Carlyle 06CC User Manual

Installation

Instructions

06CC

Compound Cooling

Compressor

GENERAL

1. Inspect compressor for shipping damage and file claim

with shipping company if damaged or incomplete.

2. Check compressor nameplate for correct model and

voltage designation.

3. Before installation, review all Carlyle compressor application literature to assure yourself that the proper compressor has been selected and is being applied in a

proper manner. The required application literature is

available through Carlyle.

SAFETY INSTRUCTIONS

DANGER

Failure to follow these instructions will result in severe

personal injury or death.

ELECTRIC SHOCK HAZARD. Do not operate compressor or provide electric power to it unless the compressor

terminal box is installed and the terminal box cover is in

place and secured.

DO NOT provide power to unit or turn on compressor unless suction and discharge service valves are open.

DO NOT remove the compressor terminal box cover until

all electrical sources have been disconnected.

DO NOT USE oxygen or other industrial gases for tightness/pressure testing. Use nitrogen or inert gas.

WARNING

Failure to follow these instructions may result in serious

injury or death.

CONTENTS UNDER PRESSURE. Compressor contains oil and refrigerant under pressure. Pressure must

be relieved before installation, servicing or opening any

connections.

HOT and COLD surface temperatures can occur during

operation and can result in severe burns or frostbite.

USE ONLY approved refrigerants and refrigeration oils.

NEVER EXCEED specified test pressures. System

strength/tightness test pressure may not exceed the

compressor maximum Test pressure on the Nameplate.

Close shutoff valves to isolate compressor if necessary.

CHECK THE REFRIGERANT TYPE. Charge only with

refrigerant that conforms to AHRI Standard 700.

Only qualified, authorized, and appropriately trained HVAC

or refrigeration personnel, should install, commission, and

maintain this equipment.

Use appropriate personal safety equipment where required.

Safety goggles, gloves, protective clothing, safety boots, and

hard hats should be worn where necessary.

OPERATING LIMITS: Refer To Application

Guide

GENERAL INSTALLATION PROCEDURES

Holding Charge

Compressor is factory supplied with a 7 to 20 lb (0.5 to

1.4 bar) charge of dry air or nitrogen. This internal pressure

must be relieved before attempting to remove any compressor fitting or part.

Relieve holding charge by removing the cap on the interstage connection fitting and depressing the internal disc.

See Fig. 1A for applicable interstage pressure connection fitting location.

Service Valves

Remove valve pads and attach factory-supplied suction and

discharge gaskets and service valves to the compressor.

Torque 5/16-in. -18 mounting bolts 20 to 25 lb-ft (27 to

34 Nm) and 1/2-in. -13 mounting bolts 80 to 90 lb-ft (109 to

122 Nm). When brazing piping to valve, wrap the valve in a

wet cloth to prevent heat damage.

Oil

1. Check to see that oil level is 1/4 to 3/4 of the way up on

compressor sight glass before starting and after 15 to

20 minutes of operation. Compressors may be shipped

with or without an oil charge based on model. All compressors must contain the specified oil charge prior to

start-up as a condition of warranty.

2. To add oil: Relieve internal crankcase pressure, isolate

crankcase, and add oil through the oil fill connection

(see Fig. 1A and 1B). To remove excess oil: Reduce internal crankcase pressure to 2 psig (1.15 bar), isolate

crankcase, then loosen the oil drain plug allowing oil to

seep out past the threads of the plug.

CAUTION

With the compressor crankcase under slight pressure, do

not remove the oil drain plug as the entire oil charge

could be lost. Do not reuse drained oil or oil that has

been exposed to the atmosphere.

CAUTION

Do not charge oil through the suction line or through the

compressor suction access fittings. See Fig. 1A for the

recommended oil charging port. Adding oil into the suction side of the compressor can cause damage to the

suction/discharge valves, pistons, and/or connecting

rods.

