appropriately.

Figure 7

The drive also has the capability to interface with either sinking or sourcing logic controls. Sourcing

(PNP) logic is selected by jumpering TB1 terminals 2 & 3. This places an internal pull down resistor

on each input. The external switch or sensor must then drive the input high to activate the input.

Sinking (NPN) logic is selected by jumpering TB1 terminals 1 & 2. This places an internal pull up

resistor on each input. The external switch or sensor must then sink (pull down) the input to common

to activate the input.

Figure 8

13

5555

Human Machine Interface (HMI)

5.1 Description of Interface

The Human Machine Interface (HMI) is the primary method for accessing the drive's parameters. It

allows for custom user configuration, monitoring, and troubleshooting. As seen in Figure 9, the HMI

consists of a 4 line by 20 characters display, 11 button keypad, and 4 LEDs.

DM01: ELITE PRO V3

REFERENCE: 12.34%

SPEED: 0.00%

STATUS: STOP

Figure 9

Index Item Description

1 F1-F3

2 Run Key Places the drive in run mode when in local mode

3 Stop Key Stops the drive in all modes

4 Esc Key

5 Reset/Right Key

6 Local/Remote Key Switches the drive between local and remote control

7 Enter Key

8 Up/Down Keys

9 Run LED

10 Local LED

11 Alarm LED

12 Fault LED

Softkeys. The functionality of each of these keys varies depending

upon the displayed menu. When utilized, text above the key

displays its function.

• Returns to the previous menu

• Moves cursor one place to the left

• Clears drive fault (on a DM screen)

• Moves cursor one place to the right

• Used to accept/enter parameter values

• Moves cursor one place to the right

• Scrolls to the next menu display

• Increments/decrements cursor value

On: Drive is in run mode and has reference

Flashing: Drive is in run mode with no reference

Off: Drive is not in run mode

On: Drive is in Local mode

Off: Drive is in Remote mode

On: An alarm is present

Off: No alarms present

On: A fault is present. Fault is not active and can be reset.

Flashing: Fault present and currently active. Cannot be reset.

Off: No faults present

Table 2: HMI Description

14

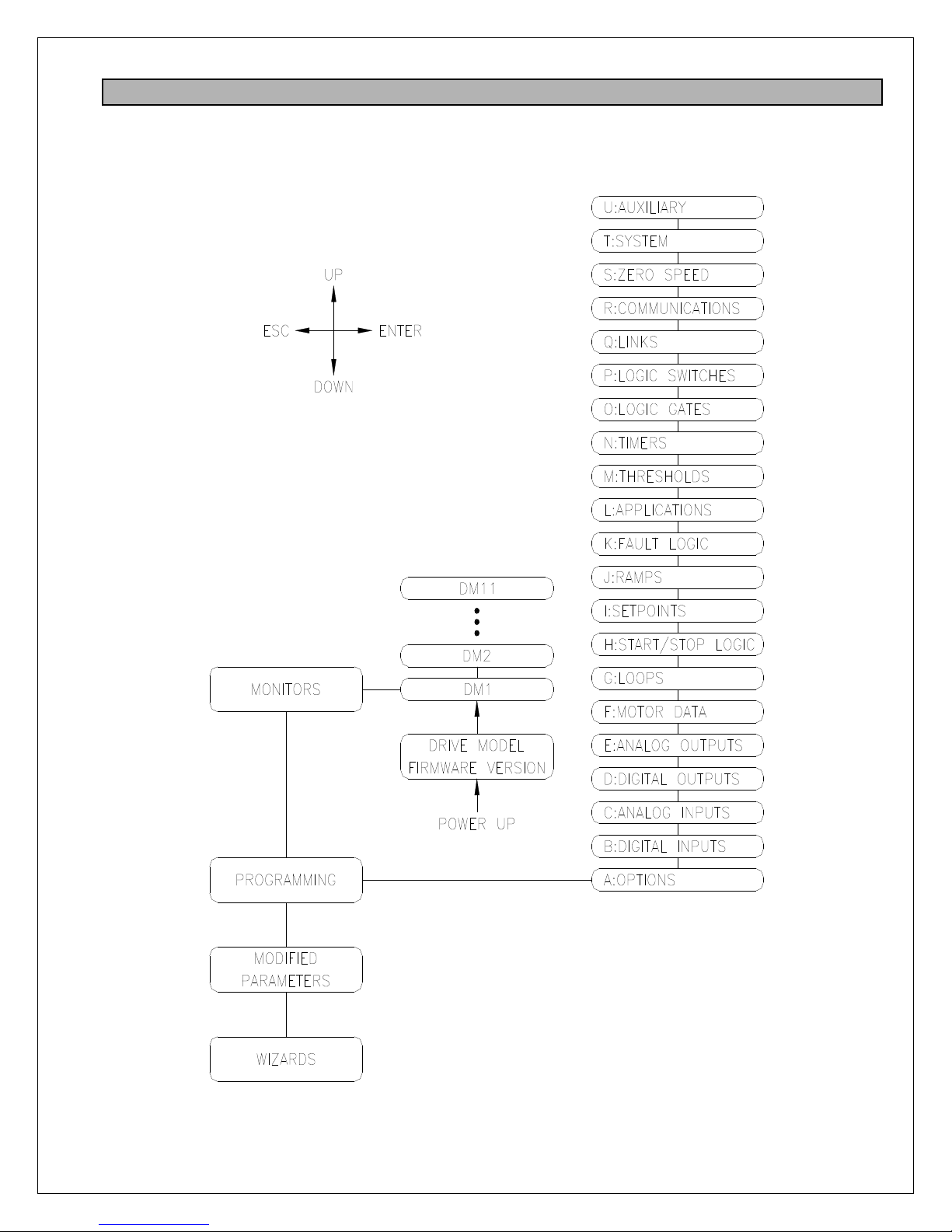

5.2 Menu Structure

When power is applied to the drive, the HMI displays the drive's firmware version. After a short

timeout, the Drive Monitor 1 (DM1) screen is displayed. Navigation through the menu is achieved by

using the Up, Down, Escape, and Enter keys.

Figure 10

15

Monitors

The Monitors section contain the Drive Monitor screens. Each of theses screens displays various

drive status information.

Monitor Description

DM01 Reference/Speed

DM02 Armature Status

DM03 Field Status

DM04 Fault Status

DM05 Alarm Status

DM06 Velocity Loop Status

DM07 Current Loop Status

DM08 Field Loop Status

DM09 Loop Outputs

DM10 Feedback Status

DM11 Drive Model/Firmware

Table 3: Drive Monitor Descriptions

Programming

The drive parameters are located under the Programming section. Each drive parameter has a

unique identifier tag that consists of an alpha group code, and numeric block code, and a two digit

numeric index. For example, parameter C2.04 is in Group C, Block 2, and Index 4. When the

programming section is first displayed, the first parameter (A1.01) is displayed with the Group Code

flashing (i.e. the 'A'). The Up/Down keys are then used to change the Group Code to the desired

value. Pressing the Reset/Right key will move the cursor to the right and cause the Block Code to

begin flashing. The Up/Down keys are then used to change the Block Code. Pressing the

Reset/Right key will move the cursor to the right and cause the Index Code to begin flashing. Again,

the Up/Down keys are used to change the Index to display the desired parameter. Pressing Escape

will move the cursor left.

In order to simplify the menu, some parameters are hidden when they are not applicable. However,

in some cases it may be desired to view these hidden parameters. There are two ways to view these

hidden parameters. The first method is to change parameter A1.01 from STANDARD to

ADVANCED. This makes all parameters visible. The second method is to use a certain keystroke

while scrolling through the parameters. Pressing the F2 key before pressing the Up or Down keys

will force the display to show the next/previous parameter (whether it is hidden or not).

Once a parameter is displayed, pressing the Enter key will allow its value to be modified. The current

value of the parameter (or a digit in its value) will begin flashing. The Up/Down keys are used to

adjust the value. If the parameter is a numeric value, the Reset/Right key can be used to shift the

cursor to the right to allow other digits to be adjusted. Pressing the Reset/Right key when the cursor

is on the last digit will cause the cursor to be placed on the first digit. Once the desired value is

displayed, the value can be entered by pressing the Enter key. The Escape key will exit the

parameter adjustment screen without changing the parameter value.

Note: When parameters are altered via the keypad, the changes are saved automatically.

Modified Parameters

This section contains a list of parameters that have been modified from the default factory preset

value. The Up/Down keys are used to scroll through the list.

Wizards

This section contains various drive related wizards that aid in drive setup.

16

6666

Start Up Procedure

6.1 Pretest

1. Verify each phase of the 3 phase power supply. Input voltage should be checked ahead

of the supplying circuit breaker, disconnect switch, etc. before it is switched on.

2. Connections should be visually inspected and checked for tightness. An ohmmeter can

be used to check for ground faults. Ground faults in un-isolated circuits of the armature

and field can cause fuse blowing and damage to the motor and control. To check for

grounds with an ohmmeter, select a high resistance scale such as R x 100K ohms or

greater. Test from each connection terminal (including shields) to chassis ground and be

suspicious of any resistance reading less than 500K ohms. NOTE: An exception to this

test would be made where the drive's 3 phase input is connected to a grounded "Y" type

transformer secondary.

3. Adjust external reference (Analog Input 1) at terminal 10 to 0 volts.

4. Apply single phase control power and three phase bridge power. On initial power up, the

drive should display an Invalid Motor Data fault. Press CLOSE to exit. When asked to

run the Basic Setup Wizard, select YES. If the wizard was cancelled, it can be re-started

6.2 Adjustment Procedure: Velocity (Speed) Regulator

from the Wizards section in the menu.

