Component Testing

Carlin Combustion Technology, Inc.

70 Maple Street

East Longmeadow, MA 01028

Tech Service Hotline: 1-800-989-2275

Carlin Ignitor Testing Procedure

This test procedure consists of three tests. The first test should be

the ignitor spark test. The second test is a secondary coil resistance

test. The third test consists of an input current test. The following is a

step by step procedure to perform these tests. It is important that all

three of these tests be performed.

41000 Ignitor Spark Test

1. Turn off the power to the burner/appliance.

2. Disconnect the ignitor wires in the burner junction box.

3. Release the ignitor hold down screws or clips.

4. Swing the ignitor plate fully open.

5. Bend the copper ignitor clips until the clip ends are from 5/8” to ¾” apart (see

figure 1).

6. Connect a test power cord with a switch to the ignitor leads in the burner

junction box.

7. Turn on the test power cord switch to power the ignitor.

8. Check for spark across the ignitor clip ends (see Figure 1).

9. If spark occurs, proceed the secondary coil test below.

10. If spark does not jump the gap, or if the spark jumps intermittently, ignitor is

defective and should be replaced.

11. Turn off power to the ignitor.

Figure 1

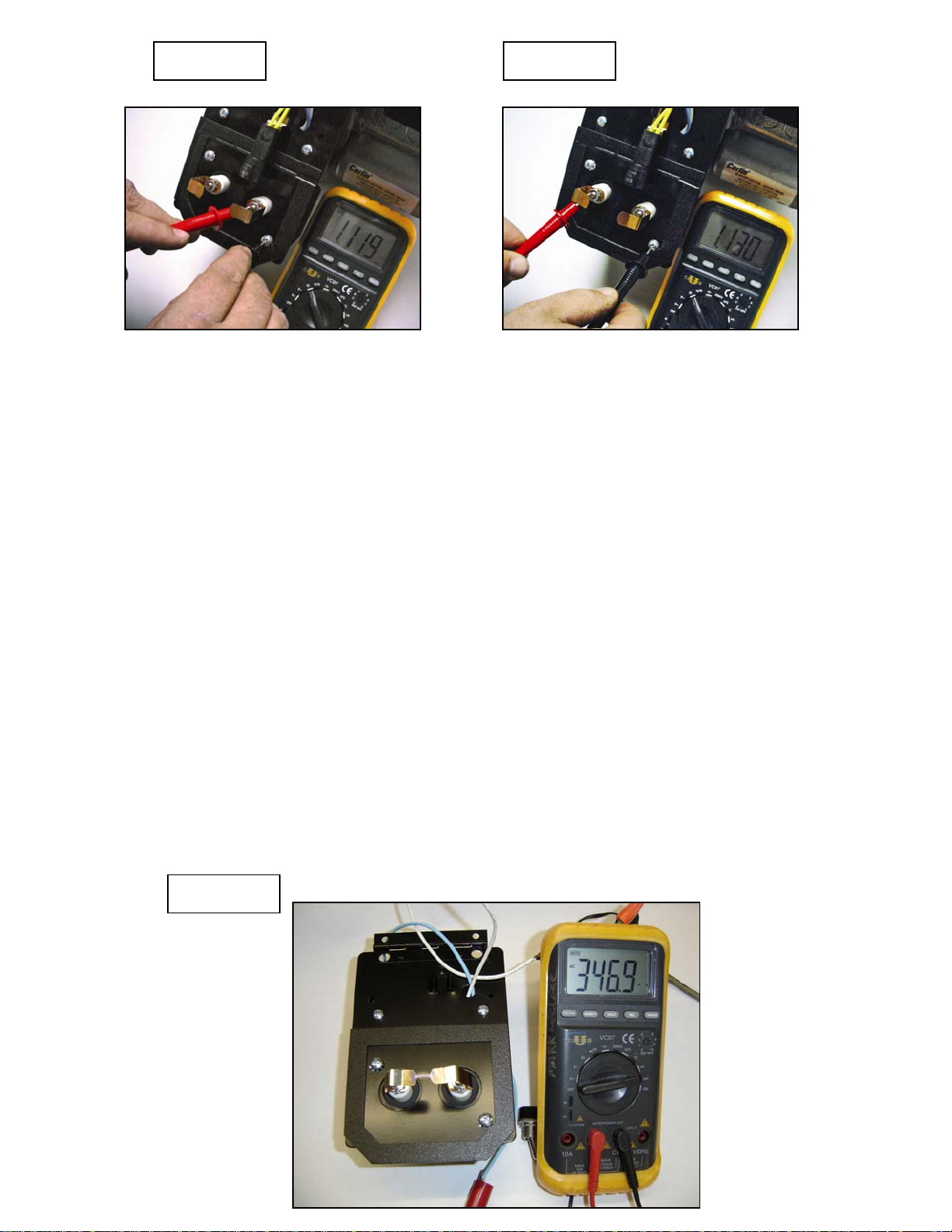

41000 Secondary Coil Resistance Test

1. Turn off the power to the burner/appliance.

2. Release the ignitor plate hold down screws or clips.

3. Swing the ignitor plate fully open.

4. Use an ohmmeter to check the resistance from electrode to ground for each of

the electrodes (Figure 2 and 3).

5. The secondary coils are good if the difference between the two readings is less

than 10%.

6. If the difference in the electrode-to-ground resistance is more than 10%, the

secondary coil may be failing. Replace the ignitor.

7. If the difference between electrode-to-ground is within 10%, proceed with the

input current test.

Figure 2 Figure 3

41000 Input Current Test

1. Turn off the power to the burner/appliance.

2. Disconnect the ignitor wires in the burner junction box.

3. Release the ignitor hold down screws or clips.

4. Swing the ignitor plate fully open.

