Page 1

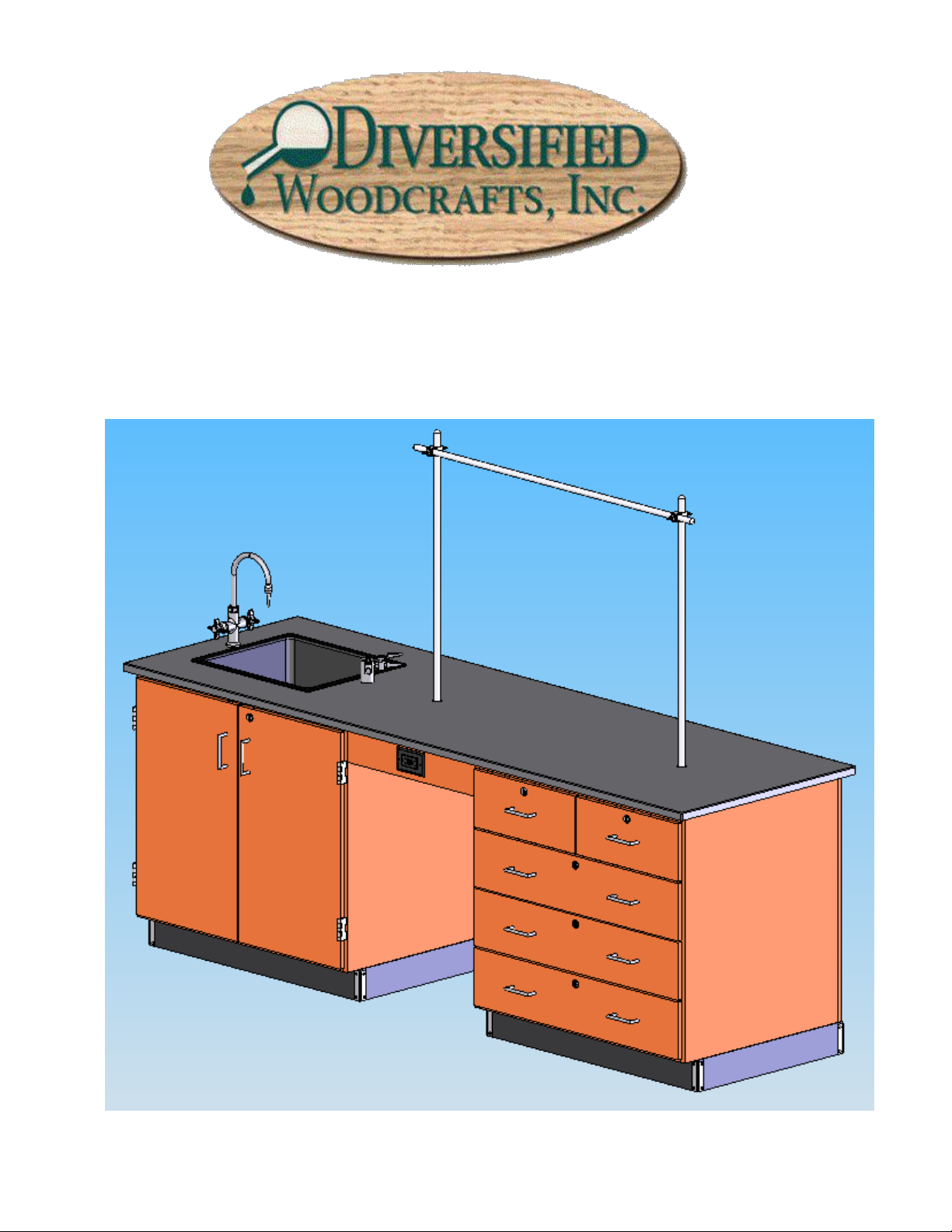

1116 INSTRUCTOR’S DESK

ASSEMBLY INSTRUCTIONS

Page 2

2

TABLE OF CONTENTS

PAGE

REVISONS TABLE………………………………………………………………………………………………………………………………………………………………………………………………………………….……………………………………………………………………………………..…………………………………1

ASSEMBLY COMPONENTS………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………...………………2