1. Presets

Use the Basic Setup Wizard to set the required parameters. The wizard will step you

through various drive parameters. When a parameter is displayed, press the ENT key

to edit its value. There are a number of required parameters. The wizard will not

allow you to proceed until a valid value has been entered. It is recommended that the

drive initially be setup using armature feedback even if a tachometer or encoder will

be used. This allows the proper feedback signal to be verified before using it for

control. After the motor data is entered in the wizard, the drive should begin

producing field output. Depending upon the wizard data entered, you may have the

option to operate the field in either open or closed loop mode. After the field mode is

selected, the wizard will display a field status screen showing the field voltage and

field current. Verify the displayed values correspond to the motor nameplate. In many

cases, when a motor is cold and the nameplate field voltage is applied, the field

current will be much higher than its rated nameplate value. As the motor warms up,

the field winding resistance should increase, which will cause the field current to

decrease. If open loop was selected and the field output requires additional

adjustment, press the ENT key while the status screen is displayed. This allows

adjustment of Open Loop Reference (G3.03). Regardless of the mode, please

ensure the field levels are correct before proceeding.

2. Clear any Faults

When the wizard is completed, the drive will try to clear any faults that are present. If

a fault is still present (i.e. the Fault LED is on or flashing), navigate to the DM04

screen to display the current fault. Once the fault condition is removed, the fault can

be cleared by pressing the RESET key while on any DM screen.

3. Validate E-STOP

When an E-STOP is activated, the status display on the DM01 screen should display

E-STOP. When the E-STOP is cleared, the status should display STOP or FAULT. If

E-STOP is always displayed, not all interlocks have been made. Please refer to the

wiring diagram in Figure 6 on page 12. The 24V from terminal 38 should flow through

all the interlocks to terminal 9. Do not proceed until the E-STOP functions properly.

4. Safety Check

During the following steps the motor will be rotated. If excessive speed or wrong

direction of rotation could damage the load, it may be wise to de-couple the load until

17

5. Check Motor Rotation

6. Validate External Start/Stop

7. Validate Reverse Direction (optional, EP4 regenerative unit required)

8. Validate Tachometer Feedback (required only if a motor mounted tachometer is used)

9. Validate Encoder Feedback (required only if a motor mounted encoder is used)

proper control is verified.

While displaying the DM01 screen, place the drive in local mode by pressing the

LOCAL/REMOTE key. The Local LED should be on. Press and hold the F1 key to

jog the drive. The armature contactor should close and the motor should rotate slowly.

Observe the direction of rotation. Release F1 to stop the drive. If the motor rotation is

reversed, remove all power and reverse the motor armature or field wires. If used,

observe proper polarization of the series field winding per the instructions in Section

4.2. After re-applying power, repeat this step to verify motor direction.

Press the LOCAL/REMOTE key to return the drive to Remote mode. The Local mode

LED should be off. Adjust the external reference signal connected to terminal 10 to its

minimum. Typically, the reference value on DM01 should be approximately zero.

Place the drive in Run mode via the external contacts. Slowly increase the external

reference until the motor is rotating. Issue a stop command using the external

contacts and verify the motor stops and the contactor de-energizes.

With reference at minimum, run the drive in the reverse direction. Slowly increase the

reference and verify motor runs in reverse direction. Stop drive.

Proper tachometer operation should be checked while the drive is running in Armature

Feedback. Place the drive in run mode and run at a low speed (approximately 20%).

On the display, navigate to DM10. Compare Armature feedback to Tachometer

feedback. The values should be approximately equal (within 5%). If the values have

approximately the same value but the wrong polarity, press the Stop button and invert

the tachometer feedback by setting parameter F2.02 to On. Place the drive back in

the run mode and re-check. If the values are not equal, verify the tachometer data is

entered properly in section F2 (or the wizard) and jumpers J1-J3 are set properly.

Once corrected and the values are equal at low speeds, increase speed and check at

higher speeds. If the values are approximately equal throughout the speed range, the

drive can be placed in the tachometer feedback. With the drive in the stop mode, set

parameter G2.15 to Tachometer. Run drive and verify proper operation.

Proper encoder operation should be checked while the drive is running in Armature

Feedback. Place the drive in run mode and run at a low speed (approximately 20%).

On the display, navigate to DM10. Compare Armature feedback to Encoder feedback.

The values should be approximately equal (within 5%). If the values have

approximately the same value but the wrong polarity, press the Stop button and invert

the encoder feedback by setting parameter F3.03 to On. Place the drive back in the

run mode and re-check. If the values are not equal, verify the encoder data is entered

properly in section F2 (or the wizard). Once corrected and the values are equal at low

speeds, increase speed and check at higher speeds. If the values are approximately

equal throughout the speed range, the drive can be placed in the encoder feedback.

With the drive in the stop mode, set parameter G2.15 to Encoder. Run drive and verify

proper operation.

18

6.3 Adjustment Procedure: Constant Horsepower

1. Presets

Set up the Elite Pro V3 drive as a normal velocity regulator to run at the motor's base

speed using tachometer or encoder feedback with closed loop field control. Refer to

Section 6.2 above. Once correct operation in this mode has been achieved, proceed

2. Parameters

3. Test

with the following steps.

Re-run the Basic Setup Wizard and set the Operating Mode to CONST HP

(CROSSOVER). Continue through the wizard and enter additional motor data

(specifically the extended speed field amps, and extended speed value). If

tachometer is used, re-scale Jumpers J1-J3 as instructed by the wizard.

With reference at minimum, place drive in run mode. Navigate to DM03 and verify the

motor field current is at the base speed level. Navigate to DM02 to display the

armature voltage. Slowly increase reference until armature voltage is approximately

85% of the nameplate value (204V for 240V armatures, or 425V for 500V armatures).

Return to DM03 and monitor the motor field current, while increasing the speed

reference. The field current should begin decreasing as the speed reference is

increased. When the maximum reference is applied, the field current should be

approximately at the extended speed field current level. Return to DM02 and verify

armature voltage is at the motor's rated armature voltage level.

6.4 Adjustment Procedure: Torque (Current) Regulator

1. Presets

Set up the Elite Pro V3 drive as a normal velocity regulator to run at the motor's base

speed using armature feedback. Refer to Section 6.2. Once correct operation in this

2. Parameters

3. Test

mode has been achieved, proceed with the following steps.

Re-run the Basic Setup Wizard and set the Operating Mode to TORQUE. Continue

through the wizard and enter any required data.

With reference at minimum, place drive in run mode. Navigate to DM02 to display the

armature current. Slowly increase reference and verify control of armature current.

6.5 Calibration & Fine Tuning

1. If the drive is using armature feedback (i.e. G2.15 is set to ARMATURE), then IR

Compensation (G2.09) can be adjusted to improve the speed regulation with load

changes. Adjustment is best done when the motor or machine can be loaded normally. If

the motor is normally operated at a particular speed, adjust IR Compensation (G2.09)

while running at that speed. If the motor operates under load over a wide speed range,

pick a speed near mid-range to make the adjustment. Adjust as follows:

Operate the unloaded motor at the normal or mid-range speed and note the exact

speed using a hand tachometer or other speed measuring device. While still

monitoring speed, apply normal load. The reduction in speed of a fully loaded motor

will usually fall between 2 and 13% of rated or "base" speed. Slowly increase IR

Compensation (G2.09) until the loaded speed equals the unloaded speed measured

in the previous step. Making this adjustment may now cause the unloaded speed to

be slightly higher. Repeat this procedure until there is no difference between loaded

and unloaded speed levels. Use care not to set the adjustment too high or speed

increase with load and instability may result. NOTE: For this adjustment, do not use

armature voltage feedback (AFB) to measure speed. Armature voltage is not an exact

indication of loaded motor speed!

19

2. The Current Proportional Gain (G1.16), Current Integral Time (G1.17), Velocity

Proportional Gain (G2.21), and Velocity Integral Time (G2.22) parameters are preset

by Carotron to provide stable and responsive performance under most load conditions.

When required, the drive performance can be optimized for a particular application or to

correct undesirable operation by use of these adjustments. The adjustments are complex

though and can adversely affect operation if not properly set. In general, the settings that

give the most stable operation do not always give the fastest response.

