APL 100

Operating Manual

Copyright by Carl Valentin GmbH / 7952505A11.13

Information on the scope of delivery, appearance, performance,

dimensions and weight reflect our knowledge at the time of printing.

We reserve the rights to make modifications.

All rights, including those regarding the translation, are reserved.

No part of this document may be reproduced in any form (print,

photocopy or any other method) or edited, copied or distributed

electronically without written permission from Carl Valentin GmbH.

Due to the constant further development of our devices discrepancies

between manual and device can occur.

Please check www.carl-valentin.de for the latest update.

Trademarks

Centronics

®

is a registered trademark of Data Computer Corporation.

Microsoft

®

is a registered trademark of Microsoft Corporation.

Windows 2000

®

, 2003®, XP®, Vista®, 7®, 8®, Windows ServerTM 2008,

Windows Server

TM

2008 R2, Windows ServerTM 2012 are registered

trademarks of Microsoft Corporation.

TrueType

TM

is a trademark of Apple Computer, Inc.

Zebra

®

and ZPL II® are registered trademarks of ZIH Corporation.

The pneumatic applicator complies with the following safety

guidelines:

CE

EG Low-Voltage Directive (2006/95/EC)

EG Electromagnetic Compatibility Directive (2004/108/EG)

EG Machinery Directive (2006/42/EG)

Carl Valentin GmbH

Postfach 3744

78026 Villingen-Schwenningen

Neckarstraße 78 – 86 u. 94

78056 Villingen-Schwenningen

Phone

Fax

+49 (0)7720 9712-0

+49 (0) )7720 9712-9901

E-Mail

Internet

info@carl-valentin.de

www.carl-valentin.de

Applicator APL 100 Table of contents

11/13 Operating Manual 3

Table of Contents

Table of Contents ............................................................................. 3

1 Introduction ............................................................................ 5

1.1 General Instructions ................................................................ 5

1.2 Intended Use ........................................................................... 5

1.3 Environmentally-Friendly Disposal .......................................... 6

2 Safety Instructions ................................................................ 7

2.1 Safety Marking ......................................................................... 8

2.2 Operating Conditions ............................................................... 9

3 Product Description ............................................................ 13

3.1 Important Characteristics ...................................................... 14

3.2 Technical Data ....................................................................... 14

3.3 Device Overview .................................................................... 15

3.4 Pads ...................................................................................... 17

4 Installation ............................................................................ 19

4.1 Scope of Delivery .................................................................. 19

4.2 Mounting the Applicator to the Printer ................................... 20

4.3 Piercing the Universal Tamp Pad .......................................... 21

4.4 Preparing for Using a Sprint-Mounted Tamp Pad ................. 22

4.5 Mounting the Pad .................................................................. 23

4.6 Mounting the Stopper ............................................................ 24

4.7 Connections ........................................................................... 25

5 Configuration ....................................................................... 27

5.1 Configuration Parameter ....................................................... 27

5.2 Settings in printer function menu ...... Fehler! Textmarke nicht

definiert.

6 Signal Diagrams .................................................................. 32

6.1 Print - Apply ........................................................................... 32

6.2 Apply - Print ........................................................................... 32

7 Mechanical Adjustments .................................................... 33

7.1 Aligning the pad ..................................................................... 33

7.2 Adjusting the Parallelism between Pad and Dispense Edge 34

7.3 Opening the Holes on the Blow Tube .................................... 35

7.4 Aligning the Blow Tube .......................................................... 36

7.5 Adjusting the Stopper ............................................................ 37

8 Pneumatic Adjustments ..................................................... 39

8.1 Control Valves ....................................................................... 39

8.2 Adjusting the Pad Movement Speed ..................................... 41

8.3 Adjusting Vacuum and Supporting Air................................... 42

9 Operation .............................................................................. 43

9.1 Loading the Label Material .................................................... 43

9.2 Setting the Dispenser Mode .................................................. 44

9.3 Test Mode .............................................................................. 45

9.4 Standard Operation ............................................................... 47

10 Applicator Interface ............................................................. 49

10.1 Pin Assignment ...................................................................... 49

10.2 Internal Circuit of Outputs ...................................................... 49

10.3 Signal Assignment D-Sub 15 pin ........................................... 50

Table of Contents Applicator APL 100

4 Operating Manual 11/13

11

Error Messages .................................................................... 51

11.1 Error Messages of the Printer ............................................... 51

11.2 Error Messages of the Applicator .......................................... 51

12 Declaration ........................................................................... 53

12.1 Extended Declaration ............................................................ 53

12.2 EC-Declaration of Conformity ................................................ 54

13 Index ..................................................................................... 55

Applicator APL 100 Introduction

11/13 Operating Manual 5

1 Introduction

1.1 General Instructions

Important information and instructions in this document are

designated as follows:

DANGER identifies an extraordinarily great and immediate

danger which could lead to serious injury or even death.

WARNING identifies a possible danger would could lead

to serious bodily injury or even death if sufficient

precautions are not taken.

CAUTION indicates a potentially dangerous situation

which could lead to moderate or light bodily injury or

damage to property.

NOTICE gives you tips. They make a working sequence

easier or draw attention to important working processes.

Gives you tips on protecting the environment.

Handling instruction

Optional accessories, special fittings

Time

Information in the display

1.2 Intended Use

The device is a state-of-the-art device which complies with the

recognized safety-related rules and regulations. Despite this, a

danger to life and limb of the user or third parties could arise and

the device or other property could be damaged while operating

the device.

The device may only be used while in proper working order and

for the intended purpose. Users must be safe, aware of potential

dangers and must comply with the operating instructions. Faults,

in particular those which affect safety, must be remedied

immediately.

The applicator mounted on a label printer of the Compa II series is

intended to print suitable media which have been approved by the

manufacturer. Any other or additional use is not intended. The

manufacturer/supplier is not liable for damage resulting from

misuse. Any misuse is at your own risk.

Intended used includes heeding the operating manual, including

the maintenance recommendations/regulations specified by the

manufacturer.

NOTICE!

The complete documentation is included in the scope of

delivery on CD ROM and can also currently be found in the

internet.

Introduction Applicator APL 100

6 Operating Manual 11/13

1.3 Environmentally-Friendly Disposal

Manufacturers of B2B equipments are obliged to take-back and

dispose old equipment which was manufactured after 13 August 2005.

In principle, these old equipments may not be delivered to communal

collecting points. They may only be organised used and disposed by

the manufacturer. Valentin products accordingly labelled can therefore

in future be returned to Carl Valentin GmbH.

Thereupon old equipment is professionally disposed.

Thereby Carl Valentin GmbH observes all obligations in the context of

old equipment disposal in time and makes therewith the smooth

selling of products furthermore possible. Please understand that we

can only take-back equipment that is send free of carriage charges.

Further information on the WEEE directive is available on our website

www.carl-valentin.de.

Applicator APL 100 Safety Instructions

11/13 Operating Manual 7

2 Safety Instructions

Before mounting the delivered components disconnect the printer

from the power supply and close the shutoff valve at the

applicator.

Only connect the device to other devices which have a protective

low voltage.

Switch off all affected devices (computer, printer, accessories)

before connecting or disconnecting.

In operation, moving parts are easily accessible. This applies

especially for the zone, where the pad is moved between the

starting and the labelling position. During operation do not reach

into that zone and keep long hair, loose clothes, and jewellery

distant.

Before any manipulations in those areas, close the shutoff valve.

The device may only be used in a dry environment, do not expose

it to moisture (sprays of water, mists, etc.).

Do not use the device in an explosive atmosphere.

Do not use the device close to high-voltage power lines.

Operate the direct print module only in an environment protected

against abrasive dust, swarf and other similar impurity.

NOTICE!

With the open printing unit (due to construction) the requirements

of EN60950-1 regarding fire protection casing are not fulfilled.

These must be ensured by the installation into the end device.

Carry out only the actions described in these operating

instructions. Any work beyond this may only be performed by the

manufacturer or upon agreement with the manufacturer.

Unauthorized interference with electronic modules or their

software can cause malfunctions.

Other unauthorized work on or modifications to the device can

also endanger operational safety.

Always have service work done in a qualified workshop, where the

personnel have the technical knowledge and tools required to do

the necessary work.

There are warning stickers on the direct print modules that draw

your attention to dangers. Therefore the warning stickers are not

to be removed as then you and others cannot be aware of

dangers and may be injured.

When incorporating the unit into the overall system, make sure

that safety precautions are taken so that no-one is able to reach

into the working area.

The direct print module must be integrated with the Emergency

Stop circuit when it is incorporated into the overall machine.

Before starting the machine, all protective guards must be fitted.

