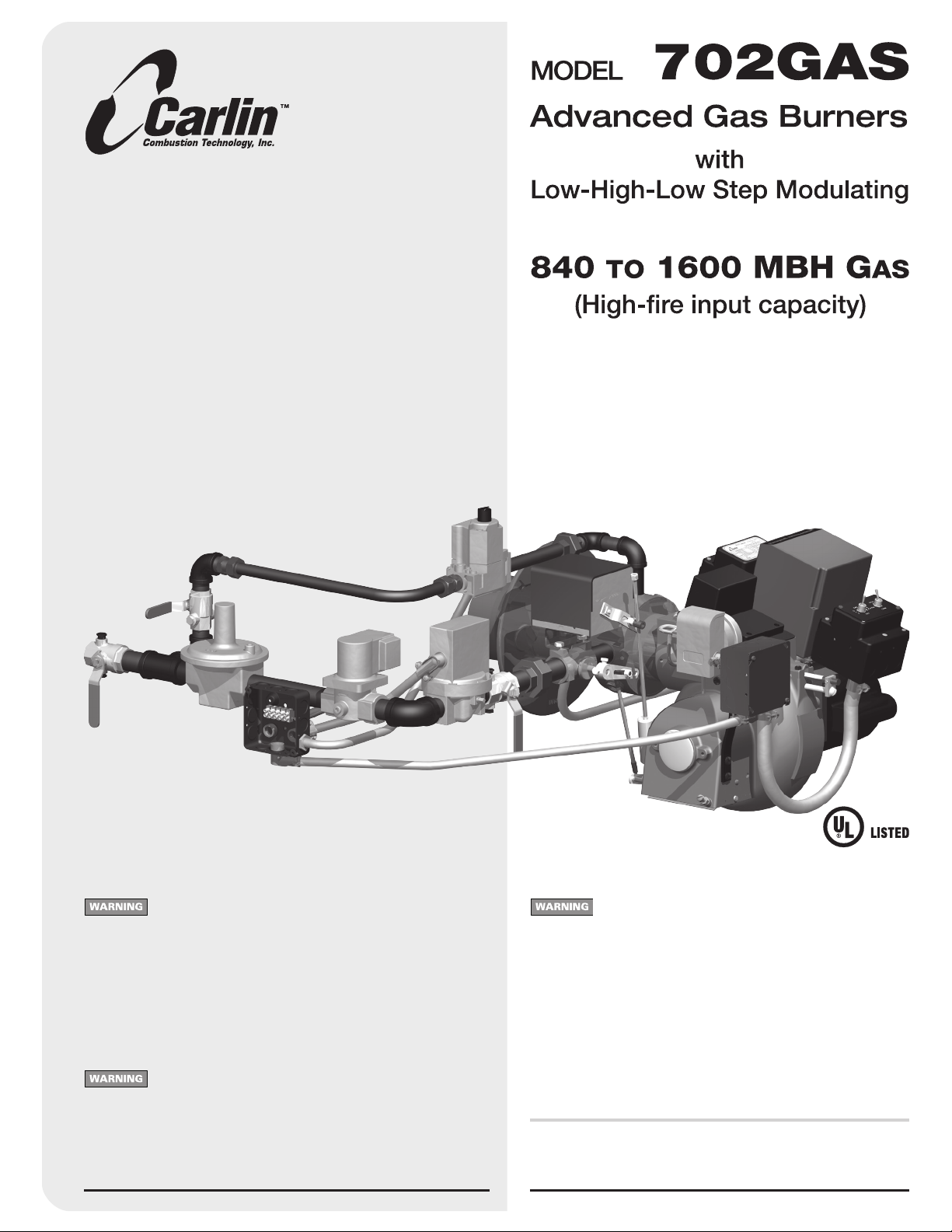

Carlin 702GAS User Manual

Instruction manual

™

Except where specifically stated otherwise, this manual

must be used only by a qualified service technician.

In the state of Massachusetts, this product must be

installed by a licensed Plumber or Gas Fitter.

Failure to comply with the above or other requirements in

this manual could result in severe personal injury, death

or substantial property damage.

USER — Refer only to User care and maintenance

on back page for information regarding operation of this

burner. The burner Instruction Manual is intended only for

your service technician. The burner and heat exchanger

must be inspected and started at least annually by your

service technician.

Check burner cartons carefully. The Model 702GAS gas

burner was assembled and tested at the factory before

shipment. If the burner was ordered with a completed

assembled gas train, the train was pressure tested and

electrically checked for proper operation. Where possible,

the gas train or components were shipped in the same

carton as the burner. Check your packing slip for the

number of cartons shipped from the factory.

