Carlin Flame Funnel 1050FFD, Flame Funnel 1150FFD Installation And Operating Instructions Manual

IT IS IMPORTANT THAT THE INSTALLATION OF

THE OIL BURNER, PIPING AND FITTINGS, SAFETY

DEVICES, CONTROLS, ELECTRICAL WIRING AND

EQUIPMENT BE DONE IN ACCORDANCE WITH NATIONAL AND/OR LOCAL REGULATIONS OF THE

AUTHORITIES HAVING JURISDICTION OVER SUCH

INSTALLATION.

Installation

and

Operating

Instructions

For

Carlin Flame Funnel®

Oil Burners

Models 1050FFD and

1150FFD

SPECIFICATIONS

MODEL NUMBER

ITEM

Fuel Specification No. 2

Firing Range

High-Fire*

Low-Fire

Motor HP, RPM, Hz 1, 3450, 60

Motor Volts, 1-phase

Motor Amps; 115 volts, 1-phase

Control Volts, Hz 120, 60 120, 60

Ignitor Volts 120 120

Burner Housing Rugged casting Rugged casting

Blower Wheel, Dia. x W. 7" x 5" 7

Flame Retention Ring, O.D. 3

2-Stage Fuel Unit Pressure 100 100

Low and High-Fire Oil Valve 120V, 60-Hz 120V, 60-Hz

Damper Motor with End Switch 120V, 60-Hz 120V, 60-Hz

Oil Nozzle Specs. (3) 45°SS (3) 45°SS

Approximate Shipping Weight 135 lbs. 145 lbs.

** Gph ratings are based on sea level to 2,000 ft. elevation. For every

1,000 ft. rise over 2,000 ft., reduce the maximum gph rating by 4%.

**Motor volts and phase must be specified when ordering.

3-phase

230 volts, 1-phase

230 volts, 3 phase

460 volts, 3 phase

1050FFD 1150FFD

ASTM D396

15.00-25.00*

9.00-12.00

115/208-230**

208-230/460**

16.4

8.2

4.0

2.0

13

/16" 41/4"

No. 2

ASTM D396

20.00-35.00*

12.00-15.00

1

1

/2, 3450, 60

115/208-230**

208-230/460**

22.0

11.0

5.0

2.5

5

/8" x 5"

Copyright 2016 — Carlin Combustion Technology, Inc.

©

Carlin Combustion Technology, Inc.

126 Bailey Rd North Haven, CT 06473

Ph 203-680-9401 Fx 203-680-9403

Tech Support 800-989-2275 carlincombustion.com

Description

Model 1050FFD and Model 1150FFD Flame-Funnel oil

burners for use with No. 2 fuel oil are low-high-low (step

modulating) high speed flame retention burners. Oil flow

rate is step-modulated by the use of two oil valves and

three nozzles, low-fire from the first nozzle and high-fire

added by the second and third nozzles firing simultaneously. Combustion air is controlled by a damper motor. Its end

switch energizes the second-stage valve as the air shutter

opens.

Due to the low-high-low feature of these burners they are

very versatile and efficient.

1. They can operate in forced draft boilers or furnaces at

pressures up to 0.50 inches W.C.

2. They will save typically, 20% in seasonal fuel consumption compared to conventional single-stage flame retention burners.

3. They can operate with or without refractory lined combustion chambers.

4. They are superior for process applications.

5. They can be installed through fire door openings.

Low-High-Low

(step-modulation) firing

Advantages: There are several strong advantages to lowhigh-low firing in both heating and process applications:

1. Smooth ignition both in natural and forced draft operations.

2. Closer control than with a single input.

3. Less strain or wear on the burner, boiler and combustion

chamber components:

a. Longer cycles.

b. Gradual changes; less thermal shock.

4. Lower fuel consumption:

a. Higher efficiencies of both low and high-fire.

b. Lower stand-by loss due to longer ON cycles and to

the closed air damper during OFF cycles.