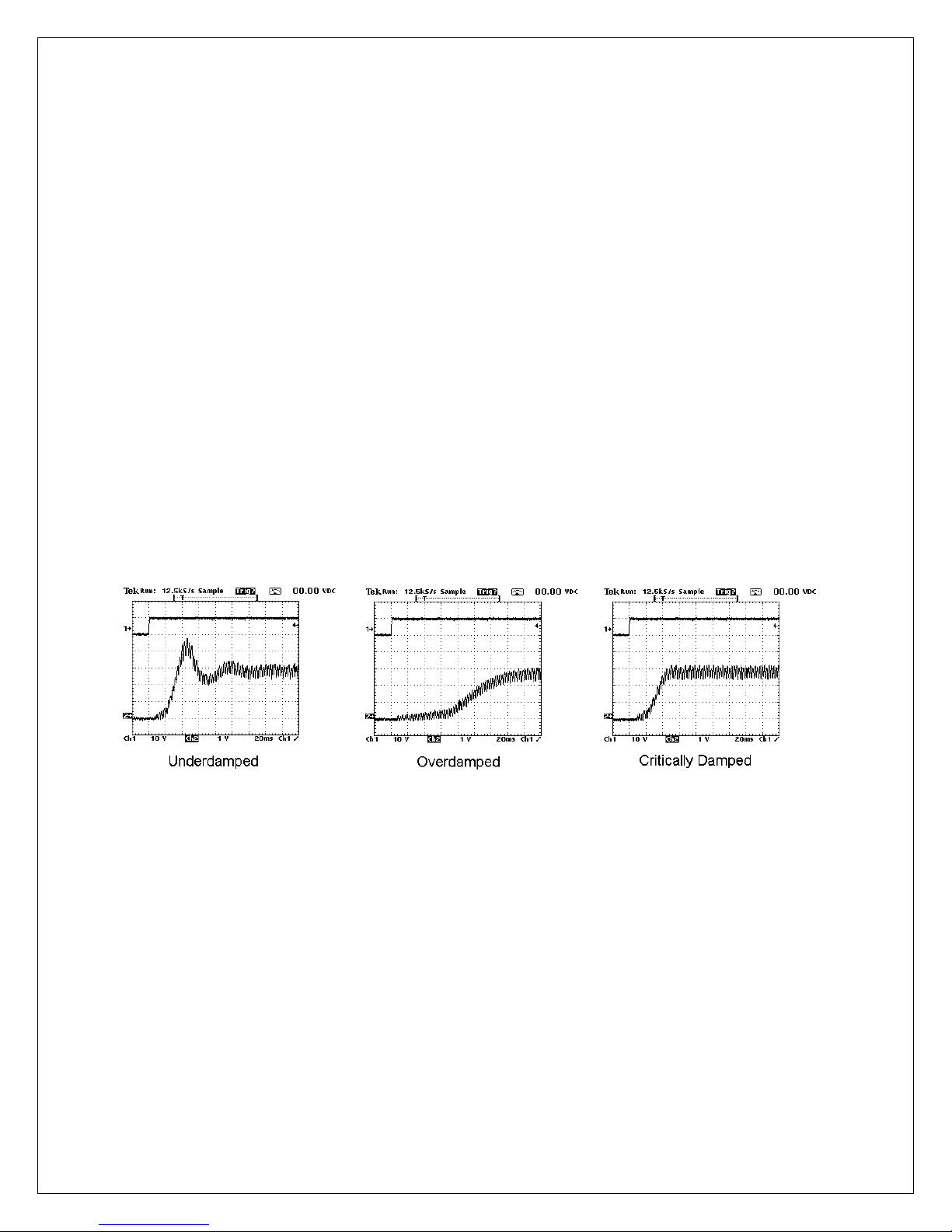

Current Loop

The current loop can be manually tuned by directly applying a stepped reference and

monitoring the current feedback. In order to adjust properly, connect an oscilloscope

between common and the A.IFB testpoint on the control board. The rotor shaft must not

rotate during this procedure. Therefore, set Field Enable (G3.01) to DISABLE to remove

voltage from the shunt field. Set Reference Select (G1.01) to STEP. Set the Step

Reference (G1.22) initially to a low value (around 20%). Set the Step Duration (G1.23) to

500ms. Place the drive in the run mode. Set Step Enable (G1.24) to ENABLE to apply a

step change to the PI loop. The current feedback signal should respond quickly with

minimum overshoot. Adjust the Current Proportional Gain (G1.16) and Current Integral

Time (G1.17) parameters and re-apply the Step Enable until a critically damped waveform

as seen in Figure 11. Increasing the proportional gain improves the response but

increases the overshoot. Reducing the integral time improves the response but can cause

instability if set too low. Once a critically damped waveform is obtained, increase the Step

Reference to 40% and repeat above. Continue until a Step Reference of 100% is

achieved. Return Field Enable (G3.01) to ENABLE and Reference Select (G1.01) to

NORMAL when complete.

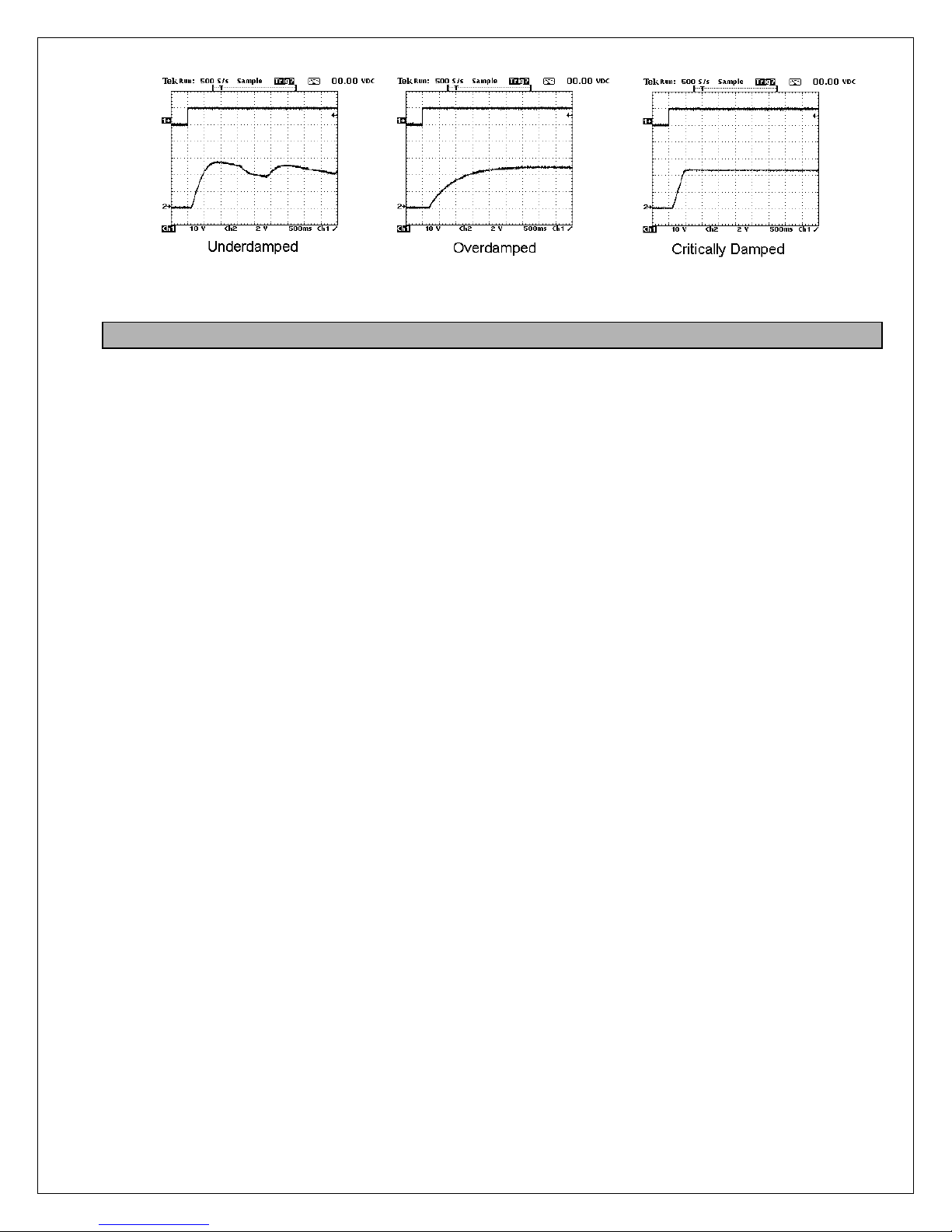

Velocity Loop

In order to adjust properly, connect an oscilloscope to Analog Output 1 Terminal 21

(Velocity Feedback). Using the HMI, temporarily set the Reference Select (G2.29) to

STEP. Set Step Reference (G2.30) to 20% and Step Duration (G2.31) initially to 2

seconds. Place the drive in the run mode and apply a step change by setting Step Enable

(G2.32) to ENABLE. Observe the response of the drive on the oscilloscope. The motor

speed should respond quickly with minimum overshoot. Adjust the Velocity Proportional

Gain (201) and Velocity Integral Time (202) parameters to obtain a critically damped

waveform as seen in Figure 12. Increasing the proportional gain improves the response

but increases the overshoot. Reducing the integral time improves the response but can

cause instability if set too low. Repeat above in steps gradually increasing the Step

Reference to 100% (or the max required speed is obtained). Once complete, return

Reference Select (G2.29) to NORMAL.

20

Figure 11

6.4 Password Protection

If password protection is required, set the appropriate password under A1.04. Please note

that this is a special hidden parameter. You must first display A1.03. Then press F2 key and

then the Up key to display A1.04. Once A1.04 has a value other than zero, parameters can

be viewed but cannot be changed. Changes can only be made by first entering the password

into parameter A1.05. Once all changes have been made, A1.05 can be manually returned

to 0 to logout. The drive also has a timeout feature, that automatically clears the entered

password in A1.05 after 5 minutes.

