Carlon CS863, CS12106, CS665, CS14126, CS1085 Installation Instructions And Accessory Applications

...Page 1

®

Installation Instructions

and Accessory Applications

English

Mounting Feet:

This enclosure is shipped with its mounting brackets and

installation screws packaged inside. Bracket design permits this

enclosure mounted with major dimension vertical. The purchase

of mounting feet (Part No. CJB 159) permits this enclosure to

be mounted with the major dimension horizontal to the ground.

(Cut out style only.) Use athead screw (1/4-20x1/2”) to secure

brackets to enclosure. Securely tightening the mounting brackets

will insure positive positioning of the enclosure. Torque limits for

these athead screws are 50 in-lbs (maximum).

Covers:

The fastenings for the cover are captive slotted stainless steel

lister head screws (10-32), which are factory installed. The

torqued down limits for these screws are 25 in-lbs (maximum).

Installation of Conduit:

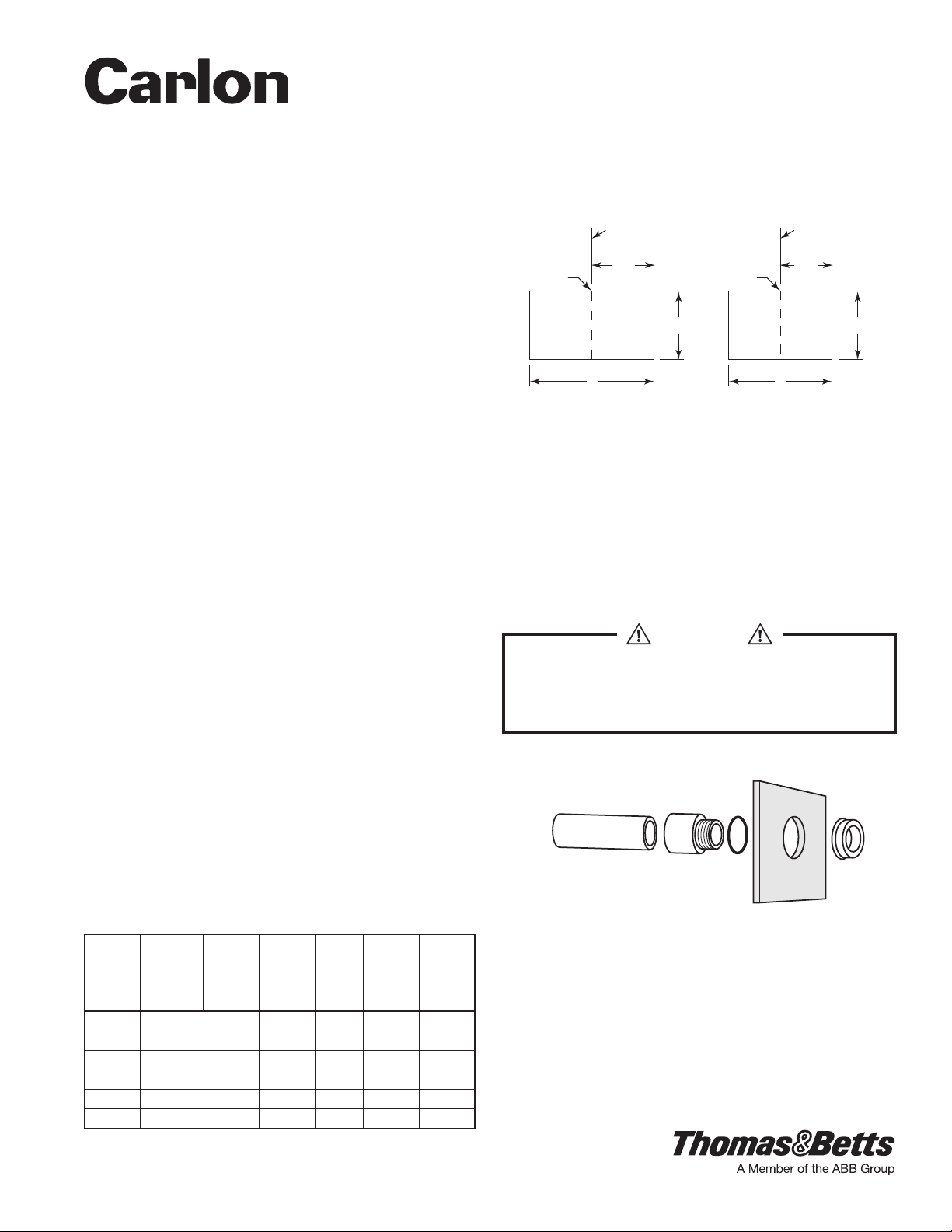

1) CONDUIT HOLES:

Cut holes in enclosure (when required) at the desired location.

The use of a standard hole saw is the preferred method.

For proper location of hubs, prepare a paper template with

the recommended B x C (End Installation) or A x C (Side

Installation) dimensions. Reference the table below for the

specic enclosure size. Position a standard hole saw anywhere

within the rectangle and drill (care should be taken to prevent

damaging the bosses). The maximum hub and hole size varies

with the size of the enclosure.

Reference point F should always be centered midway

between the bosses.

For side installation on hinge models, hinge side, conduit holes

should be positioned a minimum of 1” from bottom of hinge

assembly. All other dimensions are the same as on hingeless

models.