Operation: A true low-high-low burner controls both air and

oil flow rates. A low-fire start burner (low-high-off) controls

only the oil rate and has a fixed air setting with none of

the preceding advantages. The low-high-low burner cycle

operates as follows:

1. Call for heat. Burner motor and ignition are energized. Air

is in the low-fire position. The low-fire oil valve admits oil

to the low-fire nozzle and its spray ignites, burning clean

with proper air/fuel ratio.

2. If demand exceeds low-fire, the damper motor is energized through a high-fire operating control (aquastat,

airstat, pressuretrol, or outdoor thermostat). As the

damper motor approaches a wide open position, the

auxiliary end switch energizes the high-fire valve and the

full fire with open air, burns clean with high C02 and high

efficiency.

3. As the high-fire input begins to exceed the demand of

the high-fire operator, the operating control opens to

de-energize the damper motor. As the damper motor

returns the air shutter to low-fire the auxiliary end switch

in the damper motor opens and de-energizes the highfire valve.

4. If the demand exceeds low-fire, the high-fire operating

control would again call for more heat as in Step 2 and

then followed by Step 3.

5. If, after returning to low-fire, the load should drop to

below the low-fire output, the operating limit would shut

off the burner completely.

Both models are completely pre-wired and fire-tested at

the factory. Photocells are factory-mounted in air tube.

Self-checking ultraviolet detectors, miniature UV and lead

sulphide detectors are assembled to the factory-located

nipple on the burner-mounting flange.

Unpacking

Remove form-in place top which will expose assembled

burner and pedestal carton. Note that primary control is

mounted to burner. Carefully lift entire burner from carton.

BE CAREFUL NOT TO BEND OIL LINES AND DO NOT

PULL WIRING HARNESS WHEN LIFTING BURNER.

Assemble Pedestal (when used)

1. Carefully tip burner back on housing to expose pedestal

mounting hole.

2. Fasten pedestal to mounting block. The pedestal height

is adjustable from 10¾" minimum to 13½" maximum to

centerline of air tube.

3. Tighten at desired height.

2 32961 110916

Installing the Burner

Before installing, check the following items:

1. The combustion space can be larger, but not smaller

than indicated by the dimensions in Table 3, page 4. An

exception is as follows: When a refractory chamber is

used, the length can be reduced by 10 percent, only if

necessary.

