Carlo Gavazzi RGC1S, RGS1S Installation Instructions

RGC1S, RGS1S

Y2 =

100mm

Y1 = 50mm

50mm

X = 20mm

2

0mm

2

0mm

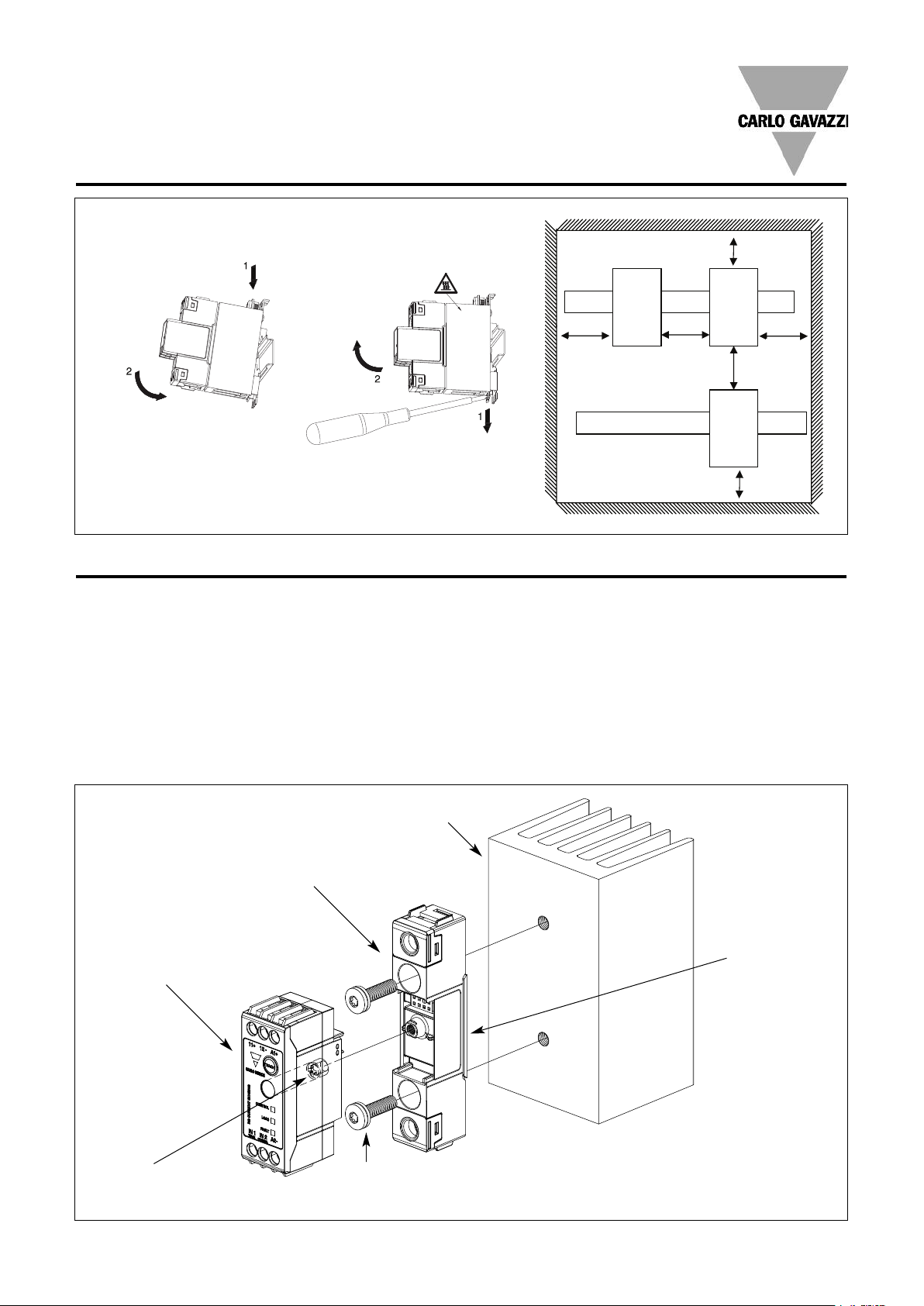

Mounting on DIN rail

Dismounting from DIN rail

Installation Instructions

Mounting on DIN rail

Dismounting from DIN rail

Mounting Instructions for RGS1S

Thermal stress will reduce the lifetime of the SSR. Therefore it is necessary to select the appropriate heatsinks, taking into account the

surrounding temperature, load current and the duty cycle.

A small amount of thermally conductive silicone paste must be

applied to the back of the SSR. The RG Power Module should be first

mounted on the heatsink with two M5 screws. Gradually tighten each

screw (alternating between the two) until both are tightened with a

torque of 0.75Nm. Then tighten both screws to their final mounting

torque of 1.5Nm.

X

= Refer to

X

Derating vs.

Spacing Curves

X

In case of a thermal pad attached to the back of the SSR, no thermal

paste is required. The RG Power Module is gradually tightened (alternating between the 2 screws) to a maximum torque of 1.5Nm.

Once the power module is tightened to heatsink, the control module

can be mounted on top of the power module and screwed with a

torque of 0.3Nm to ensure good contact between the 2 units.

Heatsink

RG Power Module

Heatsink Compound or

RG Current Sensing

Control Module

Thermal Pad

(not provided with SSR

unless requested)

1 screw M4, Philips PH1

(provided with SSR)

Max. mounting torque: 0.3mm

22 Specifications are subject to change without notice (18.03.2013)

2 screws + washer M5 x 30mm

(not provided with SSR)

Max. mounting torque: 1.5Nm

Loading...

Loading...