Page 1

4008 RV By-Pass Pump By SHURflo

Installation & Maintenance Manual

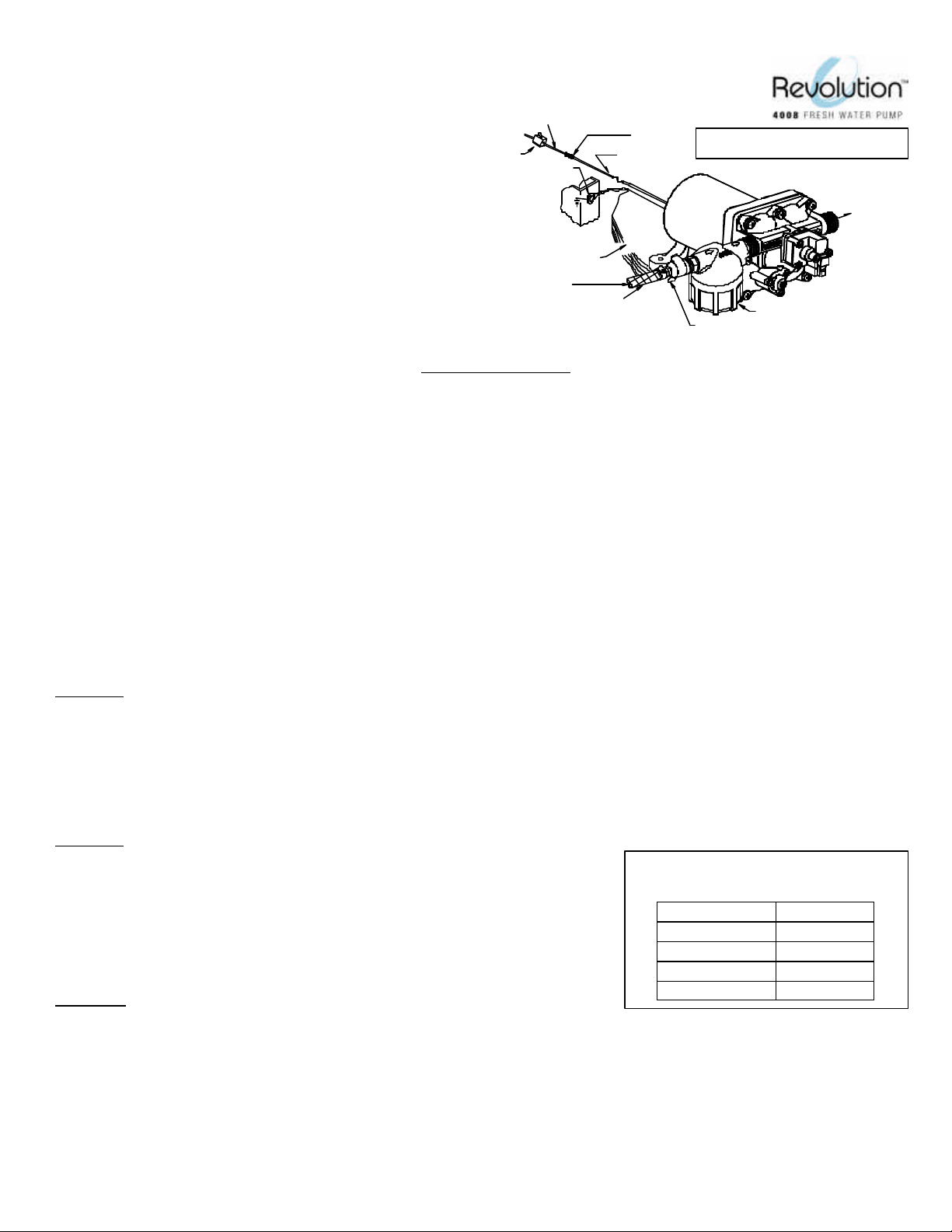

Installation Preparation

The goal of installation is to provide a quiet, easyto-maintain installation with good flow and low

backpressure. This can be accomplished with

16GA [1,29mm] min.

SWITCH

GROUND

CONNECTOR

FUSE

FUSE

Typical Pump Installation

the following guidelines:

• Mount on a solid surface in an accessible

location for strainer cleaning and pump main-

tenance.

• Use flexible high-pressure hose on the pump

inlet and outlet [such as SHURflo Kit 94 -591-

00]. The pumps ports and strainer should not

be connected to plastic or rigid pipe, or the

pump's normal motion will transmit through

rigid plumbing causing noise, and possibly

loosening or cracking components.

• Pump must use an adequate 50 -mesh strainer

[such as SHURflo 255 series strainers].

• Use a minimum of 1/2" [13mm] Inner Diame-

ter plumbing. Smaller ID plumbing will cause

cavitation, high backpressure, low flow and

POTABLE H20 INLET

Installation Guidelines

• Solid surface within 6 feet of tank • Accessible location

• Minimize flow restrictions in the system • Strainer on pump inlet

• No accumulator needed • Properly sized wiring

• Flexible hose on inlet and outlet • Proper electrical protection

• Minimize plumbing elbows and valves • Properly sized plumbing

SOLID SURFACE

HIGH -PRESSURE

FLEXIBLE HOSE

STRAINER

SWIVEL FITTINGS

noise.

