Carlyle Tools 6-1135, 6-1136 Instruction Manual

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks, cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

The risk of exposure to these types of chemicals varies depending on how frequently you work

with certain chemicals. To reduce your exposure to these chemicals, work in a well-ventilated area

and work with approved safety equipment, such as dust masks that are specifically designed to

filter out microscopic particles.

WARNING: This product can expose you to chemicals including nickel, which is known to

the State of California to cause cancer and birth defects or other reproductive harm. For

more information go to www.P65Warnings.ca.gov.

THIS INSTRUCTION MANUAL

CONTAINS IMPORTANT SAFETY

INFORMATION.

READ CAREFULLY AND UNDERSTAND

ALL INFORMATION BEFORE

OPERATING THIS TOOL!

SAVE THIS MANUAL FOR

FUTURE REFERENCE.

ADVERTENCIA

El polvo ocasionado por del lijado neumático, el aserrado, la rectificación, la perforación y

otras actividades de construcción puede contener sustancias químicas conocidas como agentes

causantes del cáncer, defectos de nacimiento y otros daños reproductivos. Algunos ejemplos de

dichas sustancias químicas son:

• plomo de pintura a base de plomo,

• la silica cristalina proveniente del ladrillo, cemento y otros productos de mampostería, y

• el arsénico y el cromo proveniente de maderos tratados con sustancias químicas

El riesgo de ser expuesto a estos tipos de sustancias químicas varía según la frecuencia con la

cual usted trabaja con ciertas sustancias químicas. Para disminuir la posibilidad de exposición a

dichas sustancias químicas, usted debe trabajar en un área bien ventilada y con equipo aprobado

de seguridad, tal como las mascarillas de polvo las cuales son diseñadas específicamente para

filtrar las partículas microscópicas.

ADVERTENCIA: Este producto le podrá exponer a ciertos químicos, para incluir el

níquel, conocidos en el Estado de California por ocasionar cáncer y defectos congénitos u

otros daños a la reproducción. Para mayores informes, visite: www.P65Warnings.ca.gov.

AVERTISSEMENT

Les travaux de construction effectués à l’aide d’un outil électrique, comme le sablage, le sciage, le meulage et le perçage, produisent de la poussière qui contient des produits chimiques. De tels produits sont

reconnus comme cancérigènes. Ils peuvent aussi causer des anomalies congénitales ou nuire d’une

autre manière à la reproduction. Voici quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristallisée contenue dans les briques, le ciment et d’autres produits de maçonnerie;

• l’arsenic et le chrome contenus dans le bois de sciage traité avec des produits chimiques.

Les risques d’exposition à ces produits chimiques varient selon la fréquence d’utilisation de certains

matériaux. Pour réduire l’exposition, il est recommandé de travailler dans un endroit bien aéré et de

porter de l’équipement de protection approuvé tel qu’un masque antipoussière spécialement conçu pour

filtrer les particules microscopiques.

AVERTISSEMENT: Ce produit pourrait vous exposer à des produits chimiques,

notamment du nickel, qui est reconnu par l’État de la Californie comme causant le cancer,

des anomalies congénitales ou d’autres pathologies du système reproductif. Pour en

savoir plus, veuillez visiter le www.P65Warnings.ca.gov.

LAS INSTRUCCIONES EN ESPAÑOL

COMIENZAN EN LA PÁGINA # 7.

ESTE MANUAL DE INSTRUCCIONES

CONTIENE IMPORTANTES

INFORMACIONES DE SEGURIDAD

¡LEA CUIDADOSAMENTE Y

ASEGÚRESE DE COMPRENDER

TODAS ESTAS INFORMACIONES,

ANTES DE PROCEDER CON EL

FUNCIONAMIENTO DE ESTA

HERRAMIENTA!

CONSERVE ESTE MANUAL PARA

TENER UNA REFERENCIA EVENTUAL.

LINSTRUCTIONS EN FRANÇAIS

À PARTIR DE LA PAGE 12 CE

GUIDE D'UTILISATION RENFERME

D'IMPORTANTES CONSIGNES DE

SÉCURITÉ.