C Series Enclosures do not have the same conduit placement

requirements. It is recommended that hole locations be

centered on the sides a minimum of 1-1/2” from the bottom

and 2-1/2” from the top.

TEMPLATE DIMENSIONS FOR LOCATION

OF ELECTRICAL FITTING IN CUTOUT BOXES

PS, PJ, CS, CJ, CV & CC MODELS

Catalog

Number

CS665 6x6x5-3/4 5-1/4 2-3/4 2-1/4 1-1/2 1-1/2

CS863 8x6x3-1/2 7-1/8 2-3/4 1-5/8 1-1/2 1-1/2

CS1085 10x8x5-3/4 4 4-3/4 2-1/4 1-1/2 1-1/2

CS12106 12x10x6-3/4 4-3/4 6-3/4 3-3/4 2-1/2 2-1/2

CS14126 14x12x6-3/4 6 8-3/4 4-1/2 3-1/2 3-1/2

CS16147 16x14x7-1/2 6-3/4 10-3/4 4-1/2 3-1/2 3-1/2

Inside Box

Size

Side

Installa-

tion

A

End

Installa-

tion

B C

Long

Side

Max.

Conduit

Size

Short

Side

Max.

Conduit

Size

Line up with scribe

Line on “TOP” or “BOTTOM”

of box.

1/2

F F

Figure 1

B

B A

C C

Line up with scribe

Line on side of box.

1/2

A

2) CONDUIT CONNECTIONS:

a. Metallic Conduit:

1. Secure the conduit connector (hub) onto the conduit, as

the hub shall be connected to the conduit BEFORE the

hub is connected to the enclosure.

2. Secure conduit connector (hub) into the prepared

enclosure hole using the connector locknut.

3. Attach grounding bushing having the proper size ground

wire lug over the connector locknut.

CAUTION

In accordance with the National Electrical Code, the

enclosure must be bonded between the grounding

bushings or between the grounding bushings and

the equipment grounding terminal (when provided).

Carlon Watertight Hubs

(See Hub Section)

Figure 2

b. Nonmetallic Conduit (see illustration above): Secure

conduit to the conduit connector (hub), and the

hub shall be connected to the conduit BEFORE the

hub is connected to the enclosure, then secured

into the prepared hole using the connector locknut.

NOTE: Ground bushing not required when

attaching to nonmetallic conduit.

