CARLO GAVAZZI ISMG 315, ISMG 320 User Manual

User Manual

ISMG 315 / ISMG 320

Three-Phase Solar Inverter

© 2010 Carlo Gavazzi Automation All rights reserved V 1.3 July 2010

2

Safety

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE – This manual contains

important instructions for Models ISMG 315 and ISMG 320 that shall be followed

during installation and future maintenance of the ISMG inverter.

Safety Precautions/Safety Notes

Only trained skilled and qualified electrical personnel shall carry out e electrical

installation, wiring, opening of the ISMG inverters. Even when no external voltage

is present, or the device is disconnected, the ISMG inverters can still store high

voltages and cause of electric shocks.

The temperature of the external heat sinks of the device can reach over 70°C

(158°F) in normal operation (Ambient temperature rating: 45°C / 113°F). There is

high risk of burn injury if these parts are touched.

The following general safety precautions must be observed during all operation

phases, service and installation of this device. Failure to comply with these safaty

precautions or specific warnings, elsewhere in this manual, violates safety

standards of design, manufacture, and intended use of the device. The

manufacturer assumes no liability for the customer’s failure to comply with these

requirements.

Safety Symbols

safety information prevent serious injuries or death to users

!

To reduce the risk of injury and to ensure the continued safe operation of this

product, the safety related information, contained in this manual are marked with

the below listed signs.

Warning, risk of electric shock

These

and/or installers.

Earth ground symbol

Caution

These information prevent damage to the product.

Intended Use

ISMG3 Series inverters shall be installed according to the specific norms and

regulations of your local building and safety department to meet the following

qualifications:

Electrical installation must be carried out correctly to meet the applicable

regulations and standards;

ISMG3 Series inverters shall be installed in a well ventilated environment and

protected against rain, condensation, moisture and dust;

ISMG3 Series inverters shall be installed in a permanent location according to

the instructions stated in this manual;

ISMG3 Series inverters shall operate according to the technical specifications

stated in this manual.

General Safety Precautions

Remove all conductive jewelry or personal accessories prior to installation or

service of the device, parts, connectors, and/or wirings.

Only trained and qualified personnel is authorised to mount, reconfigure or

repair this device.

Only licensed electricians are entitled to install permanently wired

equipments.

Make sure of standing on an insulated surface when working on the

operating device (i.e: avoid grounding of the person).

Instructions and information on cautions contained in this manual must be

carefully read and followed.

Use proper lifting techniques whenever handling enclosure, equipment or

parts.

The ISMG3 inverter must be provided with an equipment-grounding

conductor connected according to local norms and regulations.

The AC Neutral connection is only for voltage sensing and shall be neither

used to carry currents nor connected to ground inside the inverter.

The list does not contain all measures pertinent to the safe operation of the

device. If special problems arise which are not described in sufficient detail

for the purposes of the buyer, contact your local Carlo Gavazzi National Sales

company or specialized dealer or technician.

Safe Installation and Operation

Installation of the device must be in accordance with the relevant national or

local regulations. Correct grounding and short circuit protection must be

provided to ensure operational safety.

Read all instructions and caution remarks in the manual before installation.

Switch off the circuit breakers before installation and wirings. Avoid standing

on wet surfaces when working on the inverter.

PV arrays will be energized when exposed to light. Cover the arrays with

opaque (dark) material during installation and wiring. Always make sure the

DC switch is on the OFF position.

Check both of the AC and DC connections with a digital volt meter prior to

any installation or removal procedures.

Close the cover properly before switching on the circuit breakers.

Not to install the inverter exposed to direct sunlight

When no external voltage is present; the ISMG3 inverter can still contain high

voltages. There is still risk of electrical shocks.

Allow at least 5 minutes for the inverter to discharge completely after

disconnecting the AC and DC sources from the inverter.

External heat sinks can reach a relatively high temperature in normal

operation and cause skin burn injury if touched. Pay attention to it.

To prevent the risk of fire hazard, do not cover or obstruct the heat sink.

Any modification to the electrical system shall be carried out only by qualified

electricians.

!

Wiring the inverter

WARNING!

All electrical installation and the wiring methods shall be done in

accordance with the relevant national or local electrical regulations

and should follow the important safety instructions in this manual.

WARNING!

Make sure that you use suitable connecting cables for both the AC

and DC wirings. The cables must be adequately dimensioned and

suitably inert to temperature fluctuation, UV radiation and other

possible hazards.

WARNING!

Reconfirm that all connections have been performed properly and

all screws are properly tightened.

Connection of the DC cable

For DC Input Terminals, use wire size 10 to 16 mm2 (#8 to #6 AWG), 90°C

(194°F) Copper Wire.

CAUTION!

Identify the different polarity of DC voltage on each PV string and

connect respectively to the input terminals. Make sure the DC

voltage that PV arrays generate is equal or less than 850 VDC in any

case.