5. Bend the copper ignitor clips or springs until the clip ends are ½” apart.

6. Set a multimeter to read AC milliamps.

7. Using a test power cord with a switch, wire the ignitor blue lead to one of the

multimeter leads. Wire the other lead of the multimeter to the hot side of the

test cord. Wire the white ignitor wire to the neutral side of the test cord.

(Figure 4)

8. Insure the multimeter is set for AC milliamps and turn on the test power cord

switch to power the ignitor. If there is no spark, replace the ignitor.

9. Monitor the input current with the multimeter set on AC milliamps for 5

minutes.

10. If at any time the reading drops below 300 milliamps AC, the ignitor should be

replaced.

11. Turn off the power to the ignitor.

12. Remove the power test cord.

13. Readjust ignitor clip spacing (1 inch ± 1/8 inch).

14. Wire the ignitor in its original condition (per burner wiring diagram).

15. Replace all components to normal condition.

Figure 4

Oil

Carlin U – Residential Oil Burners – Page 70

coil is normal by measuring the resis-

tance across the coil.

between the

bottom two

Valves

Carlin SVC-10FF

Application tips

1. Carlin solenoid oil safety shut-off

valves help to provide years of safe,

effi cient oil burner performance

while adding reliability to the burner

and oil delivery system.

2. Carlin’s SVC oil valves are direct-acting, two-way, normally-closed. Use

on single or two-pipe oil systems to

isolate the fuel pump, preventing the

possibility of oil tank siphoning.

3. Carefully review the burner instruction manual when applying to ensure the oil valve is correctly wired

and the burner fuel lines are correctly installed.

Field testing oil valves

Always disconnect power source

before wiring to avoid electrical

shock or damage to electrical components.

Checking SVC-10FF coil resistance

• You can determine whether the oil valve

coil is normal by measuring the resistance across the coil.

• Disconnect power to the burner. Then

disconnect one of the oil valve wires in

the junction box.

• Measure the resistance from one coil

wire to the other. If the coil is good, the

resistance should be between 494 and

526 ohms. If not, replace the oil valve.

