CARLO GAVAZZI LDI 35 - CONFIGURATION SOFTWARE, LDI35.AV0, LDI35.AV2, LDI35.CF Operating Instructions Manual

Page 1

ENGLISH

LDI 35

OPERATING INSTRUCTIONS

• General features 2

• Technical features 3

• Installation 10

• Preliminary operations 12

• Front panel description 13

• Operating mode 15

Important:

We suggest you keep the original packing for a further shipping of the

instrument.

In order to guarantee a correct use of the instrument, we recommend

the user to carefully read the present instruction manual.

Page 2

2

ENGLISH

CARLO GAVAZZI Instruments

Multi-range µP-based panel indicators/controllers for voltage, cur-

rent and temperature measurements

LDI35.AV0 / LDI35.AV2 / LDI35.CF

rev.0

Operating instructions

Important:

We suggest you keep the original packing for a further shipping of the

instrument.

In order to guarantee a correct use of the instrument, we recommend the

user to carefully read the present instruction manual.

GENERAL FEATURES

The most important features are:

•measurement of the input value;

•display of the measured value;

•one control point of the measured value (if available);

•display of the maximum measured value.

The main programming parameters are:

•input selection;

•programming of: electrical scale, displayed scale and decimal point

position;

Page 3

3

ENGLISH

•selection of displaying mode;

•programming of all the parameters relating to the set-point (if available);

•programming of all the parameters relating to the digital filter.

TECHNICAL FEATURES

ACCURACY (VOLTAGE AND CURRENT)

LDI35.AV0: ±0.3% F.S., ±1 dgt (@ 25°C ±5°C, R.H. ≤60%);

LDI35.AV2:

VDC and ADC: ±0.3% F.S., ±1 dgt (@ 25°C ±5°C, R.H. ≤60%);

V AC and AAC: ±0.5% F.S., ±1 dgt (@ 25°C ±5°C, R.H. ≤60%, 50/60Hz,

5 to 100% F.S.).

ACCURACY (LDI35.CF: RTD/Ω TEMPERATURE)

Pt100/Pt1000: ±0.3% F.S., ±2 dgt (@ 25°C ±5°C, R.H. ≤60%);

Ni100: ±0.5% F.S., ±2 dgt (@ 25 °C ±5°C, R.H. ≤60%);

Ω: ±0.3% F.S., ±2 dgt (@ 25°C ±5°C, R.H. ≤60%).

ACCURACY (LDI35.CF: TC TEMPERATURE)

±0.3% F .S., ±2 dgt (@ 25°C ±5°C, R.H. ≤60%) from -50°C to the limit of

the input range;

±1% F .S., ±2 dgt (@ 25°C ±5°C, R.H. ≤60%) from -200°C to -5°C of the

input range.

TEMPERATURE DRIFT (VOLTAGE AND CURRENT)

LDI35.AV0: ±200 ppm/°C;

LDI35.AV2: ±200 ppm/°C.

Page 4

4

ENGLISH

TEMPERATURE DRIFT (LDI35.CF: RTD / TC / Ω)

± 200 ppm/°C.

SAMPLING RATE

LDI35.AV0: 4 times/second, dual slope 16 bits A/D converter

LDI35.AV2: 2 times/second, dual slope 16 bits A/D converter

LDI35.CF temperature measurement: 2 times/second, dual slope

16 bits A/D converter

DISPLAY

7-segment LED, h 14.2 mm; 3 1/2 digits or 3 digits + dummy zero.

MAXIMUM INDICATIONS

LDI35.AV0: 3 1/2 digit: 1999; 3 + 0 digit: 9990;

LDI35.AV2: 3 1/2 digit: 1999 (DC/AC); 3 + 0 digit: 9990 (DC/AC);

LDI35.CF: temperature: depending on the range and on the type of

probe; resistance: 199.9 Ω (STD) / 1999 Ω (on request).

MINIMUM INDICATIONS

LDI35.AV0: 3 1/2 digit: -1999; 3 + 0 digit: -1990;

LDI35.AV2: 3 1/2 digit: -1999 (DC), 0 (AC); 3 + 0 digit: -1990 (DC), 0 (AC).

LDI35.CF: temperature: depending on the range and on the type of

probe; resistance: 0.