WARNING!

Route the DC connection cables to the ISMG3 inverters away from

any possible hazards that could damage the cables.

WARNING!

Hazardous voltage is still present on the device after disconnection

of all PV DC inputs. Allow 5 minutes for the inverter to discharge

the energy completely.

WARNING!

PV arrays will be energized when exposed to light. Cover the arrays

with opaque materials during installation and wiring.

!

!

!

Connection of the AC cable

For AC Output Terminals, use wire size 6 to 10 mm2 (#10 to #8 AWG), 90°C

(194°F) Copper Wire.

WARNING!

Make sure that the circuit breaker of utility mains is switched OFF

before connecting the power cables from the breaker to the AC

connector.

Interaction with the Utility Grid

CAUTION!

The default interface protection has been verified according to the

valid low-voltage national grid connection standards. Only the

authorized installers can change the tripping-limit settings under

the approval of the distribution network operator (DNO).

CAUTION!

Confirm the grid connection standard is selected correctly before

tied with the grid (Std. DK5940 for Italy, VDE0126-1-1 for Germany

or RD1663 for Spain). Please refer to the Section 3.3.5 Setting

Operation for the selection of the grid connection standards.

CAUTION!

The default interface protection is saved permanently in the

EEPROM and won’t be erased even if the inverter shuts down.

Repair and Maintenance

The inverter contains no user serviceable parts inside, except for the fans.

Only CARLO GAVAZZI LOGISTICS SpA trained staff is authorized to repair the

unit. Please return the equipment for further examination if the faults are not

caused by fans.

WARNING!

Not to make alterations or tamper assembly in the inverter unless

expressly specified elsewhere in this Manual. Doing so may result

in injury, electric shock, or fire and of corse void the warranty.

2

1.

2.

Contents

INTRODUCTION 3

1.1

1.2

1.3

1.4

INSTALLATION 12

2.1

2.2

2.3

2.3.1

G

ENERAL

S

PECIFICATIONS

F

EATURES

A

CCESSORIES

P

LACEMENT

M

OUNTING

W

IRING THE INVERTER

3

5

11

11

12

14

20

Connection of the AC cable................................................................27

3.

2.3.2

2.3.3

2.4

OPERATION 36

3.1

3.2

3.3

3.3.1

3.3.2

3.3.3 Produced Power Graphs.......................................................................52

3.3.4

Connection of the DC cable ...............................................................29

Connection of the Communication cable .........................................32

W

IRING INVERTER IN PARALLEL

O

VERVIEW

O

PERATION FEATURES

LCD D

LCD Backlight Indication ....................................................................41

Display messages flow .......................................................................43

Error Messages...................................................................................54

36

39

ISPLAY

40

35

3.3.5

3.4

3.4.1

3.4.2

Setting Operation ...............................................................................55

A

UTO TEST (ONLY FOR

Auto test PC Software ........................................................................58

Use Self-testing...................................................................................62

ISMG315IT

3

AND

ISMGT320IT) 57

4.

5.

3.5

3.6

TECHNICAL DOCUMENTATION 73

4.1

4.2

4.3

4.4

WARRANTY INFORMATION 80

E

RROR MESSAGES DESCRIPTION

T

ROUBLESHOOTING

O

UTLINE DRAWING

E

FFICIENCY

DE-

RATING OPERATION

MPP E

74

FFICIENCY

68

73

75

78

64

4

List of Figures

Fig1.1.1

Fig 2.1.1

Fig 2.2.2

Fig 2.2.3

Fig 2.2.4 Hook the Inverter on the mounting bracket and then fasten the screw

19

Fig 2.3.1

Fig 2.3.2

Fig 2.3.3

Fig 2.3.4

Fig 2.3.5

Fig 2.3.6

Grid Connected Solar System Overview...................................................4

Clearances required for ISMG3 inverter installation ..........................13

Inverter mounting bracket ...................................................................15

Fasten the mounting bracket ...............................................................16

Turn the DC disconnect switch OFF......................................................20

Loosen the screws .................................................................................21

Open the front lid of the wiring box.....................................................22

Removal of the covers for the cable through holes ............................23

Wiring box front view ...........................................................................24

Utility Grid Configuration .....................................................................26

Fig 2.3.1.1

Fig 2.3.2.1

Fig 2.3.2.2

Fig 2.3.2.3

Fig 2.3.3.1

Fig 2.3.3.2

Fig 2.3.3.3

Fig 2.3.3.4

Fig 3.3.1

Fig 3.3.1.1

Fig 3.4.1.1

Fig 3.4.1.3 Auto-test process ..............................................................................61

AC Terminal Block for AC cable connections ..................................27

ISMG3 Inverter supports two (2) independent PV strings....................29

PV Inverter Connections ..................................................................30

PV Strings in Parallel ........................................................................30

