CARLO GAVAZZI MDI 40 TF - CONFIGURATION SOFTWARE, MDM 40 TF - CONFIGURATION SOFTWARE, MDI 40 TF, MDM 40 TF Instruction Manual

Page 1

Page 2

V

MDM

Digital Meter

al1 al2

RPM

F

S

Page 3

ENGLISH

MDI40.TF Rate meter and

controller

OPERATING INSTRUCTIONS

• General Features 2

• Technical Features 3

• Installation 7

• Preliminary Operations 12

• Front Panel Description 13

• Operating mode 15

Important:

We suggest you keep the original packing for a further

shipping of the instrument.

In order to guarantee a correct use of the instrument, we

recommend the user to carefully read the present instruction manual.

Page 4

3

ENGLISH

2

ENGLISH

•operating mode;

•scaling;

•display;

•commands;

•alarm set-points;

•filter;

•analogue output;

•serial output.

TECHNICAL FEATURES

ACCURACY ± 0.01 % F.S., ± 3 dgt (@ 18°C to 23°C);

RESPONSE TIME Time base + ≤ 200 msec.

TEMPERATURE DRIFT ± 100 ppm/°C.

DISPLAY 7-segment, red LED, h 14.2 mm.

MAXIMUM INDICATIONS 9999.

MINIMUM INDICATIONS -1999.

INPUTS 2 measuring inputs (channel "A" and channel "B"); 2 ranges:

range r1: 0.001 to 500Hz; minimum duration of ON signal 500µsec;

period measurement: 2ms to 1000s;

range r2: 0.1 to 50KHz, minimum duration of ON signal 9µsec;

period measurement: 20µs to 10s;

INPUT TYPE

DC: NPN (pins 6 to 7):

ON<2VDC; OFF - Open collector, leakage current ≤1mA.

DC: PNP (pins 6 to 7):

ON>10VDC; OFF - Open collector, leakage current ≤1mA.

CARLO GAVAZZI Instruments

Multi-range

µP-based panel rate meter

MDI40.TF

rev. 0

OPERATING INSTRUCTIONS

Important:

We suggest you keep the original packing for a further shipping of the

instrument.

In order to guarantee a correct use of the instrument, we recommend the

user to carefully read the present instruction manual.

GENERAL FEATURES

Features:

•display of measured value;

•two independent control points;

•scaling capability;

•transmission of measured value.

Programming parameters:

•password;

•three levels of password protection;

•range: 500 Hz or 50 KHz;

•time base;

Page 5

5

ENGLISH

4

ENGLISH

Output type: 2 contacts SPST, NO, 5A/250VAC/VDC 40W/1200VA,

130.000 cycles.

Min. response time: < 400 msec. filter excluded.

Insulation: see table 1.

DIGITAL FILTER

Operating range: 0 to 9999. Filtering coefficient: from 1 to 255.

ANALOGUE OUTPUT (ON REQUEST)

From 0 to 20mADC / from 0 to 10VDC, programmable within the whole

analogue output range. Accuracy: ±0.3% F.S. (@ 18°C to 23°C). Response time: 500ms (filter excluded). Temperature drift: ±200 ppm/°C.

Load: ≤500 Ω (mA output): ≥10kΩ (V output). Insulation: see table 1.

SERIAL TRANSMISSION RS485 (ON REQUEST)

Multidrop: uni-directional (STD); bi-directional (on request); 2 or 4 wires;

max. distance 1200m; termination and/or line biasing directly on the

instrument; 255 programmable addresses; data format: 1 start bit, 8 data

bits, no parity, 1 stop bit; baud rate: 1200, 2400, 4800 and 9600 bauds

selectable by key-pad; communication protocol according to the standard MODBUS, JBUS.

Uni-directional communication:

dynamic data (reading only): measurement, valley data, peak data,

alarm status;

Static data (reading): all programming data;

Bi-directional communication:

dynamic data (reading only): measurement, valley data, peak data,

alarm status;

Static data (reading/writing): all programming data, reset of peak and

valley data, reset of alarm set-points with latch.

DC: NAMUR: ON ≤ 1mADC; OFF ≥ 2.2 mADC

DC: TTL (pins 6 to 4): ON > 4VDC; OFF ≤ 2VDC.

DC: Free of voltage contact: ON<1KΩ; OFF>20KΩ.

AC: PICK-UP voltage up to 100VAC: ON > 2VAC; OFF < 1VAC.

AC: PICK-UP voltage up to 500VAC: ON > 9VAC; OFF < 6VAC.

KEYPAD

4 keys for programming and displaying; "S" for menu selection; "UP" and

"DOWN" for value programming/function selection; "F" for special functions and "esc" (escape).

PASSWORD

From 0 to 255, numeric code of max. 3 digits, 3 protection levels of the

programming data.

FUNCTIONS

• Frequency measurement of both channels A and B.

• Other functions: Fa-Fb, Fa/Fb, [(Fa-Fb)/Fb]*100, [Fb/(Fa+Fb)]*100, 1/

Fa, Fa (Fb for rotation sensing).

