Carlin EZGasPro User Manual

™

Pro

Instruction manual

Ratings

Input: .................................. 50,000 to 275,000 Btuh

Fuels: ............................ Natural gas or propane gas

Max. supply pressure ............... 14 inches w.c.

Min. supply pressure .................. 5 inches w.c.

Manifold pressure ...................3.5 inches w.c.

Electrical: Power ............................ 120V/60 Hz/1-Phase

Motor .............1/15, 1/7, or 1/6 HP, 3450 RPM

Current .............. Approx. 2.0, 2.5 or 2.3 amps

Ignition: ............ Carlin Model 41800 solid state ignitor

Control: Carlin Model 60200FR microprocessor control

Agencies: ....UL Listed (US and Canada)

LISTED

Installer/servicer — Except where specifically stated

otherwise, this manual must be used only by a qualied

service technician. (In the state of Massachusetts, this

product must be installed by a licensed Plumber or Gas

Fitter.) Failure to comply with this or other requirements in

this manual could result in severe personal injury, death

or substantial property damage.

Contents

PLEASE read this rst ......................................... 2

Codes and standards .......................................... 2

EZGas Pro burner at-a-glance ............................ 3

Prepare site • prepare burner • mount burner ..... 4

Install gas piping .................................................. 9

Wire burner ........................................................ 10

Check system • start-up burner/appliance ......... 11

Perform checkout procedure • ll out certicate 14

Maintenance and service procedures................ 15

Troubleshooting ................................................. 17

Dimensions and mounting information .............. 19

Replacement parts ............................................ 20

Copyright 2013 — Carlin Combustion Technology, Inc.

©

User — Refer only to User’s Information manual for in-

formation regarding operation of this burner. The burner

Instruction Manual is intended only for your service techni-

cian. The burner and heat exchanger must be inspected

and started at least annually by your service technician.

Carlin Combustion Technology, Inc.

70 Maple Street East Longmeadow, MA 01028

Ph 413-525-7700 Fx 413-525-8306

Tech support 800-989-2275

carlincombustion.com

Model EZGas Pro gas burner — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

PLEASE read this rst . . .

Special attention ags

Please pay particular attention to the following when you see them through-

out this manual.

Noties you of hazards that WILL cause severe personal

injury, death or substantial property damage.

Noties you of hazards that CAN cause severe personal

injury, death or substantial property damage.

Noties you of hazards that WILL or CAN cause minor per-

sonal injury or property damage.

Noties you of special instructions on installation, operation or

maintenance that are important, but are not normally related

to injury or property damage hazards.

General information

Burner applications

Follow all instructions in this manual and the appliance manual. Where ap-

pliance instructions differ from this manual, follow the appliance instructions.

Read the label attached to the burner air tube to verify the burner is correct

for the appliance being used. See page 7 for procedures.

Damage or shortage claims

The consignee of the shipment must le damage or shortage claims im-

mediately against the transportation company.

When calling or writing about the burner . . .

Please provide us with the UL serial number and burner model number to

assist us in locating information. Enter this information on the Installation

Certicate in this manual. The certicate information can be helpful when

troubleshooting or obtaining replacement parts.

Follow the guidelines below to avoid potential severe

personal injury, death or substantial property damage.

Installer/service technician . . .

• Read all instructions before proceeding. Perform all proce-

dures, and in the order given to avoid potential of severe

personal injury, death or substantial property damage.

• Before leaving the site after startup or service, review the

User’s information manual with the user. Make the user

aware of all potential hazards and perform the training

outlined below.

Train the user . . .

• To properly operate the burner/appliance per this manual,

the appliance instructions and the User’s information

manual.

• To keep this manual at or near the burner/appliance for

ready access by the user and service technician.

• To contact the service technician, gas supplier or re department should the user smell gas.

• To keep the appliance space free of ammable liquids or

vapors and other combustible materials.

• Do not use laundry products, paints, varnishes or other

chemicals in the room occupied by the burner/appliance.

• To contact the service technician at least annually for startup

and burner/appliance service.

When servicing the burner . . .

Fill out burner adjustment label

Fill out the burner adjustment label, located on the front of the hinged

cover plate (or on French language plate) after completing installation and

burner setup.

Should overheating occur: (1) shut off the manual gas control

to the appliance, (2) do not shut off the control switch to the

pump or blower.

Codes and standards

The installer/servicer is solely responsible for compliance with all

applicable codes and standards.

Burner listing

Carlin EZGas Pro burners are C-UL listed, for use

in the US or Canada, per ANSI Z21.17/CSA2.7-

latest edition, for use with natural gas or propane

gas. Specify Canadian application when ordering

the burner to obtain proper labeling and manuals.

Codes

The installation must conform with local codes or, in the absence of local codes, with the Standard

for the Installation of Domestic Gas Conversion Burners, ANSI Z21.8, and the National Fuel Gas

Code, ANSI Z223.1, or the CAN/CGA-B149, Installation Codes. The electrical installation must also

conform with local codes or, in the absence of local codes, with the National Electrical Code, ANSI/

NFPA 70, or the Canadian Electrical Code, CSA C22.1/CSA C22.2.

– 2 –

• Disconnect electrical supply to burner before attempting

to service to avoid electrical shock or possible injury from

moving parts.

• Burner and appliance components can be extremely hot.

Allow all parts to cool before attempting to handle or

service to avoid potential of severe burns.

Carlin part number MNEZGas Rev. 10/28/13

Model EZGas Pro gas burner — Instruction manual

REV DESCRIPTION ECN BY DATE

.

Released to Production

Where appliance instructions differ from this manual, follow the appliance instructions.