LISEZ-LE ATTENTIVEMENT ET

ASSUREZ-VOUS D'AVOIR BIEN COM-

PRIS TOUTES LES DIRECTIVES AVANT

D'UTILISER CET OUTIL!

CONSERVER CE GUIDE POUR CON-

SULTATION ULTÉRIEURE.

3/8" RIGHT ANGLE AIR DRILL WITH KEYED CHUCK

Taladro neumático de 3/8" con

mandril y llave de 90°

Perceuse pneumatique 3/8 po avec

mandrin a 90° et a cle

6-1135

WARNING

FAILURE TO OBSERVE THESE WARNINGS COULD RE SULT IN IN JU RY.

CON TAINS IMPORTANT

SAFETY INFORMATION.

READ THIS IN STRUC TION

MANUAL CARE FUL LY AND

UN DER STAND ALL IN FOR MA TION

BE FORE OP ER AT ING THIS TOOL.

It is the responsibility of the owner to

make sure all personnel read this manual

prior to using the device. It is also the

responsibility of the device owner to keep

this manual intact and in a convenient

location for all to see and read. If the

manual or product labels are lost or not

legible, contact NAPA for replacements.

If the operator is not fluent in English,

the product and safety instructions shall

be read and discussed with the operator

in the operator's native language by the

purchaser/owner or his designee, making

sure that the operator comprehends its

contents.

• Always operate, inspect and maintain

this tool in accordance with American

National Standards Institute Safety

Code of Portable Air Tools (ANSI

B186.1) and any other applicable

safety codes and regulations.

• For safety, top performance

and maximum durability of

parts, operate this tool at 90

psig; 6.2 bar max air pressure with 3/8"

diameter air supply hose.

• Always wear impact-resistant

eye and face protection when

operating or performing

maintenance on this tool (users and

bystanders).

• High sound levels can cause

permanent hearing loss.

Always use hearing protection

as recommended by your employer an

OSHA regulations while using this tool

(users and bystanders).

• Operators and maintenance personnel

must be physically able to handle the

bulk, weight and power of this tool.

• Keep tool out of reach of children.

• Air powered tools can vibrate

in use. Vibration, repetitive

motions or uncomfortable

positions over extended periods of time

may be harmful to your hands and arms.

Discontinue use of tool if discomfort,

tingling feeling or pain occurs. Seek

medical advice before resuming use.

THIS INSTRUCTION MAN U AL

• Air under pressure can cause

severe injury. Never direct air at

yourself or others. Always turn

off the air supply, drain hose of

air pressure and detach tool

from air supply before installing,

removing or adjusting any

accessory on this tool, or before

performing any maintenance on

this tool. Failure to do so could result in

injury. Whip hoses can cause serious injury.

Always check for damaged, frayed or loose

hoses and fittings, and replace immediately.

Do not use quick detach couplings at tool.

See instructions for correct set-up.

• Do not operate a damaged or worn tool.

Do not use quick-detach couplings at

tool. See instructions for correct set-up.

• Place tool on the work before starting

the tool. Do not point or indulge in any

horseplay with this tool.

• Slipping, tripping and/or falling

while operating air tools can be

a major cause of serious injury or

death. Be aware of excess hose left on the

walking or work surface.

• Keep body working stance balanced

and firm. Do not overreach when

operating the tool.

• Anticipate and be alert for sudden

changes in motion during start up and

operation of any power tool.

• Note direction of rotation BEFORE

operating this tool

• Do not carry tool by the hose.

Protect the hose from sharp

objects and heat.

• Tool shaft may continue to rotate

briefly after throttle is released.

Avoid direct contact with

accessorie during and after use. Gloves will

reduce the risk of cuts or burns

• Keep away from rotating end of

tool. Do not wear jewelry or

loose clothing. Secure long hair.

Scalping can occur if hair is not kept away

from tool and accessories. Choking can

occur if neckwear is not kept away from tool

and accessories.

• This tool is not insulated against

electric shock.

• This tool must not be used in

explosive atmospheres.