© Copyright 2011 — Carlin Combustion Technology, Inc.

Carlin Combustion Technology, Inc.

70 Maple Street East Longmeadow, MA 01028

Ph 413-525-7700 Fx 413-525-8306

Te ch su p p ort 800-989-2275

carlincombustion.com

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

PLEASE read this first . . .

Contents

PLEASE read this first .............................................................2

General information ................................................................3

1. The Carlin Model 702GAS gas burner ................................4

2. Preparesite•assembleburner•mountburner ......6

3. Install gas piping .............................................................12

4. Wire the burner ................................................................14

6. Checkout procedure — before starting the burner .........16

7. Set burner initial head and damper positions .................17

8. Adjust the burner using test instruments ........................18

9. Maintenance and service procedures .............................22

10. Repair parts ...................................................................24

11. Dimensions ....................................................................28

User care and maintenance .................................... Rear cover

Special attention flags . . .

Please pay particular attention to the following when you see them throughout this manual.

Notifies you of hazards that WILL cause severe personal injury,

death or substantial property damage.

Notifies you of hazards that CAN cause severe personal injury,

death or substantial property damage.

Notifies you of hazards that WILL or CAN cause minor personal

injury or property damage.

Notifies you of special instructions on installation, operation or

maintenance that are important, but are not normally related

to injury or property damage hazards.

– 2 –

Before installing or

servicing:

Should overheating occur:

(1) Shut off the gas supply to the burner.

(2) DO NOT shut off the control switch to the boiler

circulator or the burner.

Follow the guidelines below to avoid potential severe

personal injury, death or substantial property damage.

Installer/service technician . . .

• Read all instructions before proceeding. Perform all procedures,

and in the order given to avoid potential of severe personal injury,

death or substantial property damage.

• Before leaving the site after startup or service, review the User

care and maintenance page with the user. Make the user aware of

all potential hazards and perform the training outlined below.

Installer/service technician —

Train the user . . .

• To properly operate the burner/appliance per this manual and the

appliance instructions. See User care and maintenance.

• To keep this manual at or near the burner/appliance for ready

access by the user and service technician.

• To contact the service technician if he encounters problems with

the burner/appliance.

• To keep the appliance space free of flammable liquids or vapors

and other combustible materials.

• To never use laundry products, paints, varnishes or other chemicals

in the room occupied by the burner/appliance.

• To contact the service technician at least annually for startup and

burner/appliance service.

When servicing the burner . . .

• DISCONNECT ELECTRICAL SUPPLY and all other electrical con-

nections to burner before attempting to service to avoid electrical

shock or possible injury from moving parts.

• CLOSE all manual gas valves before disconnecting any portion

of gas lines and before cleaning or removing any parts from the

burner or related equipment.

• Burner and appliance components can be extremely hot. Allow

all parts to cool before attempting to handle or service to avoid

potential of severe burns.

Carlin part number MN702G Rev. 03/14/11

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

General information

Burner applications

Follow all instructions in this manual, the primary control data sheet and

the appliance manual.

Verify the burner is correct for the appliance being used and for all applicable codes/standards.

Adjust the firing rate if necessary due to positive overfire pressure and/or

altitudes more than 2,000 feet above sea level. See the NOTICE under the

Ratings information at right. Where appliance application information is

available, the recommended firing rate and burner information will include

appropriate adjustments for positive overfire pressure and recommendations for high altitudes. Follow the appliance manual guidelines when

available.

Damage or shortage claims

The consignee of the shipment must file damage or shortage claims immediately against the transportation company. See the NOTICE on page 1

for burner carton information.

When calling or writing about the

burner:

Please provide us with the UL serial number and burner model number

to assist us in locating information. This information can be helpful when

troubleshooting or obtaining replacement parts.