TA04617 C Page 1 of 4

Page 2

CAUTION

To prevent enclosure damage and attain the enclosure

requirements, the conduit should be aligned so as to

prevent unnecessary stress on the enclosure walls.

To obtain maximum corrosion protection, with

metallic conduit and hub assemblies, cover (coat)

all exposed metal and seal off the conduit openings

where the conductors enter the enclosures.

Grounding of Equipment:

Install the grounding conductor in accordance with the

requirements of the National Electrical Code. See illustrations

below for metallic and nonmetallic conduit.

Hubs:

For metallic conduit application the use of a Listed Hub and

Grounding Bushing System is required.

For nonmetallic conduit application, use Carlon’s male adapter

(sizes E943 through E943R) and “O” ring (sizes E943DX through

E943RX) with bushing (sizes E943DY through E943RY).

Hinge Caps (included):

Metallic Conduit NonMetallic Conduit

CONNECTOR LOCKNUT

GROUNDING BUSHING

GROUNDING CONDUCTOR

EQUIPMENT

GROUNDING

TERMINAL

(WHEN PROVIDED)

Figure 3

Figure 4

Catalog Number CH 100R, have been added to the design

to reduce dirt and dust accumulation in the hinge pin and lid

assembly.

To position the hinge caps, align the snap tang and push.

To remove hinge caps, insert a point (such as a pencil) in the

lid hinge section and push the pencil point toward the side

of the enclosure. This will permit the snap tang to clear the

molded interference. Then pull the hinge cap from the slot.

EXTERIOR PAINTING OR FINISHING – PLEASE CONTACT THOMAS & BETTS FOR LIST OF

APPROVED FINISHING SYSTEMS.

NOTE: Enclosure drilled for conduit or other fabrication steps may NOT be returned for credit.

WARRANTY: Thomas & Betts sells this product with the understanding that the user will perform all necessary tests to

determine the suitability of this product for the user’s intended application. Thomas & Betts warrants that this product will

be free from defects in materials and workmanship for a period of two (2) years following the date of purchase. Upon prompt

notication of any warranted defect, Thomas & Betts will, at its option, repair or replace the defective product or refund the

purchase price. Proof of purchase is required. Misuse or unauthorized modication of the product voids all warranties.

Limitations and Exclusions: THE ABOVE WARRANTY IS THE SOLE WARRANTY CONCERNING THIS PRODUCT, AND

IS IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY

DISCLAIMED. LIABILITY FOR BREACH OF THE ABOVE WARRANTY IS LIMITED TO COST OF REPAIR OR

REPLACEMENT OF THE PRODUCT, AND UNDER NO CIRCUMSTANCES WILL THOMAS & BETTS BE LIABLE FOR

ANY INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Thomas & Betts Corporation

Memphis, Tennessee

TA04617 C Page 2 of 4

www.tnb.com

© 2017 Thomas & Betts All Rights Reserved.

Page 3

MD

Directives d'installation

et utilisations d'accessoires

Français

Pattes de fixation:

Ce boîtier est livré avec ses brides de xation et ses vis de montage

emballées à l'intérieur. La conception des brides permet à ce boîtier

d'être monté à la verticale. L'achat de pattes de xation (Pièce No.

CJB 159) permet à ce boîtier d'être monté à l'horizontale (style

disjoncteur uniquement.). Utiliser la vis à tête plate (1/4-20x1/2po)

pour xer les brides au boîtier. Bien serrer les brides de xation

assurera la bonne mise en place du boîtier. Les limites de couple

pour ces vis à tête plate sont 50po-lb (maximum).

Couvercles:

Les attaches pour le couvercle sont des vis fendues imperdables

à tête cylindrique bombée (10-32), posées en usine. Les limites de

couple pour ces vis sont 25po-lb.

Installation du conduit:

1) TROUS POUR LE CONDUIT:

Découper des trous dans le boîtier (s'il y a lieu) à l'emplacement

choisi. L'utilisation d'une scie-cloche standard est la méthode

préférée.