• Do not lubricate tools with

flammable or volatile liquids

such as kerosene, diesel or jet

fuel.

• Drill bits can bind suddenly

and causing rotation of the

work piece or tool, causing

injury to arms and/or shoulders. Enough

torque is generated to cause falls. Always

use sharp bits. Use less downward

pressure at breakthrough.

• Do not force tool beyond its rated

capacity.

• RPM OF THE ACCESSORY

RPMRPMRPM

MUST EXCEED TOOL RPM

• Never use dull, chipped or damaged

accessories. Never cool a hot

accessory in water as brittleness

and early failure can result, Accessory

breakage or tool damage may result

from prying. Take smaller bites to

avoid getting stuck.

• Use replacement parts and accessories

recommended by NAPA.

• Servicing and repairs should only be

made by an authorized service center.

• Do not use (or modify) the tool

for any other purpose than that

for which it was designed without

consulting the manufacturer's

authorized representative.

• Do not remove any labels. Replace

damaged labels.

• Failure to heed these warnings may

result in personal injury and/or property

damage.

WARNING: This product

can expose you to chemicals

including nickel, which is

known to the State of California

to cause cancer and birth defects

or other reproductive harm.

For more information go to

www.P65Warnings.ca.gov.

PLEASE REVIEW ALL WARNING INSTRUCTIONS PRIOR TO OPERATION. SAVE THIS MAN U AL FOR FUTURE REF ER ENCE.