Safety Instructions Applicator APL 100

8 Operating Manual 11/13

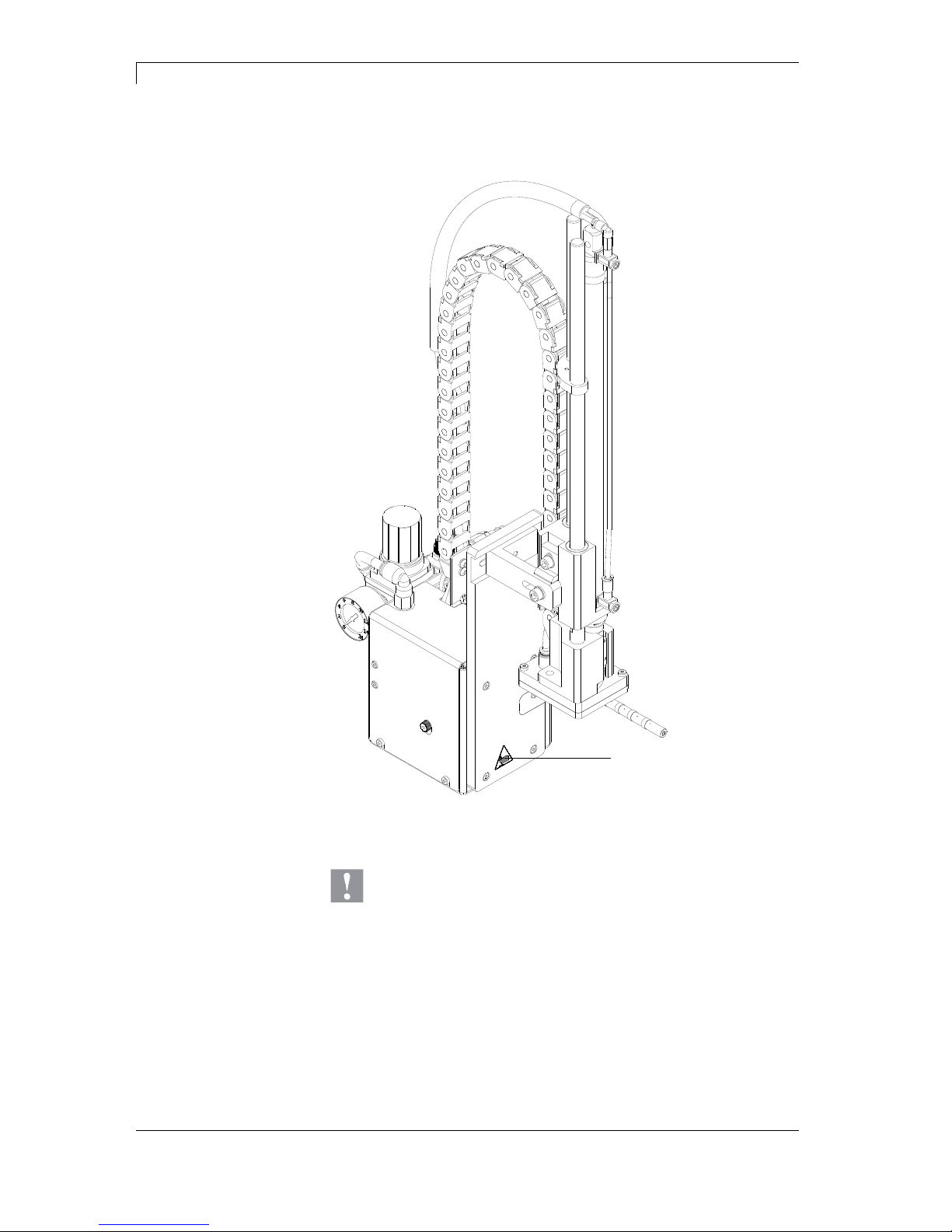

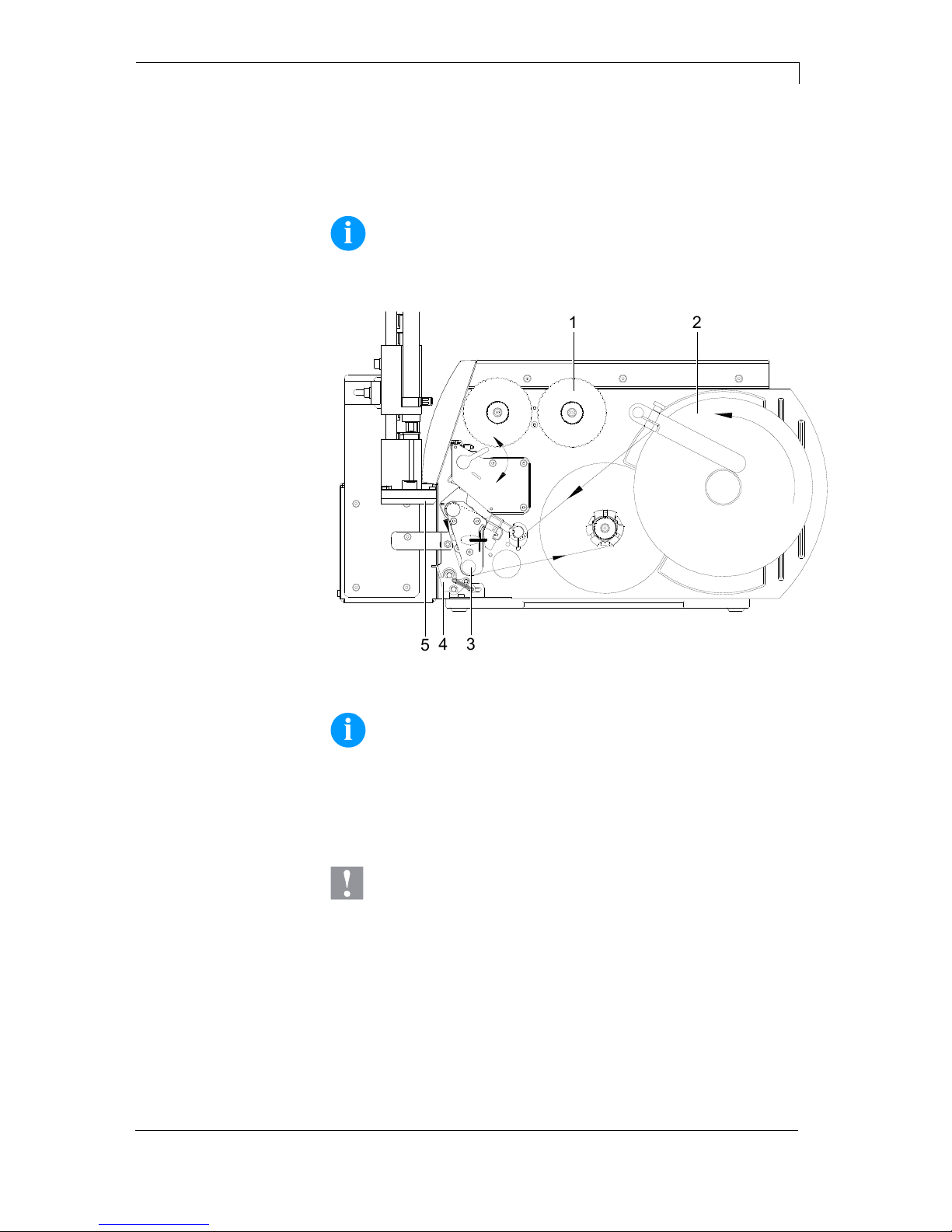

2.1 Safety Marking

1

Figure 1

CAUTION!

There is a risk of injury due to the movement of the pad

downwards and back up again.

Do not reach into the working area of the pad.

Keep hair, loose clothing and items of jewellery out of

this area.

When incorporating the unit into the overall system,

safety precautions must be taken so that no-one is

able to reach into the working area.

1 = Risk of crushing due to

1 = the movement of the pad

Applicator APL 100 Safety Instructions

11/13 Operating Manual 9

2.2 Operating Conditions

Before initial operation and during operation these operating

conditions have to be observed to guarantee save and interferencefree service of our printers.

Therefore please carefully read these operating conditions.

Shipment and storage of our printers are only allowed in original

packing.

Installation and initial operation of printer is only allowed if operating

conditions were fulfilled.

Commissioning is prohibited until it can be established that, where

relevant, the machine into which the partly completed machinery is to

be incorporated complies with the provisions of Machinery Directive

2006/42/EC.

Initial operation, programming, operation, cleaning and service of our

printers are only recommended after careful study of our manuals.

Operation of printer is only allowed by especially trained persons.

NOTICE!

Perform trainings regularly.

These indications are also valid for someone else's equipment

supplied by us.

Only use original spare and exchange parts.

CPU of printer is equipped with a lithium battery (type CR 2032) for

which the battery regulation is to apply. This regulation plans that

unloaded batteries have to be given to used battery collecting

containers of trade and public carries. In case that batteries were not

completely discharged you have to make arrangements for shortcircuits. At a shutdown of printer the battery has to be disposed in

either case separately from printer.

DANGER!

Danger of life by explosion!

Use non-conducting tools.

The installation place of printer should be even, free of vibration and

currents of air are to be avoided.

The printers have to be installed to ensure optimal operation and

servicing.

Instructions for

lithium battery

Conditions for

installation place

Safety Instructions Applicator APL 100

10 Operating Manual 11/13

The installation of the power supply to connect our printers has to be

effected according to the international rules and regulations,

especially the recommendations of one of the three following

commissions:

International Electronic Commission (IEC)

European Committee for Electro technical Standardisation

(CENELEC)

Verband Deutscher Elektrotechniker (VDE)

Our printers are constructed according to VDE and have to be

connected to a grounded conductor. The power supply has to be

equipped with a grounded conductor to eliminate internal interfering

voltage.