• No need for an accumulator with by -pass pumps.

• Pump is designed for intermittent duty only: Do not use these pumps for running a Reverse-Osmosis [RO] Filtration

System. High pressure-continuous duty usage will shorten the life of the pump and is not covered under warranty.

• Wire Size is 16 GA MINIMUM, 12GA is recommended ---See Wire Chart in Electrical Section for minimum sizing.

• Minimum power requirement is a 10 Amp circuit.

• Reduce restrictions on inlet and outlet. This includes small inner diameter shut-off valves, winterizing valves and

elbows.

• If the RV has an Intellitec Pump Controller, it must be rated at 10 or 15 amps; If the controller is rated at 7.5 Amps, a

new controller or a high-amp relay must be used.

Mounting

• Mount the pump within 6 feet of the tank for best performance and pump life. The pump will pull farther, but the farther it

pulls the more work it does, increasing vibration and noise, and reducing the output and pump life.

• Mount pump in a space of at least 1 cubic foot for adequate ventilation to prevent overheating.

• Pump may be mounted in any position.

• Mount pump for easy access for cleaning strainer, maintenance and service.

• Mount pump on a solid surface to prevent vibration and noise.

Electrical

• The pump works best on an individual filtered circuit, protected by the recommended fuse or breaker specified on the label.

• A 15-Amp switch is recommended and should be on the positive lead.

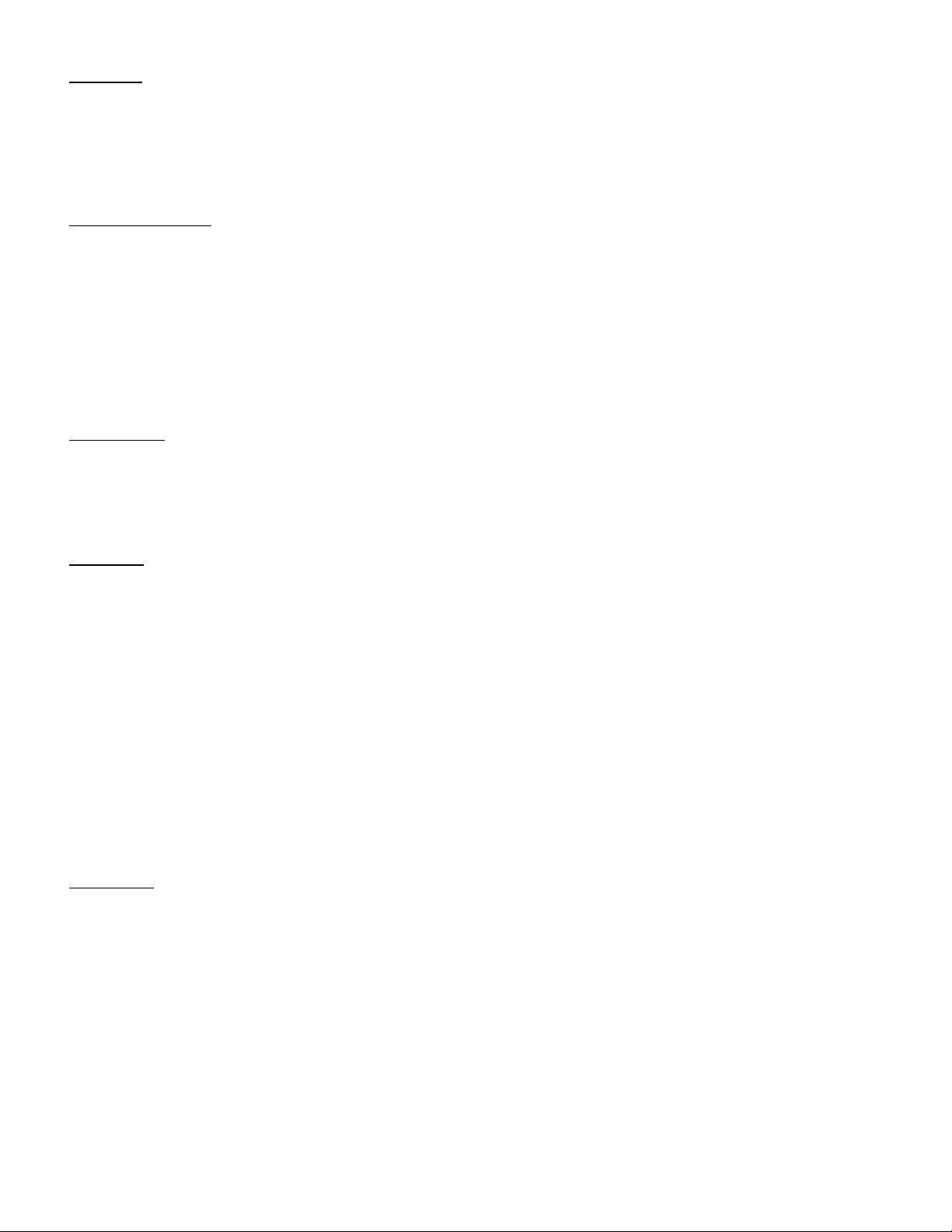

• Wire Sizing: Proper wire sizing is required for good pump operation. If the

wire is too small, low voltage will affect the pump performance and can create

a fire hazard.