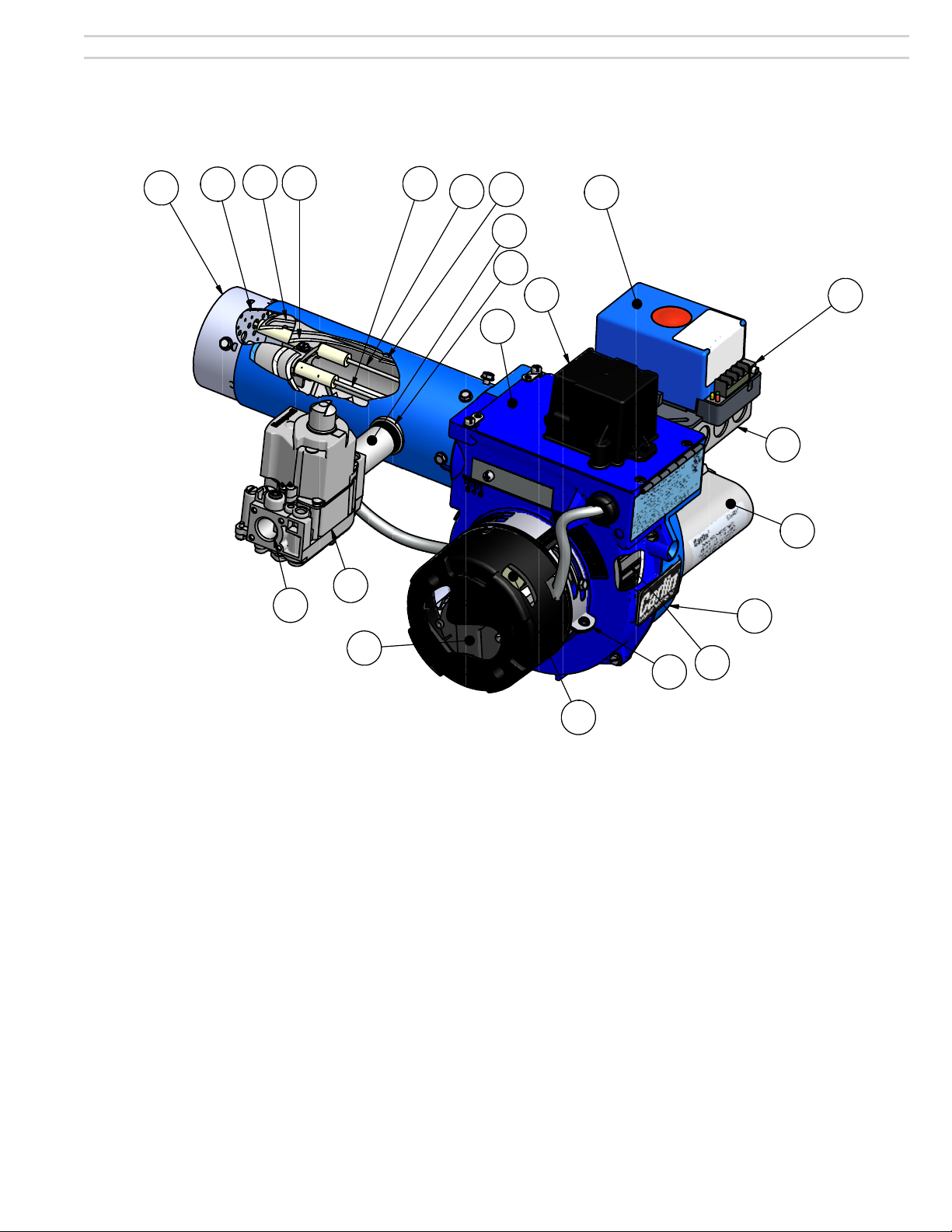

EZGas Pro burner at-a-glance

3

1

2

9

4

8

5

6

7

12

21

20

19

10

11

22

18

17

16

14

15

13

1 Air tube (ange omitted for clarity), with powder coat paint nish

2 Diffuser plate (interchangeable hole or slot pattern)

3 Gas manifold (concentric cylinders swaged at ends) — Gas manifold

delivers gas to gas openings on inner wall of manifold near the dif-

fuser plate.

4 Ignitor electrode

5 Flame rod

6 Gas orice nipple — see pages 7 and 8 for orice sizing requirements

7 Gas inlet connection (gas entrance to gas manifold)

8 Gas manifold outer wall

9 Gas manifold inner wall

10 Hinged cover plate (for access to blower wheel & electrodes)

11 Ignitor — Carlin Model 41800 solid state electronic ignitor — 9,000

volts, continuous duty rated)

Carlin part number MNEZGas Rev. 10/28/13

12 Primary control (Carlin Model 60200FR microprocessor-based inter-

rupted ignition ame supervisory control, for use with ame rod ame

rectication)

13 Flame current test jack

14 Burner junction box

15 Motor (Carlin PSC motor, with permanently-lubricated bearings and

automatic thermal overload protection)

16 Blower housing (cast aluminum), with powder coat paint nish

17 Blower wheel

18 Air band with indicator — Only a single adjustment required for setting

combustion air; see page 7 for starting setting based on appliance

model and input)

19 Airow proving switch — Prevents burner from ring if air is not moving

20 Combination gas valve (with integral gas pressure regulation — set for

3½” w.c. outlet pressure) - 24V

21 Gas supply entrance — ¾” NPT; 5” w.c. min; 14” w.c. max

22 24V Transformer

– 3 –

Model EZGas Pro gas burner — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

