Page 1

www.carlonsales.com

6

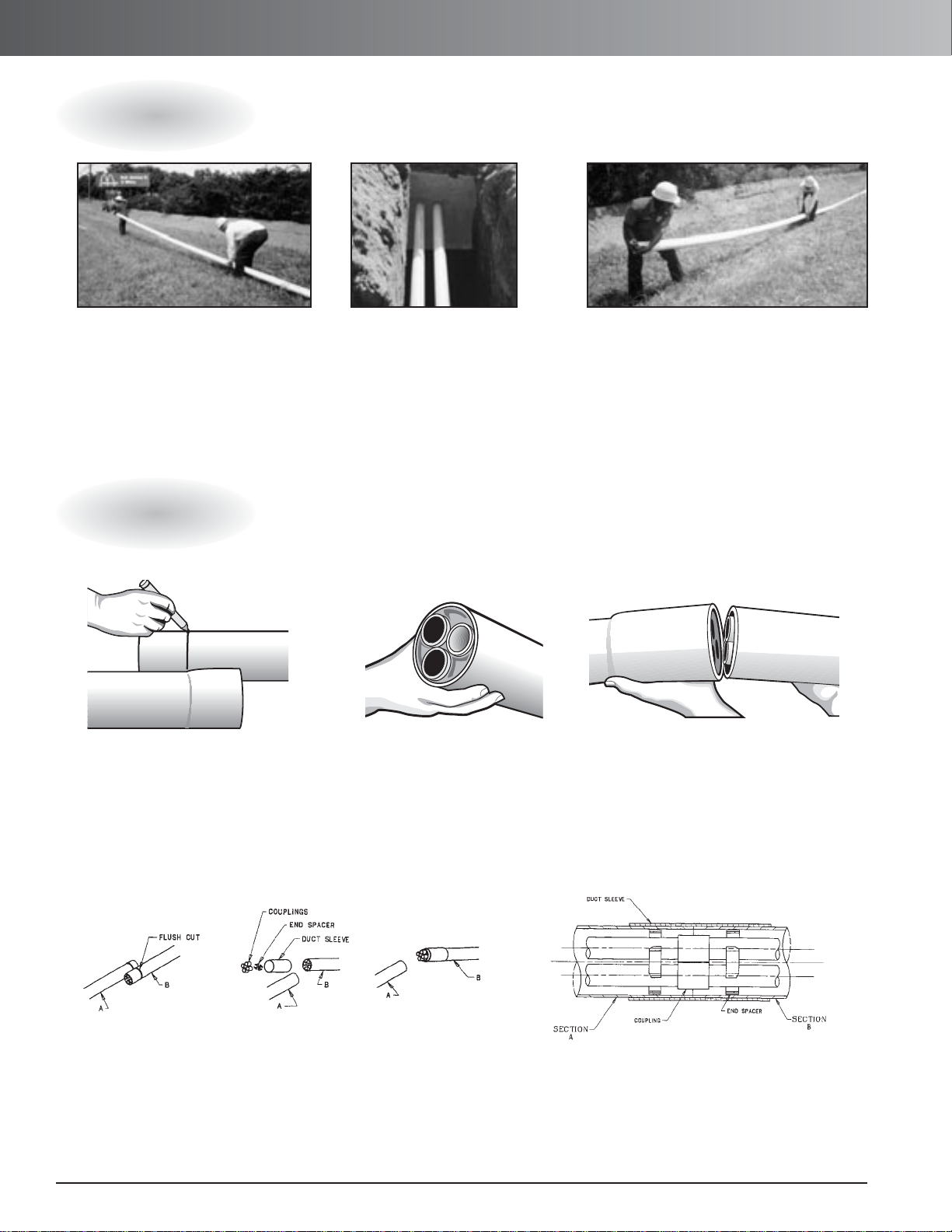

Multi-Gard®PVC – Assembly/Field Cuts

Assembly

Field Cuts

1.

Distribute Multi-gard sections along

the sides of the trench with male ends

pointing towards starting vault entrance.

2.

Remove protective cap and

install Multi-Gard terminator on

male end. Install first section

into vault opening or enclosure

making sure the print line is on

the top stating “INSTALL PRINT

LINE UP.” (See next page for

terminations.)

2. A spare spacer may be

installed to align the innerducts

if they seem loose.

2. Align innerducts on Multi-Gard section “A” with

couplings on section “B”. Solvent cement each coupling

for air tight seal and push until both ends are flush.

Apply solvent cement to both ends of Multi-Gard and

slide sleeve until it is centered on both sections.

3.

