Page 1

Adjustable Floor Box

Kit with White Cover

THE FAST, EASY WAY TO PUT A PLUG

ANYWHERE YOU NEED IT!

• Eliminates extension

cords

•Great for home offices &

entertainment rooms

• Easy to use – kit

includes everything you

need!

ADJUSTS TO MOST

FINISHED FLOOR HEIGHTS!

Kit includes:

• Nonmetallic White

Cover

• Adjustable 20 cu. in.

Nonmetallic Floor Box

• Duplex Receptacle

• Molded Cable Clamps

• Mounting Bracket

• All mounting hardware

2-HR-F

FLOOR BOX

696Y

Assembled in USA

Patent #5,289,934

B121BFBRW

NEW!

Page 2

INSTALLATION INSTRUCTIONS

This floor box is designed to be mounted on a

joist or subfloor. It can be installed on the top of

the joist or from the bottom if the thickness of

the joist is sufficient to allow installation of the

box. If the unit is to be installed from the bottom

of the joist, check prior to installation to ensure

there is sufficient adjustment remaining as this

type of installation is non-standard.

The unit can also be installed using the old work

(small) bracket that is included. This bracket

facilitates the installation of the box in areas

where the larger new work bracket cannot be

used. The old work bracket edge is hidden by the

cover when installed. However, before cutting into

the wood, you must ensure that the mounting

screws will properly support the bracket/box

installation.

For planning purposes please ensure that the

maximum installed height to the bottom of the

cover does not exceed 1-3/4" above the top of the

mounting bracket.

The kit is listed as a floor box by Underwriters

Laboratories. The kit also has a two (2) hour fire

classification. Only covers manufactured for this

box can be used with this assembly.

Floor box kit should be installed by a certified

electrician.

Install clip over subfloor.

Screw in to adjust to height

of flooring or carpet.

Beautiful flush fit every time!

2-HR-F

FLOOR BOX

696Y

Assembled in USA

Patent #5,289,934

Page 3

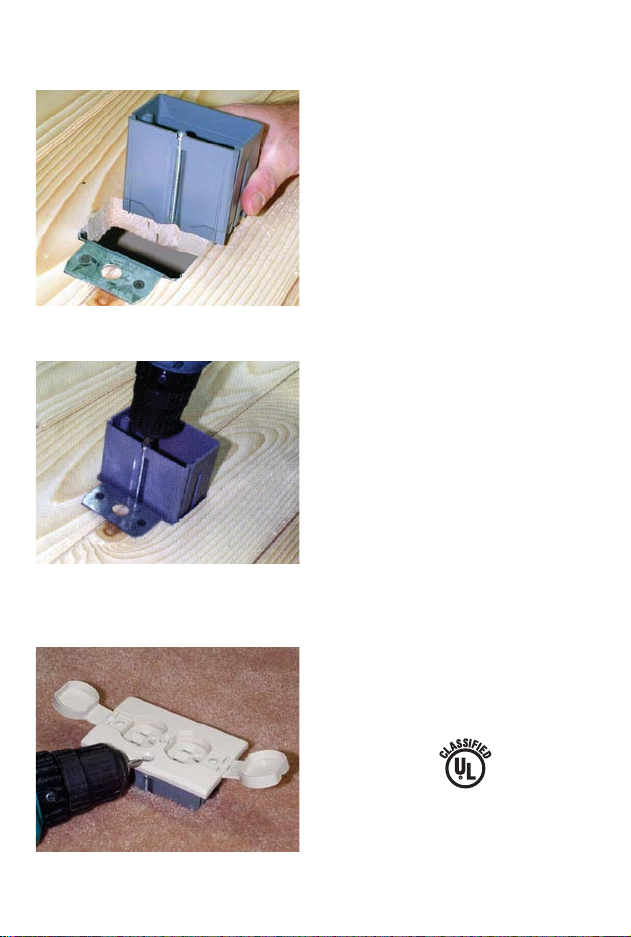

Installation – New Work Bracket

1. The new work metal bracket may be installed on the

floor joist below a 3/4 inch subfloor. When a thicker

subfloor is used we recommend cutting a hole in the

subfloor using the box as a template and adjacent to

the joist so the mounting screws will engage the joist

as well as the subfloor. Use the four (4) #6 1-3/4"

self-tapping screws suppled with the kit to mount the

bracket.