Figure 12

21

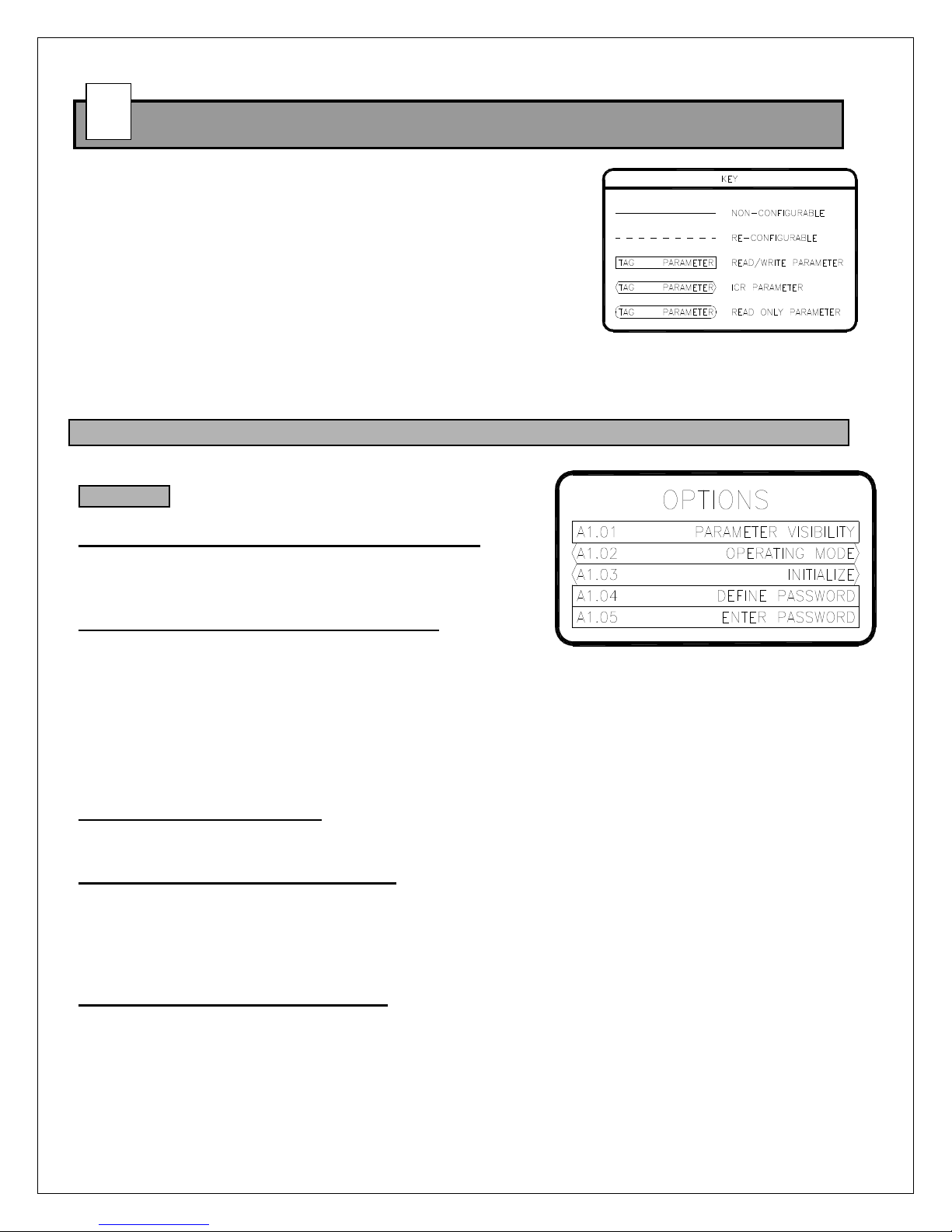

7777

Programming & Adjustments

Programming and adjustment of the Elite Pro is accomplished by

changing parameter settings. Each parameter has a Tag identifier

and a descriptive name. Parameters are separated into groups

and blocks according to their function. The following sections

contain each software block diagram and descriptions of each

parameter function. Refer to Figure 13 for key conventions that are

used in the block diagrams. Each parameter is one of three types:

Read-Write (RW), Inhibit Change while Running (ICR), or ReadOnly (RO). ICR parameters can be changed only when the drive is

not running.

7.1 A: Options

These parameters set the drive's basic operating mode.

A1: Options

A1.01 Parameter Visibility (R/W, Preset: Standard)

When set to Standard, parameters that are typically not

relevant to the current operating mode are hidden.

When set to Advanced, all parameters are visible.

A1.02 Operating Mode (ICR, Preset: Velocity)

Sets the drive's operating mode.

VELOCITY

A1.03 Initialize (ICR, Preset: 0)

9999: Re-initializes the drive and returns all parameters to the factory default setting.

Range: 0..65535

A1.04 Define Password (R/W, Preset: 0)

A numeric password may be set to prevent unauthorized parameter changes. After a numeric

password has been entered, the drive allows all parameters to be viewed, but prevents changes

from being made. Only after a valid password has been entered into A1.05 can changes be

made. This parameter requires a special keystroke to display. With A1.03 displayed, press F2

and then UP. Range: 0..65535

A1.05 Enter Password (R/W, Preset: 0)

If a numeric password has been defined in parameter A1.04, the same password must be

entered into parameter A1.05 before any parameter changes can be made. As a security

feature, the drive automatically clears the entered password after 5 minutes. Parameter A1.05 is

typically only visible after a password is defined in parameter A1.04. Range: 0..65535

Drive regulates motor speed.

CONST HP (CROSOVER)

Drives regulates speed utilizing the motor's extended speed range. Also known as field

weakening or field crossover.

TORQUE

Drive regulates motor torque (or armature current).

Figure 13

Figure 14

22

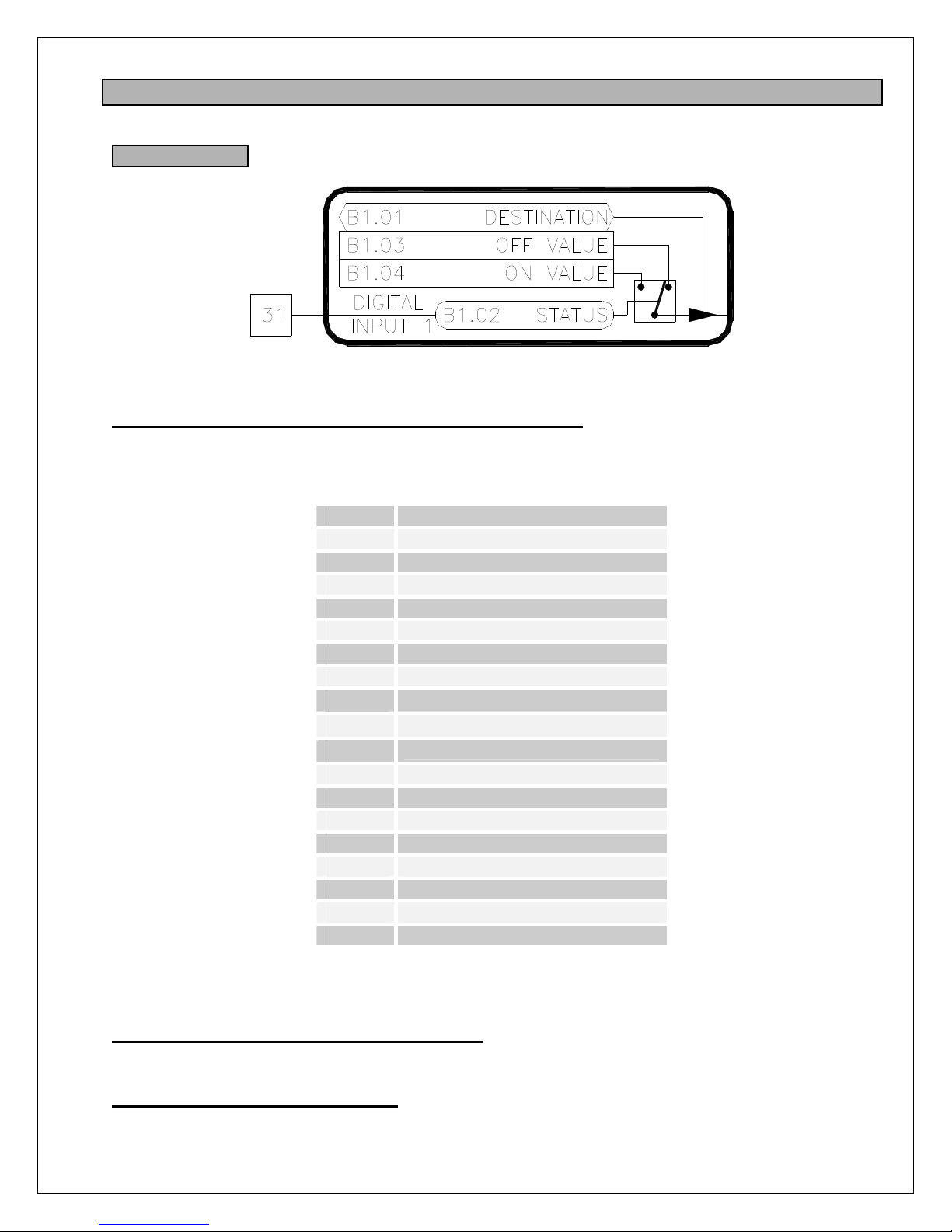

7.2 B: Digital Inputs

These parameters configure the drive's physical digital inputs (digital & frequency).

B1: Digital Input 1

B1.01 Digital Input 1 Destination (ICR, Preset: H1.02 [Run])

Determines the function of the digital input. Each digital input can control (or write to) any R/W

parameter in the drive. The destination parameter contains the tag of the parameter the input will

control (i.e. the target parameter). Refer to Table 4 for a list of commonly used functions.

Value Function

H1.02 Start-Run-Run Fwd*

H1.03 /Stop-Run Rev*

H1.04 Jog-Jog Fwd*

H1.05 Rev-Jog Rev*

H1.08 /Coast Stop

H1.09 /Quick Stop

H1.10 /Dynamic Brake Stop

I

1.01

I

1.02

I

1.03

J1.18 Ramp 1 Bypass

K1.14 External Fault

K1.15 Fault Reset

L1.01 PID Enable

L1.02 PID Reset

L6.01 MOP Increase

L6.02 MOP Decrease

L6.07 MOP Reset

Table 4: Common Digital Input Functions

*The actual function is determined by the H1.01 setting.

B1.02 Digital Input 1 Status [Terminal 31] (RO)

Displays the status of the digital input. A value of OFF indicates the digital input is off or not

activated. A value of ON indicates the digital input is on or active.

B1.03 Digital Input 1 Off Value (RW)

This is the value written to the target parameter when the digital input's status is OFF. The limits

and units of these parameters will change to match the limits and units of the target parameter.

Figure 15

Aux Reference Enable

Ref Select (MSB)

Ref Select (LSB)

23

B1.04 Digital Input 1 On Value (RW)

This is the value written to the target parameter when the digital input's status is ON. The limits

and units of these parameters will change to match the limits and units of the target parameter.