Positions of the communication ports and termination switch....32

RJ-45 Pins and Signals......................................................................33

RS-232 connection (ISMG-45S0918) ...............................................34

RS-485 connection ...........................................................................34

Front panel of the ISMG3 inverter .......................................................40

3 colours LCD backlight....................................................................41

Search for inverters..........................................................................58

Fig 4.1.1

Fig 4.2.1

Fig 4.2.2

Outline Drawing of ISMG3....................................................................73

Efficiency of the ISMG320 = 96.0% ......................................................74

Efficiency of the ISMG315 = 95.5% ......................................................74

Fig 4.3.1

Temperature de-rating curve of the ISMG320....................................75

Fig 4.3.2

Fig 4.3.3 Output Power v.s. Grid voltage of the ISMG320 ..................................77

Fig 4.4.1

Fig 4.4.2

DC Power curve of the independent PV string of the ISMG320.....76

MPP Efficiency of the two PV strings in parallel .................................78

MPP Efficiency of the two PV strings in individual..............................78

2

1. Introduction

1.1 General

The Carlo Gavazzi ISMG3 product family is a series of grid-connected photovoltaic

inverters which are designed to convert DC power generated by photovoltaic

arrays to AC power that is delivered into the utility grid. The ISMG315 and

ISMG320 are devices of the family with three (3) phases AC outputs for the

European market. The overview of the grid-tied solar energy system is shown in

Fig 1.1.1. ISMG3 inverters utilize the state-of-the-art technology to achieve the

purpose of high reliability and ease of use. In addition, ISMG315 and ISMG320

comply with the requirements of VDE0126-1-1, RD1663/RD661 and DK5940

Standards. Furthermore the 3-phase ISMG3 inverters are certified to comply with

the Standard EN50178 and EN55022 EMC Regulations with Class A device.

The ISMG3 inverter is designed to operate automatically once it is installed and

commissioned correctly according to the technical specifications. When the DC

input voltage generated by the photovoltaic arrays raises above the minimum

MPPT voltage setting, the embedded controller starts and goes into the system

initialization mode. If the DC input voltage goes above the PV Start voltage point,

the inverter will go into Checking mode (Riso check) and monitor all parameters

needed for grid connection. During this time, the ISMG3 inverter is not generating

AC power yet. Once all conditions necessary for grid connection are satisfied, the

ISMG3 inverter goes into the Grid/MPP mode and begins feeding the AC power

into the grid. When the input DC voltage falls below the pre-set threshold voltage

setting, the ISMG3 inverter will then shut off the output AC power. And the

inverter will shut down itself when the DC input voltage is under the minimum

3

MPPT voltage setting. The ISMG3 inverter will be awakened again automatically

when the input DC voltage rises above the minimum MPPT voltage point.

We appreciated your choice of Carlo Gavazzi ISMG3 inverters for your power

conversion devices in your solar power system. This document contains the

information you need for the installation and settings of the ISMG3 inverters.

Therefore, it is strongly recommended to read this manual carefully before the

ISMG3 inverter installation and settings.

Fig1.1.1 Grid Connected Solar System Overview

4

1.2 Specifications

Specifications for ISMG315 and ISMG320

Name-Part number ISMG 315 ISMG 320

Grid output (AC)

Grid voltage, nominal 400VAC 3PH/N/PE

Grid voltage, operating range

320 ~ 460VAC

Grid frequency, nominal 50 Hz

Grid frequency, operating

48~52.5 Hz (adjustable)*

range

Nominal Output Power

15,000 W 20,000 W (19,990W**)

Maximum output power 16,500 W 22,000 W

Nominal Output Current

Maximum Output Current

21.8 A 29.0 A

28.2 A 31.9 A (31.88A**)

Waveform True sine

Power factor > 0.99 @ nominal power

Total Harmonic Distortion < 5 %

DC Component < 0.5 %

Phase Three Phase

Solar input (DC)

Maximum DC Power

17,300 W 23,100 W

Maximum input voltage 850 VDC

Input voltage range 300 ~ 850 VDC

MPP voltage range 400 ~ 850 VDC

PV start voltage 400 VDC (adjustable)

Nominal voltage 630 VDC

Nominal

input current 2x19.7A (39.4 A) 2x26.3A (52.5 A)

5

Maximum input current 2x21.6A (43.3 A) 2x28.9A (57.8 A)

General

Name-Part number ISMG 315 ISMG 320

Maximum efficiency

CEC efficiency

96.7 % 97.0 %

95.5 % 96.0 %

Night consumption < 1W

Environmental

Operating temperature range -25° ~ +60°C (-13° ~ +140°F)

Storage temperature range -25° ~ +70°C (-13° ~ +158°F)

Maximum full power operating

50°C (122°F) 45°C (113°F)

ambient

Relative humidity Max. 95 %

Mechanical

Outdoor enclosure IP55, ref. IEC 60529(2001)

