Page 1

Specifications are subject to change without notice (30.03.2007) 1

Type Rated operational Rated operational Control voltage

voltage U

e

current I

e

Uc*)

RSE: E-series, 22: 127/220 VACrms, 50/60 Hz 03: 3 A -B: 24 to 110 VAC/DC

motor controller 40: 230/400 VACrms, 50/60 Hz 12: 12 A & 110 to 480 VAC

48: 277/480 VACrms, 50/60 Hz

60: 346/600 VACrms, 50/60 Hz

*) The control voltage should never be higher than the rated operational voltage.

Solid State Relay

Motor controller

E-line housing

Rated operational voltage

Rated operational current

Control voltage

Ordering Key

Motor Controllers

AC Semiconductor Motor Controller

Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - B

RSE 40 03 - B

•Soft starting and stopping of 3-phase

squirrel cage motors

•Rated operational voltage: Up to 600 VACrms, 50/60 Hz

•Rated operational current: 3 A or 12 AAC 53 b

•Potential-free control input

•LED-indications for supply and operation

•Transient overvoltage protection built-in

• Integral bypassing of semiconductors

Product Description

Compact easy-to-use AC

semiconductor motor controller. With this controller 3phase motors with nominal

load currents up to 12 A can

be soft-started and/or soft-

Type Selection

stopped. Starting and stopping time as well as initial

torque can be independently

adjusted by built-in potentiometers.

Input Specifications (Control Input)

Control voltage U

c

A1-A2: 24 - 110 VAC/DC ±15%,

12 mA

A1-A3: 110 - 480 VAC ±15%,

5 mA

Rated insulation voltage 630 V rms

Overvoltage cat. III (IEC 60664)

Dielectric strength

Dielectric voltage 2 kVAC (rms)

Rated impulse withstand volt. 4 kV (1.2/50 µs)

Output Specifications

Utilization category AC-53b Integral bypassing

of semiconductors

Overload current profile

(overload relay trip class)

RSE ..03-B 3A: AC-53b:3-5:30

RSE ..12-B 12A: AC-53b:3-5: 180

Min. load current

RSE ..03-B 100 mAAC rms

RSE ..12-B 200 mAAC rms

Page 2

2 Specifications are subject to change without notice (30.03.2007)

M

3~

RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - B

Power supply

Overvoltage cat. III (IEC 60664)

Rated operational volt. (Ue)

through terminals L1-L2-L3 (IEC 60038)

22 127/220 VAC rms ±15%

50/60 Hz -5/+5 Hz

40 230/400 VAC rms ±15%

50/60 Hz -5/+5 Hz

48 277/480 VAC rms ±15%

50/60 Hz -5/+5 Hz

60 346/600 VAC rms ±15%

50/60 Hz -5/+5 Hz

Voltage interruption ≤ 40 ms

Dielectric voltage None

Rated impulse withstand volt. 4 kV (1.2/50 µs)

Rated operational power 2 VA

supplied from L1-L3

Accuracy

Ramp up 5.5 - 7.5 s on max.

≤ 0.5 s on min.

Ramp down 6 - 10 s on max.

≤ 0.5 s on min.

Initial torque 70 - 100% on max.

5% on min.

EMC

Electromagnetic Compatibility

Immunity acc. to EN 61000-6-2

Indication for

Power supply ON LED, green

Ramp up/down bypassing relay

LED, yellow

Environment

Degree of protection IP 20

Pollution degree 3

Operating temperature -20° to +50°C (-4° to +122°F)

Storage temperature

-50° to +85°C (-58° to +185°F)

