Well clamp with sensor retainer spring

Microprocessor

Temperature Controls

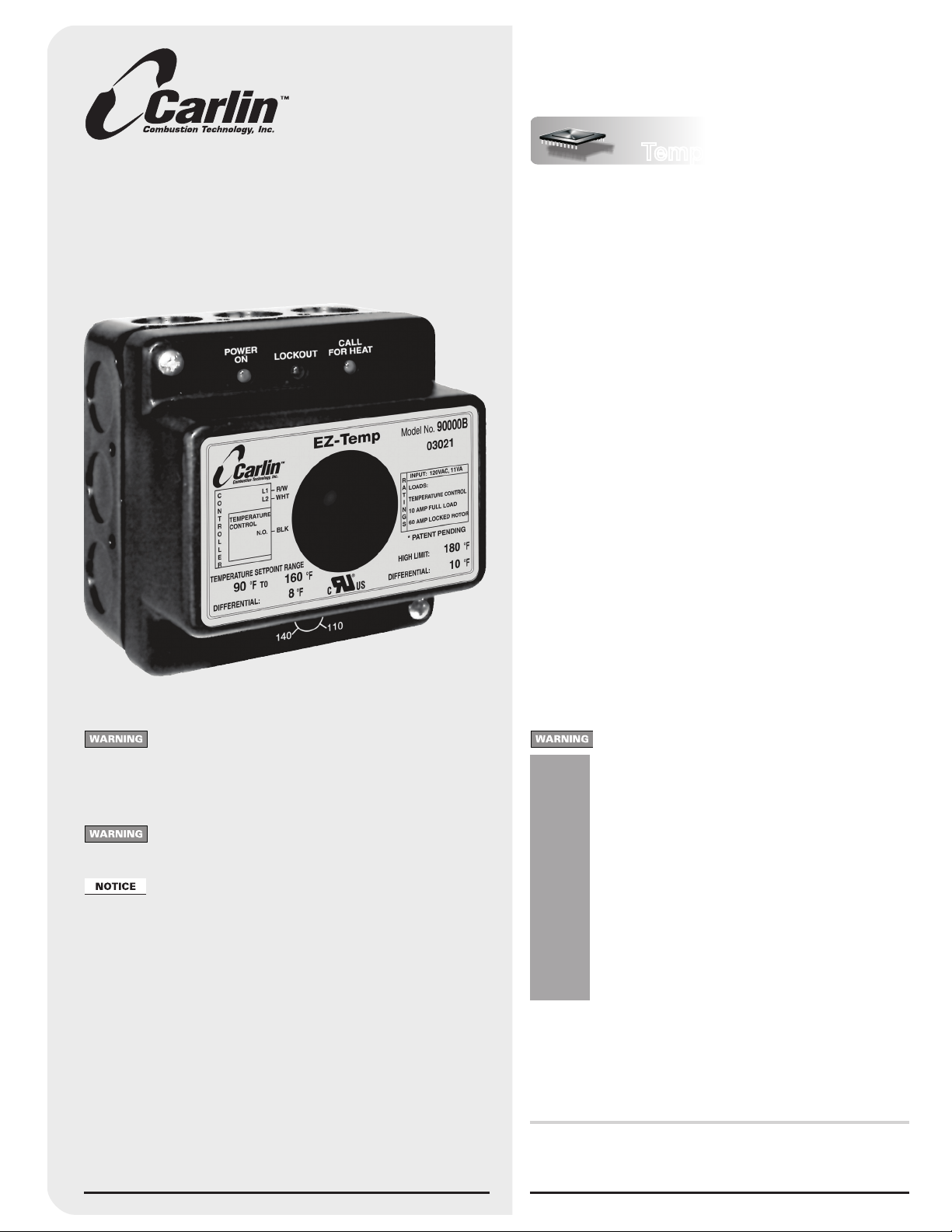

EZ-Temp

TM

Instruction Manual

Installer/servicer — Except where specifically stated otherwise,

this manual must be used only by a qualified service technician.

Read and follow all instructions in this manual and in the appliance

manual. Failure to comply with this or other requirements in this

manual could result in severe personal injury, death or substantial

property damage.

This symbol calls out a hazard that could cause severe personal

injury, death or substantial property damage if the instructions

given are not followed.

Wiring: Refer to EZ-Temp data sheet for wiring information.

Verify ratings: Verify the ratings of the control meet the require-

ments of the appliance as specified in the appliance instructions.

Refer to the EZ-Temp control data sheet for required electrical

supply and load ratings. Verify that the controls, wiring and installation comply with all applicable codes.

Electrical shock hazard: Disconnect power to appliance when

wiring or servicing any electrical component.