• Peak and valley.

ALARM

Type: OFF: out of range alarm; UP: up alarm; DO: down alarm; D.DO:

down alarm with disabling at power-on; UP .L: up alarm with latch; DO.L:

down alarm with latch.

Set point adjustment: in the whole range of visualization.

Hysteresis: in the whole range of visualization.

Set-point limit adjustment: programmable minimum and maximum limits.

Activation time delay: from 0 to 255s

De-activation time delay: from 0 to 255s

Relay status: programmable normally energized / de-energized.

Page 6

7

ENGLISH

6

ENGLISH

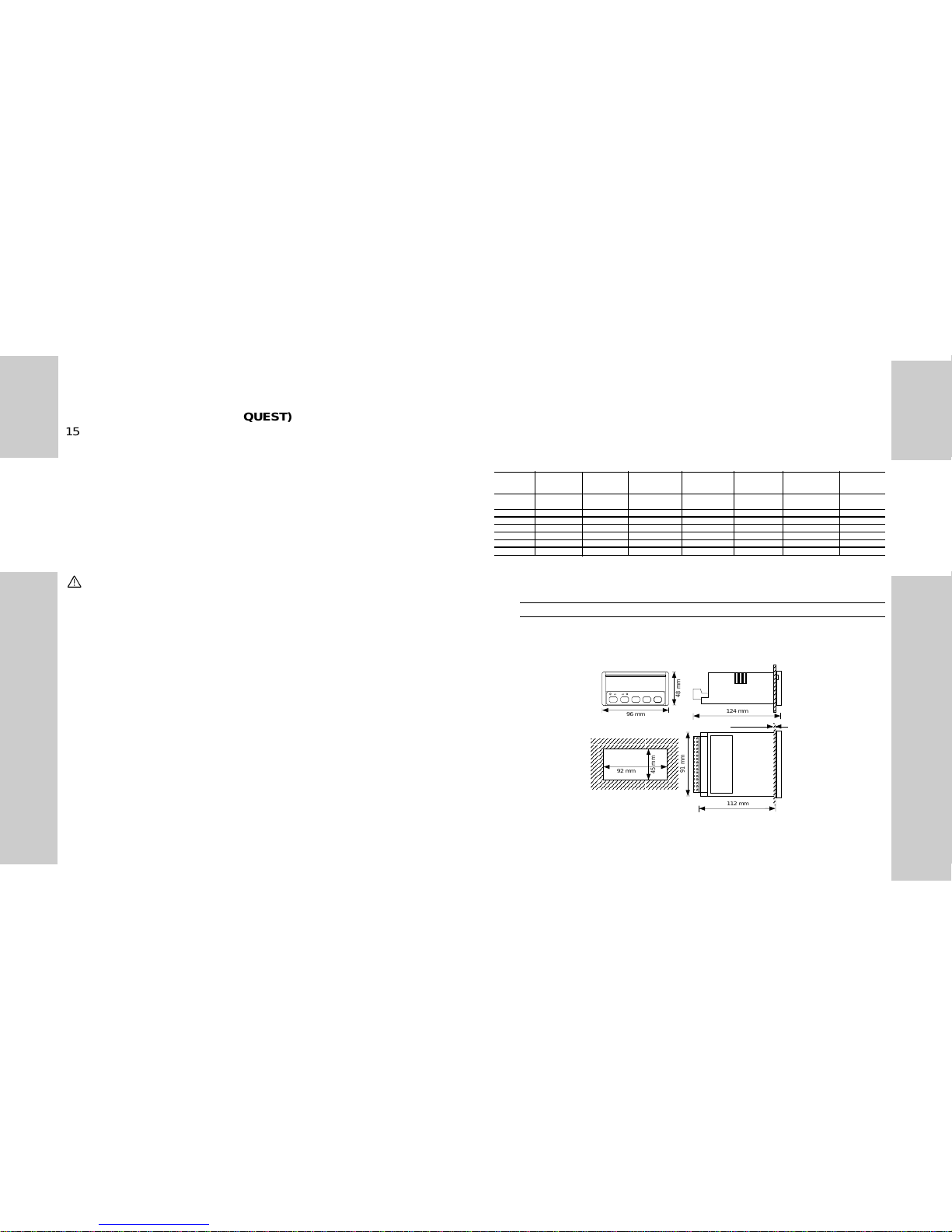

PROTECTION DEGREE / WEIGHT

IP 65 (standard), 470 g. approximately (included analogue output and

packing)

AC Input RL1 Output RL2 Output Analogue DC Power Serial

Power Supply Output Supply Output

AC Power

Supply ––– 4kV 4kV 4kV 4kV ––– 4kV

Input 4kV ––– 2kV 2kV 500V 2kV 500V

RL1 Output 4kV 2kV ––– 2kV 2kV 2kV 2kV

RL2 Output 4kV 2kV 2kV ––– 2kV 2kV 2kV

Anal. Output 4kV 500V 2kV 2kV ––– 2kV 500V

DC Power S. ––– 2kV 2kV 2kV 2kV ––– 2kV

Serial Output 4kV 500V 2kV 2kV 500V 2kV –––

Tab.1: insulation table

INSTALLATION

Overall dimensions and panel cut-out

AAAAAA

A

AAAAAA

A

AAAAAA

A

92 mm

45 mm

124 mm

F

S

al1

al2

96 mm

48 mm

91 mm

112 mm

max. 10

mm

EXCITATION OUTPUT (ON REQUEST)

