Carl Valentin VARIO III series, 103/8 T, 107/12, 107/24, 108/12 T Service Instructions Manual

...

VARIO III

Service Instructions

Copyright by Carl Valentin GmbH / 7956045.0314

Information on the scope of delivery, appearance, performance,

dimensions and weight reflect our knowledge at the time of printing.

We reserve the rights to make modifications.

All rights, including those regarding the translation, are reserved.

No part of this document may be reproduced in any form (print,

photocopy or any other method) or edited, copied or distributed

electronically without written permission from Carl Valentin GmbH.

Due to the constant further development of our devices discrepancies

between manual and device can occur.

Please check www.carl-valentin.de for the latest update.

Trademarks

Centronics

®

is a registered trademark of Data Computer Corporation.

Microsoft

®

is a registered trademark of Microsoft Corporation.

Windows 2000

®

, 2003®, XP®, Vista®, 7®, 8®, Windows ServerTM 2008,

Windows Server

TM

2008 R2, Windows ServerTM 2012 are registered

trademarks of Microsoft Corporation.

TrueType

TM

is a trademark of Apple Computer, Inc.

Zebra

®

and ZPL II® are registered trademarks of ZIH Corporation.

Carl Valentin label printers comply with the following safety guidelines:

CE

EG Low-Voltage Directive (2006/95/EC)

EG Electromagnetic Compatibility Directive (2004/108/EC)

Carl Valentin GmbH

Postfach 3744

78026 Villingen-Schwenningen

Neckarstraße 78 – 86 u. 94

78056 Villingen-Schwenningen

Phone

Fax

+49 (0)7720 9712-0

+49 (0)7720 9712-9901

E-Mail

Internet

info@carl-valentin.de

www.carl-valentin.de

Vario III Series Table of Contents

03.14 Service Instructions 3

Table of Contents

Table of Contents ............................................................................. 3

1 Notes on this Document ....................................................... 5

1.1 User Notes ............................................................................... 5

1.2 Instructions .............................................................................. 5

1.3 Cross References .................................................................... 6

2 Safety Instructions ................................................................ 7

2.1 General Safety Instructions ..................................................... 7

2.2 Safety Handling When Working With Electricity ...................... 9

2.3 Environmentally-Friendly Disposal ........................................ 10

3 Connector Pin Assignment (Printer Rear) ........................ 11

4 Cleaning ............................................................................... 13

4.1 General Cleaning ................................................................... 14

4.2 Cleaning the Pressure Roller ................................................ 14

4.3 Cleaning the Printhead .......................................................... 15

4.4 Cleaning the Label Photocell ................................................. 16

5 Replacing Components ...................................................... 17

5.1 Tools List ............................................................................... 17

5.2 Replacing the Printhead ........................................................ 18

5.3 Replacing the Pressure Roller ............................................... 20

5.4 Replacing the Label Photocell ............................................... 21

5.5 Replacing the CPU PCB ....................................................... 22

5.6 Replacing the Power Supply ................................................. 24

5.7 Replacing the WLAN module ................................................ 25

5.8 Replacing the Battery ............................................................ 26

6 Adjustments, settings and alignments ............................. 27

6.1 Adjusting the print mechanism .............................................. 27

6.2 Adjusting the Printhead ......................................................... 28

6.3 Adjusting Parallelism of Printhead ......................................... 29

6.4 Adjusting Pressure of Printhead ............................................ 30

6.5 Adjusting Pressure Balance Right/Left .................................. 30

6.6 Adjusting the ribbon rewinder/unwinder ................................ 31

6.7 Adjusting the Cutter Ledge .................................................... 32

6.8 Error Correction of Cutting Edge ........................................... 33

6.9 Oil and Lubricate ................................................................... 34

7 Refitting Options ................................................................. 35

7.1 I/O Plate ................................................................................. 35

7.2 Dispensing Unit ..................................................................... 36

7.3 Cutting Unit ............................................................................ 38

8 Error correction ................................................................... 41

9 Control inputs and outputs ................................................ 51

10 Wiring Plan ........................................................................... 57

10.1 CPU Component Placement Specification ............................ 58

11 Index ..................................................................................... 59

Vario III Series Notes on this Document

03.14 Service Instructions 5

1 Notes on this Document

1.1 User Notes

This service manual is intended for qualified service and maintenance

staff.

This manual contains information about hardware and mechanical

part of the label printers 103/8 T, 104/8, 107/12, 107/24 and 108/12 T.

Information about operation of printer can be taken from our operating

manual.