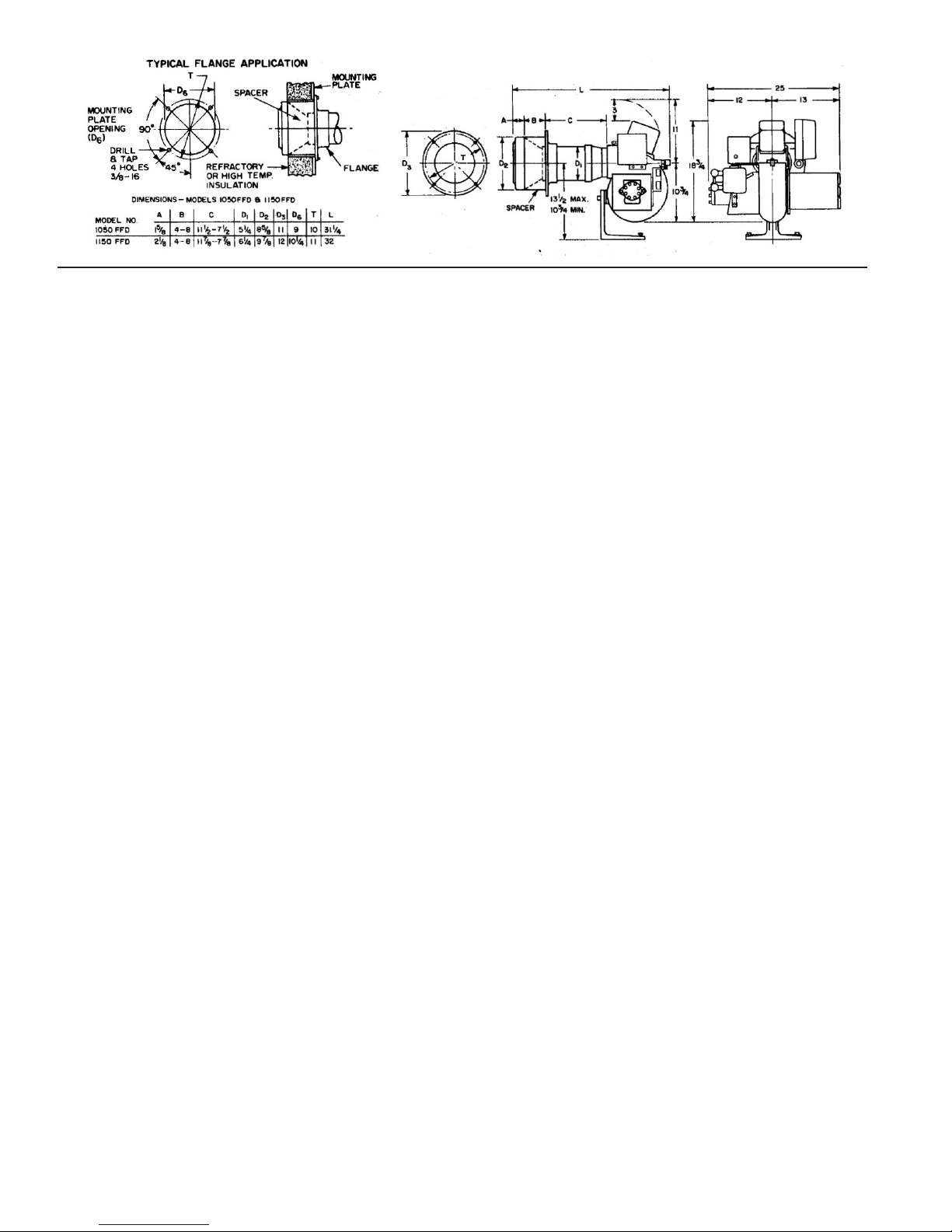

2. The mounting plate opening and tappings must be

according to the dimensions shown at the top of the

previous page. (See Typical Flange Application.)

3. The diameter of the opening in the refractory or front

insulating block should equal the diameter of the opening

in the mounting plate.

4. Dimension “B”, the length of the stainless steel spacer,

should be approximately equal to the distance from the

outside of the front plate to the inside of the insulation or

refractory. See Fig. 1. When the above requirements are

met, proceed as follows:

a. Insert end of burner into opening and fasten flange

to mounting plate using four 3/8-16 x 3/4 cap

screws provided.

b. The burner mounting flange is designed to support

the burner by itself. The pedestal is furnished for

ease of installation and service where the burner is

close to the floor, also for additional support when

the mounting plate is not sufficiently strong. For the

latter purpose, blocks or bricks may be used, or a

steel shelf or the like may be fabricated and fastened to the boiler front or to the floor to support the

pedestal.

c. Make sure burner is approximately level or, if delib-

erately pitched down for a low crown sheet, that the

angle is correct.

If a system is being converted from heavy oil, the oil storage

tank must be clean. Install properly sized copper oil lines

all the way to the tank if possible. If not, replace as much of

the old piping as possible with copper lines. Also replace

old filters and fire-protective valves with new ones properly

sized.

VALVES AND FILTERS: Domestic-type fire-protective

valves, check valves, and oil filters are too small and too

restrictive for the 40 gph pumping rate of the fuel unit. Use

fittings which are equal or greater in size than the oil line on

both suction and return.