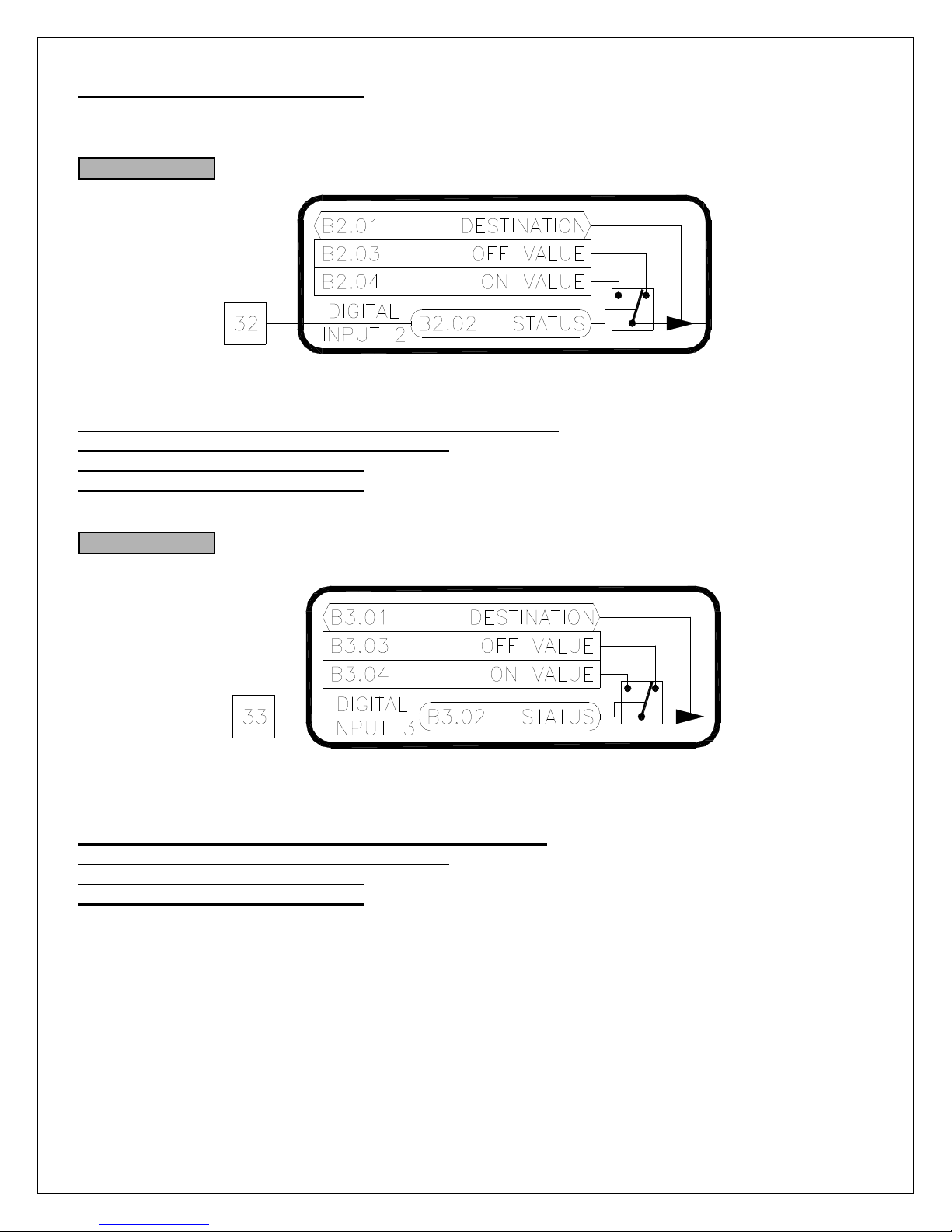

B2: Digital Input 2

B2.01 Digital Input 2 Destination (ICR, Preset: H1.03 [/Stop])

B2.02 Digital Input 2 Status [Terminal 32] (RO)

B2.03 Digital Input 2 Off Value (RW)

B2.04 Digital Input 2 On Value (RW)

Digital Input 2 is functionally equivalent to Digital Input 1. Refer to B1.XX

B3: Digital Input 3

B3.01 Digital Input 3 Destination (ICR, Preset: H1.04 [Jog])

B3.02 Digital Input 3 Status [Terminal 33] (RO)

B3.03 Digital Input 3 Off Value (RW)

B3.04 Digital Input 3 On Value (RW)

Digital Input 3 is functionally equivalent to Digital Input 1. Refer to B1.XX

Figure 16

Figure 17

24

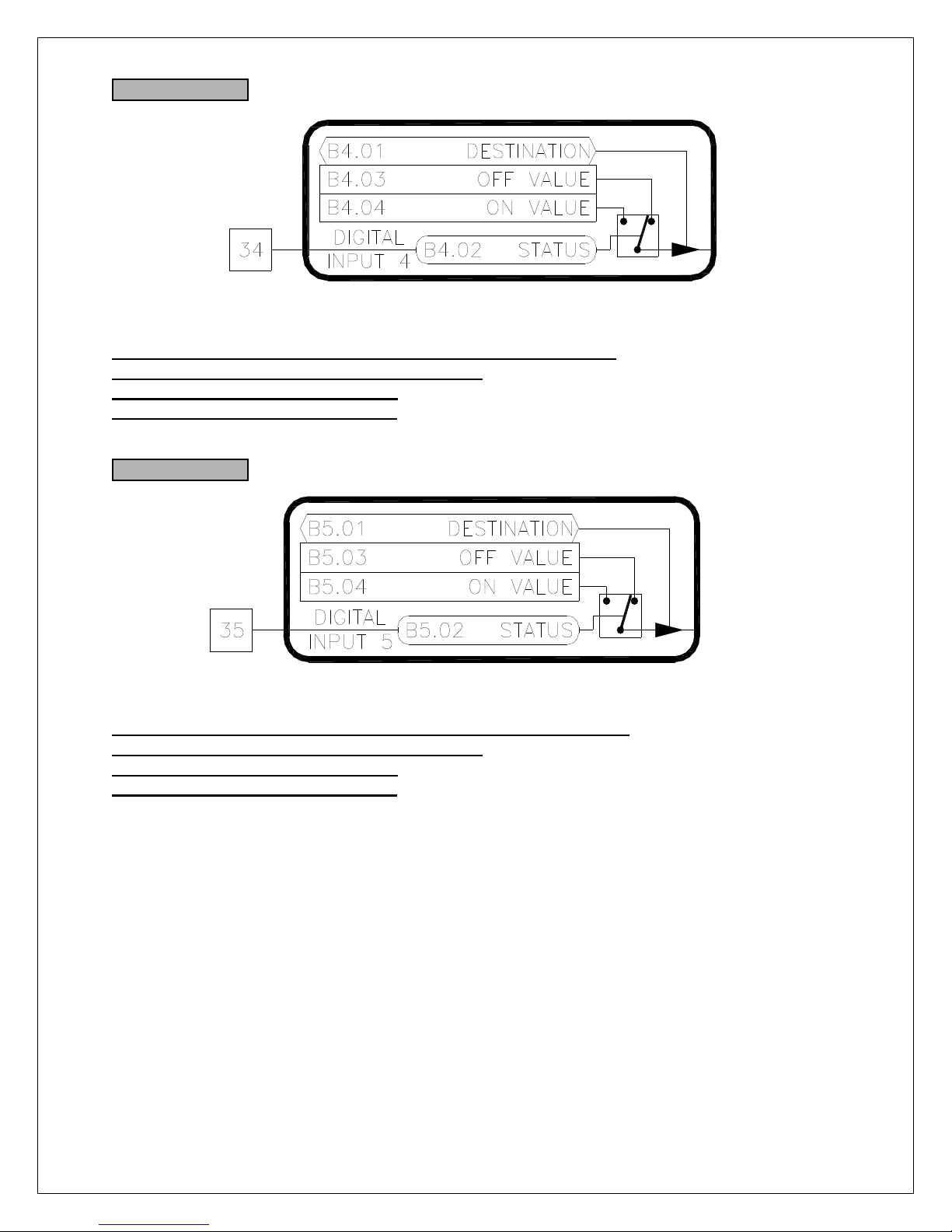

B4: Digital Input 4

B4.01 Digital Input 4 Destination (ICR, Preset: H1.05 [Reverse])

B4.02 Digital Input 4 Status [Terminal 34] (RO)

B4.03 Digital Input 4 Off Value (RW)

B4.04 Digital Input 4 On Value (RW)

Digital Input 4 is functionally equivalent to Digital Input 1. Refer to B1.XX

B5: Digital Input 5

B5.01 Digital Input 5 Destination (ICR, Preset: I1.02 [RefSelMsb])

B5.02 Digital Input 5 Status [Terminal 35] (RO)

B5.03 Digital Input 5 Off Value (RW)

B5.04 Digital Input 5 On Value (RW)

