Page 1

Specifications are subject to change (10.05.2002) 1

Type Rated operational Rated operational Control voltage

voltage U

e

current I

e

U

c

RSE: 22: 127/220 VAC, 50/60 Hz 25: 25 AAC 53b C:

Integral, 40: 230/400 VAC, 50/60 Hz 24 to 110 VAC/DC

motor controller 48: 277/480 VAC, 50/60 Hz & 110 to 480 VAC

60: 346/600 VAC, 50/60 Hz

Integral Motor Controller

Rated operational voltage

Rated operational current

Control voltage

Ramp selector

Ramp version number

Ordering Key

Motor Controllers

AC Semiconductor Motor Controller

Type RSE..-CR1

• Soft starting and stopping of 3-phase

squirrel cage motors

• Ramp selector setting for

Pump or Compressor motors

• Initial Torque setting with kick-start option

• Rated operational current: 25 AAC 53 b

• Rated operational voltage: Up to 600 VAC, 50/60 Hz

• Potential-free control input

• LED- indications for power supply, ramping, bypassing

relays, phase sequence and overheating.

• Integral over-temperature protection

• Auxiliary relays for end of ramp, over-temperature

and phase sequence alarms

• Built-in transient over-voltage protection

Product Description

The RSE-CR1 is an AC semiconductor controller specifically designed to switch

pump and compressor

motors using start and stop

ramps matched to the application. Initial torque is user

adjustable with optional kickstart to allow matching of the

start conditions with the

motor load. The start ramp

can be adjusted to last up to

20 s. Two stop ramps can be

Type Selection

selected: pump or compressor. The pump setting produces an immediate drop in

load voltage down to the level

of the initial torque setting, followed by a gradual ramp

down lasting up to 20 s. The

compressor ramp down

option drops the voltage

immediately to zero, but this

drop can be delayed by maintaining full load voltage for up

to 20 s.