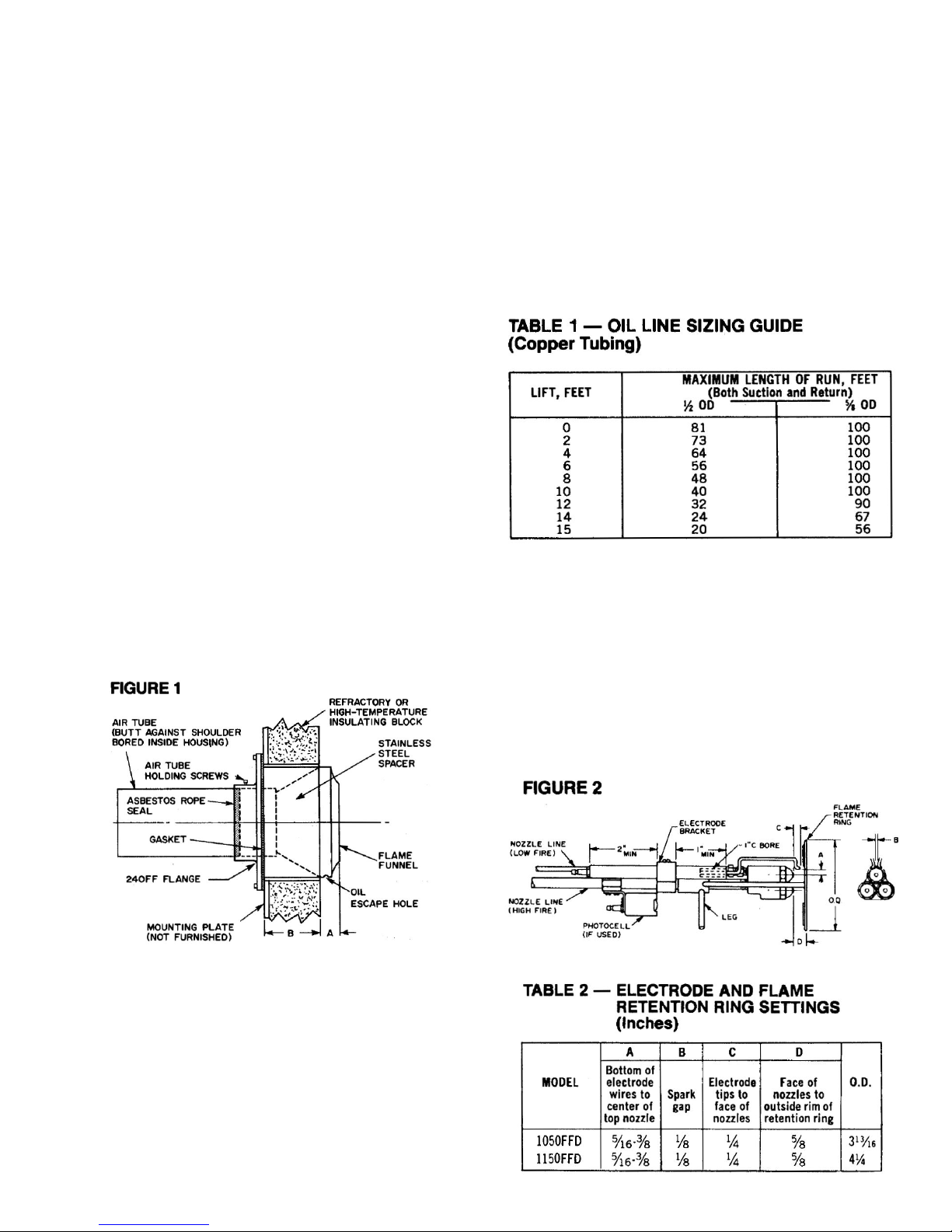

OIL LINE SIZES: Table 1 shows the OD of the copper tubing recommended, depending upon the lift and the length

of run.

NOTES

1. If lift exceeds 15 feet or if the length of run exceeds the

above, use a booster pump and system.

2. Sizes shown apply to both suction and return line for a

two-pipe system for one burner only.

3. For a multiple burner installation, use a separate suction

line for each burner. If a common return is used, it must

be increased by one size for each additional burner.

4. For one-pipe (gravity or no-lift) installations, use 1/2-inch

OD tubing for runs up to 94 feet long, and 5/8-inch OD

for runs of 95 to 150 feet long.

Oil Supply Piping

GENERAL: In systems where the bottom of the tank is

higher than, or about equal to, the level of the fuel unit, a

one-pipe system may be used. In systems requiring lift, a

two-pipe installation is required. It is essential that all air

leaks be eliminated before starting the burner. Overhead

systems should be avoided. In no case should the top of

the tank be more than 12 feet above the fuel unit. Flexible

copper tubing with flared end-fittings is strongly recommended.

32961 110916 3

Loading...

Loading...