Cooling Intelligent control fan

DC input - Accept wire size of 10 to 16 mm2

(#8 to #6 AWG)

Input & Output terminals

AC output - Accept wire size of 6 to 10 mm2

(#10 to #8 AWG)

Weight/Shipping weight 75 kg / 85kg (165.3 lb / 187.3 lb )

Dimensions (HxWxD) 890.5×751×245.5 mm (35.1×29.6×9.7 inches)

Shipping dimensions (HxWxD) 1130×900×700 mm (44.6×35.5×27.6 inches)

Interface

Communication RS232 and RS485

Display 128 * 64 graphic display

Certifications

Directive 2004/108/EC

EN 55022(1998) : IEC/CISPR22

Electromagnet Compatibility

EN 61000-6-2(2005)

EN 61000-6-4(2007)

EN 61000-3-11(2000)

6

EN 61000-3-12(2004)

configured with the approval of the local utility

trip limits and may be

on the ISMG315IT and on the

Low-Voltage Regulation

Directive 2006/95/EC

EN 50178(1997), covered by IEC 62103(2003)

VDE 0126-1-1(2006), RD 1663(2000) / RD 661

Network Monitoring

(2007), DK 5940(2007) / Enel Connections Guide

(2008), Section F

RoHS Directive 2002/95/EC

* Some factory settings can be re-

provider. This inverter is provided with adjustable

aggregated over 200kW on a single Point of Common Coupling.

** The

output power

capacity is limited to 19.99 kW

ISMG320IT according to the DK5940 for the Italian market only.