RSE 40 25 - C R 1

Rated operational current I

e

Motor Rating

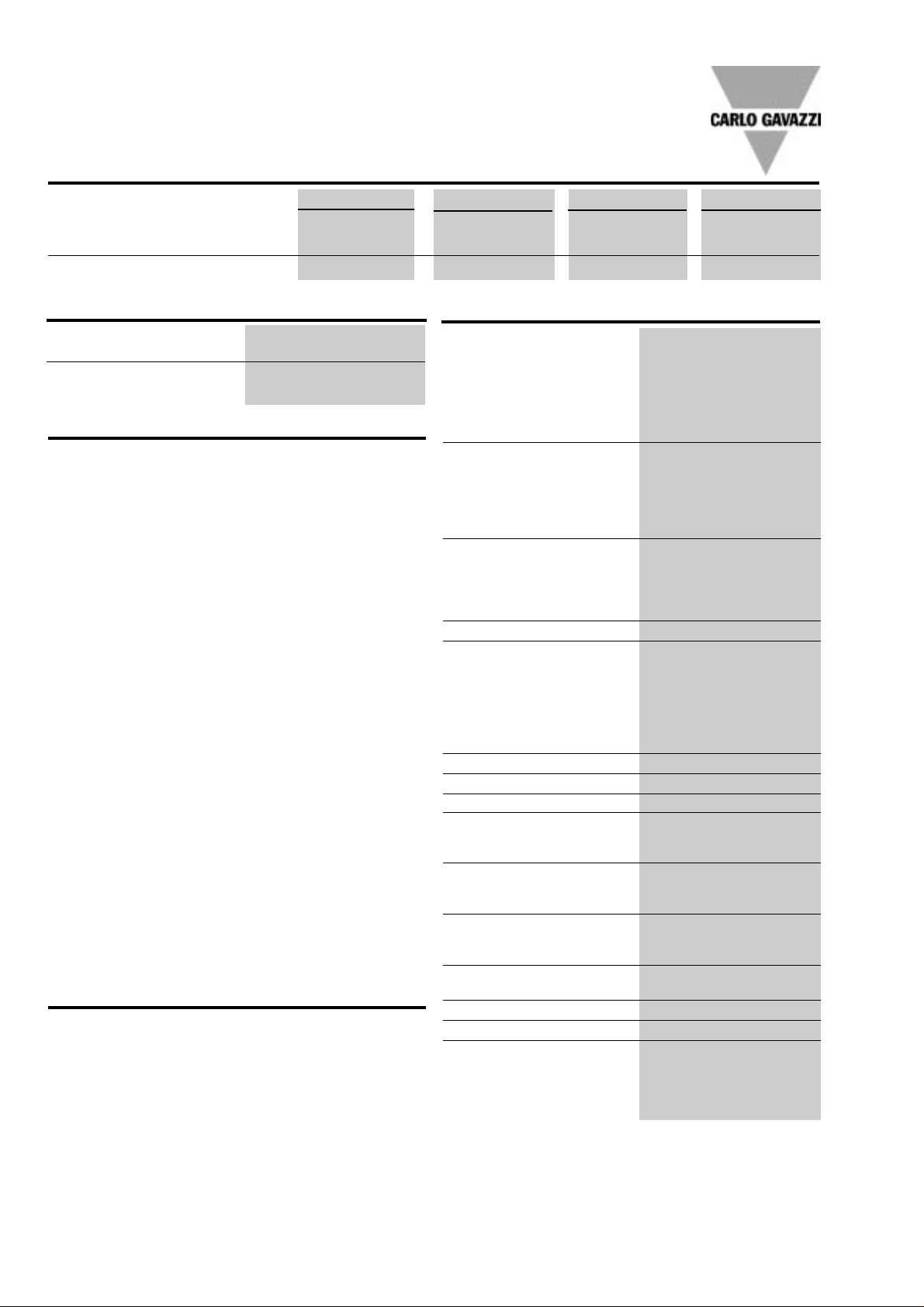

5.5 kW/10 HP 11 kW/15 HP 15 kW/20 HP 18.5 kW/25 HP

25 AAC 53b RSE2225-CR1 RSE4025-CR1 RSE4825-CR1 RSE6025-CR1

Selection Guide

Control input specification

Control terminals A1 - A2 Control terminals A1 - A3

Control supply voltage Uc 24 - 110 VAC/DC ± 15% 110 - 480 VAC ± 15%

Control supply current approx. 12 mA approx. 5 mA

Rated frequency for AC 50-60 Hz ± 10% 50-60 Hz ± 10%

Rated insulation voltage 630 V rms 630 V rms

Overvoltage cat. III (IEC 60664) Overvoltage cat. III (IEC 60664)

Dielectric strength

Dielectric voltage 2 kVAC (rms) 2 kVAC (rms)

Rated impulse withstand volt. 4 kV (1.2/50 µs) 4 kV (1.2/50 µs)

Page 2

2 Specifications are subject to change (10.05.2002)

RSE..-CR1

Accuracy

Ramp up 20 ±10% on max.

≤ 0.5 s on min.

Ramp down 20 ±10% on max.

≤ 0.5 s on min.

Initial torque 50% ±5% on max.

< 5% on min.

Indication for

Power supply ON LED, green

Ramping LED, yellow (flashing)

Bypassing relays LED, yellow (constant ON)

Wrong phase sequence LED, red (flashing)

Overheated LED, red (constant ON)

Environment

Degree of protection IP 20

Pollution degree 3

Operating temperature -20°to +5 0 ° C ( - 4 °to +122°F)

Storage temperature

-50° to +85°C (-58° to +185°F)