Each consecutive 20' section can now be

placed by inserting the male end into the gasketed belled end 1/2

" to the gasket depth. Make

sure the print line is upright. (If not, rotate the

outer duct until it is.) Now push the sections

together with a firm push until belled end seats

against insertion line.

3. Raise both ends and align the innerducts

on the male end into the coupling body on

the female end. Lower both ends and the

innerducts will automatically return to their

original position as the joints are forced

together.

Joining Male and Female Ends

Joining Two Male Ends

1. Lay the Multi-Gard sections side by

side and mark the male end at the

base of the bell on the female end.

Make a straight cut using

a standard carpenter saw.

1. Flush cut Multi-Gard sections “A” + “B” as shown in figure 1. Slide

outerduct sleeve over Multi-Gard section “B” as shown in figure # 2.

Insert end spacer into Multi-Gard plain end (chamfer side in) as

shown in figure #2. Press couplings onto innerducts of Multi-Gard

section “B” as shown in figure #3.

FIGURE 1

FIGURE 2

FIGURE 3

M CC4

–

Gross Automation (877) 268-3700 · www.carlonsales.com · sales@grossautomation.com

Page 2

www.carlonsales.com

7

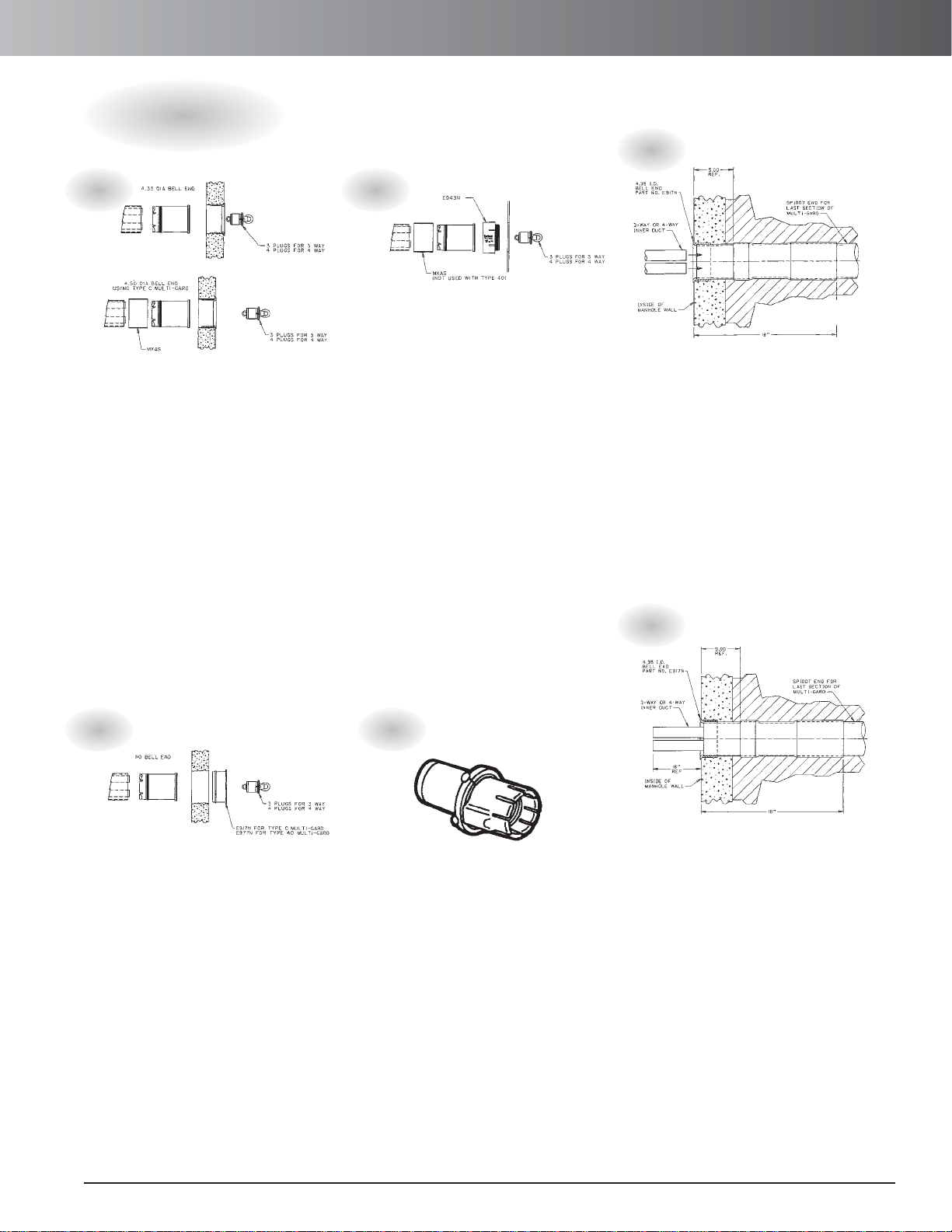

Multi-Gard®PVC – Terminations

Standard Terminators (Type 1) allow

Multi-Gard to be terminated into a

standard pre-cast termination.