7

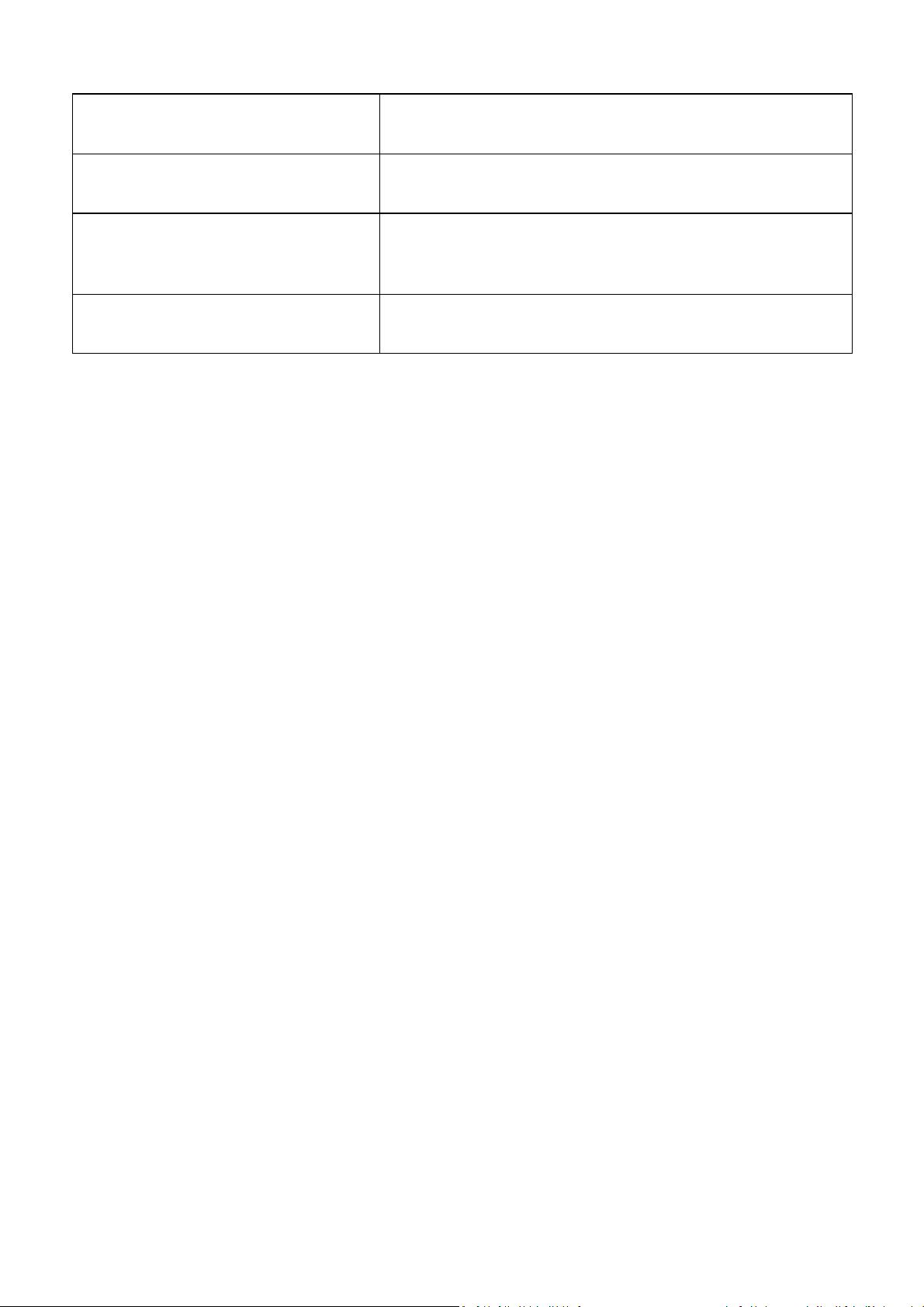

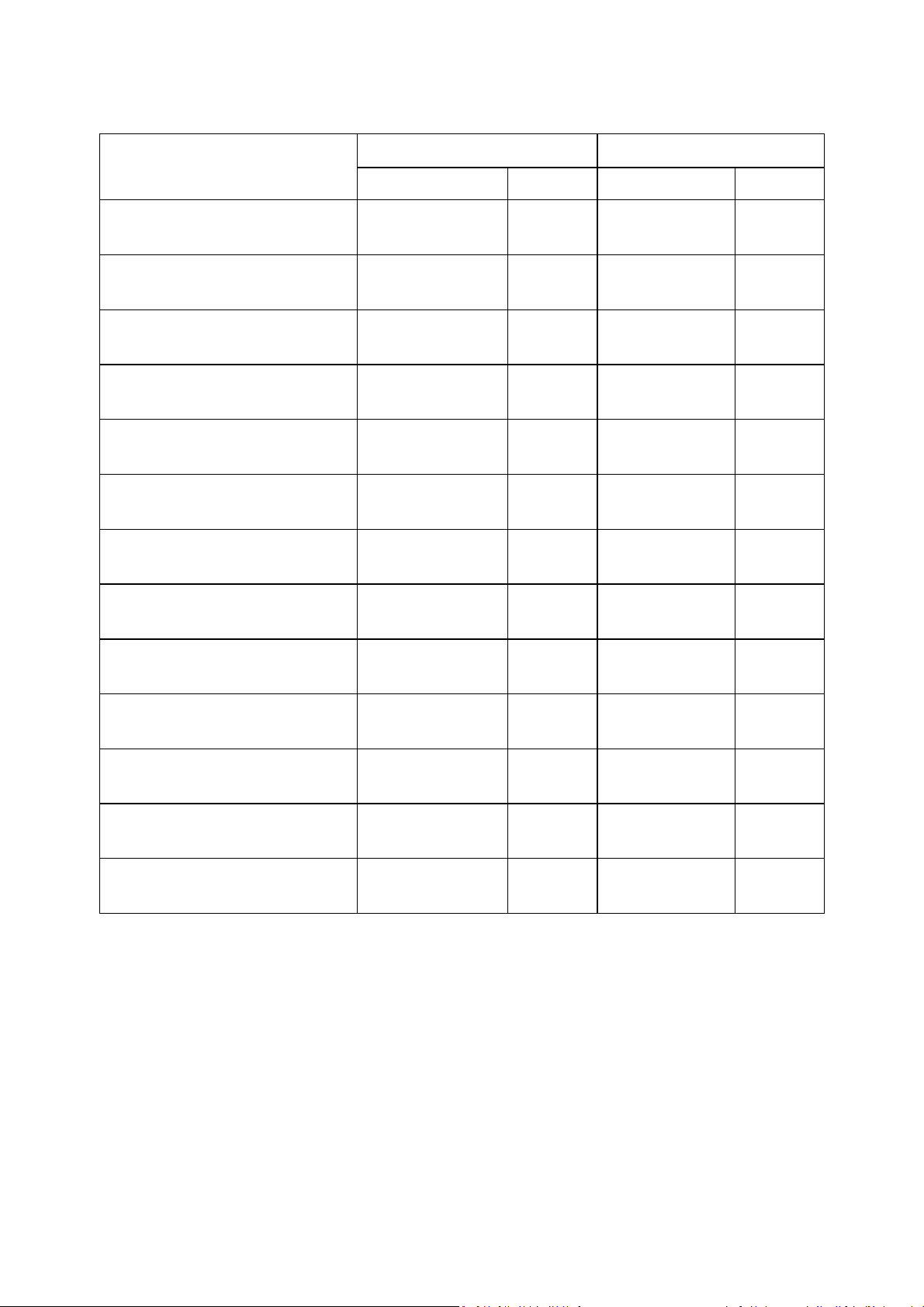

Adjustable voltage, Frequency and Reconnection Settings (1)

DK5940 VDE0126-1-1

Setting

Range Default Range Default

Over-frequency (Hz) 50.05~50.95 50.25 50.05~50.15 50.15

Over-frequency

disconnection time (cycle)