Power line voltage and power line frequency: See type plate

Allowable tolerance of power line voltage:

+6% to −10% of nominal value

Allowable tolerance of power line frequency:

+2% to −2% of nominal value

Allowable distortion factor of power line voltage: <=5%

In case your net is infected (e.g. by using thyristor controlled

machines) anti-interference measures have to be taken. You can use

one of the following possibilities:

Provide separate power supply to our printers.

In case of problems please connect capacity-decoupled isolation

transformer or similar interference suppressor in front of our

printers.

Emitted interference according to EN 61000-6-3: 2007

industrial sector

Interference voltage to wires according to EN 55022: 09-2003

Interference field power according to EN 55022: 09-2003

System perturbation according to EN 61000-3-2: 09-2006

Flicker according to EN 61000-3-3: 1955 + A1:2001 + A2:2005

Installation of

power supply

Technical data of

power supply

Anti-interference

measures

Stray radiation and

immunity from

disturbance

Applicator APL 100 Safety Instructions

11/13 Operating Manual 11

Immunity to interference according to EN 61000-6-2: 2005

industrial sector

Stray radiation against discharge of static electricity according to

EN 61000-4-2: 12-2001

Electromagnetic fields according to EN 61000-4-3: 11-2003,

ENV 50204: 03-1995

Fast transient burst according to EN 61000-4-4: 07-2005

High-frequency tension according to EN 61000-4-6: 12-2001

NOTICE!

This is a machine of type A. This machine can cause

interferences in residential areas; in this case it can be required

from operator to accomplish appropriate measures and be

responsible for it.

EN 415-2 - Safety of packaging machines

EN 60204-1:2006 - Safety of machinery – Electrical equipment of

machines – Part 1

All connecting lines have to be guided in shielded lines. Shielding has

to be connected on both sides to the corner shell.

It is not allowed to guide lines parallel to power lines. If a parallel

guiding cannot be avoided a distance of at least 0.5 m has to be

observed.

Temperature of lines between: −15 to +80 °C.

It is only allowed to connect devices which fulfil the request 'Safety

Extra Low Voltage' (SELV). These are generally devices which are

checked corresponding to EN 60950.

The data cables must be completely protected and provide with metal

or metallised connector housings. Shielded cables and connectors are

necessary, in order to avoid radiant emittance and receipt of electrical

disturbances.

Allowable lines

Shielded line:

4 x 2 x 0,14 mm² ( 4 x 2 x AWG 26)

6 x 2 x 0,14 mm² ( 6 x 2 x AWG 26)

12 x 2 x 0,14 mm² (12 x 2 x AWG 26)

Sending and receiving lines have to be twisted in pairs.

Maximum line length:

with interface V 24 (RS-232C) - 3 m (with shielding)

with Centronics - 3 m (with shielding)

USB - 5 m

Ethernet - 100 m

Stray radiation and

immunity from

disturbance

Machine safety

Connecting lines to

external machines

Installation of

data lines

Safety Instructions Applicator APL 100

12 Operating Manual 11/13

To avoid inadmissible heating, free air convection has to be ensured.

Protection according IP: 20

Ambient temperature °C (operation): Min. +5 Max. +35

Ambient temperature °C (storage): Min. −25 Max. +60

Relative air humidity % (operation): Max. 80

Relative air humidity % (storage): Max. 80

(bedewing of printers not allowed)

We do not take any responsibility for damage caused by:

Ignoring our operating conditions and operating manual.

Incorrect electric installation of environment.

Building alterations of our printers.

Incorrect programming and operation.

Not performed data protection.

Using of not original spare parts and accessories.

Natural wear and tear.

When (re)installing or programming our printers please control the

new settings by test running and test printing. Herewith you avoid

faulty results, reports and evaluation.

Only specially trained staff is allowed to operate the printers.

Control the correct handling of our products and repeat training.

We do not guarantee that all features described in this manual exist in

all models. Caused by our efforts to continue further development and

improvement, technical data might change without notice.

By further developments or regulations of the country illustrations and

examples shown in the manual can be different from the delivered

model.

Please pay attention to the information about admissible print media

and the notes to the printer maintenance, in order to avoid damages

or premature wear.

We endeavoured to write this manual in an understandable form to

give and you as much as possible information. If you have any queries

or if you discover errors, please inform us to give us the possibility to

correct and improve our manual.

Air convection

Limit values

Guarantee

APL 100 Series Product Description

11/13 Operating Manual 13

3 Product Description

The applicator APL 100 is an optional device to use with label printers

of the Compa or Compa II series for automatically applying the printed

label onto the product. The labels are transferred with a pad, which

moves between the two positions, starting position and labelling

position, by a compressed-air driven pneumatic cylinder.

In the starting position, the label is picked up from the printer.

A sensor at the cylinder signals when the pad is in the starting

position.

The label is removed from the carrier ribbon directly at the

dispense edge of the printer. It is sucked on the pad by a vacuum

via drillings at the bottom of the pad.

For support, the label is also blown against the pad (supporting

air) with an air current coming from a blow tube.

The correct transfer of the label is controlled by a vacuum sensor.

Next, the pad is moved down into the labelling position. Reaching

the labelling position is confirmed by another sensor (labelling

position sensor).

In the labelling position the label is transferred onto the product.

While the pad is moving back into the starting position, the

vacuum sensor checks whether the label has been removed from

the pad.

The label can be applied with three different methods:

Stamp on

The label is pressed directly onto the product.

Blow on

The pad moves to a pre-adjusted position approximately 10 mm away

from the product. The label is blown onto the product by an air stream.

Roll on

In the starting position the label is forwarded until touching the roller of

the roll on pad. At the labelling position the roller is pressed onto the

product. Then the label is applied and rolled on by the movement of

the product.

Application

of the label

Product Description Applicator APL 100

14 Operating Manual 11/13

3.1 Important Characteristics

The supporting air and the vacuum as well as the speed of the

cylinder are adjustable. That way the applicator can be adapted to

different label materials and sizes.

The pressure for the cylinder movement is reduced in relation to

the operating pressure of the entire labelling machine so that the

danger of injury is reduced as much as possible.

To avoid contamination within the vacuum channels they are

cleaned by air pressure impulse at the end of each application.

For integration into a superordinated process the printers are

equipped with 'Dispenser I/O'.

3.2 Technical Data

Label transfer method Stamp on Blow on Roll on

Labe width (mm) 25 - 176 25 - 176 25 - 176

Label height (mm) 25 - 200 25 - 100 80 - 200

Cylinder stroke (mm) 300 300 300

Pad stroke below printer (mm) 180 180 180

Compressed air pressure 5 bar 5 bar 5 bar

Product surface flat flat flat

Product height variable

Product height fixed

Product fixed

Product linear movement

Applicator APL 100 Product Description

11/13 Operating Manual 15

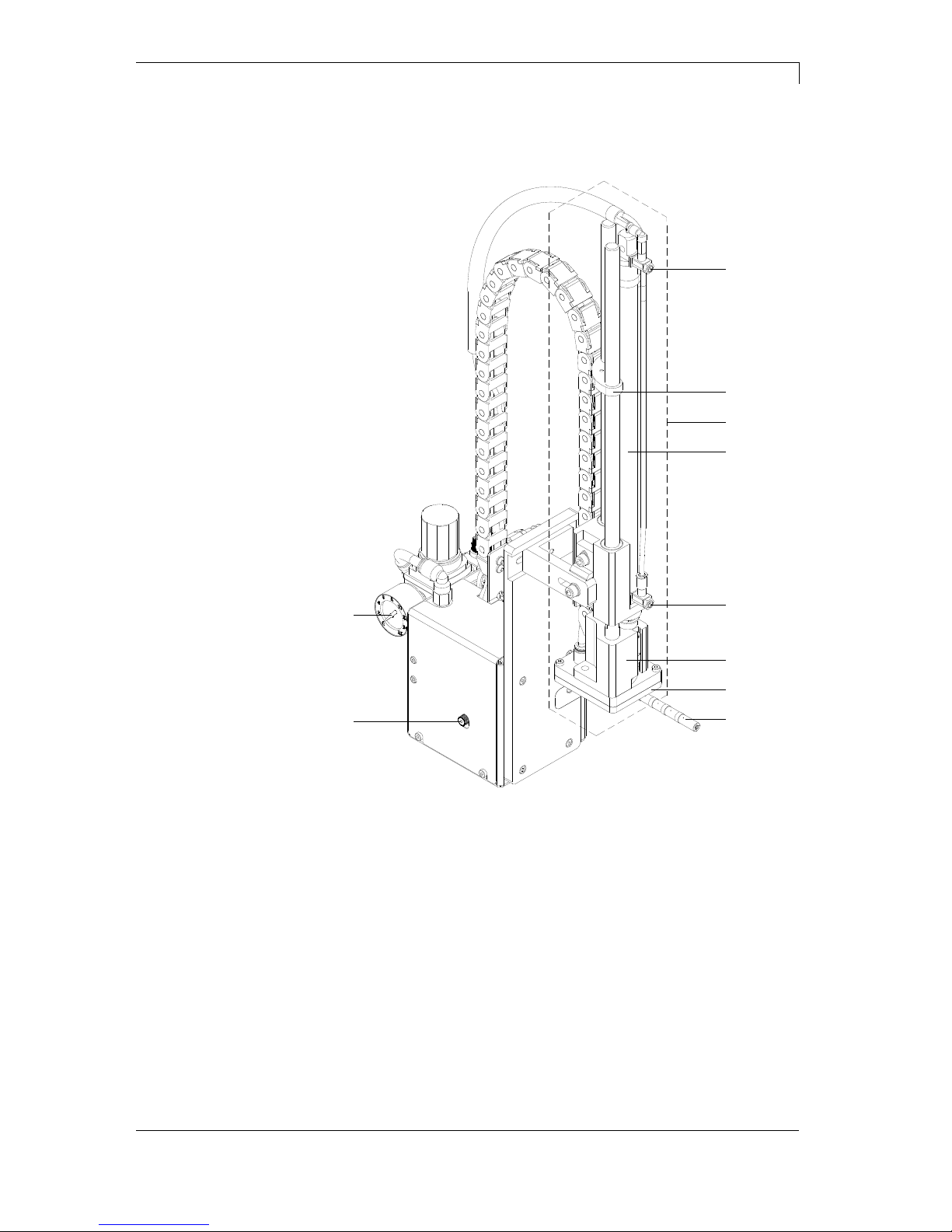

3.3 Device Overview

1

2

3

4

5

6

7

8

10

9

Figure 2

11 = Upper cylinder throttle valve

02 = Stopper for the operation mode 'Blow on'