3. When additional oil or a complete oil change is required, use only the listed Carlyle approved oils.

Manufacturer Brand Name

Totaline 150

Witco Suniso 3GS

IGI Petroleum Ind. Cryol-150

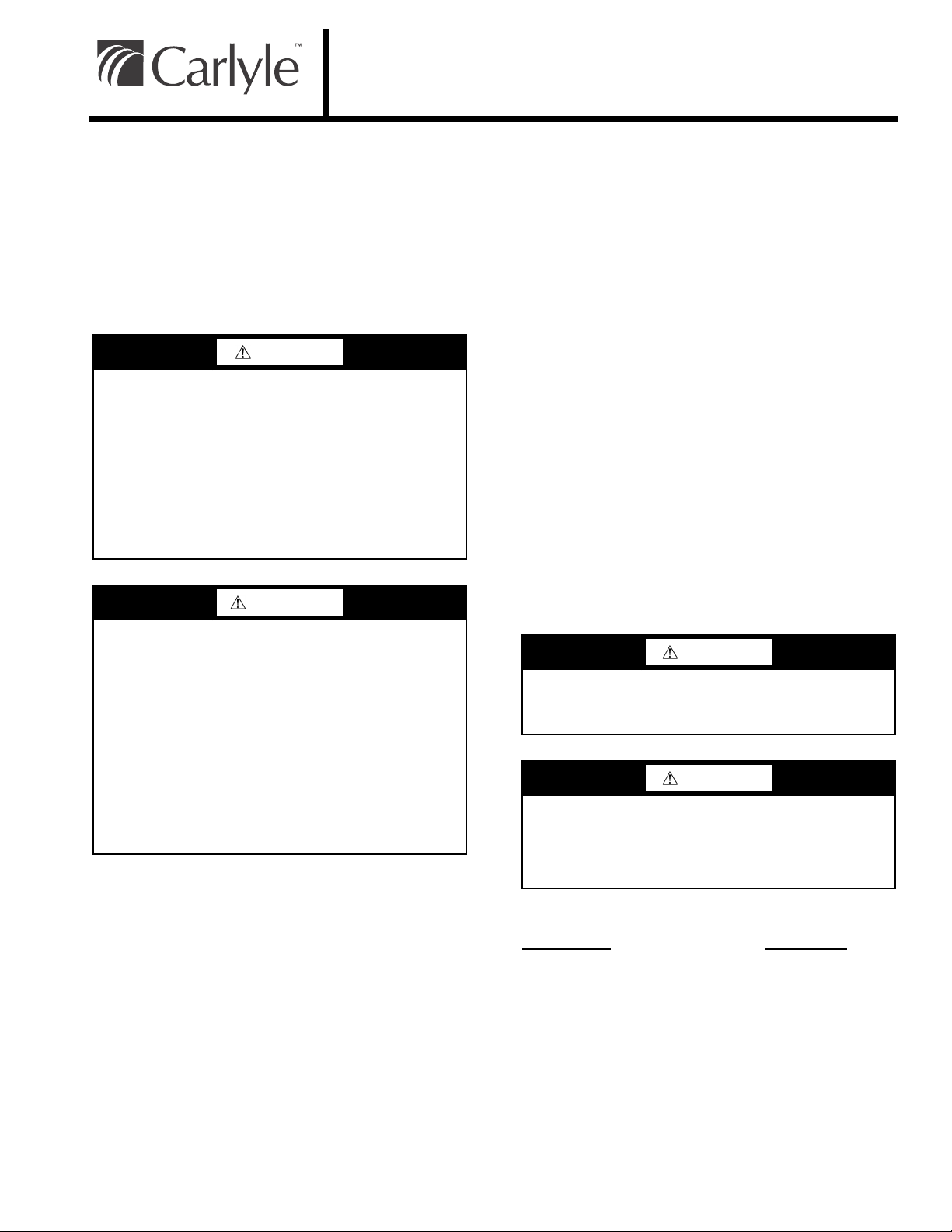

CONNECTION FROM

SUBCOOLING HEAT

EXCHANGER

1/4”-NPT LOW STAGE

PRESSURE TAP (NOT SHOWN)

*BOTTOM OF CYLINDER HEAD HAS A BOSS

AND 1/4” NPT JUST LIKE THE TOP.