SHUT OFF POWER TO THE PUMP WHEN LEAVING THE RV UNATTENDED.

Plumbing

Minimum Wire Size for a 10% voltage drop on a

12VDC, 10 Amp Circuit. Length is the distance from

the power source to pump and back to ground.

Feet [Meters] AWG [mm²]

0 - 25 [0 - 7.6] 16 [1.3]

25 -50 [7.6 - 15.2] 14 [2.1]

50 - 70 [15.2 - 21.3] 12 [3.3]

70 -110 [21.3 - 33.5] 10 [5.3]

Installation of a strainer is required to prevent debris from entering the pump.

For noise and vibration reduction we recommend at least 18 in. [.5 M ] of 1/2" [13mm] I.D. flexible high-pressure hose to

both ports. The pump ports and strainer should not be connected to plastic or rigid pipe. This hose should be anchored

where it meets the hard plumbing to reduce plumbing vibration.

911-1008-D Page 1 of 3

Page 2

Using a pan to catch the remaining water, remove the plumbing at the pump's inlet/outlet ports. Turn the pump ON,

Operation

This pump is designed for intermittent duty only.

The pump operates normally up to about 40-psi, where a spring -loaded by-pass valve opens, allowing flow back from the

output side to the input side, providing smooth, steady flow with virtually no cycling, all the way down to a trickle. As a

faucet is opened back up, the pressure will drop, the by -pass will close and full flow is again obtained. This allows good

flow, even with today’s restrictive showers and pullout sprayer faucets. Performance will vary, of course, depending on the

voltage to the pump; lower voltage = lower flow, higher voltage = higher flow. Remember your electrical safety: It is

always best to shut power to the pump OFF when leaving the RV unattended.

About The By-Pass NOTE: By -pass adjustment should be performed by professional technicians with proper

gauges and equipment.

The by-pass is a spring loaded diaphragm that opens up allowing water from the discharge side back to the inlet side.

The by -pass is set to begin opening at about 40 psi and creating full by -pass at about 62 psi (for 55 psi models), lower

pressure pumps will vary depending on the by -pass and pressure switch settings. If the switch or by-pass are adjusted too

much, the by -pass and switch shut -off can overlap and THE PUMP WILL NOT SHUT OFF. Screwing the switch screw in

clockwise will raise the shut -off pressure. Unscrewing the switch screw counterclockwise will lower the pump shut-off pressure. Screwing the by -pass screw in will raise the pressure at which the by-pass starts and raise the full by-pass pressure.

Unscrewing the by -pass screw counterclockwise will lower the pressure at which by -pass starts and lower the full by -pass

pressure. WARNING: If full by-pass is reached before the shut-off setting, the pump will not shut off. Full by -pass

pressure setting should be at least 5 psi higher than pump shut off pressure.

Maintenance

Normal pump maintenance is all that is needed: Checking and cleaning of the strainer, normal sanitizing and winterizing

and occasionally checking all plumbing hardware and fittings for tightness. Lack of sanitizing is the number one reason for

premature pump failure and poor performance over time. Lack of sanitizing will cause scale build -up on the diaphragm

and valves, causing low flow and leak back [occasional pump cycling with no faucets open or tank filling up when hooked

up to city water].

Sanitizing

Potable water systems require periodic maintenance to keep components working properly and deliver a consistent flow of

fresh water. Sanitizing is recommended: prior to storing, after a period of storage, or any time the system is opened or

contaminated, as follows: NOTE: Check your Vehicle Owner’s Manual for specific instructions. By-pass any filters

or remove filter cartridges.

1. Determine the amount of common household bleach needed to sanitize the tank.

A) 2 ounces of bleach per 15 gallons tank size: 60 gallon tank [15 x 4] = 4 x 2 ounces = 8 ounces of bleach.

B) I ml bleach per 1 liter tank size: 300 liter tank = 300 milliliters of bleach.

2. Mix the bleach with water in a container such as a gallon jug. If tank is filled through a pressurized fitting, pour the bleach

into the hose before attaching the hose to the city water entry.

3. Pour the bleach solution into the tank and fill the tank with potable water. Rock RV back and forth to coat top and sides of

potable water tank.

4. Open all faucets (Hot & Cold) allowing the water to run until the odor of chlorine is detected. Allow four (4) hours of

contact time to disinfect completely. Doubling the solution concentration allows for a contact time of one (1) hour.

5. Drain the tank. Refill the tank and flush the system once or twice until the odor has decreased. The residual chlorine

odor and taste is not harmful.

Winterizing Refer to the vehicle owner’s manual for specific winterizing instructions.

If water is allowed to freeze in the system, serious damage to the plumbing and pump may occur. Failures of this type will

void the warranty. The best guarantee against damage is to completely drain the pump and perform the following:

1. Drain the water tank. If the tank doesn't have a drain valve, open all faucets allowing the pump to operate until the tank

is empty.

2. Open all the faucets (including the lowest valve or drain in the plumbing), allow the pump to purge the water from the

plumbing, and then turn the pump OFF.

3.

allowing it to operate until the water is expelled. Turn OFF power to the pump once the plumbing is emptied. Do not

reconnect the pump plumbing. Make a note at tank filler as a reminder: "Plumbing is disconnected".