Terminals Self lifting screw terminals

Control terminals nominal 2.5 mm

2

, AWG 14

Min. 0.5 mm

2

, AWG 20

Mounting torque max. 0.6 Nm

Power terminals nominal 10 mm

2

, or 2 x 6 mm

2

AWG 6 or 2 x AWG 10

Min. 1 mm

2

, AWG 16

Mounting torque max. 2.0 Nm

Approvals UL, CSA

CE-marking Yes

EMC Immunity EN 50 082-2

Electrostatic discharge (ESD) IEC 61000-4-2,

IEC 60947-4-2,

IEC 60801-2

Radio Frequency IEC 61000-4-3

Electromagnetic fields IEC 60947-4-2

ENV 50140

Radio Frequency IEC 61000-4-6

common mode IEC 60947-4-2

ENV 50141

Simulation of GSM signals

900 Mhz ENV 50204

Burst / Fast transients IEC 61000-4-4

Surge IEC 61000-4-5

Wire Conducted Emission EN 55011*

CISPR 11

IEC 60947-4-2

* For AC mains: 150kHz - 30MHz

Mode of Operation

General

This motor controller is intended

to softstart / stop 3-phase

squirrel cage induction motors,

especially in pump and compressor systems. Three useradjusted potentiometers are

provided to enable matching of

the ramp profiles to the specific

load. This device can also be

used in other applications with

similar load characteristics.

Starting

During motor starting this motor

controller can provide a gradual

ramp up with a maximum duration of 20 s; this is user adjusted

with the Ramp Start potentiometer. The Initial Torque

potentiometer can be adjusted

from 5 to 50% of maximum

torque (at full load voltage) to

match the load inertia. For

loads with high inertia, a kickstart can be user selected to

supply full voltage to the load

for 200 ms. After the kick-start

is performed, the voltage is

dropped according to the initial

torque % setting and ramp up

occurs. When the starting ramp

is completed, the bypass relays

and end of ramp relay (normally

open) are activated.

Stopping

This motor controller is

equipped with specific settings

for PUMP and COMPRESSOR

applications, although it can

also be utilised in other applications. The PUMP scale on the

Ramp Stop potentiometer

allows a ramp down with maximum duration of 20 ms (user

adjusted). At the beginning of

the downward ramp the full load

voltage is immediately reduced

to the level of the initial torque

setting to cause an immediate

deceleration of the PUMP system. The voltage is thereafter

reduced gradually to zero to

provide a smooth deceleration

and therefore minimise vibration

and potential leakage in the system under pressure. The COMPRESSOR setting provides an

immediate total reduction of

voltage to zero. This stopping

ramp can also be delayed by up

to 20 s to allow the system to

continue running until a new

control signal is applied. This

will help avoid unnecessary

stop-start sequences that can

damage the COMPRESSOR

system.

General Specifications

Alarm Relays

Over-temperature Alarm

- If over-temperature is detected

on the internal heatsink (>100ºC

approx.) when the motor controller is not ramping, the device

will not start, ramp up will not

occur and the alarm relay

(Normally Closed) contact will

open.

- When the temperature drops

below the critical level, reset will

only take place if the supply is

interrupted and re-applied.

- If over-temperature is detected

on the internal heatsink (>100ºC

approx.) when the bypass relays

are activated, the alarm relay

(Normally Closed) contact will

open to indicate fault.

Wrong phase sequence alarm

- At connection of power the

motor controller will start normally

- The alarm relay (Normally

Closed) contact opens

Supply Specifications

Overvoltage cat.III IEC (60664) 220 V 400 V 480 V 600 V

Operating supply voltage Uc 127/220 VACrms 230/400 VACrms 277/480 VACrms 346/600 VACrms