Under-frequency (Hz) 49.05~49.95 49.75 47.55~49.95 47.55

Under-frequency

disconnection time (cycle)

Over-voltage (Vac) 235~270 270 235~260 260

Over-voltage

disconnection time (cycle)

Under-voltage (Vac) 188~225 188 188~225 188

Under-voltage

disconnection time (cycle)

Dc injection tripping

current (A)

Dc injection

disconnection time (cycle)

1~3 3 1~8 8

1~4 4 1~8 8

1~4 4 1~8 8

1~8 8 1~8 8

0.10~0.60 0.60 0.10~0.80 0.80

1~4 4 1~8 8

Insulation resistance trip

setting (MOhm)

PV start voltage (Vdc) 400~800 400 400~800 400

Reconnect delay* (s) 20~300 20 30~300 30

* Once a grid failure occurred, the ISMG3 inverter waits 20~600 seconds before

the next connection to the grid. The default setting is 20 seconds for DK5940

(Italy), 30 seconds VDE0126 (Germany) and 180 seconds for RD1663 (Spain).

0.5~10 1.0 0.5~10 1.0

8

Adjustable voltage, Frequency and Reconnection Settings (2)

RD1663 User

Setting

Range Default Range Default

Over-frequency (Hz) 50.05~50.95 50.95 50.05~54.50 50.95

Over-frequency

disconnection time (cycle)

Under-frequency (Hz) 48.05~49.95 48.05 45.50~49.95 49.05

Under-frequency

disconnection time (cycle)

Over-voltage (Vac) 235~249 249 235~276 264

Over-voltage

disconnection time (cycle)

Under-voltage (Vac) 199~225 199 160~225 196

Under-voltage

disconnection time (cycle)

Dc injection tripping

current (A)

Dc injection

disconnection time (cycle)

1~8 8 1~250 4

1~8 8 1~250 4

1~8 8 1~150 4

1~8 8 1~150 4

0.10~0.80 0.80 0.10~0.80 0.80

1~150 8 1~150 8

Insulation resistance trip

setting (MOhm)

PV start voltage (Vdc) 400~800 400 400~800 400

Reconnect delay* (s) 180~300 180 20~600 20

* Once a grid failure occurred, the ISMG3 inverter waits 20~600 seconds before

the next connection to the grid. The default setting is 20 seconds for DK5940

(Italy), 30 seconds VDE0126 (Germany) and 180 seconds for RD1663 (Spain).

0.5~10 1.0 0.5~10 1.0

9

Measurement precision

Range

Resolution

Accuracy

Display Measurement

Input voltage (VDC)

Input Current (IDC)

Grid voltage (VAC)

Grid current (IAC)

Grid frequency (Hz)

Output power (W)

Energy yield (kWh)

0~900V 0.1V 0.3V ±2V

0~50000mA 100mA 15mA ±500mA

0~300V 0.1V 0.3V ±1V

0~60000mA 100mA 30mA ±500mA

45~65Hz 0.01Hz 0.001Hz ±0.02Hz

0~22000W 1W 1W ±50W

0~65535×103kWh 0.1kWh 2.2×10-6kWh 1%

10

1.3 Features

High conversion efficiency

Dual-MPP trackers (Can be connected in parallel)

IP55 enclosure (Outdoor)

Graphical display (Internal mini-datalogger)