15VDC / 40mA (12VDC / 60mA) (non-stabilized)

POWER SUPPLY INPUT

230VAC -15% +10% 50/60Hz (standard) (200mAT protection fuse*);

115 VAC -15% +10% 50/60Hz (on request) (200mAT protection fuse*);

48 VAC -15% +10% 50/60 Hz (on request) (630mAT protection fuse*);

24 VAC -15% +10% 50/60 Hz (on request) (630mAT protection fuse*);

120VAC-15% +10% 50/60 Hz (on request) (200mAT protection fuse*);

240VAC-15% +10% 50/60 Hz (on request) (200mAT protection fuse*);

9 to 32VDC galvanic insulation (1AT protection fuse*);

40 to 155VDC galvanic insulation (315mAT protection fuse*).

*note: the mains has to be protected by means of a proper fuse type

SELF CONSUMPTION

8VA

OPERATING TEMPERATURE

From 0 to +50°C (R.H. <90% non-condensing).

STORAGE TEMPERATURE

From -10 to +60°C (R.H. <90% non-condensing).

INSULATION REFERENCE VOLTAGE

300VRMS

INSTALLATION CATEGORY CAT III - 300V (EN61010-1).

DIELECTRIC STRENGTH 4000 VRMS for 1 minute.

EMC IEC 801-2, IEC 801-3, IEC 801-4 (level 3).

SAFETY STANDARDS EN 61010-1, IEC 1010-1, VDE 0411.

CONNECTIONS screw-type, detachable.

HOUSING SIZE / DIMENSIONS / MATERIAL

1/8 DIN / 48 x 96 x 124 mm / ABS, self-extinguishing: UL 94 V-0.

Page 7

9

ENGLISH

8

ENGLISH

Signal from a 2-wire inductive proximity

sensor (NAMUR). NOTE: When using

a NAMUR input, the terminals 5 and 6

must be jumpered.

Signal from capacitive or inductive

switches, type NPN or PNP, 3 wires.

NOTE: when using a NPN or PNP input, the terminals 6 and 7 must be

jumpered.

Signal from a PNP/NPN encoder

Mounting

Insert the instrument into the panel and fasten it by fixing the two lateral

brackets (1) supplied with the instrument to the appropriate location (2),

and subsequently locking them by means of the 2 screws (3) supplied

with the instrument.

Connections

According to the requirements of EN61010-1 the power supply

input of the instrument to be connected to the mains must be

protected against short circuit by means of appropriate fuses

(see "power supply input").

General connection label for MDI40.TF1

3

2

1

Page 8

11

ENGLISH

10

ENGLISH

AC signals from pick-up up to 100VAC

AC signals up to 500VAC

Double input signal from 2 capacitive or

inductive switches, type NPN or PNP, 3

wires.

NOTE: when using a NPN or PNP input, the terminals 6 and 7 must be

jumpered.

General connection label for MDI40.TF2

Page 9

13

ENGLISH

12

ENGLISH

FS

CARLO GAVAZZ

al1 al2

2

1

4

3

FRONT PANEL DESCRIPTION

1.Key-pad:

functions available outside the programming phase.

Keys to be pressed:

Displays set-point 1 corresponding to a password between 0

and 255;

Displays set-point 2 corresponding to a password between 0

and 255;

For longer than 2 seconds: modification of set-point 1 (pass-

word between 128 and 255 only);

For longer than 2 seconds: modification of set-point 2 (pass-

word between 128 and 255 only);

The command input (display hold function or key-pad disabling) must be

connected across the terminals 3 and 4 (only free of voltage contact).

The voltage signals must be connected as follows:

• 500V , channel A to the terminals 1 and 5, channel B to the terminals 3

and 5.

• 100V , channel A to the terminals 2 and 5, channel B to the terminals 4

and 5.

Note: when using only input channel A, connect the unused B channel

terminals 3 and 4 to the terminal 5

The command input (display hold function or key-pad disabling) must be

connected across the terminals 5 and 6 (only free of voltage contact).

PRELIMINARY OPERATIONS

Before supplying the instrument, make sure that the power supply

voltage correspond to what is shown on the label. Example:

MDI40.TF1.D.2.A.XX.IX

SER.N. 990600/20078

POWER 230 VAC 50/60 Hz

INPUT NPN, PNP

N. 2 control set points

OUTPUT 0/20 mA - 0/10 VDC

Page 10

15

ENGLISH

14

ENGLISH

modification of the selection or programming will not be saved if the

S

key has not been previously pressed)

2.Display

Alphanumeric indication by means of a 7-segment display:

• of the measured value;

• of the programming parameters;

• of the measuring abnormal conditions.