4. All faucets must be left open to guard against any damage.

5. Potable anti -freeze may be poured down drains and toilets to protect p-traps and toilet seals. Sanitize the plumbing system

before putting the plumbing system back in service.

911-1008-D Page 2 of 3

Page 3

Troubleshooting

Vibration induced by driving can loosen plumbing, strainers and pump hardware. Check for system

components that are loose. Also, refer to the chart below for trouble -shooting tips.

PUMP WILL NOT START/ BLOWS CIRCUIT:

• Electrical connections, fuse or breaker, main switch, and ground

connection.

• Is the motor hot? Thermal breaker may have triggered; it will reset

when cool.

• Is voltage present at the switch? Bypass the pressure switch.

Does the pump operate?

• Charging System for correct voltage (±10%) and good ground.

• For an open or grounded circuit, or motor; or improperly sized

wire.

• For seized or locked diaphragm assembly (water frozen?).

WILL NOT PRIME/SPUTTERS: (No discharge/Motor runs)

• Is the strainer clogged with debris?

• Is there water in the tank, or has air collected in the hot water

heater?

• Is the inlet tubing/plumbing sucking in air at plumbing connections

(vacuum leak)?

• Is inlet/outlet plumbing severely restricted or kinked? Restrictive

valves?

• Proper voltage with the pump operating (±10%).

• For debris in pump inlet/outlet valves or swollen/dry valves.

• Pump housing for cracks or loose drive assembly screws.

RAPID CYCLING:

• For restrictive plumbing and flow restrictions in faucets/shower

heads.

PUMP WILL NOT SHUT-OFF / RUNS WHEN FAUCET IS CLOSED:

• Output side (pressure) plumbing for leaks, and inspect for leaky valves

or toilet.

• For air trapped in outlet side (water heater) or pump head.

• For correct voltage to pump (±10%).

• For loose drive assembly or pump head screws.

• Are the valves held open by debris or is the rubber swollen?

• Pressure switch operation. By -pass set higher than shut -off

NOISY OR ROUGH OPERATION:

• For plumbing which may have vibrated loose.

• For a restricted inlet (clogged strainer, kinked hose, restrictive

valves).

• Is the pump plumbed with rigid pipe causing noise to transmit?

• Does the mounting surface amplify noise (flexible)? Does it bang

like a drum?

• For mounting feet that are loose or are compressed too tight.

• For air in the system. Check all fixtures for air and bleed system.

• The motor with pump head removed. Is noise from motor or pump

head?

LEAKS FROM PUMP HEAD OR SWITCH:

• For loose screws at switch, by -pass or pump head.

• Switch diaphragm ruptured or pinched.

• For punctured diaphragm if water is present in the drive assembly.

• Water filter/purifier should be on separate feed line.

• Shut-off pressure set too low.

55 psi models: part kits

4

No. Component Part Kit

1 Upper Assembly 94-800-00

2 Valve Assembly 94-800-01

3 2.5° Drive Assembly 94-800-02

1

3

2

4 Motor 11-302-00

N/S Check Valve 94-800-03

1,2,3 Pump Head 94-800-04

N/S Pressure Switch 94-800-05

LIMITED WARRANTY

SHURflo warrants its aftermarket retail 4008 series potable water pumps to be free from material and workmanship defects under normal use and service for 2

years from the date of purchase with purchase receipt or 2 years from the date of manufacture indicated on the motor nameplate if no purchase receipt is

available, as outlined in document MS-030-152. Pumps installed as original equipment are warranted for 1 year, and fall under the warranty supplied by the

manufacturer, as outlined in document MS-030-123. This limited warranty is in lieu of all other warranties, expressed or implied (including without limitation

implied warranties of merchantability and fitness for a particular purpose), and no other person is authorized to give any other warranty or assume obligation or

liability on SHURflo's behalf. SHURflo shall not be liable for any labor, damage or other expense, nor shall SHURflo be liable f or any indirect, incidental or

consequential damages of any kind incurred by the use or sale of any defective Product or part. This limited warranty covers Products distributed within the

United States of America and Canada. Other world market areas should consult with the distributor for any deviation from this document. The limited warranty

will not apply to pumps that were improperly installed, misapplied, or are incompatible with components not manufactured by SHURflo. Product failure due to

foreign debris is not covered under the terms of this limited warranty. SHURflo will not warrant any Product that is physically damaged, or altered outside

SHURflo. Warranty claims may be resolved by an authorized dealer service center, or by a SHURflo service center. Returns are to be shipped with charges

pre-paid. Package all returns carefully. SHURflo will not be responsible for freight damage incurred during shipping to a service center. For complete Limited

Warranty details, consult SHURflo.

Typical Performance

PSI/Bar GPM [LPM] Amps

0/0 3.0 [11.3] 2.8

10/0.7 2.3 [8.7] 3.2

20/1.4 1.9 [7.2] 4.2

30/2.1 1.6 [6.0] 5.1

40/2.8 1.4 [5.3] 6.1

50/3.4 0.8 [3.0] 6.8

55/3.8 0 7.5

Visit our Web Site at http://www.shurflo.com

Shurflo reserves the right to update specifications,

change prices, or make substitutions without notice.