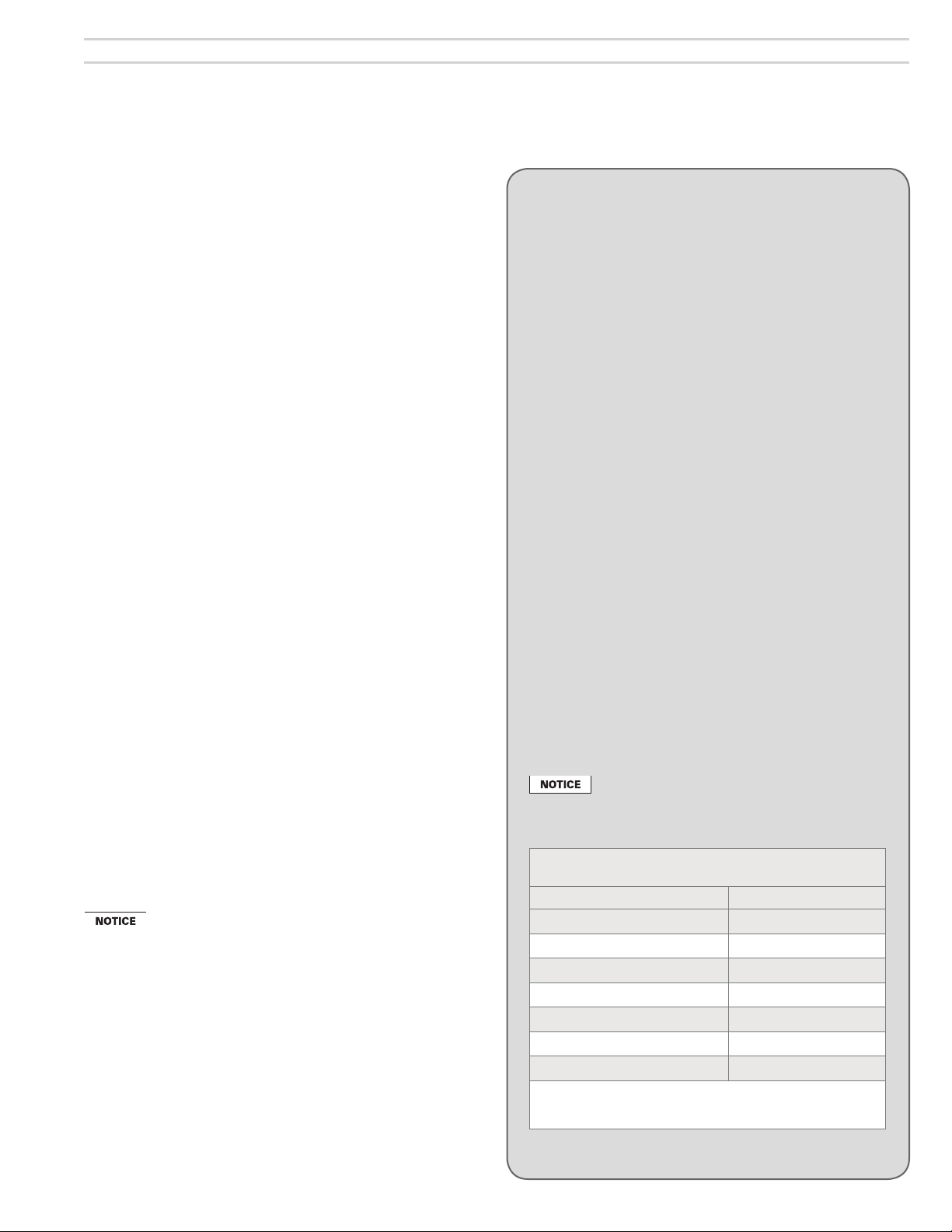

Ratings

( With 0.00” w.c. overfire pressure, altitude 2,000 feet max.; see NOTICE below)

Gas Input

..................................................................................... High fire: 840 to 1,600 MBH

........................................................................................ Low fire: 490 to 940 MBH

Fuels

..............................................................................................Natural gas or propane

Gas train: (available in straight or angled configuration)

....................................................... (2) Main gas valves & RV-61 or RV-81 regulator

.......................................................................Butterfly gas valve for input regulation

..................................................1” gas train standard; 1¼” or 1½” gas train available

Electrical

Power ...................................................................................... 120V/60 Hz/1-Phase

Limit circuit input (RM7897C) ..............................................................120 vac/60 hz

Control circuit load (120 vac) ........................................................................

Motor................................................................

....................................................

Gas valve power...................................................................................120 vac/60 hz

Damper motor (with end switch) .....................................................

1/2 hp, 3450 rpm, 48-frame, “N” flaNge

115 / 208-230 vac/60 hz/1-ph, 8.4 / 3.8-4.2 amps

Ignition & primary control

........................................................Carlin Model 41000 solid state electronic ignitor

Ignition voltage ......................................................................................14,000 volts

Primary control ..........................................................................Honeywell RM7897C

1.2 amps

hoNeywell m436a

Codes and standards

Certification

702GAS burners are U.L. listed for the U.S., certified to comply with:

• UL 795, for use with natural gas or propane.