1. Remove watertight plugs in order to

assure total insertion of the Multi-Gard

innerducts.

2. Install terminators into male end of

Multi-Gard to full depth.

3. Replace watertight plugs into the

terminator and tighten.

4. Insert prepared male end into the

pre-cast terminator with print line facing

upward. Solvent cement into place.

5. Use shim enclosed for terminator

requiring a connection of Type C

(4.35 O.D.) into a Type 40 (4.50 O.D.)

termination.

Use a Type 6 Enclosure Terminator at

entrances into metal or non-metallic

enclosures above ground.

1. Remove watertight plugs in order to

assure total insertion of the Multi-Gard

innerducts.

2. Install terminators into male end of

Multi-Gard to full depth.

3. Replace watertight plugs into the

terminator and tighten.

4. Install threaded adapter over end of

Multi-Gard using solvent cement. Insert

adapter through enclosure hole and

provide 4" locking ring.

5. Use shim enclosed for terminator

requiring a connection of type C (4.35

O.D.) termination.

The pass-through terminator is designed to

allow for continuous ducts through the vault

or hand hole for cable pulling.

1. Install terminator into vault following steps

1 through 5 for standard Type 1 terminator.

2. Cut innerduct of pass through kit 10" longer

than the width of the manhole. Add spacers

as needed.

3. Upon completion, remove the watertight

plugs and install innerducts to traverse

manhole/handhole by cutting to length

inserting into one side of handhole and

raising or bowing center of innerduct span

to insert into the pass-through terminator

on the opposite side. (See pass-through kits

on page 276.)

Use a Type 1 Standard Terminator also at an

entrance where a pre-cast terminator is not

available or a knockout is used:

1. Insert the male end section of Multi-Gard

4 inches past the inside wall of the vault

with print line facing upward.

2. Remove the protective cap from the male

end of the Multi-Gard.

3. Remove the watertight plugs and insert

the terminator to full depth.

4. Install bell fitting over the end of

Multi-Gard using solvent cement, and

replace plugs.

5. Slide Multi-Gard section until bell fitting is

flush with inside, and then seal entrance as

required by job specifications.

Use the jet terminator for jetting operations.

1. Remove watertight plugs in order to assure

to total insertion.

2. Apply standard grade solvent cement

(VC9962) to male end of Multi-Gard. Install

jet terminator to insertion line.

3. Replace watertight plugs into terminator

and tighten.

4. Apply standard grade solvent cement to

terminator male end and insert into pre-cast

bell end. (Install PVC bell fitting in kit if precast bell end is not available).

5. Use shim enclosed for terminator requiring

a connection of Type C (4.35" O.D.) into a

Type 40 (4.50" O.D.) termination.

6. Measure between ends of terminators on

opposite ends of vault, and cut innerduct to

length.

7. Solvent cement each coupling into place or

use mechanical coupling rated for use with

high speed air blowing systems.

Use split plugs for sealing Multi-Gard cells

where cable has been installed.

(See page 274)

Terminations

1.

3.

5.

4.

2.

6.

Gross Automation (877) 268-3700 · www.carlonsales.com · sales@grossautomation.com

Page 3

www.carlonsales.com

8

Multi-Gard®PVC – Installation

All PVC Trenching installation allows

Multi-Gard to be placed in the trench

one section at a time or over the

trencher for continuous feed.

Open trenching with Type C Multi-Gard

is recommended for direct burial or

concrete encased applications.

• Install one section at a time.

• Multiple-cells are installed as soon

as product is placed.

• Economical installation with

installation speed as fast as the

trencher.

• Easy installation with standard

equipment.

• Gasketed coupling body prevents

conduit pulling apart during

installation.

• Industry standard outer duct in

Type C is suitable for direct burial.

• Schedule 40 outershell and

Schedule 80 outershell are

available where extra protection

is necessary.

• Spacers inside outershell allow

PVC innerduct internal movement

allowing for more flexibility.

Paved Areas In paved areas, the surface should be carefully

cut to prevent unnecessary excessive width at the top of the

trench and help reduce the amount of surface to be repaved.

Trench Width For economical operation, particularly where

paving is involved, the trench width should be no greater than is

needed to provide adequate working space. Generally, this

dimension is controlled by the types of excavating equipment

used. As a minimum, the trench must be 5 inches wider than the

width of the conduit structure where backfill will be used and 3

inches wider where concrete encasement will be used.