2. If the new work bracket is installed from the underside of the joist, ensure the alignment with the box

and opening before installing the bracket. Use the

four (4) #6 1-1/4" self-tapping screws supplied with

the kit to mount the bracket.

3. The romex wire can then be pulled through the

desired clamp and the box aligned in the bracket

slide. Ensure the adjusting screw is aligned on the

bracket and rotate the screw clockwise using an electric or pneumatic POWER screw gun. (The adjusting

screw can be turned manually with a screwdriver, but

this is a self-tapping screw that is cutting threads

into hardened steel and it will be very, very difficult.)

4. Adjust the box flush to

1

/2" above floor, leaving

sufficient room to complete the installation.

5. Wire the receptacle in accordance with the National

Electrical Code.

6. Cut the top of the tube containing the Dow Corning

#4 sealant and apply an 1/8 inch bead of the sealant

around the outside rib of the cover that mates with

the box. Align the receptacle on the recessed bosses

and place the cover on the box with outlet caps open.

Push cover into the box until rib on bottom of cover

engages with box.

7. Insert the two (2) 6-32x1 inch flat-head machine

screws in the holes in the cover, ensuring that the

screw is aligned with and captivates the receptacle.

DO NOT OVER TORQUE. Tighten the screws to a

maximum of 6 to 8 inch pounds. Ensure bottom of

cover is still engaged with box.

8. Remove the plug on the cover that hides the adjusting screw opening and set it aside where it will not

be misplaced.

9. Using the adjusting screw, adjust the assembly so

cover flange is flush with floor covering. Do not preload the cover against the floor covering. Place the

“button” you previously set aside in a safe place over

the adjusting screw opening.

10. In order to ensure a watertight seal, apply a thin layer

of the Dow Corning #4 sealant around the cap and

cover mating surfaces.

11. Turn the coin slot lock in the center of the cover in

either direction to lock the outlet caps.

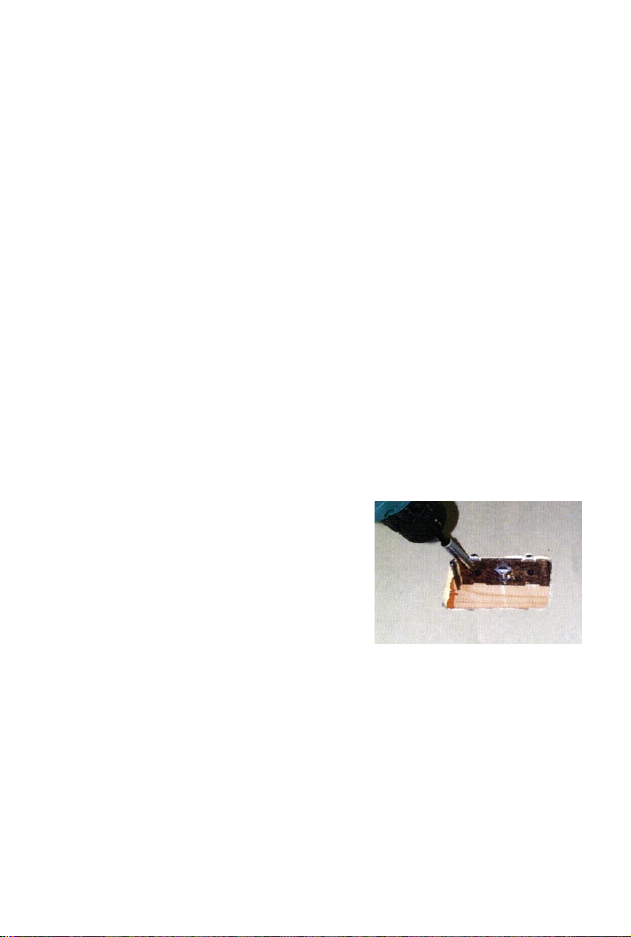

Installation – Old Work Bracket

1. As indicated in the prior instructions,

ensure there is sufficient depth of

the floor covering to install the old

work bracket. If not, the bracket

must be installed adjacent to a joist

where the screws will engage the

joist/flooring for support.