1. Prepare site • prepare burner • mount burner

Inspect installation site

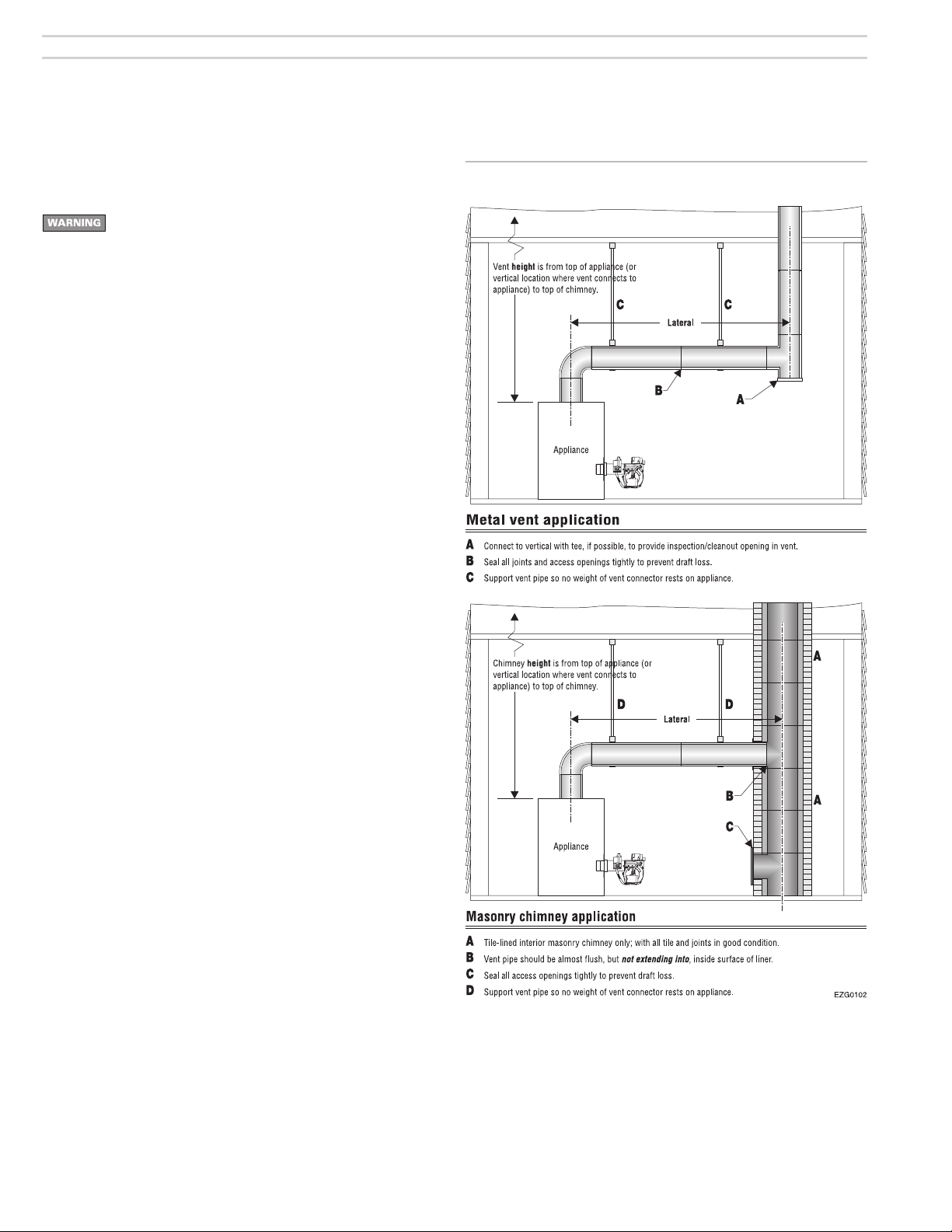

Figure 1 Vent and vent connector installation

Inspect, repair and/or replace vent system

Do not install this burner unless you have veried

the entire vent system and the appliance are in good

condition and comply with all applicable codes.

The vent and chimney must be sized and constructed

in accordance with all applicable codes. If intended for

use with an oil burner as well, the vent system must

comply with relevant codes for both gas and oil ring.

Appliances equipped with a gas conversion burner are

treated as fan-assisted appliances.

The vent system must not be pressurized unless the

vent piping and vent system are designed accordingly.

The vent must provide draft at all times (negative pres-

sure in vent).

Do not install or use an existing manual damper in the

vent connector or vent.

Do not connect the appliance vent connector to a

chimney or vent serving a replace, incinerator or

solid-fuel-burning apparatus.

In a cold climate, do not vent into a masonry

chimney that has one or more sides exposed to

the outside. Install a listed stainless steel liner to

vent the ue products.

A defective vent system could result in severe personal

injury, death or substantial property damage.

Vent/chimney sizing

• Follow all local codes when sizing the vent and chimney

• Refer to the appliance manufacturer’s manual, when available,

for venting recommendations.

Prepare vent/chimney

• Secure all metal vent joints with screws, following the vent

manufacturer’s instructions. Seal all joints in the vent system

and chimney. Repair masonry chimney lining and repair all

mortar joints as needed.

• Where draft uctuations are likely, install a double-acting barometric draft regulator in the vent piping. (The damper must be

located in the same space as the appliance.) Install a manual

reset spill switch in the top of the draft regulator outlet. Wire the

switch into the appliance limit circuit to shut off the appliance/

burner if sustained downdraft should occur. Refer to the appli-

ance manufacturer’s instruction manual for recommendations

regarding the need for a barometric draft regulator.

• Provide support for the vent piping. Do not rest the weight of

any of the vent piping on the appliance ue outlet.