MEASUREMENT (VOLTAGE / CURRENT)

LDI35.AV0: DC voltage/current.

LDI35.AV2: DC voltage/current and AC voltage/current (measurement

Page 5

5

ENGLISH

of the average value resulting from the sine half-wave rectification of the

input voltage/current by RMS calibration).

VOLTAGE / CURRENT INPUTS (LDI35.AV0)

200 mVDC, range: -199.9 mVDC to 199.9 mVDC

20 VDC, range: -19.99 VDC to 19.99 VDC

200 VDC, range: -199.9 VDC to 199.9 VDC

2 mADC, range: -1.999 mADC to 1.999 mADC

20 mADC, range: -19.99 mADC to 19.99 mADC

Other inputs are available by acting on the scaling parameters.

VOLTAGE / CURRENT INPUTS (LDI35.AV2)

200 VDC, range: -199.9 VDC to 199.9 VDC

500 VDC, range: -500 VDC to 500 VDC

2 ADC, range: -1.999 ADC to 1.999 ADC

5 ADC, range: -5.00 ADC to 5.00 ADC

200 VAC, range: 0 VAC to 199.9 VAC

500 VAC, range: 0 VAC to 500 VAC

2 AAC, range: 0 AAC to 1.999 AAC

5 AAC, range: 0 AAC to 5.00 AAC

Other inputs are available by acting on the scaling parameters.

FREQUENCY RANGE (VOLTAGE / CURRENT - LDI35.AV2)

From 40 to 400 Hz (accuracy: ± 0.5% F.S., ± 2 dgt @ 25 °C, 400 Hz).

OVER-RANGE (VOLTAGE / CURRENT)

Continuous: 1.2 Un/In (rated inputs), for 1 second: 2 Un/In.

Page 6

6

ENGLISH

INPUTS (RTD TEMPERATURE / Ω)

CFX: RTD, Pt100, range: -200 °C / -328 °F to +850 °C / 1562 °F

CFX: RTD, Ni100, range: -60 °C / -76 °F to +180 °C / 356 °F

CFX: Ω, 200.0 Ω, range: 0 Ω to 199.9 Ω

CFP: RTD, Pt1000 range: -200 °C / -328 °F to +850 °C / 1562 °F

CFP: Ω, 2000Ω range: 0 Ω to 1999 Ω

Other inputs are available by acting on the scaling parameters.

INPUTS (TC TEMPERATURE)

CFX/CFP: TC-J, range: -50 °C / -58 °F to +760 °C /+1400 °F

CFX/CFP: TC-L, range: -50 °C / -58 °F to +760 °C / +1400 °F

CFX/CFP: TC-K, range: -200 °C / -328 °F to +1260 °C / +1999 °F

CFX/CFP: TC-S, range: +350 °C / +1750 °C

CFX/CFP: TC-T, range: -200 °C / -328 °F to +400 °C / +752 °F

Other inputs are available by acting on the scaling parameters.

COMPENSATION (RTD/Ω)

For 3-wire connections, line resistance up to 10 Ω.

COMPENSATION (TC)

Cold junction, within a temperature range from 0 to 50 °C of ambient

temperature.

ALARM SET-POINTS

0 (standard) 1 (on request).

Alarm type: the alarm is active only for under/over-range, high alarm, low

alarm, low alarm with disabling at power-on, high alarm with latch, low

Page 7

7

ENGLISH

alarm with latch.

Set-point and hysteresis level: programmable from 0 to 100% of the

displayed range;

Activation/deactivation time delay: programmable from 0 to 255 seconds;

Relay status: selectable; normally energized/de-energized;

Output contacts: 1 SPDT; rating: 5A, 250VAC/VDC, 40W/1200VA,

130.000 cycles;

min. response time: ≤500 ms (filter excluded, set-point activation time

delay: “0”);

Insulation: 2000VRMS between output and measuring inputs; 2000VRMS

between output and excitation output.

DIGITAL FILTER

Operating range: from 0 to 1999 / 9990;

Filtering coefficient: from 1 to 255.

DATA HOLD

Automatic storage (RAM only) of the maximum value measured from the

previous storage reset onwards.