Screw terminals

Tightening torque

Max. 0.5 Nm acc. to IEC 60947

Terminal capacity 2 x 2.5 mm

2

Approvals CSA (<7.5 HP @ 600 VAC),UL, cUL

CE-marking Yes

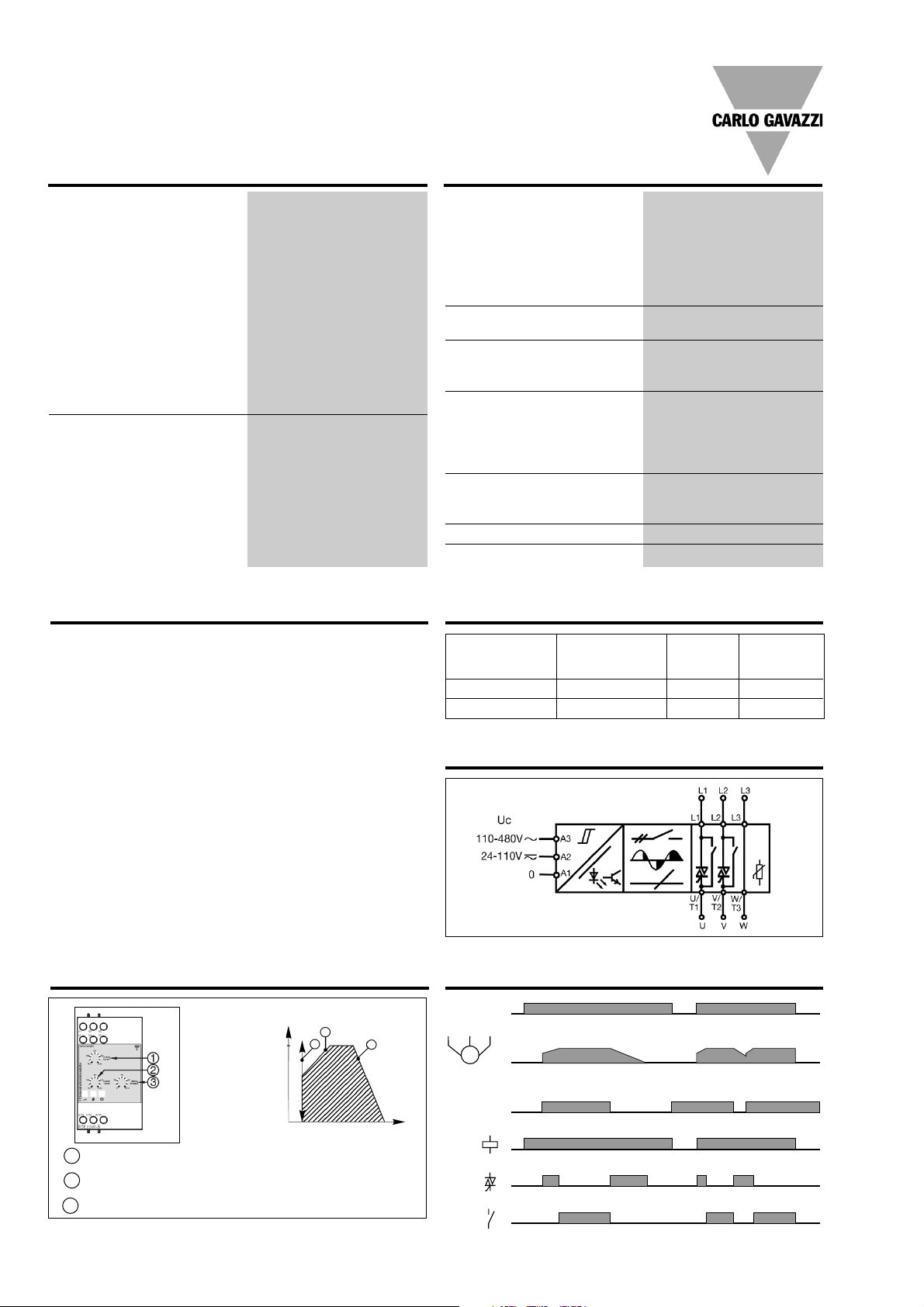

Mode of Operation

Rated opera- I2t for fusing I

TSM

dI/dt

tional current t = 1 - 10 ms

3 A 72 A2s 120 A

p

50 A/µs

12 A 610 A

2

s 350 A

p

50 A/µs

Semiconductor Data

This motor controller is intended to be used to softstart/

softstop 3-phase squirrel cage

induction motors and thereby

reduce the stress or wear on

gear and belt/chain drives and

to give smooth operation of

machines. Soft starting and/or

stopping is achieved by controlling the motor voltage.