– 4 –

Carlin part number MNEZGas Rev. 10/28/13

Model EZGas Pro gas burner — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

1. Prepare site • prepare burner • mount burner (continued)

Inspect installation site

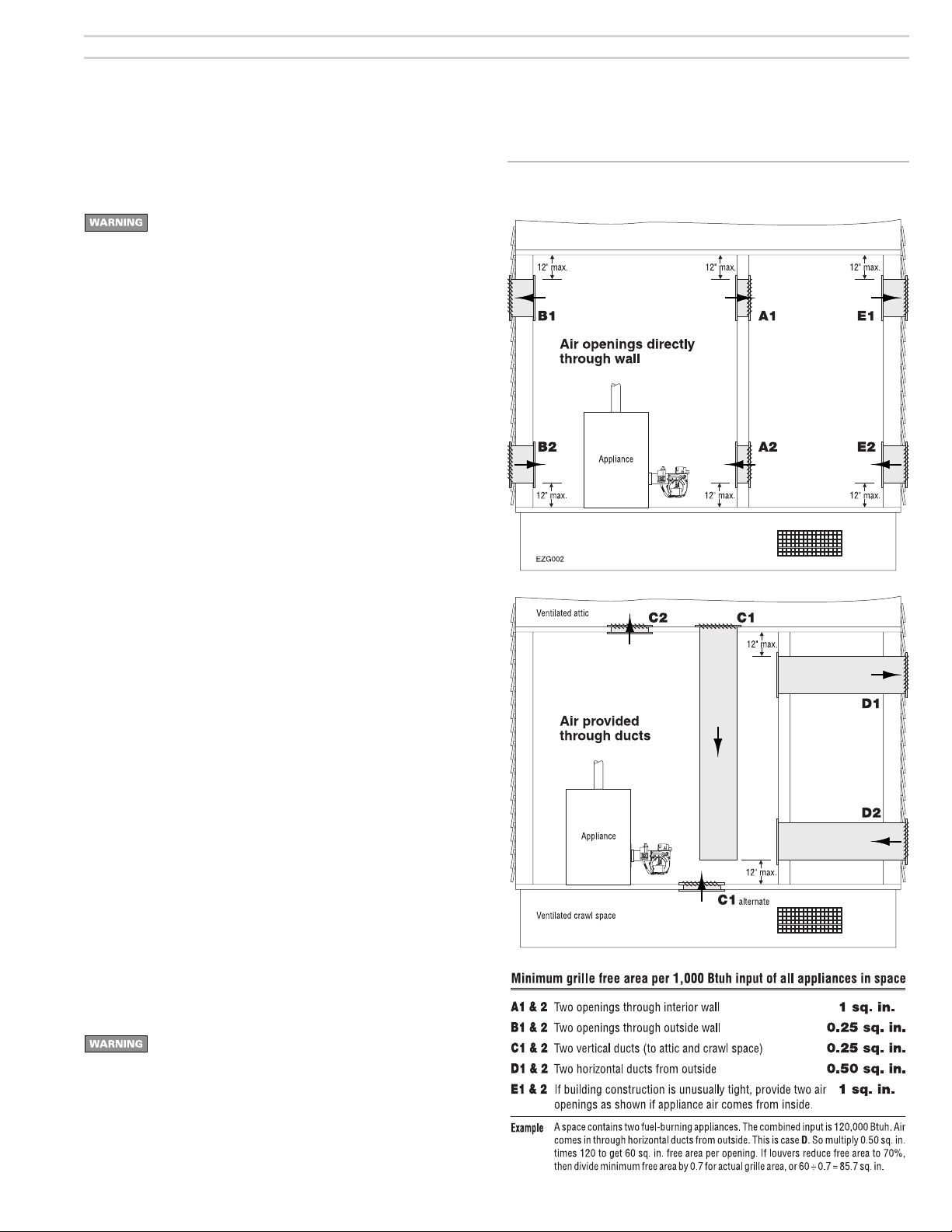

Figure 2 Locating & sizing air openings

Verify combustion/ventilation air openings

Installing the burner/appliance in a space that does not provide

enough air for combustion and ventilation can result in severe

personal injury, death or substantial property damage. Follow

all applicable codes and guidelines below to ensure space

has sufcient air openings.

Large spaces

For appliances located in basements, ventilated crawl spaces or other

large areas, no additional air openings should be necessary. Exception: If

the building construction is unusually tight (see National Fuel Gas Code

for denition), you will need to provide air openings into the building if ap-

pliance air comes from inside. Provide one opening within 12 inches of the

ceiling, and one opening within 12 inches of the oor. Size each opening to

provide free area (after deduction for louvers) of 1 square inch per 1,000

Btuh input of all fuel-burning appliances in the building.

Conned spaces — air from inside building

If air openings connect to areas inside the building, provide two openings,

one within 12 inches of the ceiling, the other within 12 inches of the oor.

Each opening must have a free area (after deduction for louvers) of 1 square

inch per 1,000 Btuh of all appliances in the space. If the building construc-

tion is unusually tight (see National Fuel Gas Code for denition), you will

need to provide air openings into the building. Provide two openings sized

and located as for the openings into the boiler space.

Conned spaces — air from outside

If air openings connect directly to outside, provide two openings, one within

12 inches of the ceiling, the other within 12 inches of the oor. Each opening

must have a free area (after louver deduction) of:

• If directly through side wall: 1 square inch for each 4,000 Btuh of all

appliances in the space.

• If through vertical ducts: 1 square inch for each 4,000 Btuh of all appli-

ances in the space.

• If through horizontal ducts: 1 square inch for each 2,000 Btuh of all

appliances in the space.

Optional outside air connection

For spaces not tted with large enough air openings, you may be able to

apply the optional burner cover kit (RESCVR5S) with Outside Air/Direct Vent

kit (50433KIT) to provide outside combustion air to the burner. You must

use a vent outlet/air inlet termination approved by the appliance manufac-

turer. Refer to the appliance and outside air kit manuals for instructions.

You will also have to apply this option if the appliance space may contain

corrosive contaminants, such as laundry products, paints, varnishes or

other chemicals.

Even when using the optional outside air kit, make sure the

space provides enough ventilation to prevent overheating of

the appliance, burner and controls. If there is risk of over-

heating, you must install ventilation air openings sized large

enough to provide air for cooling the equipment. Failure to

provide ventilation can result in severe personal injury, death

or substantial property damage.