6-1135 2 Rev. 09/17/18

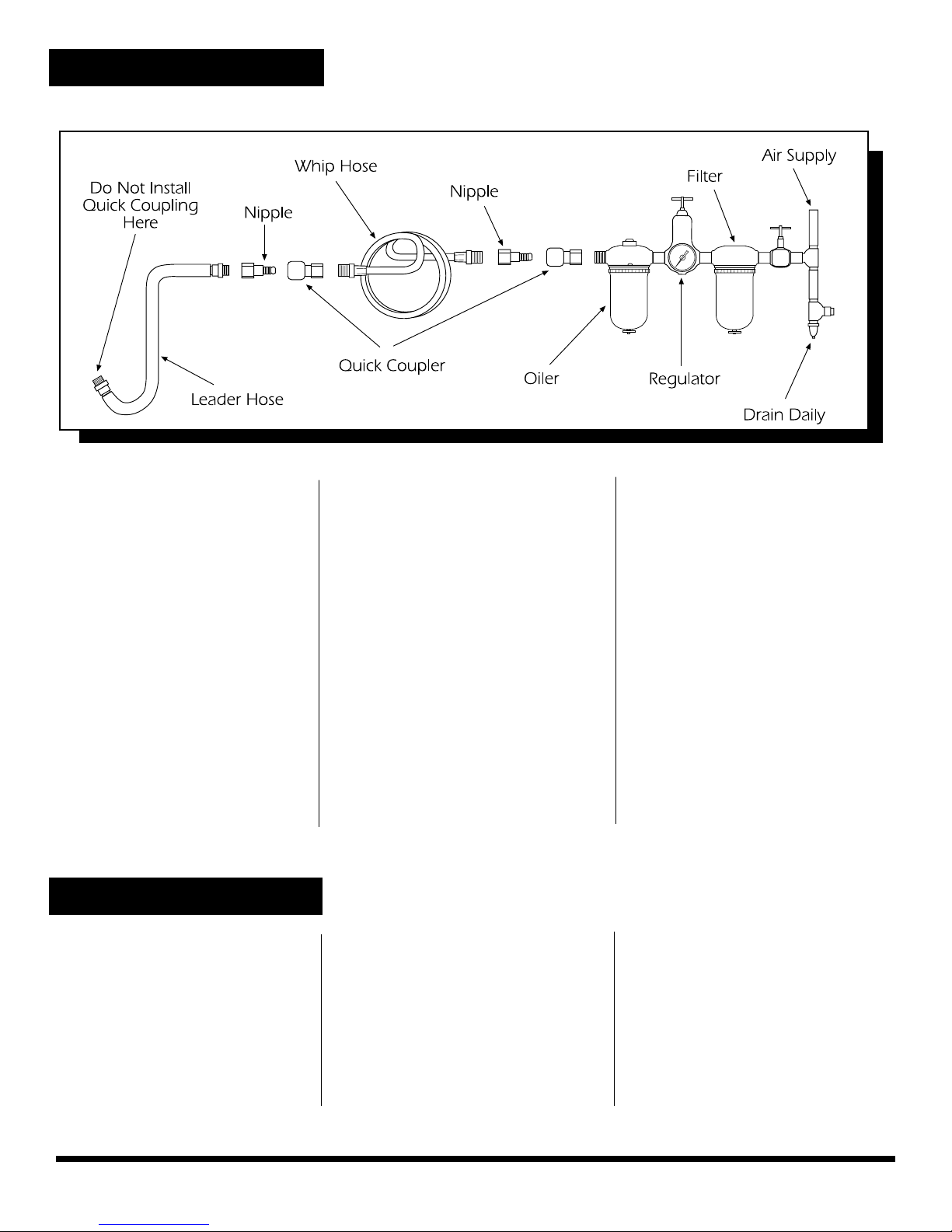

AIR SUPPLY

Tools operate on a wide range of

air pressures. It is recommended

that air pressure measures 90 psig

at the tool with the trigger fully

depressed and no load applied to

the tool. Higher pressure (over 90

psig; 6.2 bar) raises performance

beyond the rated capacity of the

tool, which will shorten tool life

and could cause injury.

Always use clean, dry air. Dust,

corrosive fumes and/or water in

the air line will cause damage to

the tool. Drain the water from air

lines and compressor prior to running tool. Clean the air inlet filter

LUBRICATION

screen weekly. The recommended

hookup procedure can be viewed

in the Figure 1.

The air inlet used for connecting

air supply has standard 1/4" NPT.

Line pressure should be increased

to compensate for unusually long

air hoses (over 25 feet). Minimum

hose diameter should be 3/8" I.D.

and fittings should have the same

inside dimensions and be tightly

secured.

Always turn off the air supply,

drain hose of air pressure and

detach tool from air supply before

installing, removing or adjusting

any part or accessory on this

tool, or before performing any

maintenance on this tool.

Ensure an accessible emergency shut off valve has been

installed in the air supply line

and make others aware of its

location.

Lubricate the air motor daily with

NAPA air tool oil. If no air line oiler

is used, run 1/2 oz. of oil through

the tool. The oil can be squirted

into the tool air inlet or into the

hose at the nearest connection to

the air supply, then run the tool. A

rust inhibitive oil is acceptable for

air tools.

PLEASE REVIEW ALL WARNING INSTRUCTIONS PRIOR TO OPERATION. SAVE THIS MAN U AL FOR FUTURE REF ER ENCE.

6-1135 3 Rev. 09/17/18

WARNING: After an air tool

has been lubricated, oil

will discharge through the

exhaust port during the first

few seconds of operation. The

exhaust port must be covered

with a towel before applying

air pressure to prevent serious

injury.