Scald hazard: Water hotter than 130°F can cause serious burns or

death. Follow water heating appliance manufacturer’s guidelines

when installing temperature limit controls - DO NOT install a control

that can be set at a higher temperature than specified. Also verify

that the installation includes all water temperature regulating

means needed to ensure the safety of building occupants, in

compliance with all applicable codes.

Verify operation: Test the controls/appliance to verify the appliance

operates as specified in the appliance manual before leaving the

installation.

© Copyright 2008 — Carlin Combustion Technology, Inc.

Carlin Combustion Technology, Inc.

70 Maple Street East Longmeadow, MA 01028

Ph 413-525-7700 Fx 413-525-8306

Te c h s u p p o r t 800-989-2275

carlincombustion.com

EZ-Temp Microprocessor Temperature Control — Instruction manual

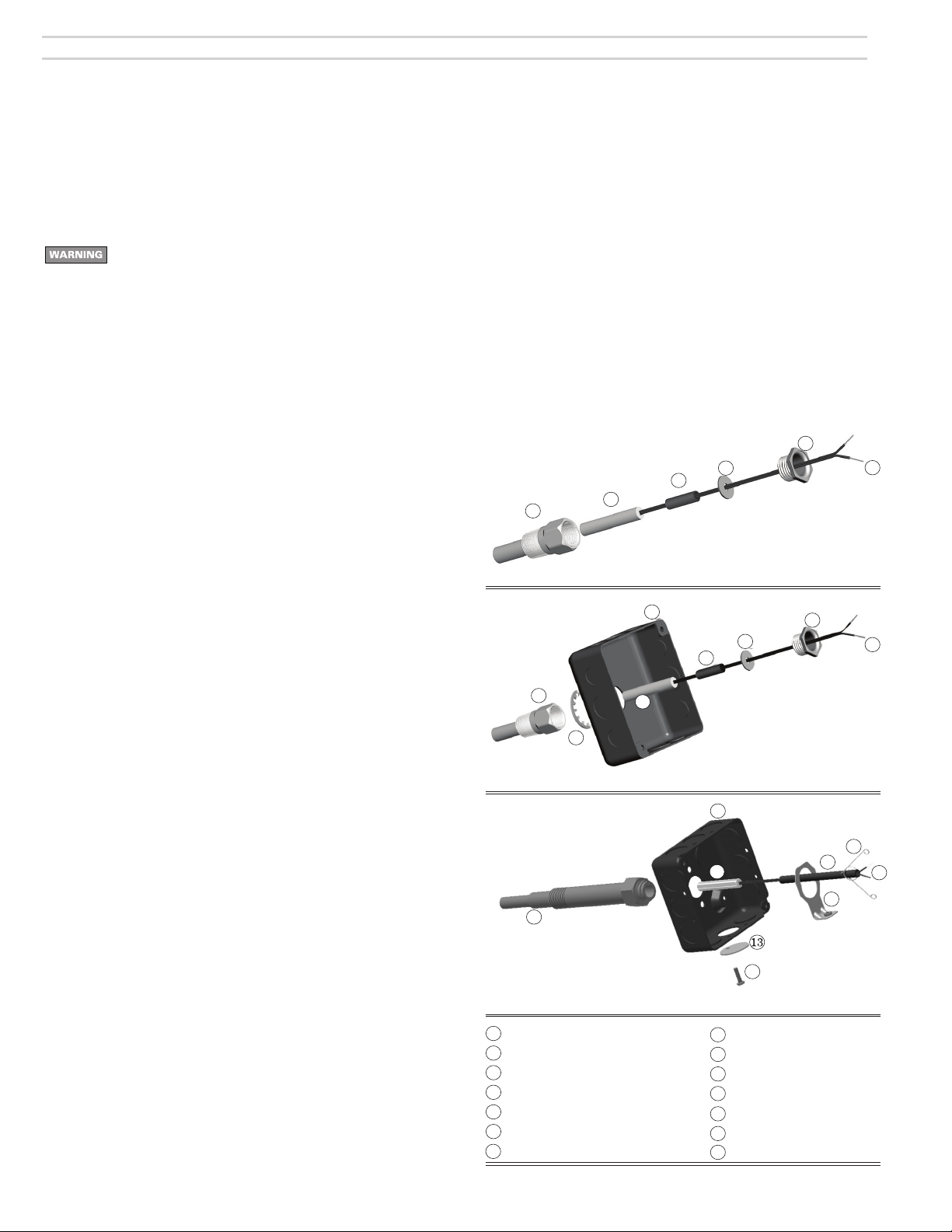

Sensor, J-box & wellEZ-Temp

Sensor & existing well, J-box

B

C

1

2

3

4

5

6

7

10

11

1

2

3

4

5

6

8

9

6

2

7

1

2

3

4

5

6

7

8

9

10

11

EZ-Temp well

EZ-Temp sensor

EPDM rubber retainer

Retainer washer

Jam nut

Sensor leads

J-box, 4 x 4

Lock washer

Existing well

Well clamp

Sensor retainer spring

12

12

3.8” rubber retainer

13

Flat washer

A

Tensioning screw

14

14

Install sensor(s)

To install a new immersion well:

1. Turn off power to the appliance and close isolation valves.

2. Follow appliance instructions to drain the appliance so water line is below

the insertion tapping.