During running operation the

semiconductor is bypassed by

an internal electromechanical

relay.

The initial torque can be adjusted from 0 to 85% of the

nominal torque.

The soft-start and soft-stop

time can be adjusted from 0.5

to approx. 7s.

A green LED indicates supply.

Two yellow LEDs indicate

Ramp up/down and Running

mode.

Overload protection is not provided in this motor controller

and must therefore be installed separately.

The controller is switching

2 lines. The 3rd line is continuously connected to the load.

Functional Diagram

Operation Diagram 2 Operation Diagram 1

Time

Motor voltage

100%

1

Ramp-up time 0.5 to 6.5s. Time from zero load voltage to full load

voltage.

Ramp-down time 0.5 to 8.0s. Time from full load voltage to zero

load current.

Initial torque 0 to 85% voltage at the start of the ramp-up function.

2

3

1

2

3

Mains Ue

Control input Uc

LED

LED

LED

Supply Specifications General Specifications

Page 3

Specifications are subject to change without notice (30.03.2007) 3

Dimensions

Weight 270 g

Housing material PC/ABS Blend

Colour Light grey

Terminal block PBTP

Colour Ligh grey

Bottom clip POM

Colour Black

Diode cover PC

Colour Grey Transparent

Front knob PA

Colour Grey

Housing Specifications

Applications

RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - B

Changing from Direct ON

Line start to soft start

(Line controlled soft-start)

(Fig. 1 & Fig. 2)

Changing a Direct On Line start

into a soft start is very simple

with the RSE soft-starting relay:

1) Cut the cable to the motor

and insert the RSE relay.

2) Connect control input to two

of the incoming lines.

Set

initial torque to minimum

and

ramp up and down to maximum.

3) Power up again - adjust the

start torque so the motor

starts turning immediately

after power is applied, and

adjust ramp time to the

appropriate value.

When C1 is operated, the

motor controller will perform

soft-start of the motor. When

C1 is switched off, the motor

will stop, the motor controller

will reset and after 0.5 s a new

soft-start can be performed.

Please note that the controller

does not insulate the motor

from the mains. Contactor C1

is therefore needed as a service switch for the motor.

Fig. 1

Fig. 2 For voltages higher than 480 VAC

Soft-start and soft-stop

(Fig. 3)

When S1 is closed, soft-start

of the motor will be performed

according to the setting of the

ramp-up potentiometer and

the setting of the initial torque

potentiometer. When S1 is

opened, soft-stop will be performed according to the setting of the ramp-down

potentiometer.

1L1 3L2 5L3

L1 L2 L3

A1

A2

A3

U/T1 U/T2 W/T3

M

Fig. 3

S1

I > I >

I >

~

L1 L2 L3L1 L2 L3

C1 C1

L1 L2 L3

L1 L2 L3

M

M

U/T1 U/T2 W/T3

U/T1 U/T2 W/T3

A1

A2

A3

L1 L2 L3L1 L2 L3

N

L1 L2 L3

L1 L2 L3

M

M

U/T1 U/T2 W/T3

U/T1 U/T2 W/T3

A2

A3

A1

All dimensions in mm

Page 4

4 Specifications are subject to change without notice (30.03.2007)

RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - B

Time between rampings

To prevent the semiconductors from overheating, a certain time between ramping

should be allowed. The time

between rampings depends

on the motor current during

ramping and ramp time (see

tables below).