Three-phase balanced outputs

Easy installation

Smart self-diagnosis

High power / small size ratio

High reliability @ competitive price

Conformity to VDE 0126-1-1 (ENS), RD1663/RD661

DK5940/Enel Connections Guide (2008), Section F

1.4 Accessories

Operation Manual (incl. warranty page) 1 pcs

Mounting Bracket 1 pcs

Fixing screws (bet. the inverter and bracket) 2 pcs

Cross jumper (for input terminal) 1 pcs

Auto Test Software CD-ROM 1 pcs

Mounting screws 10 pcs

11

2. Installation

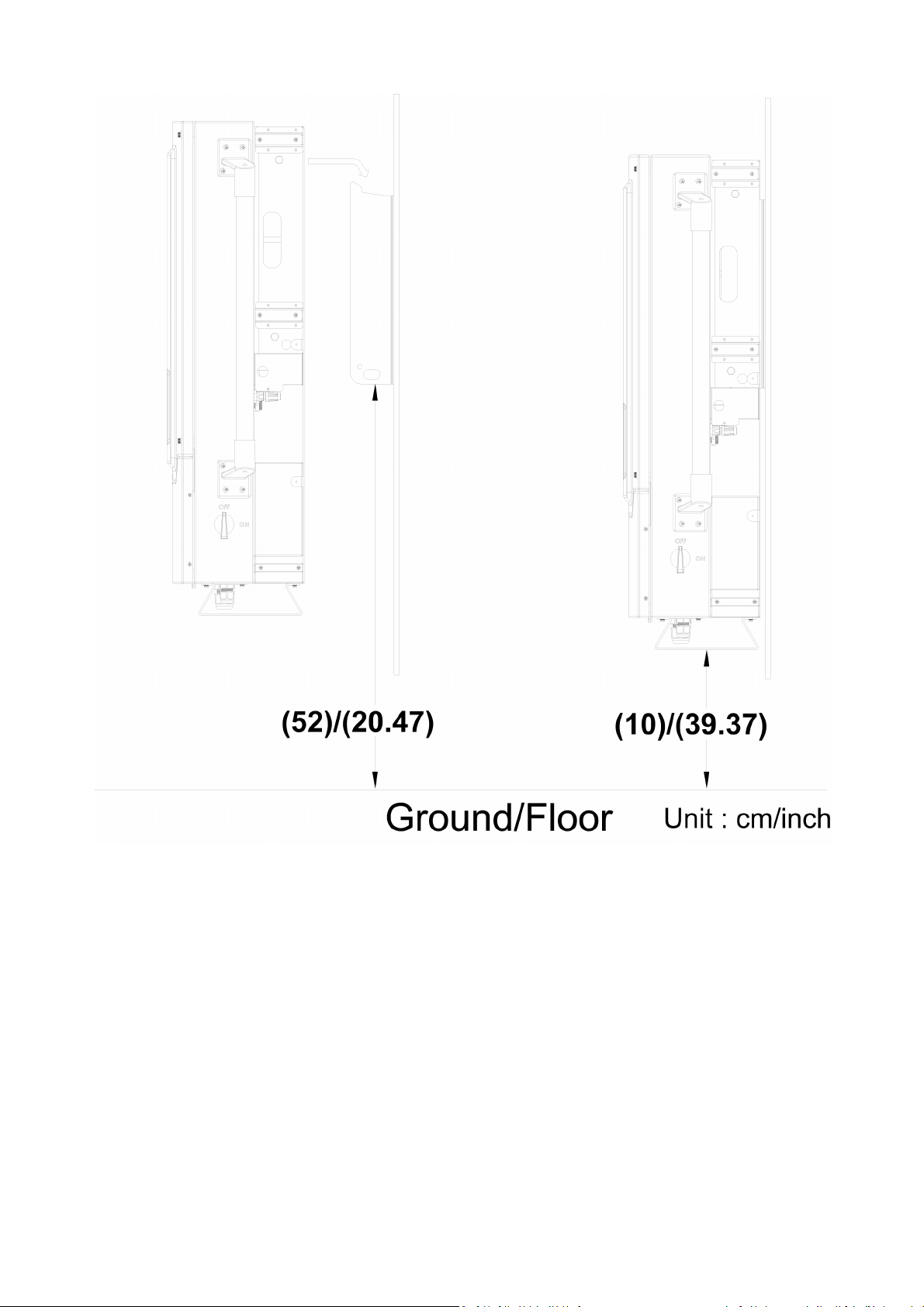

2.1 Placement

∙ ISMG3 inverters, that must be vertically mounted, can be located indoor or

outdoor according to protection degree of enclosure IP55.

∙ Leave at least 50 cm (19.7 inches) of free space above and 100 cm (39.4

inches) below the inverter when installed outdoor. Allow 20 cm (7.9 inches)

between inverters when installing multiple inverters for better ventilation (see

Fig 2.1.1).

∙ Mount the inverter on a wall that is strong enough to withstand the inverter

with 75 kg weight.

∙ Avoid mounting the inverter on a location directly exposed to sunlight to

maintain the ambient temperature of the inverter within -25° and 60 °C (-13°

and 140°F). Humidity shall be within 0% and 95%.

12

WARNING!

Some parts of the cooling surface can reach temperatures over

70°C (158°F) when the inverter is in operation. Do not operate the

inverter where it exposes to flammables, explosive atmospheres or

close to combustibles or unknown materials that may result in

fire/expolsion danger.

WARNING!

Do not expose the inverter to the corrosive liquids and/or gases.

Keep DC wirings as short as possible to minimize power loss.

The mounting bracket should be fastened on a concrete or a masonry wall

with the recommended anchors.