3.LED

Indication of the alarm set-point status.

4.Engineering unit window

To insert the interchangeable engineering unit in the special

window, proceed as follows: remove the front cover by inserting a

suitable screw driver in the special slot on the short sides of the front

panel; force gently until the front cover is completely removed. Insert

the desired engineering unit by means of a pair of tweezers. Replace

the front cover by inserting it first in the lower part and then in the upper

part of the locking system.

OPERATING MODE

• Power-on

When you switch the unit on, the display shows for approximately 5

seconds the instruments' software revision, for example: r.0.

• Displaying, control and diagnostics

The instrument shows continuously the value of the input variable as

defined in the programming phase.

+ Displays highest measured value (peak function);

+ Displays lowest measured values (valley function);

For longer than 2 seconds: acknowledge of an alarm (if the

relays have the latch function)

1. Key-pad:

functions available in the programming phase.

Keys to be pressed:

For longer than 2 seconds: programming phase entry and

password confirmation;

Menu selection (from the first to the last);

Menu selection (from the last to the first);

Confirmation and entry:

• in the configuration menus;

• in the secondary menus relating to parameters.

In the selected menu / secondary menu:

• increase of displayed value

• modification of parameter selection;

In the selected menu/secondary menu:

• decrease of displayed value

• modification of parameter selection;

In the menus: exit from the programming phase (message

"End" on the display) and return to the measuring and control function;

In the secondary menus: exit and return to the main menu (

the

F

F

F

F

S

S

Page 11

17

ENGLISH

16

ENGLISH

"PAS" message for the second time; enter the desired numerical code

using the "

" or " " keys, then confirm it by pressing the "S" key:

the display will show the first configuration menu ("InP");

•if the Password has already been entered, you can modify it following

the procedure described at No. 2); after the "PAS" message has been

shown a second time, enter the new numerical code using the "

"

or "

" keys and confirm it by pressing the "S" key: the display will

show the first configuration menu ("InP").

Data protection levels:

•if the Password is "0", the configuration data are not protected by

undesired access;

•if the Password is a number between "1 and 127", the configuration data

are entirely protected against undesired access;

•if the Password is a number between "128 and 255", the configuration

data are protected against undesired access except for the programming of the values ("SEt") of set-point 1 and/or 2.

It is possible to reset the Password by entering the number 3584.

•All programming/configuration steps of the instrument are shown

in the flow chart on the last page of this manual. The flow chart

gives the operator a better understanding of the programming

structure of the instrument, indicating the current function with

regard to the others. The flow chart also makes it easier to

understand the commands used in the programming phase.

See the chapter "Front panel description" for information regarding the

use of the key-pad and the relevant main functions.

The value shown on the display is continuously compared with the value

of the two set-points and of the other parameters, thus generating the

control function by energizing/de-energizing the output relays.

• Programming

This phase is identified by the blinking of the decimal point on the right

side of the display.

To enter the programming phase, press the "

S

" key until "PAS" is

shown on the display; then "0" is displayed: the correct numerical code

(Password) is to be entered. The following conditions may occur:

• 1) the operator hasn't entered any Password: press the "S" key

again to enter the configuration menus of the instrument;

• 2) the operator has already entered a Password: select the correct

Password by means of the "

" key (to increase the value) or " "

key (to decrease it) until the desired value is displayed. Press the "S"

key to confirm the value: if the Password is correct, then the display will

show "PAS" again followed by the relating numerical code; press the

"S" key once more in order to display the first configuration menu; if

the Password is not correct, the display shows "End" and the instrument

goes back to the measuring and control phase.

PROGRAMMING OF A NEW PASSWORD AND AUT OMATIC SELECTION OF THE PROTECTION LEVEL OF THE CONFIGURATION

DATA.

To enter the new Password:

•if the Password is "0", press the "S" key when the display shows the

Page 12

19

ENGLISH

18

ENGLISH

F1 : frequency, tachometer, rate mode A or B channel

The instrument measures the frequency either on input A or on input B

and executes the following calculation: display=Fa/Pu.1*PS.1 (or Fb/

Pu.2*PS.2). It can be used, for example, to measure the rotation speed

of a motor, or to display frequency in Hz and kHz, as tachometer mode:

RPS, RPM, RPH, MPS, MPM, MPH and as rate meter: flow (m

3

, cm3,

mm3,kg/m3, g/cm3, l/s, l/min, l/h, m3/s, m3/min, m3/h, t/h, kg/s) or speed

(mm/s, cm/s, m/s, mm/min, cm/min, m/min, mm/h, cm/h, m/h, km/h, in/

s, ft/s, yd,s, in/min, ft/min, yd/min, in/h, ft/h, yd/h).

F2 : A - B, frequency (speed) difference

The instrument measures the frequency of input A and input B and

executes the following calculation: display=(Fa/Pu.1*PS.1)-(Fb/

HOLD

Input

Input A

Display

HOLD

Input

Input A - B

Display

Glossary of displayed symbol:

• PAS :

protection key: programmable

from 0 to 255.