EXCITATION OUTPUT VOLTAGE (on request)

15 VDC insulated, not stabilized / max. 40 mA.

EXCITATION OUTPUT INSULATION

100VRMS between output and measuring input

4000VRMS between output and AC power supply input

500VRMS between output and DC power supply input.

Page 8

8

ENGLISH

POWER SUPPLY INPUT

230 VAC -15% +10% 50/60 Hz (standard);

115 VAC -15% +10% 50/60 Hz (on request);

240 VAC -15% +10% 50/60 Hz (on request);

120 VAC -15% +10% 50/60 Hz (on request);

48 VAC -15% +10% 50/60 Hz (on request);

24 VAC -15% +10% 50/60 Hz (on request);

Insulation: 4000 VRMS between power supply input and all the other

inputs/outputs;

9 to 32 VDC, G.I., max. starting current: ≤1.2A/200 ms (on request);

40 to 150 VDC, G.I., max. starting current: ≤0.6A /200 ms (on request);

Insulation: 500 VRMS between power supply input and all the other inputs/

outputs;

Self-consumption: 6.5 VA.

OPERATING TEMPERATURE

From 0 to +50°C (R.H. < 90% non-condensing)

STORAGE TEMPERATURE

From -10 to +60°C (R.H. < 90% non-condensing)

STABILITY OF ACCURACY

6 months

REFERENCE VOLTAGE FOR THE INSULATION

300 VRMS to earth

Page 9

9

ENGLISH

DIELECTRIC STRENGTH

4000 VRMS for 1 minute

NOISE REJECTION

NMRR: 40 dB, from 40 to 60 Hz

CMRR: 100 dB, from 40 to 60 Hz

EMC: IEC 801-2, IEC 801-3, IEC 801-4 (level 3), EN 50081-1, EN 50082-1.

IN ACCORDANCE WITH THE FOLLOWING SAFETY STANDARDS

EN 61010-1, IEC 1010-1, VDE 0411.

CONNECTIONS

Screw-type terminal board.

CASE SIZE / DIMENSIONS / MATERIAL

1/8 DIN / 48 x 96 x 83 mm / ABS, self-extinguishing: UL 94 V-0.

WEIGHT

340 g. approximately (packing included).

PROTECTION DEGREE

IP 50 (standard) / IP 65 (on request).

Page 10

10

ENGLISH

INSTALLATION

Overall dimensions and panel cut-out

(all quotes are expressed in mm)

91 mm

75 mm

max. 10

mm

83 mm

AAAAAA

A

AAAAAA

A

AAAAAA

A

92 mm

45 mm

F

96 mm

48 mm

S

Mounting

Insert the instrument into the panel and fasten it by fixing the two lateral

brackets (1) supplied with the instrument to the appropriate location (2).