If a problem arises that cannot be solved with help of this service of

manual, then please contact your responsible distributor.

1.2 Instructions

Basic information and warning references with the corresponding

signal words for the danger level are as follows specified in this

manual:

DANGER identifies an extraordinarily great and immediate

danger which could lead to serious injury or even death.

WARNING identifies a possible danger would could lead

to serious bodily injury or even death if sufficient

precautions are not taken.

CAUTION indicates a potentially dangerous situation

which could lead to moderate or light bodily injury or

damage to property.

NOTICE gives you tips. They make a working sequence

easier or draw attention to important working processes.

Gives you tips on protecting the environment.

Handling instruction

Optional accessories, special fittings

Datum Information in the display

Notes on this Document Vario III Series

6 Service Instructions 03.14

1.3 Cross References

References to specific items in a figure are marked with item

numbers. They are identified with parentheses in the text, e.g. (9). If

no figure number is provided, item numbers in the text always refer to

the graphic directly above the text. If a reference is made to another

graphic, the figure number is specified, e.g. (2, in figure 5).

For a cross reference to chapters and sections, the chapter number

and page number are specified, e.g. a reference to this section: see

chapter 1.3.2, on page 35).

References to other documents have the following form: See

'operating manual'.

Item numbers

Cross references to

chapters and sections

References to other

documents

Vario III Series Safety Instructions

03.14 Service Instructions 7

2 Safety Instructions

2.1 General Safety Instructions

Keep the area around the device clean during and after

maintenance.

Work in a safety-conscious manner.

Store dismantled device parts in a safe place while maintenance

is being performed.

CAUTION!

The drawing in of items of clothing by moving parts can

lead to injuries.

If possible, do not wear clothing which could be

caught by moving device parts.

Button or roll up shirt or jacket sleeves.

Tie or pin up long hair.

Tuck the ends of scarves, ties and shawls into your

clothing or secure them with non-conductive clips.

DANGER!

Risk of death from increased flow of current via metals

parts which come into contact with the device.

Do not wear clothing with metal parts.

Do not wear jewellery.

Do not wear glasses with a metal frame.

If a possible danger to your eyes is present, wear protective goggles,

especially in the following cases:

when knocking in or knocking out pins and similar parts with a

hammer

when using an electric drill

when using spring hooks

when loosening or inserting springs, snap rings and gripping rings

when soldering

when using solvents, cleaning agents or other chemicals

Workplace and

method of working

Clothing

Protective clothing

Safety Instructions Vario III Series

8 Service Instructions 03.14

WARNING!

Risk of injury in case of missing or faulty protective

equipment.

After performing maintenance work, attach all safety

equipment (covers, safety precautions, ground cables

etc.).

Replace faulty parts and those which have become

unusable.

The label printer is designed for power supply systems of

110-230V. Connect the print module only to electrical outlets with a

ground contact.

Couple the print module to devices using extra low voltage only.

Before making or undoing connections, switch off all devices involved

(computer, printer, accessories etc.).

Operate the print module in a dry environment only and do not get it

wet (sprayed water, mist etc.).

Do not operate the label printer in explosive atmosphere and not in

proximity of high voltage power lines.

Operate the label printer only in an environment protected against

abrasive dust, swarf and other similar impurity.

If the label printer is operated with the cover open, ensure that

clothing, hair, jewellery and similar personal items do not contact the

exposed rotating parts.

The print unit can get hot during printing. Do not touch the printhead

during operation. Cool down the print unit before changing material,

removal or adjustment.

Carry out only the actions described in these operating instructions.

Any work beyond this may only be performed by the manufacturer or

upon agreement with the manufacturer.

Unauthorized interference with electronic modules or their software

can cause malfunctions.

Other unauthorized work or modifications to the label printer can

endanger operational safety.

Always have service work done in a qualified workshop, where the

personnel have the technical knowledge and tools required to do the

necessary work.

There are warning stickers on the label printer that draw your attention

to dangers. Therefore the warning stickers are not to be removed as

then you and others cannot be aware of dangers and may be injured.

DANGER!

Danger to life and limb from power supply!

Do not open the casing.

Protective equipment

General safety

instructions

Vario III Series Safety Instructions

03.14 Service Instructions 9

2.2 Safety Handling When Working With Electricity

The following work may only be performed by instructed and

trained electricians:

work on the electrical assemblies

work on the device while it is open and connected to the

power supply.

Locate the emergency-stop or power switch so that it can be

actuated in case of an emergency.