Carlin part number MNEZGas Rev. 10/28/13

– 5 –

Model EZGas Pro gas burner — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

1. Prepare site • prepare burner • mount burner (continued)

Inspect installation site

Verify combustion/ventilation air openings (continued)

When sizing air openings for combustion and ventilation,

include air required for exhaust fans and other appliances,

such as clothes driers, that require air for operation.

Check appliance manual and applicable codes for required sizing of com-

bustion and ventilation air openings.

• Verify that openings are unobstructed.

• Verify that appliance space and air source spaces are free of:

– Gasoline or other ammable liquids or vapors.

– Combustible materials.

– Air contaminants, such as laundry products, paint, thinner, varnish,

etc.

• Conrm with user that the area will be kept free of these materials at

all times.

Prepare the appliance

Burner input: Install a gas burner sized for the normal input

rating of the appliance. Do not install a burner with a higher

ring rate than the appliance rating. Do not install a burner

with a ring rate more than 10% lower than the appliance

rating. The appliance and vent system could be damaged

due to condensation.

Seal the appliance: Seal all ue-gas containing joints. Seal

all connections to the vent piping for breeching.

Clean the appliance: Clean the appliance thoroughly and

seal all joints. Test all electrical components and verify the

relief valve works (boilers only).

Verify combustion chamber dimensions comply with the

minimum dimensions shown in Figure 3, page 7. Install or

replace combustion chamber liner if required by the appliance

manufacturer. The burner must not extend into the combus-

tion chamber. The end of the burner air tube must be within

¼” of the inside face of the combustion chamber. If the space

around the burner air tube is more than ¼”, wrap the burner

air tube with minimum 2300-°F-rated ceramic ber blanket

to seal off the gap.

Repair or replace damaged appliance components.

Inspect the appliance thoroughly. Follow appliance manufac-

turer’s guidelines for repair or replacement of any component

found defective.

When cleaning the appliance or working with ceramic ber

refractories or berglass insulation, see WARNING on this

page. Failure to comply with the above could result in severe

personal injury, death or substantial property damage.

Verify clearances

• Verify that the burner/appliance will maintain all clearances to combustible walls or oor and all clearances required for service/maintenance

as required in the appliance manual and applicable codes.

– 6 –

Ceramic ber or

Fiberglass insulation

Ceramic ber materials, such as chamber liners,

may contain carcinogenic particles (chrysto-

balites) after exposure to heat. Airborne particles

from berglass or ceramic ber components have

been listed as potentially carcinogenic by the

State of California. Take the following precautions

when removing, replacing and handling these

items.

Avoid breathing dust and avoid contact with

skin or eyes. Wear long-sleeved, loose-tting

clothing, gloves and eye protection. Use a NIOSH

N95 certied respirator. This respirator meets

requirements for protection from chrystobalites.

Actual job requirements or NIOSH regulations

may require other or additional protection. For

information, refer to the NIOSH website, http://

www.cdc.gov/niosh/homepage.html.

Ceramic ber removal: To prevent airborne dust,

thoroughly wet ceramic ber with water before

handling. Place ceramic ber materials in a plastic

bag and seal to dispose.

Avoid blowing, tearing, sawing or spraying

berglass or ceramic ber materials. If such op-

erations are necessary, wear extra protection to

prevent breathing dust.

Wash work clothes separately from other laun-

dry. Rinse clothes washer thoroughly afterwards

to prevent contamination of other clothing.

NIOSH First aid procedures:

Eye exposure — irrigate immediately

Breathing — fresh air.

Prepare appliance for burner mounting

The universal ange supplied with EZGas Pro burners

is for ring chambers with negative or positive overre pressure. The ange should be sealed with high

temperature silicone. Failure to comply could result in

severe personal injury, death or substantial property

damage.

See page 19 for required dimensions and bolt locations.

Carlin part number MNEZGas Rev. 10/28/13

Model EZGas Pro gas burner — Instruction manual

Note 1 Note 3

(in inches)

Note 2

Note 4

Usable Tube Length

Where appliance instructions differ from this manual, follow the appliance instructions.

1. Prepare site • prepare burner • mount burner (continued)

Inspect burner and components

Do not install or operate the burner if any component is dam-

aged or if burner does not comply with the specications or

any other guidelines in this manual.