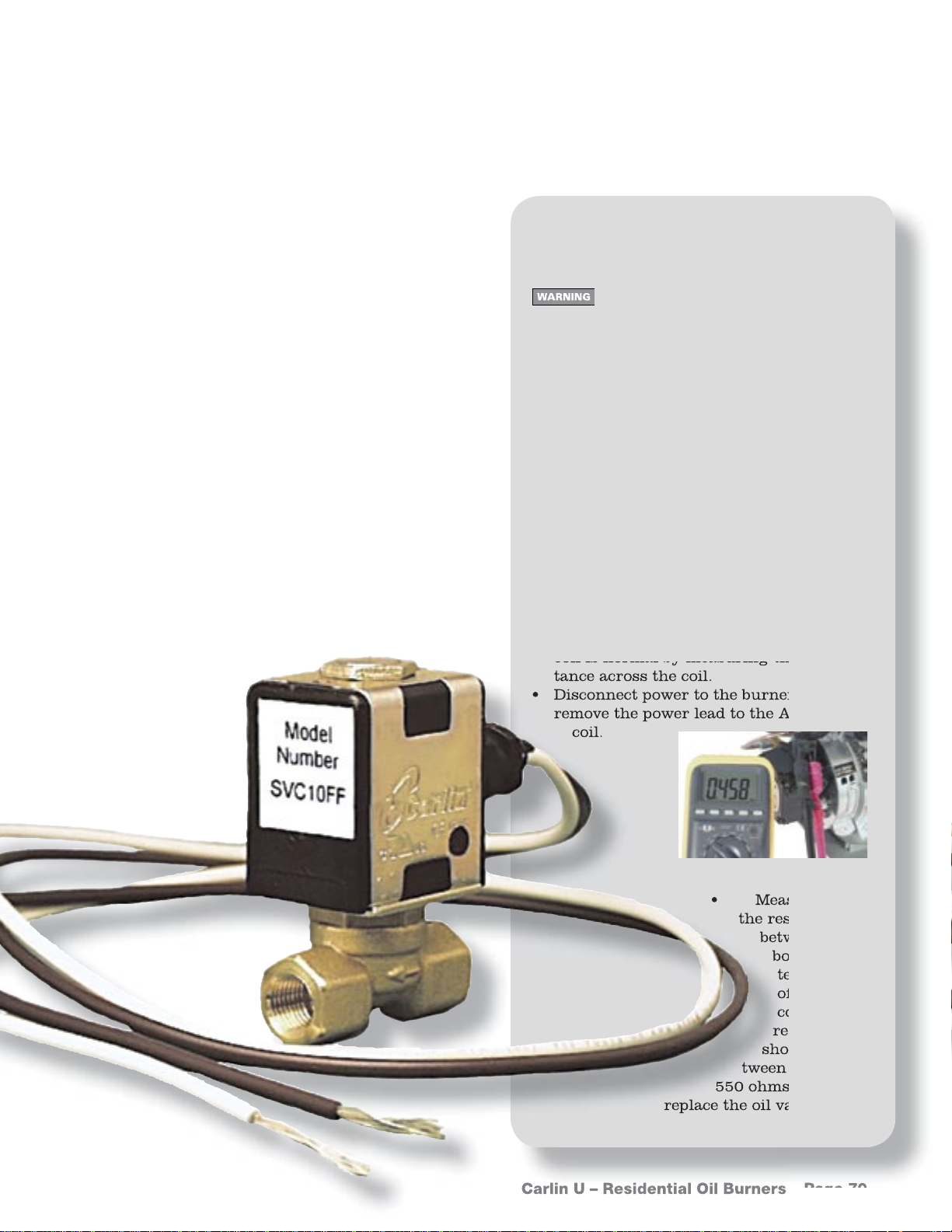

Check A2VA-3006 oil valve coil resistance

• You can determine whether the oil valve

coil is normal by measuring the resistance across the coil.

• Disconnect power to the burner. Then

remove the power lead to the A2VA-3006

coil.

• Measure

the resistance

between the

bottom two

terminals

of the

coil. The

resistance

should be be-

tween 350 and

550 ohms. If not,

replace the oil valve.

Carlin U – Residential Oil Burners – Page 70

Nozzle line heater

Field testing

Advantages

• Heating the oil reduces viscosity.

Nozzle line heaters

• You can check the

integrity of a nozzle

line heater using your

Carlin multimeter.

• Disconnect power to

the burner and appliance. Make sure the

burner and all internal

parts are cool to the

touch.

• Separate the nozzle line

heater at its disconnet.

• Insert the probes of

your multimeter into

the nozzle line heater

connector sockets.

• Set the meter for ohms

and read the resistance.

• The heater is acceptable if the resistance is

between 600 ohms and

1,500 ohms.

• Start-ups are cleaner

with heated oil.

Carlin U – Residential Oil Burners – Page 75

• Replace the heater if

the resistance is less

than 600 ohms or more

than 1,500 ohms.

