Page 1

Made in the U.S.A.

P&C Flex®Installation & Fittings

www.carlonsales.com

Part Std. Std.

Ctn.

No. Size

Ctn. Qty. Wt. (lbs.)

E940H 11/

2"25 4

E940J 2" 30 5

E940K-CAR 21/2"4 2

E940L-CAR 3" 5 3

E940M 31/2"20 13

E940N-CAR 4" 5 4

Couplings

Part Std. Std.

Ctn.

No. Size

Ctn. Qty. Wt. (lbs.)

P258H 11/

2

"50 2

P258JT 2" 60 3

P258K 21/2"25 2

P258LT 3" 30 3

P258NT 4" 48 8

Plugs

1. Trenching

Trench should be graded true and free from stones or soft

spots. Backfill should also be free of stones and be firmly

tamped around the sides of the conduit, to develop maximum

supporting strength. Tamping on top of the conduit is not

recommended.

2. Backfill

In rocky soil where it is impossible to have an even trench

bottom, a selected backfill should be put in before laying the

conduit. Selected backfill (not tamped) at least 6" over the

top of the conduit is recommended. After

final backfill is placed, taming may be used

to finish the grade.

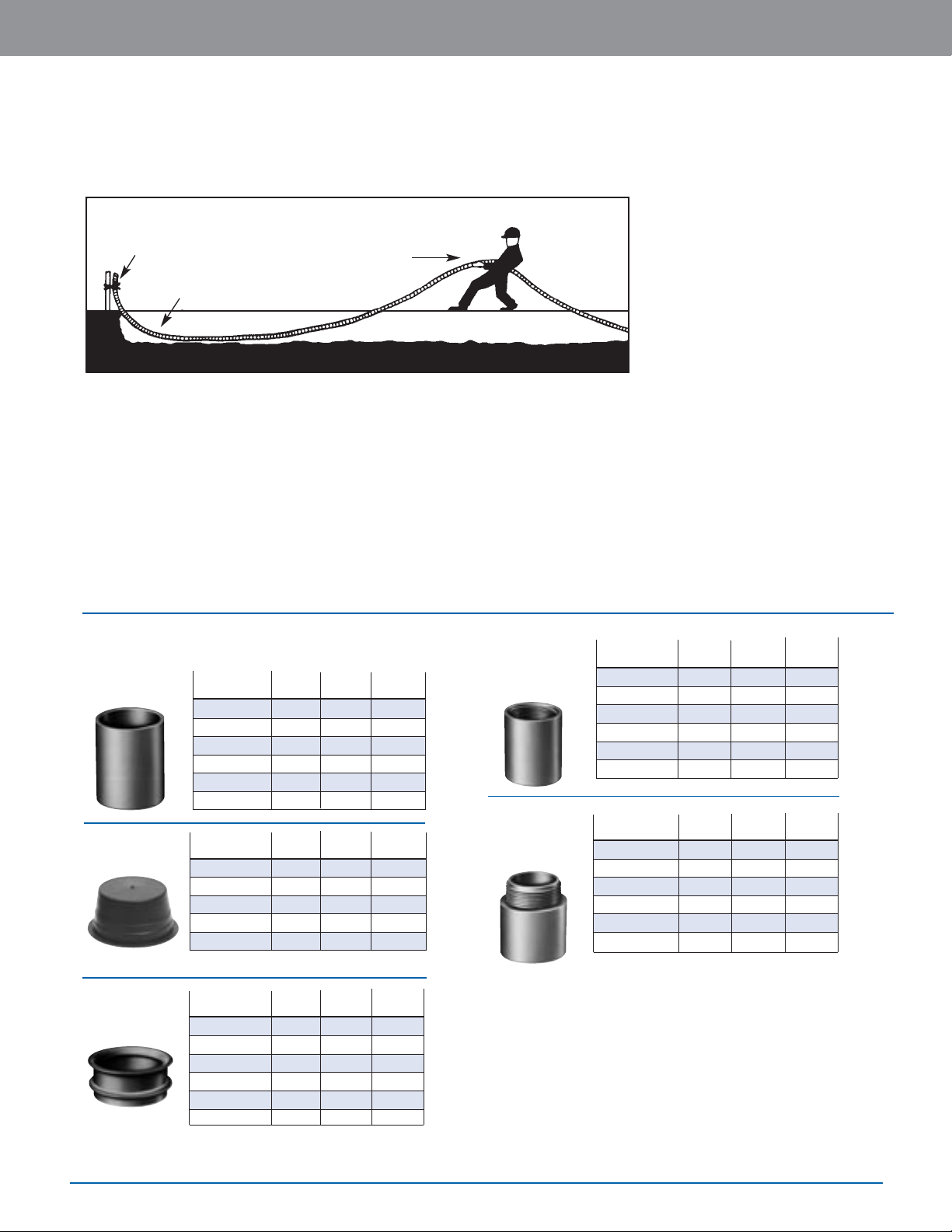

3. Duct Placement

Duct may be unreeled directly into trench or

along side trench and subsequently placed

in trench. After placing in trench, secure one

end and stretch it by hand to take up the

slack. Spot backfill to hold in position. Do

not use mechanical stretching equipment.

4. Changes in Direction

Avoid unnecessary turns, dips, or changes in direction. Keep bends as gradual

as possible to assure ease of cable pull-in after duct installation.

5. Pneumatic Rodding

All commonly used vacuum or pressure can be used to rod P&C Flex. The line

carrier (mouse, puck, rocket) should be soft, flexible material designed to fit

snugly into duct without interference.

6. Mechanical Rodding

All commonly used mechanical rodding equipment can be used to rod P&C

Flex. The tip should have a ball-type arrangement to keep rod from catching in

the convolutions on the inside of duct.

P&C Flex®Conduit Fittings

Part Std. Std.

Ctn.

No. Size

Ctn. Qty. Wt. (lbs.)

E997H-CAR 11/2"10 .9

E997J-CAR 2" 10 1.2

E997K-CAR 21/2"10 1.9

E997L-CAR 3" 10 2.1

E997M 31/2"40 10.2

E997N 4" 30 10.7

Bell Ends

(Schedule 40)

Part Std. Std.

Ctn.

No. Size

Ctn. Qty. Wt. (lbs.)

E942H 11/2"25 3

E942J 2" 30 6

E942K-CAR 21/2"4 1.4

E942L-CAR 3" 3 1.5

E942M 31/

2"20 12

E942N-CAR 4" 7 5

Female

Adapters

Part Std. Std.

Ctn.

No. Size

Ctn. Qty. Wt. (lbs.)

E943H 11/2"25 3

E943J 2" 5 7

E943K-CAR 21/2"5 1.2

E943L-CAR 3" 5 2

E943M 31/

2

"30 14

E943N-CAR 4" 5 3

Terminal

Adapters

49

P&C Flex®Corrugated Flexible Conduit Installation

Techniques

STRETCH DUCT IN ONE DIRECTION

AWAY FROM SECURED END

SPOT BACKFILL

KEEP BENDS AS GRADUAL

AS POSSIBLE

SECURE END

Gross Automation (877) 268-3700 · www.carlonsales.com · sales@grossautomation.com

Loading...

Loading...