INTERSTAGE

MANIFOLD

1/2-13 UNC —

LIFTING LUG CONNECTION

(LUG NOT SUPPLIED WITH COMPRESSOR)

1/4” NPT OIL FILL (SUMP)

CONNECTION. ALSO LOW

SIDE OIL SAFETY

SWITCH CONNECTION

1/4-NPT INTERSTAGE

PRESSURE TAP

(INCLUDES SCHRADER

FITTING TO RELIEVE

CRANKCASE PRESSURE)

Fig. 1A — 06CC Compressor, Front View

SUCTION VALVE

LOCATION

1/4” NPT HIGH SIDE

OIL SAFETY SWITCH

CONNECTION

SUCTION MANIFOLD

(TO LOW STAGE

CYLINDERS)

7/16”-20 SAE OIL DRAIN

CONNECTION ADAPTER

PART NO. DE14CA126

Fig. 2 — 5-Pin Plate Assembly

1/4 NPT HIGH STAGE PRESSURE TAP

CYLINDER HEAD

SENSOR (HIGH STAGE

DISCHARGE TEMP.)

(NOT SHOWN)

DISCHARGE

SERVICE

VALVE

HIGH SIDE

CYLINDER

HEAD

OIL LEVEL

SIGHTGLASS

CRANKCASE HEATER (ACCESSORY)