SHURflo SHURflo East SHURflo Europe, Middle East, Africa

5900 Katella Avenue 52748 Park Six Court Pentair Water Belgium bvba

Cypress, CA 90630 Elkhart, IN 46514-5427 Industriepark Wolfstee, Toekomstlann 30

Phone (562) 795-5200 Phone (562) 795-5200 B-2200 Herentals, Belgium

Toll Free (800) 854-3218 Toll Free (800) 854-3218 Phone +32-14-283500

Fax (562) 795-7564 Fax (574) 264 -2169 Fax +32-14-283505

911-1008 Rev D

© 2009 SHURflo, LLC All Rights Reserved

Page 3 of 3

FLOW TECHNOLOLIES GROUP

5900 Katella Ave, Cypress, CA 90630

Phone (800) 854-3218 • (562) 795-5200 • Fax (562) 795-7564

www.shurflo.com

Page 4

Dérivation 4008 de SHURflo pour véhicules de loisirs

16GA [1,29mm] min.

Manuel d’installation et de maintenance

INTERRUPTEUR

Préparation à l’installation

L’objectif de l’installation est d’obtenir une installation silen-

GROUND

cieuse,

facile d’entretien et délivrant un bon débit avec un faible retour.

Ceci peut être réalisé en suivant les instructions suivantes :

• Effectuez le montage sur une surface solide dans un

endroit accessible pour faciliter le nettoyage du filtre

et la maintenance de la pompe.

• Utilisez un tuyau flexible haute pression sur l’admission

et la sortie de la pompe [comme le Kit SHURflo 94-591-

SURFCE SOLIDE

ADMISSION H20

POTABLE

HAUTE PRESSION

00]. Les orifices de la pompe et le filtre ne doivent pas

être raccordés à une tuyauterie en plastique ou rigide, sinon le mouvement normal de le pompe sera transmis

par la tuyauterie rigide et provoquer du bruit et éventuellement un desserrage ou la rupture de composants.

-La pompe doit utiliser un filtre adéquat de maille 50

[comme les filtres SHURflo de la série 255].

• Utilisez une tuyauterie d’un diamètre intérieur minimum

de ½ po [13mm]. Une tuyauterie d’un diamètre inférieur

provoquera une cavitation, un retour élevée, un faible

débit et du bruit. -Un accumulateur n’est pas nécessaire avec les pompes de dérivation.

Instructions d’installation

· Surface solide à 2 m (6 ft) du réservoir · Endroit accessible

· Minimiser les restrictions de débit dans le circuit · Filtre sur l'admission de lapompe

· Pas d’accumulateur nécessaire · Câblage de calibre correct

· Tuyau flexible sur l’admission et la sortie · Protection électrique correcte

· Minimiser les coudes de tuyauterie et les vannes · Tuyauterie de taille appropriée

Fuse = fusible

Ground = masse

Typical pump installation = Installation typique de pompe

• La pompe est conçue pour un service intermittent

uniquement : N’utilisez pas ces pompes pour l’exploitation d’un

système de filtration par osmose inverse [OI]. Le fonctionnement continu en haute pression raccourcit la durée de vie de la

pompe et n’est pas couvert pas la garantie.

• Le calibre des câble est de 16 GA MINIMUM, 12 GA est

conseillé---Reportez-vous au tableau des câbles dans la sec-

tion Électricité pour le calibre minimum. -L’alimentation minimum requise est un circuit de 10 A.

• Réduisez les restrictions sur l’admission et la sortie. Ceci inclut les robinets à petit diamètre interne, les vannes d’hiver-

nage et les coudes.

• Si le véhicule de loisir comporte un contrôleur de pompe Intellitec, son intensité doit être de 10 ou 15 A ; si

l’intensité du contrôleur est de 7,5 A, un nouveau contrôleur ou un relais à ampérage élevé doit être utilisé.

CONNECTEUR

FUSE

RACCORDS PIVOTANTS

Typical Pump Installation

FILTRE

Montage

• Montez la pompe dans un rayon de 2 m (6 pieds) du réservoir pour un rendement et une durée de vie de la pompe optimum. La

pompe aspire de plus loin, mais plus elle aspire de loin, plus elle force, ce qui augmente les vibrations et le bruit et réduit

le refoulement et sa durée de vie.

• Montez la pompe dans un espace d'au moins 1 pied cube pour assurer une ventilation adéquate et éviter une surchauffe.

• La pompe peut être montée dans n'importe quelle position.

• Montez la pompe de façon à faciliter l'accès pour le nettoyage du filtre, la maintenance et les réparations.

• Montez la pompe sur une surface solide pour éviter les vibrations et le bruit.

Électricité

• La pompe fonctionne le mieux sur un circuit filtré individuel, protégé par l'utilisation d'un

fusible ou d'un court- circuit spécifié sur l'étiquette.

• Un contacteur de 15 A est conseillé et doit se trouver sur le conducteur positif.

• Dimensions des câbles : des dimensions correctes des câbles sont requises pour un

bon fonctionnement de la pompe. Si le câble est trop petit, la basse tension affectera

le rendement de la pompe et peut créer un risque d'incendie.