03 = Cylinder unit

04 = Pneumatic cylinder

05 = Lower cylinder throttle valve

06 = Pad holder

07 = Pad (application specific)

08 = Blow tube for supporting air

09 = Knurled screw for attaching the applicator to the printer

10 = Main pressure manometer

Front view

Product Description Applicator APL 100

16 Operating Manual 11/13

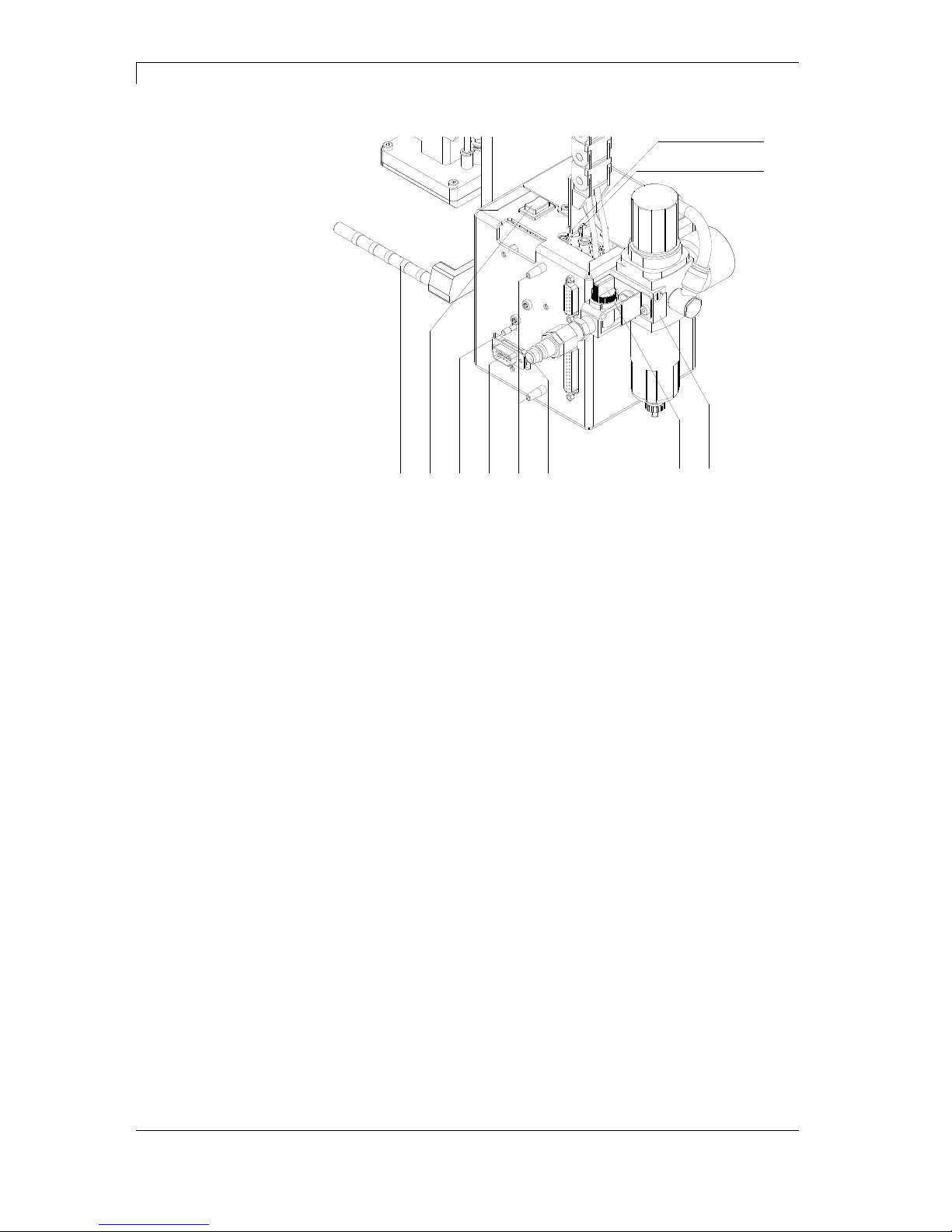

1

2

34

5678910

Figure 3

11 = Supporting air throttle valve

02 = Vacuum throttle valve

03 = Service unit

04 = Shutoff valve

05 = Compressed air connector

06 = Pins

07 = Interface to the printer

08 = Knurled screw for attaching the applicator to the printer

09 = Pre-dispense key

10 = Blow tube for supporting air

Rear view

Applicator APL 100 Product Description

11/13 Operating Manual 17

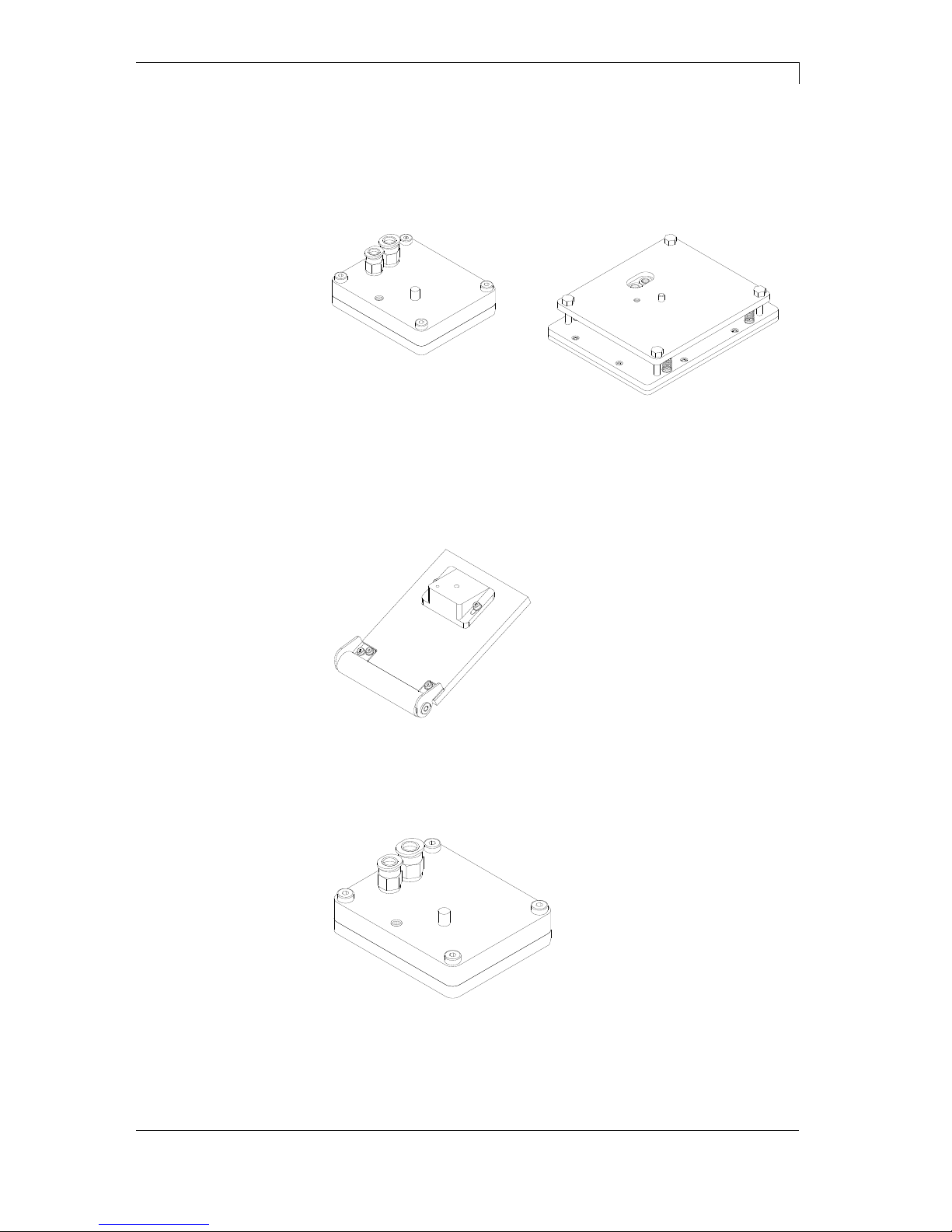

3.4 Pads

Universal tamp pad Universal tamp pad

Standard sizes:

70 x 60 mm and 90 x 90 mm

Standard sizes:

116 x 102 mm and 116 x 152 mm

Figure 4 Figure 5

Universal tamp are available in different standard sizes. According to

the size of the label the holes may be pierced by the customer. For

that purpose a piercing pin is included in the delivery contents.