Digital Input 5 is functionally equivalent to Digital Input 1. Refer to B1.XX

Figure 18

Figure 19

25

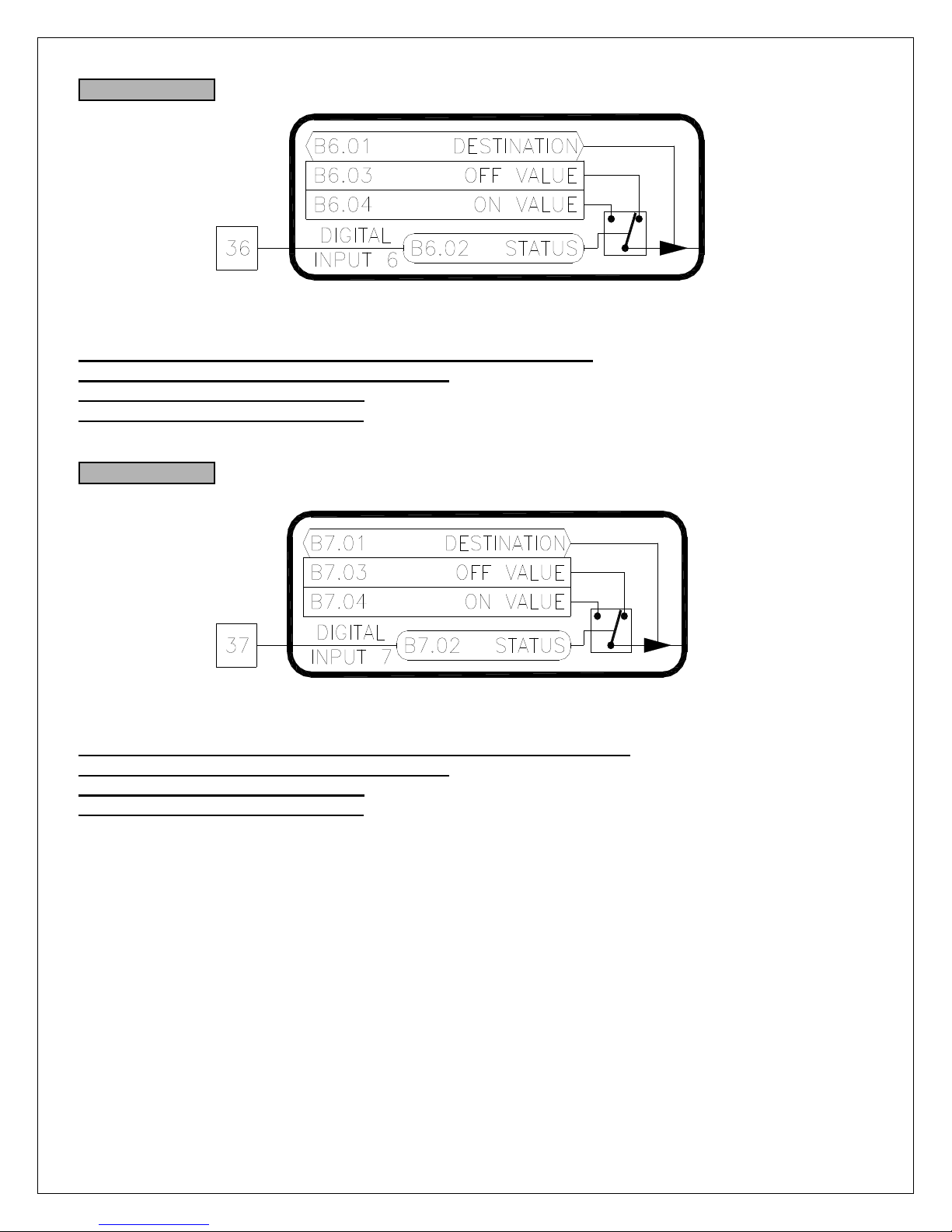

B6: Digital Input 6

B6.01 Digital Input 6 Destination (ICR, Preset: I1.03 [RefSelLsb])

B6.02 Digital Input 6 Status [Terminal 36] (RO)

B6.03 Digital Input 6 Off Value (RW)

B6.04 Digital Input 6 On Value (RW)

Digital Input 6 is functionally equivalent to Digital Input 1. Refer to B1.XX

B7: Digital Input 7

B7.01 Digital Input 7 Destination (ICR, Preset: K1.15 [ExtFaultReset])

B7.02 Digital Input 7 Status [Terminal 37] (RO)

B7.03 Digital Input 7 Off Value (RW)

B7.04 Digital Input 7 On Value (RW)

Digital Input 7 is functionally equivalent to Digital Input 1. Refer to B1.XX

Figure 20

Figure 21

26

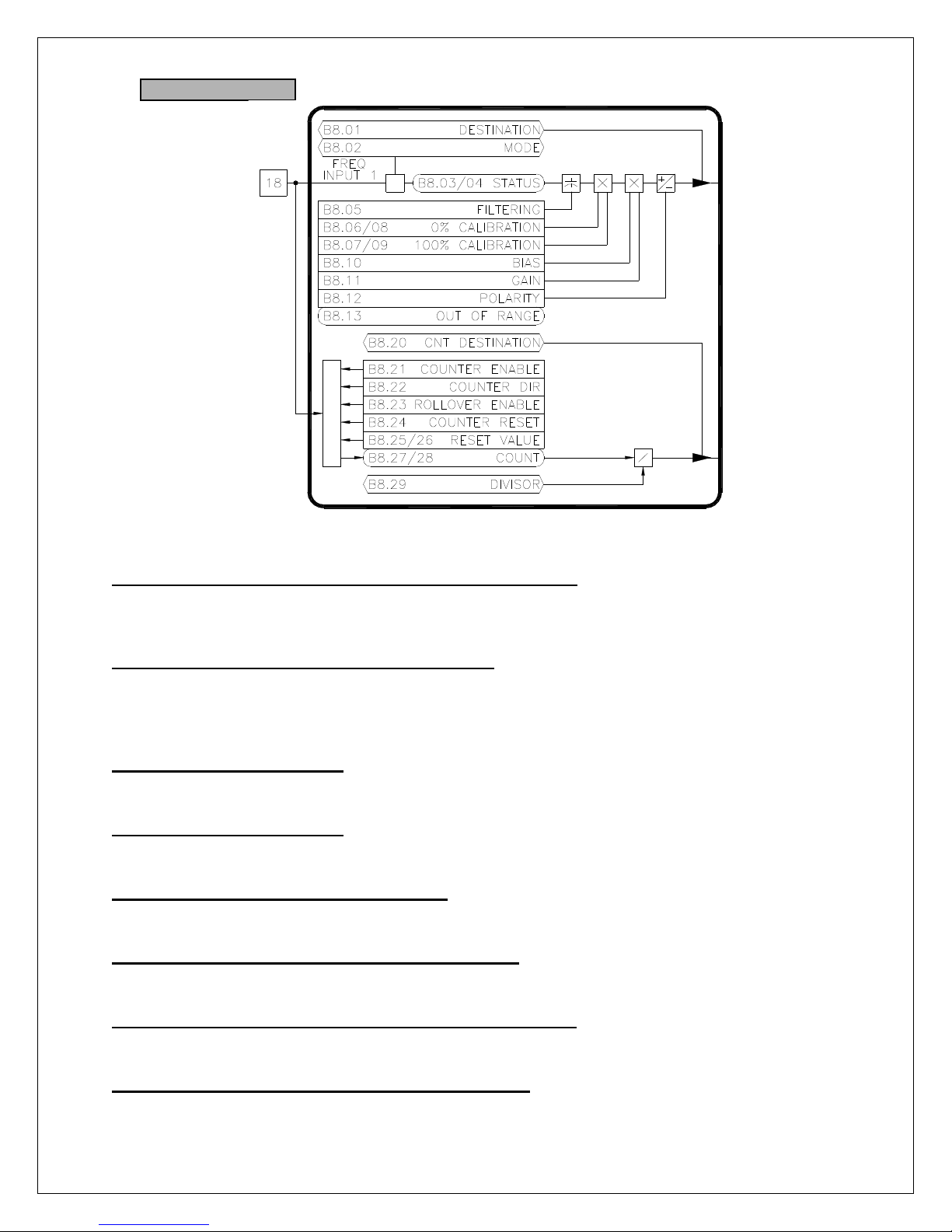

B8: Frequency Input

B8.01 Freq Input Destination (ICR, Preset: 00.00 [Not Set])

The frequency input can control (or write to) any R/W parameter in the drive. The destination

parameter contains the tag of the parameter the input will control (i.e. the target parameter).

Refer to Table 5 on page 29 for a list of commonly used functions.

B8.02 Freq Input Mode (ICR, Preset: Freq Input)

The frequency input can operate in either the FREQ INPUT or SONIC INPUT modes. In the

frequency input mode, the input level is determined by the input frequency. The sonic mode is

used in conjunction with Carotron's sonic transducer (P/N: C10757-000 or C11307-000) to

measure distance.

B8.03 Freq Input Status (RO)

Valid only when B8.02 equals FREQ INPUT. Displays the frequency input level at terminal 18 in

Hertz.

B8.04 Freq Input Status (RO)

Valid only when B8.02 equals SONIC INPUT. Displays the measured distance of the sonic

transducer connected to terminal 18 in inches.

B8.05 Freq Input Filtering (R/W, Preset: 0)

Sets the level of digital filtering applied to the input signal. The adjustment ranges from 0 (no

filtering) to 15 (heavily filtered).

B8.06 Freq Input 0% Calibration (R/W, Preset: 0Hz)

Defines the minimum input frequency in Hertz. An input value below this level will be ignored.

This parameter is only used when in the FREQ INPUT mode. Range: 0..50,000Hz

B8.07 Freq Input 100% Calibration (R/W, Preset: 50000Hz)

Defines the maximum input frequency in Hertz. An input value above this level will be ignored.

This parameter is only used when in the FREQ INPUT mode. Range: 0..50,000Hz

B8.08 Freq Input 0% Calibration (R/W, Preset: 6.00")

Defines the minimum input distance in inches. An input value below this level will be ignored.

This parameter is only used when in the SONIC INPUT mode. Range: 0..420"

Figure 22

27

B8.09 Freq Input 100% Calibration (R/W, Preset: 420.00")

Defines the maximum input distance in inches. An input value above this level will be ignored.

This parameter is only used when in the SONIC INPUT mode. Range: 0..420"

B8.10 Freq Input Bias (R/W, Preset: 0.00)

Defines the value of the target parameter when the input signal is less than or equal to the 0%

Calibration. Note that the formatting of this parameter will change to match that of the target

parameter. For example, if the target parameter is in percent, this parameter will be in percent. If

the target parameter is True/False, this parameter will be True/False.

B8.11 Freq Input Gain (R/W, Preset: 100.00)

Defines the value of the target parameter when the input signal is greater than or equal to the

100% Calibration. Note that the formatting of this parameter will change to match that of the

target parameter.

B8.12 Freq Input Polarity (R/W, Preset: Positive)

Defines the polarity of the target parameter. When set to POSITIVE, the target parameter will

have a positive value. Likewise, when set to NEGATIVE, the target parameter will be negative.

B8.13 Out of Range (RO)

Displays the status of the sonic transducer distance measurement. If B8.04 is 10% less than

B8.08 or B8.04 is 10% greater than B8.09, this parameter will be TRUE indicating the target is

out of range.

B8.20 Counter Destination (ICR, Preset: 00.00 [Not Set])

The drive has a counter associated with the frequency input. This count value can control (or

write to) any R/W parameter in the drive. The destination parameter contains the tag of the

parameter the input will control (i.e. the target parameter).

B8.21 Counter Enable (R/W, Preset: Disabled)

The counter is enabled when set to ENABLED.

B8.22 Counter Direction (R/W, Preset: Up)

Controls the direction of the counter. When set to UP, each pulse on the input will cause the

counter (B8.26/27) to increase. When set to DOWN, each pulse on the input will cause the

counter to decrease.

B8.23 Rollover Enable (R/W, Preset: Disabled)

When ENABLED, the counter is allowed to rollover from maximum to minimum when counting

up, or to rollover from minimum to maximum when counting down. If DISABLED, rollover is not

allowed and the count value will stop and hold its value at the maximum or minimum.