COUPEZ L'ALIMENTATION ÉLECTRIQUE DE LA POMPE QUAND VOUS LAISSEZ

LE VÉHICULE SANS SURVEILLANCE.

Taille minimum des câbles pour une chute de

tension de 10 % sur un circuit 12 V cc, 10 A. La

longueur est la distance de la source d’alimen-

tation à la pompe et vers la masse.

Pieds [Mètres] AWG [mm2]

0–25 [0-7,6] 16 [1,3]

25–50 [7,6-15,2] 14 [2,1]

50–70 [15,2-21,3] 12 [3,3]

70–110 [21,3-33,5] 10 [5,3]

Plomberie

L’installation d'un filtre est requise pour empêcher l'entrée de débris dans la pompe. Afin de

réduire le bruit et des relations, nous recommandons un tuyau flexible haute pression de 18 po [0,5 m] et d'un diamètre intérieur minimum de ½ po [13 mm] sur les deux orifices. Les orifices de la pompe et le filtre ne doivent pas être raccordés à un tube en plastique ou rigide. Ce tuyau doit être fixé à l'emplacement de connexion à la plomberie dure afin de réduire les vibrations de

tuyauterie.

911-1008-D Page 1 of 3

Page 5

Fonctionnement

Cette pompe est conçue pour un service intermittent uniquement.

La pompe fonctionne normalement jusqu'à une pression de 40 psi, où une soupape de dérivation à ressort s’ouvre et permet

au débit de sortir de revenir au côté d'admission afin d'assurer un débit régulier et stable avec pratiquement aucun cycle, jusqu'à un mince filet. Quand le robinet est rouvert, la pression chute, la soupape de dérivation se ferme et le plein débit est à nouveau

obtenu. Ceci permet un débit correct, même avec les douches économiques et les têtes de robinet rétractables d'aujourd'hui. Bien sûr,

leur rendement varie en fonction de la tension sur la pompe ; basse tension = débit faible, haute tension = débit élevé. N'oubliez pas

votre sécurité électrique : il est toujours préférable de couper l'alimentation électrique de la pompe quand vous laissez le véhicule sans surveillance.

Au sujet de la dérivation REMARQUE : le réglage de la dérivation ne doit être effectué que par des techniciens professionnels utilisant des manocontacts et un équipement adaptés

La dérivation consiste en une membrane à ressort qui s’ouvre pour permettre le passage de l'eau du côté du refoulement vers le c ôté

d'admission. La dérivation est configurée de façon à s’ouvrir à environ 40 psi et à créer une dérivation complète à environ 62

psi. Le manocontact sur la pompe est réglé pour un arrêt à 55 psi. Si le manocontact ou la dérivation sont réglés trop haut, ils

peuvent se chevaucher et LA POMPE NE S'ARRÊTERA PAS . Vissez la vis du manocontact dans le sens des aiguilles d'une

montre pour relever la pression d'arrêt. Dévissez la vis du manocontact dans le sens contraire des aiguilles d'une montre pour

diminuer la pression d'arrêt de la pompe. Vissez la vis de la dérivation pour augmenter la pression à laquelle celle-ci démarre

et augmenter la pression de dérivation complète. Dévissez la vis de la dérivation dans le sens contraire des aiguilles d'une

montre pour diminuer la pression à laquelle celle-ci démarre et abaisser la pression de dérivation complète. AVERTISSE-

MENT : si la dérivation complète est atteinte avant le réglage d'arrêt, la pompe ne s'arrêtera pas. Le réglage de la pression

de dérivation complète doit être supérieur d'au moins 5 psi à la pression d'arrêt de la pompe.

Maintenance

Seule une maintenance normale de la pompe est nécessaire: une vérification et un nettoyage du filtre, une désinfection et un hivernage normaux et une vérification occasionnelle du serrage de toute la tuyauterie et tous les raccords. Le manque de désinfection constitue la principale cause de défaillance prématurée des pompes et d'un rendement médiocre dans la durée. Le manque de

désinfection provoque une accumulation de calamine sur la membrane et les vannes, ce qui réduit le débit et provoque une

fuite en retour [cycles occasionnels sans robinets ouverts ou remplissage du réservoir lors du raccordement au réseau d'eau

public].

Désinfection

Les systèmes d'eau potable nécessitent une maintenance périodique afin de maintenir le fonctionnement correct des composants et de délivrer un

débit constant d'eau fraîche. Une désinfection est recommandée : avant le remisage, après une période de remisage, chaque fois que le système est

ouvert ou contaminé, comme suit:

REMARQUE : consultez le manuel du propriétaire de votre véhicule pour les instructions spécifiques. Dérivez tous filtres ou dép osez les

cartouches de filtres.

1. Déterminez la quantité d’eau de Javel ménagère courante nécessaire pour désinfecter le réservoir.

(A) 2 onces d'eau de Javel pour 15 gallons de contenance du réservoir : réservoir de 60 gallons [15 x 4] = 4 x 2 onces = 8 onces d'eau

de Javel

(B) 1 ml d’eau de Javel par litre de contenance du réservoir : réservoir de 300 litres = 300 millilitres d'eau de Javel.