On request, tamp pads customized to the label sized are delivered.

Figure 6

Roll-on pads are only produced on request customized to the label

size.

Figure 7

Blow pads are only produced on request customized to the label size.

Tamp pads

Roll-on pads

Blow pads

Applicator APL 100 Installation

11/13 Operating Manual 19

4 Installation

4.1 Scope of Delivery

NOTICE!

Please keep the original packaging in case the applicator must

be returned.

1234

Figure 8

1 = Applicator with cylinder

2 = Pad (according to command)

3 = Cylinder screw (part of the pad)

4 = Piercing pin (at universal tamp pads only)

CAUTION!

The label printer and the applicator can be damaged by

moisture and water.

Set up the label printer with applicator only in dry locations

protected from splash water.

Installation Applicator APL 100

20 Operating Manual 11/13

4.2 Mounting the Applicator to the Printer

CAUTION!

Danger of injury by inadvertent move out of the cylinder.

Disconnect the printer from the power supply before

mounting the applicator.

Connect the compressed air only after mounting the

applicator to the printer.

12 34

Figure 9

1. Insert the pins (6, Figure 3) on the back of the applicator (2) into

the holes (3) of the printer.

2. Press the applicator against the printer. That way the plug of the

applicator will be connected to the peripheral port (4) of the

printer.

3. Fix the applicator (2) with the screw (1).

CAUTION!

Malfunctions by inadequate operational surface space.

Ensure a stable standing of the printer.

Applicator APL 100 Installation

11/13 Operating Manual 21

4.3 Piercing the Universal Tamp Pad

On the bottom of the pads there are holes for sucking and holding the

labels by vacuum. When an universal tamp pad is delivered these

holes are covered by the sliding foil and must be opened according to

the label size. For that purpose a piercing pin is included in the

contents of delivery.

2

m

m

123

4

Figure 10

1. Place a label (1) to be operated on the bottom side of the pad (2).

Note the position of the slanted edge (3).

2. Align the label to the side edge in such a way that it reaches over

the rear edge of the pad by 2 mm.

3. Open all the holes, which are certainly covered by the label.

Open the holes completely by turning the piercing pin (4) inside

the holes.

CAUTION!

Malfunctions by a too weak vacuum.

Do not open holes which are located less than 1 mm

from a label edge.

Installation Applicator APL 100

22 Operating Manual 11/13

4.4 Preparing for Using a Sprint-Mounted Tamp Pad

NOTICE!

For using a spring-mounted universal tamp pad (> 90 x 90 mm)

the fitting of the cylinder unit must be changed.

The cylinder unit (6) can be mounted on the bracket (1) in two

different positions.

When the applicator is delivered, the cylinder unit is mounted on the

bracket using the upper threaded hole (4). That position is suitable for

the most pads.

1

2

3

4

5

6

Figure 11

1. Loosen the screw (3) and washer (2).

2. Dismount the cylinder unit (6) from the connecting bracket.

3. Fix the cylinder unit (6) with the screw (3) at the connecting

bracket (1) by using the lower threaded hole (5).

Applicator APL 100 Installation

11/13 Operating Manual 23

4.5 Mounting the Pad

6

7

8

1

2

3

4

5

Figure 12

1. Pull the tube (6) out of the push-in-fitting.

2. Insert the pin (5) on the pad (8) into the hole on the bottom side of

the pad holder (7).

3. Fix the pad (8) with the screw (1) at the pad holder (7) and make a

rough adjustment of the pad to the printer dispense plate.

4. Insert the vacuum tube (2) an the blowing air tube into the

appropriate push-in-fittings (3,4) of the pad.

5. Insert the tube (6) into the appropriate push-in-fitting on the

cylinder.

CAUTION!

Danger of collision of the pad with other parts of the labelling

system.

Before connecting the applicator to the compressed air

supply please roughly align the pad in all directions..

Installation Applicator APL 100

24 Operating Manual 11/13

4.6 Mounting the Stopper

NOTICE!

In the operating modes 'Stamp on' and 'Roll on' the stopper is

not needed.

213

4

3

1

Figure 13

When the applicator is delivered, the stopper (1) is mounted on the

rods (4). With this stopper the labelling position for the operation mode

'Blow on' can be adjusted.

1. Slide the stopper (1) with the rubber buffer (2) down onto the rods.

2. Adjust the stopper (1) (see chapter 7.5, page 37).

In the operating modes 'Stamp on' and 'Roll on' the stopper is not

needed. The stopper may not limit the pad movement.

1. Loosen the screw (3) at the stopper (1).

2. Slide the stopper (1) as far as possible upwards and tighten the

screw (3).

or

3. Remove the stopper (1) upwards from the rods (4).

Operating mode

'Blow on'

Operating modes

'Stamp on' and

'Roll on'

Applicator APL 100 Installation

11/13 Operating Manual 25

4.7 Connections

54321

Figure 14

1. Prepare the printer connections to the power supply and to the

computer (see operating manual of the label printer).

2. Close the shutoff valve (3 / lever at the valve is turned across the

air flow direction).

3. Connect the applicator to the compressed air supply.

The connector (2) for the compressed air supply is located at the

rear of the service unit. The connector is suitable for a 1/4"

coupling plug (1) or a tube with a diameter of 8 mm.

4. The air pressure for operating the applicator is pre-adjusted to

0,5 MPa (5 bar). Check the pressure at the manometer (5) of the

service unit. Correct the adjustment if necessary:

Pull knurled knob (4) up.

Turn knob to tune required operating pressure of 5 bar.

Push knob down.

5. Open the shutoff valve (3 / lever is turned in the air flow direction).

6. Switch on the power supply of the printer.

CAUTION!

The pad will immediately be moved in the starting position.

Danger of crushing to hand and fingers by the moving pad.

Do not reach into the zone of the moving pad.

Keep long hair, loose clothes and jewellery distant

from the zone of the moving pad.

Danger of striking by the moving rods.

Do not reach or bend into the zone of the moving rods.

Applicator APL 100 Configuration

11/13 Operating Manual 27

5 Configuration

The label applicator can be operated in different ways. While the

original process stays the same, the operation mode can be chosen

within the function menu of the connected label printer.

The most important setting is the selection between the operating

modes 'Stamp on', 'Blow on' and 'Roll on'. Additionally the applicator

has different application modes concerning the order of printing and

applying within one labelling cycle.