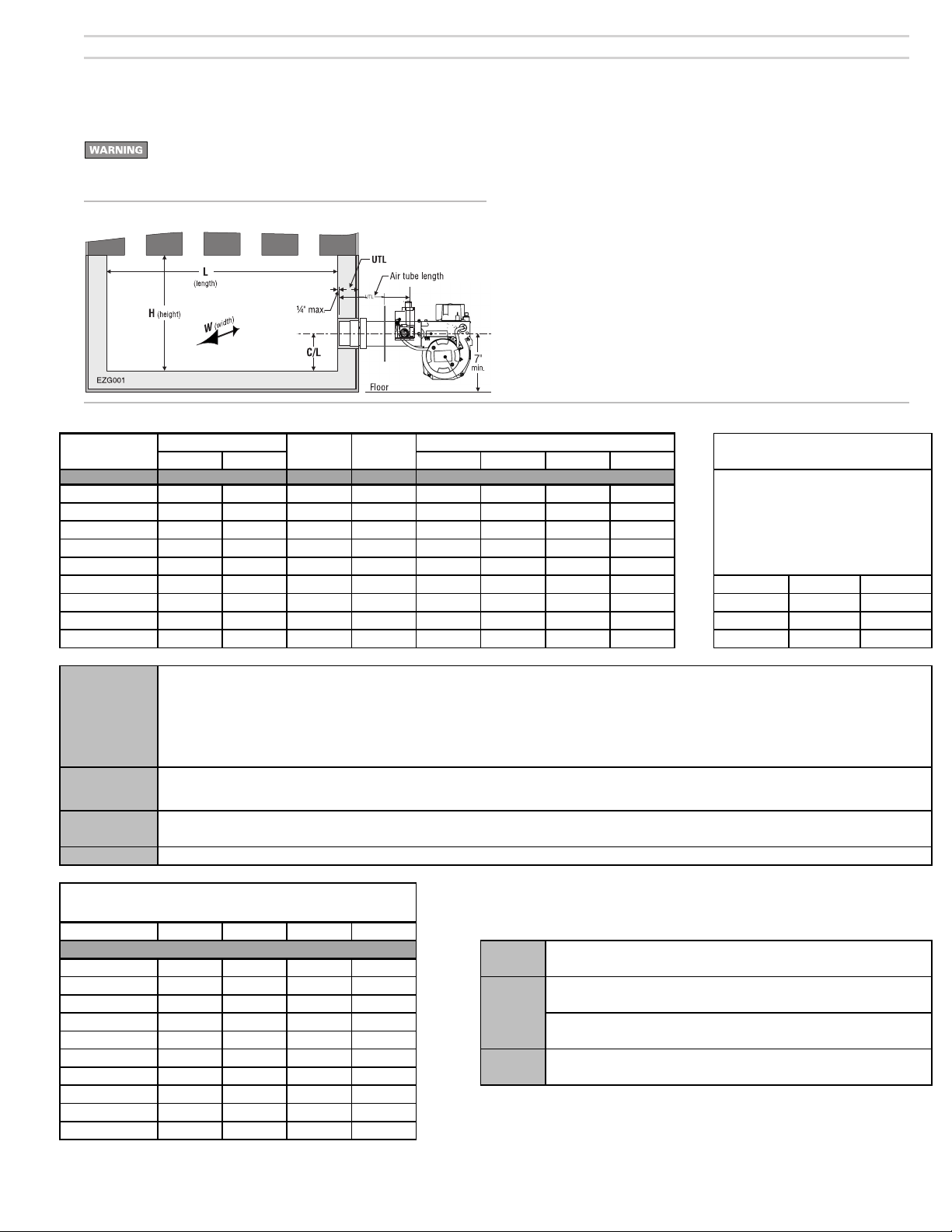

Figure 3 Combustion chamber dimensions (see Table 1)

Table 1 Burner specications for EZGas Pro burners

Appliance Diffuser Air Band

Input BTU Nat Gas Propane Plate Type C Diffuser B Diffuser A Diffuser 9-Slot Diff

50,000 - 75,000 5/32 1/8 C 1-Slot 5%

75,000 - 100,000 3/16 9/64 B or 9-Slot 1-Slot 5% 15%

100,000 - 125,000 7/32 11/64 B or 9-Slot 1-Slot 20% 30%

125,000 - 150,000 1/4 13/64 B or 9-Slot 1-Slot 30% 40%

150,000 - 175,000 9/32 7/32 B or 9-Slot 1-Slot 45% 70%

175,000 - 200,000 5/16 1/4 A or 9-Slot 2-Slot 30% 45%

200,000 - 225,000 5/16 1/4 A or 9-Slot 2-Slot 35% 60%

225,000 - 250,000 11/32 9/32 A or 9-Slot 2-Slot 45% 75%

250,000 - 275,000 13/32 5/16 A 2-Slot 55%

Air tube insertion length (UTL)

• Usable air tube length (UTL) is the distance from mounting ange to end of air

tube. Verify that the end of the air tube will be ush with, or no more than ¼ inch

short of, the inside of the appliance combustion chamber front wall when the

burner is mounted. See Figure 3 and Table 1 below for further information.

Diffuser plate

• Verify correct diffuser plate (item 2, page 3). Compare diffuser plate listed on air

tube label with diffuser plate listed in Table 1.

Gas orice drill size

• The gas orice is drilled through a plate in the end of the orice nipple (see item

6, page 3). Read the factory-drilled orice size on the label attached to the burner

air tube (see item 1, page 3) near the blower housing end. If the gas orice size

is not correct for your application, or if the label is illegible for any reason, check

the orice size directly and redrill orice or replace if necessary, as follows (next

page).

Approx. Air Band SettingOrifice Drill Size

for Insertion Depth

Burners with welded flange have fixed

insertion depths. Verify the insertion depth is

correct for the appliance. On burners with

adjustable flanges, the Usable Tube Length

(UTL) available for setting the insertion depth

varies with air tube length:

Tube Length UTL min. UTL max.

10" 1 3/4" 3 1/2"

12 1 3/4" 5 1/2"

14 1 3/4" 7 1/2"

Firing rate should be within +/- 5% of rated input for the appliance. High altitude applications: The maximum burner input at sea level is 275,000 Btuh.

Reduce this capacity by 4% per 1,000 feet above sea level. Example- max. capacity at 5,000 feet is 220,000 Btuh (20% reduction). Pressurized firing:

Note 1

Note 2

Note 3

Note 4

Maximum burner input decreases with increasing overfire pressure. Assume a reduction in maximum burner input of approximately 5% at 0.1 w.c. and

10% at 0.2 inches w.c You will have to increase the air band opening to compensate for the increased pressure. Follow the procedures given in this

manual to check combustion with instruments to determine the correct air band setting. Do not fire into a chamber with pressure higher than 0.2 inches

w.c. and never fire at a higher pressure than recommended by the appliance manufacturer.

Once the orifice is drilled, minor adjustments to the firing rate can be achieved by adjusting the gas valve outlet pressure between 3.2" and 3.8" w.c. If

the rate remains too low, re-drill the orifice with a 1/64" larger bit (for details, see Make Final Burner Adjustments in Section 4 of this manual.)