Unplug the device from the electrical outlet before performing

the following work:

removing or installing power supply units

working in the immediate vicinity of exposed power supply

parts

mechanical inspection of power supply parts

modifying the device circuits.

Ensure that the device is de-energized.

Check the workplace for possible sources of danger, e.g. moist

floors, defective extension cables, faulty protective conduction

connections.

Give another person the task of remaining near the workplace.

This person must be familiar with the location and operation of

the emergency-stop and power switches and switch off the

power if danger arises.

Use only one hand while working on electrical circuits when a

device is switched on. Hold the other hand behind your back or

put it in your jacket pocket.

This prevents the electricity from flowing through your body.

To not use worn or damaged tools.

Use only tools and testing equipment that is suitable for the

respective task.

Proceed in a very cautions and calm manner.

Avoid endangering yourself.

Switch the power off.

Request medical help (emergency physician).

Call for first aid if necessary.

Qualifications of

personnel

General precautions to

be heeded when

beginning maintenance

Additional precautions

to be heeded for

devices with exposed

energized parts

Tools

What to do in case an

accident occurs

Safety Instructions Vario III Series

10 Service Instructions 03.14

2.3 Environmentally-Friendly Disposal

Manufacturers of B2B equipment are obliged to take back and

dispose of old equipment that was manufactured after 13 August

2005. As a principle, this old equipment may not be delivered to

communal collecting points. It may only be organised, used and

disposed of by the manufacturer. Valentin products accordingly

labelled can therefore be returned to Carl Valentin GmbH.

This way, you can be sure your old equipment will be disposed of

correctly.

Carl Valentin GmbH thereby fulfils all obligations regarding timely

disposal of old equipment and facilitates the smooth reselling of these

products. Please understand that we can only take back equipment

that is sent free of carriage charges.

Further information on the WEEE directive is available on our website

www.carl-valentin.de.

Vario III Series Connector Pin Assignment (Printer Rear)