1

2

2

Page 11

11

ENGLISH

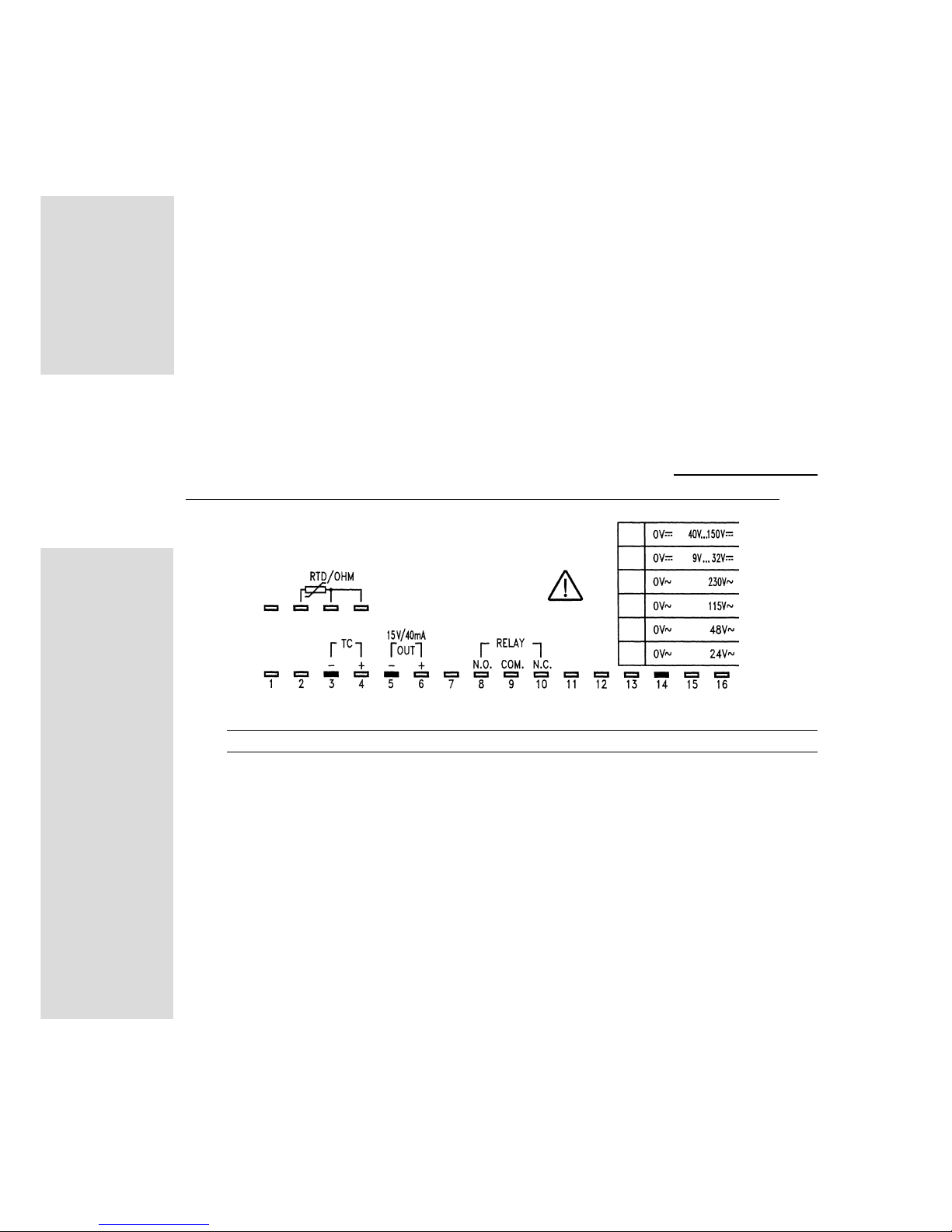

Connections

In order to select the desired range (LDI35.AV0), jumper, if necessary,

between the relevant screw terminals.

Connect LDI35.AV0 (voltmeter or ammeter) as shown in the figure.

Attention: the voltmeter input is to be connected in parallel to the source

to be measured.

Attention: the ammeter input is to be connected in series to the source

to be measured.

LDI35.AV2

LDI35.AV0

Page 12

12

ENGLISH

Connection of the signal transmitters (in the models LDI35.AV0 - 20mA):

• 2 wires: signal to the measuring input; power supply to terminal 6;

jumper also terminals 4 and 5; loop impedance 60 to 80 Ω (load 20mA).

• 3 wires: signal to the measuring input; power supply to terminals 5 and

6; jumper also terminals 4 and 5;

• 4 wires: signal to the measuring inputs; power supply to terminals 5 and 6.

Connect LDI35.CF (thermometer) as shown in the figure. For temperature/

resistances only: if there are two wires only, jumper terminals 3 and 4.

PRELIMINARY OPERATIONS

Before supplying the instrument, make sure that the power supply

voltage correspond to what is shown in the label. Example:

LDI35.AV0.D.1.XX.XX

SER.N. 970600/20078

POWER 230 VAC 50/60 Hz

INPUT CURRENT / VOLTAGE

N. 1 set point

LDI35.CF

Page 13

13

ENGLISH

FRONT PANEL DESCRIPTION

S

1. Key-pad:

functions available outside the programming phase.

Key to be pressed:

Displaying of set-point;

Displaying of maximum measured value (peak feature);

For longer than 5 seconds: reset of the maximum measured value

(the display will be blinking);

For longer than 5 seconds: reset of activated set-point (only for

set-point with latch).

1. Key-pad:

functions available in the programming phase.

Key to be pressed:

S

For longer than 2 seconds: programming phase entry and

password confirmation;

Page 14

14

ENGLISH

Menu selection (from the first to the last);

Menu selection (from the last to the first);

S

Confirmation and entry:

• in the configuration menus;

• in the secondary menus relating to parameters.