Cad

resistor to the other “F-F” terminal.

Cells

Cad cell construction

A cad cell contains:

• a sensing plate coated with cadmium

sulfi de.

• a metal grid on the cadmium sulfi de

to supply the two connections from

the sensor.

• a clear coating over the cadmium

sulfi de and grid that prevents contamination from moisture, dirt and

oil.

• a housing to mount the sensor assembly.

What does cadmium sulfi de do?

• Cadmium sulfi de is an electrical conductor.

• When cadmium sulfi de is exposed to

visible light, its resistance changes. The

stronger the light source, the lower the

resistance.

• When the burner isn’t fi ring, with the

cad cell inside and not exposed to any

light, the cad cell has a high resistance

(over 50,000 ohms).

• When the burner fl ame starts, the cad

cell sees the light from the fl ame, and its

resistance drops.

• The primary control (48245, 60200, for

examples) knows fl ame is present because it senses this resistance change.

Fixed resistance primary test

Use this method to test the performance of

a primary control, removing the cad

cell as a factor.

• Remove the cad cell wires

from the primary control’s

“F-F” terminals.

• Connect one end of a

¼-watt, 1500 ohm (1.5 kΩ)

resistor to one of the “F-F”

terminals.

• Start the burner. AFTER

fl ame has been established,

connect the other end of the 1.5

kΩ resistor to the other “F-F” terminal.

• If the primary control is operating correctly, it should accept this resistance

and operate normally. If the control does

not operate correctly, replace the control.

• Remove the resistor and replace the cad

cel leads on the “F-F” terminals.

Carlin U – Residential Oil Burners – Page 78

Field testing a cad cell

Light resistance:

Check room light resistance

1. With normal room lighting, the cad cell

resistance when in the open, as at right,

should be less than 10 kohms.

2. In the example shown, the resistance

measured 195.1 ohms. Notice that the

meter automatically adjusts the range

for the best reading. In this case, the

range shifted to ohms.

3. If the cad cell resistance is too high, try

cleaning the cell and measure the resistance again. If resistance is still too

high, replace the cell.

4. If the cad cell resistance is below 10

kohms, perform a dark resistance test.

Check dark resistance

1. With the cad cell mounted inside the

burner, with no fl ame, the cad cell

should have very little light available.

The cad cell resistance should be at least

50 kohms.

Cad cell resistance in

room light

Dark resistance:

Cad cell resistance

with no light (or when

inside burner with no

fl ame)

2. The illustration on bottom right shows

a test of dark resistance by securely

covering the end of the cell. In this instance, the cad cell resistance measured

82.2 kohms. (The meter automatically

changed the range to kilohms.)

3. If the cad cell resistance is below 50

kohms when the cad cell is mounted inside a closed burner with no fl ame, make

sure the combustion chamber is cool

and there is no stray light entering the

burner.