03.14 Service Instructions 11

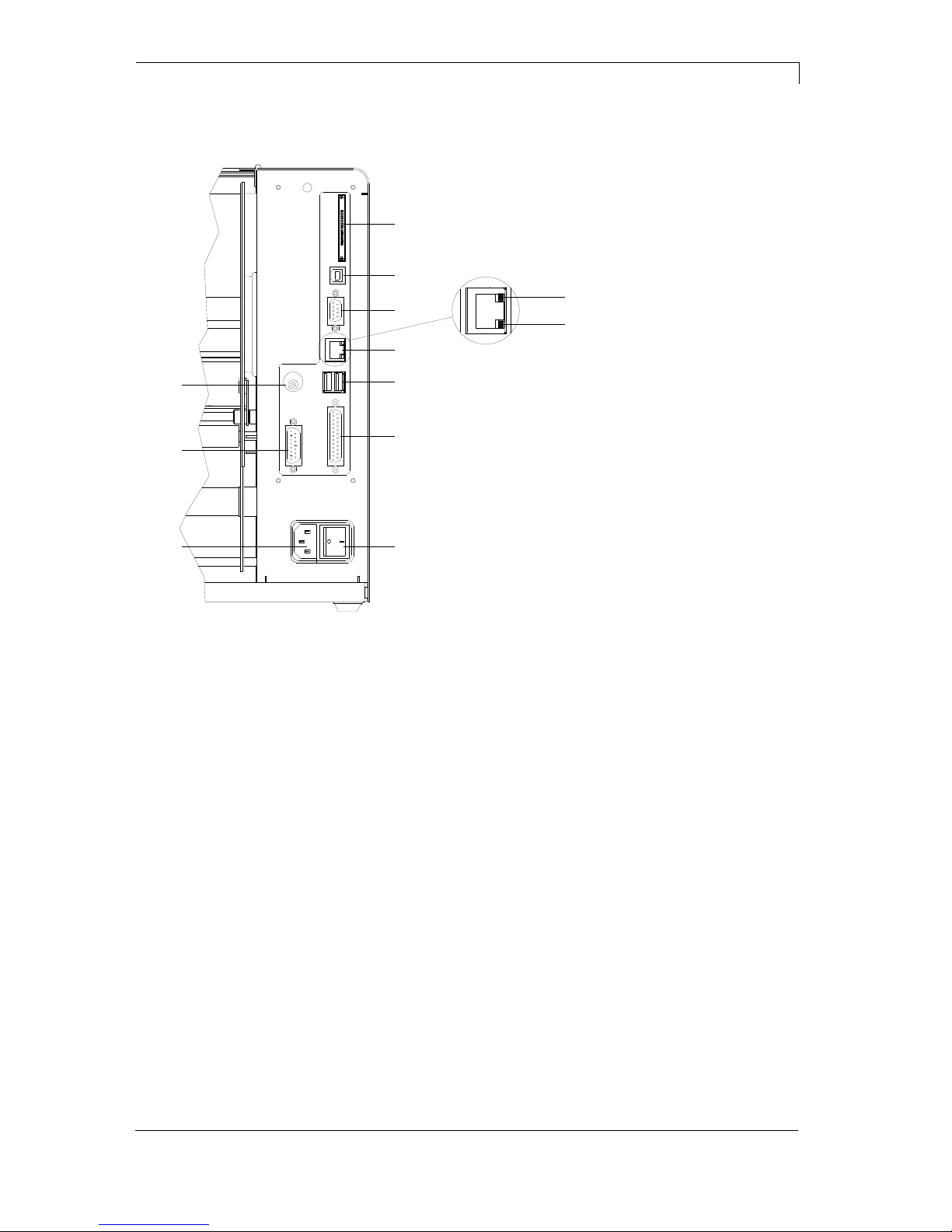

3 Connector Pin Assignment (Printer Rear)

C

A

D

E

F

B

1

2

G

H

I

J

Figure 1

A Plug-in for CF card

B USB interface

C Serial interface RS-232

Pin 2 = TXD, Pin 3 = RXD, Pin 5 = GND, Pin 7 = CTS, Pin 8 = RTS

D Ethernet 10/100 interface

E USB host for USB keyboard and USB memory stick

F Parallel interface for Centronics

G Switch On/Off

H Power supply

I External output/input (option)

J Winder connection

1 - LED orange

1 - Lighting = Connection active

1 - Flashing = Data transfer

1 - Off = No connection

2 - LED green

2 - Lighting: Speed 100 MBit

2 - Off: Speed 10 MBit

Vario III Series Cleaning

03.14 Service Instructions 13

4 Cleaning

DANGER!

Risk of death by electric shock!

Disconnect the label printer from power supply

before performing any maintenance work.

NOTICE!

When cleaning the label printer, personal protective equipment

such as safety goggles and gloves are recommended.

Cleaning task Frequency

General cleaning (see chapter

4.1, page 14).

As necessary.

Cleaning pressure roller (see

chapter 4.2, page 14).

Each time the label roll is

changed or when the printout and

label transport are adversely

affected.

Cleaning printhead (see chapter

4.3, page 15).

Each time the transfer ribbon is

changed or when the printout is

adversely affected.

Cleaning label photocell (see

chapter 4.4, page 16).

When exchanging the label roll.

NOTICE!

The handling instructions for the use of Isopropanol (IPA) must

be observed. In the case of skin or eye contact, immediately

wash off the fluid thoroughly with running water. If the irritation

persists, consult a doctor. Ensure good ventilation.

WARNING!

Risk of fire by easily inflammable label soluble!

When using label soluble, dust must be completely

removed from the label printer and cleaned.

Cleaning

schedule

Cleaning Vario III Series

14 Service Instructions 03.14

4.1 General Cleaning

CAUTION!

Abrasive cleaning agents can damage the label printer!

Do not use abrasives or solvents to clean the outer

surface of the label printer.

Remove dust and paper fuzz in the printing area with a soft

brush or vacuum cleaner.

Clean outer surfaces with an all-purpose cleaner.

4.2 Cleaning the Pressure Roller

A soiled pressure roller can lead to reduced print quality and can

affect transport of material.

CBA

Figure 2

1. Open printer cover.

2. Turn lever (C) counter clockwise to lift up the printhead (B).

3. Remove labels and transfer ribbon form the label printer.

4. Remove deposits with roller cleaner and a soft cloth.

5. Turn the roller (A) manually step by step to clean the complete

roller (only possible when printer is switched off, as otherwise the

step motor is full of power and the roller is kept in its position).