In the selected menu / secondary menu:

• increase of displayed value

• modification of parameter selection;

In the selected menu/secondary menu:

• decrease of displayed value

• modification of parameter selection.

2. Display

Alphanumeric indication by means of 7-segment LEDs:

• of the measured value;

• of the programming parameters;

• of the measuring abnormal conditions.

3. Engineering unit window

To insert the interchangeable engineering unit in the special

window, proceed as follows: remove the front cover by inserting a

suitable screw driver in the special slot on the short sides of the front

panel; force gently until the front cover is completely removed. Insert

the desired engineering unit by means of a pair of tweezers. Replace

Page 15

15

ENGLISH

the front cover by inserting it first in the lower part and then in the upper

part of the locking system.

OPERATING MODE

• Power-on

When you switch the unit on, the instrument shows for approximately 5

seconds the instruments’s software revision, for example: r.1.

• Displaying, control (if present) and diagnostics

The instrument shows continuously the value of the input variable as

defined in the programming phase.

The value shown on the display is continuously compared with the value

of the set-point and of the other parameters, thus generating the control

function by energizing/de-energizing the output relay.

• Programming

This phase is identified by the blinking of the decimal point on the right

side of the display.

To enter the programming phase, press the

S

key until “PAS” is

shown on the display; then “0” is displayed: the correct numerical code

(password) is to be entered. The following conditions may occur:

• 1) the operator hasn’t entered any Password: press the

S

key again

to enter the configuration menus of the instrument;

Page 16

16

ENGLISH

• 2) the operator has already entered a Password: select the correct

password by means of the

key (to increase the value) or key

(to decrease it) until the desired value is displayed. Press the

S

key

to confirm the value: if the password is correct, then the display will show

“PAS” again followed by the relating numerical code; press the

S

key

once more in order to display the first configuration menu; if the password

is not correct, the display shows “End” and the instrument goes back to

the measuring and control phase.

PROGRAMMING OF A NEW PASSWORD AND AUTOMATIC SELECTION OF THE PROTECTION LEVEL OF THE CONFIGURATION

DATA.

To enter the new Password:

•if the Password is “0”, press the

S

key when the display shows the

“PAS” message for the second time; enter the desired numerical code

using the

or keys, then confirm it by pressing the

S

key:

the display will show the first configuration menu (“inP”);

•if the Password has already been entered, you can modify it following

the procedure described at No. 2; after the “PAS” message has been

shown a second time, enter the new numerical code using the

or

keys and confirm it by pressing the

S

key: the display will show

the first configuration menu (“inP”).

Data protection levels:

•if the password is “0”, the configuration data are not protected by

undesired accesses;

Page 17

17

ENGLISH

•if the Password is a number between “1 and 255”, the configuration data

are entirely protected against undesired accesses;

It is possible to reset the Password by entering the number 768.

•All programming/configuration steps of LDI35 are shown in the

flow chart in the centre of this manual. The flow chart has been

conceived to make the operator better understand the programming structure of LDI35 indicating the position of the current

function with regards to the others. The flow chart also makes

more easily understandable the commands to be used in the

configuration phase.

•See the chapter “Front panel description” for information regarding the use of the key-pad and the relevant main functions.

•Glossary of displayed symbol:

(the symbols like P AS in a black background belong to the main menu;

the symbols like AC in a white background belong to the secondary menu).

PAS : access key to programming

inP : menu to select measuring inputs

For LDI35.AV2 only:

AC : AC voltage/current measurements;

dC : DC voltage/current measurements.

For LDI35.CF only:

rtd : thermoresistance/Ohm measurements;

tC : thermocouple measurements

r1 , r2 , r3 , r4 , r5 : range selection (see table “inP” in the

flow chart).

SCA : menu to program the scaling parameters

Page 18

18

ENGLISH

Lo.E: programming of the min. value of the electrical scale (see table

“inP” in the flow chart). Enter the minimum value that is to be measured

(zero scale).

Hi.E : programming of the max. value of the electrical scale (see table

“inP” in the flow chart). Enter the maximum value to be measured (full

scale).

NOTE: in the resistance measurements (“inP” ⇒ “rtd” ⇒ “r5”) the

maximum electrical full scale to be entered is: “1999” and the corresponding value of “Hi” must be “199.9” in order to take resistance

measurements with a 0.1Ω resolution.