B8.24 Counter Reset (R/W, Preset: Off)

Resets the counter (B8.26/27) to the Reset Value (B8.24/25) when ON.

B8.25 Reset Value Lo (R/W, Preset: 0)

B8.26 Reset Value Hi (R/W, Preset: 0)

The 32 bit counter will be preset to the value in these two registers when B8.23 is ON.

B8.27 Counter Lo (RO)

B8.28 Counter Hi (RO)

The 32 bit counter is split into two 16 bit sections (B8.28:B8.27). The counter has a maximum

value of 4,294,967,295.

B8.29 Divisor (ICR, Preset: 1)

The 32 bit count value is divided by this value before being written to the target parameter.

Range: 0..65535

28

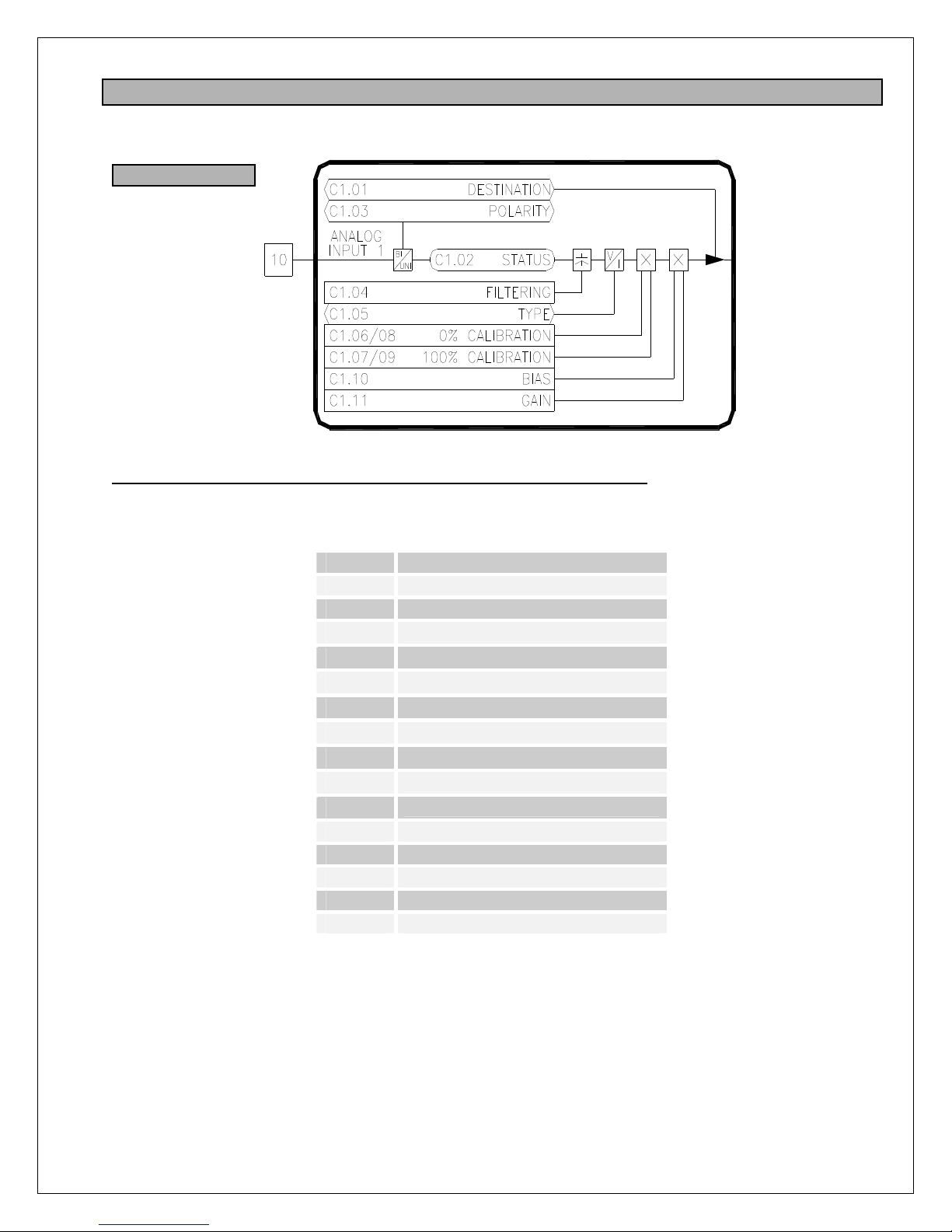

7.3 C: Analog Inputs

These parameters configure the drive's physical analog inputs.

C1: Analog Input 1

C1.01 Analog Input 1 Destination (ICR, Preset: I1.04 [Reference A])

Each of the analog inputs can control (or write to) any R/W parameter in the drive. The

destination parameter contains the tag of the parameter the input will control (i.e. the target

parameter). Refer to Table 5 for a list of commonly used functions.

Value Function

G1.05 POSITIVE CURRENT LIMIT

G1.06 NEGATIVE CURRENT LIMIT

I

1.04

I1

.05

I

1.06

I

1.07

I

1.08

I

2.02

I

2.04

I

2.06

L1.13 AUX PID SETPOINT

L1.14 AUX PID FEEDBACK

L1.23 AUX PID SCALE

L2.07 DIA CALC: EXT DIA RATIO

L4.01 TENSION CALC: TENSION SET

Table 5: Common Analog & Freq Input Functions

Figure 23

REF A

REF B

REF C

REF D

JOG REF

SETPOINT B

SETPOINT C

SETPOINT D

29

C1.02 Analog Input 1 Status (RO)

Displays the raw analog to digital conversion value. Table 6 below lists the typical status values

for common input levels.

C1.03 Analog Input 1 Polarity (ICR, Preset: Unipolar)

Configures the type of analog input signal used, either UNIPOLAR or BIPOLAR.

C1.04 Analog Input 1 Filtering (R/W, Preset: 0)

Sets the level of digital filtering applied to the input signal. The adjustment ranges from 0 (no

filtering) to 15 (heavily filtered). Range: 0..15

C1.05 Analog Input 1 Type (ICR, Preset: Voltage)

Configures the type of analog input signal used, either VOLTAGE or CURRENT.

C1.06 Analog Input 1 Unipolar 0% Calibration (R/W, Preset: 0)

Defines the minimum signal level in UNIPOLAR mode. An input value below this level will be

ignored. Refer to Figure 24. Range: 0..4095

C1.07 Analog Input 1 Unipolar 100% Calibration (R/W, Preset: 4095)

Defines the maximum raw signal level in UNIPOLAR mode. An input value above this level will

be ignored. Refer to Figure 24. Range: 0..4095

C1.09 Analog Input 1 Bipolar 100% Calibration (R/W, Preset: 2047)

Defines the maximum raw positive and negative signal levels in BIPOLAR mode. Any input

value exceeding this level will be ignored. Refer to Figure 24. Range: 0..2047

C1.10 Analog Input 1 Bias (R/W, Preset: 0.00)

Defines the value of the target parameter when the input signal is less than or equal to the 0%

Calibration. Refer to Figure 24. Note that the formatting of this parameter will change to match

that of the target parameter. For example, if the target parameter is percent, this parameter will

be percent. If the target parameter is Seconds, this parameter will be Seconds.

C1.11 Analog Input 1 Gain (R/W, Preset: 100.00)

Defines the value of the target parameter when the input signal is greater than or equal to the

100% Calibration. Refer to Figure 24. Note that the formatting of this parameter will change to

match that of the target parameter.

Signal Input Status

Voltage Current Unipolar Bipolar

+10V - 4095 2047

+7.5V - 3070 1535

+5V 20mA 2047 1023

+2.5V 10mA 1023 511

0V 0mA 0 0

-2.5V -10mA - -512

-5V -20mA - -1024

-7.5V - - -1536

-10V - - -2048

Table 6: Analog Input Status Readings

30

C2: Analog Input 2

C2.01 Analog Input 2 Destination (ICR, Preset: 00.00 [Not Set])

C2.02 Analog Input 2 Status (RO)

C2.03 Analog Input 2 Polarity (ICR, Preset: Unipolar)

C2.04 Analog Input 2 Filtering (R/W, Preset: 0)

C2.05 Analog Input 2 Type (ICR, Preset: Voltage)

C2.06 Analog Input 2 0% Calibration (R/W, Preset: 0)

C2.07 Analog Input 2 100% Calibration (R/W, Preset: 4095)

C2.08 Analog Input 2 0% Calibration (R/W, Preset: 0)

C2.09 Analog Input 2 100% Calibration (R/W, Preset: 2047)

C2.10 Analog Input 2 Bias (R/W, Preset: 0.00)

C2.11 Analog Input 2 Gain (R/W, Preset: 100.00)

Analog Input 2 is functionally equivalent to Analog Input 1. Refer to C1.XX.

Figure 24

Figure 25

31

C3: Analog Input 3

C3.01 Analog Input 3 Destination (ICR, Preset: 00.00 [Not Set])

C3.02 Analog Input 3 Status (RO)

C3.03 Analog Input 3 Polarity (ICR, Preset: Unipolar)

C3.04 Analog Input 3 Filtering (R/W, Preset: 0)

C3.05 Analog Input 3 Type (ICR, Preset: Voltage)

C3.06 Analog Input 3 0% Calibration (R/W, Preset: 0)

C3.07 Analog Input 3 100% Calibration (R/W, Preset: 4095)

C3.08 Analog Input 3 0% Calibration (R/W, Preset: 0)

C3.09 Analog Input 3 100% Calibration (R/W, Preset: 2047)

C3.10 Analog Input 3 Bias (R/W, Preset: 0.00)

C3.11 Analog Input 3 Gain (R/W, Preset: 100.00)

Analog Input 3 is functionally equivalent to Analog Input 1. Refer to C1.XX.