2. Use the box as a template and cut

out an opening in the floor cover.

3. Place the bracket on the side of the

opening where it is to be mounted

with the two tabs up and resting on

the surface. (Be careful not to drop

the bracket into the opening.)

4. Install the bracket using the two (2)

square drive trim head screws

provided in the kit. Since the screws

are installed at an angle, there may

be a small part of the screw head

that protrudes. This is to be anticipated and will not interfere with the

installation of the box.

5. Use the installation instructions for

the new work bracket from this point

forward starting with step 3.

Old work bracket

installation for tight

locations or cut-in

situations

MAINTENANCE

To ensure continued service, it is

recommended that the sealing surfaces

of the caps and cover be kept free of

debris.

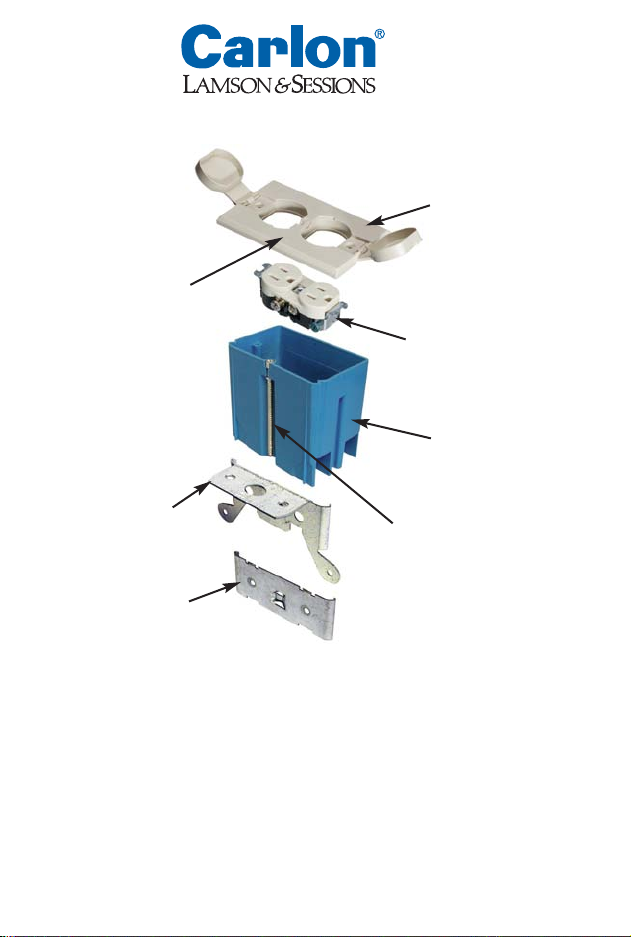

Page 4

25701 Science Park Drive • Cleveland, Ohio 44122 • www.carlon.com

Adjustable

Floor Box

Assembly

• One (1) New Work Bracket

• One (1) Old Work Bracket

• One (1) 20 cubic in. UL Listed floor box

• One (1) UL Listed white floor cover

• One (1) short shank receptacle

Package Contents

Plug

White Cover

Receptacle

Adjusting Screw

New Work Bracket

Old Work Bracket

20 cu. in. Floor Box

• Two (2) 6-32x1 flat head machine screws

• Four (4) #6 1-1/4 self-tapping flat head screws

• Two (2) #6 square drive trim head screws

• One (1) tube Dow Corning #4 sealant

• Installation instructions

Caution: The floor box has undergone a scrub water test as required by UL under criteria

specified in 514C for this type of application. However, it is not intended for nor approved for

wet locations or outdoor installation.

IS121W 01/03

© Lamson & Sessions 2003

Loading...

Loading...