Stamp on Roll on Blow on

Print-Apply

Apply-Print

Waiting position up

Apply-Print

Waiting position down

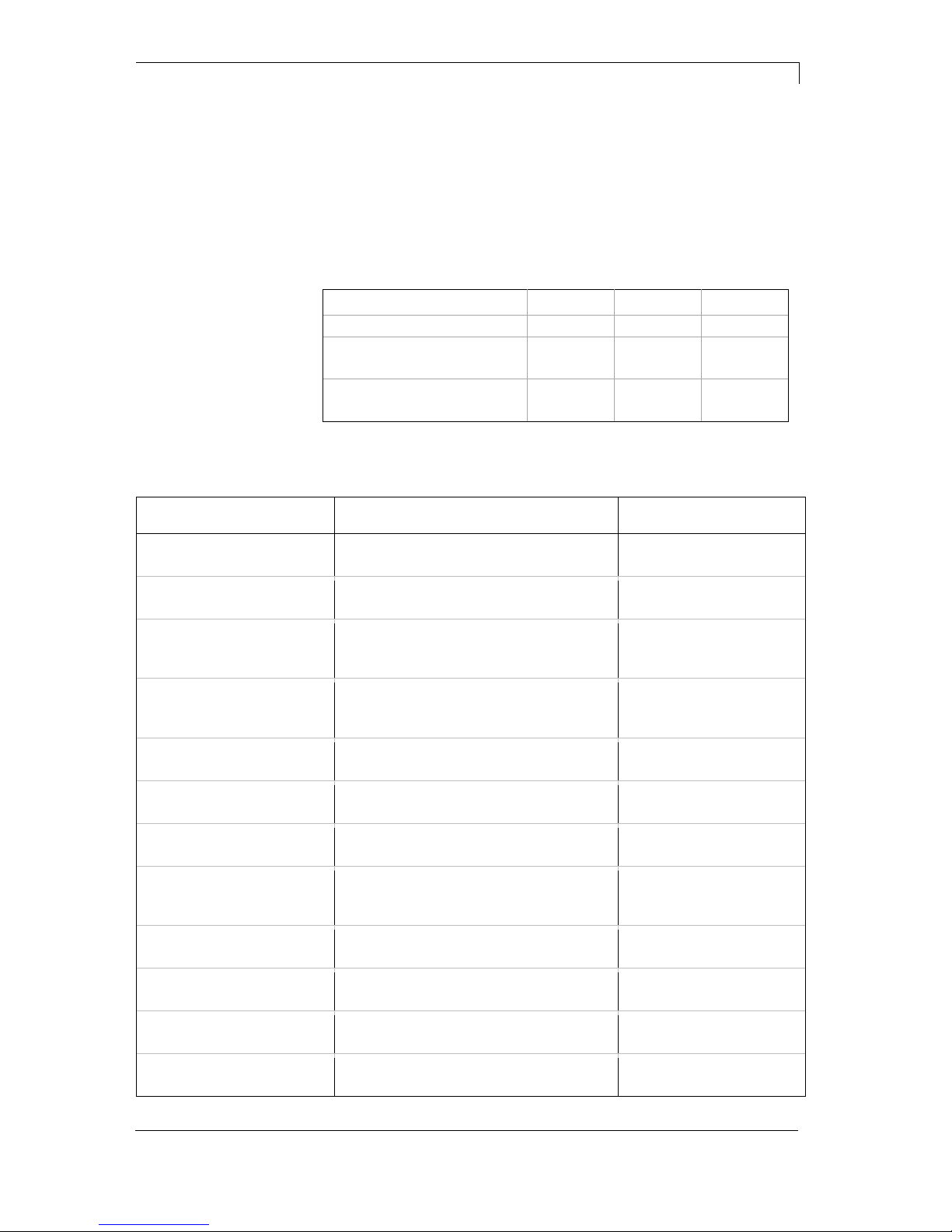

5.1 Configuration Parameter

Parameter Meaning Selection

Operating mode Setting of operating mode

Default: Stamp on

Stamp on, Blow on, Roll

on

Mode Setting of application mode

Default: Print-apply

Print-apply

Apply-print

Support delay On Setting of switch-on delay

for supporting air

Default: 0 ms

0 ... 2500 ms

in steps of 10 ms

Support delay Off Setting of switch-off delay

for supporting air

Default: 500 ms

0 ... 2500 ms

in steps of 10 ms

Pressure control Setting of compressed-air control

Default: On

On

Off

Vacuum control Setting of vacuum control

Default: On

On

Off

Blow time Setting of blow time

Default: 100 ms

0 ... 2500 ms

in steps of in 10 ms

Waiting position Waiting position of pad with dispensed

label for 'Blow on + Apply-print'

Default: Up

Up

Down

Roll on time Setting of roll on time

Default: 0 ms

0 ... 5000 ms

in steps of 10 ms

Cleaning time Setting of cleaning time

Default: 100 ms

0 ... 2500 ms

in steps of 10 ms

Timeout hub Moving up/down of pad

Default: 0 ms

0 ...5000 ms

in steps of 10 ms

Pressure time Setting of pressure time

Default: 100 ms

0 ...5000 ms

in steps of 10 ms

Configuration Applicator APL 100

28 Operating Manual 11/13

5.2 Settings in printer function menu

Switch on the label printer and the display shows the main menu.

Press key

to access the function menu.

Press key

as long as you arrive the Label applicator menu.

Press key

to select the menu.

Press key

to change to the next mode.

Stamp on:

The label remains in a fixed position. The label is pressed directly onto

the product.

Blow on:

The pad moves to a pre-adjusted position approximately 10 mm away

from the product. The label is blown onto the product by an air jet

stream. The print and apply cycle performs in a fixed position or in

linear movement of the product.

Roll on:

The label is dispensed and moved until touching the roller of the roll

on pad. In the labelling position, this roll is pressed onto the product.

Then the label is applied and rolled on by the movement of product.

Press key

to arrive the next parameter.

The applicator can be operated in two different ways concerning the

order of printing and labelling within one labelling cycle (see chapter 6,

page 32).

Print-Apply:

The print of a label is released by an external start signal. At the same

time the vacuum on the pad as well as the supporting air from the

blow tube are switched on. If the label is printed and picked up

completely from tamp, the supporting air is switched off and the lift

cylinder is controlled to move the pad down towards the labelling

position. A sensor signals when the labelling position is reached.

Following, the vacuum is switched off and the label is transferred to

the product. After applying the label, the lift cylinder is so controlled

that the pad is again moved back to the starting position.

Now the labelling cycle is finished.

Apply-Print:

Before starting the cyclic operation 'apply-print', the printing and

picking up of the first label has to be released separately by a special

signal.

The pad with the printed label is in starting position and the vacuum at

the pad is switched on.

At start of the cyclic operation when sending the start signal, the first

label is already on the pad. The following process is similar to the

mode 'print-apply' but at the end of the cycle the next label is printed

and picked up by the pad.

Now the labelling cycle is finished.

Operating modes

Application mode

Applicator APL 100 Configuration

11/13 Operating Manual 29

Press key

to arrive the next parameter.

The supporting air from the blow tube is not immediately switched on

at print start but only if the label has covered a distance.

This delay helps to prevent a turning or swinging at the front of the

label and consequently avoids faults when the label is being picked up

from printer.

Value range: 0 to 2500 ms

Step size: 0 ms

Default: 0 ms

Press key

to arrive the next parameter.

Delayed to the process of the label being picked up, the supporting air

is switched off.

In many cases, after being picked up by the pad the label edge may

still stick on the liner. This may affect the accuracy of the label

positioning or even cause faults in the labelling. Therefore, switching

off the air blow delayed can be useful to separate the label from liner

and neatly place the label on the surface of pad.

Value range: 0 to 2500 ms

Step size: 10 ms

Default: 500 ms

Press key

to arrive the next parameter.

With activated compressed air control, with help from a compressed

air sensor it is checked at each labelling cycle if the compressed air

fits with the valve block. If no compressed air is presented, the

labelling cycle is stopped and the error message 'compressed air' is

displayed.

If the parameter 'pressure control' is set to Off, the error treatment as

described above will not be effected. This can be especially helpful at

initiation of the labelling system.

For standard operation, set the parameter to On.

Press key

to arrive the next parameter.

The label transfer from printer to applicator is controlled by a vacuum

sensor. If the transfer of label fails, the sucking holes on the pad will

not be covered by the label and therefore no vacuum can originate on

the pad. Afterwards an error message appears and the label strip will

be fed back.

If the parameter 'vacuum control' is set to Off, the error treatment as

described above will not be effected. This can be especially helpful

during adjustments, because the immediate backfeed will be

cancelled and therefore it is easier to check the reasons for the faulty

transfer.

For standard operation, set the parameter to On.

Support delay On

Support delay Off

Pressure control

Vacuum control

Configuration Applicator APL 100

30 Operating Manual 11/13

Press key

to arrive the next parameter.

This parameter is only active if the operating mode 'blow on' is

selected. The time period can be adjusted, while the blowing air is

switched on for transferring the label onto product.

Value range: 0 to 2500 ms

Step size: 10 ms

Default: 100 ms

Press key

to arrive the next parameter.

NOTICE!

This parameter is only active if the operating mode 'blow on'

and mode 'apply-print' are selected.

Waiting position up:

In cyclic mode the pad with the printed label waits in the labelling

position near the dispense edge of printer for the external start signal.

Waiting position down:

In cyclic mode the printed label is transported to the labelling position

at the end of a cycle.

So the next cycle begin with blowing up the label.

Press key

to arrive the next parameter.

This parameter is only active if the operating mode 'blow on' is

selected. The time period can be adjusted while the roll on pad is

stopped in labelling position.

Value range: 0 to 5000 ms

Step size: 10 ms

Default: 0 ms

Press key

to arrive the next parameter.

This parameter is only active if the operating mode 'blow on' and 'roll

on' are selected. The time period can be adjusted for the cleaning

period of pad after application procedure.

Value range: 0 to 2500 ms

Step size: 10 ms

Default: 100 ms

Press key to arrive the next parameter.

Moving up and down of pad.

If the pad does not reach the corresponding final position within the

set time, then an error message appears ('final position above' at

moving up and/or 'final position below' at moving down).

Value range: 0 to 5000 ms

Step size: 10 ms

Default: 0 ms

Blow time

Waiting position

Roll on time

Cleaning time

Stroke timeout

Applicator APL 100 Configuration

11/13 Operating Manual 31

Press key

to arrive the next parameter.

This menu serves for the applicator setup as well as for error tracing.

Input signals of the applicator can be monitored and output signals

can be set or reset separately. With keys

and the

corresponding output for setting and/or resetting the output signals

can be selected. With keys

and the corresponding output can

be set or reset.

Input signals

I1 = Pre-dispense key (1 = key pressed, 0 = key not pressed)

I2 = Final position up (1 = pad in final position up,

0 = pad not in final position up)

I3 = Final position down (1 = pad in final position down,

0 = pad not in final position down)

I4 = Compressed air (1 = compressed air available,

0 = no compressed air available)

I5 = Vacuum (1 = vacuum at pad available, 0 = no vacuum at pad

available)

Output signals

1 = Move pad downwards (1 = On, 0 = Off)

2 = Move pad upwards (1 = On, 0 = Off)

3 = not assigned

4 = not assigned

5 = Blowing air (1 = On, 0 = Off)

6 = Supporting air (1 = On, 0 = Off)

7 = Vacuum pad (1 = On, 0 = Off)

Press key

to arrive the next parameter.