Carlin U – Residential Oil Burners – Page 79

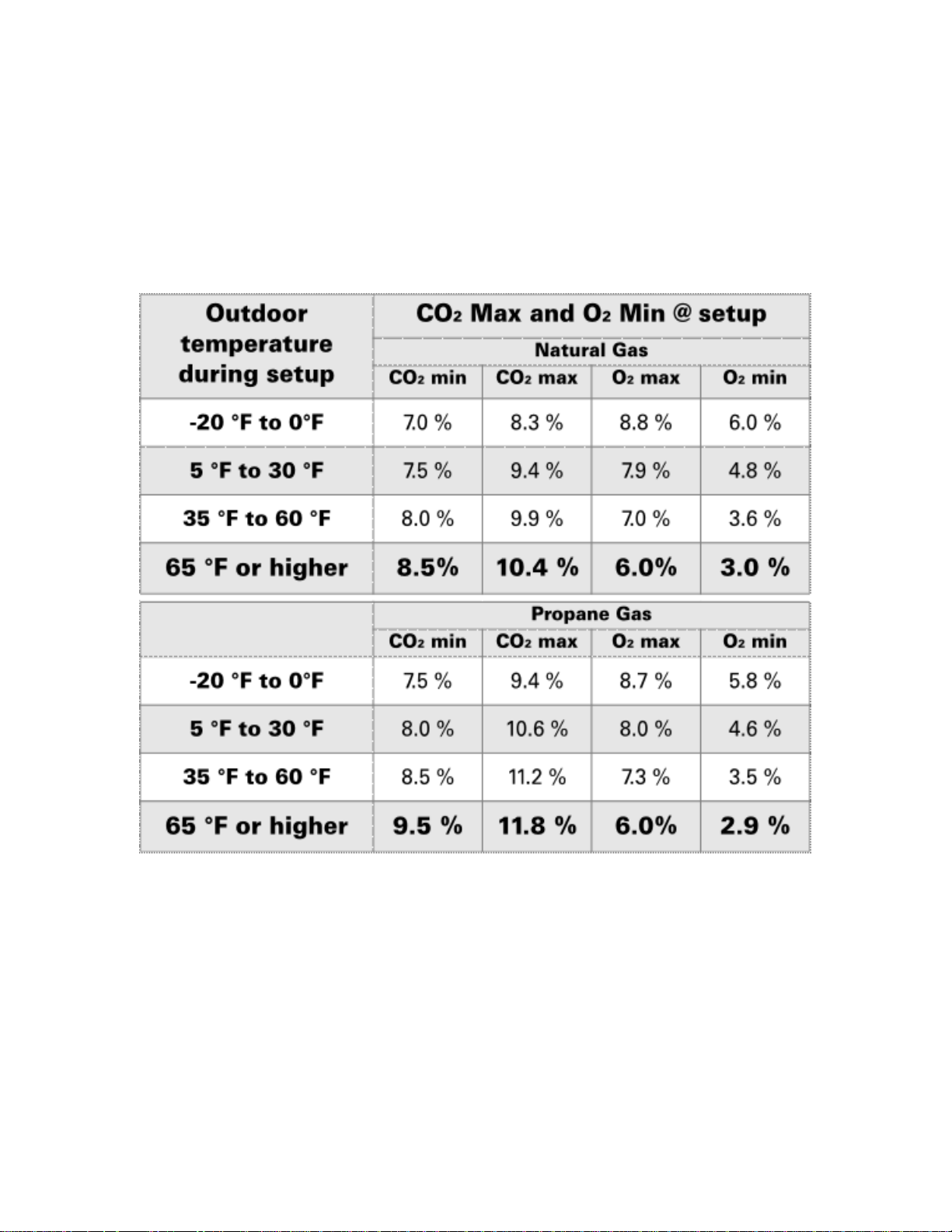

Combustion air temp

Air changes with temperature

Recommended combustion settings

based on inlet air temperature (for locations

operating with outside air temperature between -20°F and

+90°F)

As air temperature changes, so does

the CO2 and O

• Once an oil burner is setup, the fan always

pulls through about the same volume of air

(cfm) regardless of air temperature. (Air

fl ow will be reduced if the overfi re pressure

increases due to a dirty heat exchanger,

or if the inlet air is blocked or the blower

blades are dirty or linted.)

• Air density changes with temperature. The

colder the air, the more dense the air.

• The blower pulls in a constant volume of

air. If the air density changes, weight of

air (pounds) entering the burner changes.

When the air is colder (heavier), more

pounds of air enter. When the air is warmer (lighter), less pounds of air enter.

• When combustion air comes from inside,

it comes in at room temperature, so the

temperature of the air doesn't change

much throughout the year. But when air is

ducted directly from outside, it isn't heated

much before it reaches the burner. It comes

in pretty close to the outside temperature.

In the summer, it could come in at 90°F or

higher, while coming in at below -20°F in

the winter. The air temperature difference

between summer and winter could easily be

100°F for some areas.

• The table at left shows the change in the

amount of air (pounds) as the temperature

of the air changes.

• Take the air temperature into account

when you set up a burner with ducted combustion air.

2

Carlin U – Residential Oil Burners – Page 25

• % CO2 rises as air temperature rises.

• % CO2 drops as air temperature drops.

If you don't consider this, burner combustion can become very poor as air temperature changes.

• Refer to the setup temperature chart at left

for suggested setup values based on entering air temperature.

Combustion Air Temperature Chart

Thermistor Resistance

– EZ-Temp Sensors

Carlin U – Residential Oil Burners – Page 130

Thermistor Resistance

– EZ-Temp Sensors

Carlin U – Residential Oil Burners – Page 131

Loading...

Loading...