Pour choisir le bon emplacement des emboîtements, préparer

un gabarit en papier avec les dimensions recommandées B x

C (Installation en extrémité) ou A x C (Installation latérale). Se

reporter au tableau ci-dessous pour la taille spécique du boîtier.

Placer une scie-cloche standard n'importe où dans le rectangle et

percer (il faut faire attention à ne pas endommager les bossages).

La taille maximale de l'emboîtement et du trou varie en fonction de

la taille du boîtier.

Le point F de référence doit toujours être centré au milieu des

bossages.

Pour l'installation latérale sur les modèles à charnières, côté

charnière, les trous du conduit doivent être situés à plus de 1po

du bas des charnières. Toutes les autres dimensions sont les

mêmes que sur les modèles sans charnières.

Les boîtiers de série C n'ont pas les mêmes exigences de

placement de conduit. Il est recommandé que l'emplacement

des trous soit centré sur les côtés à plus de 1-1/2po du bas et

2-1/2po du haut.

DIMENSIONS DU GABARIT POUR L'EMPLACEMENT

DE RACCORD ÉLECTRIQUE DANS DES BOÎTES DE DISJONCTEUR

MODÈLES PS, PJ, CS, CJ, CV ET CC

Numéro

de cata-

logue

CS665 6x6x5-3/4 5-1/4 2-3/4 2-1/4 1-1/2 1-1/2

CS863 8x6x3-1/2 7-1/8 2-3/4 1-5/8 1-1/2 1-1/2

CS1085 10x8x5-3/4 4 4-3/4 2-1/4 1-1/2 1-1/2

CS12106 12x10x6-3/4 4-3/4 6-3/4 3-3/4 2-1/2 2-1/2

CS14126 14x12x6-3/4 6 8-3/4 4-1/2 3-1/2 3-1/2

CS16147 16x14x7-1/2 6-3/4 10-3/4 4-1/2 3-1/2 3-1/2

Taille inté-

rieure de

la boîte

Instal-

lation

latérale

Installa-

tion en

extré-

A

mité

B

Taille

max du

conduit,

long

C

côté

Taille

max du

conduit,

petit

côté

Aligner avec la ligne

Ligne au dessus ou au

dessous de la boîte

1/2

F F

Figure 1

B

B A

C C

Aligner avec la ligne

Ligne sur le côté

de la boîte

1/2

A

2) RACCORDEMENTS DES CONDUITS:

a. Conduit métallique

1. Fixer le raccord de conduit (emboîtement) au conduit

parce que l’emboîtement sera connecté au conduit

AVANT que l’emboîtement soit connecté au boîtier.

2. Fixer le raccord de conduit (emboîtement) dans le trou

préparé du boîtier à l'aide de l'écrou autobloquant du

raccord.

3. Fixer l'embout de mise à la terre à l'aide de la cosse

du l de mise à la terre sur l'écrou autobloquant du

raccord.

ATTENTION

Selon le National Electrical Code, le boîtier doit

être lié à la terre entre les embouts de mise à la

terre ou entre ceux-ci et la borne de mise à la

terre de l'équipement (s'il y a lieu)

Emboîtements étanches de Carlon

(Voir la section emboîtement)

Figure 2

b. Conduit non métallique (voir illustration ci-dessus):

Fixer le conduit au raccord de conduit (emboîtement)

et l’emboîtement sera connecté AVANT que

l’emboîtement ne soit connecté au boîtier et ensuite xé

dans le trou préparé en utilisant l’écrou autobloquant du

raccord.

NOTE: Embout de mise à la terre non obligatoire lors de

la xation d’un conduit non métallique.

TA04617 C Page 3 of 4

Page 4

ATTENTION

Pour éviter d'endommager le boîtier et pour atteindre les

exigences du boîtier, le conduit doit être aligné afin de

prévenir des contraintes inutiles sur les parois du boîtier.