through L1, L2, L3 ± 15% ± 15% ± 15% ± 15%

Rated frequency 50-60 Hz ± 10% 50-60 Hz ± 10% 50-60 Hz ± 10% 50-60 Hz ± 10%

Output Specifications

Utilization category AC-53b Integral bypassing

of semiconductors

Overload current profile

(overload relay trip class) 25 A:AC-53b: 4-3: 120

Page 3

Specifications are subject to change (10.05.2002) 3

Operation Diagrams

Ramp Adjustments

Mains

Overheated

LED, green

RSE..-CR1

Sequence L1-L2-L3

Control input Uc

LED, yellow

LED, red

M

3~

Alarm reset

End of ramp

Pump without kickstart Pump with kickstart Compressor without kickstart Compressor with kickstart

with delay on release and delay on release

Housing material PC/ABS Blend

Colour Light grey

Terminal block PBTP

Colour Black

Bottom clips POM

Colour Black

Front knob PC

Colour Grey

Housing Specifications

Dimensions

All dimensions in mm

Functional Diagram

Rated opera- I2t for fusing I

TSM

dI/dt

tional current t = 1 - 10 ms

25 A 1250 A2s 500 Ap 100 A/µs

Semiconductor Data

Page 4

4 Specifications are subject to change (10.05.2002)

RSE..-CR1

Fusing Considerations

The motor controller provides

by-passing of the semiconductors during running operation. Therefore the semiconductors can only be damaged

by short-circuit currents during ramp-up and ramp-down

function.

Recommended fusing

Ferraz 6.900 CP gRC 14.5140

A 3-phase induction motor

with correctly installed and

adjusted overload protection

does not short totally between

lines or directly to earth as

some other types of loads, eg

heater bands. In a failing motor there will always be some

part of a winding to limit the

fault current. If the motor is

installed in an environment

where the supply to the motor

cannot be damaged, the short

circuit protection can be considered to be acceptable if the

controller is protected by a 3pole thermal-magnetic overload relay .

Applications

Changing from Direct ON

Line start to soft start

(Line controlled soft-start)

(Fig. 1)

Changing a Direct On Line start

into a soft start is very simple

with the RSE soft-starting relay:

1) Cut the cable to the motor

and insert the RSE relay .

2) Connect control input to two

of the incoming lines.

Set

initial torque to minimum

and

ramp up and down to maximum.

3) Power up again - adjust the

start torque so the motor

starts turning immediately

after power is applied, and

adjust ramp time to the

appropriate value.

When C1 is operated, the

motor controller will perform

soft-start of the motor. When

C1 is switched off, the motor

will stop, the motor controller

will reset and after 0.5 s a new

soft-start can be performed.

Please note that the controller

does not insulate the motor

from the mains. Contactor C1

is therefore needed as a service switch for the motor .

Fig. 1

1L1 3L2 5L3

L1 L2 L3

A1

A2

A3

U/T1 U/T2 W/T3

M

Fig. 2

S1

I > I >

I >

~

L1 L2 L3L1 L2 L3

C1 C1

L1 L2 L3

L1 L2 L3

M

M

U/T1 U/T2 W/T3

U/T1 U/T2 W/T3

A1

A2

A3

Soft-start and soft-stop

(Fig. 2)

When S1 is closed, soft-start

of the motor will be performed

according to the setting of the

ramp-up potentiometer and

the setting of the initial torque

potentiometer. When S1 is

opened, soft-stop will be performed according to the setting of the ramp-down

potentiometer .

Motor full load current (AACrms) 12-16 16-20 20-25

Overload relay type :GV 2- M 16 M 20 M 22

Manufacturer : Telemecanique M 20 M 21

Overload relay type: MS 325- 12.5 20 25

Manufacturer : ABB 16

Motor protection circuit breaker type KTA3-25- 16 20 25

Manufacturer : Allan Bradley/Sprecher + Schuh

Motor controller type :

127/220 V mains RSE 22 25 - CR1

230/400 V mains RSE 40 25 - CR1

277/488 V mains RSE 48 25 - CR1

347/600 V mains RSE 60 25 - CR1

Recommended thermal-magnetic overload relay

Selection Chart

Thermal-magnetic overload relay and motor controller

Loading...

Loading...