C4: Analog Input 4

C4.01 Analog Input 4 Destination (ICR, Preset: 00.00 [Not Set])

C4.02 Analog Input 4 Status (RO)

C4.03 Analog Input 4 Polarity (ICR, Preset: Unipolar)

C4.04 Analog Input 4 Filtering (R/W, Preset: 0)

C4.05 Analog Input 4 Type (ICR, Preset: Voltage)

C4.06 Analog Input 4 0% Calibration (R/W, Preset: 0)

C4.07 Analog Input 4 100% Calibration (R/W, Preset: 4095)

C4.08 Analog Input 4 0% Calibration (R/W, Preset: 0)

C4.09 Analog Input 4 100% Calibration (R/W, Preset: 2047)

C4.10 Analog Input 4 Bias (R/W, Preset: 0.00)

C4.11 Analog Input 4 Gain (R/W, Preset: 100.00)

Analog Input 4 is functionally equivalent to Analog Input 1. Refer to C1.XX.

Figure 26

Figure 27

32

C5: Analog Input 5

C5.01 Analog Input 5 Destination (ICR, Preset: 00.00 [Not Set])

C5.02 Analog Input 5 Status (RO)

C5.03 Analog Input 5 Polarity (ICR, Preset: Unipolar)

C5.04 Analog Input 5 Filtering (R/W, Preset: 0)

C5.05 Analog Input 5 Type (ICR, Preset: Voltage)

C5.06 Analog Input 5 0% Calibration (R/W, Preset: 0)

C5.07 Analog Input 5 100% Calibration (R/W, Preset: 4095)

C5.08 Analog Input 5 0% Calibration (R/W, Preset: 0)

C5.09 Analog Input 5 100% Calibration (R/W, Preset: 2047)

C5.10 Analog Input 5 Bias (R/W, Preset: 0.00)

C5.11 Analog Input 5 Gain (R/W, Preset: 100.00)

Analog Input 5 is functionally equivalent to Analog Input 1. Refer to C1.XX.

Figure 28

33

7.4 D: Digital Outputs

These parameters configure the drive's physical digital outputs (relay & frequency/digital).

D1: Relay Output 1

D1.01 Relay Output 1 Source (ICR, Preset: S1.06 [Zero Speed])

The function of the relay output is configured by this parameter. Each output can be controlled

by any parameter in the drive. The source parameter contains the tag of the parameter that will

control the relay output. The source parameter's value is compared to the On Value and Off

Value parameters (Dx.03 & Dx.04) to determine if the relay is energized or de-energized. Refer to

Table 7 for a list of commonly used functions.

Value Function

G3.05 IN FIELD ECONOMY

H1.13 DRIVE IN RUN MODE

H1.14 DRIVE IN JOG MODE

H1.16 DRIVE RUNNING (RUN or JOG)

J1.22 DRIVE RAMPING

K2.08 DRIVE FAULT

K2.10 DRIVE READY

S1.06 AT ZERO SPEED

S1.07 AT STANDSTILL

D1.02 Relay Output 1 Absolute Value (R/W, Preset: Off)

When TRUE, the absolute value of the source parameter's value is taken before it is compared to

the Dx.03 and Dx.04.

D1.03 Relay Output 1 On Value (R/W, Preset: On)

The relay will energize (turn on) when the source parameter's value is greater than or equal to

this value. The limits and units of this parameter will change to match the limits and units of the

source parameter.

D1.04 Relay Output 1 Off Value (R/W, Preset: Off)

The relay will de-energize (turn off) when the source parameter's value is less than or equal to

this value. The limits and units of this parameter will change to match the limits and units of the

source parameter.

D1.05 Relay Output 1 Status (RO)

Displays the status of the relay output.

Table 7: Common Relay & Digital Output Functions

Figure 29

34

D2: Relay Output 2

D2.01 Relay Output 2 Source (ICR, Preset: H1.16 [Drive Running])

D2.02 Relay Output 2 Absolute Value (R/W, Preset: Off)

D2.03 Relay Output 2 On Value (R/W, Preset: On)

D2.04 Relay Output 2 Off Value (R/W, Preset: Off)

D2.05 Relay Output 2 Status (RO)

Relay Output 2 is functionally equivalent to Relay Output 1. Refer to D1.XX

D3: Relay Output 3

D3.01 Relay Output 3 Source (ICR, Preset: K2.08 [Drive Faulted])

D3.02 Relay Output 3 Absolute Value (R/W, Preset: Off)

D3.03 Relay Output 3 On Value (R/W, Preset: No)

D3.04 Relay Output 3 Off Value (R/W, Preset: Yes)

D3.05 Relay Output 3 Status (RO)

Relay Output 2 is functionally equivalent to Relay Output 1. Refer to D1.XX

Figure 30

Figure 31

35

D4: Frequency/Digital Output

D4.01 Freq/Digital Output Source (ICR, Preset: 00.00 [Not Set])

The function of this output is configured by this parameter. The output can be controlled by any

parameter in the drive. The source parameter contains the tag of the parameter that will control

the relay output. Refer to Table 7 for a list of commonly used functions when used as a digital

output. Refer to Table 8 for a list of commonly used functions when used as a frequency output.

D4.02 Freq/Digital Output Mode (ICR, Preset: Freq Out)

This open collector output can function in either a frequency or digital mode. In FREQ OUT

mode, the output is a pulse train. The frequency level of the output is based on the source

parameter's value. In DIGITAL OUT mode, the output is level is driven either on or off (similar to

a relay output).

D4.03 Freq Output Gain (R/W, Preset: 100.00%)

Used only in the FREQ OUT mode. This adjustment is used to scale the output level of the pulse

train. A gain of 100% with a source parameter value of 100% will yield maximum output

frequency (10kHz). Range: 0..300%

D4.04 Freq Output Bias (R/W, Preset: 0.00%)

Used only in the FREQ OUT mode. This adjustment is used to set a minimum frequency output

level. The percentage adjustment is based on the maximum frequency output level (10kHz).

Range: 0..300%

D4.05 Freq Output Status (RO)

Used only in the FREQ OUT mode. Displays the frequency output level.

D4.06 Digital Output Absolute Value (R/W, Preset: Off)

Used only in the DIG OUT mode. When TRUE, the absolute value of the source parameter's

value is taken before it is compared to the D4.07 and D4.08.

D4.07 Digital Output On Threshold (R/W, Preset: 0.01)

Used only in the DIG OUT mode. The output will turn on (sink current) when the source

parameter's value is greater than or equal to this value. The limits and units of this parameter will

change to match the limits and units of the source parameter.

D4.08 Digital Output Off Threshold (R/W, Preset: 0.00)

Used only in the DIG OUT mode. The output will turn off when the source parameter's value is

less than or equal to this value. The limits and units of this parameter will change to match the

limits and units of the source parameter.

D4.09 Digital Output Status (RO)

Used only in the DIG OUT mode. Displays the status of the digital output, either ON or OFF

Figure 32

36

D5: Aux LED Output

D5.01 Aux LED Source (ICR, Preset: H1.16 [Arm Pilot Status])

The function of this output is configured by this parameter. The output can be controlled by any

parameter in the drive. The source parameter contains the tag of the parameter that will control

the relay output. Refer to Table 7 for a list of commonly used functions.

D5.02 Aux LED Absolute Value (R/W, Preset: Off)

When TRUE, the absolute value of the source parameter's value is taken before it is compared to

the D5.03 and D5.04.

D5.03 Aux LED On Value (R/W, Preset: On)

The LED will turn on when the source parameter's value is greater than or equal to this value.

The limits and units of this parameter will change to match the limits and units of the source

parameter.

D5.04 Aux LED Off Value (R/W, Preset: Off)

The LED will turn off when the source parameter's value is less than or equal to this value. The

limits and units of this parameter will change to match the limits and units of the source

parameter.

D5.05 Aux LED Output Status (RO)

Displays the status of the LED output.

Figure 33

37

7.5 E: Analog Outputs

These parameters configure the drive's physical analog outputs.

E1: Analog Output 1

E1.01 Analog Output 1 Source (ICR, Preset: G2.18 [Filtered Velocity Feedback])

The function of this output is configured by this parameter. The output can be controlled by any

parameter in the drive. The source parameter contains the tag of the parameter that will control

the analog output level. Refer to Table 8 for a list of commonly used functions.

Value Function

G1.13 MOTOR ARM CURRENT

G2.07 MOTOR ARM VOLTAGE

G2.18 MOTOR SPEED

G3.09 MOTOR FIELD CURRENT

G3.13 MOTOR FIELD VOLTAGE

I

1.10

J1.21 RAMP OUTPUT

L1.25 AUX PID OUTPUT

Table 8: Common Analog & Freq Output Functions

E1.02 Analog Output 1 Gain (R/W, Preset: 100.00%)

This adjustment is used to scale the output level. A gain of 100% with a source parameter value

of 100% will yield maximum output level of 10V. Range: -300..300%

E1.03 Analog Output 1 Bias (R/W, Preset: 0.00%)

This adjustment is used to set a minimum output level. The percentage adjustment is based on

the maximum output level (10V). Range: -300..300%

E1.04 Analog Output 1 Absolute Value (R/W, Preset: Off)

When TRUE, the absolute value is taken after the Bias and Gain have been applied to the

source parameter's value. This effectively makes the output unipolar (positive only).

Figure 34

REFERENCE

38

E1.05 Analog Output 1 Status (RO)

Displays the raw digital to analog output level. Refer to Table 9 for typical values.

Status Voltage

+10V 4095

+5V 2047

0V 0

-5V -2047

-10V -4095

Table 9: Analog Output Status

E2: Analog Output 2

E2.01 Analog Output 2 Source (ICR, Preset: G1.13 [Filtered Current Feedback])

E2.02 Analog Output 2 Gain (R/W, Preset: 100.00%)

E2.03 Analog Output 2 Bias (R/W, Preset: 0.00%)

E2.04 Analog Output 2 Absolute Value (R/W, Preset: Off)

E2.05 Analog Output 2 Status (RO)

Analog Output 2 is functionally equivalent to Analog Output 1. Refer to E1.XX

Figure 35

39

7.6 F: Motor Data