Vario III Series Cleaning

03.14 Service Instructions 15

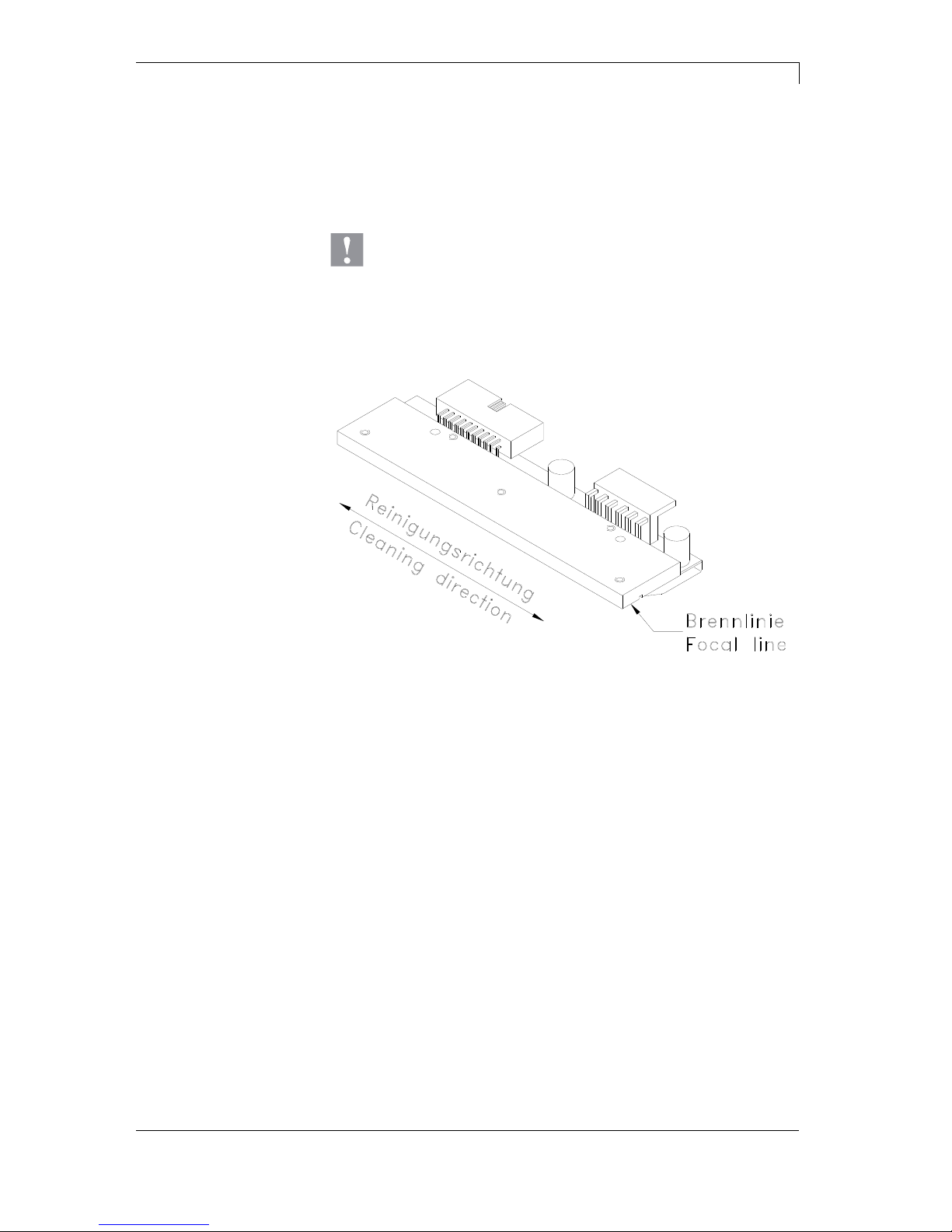

4.3 Cleaning the Printhead

Printing can cause accumulation of dirt at printhead e.g. by colour

particles of transfer ribbon, and therefore it is necessary to clean the

printhead in regular periods depending on operating hours,

environmental effects such as dust etc.

CAUTION!

Printhead can be damaged!

Do not use sharp or hard objects to clean the

printhead.

Do not touch protective glass layer of the printhead.

Figure 3

1. Open printer cover.

2. Turn lever (A, Figure 2) counter clockwise to lift up the printhead.

3. Remove labels and transfer ribbon from the label printer.

4. Clean printhead surface with special cleaning pen or a cotton

swab dipped in pure alcohol.

5. Allow printhead to dry for 2-3 minutes before commissioning the

printer.