2. Mélangez l’eau de Javel avec de l'eau dans un récipient tel qu’une bonbonne. Si le réservoir est rempli par un raccord pressurisé, versez l'eau de Javel

dans le tuyau avant de fixer celui-ci sur l'entrée de l'eau municipale.

3. Versez le mélange d'eau de Javel dans le réservoir et remplissez le réservoir d'eau potable. Secouez le véhicule d'avant en arrière afin de recouvrir le haut

et les côtés du réservoir d'eau potable.

4. Ouvrez tous les robinets (d'eau chaude et d'eau froide) et laisser l'eau couler jusqu'à ce qu'une odeur de chlore se fasse sentir. Attendez

quatre (4) heures de durée de contact pour une désinfection complète. Si la concentration de la solution est doublée, attendez une durée

de contact d'une (1) heure.

5. Vidangez le réservoir. Remplissez le réservoir et rincez le système une ou deux fois jusqu'à ce que l'odeur s'atténue. Le goût et l'odeur

résiduels de chlore ne sont pas nocifs.

Hivernage Consultez le manuel du propriétaire du véhicule pour des instructions spécifiques relatives à l'hivernage.

Si de l’eau gèle dans le circuit, la tuyauterie peut être sérieusement endommagée, ainsi que la pompe. Les défaillances de ce type annulent la garantie. La meilleure garantie contre ces dégâts et de vidanger la pompe à fond. Dans le cas de l'utilisation selon les recommandations des

fabricants, l'antigel non toxique pour eau potable est sûr pour une utilisation avec les pompes SHURflo. Effectuez ce qui suit pour

vidanger la pompe :

1. Vidangez le réservoir d’eau. Si le réservoir ne comporte pas de robinet de vidange, ouvrez tous les robinets en laissant la pompe fonctionner

jusqu'à ce que le réservoir soit vide.

2. Ouvrez tous les robinets (y compris la vanne la plus basse ou la vidange de la tuyauterie), laissez la pompe purgez l’eau de la tuyauterie et

arrêtez la pompe.

3. Récupérez l’eau restante à l'aide d'une bassine, retirez la tuyauterie aux orifices d'admission et de refoulement de la pompe. Mettez la

pompe en marche et laissez -la tourner jusqu'à ce que l'eau soit expulsée. Coupez l'alimentation électrique de la pompe une fois que la

tuyauterie est vide. Ne raccordez pas la tuyauterie de la pompe. Laissez une note de rappel sur l'orifice de remplissage du réservoir :

« Tuyauterie débranchée ».

4. Tous les robinets doivent être laissés ouverts pour protéger contre tout dégât.

5. De l'antigel potable peut être versé dans les drains et les toilettes pour protéger les siphons et les joints des toilettes. Désinfectez le système de

tuyauterie avant de le remettre en service.

911-1008-D Page 2 of 3

Page 6

Dépannage

Les vibrations provoquées par l'entraînement peuvent desserrer la tuyauterie, les filtres et la visserie de la

pompe. Vérifiez qu’aucun composant du système n’est desserré.

LA POMPE NE DÉMARRE PAS/FAIT DISJONCTER LE CIRCUIT :

• Raccords électriques, fusible ou coupe-circuit, interrupteur principal et raccor-

dement à la masse.

• Est-ce que le moteur est chaud ? Le coupe-circuit thermique peut avoir été

déclenché ; il se réarmera quand il sera froid.

• Est-ce qu'une tension et présente à l’interrupteur ? Dérivez le mano-

contact. Est-ce que la pompe fonctionne ?

• Système de charge pour la tension correcte (±10 %) et masse correcte.

• Pour un circuit ou un moteur ouvert ou à la masse ; ou un câble de mau-

vaises dimensions.

• Pour la membrane grippée ou bloquée (eau gelée?).

NE S'AMORCE PAS/TOUSSE : (Absence de refoulement/le moteur tourne)

• Est-ce que le filtre et obstrué avec des débris ?

• Présence d'eau dans le réservoir ou air récupéré dans le chauffe eau ?

• Est-ce que la tuyauterie/plomberie d'admission aspire de l’air au niveau des

raccords (prise d’air) ?

• Est-ce que la plomberie d'admission/de refoulement est sévèrement obs-

truée ou pliée ? Vannes restrictives ?

• Tension correcte avec la pompe en fonctionnement (±10 %).

• Pour des débris dans des vannes d'admission/de refoulement de la pompe

ou vannes excessives/sèches.

• Le boîtier de la pompe à la recherche de fissures ou de vis desserrées de

l'assemblage de l'entraînement.

CYCLE RAPIDE :

• Pour une plomberie restrictive et des restrictions de débit dans les robinets/

pommeaux de douche.

• Le filtre/purificateur d’eau doit se trouver sur une conduite d'alimentation

séparée.

• Pression d'arrêt réglée plus bas que la pression de dérivation.

LA POMPE NE S'ARRÊTE PAS/TOURNE QUAND LE ROBINET EST FERMÉ :

• La plomberie du côté du refoulement (pression) à la recherche de fuites et vérifiez si

des vannes ou un toilette fuient.

• Pour de l'air emprisonné dans le côté de refoulement (chauffe-eau) ou dans la

tête de la pompe.

• Pour la tension correcte vers la pompe (±10 %).