Fusing Considerations

The motor controller provides

by-passing of the semiconductors during running operation. Therefore the semiconductors can only be damaged

by short-circuit currents during ramp-up and ramp-down

function.

A 3-phase induction motor

with correctly installed and

adjusted overload protection

does not short totally between

lines or directly to earth as

some other types of loads,

e.g. heater bands. In a failing

motor there will always be

some part of a winding to limit

the fault current. If the motor

is installed in an environment

where the supply to the motor

cannot be damaged, the short

circuit protection can be considered to be acceptable if the

controller is protected by a 3pole thermal-magnetic overload relay (see table below).

If the risk of short circuit of the

motor cable, the controller or

the load exists, then the controller must be protected by

ultrafast fuses, e.g. for a 3 A

type: Ferraz 6.9 gRB 10-10,

for an 12 A type: Ferraz 6.9

gRB 10-25. Fuseholder type

CMS10 1P.

Note:

Table is valid for ambient

temperature 25°C. For higher

ambient temperature add

5%/°C to values in the tables.

The shaded areas in the tables are for blocked rotor. Do

not repeat rampings with

blocked rotor.

RSE .. 03 - B

Time between rampings

1 2 5 7.5

Ramp time (sec.)

I ramp (A)

RSE .. 12 - B

Time between rampings

1 2 5 7.5

Ramp time (sec.)

72 2.5 min 5 min 40 min N/A

60 1.5 min 3 min 13 min 17 min

48 50 sec 1.5 min 5 min 10 min

36 30 sec 1 min 3 min 7 min

24 15 sec 40 sec 1.5 min 2.5 min

12 10 sec 20 sec 50 sec 70 sec

6 5 sec 9 sec 20 sec 40 sec

I ramp (A)

Recommended thermal-magnetic overload relay

Selection Chart

Thermal-magnetic overload relay and motor controller

Motor full load current (AACrms)

0.1 - 0.16 - 0.25 - 0.4 - 0.63 - 1.0 - 1.6 - 2.5 - 4 - 6.3 - 9 -

0.16 0.25 0.4 0.63 1.0 1.6 2.5 4 6.3 9 12

M 01 M 02 M 03 M 04 M 05 M 06 M 07 M 08 M 10 M 14 M 16

0.16 0.25 0.4 0.63 1 1.6 2.5 4 6.3 9 12.5

0.16 0.25 0.4 0.63 1 1.6 2.5 4 6.3 10 16

Overload relay type GV 2Manufacturer: Telemecanique

Overload relay type MS 325Manufacturer: ABB

Motor protection circuit breaker type KTA 3-25Manufacturer: Allan-Bradley/Sprecher + Schuh

RSE 22 12 - B

RSE 40 12 - B

RSE 48 12 - B

RSE 60 12 - B

Motor controller type:

127/220 V mains

230/400 V mains

270/480 V mains

400/690 V mains

RSE 22 03 - B

RSE 40 03 - B

RSE 48 03 - B

RSE 60 03 - B

Example:

Line voltage: 230/400 V

Motor 1.5 HP: 1.1 kW

Full load current: 2.9 A

Step 1:

Select overload relay:

In this example GV 2 - M 08,

MS 325 - 4 or KTA 3-25-4A

must be used.

Step 2:

Select motor controller:

For line voltage 230/400 V and

overload, relay GV 2 - M 08 or

MS 325 - 4 with a setting of

2.9 A type RSE 40 03 -B can

be selected.

N.B.: For motors with full load

current from 12 A to 40 A, see

types RSH and RSC/RSO.

18 15 sec 30 sec 1.5 min 2.5 min

15 12 sec 20 sec 60 sec 1.5 min

12 10 sec 20 sec 50 sec 70 sec

9 8 sec 12 sec 30 sec 50 sec

6 5 sec 9 sec 25 sec 40 sec

3 2 sec 5 sec 20 sec 35 sec

1.5 1 sec 2 sec 5 sec 5 sec

Applications

Loading...

Loading...