3. Remove existing well and sensor. Apply a small amount of pipe dope to the

new well and secure in tapping.

4. Insert EZ-Temp sensor into well and secure sensor in place as described in

the following.

5. Refill appliance with water, following appliance manual procedures.

When routing sensor wires, avoid sharp edges and use strain

relief bushings at penetrations to prevent movement or electrical

shorting of the sensor. Sensor wires are not low voltage, and must

be routed in conduit.

Configuration A: Sensor and well only

1. Insert the sensor into well (1) until the sensor (2) tip bottoms in the well

socket.

2. EZ-Temp well: Slide the rubber retainer (3) over the sensor wires until it

firmly contacts the sensor casing. Slide the retainer washer (4) and the jam

nut (5) over the wires. Thread the jam nut into the well until snug.

3. Existing well: Press the sensor retainer plug (11) into the well until it securely

holds the sensor wires, to prevent movement of the sensor.

Configuration B: Sensor, EZ-Temp well and J-box

1. Insert the sensor into well (1) until the sensor (2) tip bottoms in the well

socket.

2. Slide the rubber retainer (3) over the sensor wires until it firmly contacts the

sensor casing. Slide the retainer washer (4) over the wires.

3. Slide the lock washer (8), J-box (7), and jam nut (4) over the wires.

4. Thread the jam nut into the well and tighten to secure the J-box and sensor

in place.

Configuration C: Sensor, EZ-Temp well and J-box

1. Remove the center knock-out from one side of the J-box (7).

2. Position the well clamp (10) over the end of the well (9) (sensor not yet

installed) and slide the well clamp (10) toward the side of the J-box (9)

engaging the keyslot opening with the well undercut.

3. Position the flat washer (13) over the open knockout and install the tensioning screw (14) through the flat washer (13) and into the well clamp (10),

tighten.

4. Position the rubber retainer (12) over the sensor leads until the retainer stops

at the sensor body.

5. Position the retainer spring (11) near the end of the rubber retainer as

shown.

6. Slide sensor and retainer/sping assembly into well. Squeeze retainer spring

ends together as the spring enters the well. The end of the spring should

be within the well bore.

Configurations

Carlin EZ-Temp components are available in the following configurations, allowing use

with existing wells in addition to EZ-Temp wells.

Surface-mount sensors are also available.

• Control kits

EZ-Temp controls mount to a standard 4x4 J-box or can be panel mounted.

Control kits include the control and sensor(s) (item 2) plus hardware needed

for mounting to an existing well (items 10 and 11). To obtain an EZ-Temp well

and hardware, obtain an EZ-Temp well kit, below.

• Well kits

EZ-Temp wells are available in the sizes shown below. Well kits include a

well (item 1), rubber sensor retainer (item 3), retainer washer (item 4), jam

nut (item 5), and J-box lock washer (item 8).

• Sensor Kits

Sensor kits include only the sensor (item 2). Sensors are available in single

and dual configurations (two sensors in the same assembly). For controls

that use multiple sensors, obtain separate sensor kits or a sensor kit and a

dual sensor.

Mount the control

1. Insert sensor wire terminals into the labelled openings on the back of the

control. Press into place firmly.

2. Attach the control to the 4x4 J-box or panel mount, as desired.

Wire the control

1. Control wiring (including sensor wires) must be routed through conduit

or electrical enclosures. Follow all applicable codes and the appliance

manual.

2. Follow the burner and appliance wiring diagrams to connect the control(s)

into the appliance limit circuit.

3. For specific applications, contact your Carlin supplier for further information.

Set the control

1. Follow the appliance manual to set the correct limit temperature for the

appliance. To adjust the EZ-Temp control:

• Insertascrewdriverintothesettingslotandrotateuntiltheindicatorpoints

to the desired temperature.

2. Test the operation of the appliance and the new limit control(s) to verify

correct operation.

3. NOTE: EZ-Temp controls have a subtractive differential — control contacts

trigger when the temperature setting is reached. Contacts reset after temperature drops below setpoint minus the differential amount.

– 2 –

Carlin part number MNEZT5 Rev. 12/08/2008

Loading...

Loading...