INSERTS INTO HOLE IN BOTTOM COVER

TERMINAL BOX

HIGH STAGE

INLET

NAMEPLATE

DESUPERHEATER

INJECTION LOCATION

Fig. 1B — 06CC Compressor, Rear View

ELECTRICAL

General

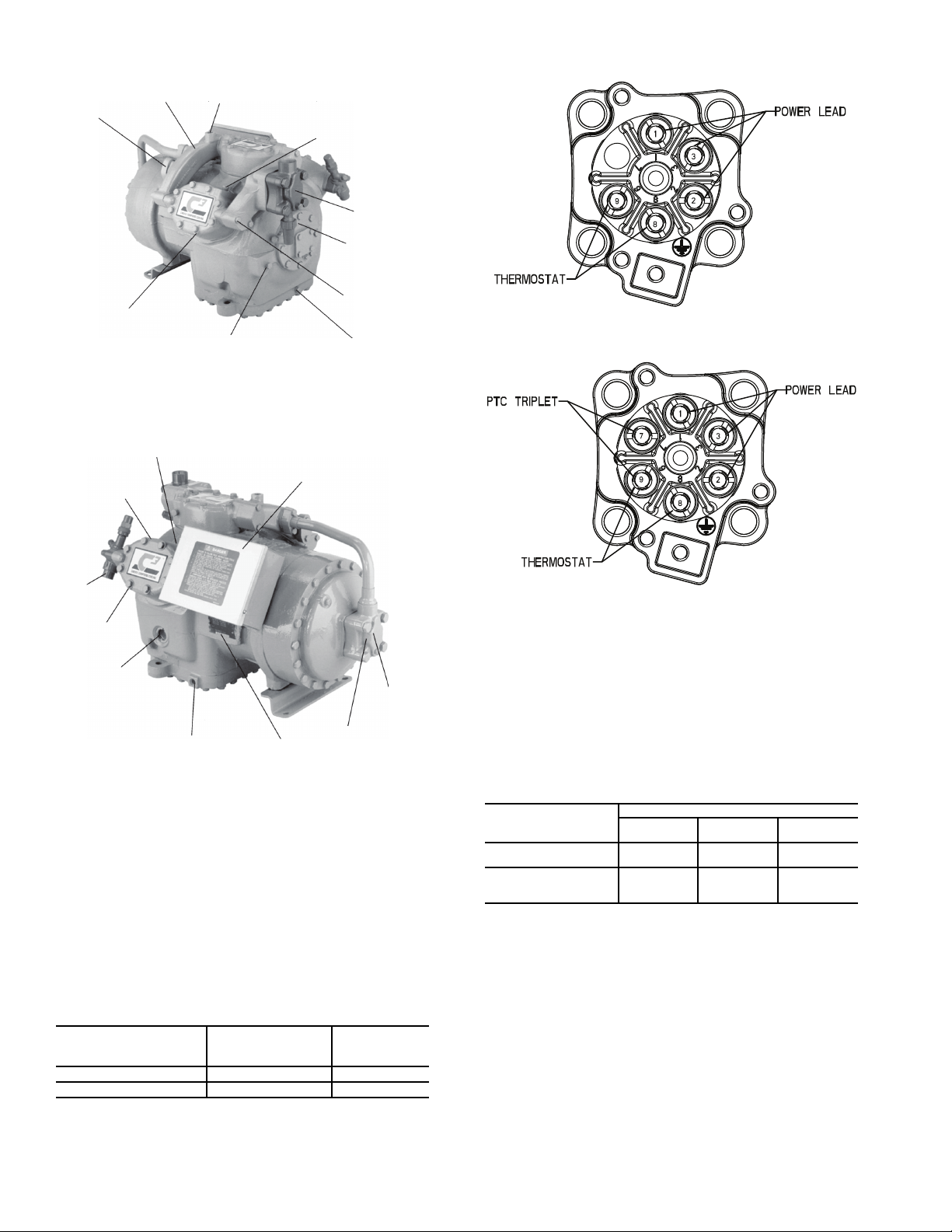

Consult the wiring diagram located inside the compressor

terminal box cover and the diagrams shown below associated with the correct terminal plate and overloads for proper

wiring connections.

The compressor will have one of 2 terminal plate configurations: either a 5-pin assembly or a 6-pin assembly. Refer to

Fig. 2 and 3 for details on each arrangement. To determine

which terminal plate arrangement is used, refer to digit 5 of

the nameplate model number and Table 1.

Table 1 — Terminal Plate Arrangement

Identification

PTC — Positive Temperature Coefficient Thermistor

Fig. 3 — 6-Pin Plate Assembly,

Universal Compressors

Each terminal plate assembly may be utilized with or without

overloads. For compressors without overloads, please be

sure adequate protection is supplied for all 3 phases of the

motor in the form of a circuit breaker or similar system. For

compressors with overloads, please refer to Table 2 and

referenced figures to ensure proper connection with the applicable overload system on the compressor.

Table 2 — Overload Systems

TERMINAL PLATE

ARRANGEMENT

5-Pin (Fig. 2)

0, 1, 2 or 3 in Digit 5

6-Pin (Fig. 3)

Any letter A through M

in Digit 5

OVERLOAD SYSTEM OPTIONS

Hybrid

Service

Hybrid

Legacy

Bi-Metal

No Yes (Fig. 6) Yes (Fig. 7)

Yes (Fig. 4) Yes (Fig. 6) Yes (Fig. 7)