This parameter is only active if the operating mode 'stamp on' is

selected. The time period can be adjusted while the pad is kept in the

labelling position for applying the label onto the goods.

Input/Output

Pressure time

Signal Diagrams Applicator APL 100

32 Operating Manual 11/13

6 Signal Diagrams

6.1 Print - Apply

Input: Print start

Print process

Supporting air

Output: Label print

Vacuum

Pad

Delay On Delay Off

Apply

Blow on

Cleaning time

Figure 15

6.2 Apply - Print

Figure 16

Applicator APL 100 Mechanical Adjustments

11/13 Operating Manual 33

7 Mechanical Adjustments

NOTICE!

Perform the mechanical adjustments in two steps

Roughly align the pad in all directions to avoid collisions

of the pad with other parts when switching on the

compressed air.

Perform the fine adjustment with compressed air

switched on to optimize the labelling process.

7.1 Aligning the pad

2

1

3

2

1

4

5

Figure 17

1. Loosen screw (3).

2. Shift the cylinder unit including the pad (4) inside the elongated

hole in such a way, that the distance between the pad and the

dispense edge (5) is about 2 mm.

3. Tighten screw (3).

1. Loosen screw (1).

2. Shift the cylinder including the pad (4) inside the elongated hole in

such a way that the lower rear edge of the pad (4) is located about

1 mm below the dispense edge (5) of the printer.

3. Tighten screw (1).

Adjustment in

print direction

Height adjustment

Mechanical Adjustments Applicator APL 100

34 Operating Manual 11/13

1. Loosen screw (2).

2. Shift the cylinder unit including the pad (4) inside the elongated

hole in such a way, that the dispensed label is aligned centrally to

the pad respectively to the open holes in an universal pad.

3. Tighten screw (2).

NOTICE!

Check the adjustment with compressed air switched on.

7.2 Adjusting the Parallelism between Pad and

Dispense Edge

123

Figure 18

1. Loosen screw (1).

2. Adjust the parallelism between the rear edge of the pad (2) and

the dispense edge (3) by turning the pad.

3. Tighten screw (1).

Side adjustment

Applicator APL 100 Mechanical Adjustments

11/13 Operating Manual 35

7.3 Opening the Holes on the Blow Tube

123

Figure 19

1. The blow tube (1) has holes for the supporting air in regular

distances of 15 mm.

2. When the applicator is delivered only the two inner holes are

open. The other holes are closed by plastic rings (3).

3. To adjust the supporting air to the label width, the plastic rings (2)

can be removed from the holes.

4. Open all holes, which affect certainly the area of the label.

Mechanical Adjustments Applicator APL 100

36 Operating Manual 11/13

7.4 Aligning the Blow Tube

21

Figure 20

The blow tube (2) for the supporting air can be rotated around its axis.

That way the direction of the supporting air can be optimized.

1. Loosen screw (1).

2. Turn the blow tube (2) in that direction that the air current supports

the sucking of the label by the pad.

234

Figure 21

For small labels direct the air current to the dispense edge (3) of

the printer (setting 3 or 4 at the scale).

For larger labels direct the air current away from the dispense

edge (3 / setting 1).

3. Tighten screw (1).

Applicator APL 100 Mechanical Adjustments

11/13 Operating Manual 37

7.5 Adjusting the Stopper

NOTICE!

For operating mode 'Blow on' only.

3

2

1

4

5

6

7

Figure 22

CAUTION!

Danger of injury by inadvertent move out of the cylinder.

Switch off the printer and close the shutoff valve for

the compressed air at the service unit.

1. Place a product sample (7) at the labelling point.

2. Pull the tubes out of the push-in-fittings (1,5).

3. Loosen the screw (3) in the stopper (2).

4. Move the pad manually in the required labelling position. The

distance between the blow pad (6) in the labelling position and the

product surface (7) must not exceed 10 mm.

5. Move the stopper (2) against the guide block (4) and tighten the

screw (3).

6. Insert the tubes into the appropriate push-in-fittings (1,5).

7. Open the shutoff valve and switch on the printer.

Applicator APL 100 Pneumatic Adjustments

11/13 Operating Manual 39

8 Pneumatic Adjustments

8.1 Control Valves

3

4

5

121 67891011

Figure 23

For adjustments of certain applicator functions it is possible to release

the control valves in the pneumatic system.

Loosen screws (1) and remove cover (2).

The compressed air control valves can be controlled manually

with integrated switch.

3-way valve (3) to control the lift cylinder

If the printer is switched on the valve will controlled by electronics and

the tamp will hold in the upper end position (home position). If the

valve switched the tamp will move in the lower end position (labelling

position).

In normal labelling operation the movement back in the upper end

position will start by a signal from labelling sensor.

NOTICE!

The switching by hand of this valve has only a result in case of

a switched off printer.

Switching the valve by hand over switch 7 the tamp will move down up

to the lowest possible position because no control is made by the

sensor.

Switching the valve by hand over switch 7 the tamp will move up.

Pneumatic Adjustments Applicator APL 100

40 Operating Manual 11/13

3

4

5

121 67891011

Figure 24

Double 2-way valve (4) for blow air

In the operation mode 'Blow on' the label will blow up to the product.

In the operating modes 'Stamp on' and 'Roll on' the blow air is

switched on for a short time after each application to avoid

contaminations within the vacuum channels.

For all described functions both valves will be controlled parallel.

By pressing the keys 8 or 9 the blow air is only switched on by one of

both internal valves.

Double 2-way valve (5) for vacuum / supporting air

The two internal valves serve the vacuum nozzle for connecting an in

this way for creating the negative pressure at the tamp and

independent of this for connecting the support air at the blow tube for

the label transfer.

By pressing switch 10 the vacuum is switched on and by pressing

switch 11 the supporting air is switched on.

Applicator APL 100 Pneumatic Adjustments

11/13 Operating Manual 41

8.2 Adjusting the Pad Movement Speed

1

2

3

4

Figure 25

The adjustment of pad movement speed can be regulated with two

throttle valves (1, 3).

Adjust the pad movement speed as necessary.

To increase the downward speed turn the screw (4) at the lower

valve (3) anticlockwise.

To increase the upward speed turn the screw (2) at the upper

valve (1) anticlockwise.

NOTICE!

The application pressure of the pad is mainly dependent on

the downward speed of the pad.

To reduce the application pressure turn screw (4) in

clockwise direction.

CAUTION!

A too high decrease of the downward speed leads to an

error message (Error 101 - Lower position).

The downward movement may not need more time as

specified in the menu Timeout Hub (see page 30).

Pneumatic Adjustments Applicator APL 100

42 Operating Manual 11/13

8.3 Adjusting Vacuum and Supporting Air

1

2

Figure 26

Adjusting the supporting air

With the valve (1) the supporting air for blowing the label to the pad

can be varied.

Adjust the supporting air in such way that the label is blown on

the pad without swirling.

To increase the supporting air turn the screw at the valve (1)

anticlockwise.

If necessary adjust the direction of the air current (see chapter

Aligning the Blow Tube, page 36).

Adjusting the vacuum

NOTICE!

With the vacuum setting the final position of the label on the

pad can be adjusted. If the vacuum is too high the label

feeding may early be stopped.

With the valve (2) the vacuum for sucking the label to the pad can be

varied.

Adjust the vacuum in such way that the label is correctly sucked.

To increase the vacuum turn the screw at the valve (2)

anticlockwise.

Applicator APL 100 Operation

11/13 Operating Manual 43

9 Operation

9.1 Loading the Label Material

NOTICE!

In dispensing mode the labels are removed after printing, and

only the liner is wound up internally.

3

1

2

4

5

Figure 27

NOTICE!

For detailed information about inserting the material please

read the operating manual of the label printer.

Insert the transfer ribbon (1).

Insert the label material.

CAUTION!

Collision between the pad (5) and the locking system (4)

during the labelling procedure.

Swivel the locking system (4) on the rewind assistant

roller (3).

Operation Applicator APL 100

44 Operating Manual 11/13

9.2 Setting the Dispenser Mode

NOTICE!

To operate the label printer in dispenser mode a print order

must be started and the printer is to be in 'waiting' mode.

Switch on the label printer and the display shows the main menu.

Press key

to access the function menu.

Press key

as long as you arrive the Dispenser I/O menu.

Press key

to select the menu.

In the upper line of display, the operating mode can be selected.

In the line below, the dispenser I/O offset (approx. 18 mm) can be set.

Press key

to change to the next operating mode.

Off:

It is printed without the labels are dispensed.

I/O static:

The input signal evaluated, i.e. it is printed as long as the signal

exists. The number of labels which was entered at the print start is

printed.

The set dispenser offset is not taken into consideration.

I/O static continuous:

For description of this operating mode, see I/O static.

Continuous means that it is printed as long as new data is transferred

via interface

The set dispenser offset is not taken into consideration.

I/O dynamic:

The external signal is evaluated dynamically, i.e. is the printer in

'waiting' mode a single label is printed at each signal changing. After

the print the set dispenser offset is executed, i.e. a backfeed is

effected.

I/O dynamic continuous:

For description of this operating mode, see I/O dynamic.

Continuous means that it is printed as long as new data is transferred

via interface.

Photocell:

The printer is controlled via photocell. The printer prints automatically

a label if the user takes away the label at the dispensing ledge. The

print order is finished when the target number of labels is reached.