NOTE: if the measured variable goes beyond the scale limits “Lo.E”/

”Hi.E”, the value displayed during the measuring phase will be blinking

and updated with reference to the measured value up to the maximum

displaying range (“dC” and temperature measurements: -1999/1999;

“AC” and resistance measurements: 0/1999).

d.P : selection of the decimal point position in the “Hi-Lo” scale.

Lo : programming of the min. value of the displayed scale. Enter the

value to be displayed in correspondence with the minimum value of the

electrical scale “Lo.E”.

Example: “Lo.E”=4.00 mA ⇒ “Lo”=100 mbar , means that when the value

measured by LDI35 is 4 mA, the displayed value will be 100 mbar.

Hi : programming of the max. value of the displayed scale. Enter the

value to be measured in correspondence with the maximum value of the

electrical scale “Hi.E”. Example: “Hi.E”=19.99 mA ⇒ “Hi”=1800 mbar,

means that when the value measured by LDI35 is 20 mA, the displayed

value will be 1800 mbar.

NOTE: electrical scale and displayed scale must have:

Page 19

19

ENGLISH

• corresponding values (Lo.E = Lo, Hi.E = Hi), if the same value is to be

both measured and displayed.

• different values, if the signal to be measured is different from the one

to be displayed (see examples of “Lo” and “Hi”).

• inverted values, if an increasing signal to be measured must correspond to a decreasing value to be displayed (scale inversion).

Example:

“Lo.E”=4.00 mA ⇒ “Lo”=1800 mbar; “Hi.E”=19.99 mA ⇒ “Hi”=0 mbar ,

means that when the measured value increases from 4 to 20mA, the

displayed value decreases from 1800 mbar to 0.

As you can see, the scales can be programmed with absolute freedom.

NOTE: to display temperature values as “°F”, it is necessary to program

the electrical scale as “°C” and enter the values for the displayed scale

according to the following relationship:

°F = (1.8 x °C) + 32.

Example:

“Lo.E”=-50 °C ⇒ “Lo”=-58 °F; “Hi.E”=+760 °C ⇒ “Hi”=+1400 °F,

means that the new measuring range becomes -58 °F to +1400 °F . The

data to be entered in the displayed scale can be calculated either by

means of the above mentioned “°F” relationship, or using the data of the

relevant measuring range (see chapter “T echnical Features”, paragraph

“Inputs (temperature)”.

diS : menu to select the displaying mode.

35 : displaying at 3 1/2 digit (1999)

30 : displaying at 3 digit + dummy zero (9990).

SP.1 : menu to select the programming of the set-point parameters.

tYP : selection of the type of control.

oFF : signalling of the abnormal condition. The relay is activated when

a burn-out condition occurs or the measurement is out of the electrical

Page 20

20

ENGLISH

range (displaying and blinking of the measured value or displaying of the

“EEE”/ “-EE” message).

Note: by selecting this function the “SE.t”, “HYS” parameters are not

active.

do : down/low alarm set-point. The relay will be activated when the

measured value goes below the set-point value.

uP : up/high alarm set-point. The relay will be activated when the

measured value goes over the set-point value.

d.do : alarm set-point similar to “do”, but with alarm inhibition eventually

present when LDI35 is switched on. The control starts only after the first

condition of non-alarm has been signalled.

uP.L : up/high alarm set-point with latch function.

The alarm functions as per “uP”, but the alarm can be reset only manually when

the

key is pressed for at least 5 seconds during the measuring phase.

do.L : down/low alarm set-point with latch function. The alarm functions

as per “do” and can be reset only manually when the

key is pressed

for at least 5 seconds during the measuring phase.

SEt : value of the alarm set-point to be programmed within the following

range: Lo. ≤ SEt ≤ Hi.

HYS : programming of the hysteresis value of the set-point. The

hysteresis is a numerical value included within the range: 0 ≤ HYS ≤

1999/9990 and represents the difference between the value of the ON

alarm status and the value of the OFF alarm status. The hysteresis

modifies the value of the OFF alarm status not only with regards to the

Page 21

21

ENGLISH

set alarm value, but also with regards to the alarm type: the hysteresis

value is summed to the set value if the

alarm type is “do” and subtracted

from the set value if the alarm type is “uP”.