• InP : input range selection menu:

r1 : from 0.001 to 500 Hz or from

2ms to 1000s;

r2 : from 0.1 to 50 KHz or from

20µs to 10s

• t.ba :

time base programming menu:

values programmable from 0.1 to 999.9;

it is the updating time of both measurement and display.

• oPr :

operating mode selection menu:

General information:

"A" means always channel A input;

"B" means always channel B input;

the signal on the channel A is managed

always according to this formula: (Fa/

Pu.1)*PS.1; the signal on the channel

B is managed always according to this

formula: (Fa/Pu.2)*PS.2. Where: Fa or

Fb is the frequency signal measured on

channel A or B; Pu.1 or Pu.2 is the

number of pulses per revolution generated by the sensor connected to channel

A or B; PS.1 or PS.2 is the prescaler

value of the sensor A or B.

Page 13

21

ENGLISH

20

ENGLISH

F4 : A/B, frequency (speed) ratio mode

The instrument measures the frequency of input A and input B and

executes the following calculation: display=(Fa/Pu.1*PS.1)/(Fb/

Pu.2*PS.2). This measuring capability is ideal for monitoring the relative

speeds of shafts, conveyor belts and other moving machinery.

F5 : B/(A+B)*100

The instrument measures the frequency of input A and input B and

executes the following calculation: display=(Fb/Pu.2*PS.2)/[(Fa/

Pu.1*PS.1)+(Fb/Pu.2*PS.2)]*100. This measuring capability is used in

all the applications where it is necessary to measure a mixture flow

between two liquids. If the instrument is equipped with an analogue

output, this signal can be transmitted to a paper recorder to show the

HOLD

Input

Input B/(A+B)

Display

HOLD

Input

Input A/B

Display

Pu.2*PS.2). This result represents the difference between the input

channels and can be used when the speed difference between two

conveyor belts has to be as low as possible without considering the

reference speed of the first conveyor (in any case within a well known

value that can be controlled by the available alarm set-point) in order to

avoid any transportation problem of the produced goods.

F3 : (A - B)/B*100, frequency (speed) error ratio

The instrument measures the frequency of input A and input B and

executes the following calculation: display=[(Fa/Pu.1*PS.1)-(Fb/

Pu.2*PS.2)]/(Fb/Pu.2*PS.2)*100. This result represents the relative

error between the 2 input channels; this measuring capability is used

when the speed difference between two conveyor belts has to be as low

as possible in any case within a well known value that can be controlled

by the available alarm set-points. If the instrument is equipped with the

analogue output, this signal can be used to correct the speed of the

second conveyor belt.

HOLD

Input

Input (A-B)/B

Display

Page 14

23

ENGLISH

22

ENGLISH

• if the time base is, for instance, three times the period being measured

(see figure below), the updating of the display is made at the end of the

time base (end gate time) as average calculation of the measured

periods P=(P1+P2+Pn)/n

F7 : A, frequency (speed) clockwise and counter clockwise rotation

sensing mode.

This measuring capability is ideal for monitoring the relative speed of

shafts, conveyor belts and other moving machinery taking into account

the rotation mode, showing the reverse speed by means of a " - " sign.

The rotation sensing is detected by means of a phase difference,

measured using the two input channels available as standard in the

instrument. If we assume that the channel A is the main channel ( see

figure on the next page), the channel B is used to detect if a signal

arrives "after" (phase displacement) the signal of the main channel

(begin gate time) meaning "clockwise" rotation or "before" meaning

mixture deviation that is connected to the quality result of the mixture

itself.

F6 : 1/A, period or average period mode

The instrument measures the frequency of input A or input B and

executes the following calculation: display=1/(Fa/Pu.1*PS.1). The time

period is directly connected to the time base that has been programmed

in the instrument (for low frequencies or long time periods):

• if the time base is in the range of the period being measured (see figure

below), the updating of the display is as fast as possible and any period

changing is updated immediately on the display;

Page 15

25

ENGLISH

24

ENGLISH

• SCA: scaling factor programming

menu.

This menu allows to scale the input

signals coming from both A and B measuring channels in such a way that they

can be shown on the display as a rate,

a frequency, a period or a speed.

The parameters that allow to scale this

input signals according to the needs

are:

Pu.1 : number of pulses per revolution

of the sensor (proximity switch) connected to channel A . Programmable

value: 1<Pu.1<9999.

PS.1 : Prescaler channel A stated in

the following way: A1*10

b1

.

A1 : 1<A1<9999.

b1 : -9<b1<9.

Pu.2 : number of pulses per revolution

of the sensor (proximity switch) connected to channel B . Programmable

value: 1<Pu.1<9999.

PS.2 : Prescaler channel B stated in

the following way: A2 *10

b2

A2 : 1< A2 < 9999.

b2 : -9 < b2 < 9.

"counter clockwise rotation". Such kinds of signals are normally generated by standard encoders.