Afin d'obtenir une protection maximale contre la corrosion,

avec les ensembles conduit et emboîtement métalliques,

recouvrir (couche) toutes les parties métalliques exposées

et sceller les ouvertures de conduit là où les conducteurs

pénètrent dans les boîtiers.

Mise à la terre de l'équipement:

Installer le conducteur de mise à la terre selon les

exigences du Code national de l'électricité. Consulter

les illustrations ci-dessous lors de l'utilisation d'un

conduit métallique ou non métallique.

Emboîtements:

Pour les conduits métalliques, l'utilisation d'un système homologué

d'embout et d'emboîtement de mise à la terre est exigée.

Pour les conduits métalliques, utiliser un adaptateur mâle Carlon

(tailles E943 à E943R) et un joint torique (tailles E943DX à E943RX)

avec un embout (tailles E943DY à E943RY).

Figure 4

Conduit métallique Conduit non-métallique

CONTRE-ÉCROU

Capuchons de charnière (fournis):

Numéro de catalogue CH 100R, ont été ajoutés à la conception an

de réduire l'accumulation de saleté et de poussière dans l'ensemble

MANCHON DE MISE À

LA TERRE

CONDUCTEUR DE MISE

À LA TERRE

ÉQUIPEMENT DU

TERMINAL DE MISE À LA TERRE

(LORSQUE FOURNI)

Figure 3

axe de charnière/couvercle.

Pour poser les capuchons, aligner le tenon à pression et pousser.

Pour retirer les capuchons, insérer une pointe (comme un crayon)

dans la section de la charnière du couvercle et pousser la pointe

avec le côté du boîtier. Cela permettra de dégager le tenon à

pression. Puis retirer le capuchon de charnière de la fente.

PEINTURE OU FINITION EXTÉRIEURE – VEUILLEZ COMMUNIQUER AVEC THOMAS & BETTS

POUR OBTENIR UNE LISTE DES SYSTÈMES DE FINITION APPROUVÉS.

NOTE: les boîtiers percés pour le passage de conduit ou autres étapes de fabrication NE doivent PAS être

retournés pour être crédités.

GARANTIE: Thomas & Betts vend ce produit à condition que l’utilisateur se charge des tests nécessaires pour déterminer

si le produit convient à l’application qu’il veut en faire. Thomas & Betts garantit que ses produits sont libres de vices de

matériaux et de fabrication pour une période de deux (2) ans de la date d’achat. Sur avis donné promptement de tout défaut

couvert par cette garantie, Thomas & Betts se réserve le choix de réparer ou de remplacer le produit défectueux ou d’en

rembourser le prix d’achat. L’avis doit être accompagné d’une preuve d’achat. Si l’outil est soumis à un mauvais usage ou s’il

fait l’objet d’une modication non autorisée, cette garantie devient nulle et non avenue.

Limitations et exclusions: CETTE GARANTIE EST LA SEULE GARANTIE VALABLE POUR CE PRODUIT. ELLE REMPLACE

TOUTE AUTRE GARANTIE, EXPRESSE OU TACITE, Y COMPRIS MAIS SANS S’Y LIMITER, TOUTE GARANTIE TACITE DE QUALITÉ

MARCHANDE OU DE CONFORMITÉ À L’USAGE AUQUEL IL EST DESTINÉ. LA SEULE RESPONSABILITÉ POUR RUPTURE DE

GARANTIE EST LIMITÉE AU COÛT DE RÉPARATION OU DE REMPLACEMENT DU PRODUIT ET THOMAS & BETTS NE POURRA, EN

AUCUN CAS, ÊTRE TENU RESPONSABLE DE DOMMAGES FORTUITS, DIRECTS OU INDIRECTS

Thomas & Betts Corporation

Memphis, Tennessee

TA04617 C Page 4 of 4

www.tnb.com

© 2017 Thomas & Betts Tous droits réservés.

Loading...

Loading...