• Burner labels list compliance, when required, with special local, state

or provincial approvals.

Install this burner in accordance with all local codes and

authorities having jurisdiction. Regulations of these authorities take precedence over the general instructions provided

in this manual.

United States installations

Burner/appliance installations in the United States must comply with the

latest editions of:

• Installation of Domestic Gas Conversion Burners, ANSI Z21.8.

• National Fuel Gas Code, ANSI Z223.1/NFPA 54.

• National Electrical Code, ANSI/NFPA 70.

Agencies

.......................................................................................................... UL Listed (US)

Reduce firing rate when required — Maximum burner capacity is

reduced when overfire pressure is positive and for altitudes above

2,000 feet. See below, and adjust firing rate/nozzle selection if

necessary.

702GAS — Maximum ring rate for

positive overre pressure and high altitude

Overre pressure

Altitudes: For altitudes more than 2,000 feet above sea level, reduce the above

capacities an additional 4% per 1,000 feet higher than 2,000 feet

above sea level.

(Inches w.c.)

0.00 1,600

0.10 1,530

0.20 1,500

0.30 1,480

0.40 1,440

0.50 1,430

0.60 1,390

Gas – MBH

• All additional applicable national, state and local codes.

Carlin part number MN702G Rev. 03/14/11

– 3 –

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

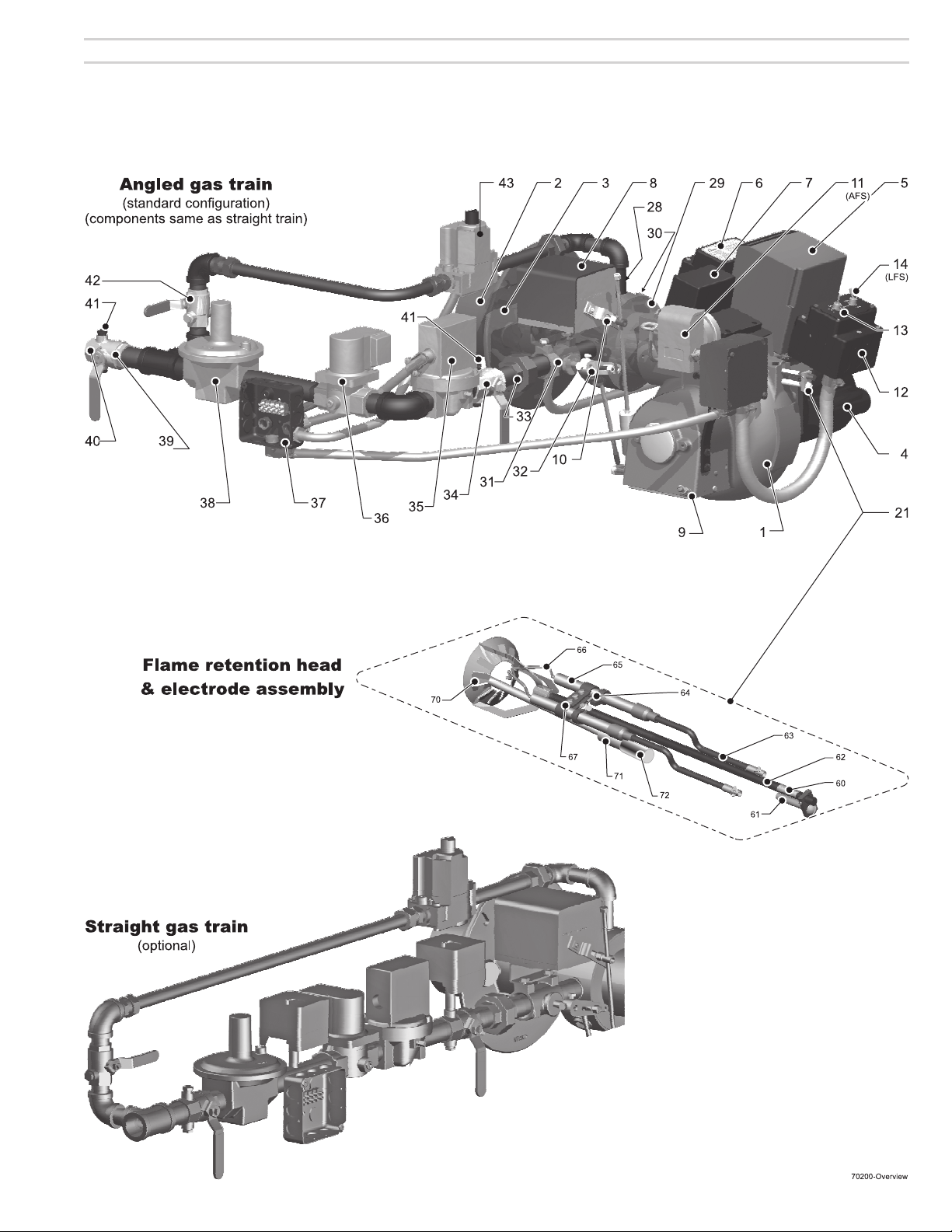

1. The Carlin Model 702GAS gas burner

702GAS overview

The Model 702GAS gas burner is a low-high-low (step modulating) burner

that utilizes a damper motor and butterfly valve to control air (and gas fuel

rate).

The burner operates on either natural gas or propane.

See the next page for gas train component locations.

Operation

Ignition for main flame is accomplished by a proved gas pilot of approximately 280,000 Btuh. Pilot gas is introduced at the main burner flame retention ring, and is ignited by a Carlin 14,000-volt electronic ignitor wired

to the two electrodes.

After the pilot flame is proven, the two main gas safety valves open. The

pilot gas valve closes after a time delay to allow main flame to establish.

Flame is monitored both for pilot flame and main flame with a UV scanner

mounted to the under side of the burner combustion head assembly.

The burner main flame begins at low fire. If additional input is required,

the damper motor opens the gas butterfly valve and air damper to their

high fire positions.

Gas is introduced into the burner through a manifold around the air tube. The

gas then circulates through a set of four orifice spuds into the air stream,

ahead of the retention ring. The spin of the air flow at the retention ring

thoroughly mixes the gas/air before it reaches the combustion zone.