Page 16

27

ENGLISH

26

ENGLISH

For instance, if the wheel has 30 cogs (30 references) that can be

detected by an inductive proximity switch, at the end of its rotation it

generates 30 pulses, so the number that has to be programmed as Pu.1

or Pu.2 parameter is 30. Pay attention: if, instead of a speed or a rate,

you have to measure and display a frequency or a period, Pu.1 and Pu.2

have to be "1" (pulse per revolution).

First example:

if you have to measure a speed of a motor with the following data:

motor speed: 800 RPM;

pulses per revolution : 1;

requested displayed value: 800 RPM;

you have to proceed in the following way:

calculate the

maximum frequency that is given by:

"[max. speed (RPM) * pulses per revolution]/60", that takes in our case:

"[800 * 1]/60 = 13.33Hz"

•

"InP": to select the proper input range that is connected to the

maximum frequency. You have to measure, in our case, 13.33Hz,

therefore the range is "r1" (from 0.001Hz to 500Hz). With the "r1" range

you can easily calculate the minimum speed the instrument can

measure and display: "[min. frequency (Hz) * 60] / pulses per revolution"

that takes in our case "[0.001 * 60]/1=0.06 RPM".

•

"t.bA": to select the proper time base in order to exploit the maximum

performance of the instrument. If the speed of the motor can be adjusted

from 100 RPM to 800 RPM we can calculate the time period corresponding to the minimum speed that is given by: "60/[min. speed

(RPM)* pulses per revolution]", that takes in our case "60/[100*1]= 0.6

What is the meaning of "prescaler"? It's a multiplier used to multiply the

measured frequency by a programmable value in order to achieve the

desired value on the display.

To allow the scaling capability of the instrument to be as powerful as

possible, this parameter has been divided into two sub parameters:

the mantissa "A" and the exponent "b". The prescaler is stated as

A * 10

b1

.

The calculation capability is from:

9999 * 10

-9

(0.000009999) max. divisor;

1 * 10

-1

(0,1) min. divisor;

9999 * 10

9

(9999000000000) max. multiplier;

1 * 10

0

(1) min. multiplier.

What is the meaning of "pulses per revolution"? It is the number of

pulses that are generated by the input connected sensor for every

complete revolution (360°) of the wheel or of the drive shaft being

detected.

Page 17

29

ENGLISH

28

ENGLISH

Second example:

if you have to measure the speed difference between two wheels,

detected by 2 inductive sensors, that have the following data:

Wheel number 1 (connected to the channel "A" of the MDI40):

max rotational speed: 700 RPM;

pulses per revolution: 4.

Wheel number 2 (connected to the channel "B" of the MDI40):

max rotational speed: 600 RPM;

pulses per revolution: 4.

you have to proceed in the following way:

calculate the

maximum frequency that is given by:

"[max. speed (RPM) * pulses per revolution]/60", that makes in our

case, for wheel 1: Fa = (700 * 4)/60 = 46.66Hz

for wheel 2: Fb = (600 * 4)/60 = 40.00Hz

•

"InP": to select the proper input range that is connected to the

maximum frequency you have to measure; in our case the value is

between 40Hz and 50Hz, therefore the range is "r1" (from 0.001Hz to

500Hz). With the "r1" range you can easily calculate the minimum speed

the instrument can measure and display: "[min. frequency (Hz) * 60] /

pulses per revolution" that makes in our case "[0.001 * 60]/4=0.015

RPM".

•

"t.bA": to select the proper time base in order to exploit the maximum

performance of the instrument. If the speed of the two wheels can be

adjusted from 100 RPM to 700 RPM (for the first wheel) and from 100

to 600 (for the second one), we can calculate the time period corresponding to the minimum speed that is given by: "60/[min. speed

(RPM)* pulses per revolution]", that makes in our case "60/[100*4]=

sec., therefore the "t.bA" would be "0.6", better if "0.7".

•

"oPr": to perform the measurement of a "speed" you have to choose

the "F1" function

•

"SCA"

•

"Pu.1": the number of "pulses per revolution" is in our case "1",

therefore "Pu.1" becomes 1.

•

"PS.1": the prescaler formed by the two sub-parameters "A1", mantissa, and "b1", exponent, has to be set in the following way:

the maximum read-out capacity of the instrument is 9999, that means

the speed can be shown as 800.0 "RPM". We have to measure "800"

but to obtain the maximum speed resolution we have to display 8000

(don't consider the decimal point). The calculation made by the

instrument according to function selection "F1" is the following:

value to be displayed = (Fa * PS.1) / Pu.1 (1)

- "Fa" according to the frequency of 800 RPM is 13.33Hz;

- "Pu.1" is 1;

- "PS.1" can be calculated from the above mentioned formula (1) that

means: (value to be displayed * Pu.1) / Fa, that makes :

(800*1) / 13.33 = 60.01, that means: 60.01 = A1*10

b1

therefore A1=6001 and b1 = -2 (10 b1 → 0.01)

•

"dSY": to show on the display 800.0 we have to move the decimal point

to "111.1";

•

"Lo": see the proper explanation on the next pages;

•

"Hi": see the proper explanation on the next pages;

The PS.2 menu is not available for the functions F1, F6 and F7.