Fig 2.1.1 Clearances required for ISMG3 inverter installation

13

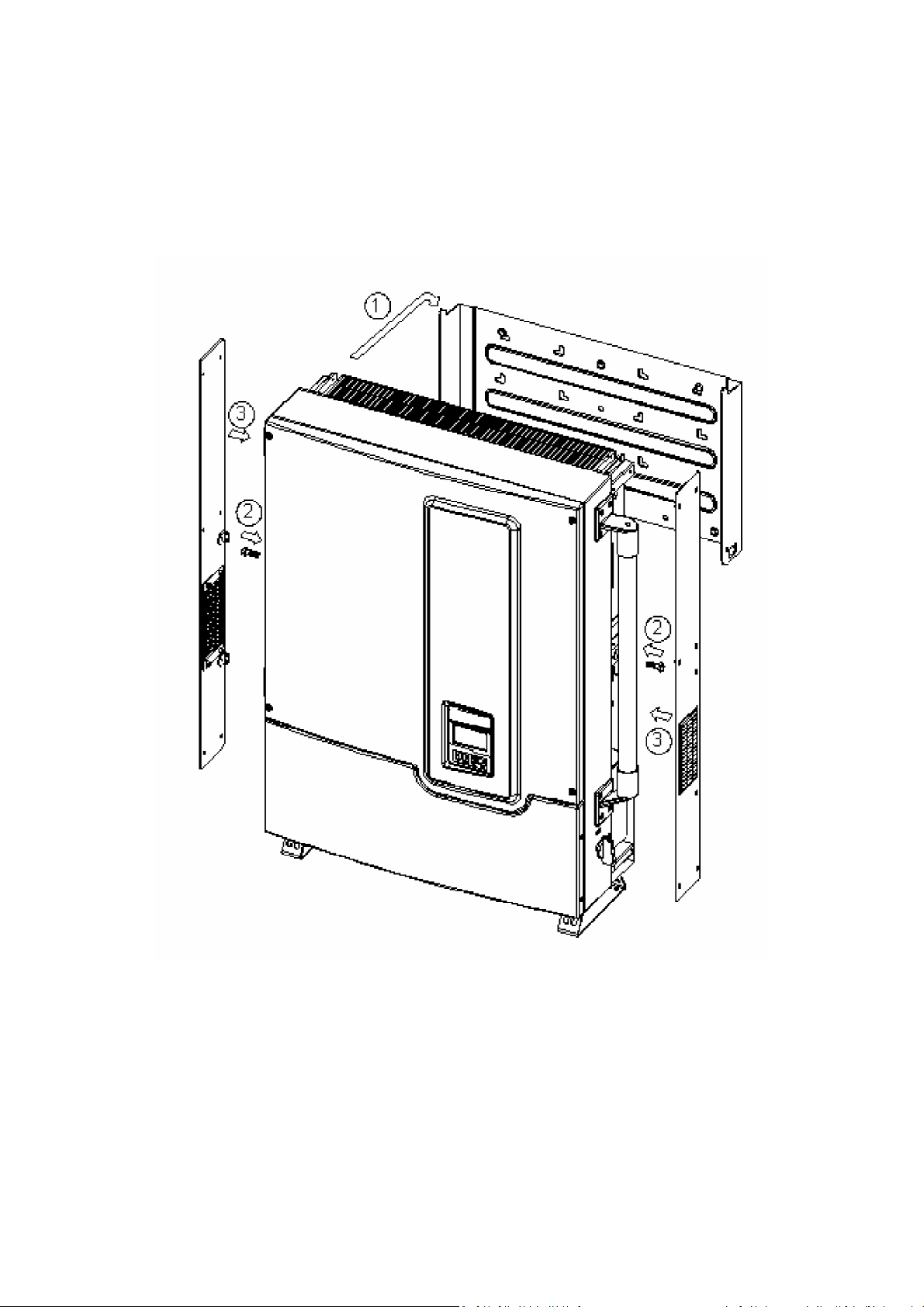

2.2 Mounting

The steps listed below describe how to mount the inverter on the wall:

1. After taking out the inverter from the carton, the attached mounting bracket

shall first be removed from the inverter by following the steps shown in Fig

2.2.1 below.

Fig 2.2.1 To remove the mounting bracket from the inverter

14

2. Use the mount bracket (Fig 2.2.2) as a template to mark the location of the

holes to be drilled in the wall. After drilling the holes, the mounting bracket is

then held against the wall and fastened to the wall with anchors as shown in

Fig 2.2.3. (At least ten (10) screws required)

For mounting on wooden wall, the suggested diameter of screw is at least

6.35mm and the length is 25.4mm. The nut size needs to be at least 12.7mm.

A minimum of 10 screws are required to mount the bracket on wooden wall

For mounting on steal plate, the suggested screw size is M8x16. A minimum

of 8 screws are required to mount the bracket on steel plate

For mounting on cement wall, the suggested anchor screw with outer

diameter of 8mmx38.1mm is recommended. The nut size needs to be at least

12.7 mm. A minimum of 8 screws are required to mount the bracket on

cement wall

Fig 2.2.2 Inverter mounting bracket

15

Fig 2.2.3 Fasten the mounting bracket

16

3. Once the mounting bracket is fastened to the wall, the inverter can be

mounted and fastened on the bracket. Hook the inverter on the mounting

bracket flanges and slip down carefully to lock it in place. And then fasten the

inverter to the mounting bracket as shown in Fig 2.2.4.

17

18

Loading...

Loading...