Individual job specifications will dictate trench width.

Trench Bed Grade and level the trench bed. Where necessary, provide sand and/or other granular backfill as bedding

material so the conduit will be evenly supported over the length

of each section.

Assembly On Top Of The Trench After preparing the

trench, the Multi-Gard can be assembled on top of the ground

outside of the trench by following the directions described on

page 5. Once joined together, the Multi-Gard can then be laid

gently into the trench. Backfill according to the job specifications.

Trench Feeding Multi-Gard Using Rollers This

procedure involves assembling the Multi-Gard above the

ground. After the first four or five lengths are assembled, place

on top of the trenching machine. The remainder of the duct can

be attached to the first section and assembled ahead of the

trencher on the ground directly above the intended place for the

trench. As the trencher advances forward, the Multi-Gard will

lay itself into the trench behind. Once placed in the trench,

backfill according to the job specification.

Trenching

Features Procedures

Gross Automation (877) 268-3700 · www.carlonsales.com · sales@grossautomation.com

Page 4

www.carlonsales.com

9

Multi-Gard®PVC – Repairs

Repairing Vacant Multi-Gard

Repairing Multi-Gard Containing Cable(s)

1. Cut out the damaged section

and insert a belled short section

(4" shorter than damaged

section) of Multi-Gard onto

either one of the ends (section A).

2. Apply 2" of cement on ends

of spigots of coupling body,

press couplings onto spigots.

3. Slide innerduct sleeve over

Multi-Gard plain end (section A).

Insert end spacer into MultiGard plain end (section B).

1.

Carefully cut out damaged section up to 10

feet. Larger sections can be accommodated

using multiple repair kits.

3.

Install corrugated innerduct and remaining

smooth innerduct into couplings by raising in

the center and guiding them into their respective openings. Install the spacers to evenly

support the innerduct.

4.

Lay one piece of split duct under the

repaired section. Install the other piece of split

duct onto the first piece and strap or tape in

place. Apply cement onto each end and slide

the slip sleeves until centered on both sections.

Backfill according to job specifications.

2.

Install the 4" split sleeve couplings over

the existing Multi-Gard. Slide the smaller split

couplings onto the individual innerduct, fitting

the cable into the split coupling. Repeat this

process on opposite side. Carefully insert the

cable(s) into the split corrugated innerduct.

4. Insert female end of slip coupling

into Multi-Gard plain end (section A).

Align sections A and B. Apply cement

to couplings. Slide slip coupling back

onto innerducts in Multi-Gard

(section B) until seated.

5. Apply cement to both

plain ends of Multi-Gard

and slide sleeve until

centered on both sections.

M SC4

–

Slip Coupling

Gross Automation (877) 268-3700 · www.carlonsales.com · sales@grossautomation.com

Page 5

www.carlonsales.com

10

Multi-Gard®PVC – Repair Kits

Repair Kits

Repairing Multi-Gard with Damaged Cables

E940F PVC Coupling

Couples PVC innerduct with solvent cement

for empty cells (standard grade qt. cement

#VC9962).

MAFPG7 Fiber Optic Simplex Plug

(cable O.D. range .57 - .65) Seals innerduct

with cable installed.

MAQPG2 Quadplex Plug (4 holes each)

Seals outershell and innerduct

1

2

3

4

5

Repair Kit Instructions:

1.

Dig around break area enough to allow vault to

drop over the repair area and rest level when the

mouseholes have been cut away for the duct.

2.

Cut away and remove outer shell and any

damaged inner-ducts, being careful to protect

any exposed cables.

3.

Cut back the outer duct to allow approximately

6

"

of inner-duct exposed.

4.

Install the splice case per manufacturer’s or

customer’s specifications, allowing enough cable

slack so no tension is felt.

2

1

3

4

1

3

2

5

6

6

48808DK PVC Pass-through Kit

(4 x 20' lengths) 20 foot lengths can be cut to

length for continuous empty innerduct.

Underground Vault & Lid needed

Choose size & construction based on dimensions

of splice cases and weight requirements. (Allow

12" on either side of splice for bending

innerduct)

Splice Case

5.

Install the quad plugs (Item #3) and single

plugs (Item #2) in duct containing cable.

6.

Install pass-through ducts (Item #4) with

coupling (Item #1) sealing with solvent cement.

7.

Set the enclosure base over the entire package

and place cover on enclosure.

8.

Refill hole as required.

Gross Automation (877) 268-3700 · www.carlonsales.com · sales@grossautomation.com

Loading...

Loading...