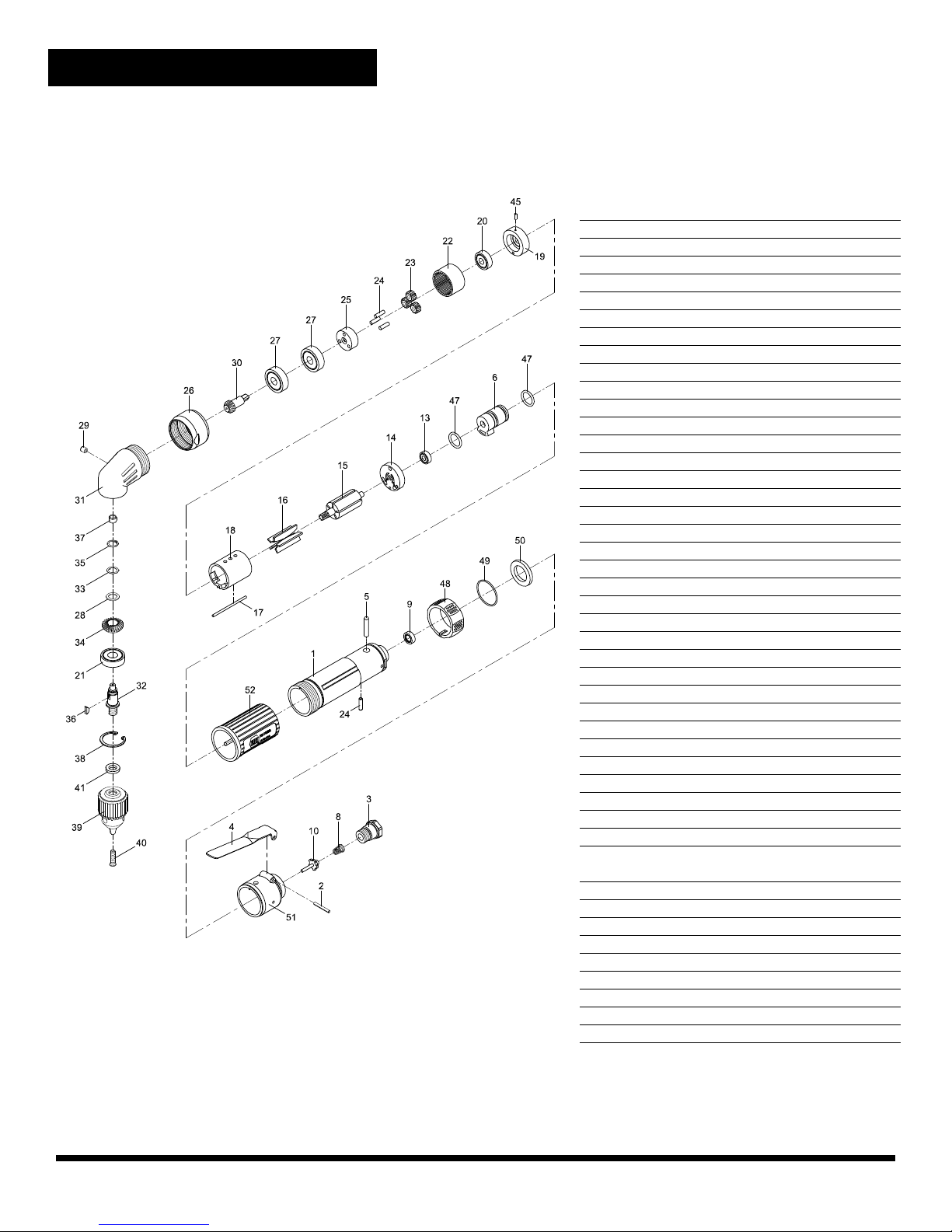

PARTS BREAK DOWN

6-1135

Ref. # Item # DESCRIPTION

QTY

1 RS113501 Motor Housing 1

2 RS2871R02 Spring Pin (3 x 22) 1

3 RS2871R03 Air Inlet 1

4 RS113504 Throttle Lever 1

5 RS113505 Pin 1

6 RS113506 Reverse Valve 1

8 RS2871R08 Spring 1

9 RS2871R09 Rubber Spacer 1

10 RS191010 Valve Stem 1

13 RS30516 Ball Bearing (696ZZ) 1

14 RS113514 Rear End Plate 1

15 RS78715 Rotor 1

16 RS78716 Rotor Blade 5

17 RS78717 Pin (2.5 x 55) 1

18 RS78718 Cylinder 1

19 RS113519 Front End Plate 1

20 RS30524 Ball Bearing (608ZZ) 1

21 RS227B25 Ball Bearing (6001ZZ) 1

22 RS78722 Internal Gear 1

23 RS78723 Planet Gear 3

24 Pin (Incl. w/ #25) 4

25 RS78725A Cage Assembly w/Pins 1

26 RS181026 Lock Nut 1

27 RS29120 Ball Bearing (6200ZZ) 2

28 RS181028 Washer 1

29 RS181029 Oil Cap (3/16") 1

30 RS181030 Bevel Gear 1

31 RS181031 Angle Housing(Incl. #29) 1

32 RS181032 Spindle 1

33 RS181033 Wave Washer (WW-10) 1

34 RS113534 Bevel Gear 1

35 RS181035 Retaining Ring (ISTW-10) 1

36 RS181036 Key (3x8) 1

37 RS181037 Bushing 1

38 RS181038 Retaining Ring (RTW-28) 1

39 RS181039 3/8" Industrial 1

Keyed Chuck w/Key

40 RS24035 Screw (M5x25) 1

45 RS188031 Spring Pin (2x5L) 1

47 RS2871R47 O-Ring (15.8x2.4) 2

48 RS113548 Reversing Valve Knob 1

49 RS2871R49 O-Ring (31x1.5) 1

50 RS113550 Muffler Material 1

51 RS113551 Rear Cover 1

52 RS113552 Rubber Grip 1

Not Shown

RS181039K Chuck Key Only 1

PLEASE REVIEW ALL WARNING INSTRUCTIONS PRIOR TO OPERATION. SAVE THIS MAN U AL FOR FUTURE REF ER ENCE.

6-1135 4 Rev. 09/17/18

OPERATION

Locate center of new hole by using

a center punch. Place drill bit tip in

punch mark. Hold drill square with

work and start motor. Apply steady,

even pressure. Do not force. Too

much pressure can cause bit to break

or overheat. Too little pressure will

keep the bit from cutting and cause

it to overheat. Reduce pressure just

before bit cuts through the work.

When bit has penetrated work and is

spinning freely, take it from the work

while the motor is running, then turn

off the drill. If the drill jams in the

work, release throttle immediately.

Disconnect the drill before removing

bit and determining cause of trouble.

Do not attempt to free the bit by

starting and stopping the motor.