DIGIT 5 OF

NAMEPLATE MODEL

NUMBER

TERMINAL

PLATE

ARRANGEMENT

0, 1, 2, or 3 5-Pin 2

Letters A through M 6-Pin Universal 3

FIGURE

2

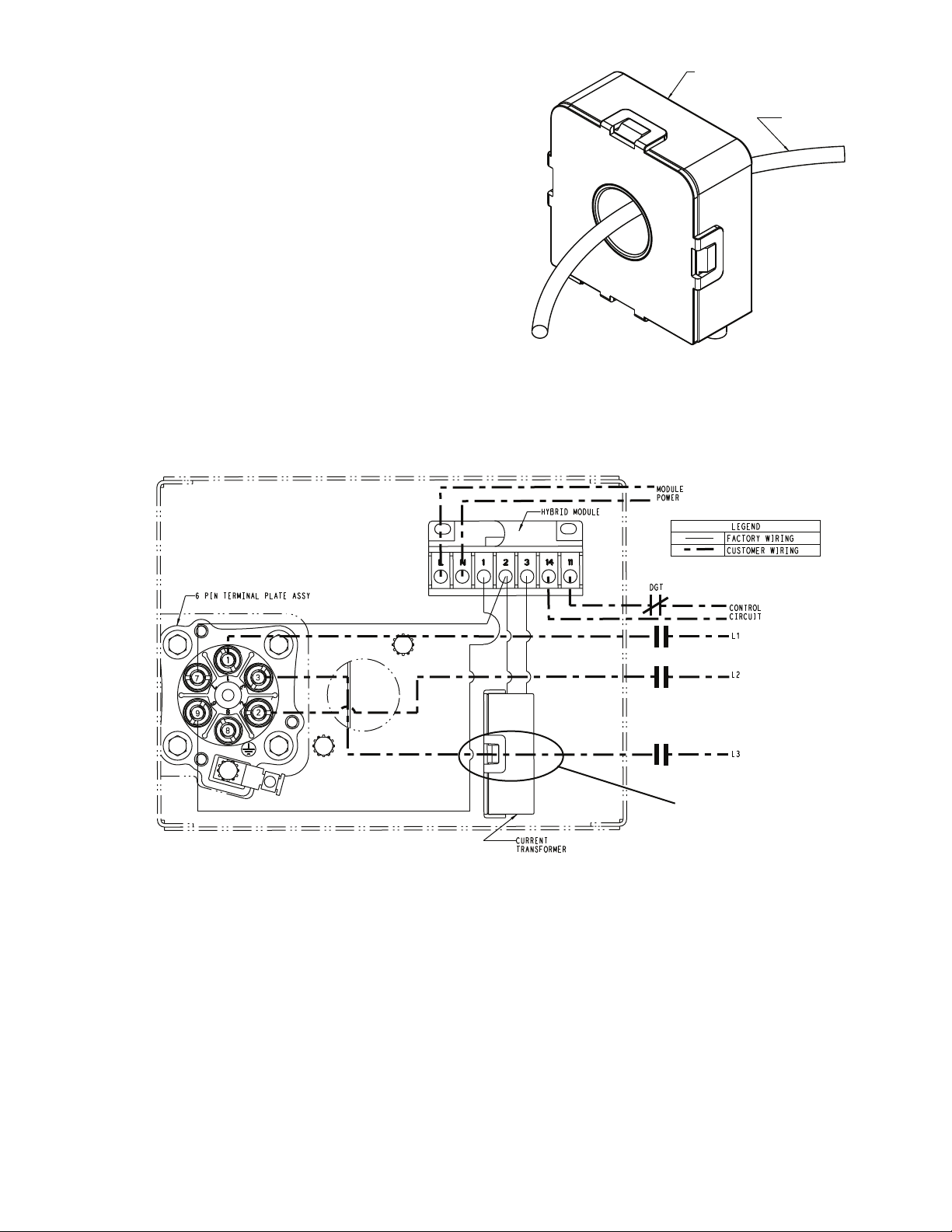

Hybrid Overload Wiring — 6-Pin Plate Assembly for Universal Compressors

1. Connect one of the 2 control circuit leads to connection

14 located on top of the module. Connect the other

control circuit lead to connection 11 located on top of

the module. Use a fork terminal or stripped and tinned

wire to prevent fraying. See Fig. 4. Torque module connections to 12 lb-in. (1.35 Nm) maximum. Be sure to

connect the discharge gas temperature (DGT) sensor

leads in line with the control circuit connections. See

Overtemperature Protection section for details.

2. Determine module power supply voltage by referring to

the 6th digit in the part number located on the left side

of module (06DANB****). The supply voltages are 115/

230 vac and 24 vac and correlate to digits B and C respectively. Connect two module power leads to module

connections L and N using a fork terminal or stripped

and tinned wire to prevent fraying. Refer to module

front label for further power supply requirements.

Torque module connections to 12 lb-in. (1.35 Nm)

maximum.

3. Route one power lead (L3) through the current transformer (CT) as shown in Fig. 4. See detail in Fig. 5.

4. Once power lead L3 is routed through the CT, make

terminal plate connections as shown in Fig. 4. Refer to

Terminal Plate Wiring section for connection details.

CT

CUSTOMER WIRING

ROUTED THROUGH

THE CT

Fig. 5 — Routing Power Lead through Current

Transformer (CT)

Fig. 4 — Hybrid Overload Wiring

3

SEE DETAIL

IN FIG. 5

Loading...

Loading...