Cleaning Vario III Series

16 Service Instructions 03.14

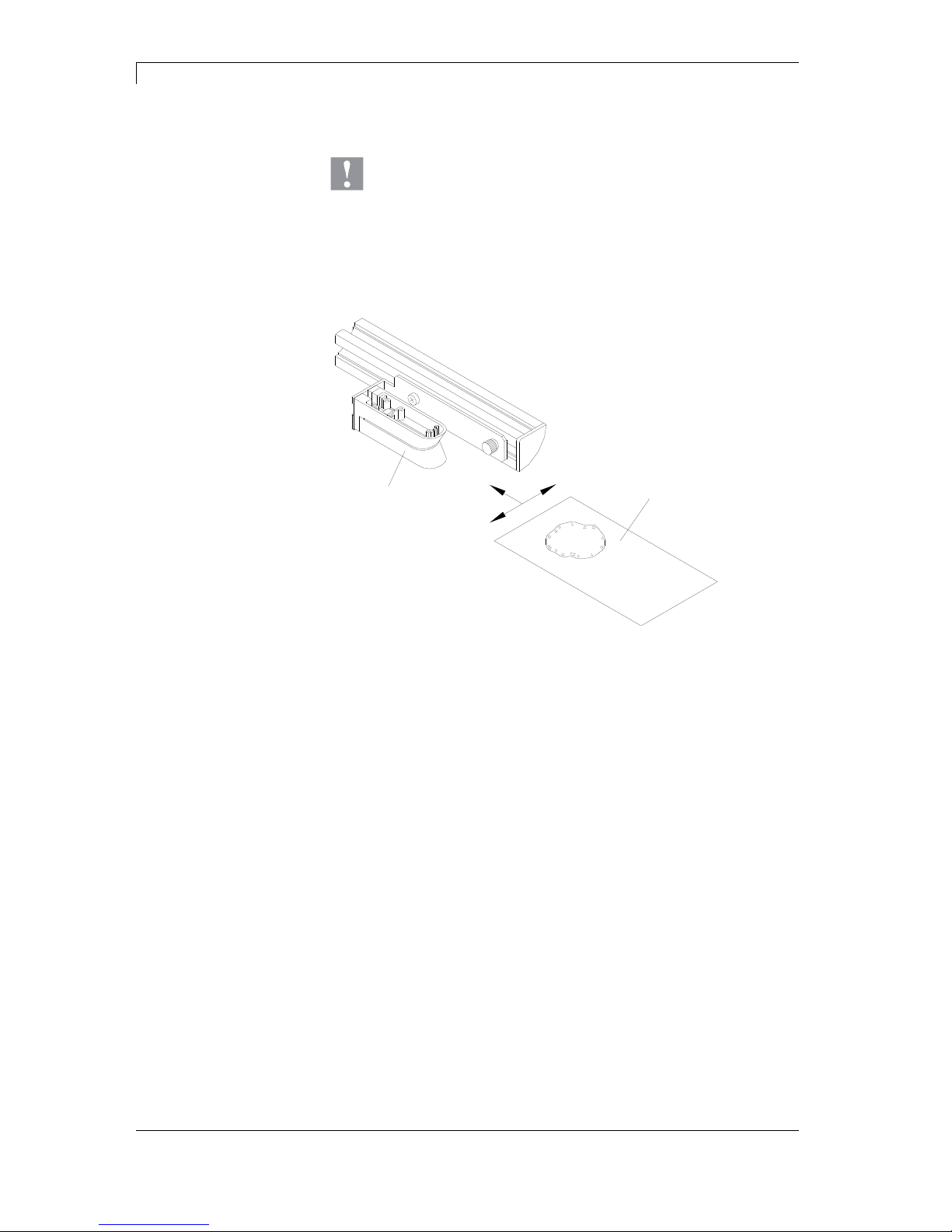

4.4 Cleaning the Label Photocell

CAUTION!

Label photocell can be damaged!

Do not use sharp or hard objects or solvents to clean

the label photocell.

The label photocell can become dirtied with paper dust and this can

adversely affect label detection.

A

B

Figure 4

1. Open printer cover.

2. Turn lever (A, in Figure 2) counter clockwise to lift up the

printhead.

3. Remove labels and transfer ribbon from the label printer.

4. Blow out the photocell (A) with pressure gas spray.

Observe strictly the instructions on the spray can!

5. Clean the label photocell (A) additionally with a cleaning card (B)

before soaked in pure alcohol. Move the cleaning card from one

side to the other (see illustration).

6. Reload labels and transfer ribbon.

Vario III Series Replacing Components

03.14 Service Instructions 17

5 Replacing Components

DANGER!

Risk of death via electric shock!

Before opening the housing cover, disconnect the

device from the mains supply and wait approx. 2 - 3

minutes until the power supply unit has discharged.

5.1 Tools List

Some service work requires the following tools:

Philips-head screwdriver, size 1

Slot screwdriver, size 1

Hexagonal wrench 2.5 mm

Flat wrench size 0.5

Replacing Components Vario III Series

18 Service Instructions 03.14

5.2 Replacing the Printhead

NOTICE!