Page 18

31

ENGLISH

30

ENGLISH

that means: PS = (value to be displayed * Pu.1) / (Fa - Fb), that makes:

(100 * 4) / 6.66 = 60.06, that means: 60.06=A*10

b

therefore A = 6001 and b = -2 (10 -2 → 0.01)

•

"Pu.2": the number of "pulses per revolution", of channel "B", is in our

case "4", therefore "Pu.2" becomes 4.

•

"dSY": to show on the display 100.0 we have to move the decimal point

to "111.1";

•

"Lo": see the proper explanation on the next pages;

•

"Hi": see the proper explanation on the next pages:

Parameter table (suggested values)

Rotational

Speed

FUNCTION

(

oPr

)

MEASUREMENT

RPS

RPM

RPH

UNIT

(

displa

y)

TIME BASE

(t.bA)

PULSE / REVOL.

(PU.1) (Pu.2)

PRESCALER

(PS.1) (PS.2)

Linear Speed

(circumferential

speed)

F1, F2

F3, F4

1

60

60

1

1

1

mm/s

cm/s

m/s

mm/min

cm/min

m/min

1

1

1

60

60

60

F1, F2

F3, F4

cm/h

km/h

MPH

60

60

60

1

1

1

Hz

kHz

1

0,1

Frequency F1

m/h

60

60

mm/h

1

1

1

1

1

1

1

1

n

n

1

60

3600

π * d * 3600

π * d * 3.6

π * d * 2.23

1000 * π * d

100 * π * d

π * d

1000 * π * d * 60

100 * π * d * 60

π * d * 60

1000 * π * d * 3600

100 * π * d * 3600

n

n / 1000

0.15 sec., therefore the "t.bA" would be "0.15", better if "0.2".

•

"oPr": to perform the measurement of a "speed difference" you have

to choose the "F2" function

•

"SCA"

•

"Pu.1": the number of "pulses per revolution" of channel "A", is in our

case "4", therefore "Pu.1" becomes 4.

•

"PS.1": the prescaler of channel "A", formed by the two sub-parameters "A1", mantissa, and "b1", exponent. It must be equal to the

prescaler of channel "B", "PS.2".

•

"Pu.2": the number of "pulses per revolution", of channel "B", is in our

case "4", therefore "Pu.2" becomes 4.

•

"PS.2": the prescaler of channel "B", formed by the two sub-parameters "A2", mantissa, and "b2", exponent. It must be equal to the

prescaler of channel "A" and can be calculated in the following way:

the maximum read-out capacity of the instrument is 9999, that

means the minimum speed difference (given subtracting the max.

speed of channel "A" and the one of channel "B") can be shown as

100.0 "RPM". We want to measure "100" but to have the maximum

speed resolution we have to display 1000 (don't consider the decimal point). The calculation made by the instrument according to

function selection "F2" is the following:

value to be displayed = [(Fa * PS.1) / Pu.1 - (Fb * PS.2) / Pu.2 ] (1)

- PS.1 = PS.2 = PS that means: A1 = A2 = A and b1 = b2 = b

- Fa according to the frequency of 700 RPM is 46.66Hz;

- Fb according to the frequency of 600 RPM is 40.00Hz;

the prescaler can be calculated from the above mentioned formula (1)

Page 19

33

ENGLISH

32

ENGLISH

• Cnd : auxiliary command selection

menu

r1 : display HOLD.

r2 : key-pad disabling.

t.in : activation time of the auxiliary

input, programmable value: 20 < t.in <

255 msec.

• SP.1 / SP.2 :

set-point programming

menu

tYP : working type:

oFF : abnormal condition notifying. The

output will be activated either when

the measurement is out of the measuring range or when it cannot be displayed

(blank display or "EEE" / "-" indication on the display).

Note: if the above mentioned function

will be selected, the Lo.S, Hi.S, SP1,

HYS parameters will not be considered.

do : down alarm.

uP : up alarm.

d.do: down alarm with disabling at

power-on.

uP.L: up alarm with latch ( the alarm

•

•

•

•

•

•

Where:

d = diameter of the circumference

n = number of pulses per revolution

dSY :

display parameter programming

menu

d.P : decimal point position selection.

Lo : minimum value of the display

scale, programmable value: -1999 < Lo

< 9999

Hi : maximum value of the display

scale, programmable value: -1999 < Hi

< 9999

These values are referred only to the

output limits of the analogue output and

to the "OFF" alarm function.

For instance: if Lo=100.0 and hi=800.0

and the alarm type "TYP" is "OFF", the

display will blink and activate the relevant output when the measured

variable goes out of the "100.0 to 800.0"

limits. If the analogue output is available, the output signals will start from

"100.0" and will arrive to "800.0".

Page 20

35

ENGLISH

34

ENGLISH

Example:

“do” alarm, if “SEt”=2200 (value of the ON alarm status) and the

hysteresis “HYS”=12, the resulting OFF value (end of alarm status) is:

2212 (resulting from 2200 +12).