Example:

“do” alarm, “SEt”=220 (value of the ON alarm status), hysteresis

“HYS”=12⇒ resulting OFF value (end of alarm status): 232 (resulting

from 220 +12).

“uP” alarm, “SEt”=220 (value of the ON alarm status), hysteresis

“HYS”=12 ⇒ resulting OFF value (end of alarm status): 208 (resulting

from 220 - 12).

NOTE: the hysteresis is to be programmed according to the displayed

range.

oF.d : programming of the value, expressed in seconds, of the time

delay at the alarm set-point’s deactivation (OFF).

Value to be programmed within the range:0 ≤ oF.d ≤ 255.

This delay can be useful when it is necessary to guarantee the alarm

output activation for a sufficiently long time which is to be acquired by the

processing system connected downstream LDI35.

on.d : programming of the value, expressed in seconds, of the time

delay at the alarm set-point’s activation (ON). This value is to be

programmed within the range: 0 ≤ on.d ≤ 255. This value can be useful

when it is necessary to avoid the alarm set-point’s activation if the alarm

duration is not long enough. Example: when the pressure of a liquid to

be measured decreases very quickly because of air bubbles, but this is

not a danger for the monitored plant.

rLY : selection of the normal status of the relay coil.

nd : normally de-energized coil.

Page 22

22

ENGLISH

nE : normally energized coil.

FiL : menu to program the digital filter’s parameters.

This function allows you to solve two different kinds of problems:

• stabilize the value of the instantaneous measurement displayed by

LDI35 when the value is not enough stable from the beginning and would

not therefore allow either a clear reading on the display or a good control

by the alarm set-point (if present);

• allow an amplitude of the displayed scale as regards to the electrical

one >2.

An example of how the electrical scale is to be used can be the

measurement of a process signal from a transmitter: 0 to 20mA, 4 to

20mA, 0 to 10V, 0 to 5V, 1 to 5V and so on, which can correspond to a

pressure, humidity, temperature, etc. In this case the measured signal

managed by the electrical scale (see “Lo.E”, “Hi.E”) has a numerical

value which is completely different from the one of the displayed scale

(see “Lo”, “Hi”).

Fi.S : programming of the activation range of the digital filter. This value

is programmable within the range: 0 ≤ Fi.S ≤ 1999/9990.

The programmable numerical value represents the fluctuation range of

the value which has been measured and displayed by LDI35. In the first

configuration phase this value must be 0 and the right value is to be

entered only after the verification of the possible fluctuation.

Example: the measured instantaneous value varies from 1204 to 1210,

and the value to be entered as “Fi.S” is 6 (1210 - 1204).

Fi.C : programming of the value of the filtering coefficient. Value to be

programmed within the range: 1 ≤ Fi.C ≤ 255.

The higher “Fi.C”, the higher the filtering of the measured value and the

Page 23

23

ENGLISH

longer the updating time of the displayed value and the alarm set-point.

NOTE: for a correct working of the filter, the relative coefficient must

satisfy the following relationship: 1 ≤ Fi.C ≤ (Fi.S x 8) ≤ 255.

Example: in order to display a temperature with a resolution of 0.1 °C, set

“Lo.E”=-20 °C ⇒ “Lo”=-20.0 °C, “Hi.E”=200 °C ⇒ “Hi”=199.9 °C. In this

case the scale ratio will be 10 times with a clear fluctuation of the value

displayed in the measuring phase. In order to stabilize the value it is

necessary to enter the parameters “Fi.S” and “Fi.C”. The value fluctuates

of 0.5°C max., therefore “Fi.S”=0.5 and the filtering coefficient is to be

entered making various attempts starting from a minimum value, for

example “Fi.C”=3. The datum will not remain stable, therefore “Fi.C” is

to be increased; in our case the optimum value is “Fi.C”=15.

End : Selection of the exit from the programming phase.

Diagnostic messages

“EEE” blinking indication: burn-out “up” or overcoming of the displaying

range (value to be displayed > 1999/9990).

“-EE“ blinking indication: burn-out “down” or overcoming of the display-

ing range > -1999/1990).

“3 or 4 blinking points“ indicate the set-point activation.

Loading...

Loading...