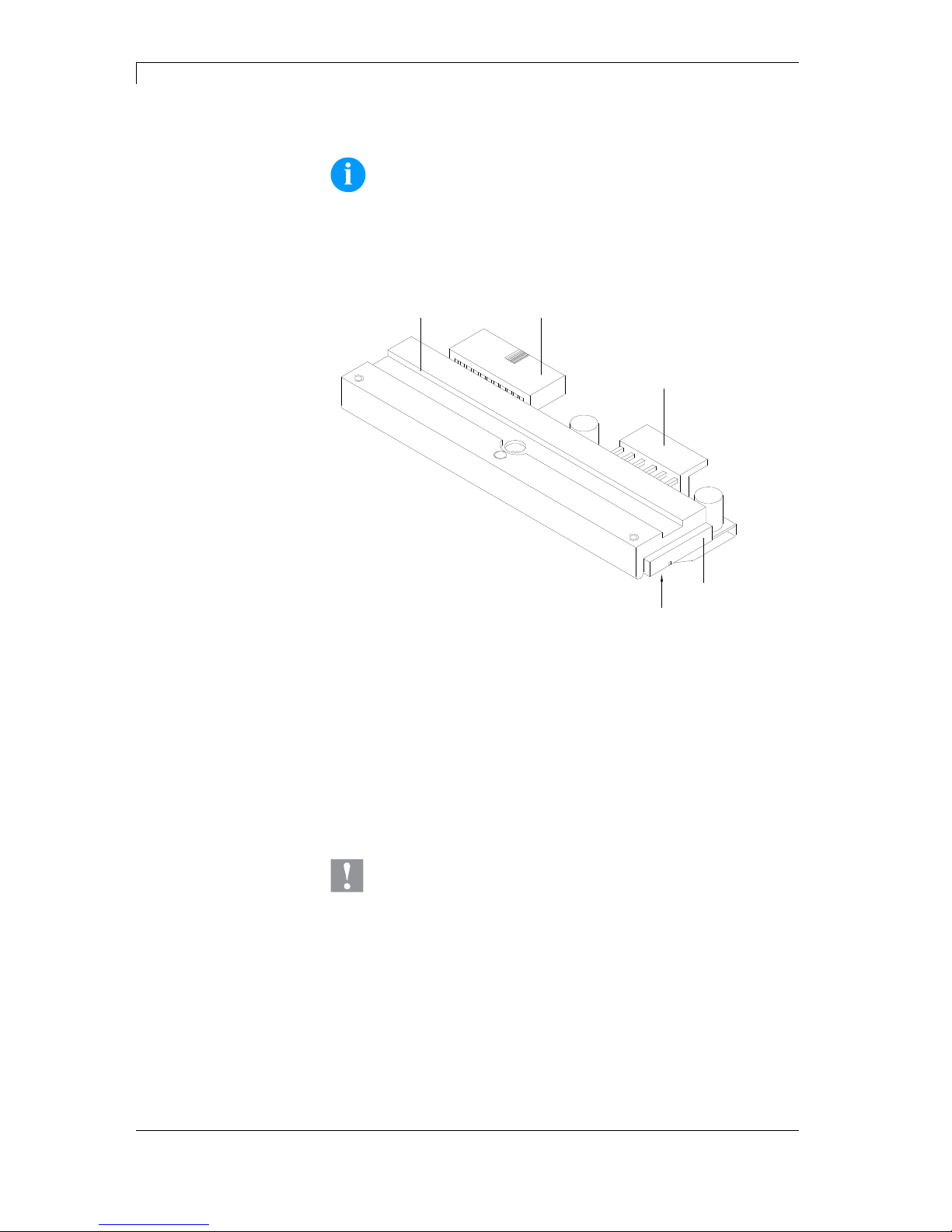

The printhead (4) is preinstalled on a head plate (1) and

aligned at the factory.

B

E

C

A

D

Figure 5

A Head plate

B Plug connection signal

C Plug connection tension

D Printhead

E Focal line

CAUTION!

The printhead can be damaged by static electricity

discharges and impacts!

Set up printer on a grounded, conductive surface.

Ground your body, e.g. by wearing a grounded

wristband.

Do not touch contacts on the plug connections (B, C).

Do not touch printing line (E) with hard objects or your

hands.