For BTU ranges that are covered by both the 9-Slot Diffuser Plate and the A or B Diffuser Plate, it is likely that either diffuser will work, but one may

provide better combustion. The 9-slot's short flame pattern favors appliances with shorter combustion chambers.

Use this as the starting setting only. Adjust air band setting, if necessary, after performing combustion testing (see page 13).

Minimum Chamber Dimensions

(VC= min. diam. Of vertical cylinder chamber)

C/L L W H VC

Notes 3, 4, 5

3 7 6 8 7

3 7 6 8 7

3 1/2 8 7 9 8

3 1/2 9 7 9 8 1/2

4 11 8 10 9 1/2

4 12 8 10 10

4 1/2 14 8 11 12

4 1/2 15 9 11 13

4 1/2 16 9 11 14

4 1/2 17 9 11 15

Note 3

Note 4

Note 5

Some tested appliances may operate satisfactorily with dimensions less than those

noted in the table.

Horizontal cylindrical chambers - diameter must be no less than column W.

Horizontal stainless steel cylindrical chambers - diameter at least 1 to 4 inches

larger than column "W" above.

A corbel may help heat transfer in a larger boiler of furnace, provided it is

recommended by the appliance manufacturer.

Carlin part number MNEZGas Rev. 10/28/13

– 7 –

Model EZGas Pro gas burner — Instruction manual

REVISION HISTORY

REV DESCRIPTION ECN BY DATE

.

Released to Production

ECN MPC 5/4/2009

Ignitor electrode

Electrode bracket

Flame rod

Support rod

REVISION HISTORY

REV DESCRIPTION ECN BY DATE

.

Released to Production

W.M.

04-06-10

QUALITY CHARACTERISTICS

CRITICAL

MAJOR

A

MAJOR

B

MINOR

NO

SYMBOL

CRITICAL

STATISTICAL

SEE QAS 1000 FOR VENDO RS QUALITY

ASSURANCE REQUIREMENTS

TOLERANCE UNLESS OTHERWISE SHOWN

THIS DOCUMENT MAY NOT BE

REPRODUCED WITHOUT WRITTEN

PERMISSION FROM CARLIN

COMBUSTION TECHNOLOGY, INC.

REMOVE BURR AND FLASH FOR

PROPER OPERATION AND GOOD

APPEARANCE

CARLIN COMBUSTION TECHNOLOGY, INC.

EAST LONGMEADOW, MA U.S.A.

PART

NUMBER

MAT'L

NUMBER

PART

DESC.

MAT'L

DESC.

ITEM

CLASS

ITEM

CLASS

EZ

GAS_RevA_FlippedElectrode_Dims

REVISION HISTORY

REV DESCRIPTION ECN BY DATE

.

Released to Production ECN MPC 5/4/2009

3 1/2"

7 3/8" Air tube lengt h

(as needed for apliance)

5 7/8"

9 1/4"

11 3/4"

6 3/4"

10 3/4"

UTL

6

1

2

3

4

7

5

8

Where appliance instructions differ from this manual, follow the appliance instructions.

1. Prepare site • prepare burner • mount burner (continued)

Inspect/redrill gas orice when required

• Turn off power to the burner/appliance before proceeding.

• Close main manual gas valve in gas line to burner. Then disconnect

the ground joint union to allow rotating burner combination gas valve.

You must disconnect power to burner and close main

manual gas valve before proceeding. Failure to do so

could result in severe personal injury, death or substantial

property damage.

• Unplug wire harness from combination gas valve.

• Remove the combination gas valve (item 20, page 3) and the orice

nipple (item 6, page 3). Remove the orice nipple from the gas valve.

• Read the correct orice drill size from Table 1, page 7. Then check

actual orice size using that size twist drill bit.

• If gas orice is smaller than required, redrill the orice to the correct size, if necessary.

• If gas orice is larger than required, obtain a replacement orice

nipple from Carlin. If necessary, drill the orice hole in the replacement orice nipple to the correct size.

Drill the orice carefully, avoiding drill wobble. Wobble will

cause the orice to be over-sized. The orice nipple should

be secured in a vise, if possible, to ensure it is steady during the drilling process.

• Write the orice size on the orice nipple label (or on the French

label attached to the burner for Canadian installations).

• Replace the gas valve and piping, using only pipe dope listed for use

with liqueed petroleum gases. Make sure the arrow on the orice

nipple label points in the direction of gas ow.