Photocell continuous:

For description of this operating mode, see Photocell.

Continuous means that it is printed as long as new data is transferred

via interface.

Operating modes

Applicator APL 100 Operation

11/13 Operating Manual 45

9.3 Test Mode

Test Mode Using the Pre-dispense Key without Print Job

1

Figure 28

The whole labelling process can be simulated without the need of a

print job or a connection to a computer by pressing the key

and

the pre-dispense key (1).

Press the key .

A blank label is fed. The vacuum at the pad as well as the

supporting air (blow tube) are switched on.

After the label has been picked up by the pad, the supporting air

is switched off.

Press the pre-dispense key (1).

The pad is moved to the labelling position. A sensor signals

when the labelling position is reached. The vacuum is switched

off and the label is placed onto the product. Then the pad is

moved back into the starting position.

NOTICE!

Please use this method to find the appropriate dispenser

offset in the printer configuration.

Operation Applicator APL 100

46 Operating Manual 11/13

Test Mode Using the Pre-dispense Key without Print Job

This method allows to check the labelling process with real print data

using the pre-dispense key (1, Figure 28).

Send a print job.

The test mode is executed in two half-cycles.

Press the pre-dispense key (1, Figure 28).

Half-cycle 1

A label is printed. The vacuum at the pad as well as the

supporting air (blow tube) are switched on. After the label has

been picked up by the pad, the supporting air is switched off.

Press the pre-dispense key (1, Figure 28) again.

Half-cycle 2

The pad is moved to the labelling position. A sensor signals

when the labelling position is reached. The vacuum is switched

off and the label is placed onto the product. Then, the pad is

moved back into the starting position.

If the label is manually removed from the pad after the first half cycle,

the half cycle 1 will be repeated when the pre-dispense key is pressed

again.

NOTICE!

Please use this method to adjust the appropriate dispenser

offset in the label design software.

Applicator APL 100 Operation

11/13 Operating Manual 47

9.4 Standard Operation

1. Check all external connections (see chapter 4.7, page 25).

2. Load the transfer ribbon and the label material (see chapter 9.1,

page 43).

NOTICE!

Ensure that the locking system (4, Figure 27) is closed.

3. Open the shutoff valve.

CAUTION!

If the pad is covered the vacuum sensor may be

calibrated faultily.

Before switching on the printer-applicator system

ensure that the pad is not covered.

4. Switch on the label printer.

CAUTION!

The pad will immediately be moved in the starting

position.

Do not reach into the zone of the moving pad.

Keep long hair, loose clothes and jewellery distant.

Do not reach or bend into the zone of the moving

rods.

5. Press the key

at the printer.

A synchronization feed is released. The processed labels have to

be removed manually. After a few seconds the printer carries out

a short backfeed to position the front edge of the next label at the

printing line.

NOTICE!

This synchronizing also has to be carried out when the print

job has been interrupted with the key

.

Synchronizing is not necessary when the printhead was not

lifted between print jobs. This also applies if the printer was

powered off between print jobs.

6. Start a print job.

Applicator APL 100 Applicator Interface

11/13 Operating Manual 49

10 Applicator Interface

10.1 Pin Assignment

Figure 29

10.2 Internal Circuit of Outputs

Figure 30

The outputs are realized by optocouplers.

With an active signal the collector emitter line of the optopoupler is

conductive.

Applicator Interface Applicator APL 100

50 Operating Manual 11/13

10.3 Signal Assignment D-Sub 15 pin

D-Sub 15 pin female connector APL 100

Pin Signal Description Active state

9

Collector signal

Upper final

position

Tamp pad is in the final

position in which the

transfer of label from the

printer can be done

Collector

emitter line

conductive

1

Emitter signal

Lower final

position

10

Collector signal

Lower final

position

Tamp pad is in the final

position in which the

transfer of label to the good

can be done.

Collector

emitter line

conductive

2

Emitter signal

Lower final

position

11

Emitter signal

Compressed-air

Control of the applicators'

compressed-air supply

Collector

emitter line

blocked

3

Emitter signal

Compressed-air

15 24V

Operating voltage

+24V/100 mA made

available by the applicator

8 GND GND connection

Applicator APL 100 Error Messages

11/13 Operating Manual 51

11 Error Messages

11.1 Error Messages of the Printer

In case an error occurred the printer stops and the print order is

interrupted. Information to causes and remedies of printer errors e.g.

no label found are to be taken from the printer manual.

1. Clear the error.

2. Press the key

to synchronize the label feed.

3. Remove the peeled labels manually.

4. Press the key

to quit the error state.

5. Press the key

to continue the print order or press key

to cancel the print order.

11.2 Error Messages of the Applicator

Error message Cause Remedy

Upper position

The upper position (start position)

was not reached.

Check final position switch for start

position and compressed-air supply.

Adjust stroke timeout.

Lower position

The lower position (labelling

position) was not reached.

Check final position switch for labelling

position and compressed-air supply.

Adjust stroke timeout.

Empty vacuum

plate

Sensor does not recognize a label at

the vacuum plate.

Check if all holes of the pad plate are

covered from the label.

Check compressed-air supply.

Print position

At print start the pad is not in printing

position (upper pad position).

Check the correct function and position

of the final position switch for the upper

position (start position).

Check the pneumati function.

CAUTION!

The pad will immediately be moved in the starting position.

Danger of crushing to hand and fingers by the moving pad.

Do not reach into the zone of the moving pad.

Keep long hair, loose clothes and jewellery distant from

the zone of the moving pad.

Danger of striking by the moving rods.

Do not reach or bend into the zone of the moving rods.

After error correction, the print of the label causing the error cannot be

repeated without re-start of the print order.

Applicator APL 100 Declaration

11/13 Operating Manual 53

12 Declaration

12.1 Extended Declaration

Declaration Applicator APL 100

54 Operating Manual 11/13

12.2 EC-Declaration of Conformity

Applicator APL 100 Index

11/13 Operating Manual 55

13 Index

B

Blow tube, adjusting ........................................................................... 36

C

Circuit output, internal ........................................................................ 49

Configuration

Operating mode .............................................................................. 27

Parameter ....................................................................................... 27

Connections ....................................................................................... 25

Control valves ............................................................................... 39, 40

D

Declaration ................................................................................... 53, 54

Device overview

Front view ....................................................................................... 15

Rear view ........................................................................................ 16

Dispenser mode ................................................................................. 44

D-Sub 15 pin, signal assignment ....................................................... 50

E

EC Declaration of conformity.............................................................. 54

Environmentally-friendly disposal ......................................................... 6

Error messages

Applicator ........................................................................................ 51

Printer ............................................................................................. 51

Extended declaration .......................................................................... 53

F

Function menu (printer)

Application modes .......................................................................... 28

Blow time ........................................................................................ 30

Cleaning time .................................................................................. 30

Input/Output .................................................................................... 31

Operating modes ............................................................................ 28

Pressure control .............................................................................. 29

Pressure time .................................................................................. 30

Roll on time ..................................................................................... 30

Stroke timeout ................................................................................. 30

Support delay Off ............................................................................ 29

Support delay On ............................................................................ 29

Test functions ................................................................................. 31

Vacuum control ............................................................................... 29

Vacuum delay ................................................................................. 29

Waiting position .............................................................................. 30

H

Holes (blow tube), opening ................................................................. 35

I

Instructions ........................................................................................... 5

Intended use ......................................................................................... 5

Interface, applicator ............................................................................ 49

Index Applicator APL 100

56 Operating Manual 11/13

L

Label application ................................................................................ 13

Label material, loading ....................................................................... 43

M

Mounting to printer ............................................................................. 20

O

Operating conditions .......................................................... 9, 10, 11, 12

Output circuit, internal ........................................................................ 49

P

Pad

Adjusting ......................................................................................... 34

Mounting ......................................................................................... 23

Movement speed ............................................................................ 41

Pad, aligning

Height adjustment ........................................................................... 33

In print direction .............................................................................. 33

Side adjustment .............................................................................. 34

Pads, models

Blow pad ......................................................................................... 17

Roll-on pad ..................................................................................... 17

Tamp pad ........................................................................................ 17

Pin assignment ................................................................................... 49

Pre-dispense key .......................................................................... 45, 46

Product description ............................................................................. 13

S

Safety instructions ................................................................................ 7

Safety marking ..................................................................................... 8

Scope of delivery ................................................................................ 19

Signal assignment, D-Sub 15 pin ....................................................... 50

Signal diagrams

Apply-Print ...................................................................................... 32

Print-Apply ...................................................................................... 32

Standard operation ............................................................................. 47

Stopper

Adjusting ......................................................................................... 37

Mounting ......................................................................................... 24

Supporting air, adjusting ..................................................................... 42

T

Technical data .................................................................................... 14

Test mode..................................................................................... 45, 46

U

Universal tamp pad

Piercing (standard tamp pad) ......................................................... 21

Preparing (spring-mounted tamp pad) ............................................ 22

V

Vacuum, adjusting .............................................................................. 42

Carl Valentin GmbH

Neckarstraße 78 – 86 u. 94 . 78056 Villingen-Schwenningen

Phone +49 (0)7720 9712-0 . Fax +49 (0)7720 9712-9901

info@carl-valentin.de . www.carl-valentin.de

Loading...

Loading...