Vario III Series Replacing Components

03.14 Service Instructions 19

CDEED

B

A

A

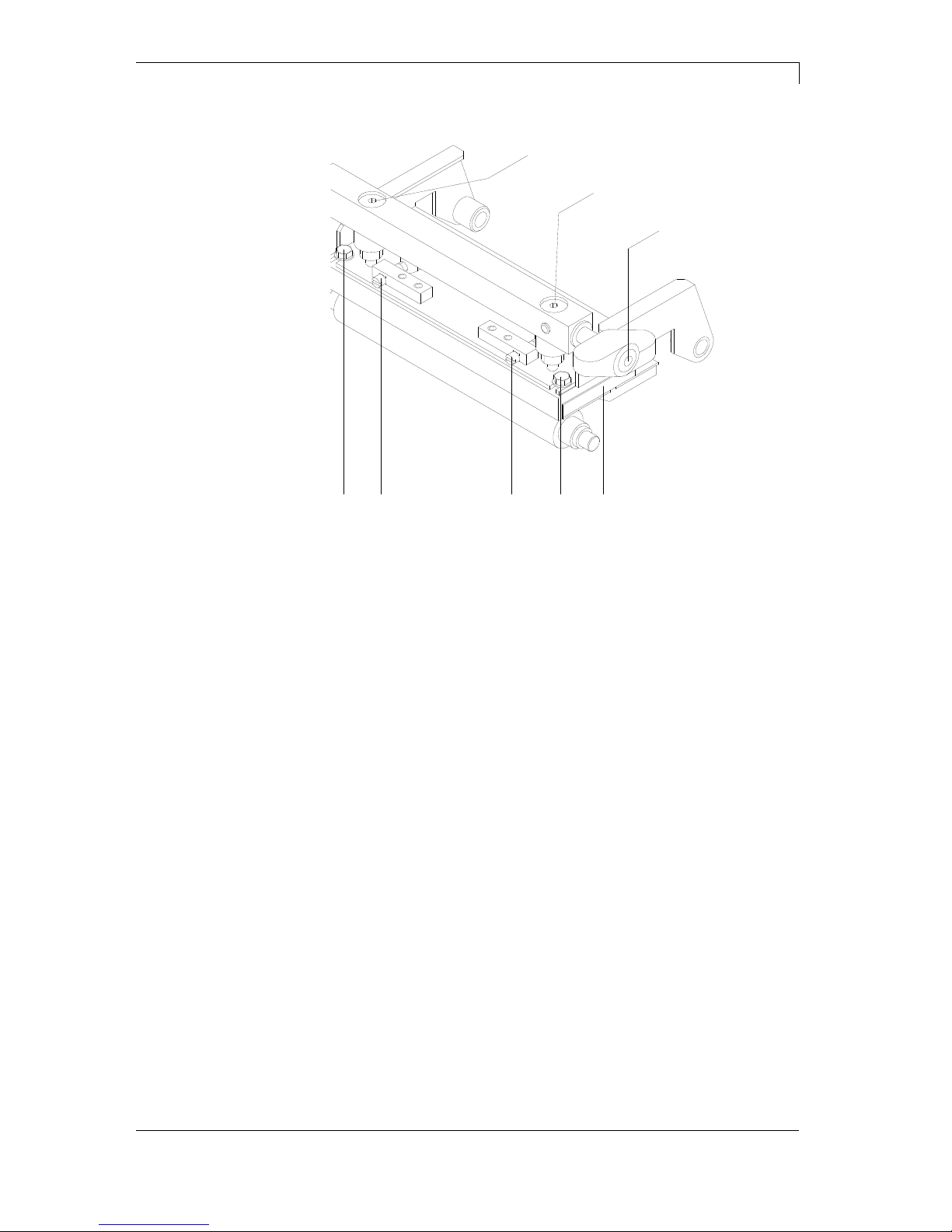

Figure 6

1. Remove labels and transfer ribbon from the label printer.

2. When printhead is closed, loosen the screws (D).

3. Turn lever (B) counter clockwise to lift up the printhead.

4. If the printhead (C) is not disengaged on the pressure roller,

continue loosen the screws (D).

5. Remove the printhead carefully to the front until you can reach the

plug connections.

6. Remove plug connections and then remove printhead (C).

1. Attach plug connections.

2. Position printhead in printhead mounting bracket in such a way

that the pin is secured in the corresponding hole in the head plate.

3. Lightly keep printhead mounting bracket on the printer roller with

one finger and check for correct positioning of the printhead.

4. Tighten again screws (D).

5. Reload labels and transfer ribbon.

6. Check resistance value on the type plate of printhead and if

necessary change the value in the Service functions/heater

resistance.

Removing the

printhead

Installing the

printhead

Loading...

Loading...