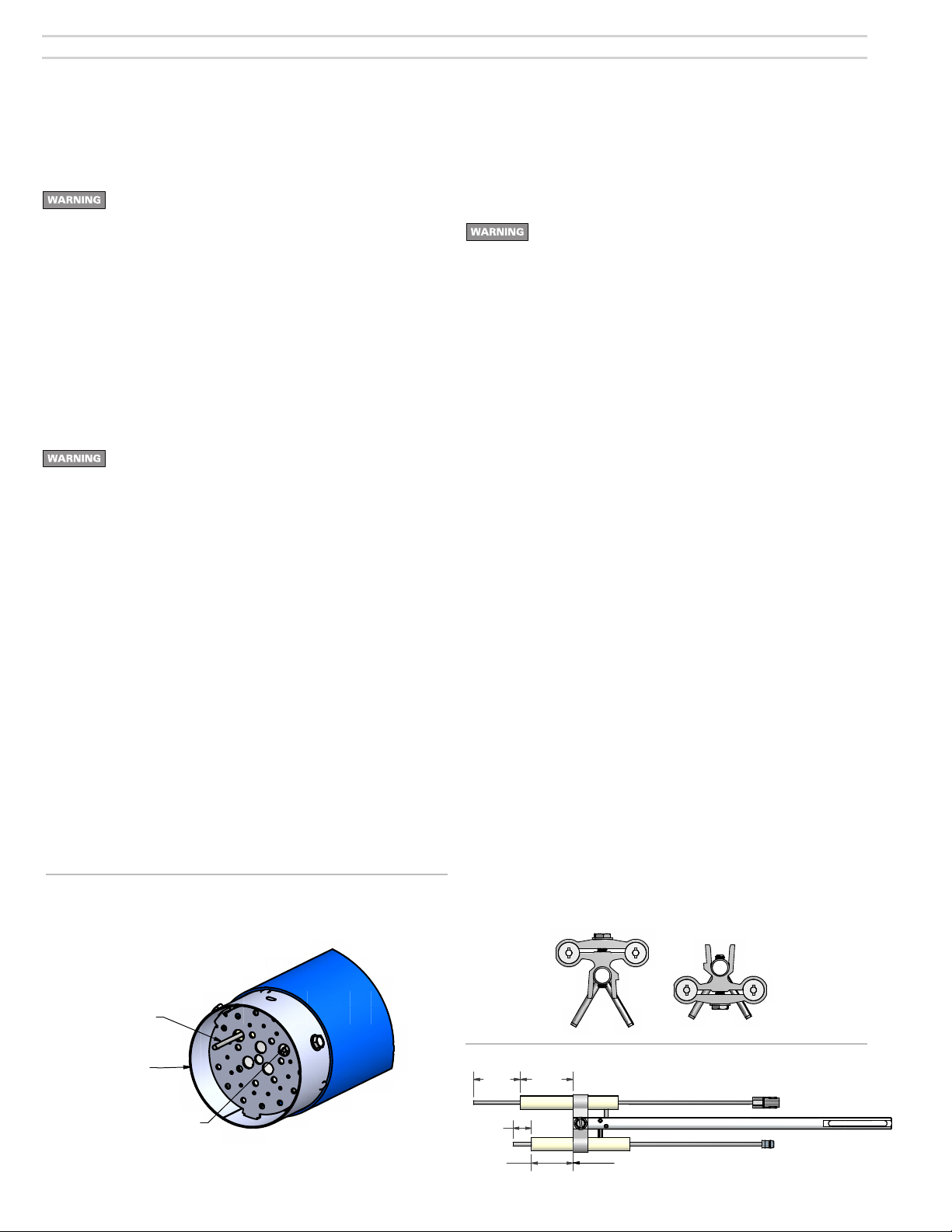

Flame rod and ignitor electrode

• Inspect the burner from air tube end. Flame rod should extend

through the diffuser plate as shown in Figure 4. Ignitor electrode

should be ush with inner face of diffuser plate as shown.

• The ame rod and ignitor electrode must not touch the diffuser or any

grounded metal surface at any point. The ame rod and electrode

should be as close as possible to the centers of the diffuser holes. If

either the ame rod or electrode is closer than 1/16” to the diffuser,

remove assembly (see page 15 for removal instructions and verify

dimensions per Figure 5). Bend the end of the ame rod or ignitor

electrode as required. Replace assembly and check spacing again.

Continue adjusting as necessary until neither rod nor electrode is

closer than 1/16” to the diffuser.

Figure 4 Flame rod and Ignitor placement

*Tip should extend in front of diffuser by 1 1/4”.

Install gas valve on burner

1. Read WARNING’s on page 9 before installing gas valve.

2. Apply a small amount of pipe dope (suitable for propane gas) to gas

valve outlet connection, gas line nipple and burner gas connection.

Assemble pipe nipple to gas valve. Install gas line nipple in burner

gas connection.

To avoid damage to gas valve, do not hold valve with a

pipe wrench or over-tighten. Use only a crescent wrench

or other means. Failure to comply could result in severe

personal injury, death or substantial property damage.

3. Connect wire harness to valve.

Inspect components and wiring

• Visually inspect all burner components and wiring.

• Verify that wiring is intact and connectors are securely connected.

• Verify that all burner components are in good condition.

Mount burner in appliance

• Verify appliance burner front plate dimensions per page 19.

• Slide gasket supplied with burner over end of air tube.

• Insert burner into appliance opening and bolt in place.

Verify and install diffuser plate

Each plate will be stamped on the face of the diffuser with a letter designating the diffuser type (Example A, B, C, 9S).

1. Install the diffuser on the air tube by placing the wide tab into the slot

at the end of the air tube with the 90o bent tabs of the diffuser plate facing

into the air tube.

2. Fasten diffuser plate to the air tube with the two screws provided.

3. Make sure the ame rod and electrode are not touching the diffuser

plate.

4. If ame rod or electrode is making contact with the diffuser plate the

burner will not prove ame and will enter a lockout condition.

Air tube orientation for right side (motor side) gas supply (Burners

with Adjustable Flange only)

1. The air tube may be rotated from the left side gas inlet to the right side

gas inlet (motor side).

2. Remove the electrode/ame rod assembly as described in the Mainte-

nance section. It should look like Figure A.

3. Remove the four 5/16 screws that hold the air tube to the burner chassis. Now the air tube can be rotated 180o so the gas inlet is on the right

side (motor side). Reinstall the four 5/16 screws, securing the tube back

onto the chassis.

4. Remove the screw holding the electrode/ame rod bracket to the aluminum rod. Reassemble the electrode/ame rod bracket to the aluminum

rod as shown in Figure B while positioning the ame rod and electrode as

shown in Figure 5.

5. Replace the electrode/ame rod assembly as described in the Maintenance section. Note that the aluminum rod must now sit on top of the

nylon washer.

Figure A

Figure B

*

End of air tube

– 8 –

Flame rod

Ignitor electrode

(Tip should be ush with inside surface of diffuser).

Figure 5 Flame rod/ ignitor electrode assembly

1.55"

0.61"

1 3/8"

1 3/4"

Support rod flush at both ends

Carlin part number MNEZGas Rev. 10/28/13

Flame rod

Ignitor electrode

Loading...

Loading...