• Pour des vis desserrées de l'assemblage de l'entraînement ou de la tête de la

pompe.

• Est-ce que des vannes sont maintenues ouvertes par des débris ou est-ce que le

caoutchouc est gonflé ?

• Fonctionnement du manocontact. Dérivation réglée plus haut que l'arrêt.

FONCTIONNEMENT BRUYANT OU IRRÉGULIER :

• Pour une plomberie qui peut être desserrée par les vibrations.

• Pour une admission restreinte (filtre obstrué, tuyau plié, vannes restrictives).

• Est-ce que la pompe est raccordée avec un tuyau rigide provoquant la transmission

de bruit ?

• Est-ce que la surface de montage amplifie le bruit (flexible) ? Est -ce qu'elle cogne

comme un tambour ?

• Pour des pieds et des montages qui sont desserrés ou sont trop comprimés.

• Pour la présence d'air dans le système. Vérifiez la présence d’air à tous les

appareils et purgez le système.

• Le moteur avec la tête de pompe déposée. Est-ce que le bruit provient du moteur

ou de la tête de pompe ?

FUITES AU NIVEAU DE LA TÊTE DE POMPE OU DU MANOCONTACT :

• Pour des vis desserrées au niveau du manocontact, de la dérivation ou de la

tête de la pompe.

• Membrane de contact rompue ou pincée.

• Pour une membrane percée en cas de présence d’eau dans l'entraînement.

Kits de pièces

N° Composant Part Kit

1 Ensemble supérieur 94-800-00

2 Ensemble de vanne 94-800-01

3 Entraînement 2,5° 94-800-02

1

3

2

4 Moteur 11-302-00

N/S Clapet antiretour 94-800-03

1,2,3 Tête de pompe 94-800-04

N/S Manocontact 94-800-05

GARANTIE LIMITÉE

SHURflo garantit que ses pompes détachées d'eau potable de la série 4008 vendues au détail sont exemptes de défaut de matériaux et de construction

dans le cadre d'une utilisation et d'entretien normaux pendant deux ans à partir de la date d'achat avec une preuve d'achat ou pendant deux ans à partir

de la date de fabrication indiquée sur la plaque signalétique du moteur si aucune preuve d'achat n'est disponible, selon la desc ription du document MS030-152. Les pompes installées en équipement d'origine sont garanties pendant un an et sont couvertes par la garantie fournie pa r le fabricant, selon la

description du document MS-030-123.Cette garantie limitée remplace toutes les autres garanties, expresses ou implicites (y compris les garanties implicites sans limitation de valeur marchande et adaptation à une utilisation particulière) et aucune autre personne n'est autorisée à exprimer une garantie ou à

assumer des obligations ou des responsabilités au nom de SHURflo. SHURflo ne pourra être tenu responsable de tous frais de main- d'œuvre, dommages ou

autres coûts et SHURflo ne pourra être tenu responsable tous dommages indirects, accidentelles ou corrélatifs provoqués par l'ut ilisation ou la vente d'un produit

ou pièce défectueux. Cette garantie limitée couvre les produits distribués aux États -Unis d'Amérique et au Canada. Dans les autres régions commerciales du

monde, consultez le distributeur pour tout écart avec ce document. La garantie limitée ne s'applique pas aux pompes qui ont été mal installées, utilisées

d’une mauvaise manière ou qui sont incompatibles avec des composants non fabriqués par SHURflo. La défaillance des produits provoquée par des débris

étrangers n'est pas couverte selon les conditions de cette garantie limitée. SHURflo ne garantit pas de produits physiquement en dommagés ou modifiés hors de

SHURflo. Les réclamations de garantie peuvent être résolues par un centre de service agréé ou par un centre de service SHURflo. Les renvois sont à expédier

avec le port prépayé. Emballez avec précaution tous les renvois.

4

Performance typique

PSI/Bar GPM [LPM] Ampères

0 3,0 [11,3] 2,0

10 / 0.7 2,3 [8,7] 3,2

20 / 1.4 1,9 [7,2] 4,2

30 / 2.1 1,6 [6,0] 5,1

40 / 2.8 1,4 [5,3] 6,1

50 / 3.4 0,8 [3,0] 6,8

55 / 3.8 0 7,5

Visit our Web Site at http://www.shurflo.com

Shurflo reserves the right to update specifications,

change prices, or make substitutions without notice.

SHURflo SHURflo East SHURflo Europe, Middle East, Africa

5900 Katella Avenue 52748 Park Six Court Pentair Water Belgium bvba

Cypress, CA 90630 Elkhart, IN 46514-5427 Industriepark Wolfstee, Toekomstlann 30

Phone (562) 795-5200 Phone (562) 795-5200 B-2200 Herentals, Belgium

Toll Free (800) 854-3218 Toll Free (800) 854-3218 Phone +32-14-283500

Fax (562) 795-7564 Fax (574) 264 -2169 Fax +32-14-283505

911-1008 Rev D

© 2009 SHURflo, LLC All Rights Reserved

FLOW TECHNOLOLIES GROUP

5900 Katella Ave, Cypress, CA 90630

Phone (800) 854-3218 • (562) 795-5200 • Fax (562) 795-7564

www.shurflo.com

Page 3 of 3

Loading...

Loading...