Specifications

Chuck Size .................3/8"

Free Speed ........... 1,400 RPM

Air Inlet ................1/4" NPT

Min. Hose Size ...........3/8" I.D.

Spindle Thread ...........3/8" -24

Avg. Air Cons. ............4 CFM

Sound Level ..............83 dbA

Net Wt. ................ 2.58 lbs.

Overall Length ..............8.46"

Recom.

Air Pressure ........90psig (6.2 bar)

Forward/Reverse

Air Inlet

WARRANTY

For a complete list of authorized air tool repair centers please visit www.toolwarrantyrepair.com.

Important: DO NOT RETURN

PRODUCT TO PLACE OF

PURCHASE.

WARRANTY POLICY: This NAPA

Professional Air Tool is warranted

against defects in material and

workmanship for a period of One (1)

Year from the date of original purchase. We will repair or replace, at

our option, any part which proves to

be defective in material or workmanship. Repairs or replacements are

warranted as described above for

the duration of the original warranty

period. This warranty does not apply

to products which have been subjected to abuse, misuse, modification,

neglect, lack of maintenance, use in a

production-related service, or repaired

by anyone other than an Authorized

Master NAPA Professional Air Tool

Service Center.

For complete listing of Authorized

Master Repair Centers, see enclosed

Customer Warranty Repair Form, or

visit www.toolwarrantyrepair.com

DOUBLE YOUR WARRANTY

By registering your tool at www.

propowerseries.com/support, NAPA

warrants to the original purchaser of

the tool to be free of defects in material and workmanship for an extended

ONE (1) YEAR from the end of the

original NAPA Air Tool Warranty, as

set forth above.

Tool registration must be completed

within Thirty (30) Days of tool purchase.

WARRANTY CLAIM PROCEDURE

If your NAPA Professional Air Tool

proves defective within its original One (1) Year (or Two (2) Year

extended) warranty period, it must

be returned to an Authorized Master

NAPA Professional Air Tool Service

Center. Customer is responsible for

shipping the tool Freight Pre-Paid

along with Proof of Purchase and

completed Customer Warranty Repair

Form.

PLEASE REVIEW ALL WARNING INSTRUCTIONS PRIOR TO OPERATION. SAVE THIS MAN U AL FOR FUTURE REF ER ENCE.

6-1135 5 Rev. 09/17/18

Loading...

Loading...