“uP” alarm, if “SEt”=2200 (value of the ON alarm status) and the

hysteresis “HYS”=12, the resulting OFF value (end of alarm status) is:

2188 (resulting from 2200 - 12).

NOTE: the hysteresis is to be programmed according to the displayed

range. This means that the hysteresys must always be much lower than

the displayed range.

of.d : OFF time delay; programmable

value: 0 < OF.d < 255.

on.d : ON time delay; programmable

value: 0 < On.d < 255.

rL Y : coil status of the relay in the

normal condition:

nd : normally de-energized coil.

nE : normally energized coil.

Note: the normally closed or open status of the alarm contact is modified by

means of an inside selectable solder

jumper.

•

•

•

•

•

•

can be reset only if the "F" key will be

held down for at least 2 seconds).

do.L : down alarm with latch ( the alarm

can be reset only if the "F" key will be

held down for at least 2 seconds).

Lo.S: value of the lower Set-point limit,

programmable value: Lo(Hi) < LoS <

Hi(Lo).

Hi.S : value of the upper Set-point

limit, programmable value: Lo.S < Hi.S

< Hi(Lo)

SEt : value of the Set-point; program-

mable value: Lo.S < SEt < Hi.S.

HYS : hysteresis value of the set-point.

The hysteresis is a numerical value

included within the range: 0 < HYS <

9999 and represents the difference

between the value of the ON alarm

status and the value of the OFF alarm

status. The hysteresis modifies the

value of the OFF alarm status not only

with regards to the set alarm value, but

also with regards to the alarm type: the

hysteresis value is summed to the set

value if the alarm type is "do" and

subtracted from the set value if the

alarm type is "uP".

•

•

•

•

•

•

•

•

•

•

•

•

Page 21

37

ENGLISH

36

ENGLISH

played value, the control set-points and

the analogue output.

NOTE: for a correct working of the

filter, the relative coefficient must satisfy the following relationship: 1 < Fi.C

< (Fi.S x 8) < 255.

• A.ou :

analogue output programming

menu.

Lo.A : value to be expressed as % of

the output range (0/20mA-0/10V) to be

generated in correspondence with the

minimum measured value. Value programmable within the range: 0.00 < Lo

< 99.99.

Hi.A :

value expressed as % of the

output range (0/20mA-0/10V) to be generated in correspondence with the

maximum measured value (Hi.E/Hi parameters). V alue to be programmed within

the range: 0.00 < Hi.A < 99.99.

Example: minimum measured value = 100, that must correspond to a

retransmitted signal of 4mA.

“Lo.A” (%) =

100 * ?mA that in our example corresponds to:

20

• FiL : filter parameter programming

menu.

This function allows you to stabilize the

instruments digital display, in order to

obtain steady readings and better control.

Fi.S : filter working range. The coeffi-

cient is given in digits and defines the

range in which the filter works, programmable value: 0 < Fi.S < 9999

The programmable numerical value

represents the fluctuation range of the

value which has been measured and

displayed by the instrument. In the first

configuration phase this value must be

0 and the right value is to be entered

only after the verification of the possible fluctuation.

Example: if the measured instantaneous value varies from 10.00 to 10.06,

the "Fi.S" value to be entered is 0.06

(10.06 - 10.00).

Fi.C : filtering coefficient value. Pro-

grammable value: 1 < Fi.C < 255.

The higher "Fi.C", the higher the filtering of the measured value and the

longer the updating time of the dis-

Page 22

39

ENGLISH

38

ENGLISH

• S.ou: selection menu of the serial

communication output.

Add : programmable address value:

1 < Add < 255

b.dr : programming of the data baud

rate:

r1: 1200 bps.

r2: 2400 bps.

r3: 4800 bps.

r4: 9600 bps.

100 * 4mA/20 = 20%, therefore enter 20.00.

Example: minimum measured value = 100, that must correspond to a

retransmitted signal of 1V.

“Lo.A” (%) =

100 * ?V that in our example corresponds to:

10

100 * 1V/10 = 10%, therefore enter 10.00.

Example: maximum measured value 800, that must correspond to a

retransmitted signal of 18mA.

“Hi.A” (%) =

100 * ?mA that in our example corresponds to:

20

100 * 18mA/20 = 90%, therefore enter 90.00.

Example: maximum measured value 800, that must correspond to a

retransmitted signal of 5V.

“Hi.A” (%) = 100 * ?V that in our example corresponds to:

10

100 * 5V/10 = 50%, therefore enter 50.00.

Also in this case it is possible to invert the scale, that is, a decreasing

value of the retransmitted signal may correspond to an increasing value

of the input variable (example: Lo.A > Hi.A).

Page 23

40

ENGLISH

In the secondary menus: press the key to go

back to the main menu (

the selection or programming

modification will not be saved if the

key has not

been previously pressed)

YES

NO

In the menus: press the key in order to exit from the

programming phase: the display shows "End" and then the

measured value

Loading...

Loading...