BASE ASSEMBLY………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………4

BACK PANEL ASSEMBLY…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………….…………………………4

APRON RAIL ASSEMBLY………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………….…………………………………….…………………5

TOP ASSEMBLY………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………5

SINK ASSEMBLY……………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………….…………………………………6

FIXTURE ASSEMBLY………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………6

ROD SOCKET ASSEMBLY…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………….…………………………………………6

BASE MOULDING ASSEMBLY………………………………………………………………………………………………………………………………………………………………………………………………………….………………………………..………..……………………………7

PULL ASSEMBLY………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………….………………………………………………………………………8

Page 3

3

Items Included In Hardware Box

Part #

Part #

1-ASSEMBLY INSTRUCTIONS

1-HARDWARE BOX

24 FT RUBBER BASE

100283

2-UPRIGHT RODS 3/4 DIA. X 36 L.

100004

1-ELECTRICAL BOX, 2X2.5

100033

1-CROSSBAR ROD, 3/4 DIA. X 48 L.

100006

1-GFI ELECTRIC OUTLET

100034

1-FIXTURE, L2900-132AWSA 90 DEG.-GAS

100048

4-SCREWS, 6X1/2 PPH

100475

1-FIXTURE,L414 HOT & COLD MIXING

100467

2-ROD SOCKET ASSEMBLY

206505

1-EPOXY SINK, L30 BLK

100699

2-ROD CLAMP ASSEMBLY

206506

1-EPOXY TOP, 30 X 96, BLK, FIXT

100497

6-STAINLESS STEEL CORNERS

100057

1-APRON WITH ELECT. 4.5X22

211289

24-STAINLESS STEEL SCREW, 6X1/2

100064

1-BACK PANEL, 94X35

212671

1-OUTLET/STRAINER EPOXY,BLK

100055

8-TRUSS HEAD SCREWS, 8 X 3/4

100649

1-PLASTIC ADJ SINK TRAP

100056

16-SCREW, WASHER FLAT HEAD #8X1 1/4

100478

1-SINK STOPPER 1 1/2, BLK

100112

2-CLEAT RAILS

100355

1-CLEAR SILICONE SEALENT

100711

---

Original Created

2-28-07

JWD

ASSEMBLY COMPONENTS

REV DESCRIPTION DATE INITIAL

Page 4

4

Assembly Instructions for

1116K and 1216K Instructor’s Desk

Items not included but needed for assembly:

1. Screwdrivers and Wrenches

2. Liquid Nail or silicone adhesive (can be found in hardware stores)

3. Contact Cement

4. Tape measure

Instructions:

1. Place the cupboard cabinet centered over the plumbing and gas.

2. Place the second cabinet in line with the cupboard cabinet leaving a 22” space between the cabinets

for the back panel.

3. Attach back panel to the back of the cabinets using the cleats and #8 x 1-1/4” phil pan head screws

provided. It is recommended that one person hold the back panel in place while a second person

actually attaches the panel. Make sure back panel is flush with the outside edges of the cabinets.

Page 5

5

4. Attach front apron between cabinets using the cleats and the 100649 #8 x ¾” screws provided. For

aesthetic purposes you may want to set the apron in 1”.

5. Outline the top of the base unit with the Liquid Nail or silicone adhesive and place top on the unit.

Let cure. Be sure to center the top on the base unit before the glue dries.

Page 6

6

6. Clean the top with water only. Be sure the area the sink is dropped in is clean and dry.

7. Put a bead of silicone seal along the cutout for the sink on the top. Lower sink in place.

8. Mount fixtures into place.

9. (If Applicable) Assemble the Rod Socket Assembly as shown in Figure 9A.

(If Applicable) Attach Rod Sockets to Top as shown in Figure 9B.

Figure 9A

Page 7

7

Figure 9B

10. Attach the rubber base molding using contact cement. After the molding is in place; screw stainless

steel corner brackets on each corner using the (100064) #6 x ½” screws provided, over the base molding.

Page 8

8

11. Reverse pulls to the exterior of unit as shown.

12. All water, electrical and gas connections should be performed by a trained professional.

P:\B Hawley\Web Downloads\Tech Manuals\705127,705128-1116K TECH MANUAL.doc

Loading...

Loading...