Firing rate adjustment

• See the “Starting and operating” section of this manual for the complete

description of the adjustment process. The following is a brief summary

only.

• High-fire air is set by adjusting the combustion head position (to control air

flow through and around the retention ring).

• Low-fire air is then adjusted by fine-tuning the position of the low fire

adjusting screw.

• Pilot gas flow is set for a smooth light-off. Then gas inputs are adjusted for

good combustion at low and high-fire air settings.

Gas pressure requirements

The 702GAS burner requires 3.4” w.c. minimum pressure at the butterfly

valve during high fire. Select a gas train that has a pressure drop no more

than the available pressure at the gas train inlet minus the 3.4” needed

at the butterfly valve.

See page 13 for gas train pressure drop information. The burner is equipped

with a 1” gas train unless a larger gas train is ordered.

Example:

A boiler has an input rating of 1,300,000 Btuh. Gas pressure available at

the gas train entrance is 6.0” w.c. Subtract 3.4” from the available 6.0”

w.c. The gas train pressure drop must be 2.6” or less. A 1” gas train has

a pressure drop of 3.3” w.c., and cannot be used. Select a 1¼” RV-61

regulator gas train, which has a pressure drop of 0.87” w.c.

LEGEND for page 5

1 Cast aluminum burner housing

2 Air tube (with gas manifold)

3 Burner flange

4 Burner motor

5 Primary control, Honeywell RM7897C

6 Carlin EZ-Contactor (burner motor contactor)

7 Ignitor (Carlin 41000)

8 Damper motor

9 Air damper & low fire adjusting screw

10 Air damper linkage

11 Air flow switch

12 Junction box (connection for 120

vac power and 120 vac control and

limit circuit input from boiler)

13 ON/OFF switch

14 Low fire hold switch (LFS)

28 Pilot orifice nipple

29 Gas manifold

30 Gas spuds (4 required)

31 Gas butterfly valve

32 Butterfly valve linkage

33 Union

34 Gas shut-off valve (with 2 test tappings)

35 Automatic gas valve (diaphragm type)

36 Automatic gas valve

37 Gas train junction box

38 Gas pressure regulator

39 Manual gas valve (with two test tappings)

40 Gas entrance connection

41 Pressure tap & bleed port

42 Pilot gas line manual valve

(with 2 test tappings)

43 Combination pilot gas valve

60 Head position indicator scale

61 Head position adjustment screw

62 Support rod

63 Electrode lead wires

64 Thermal fuse

65 Electrode ceramic insulators

66 Electrodes

67 Electrode clamp

70 Retention ring assembly

71 UV scanner tube/adapter

72 UV scanner

– 4 –

Carlin part number MN702G Rev. 03/14/11

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

1. The Carlin Model 702GAS gas burner (continued)

Carlin part number MN702G Rev. 03/14/11

– 5 –

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

2. Prepare site • assemble burner • mount burner

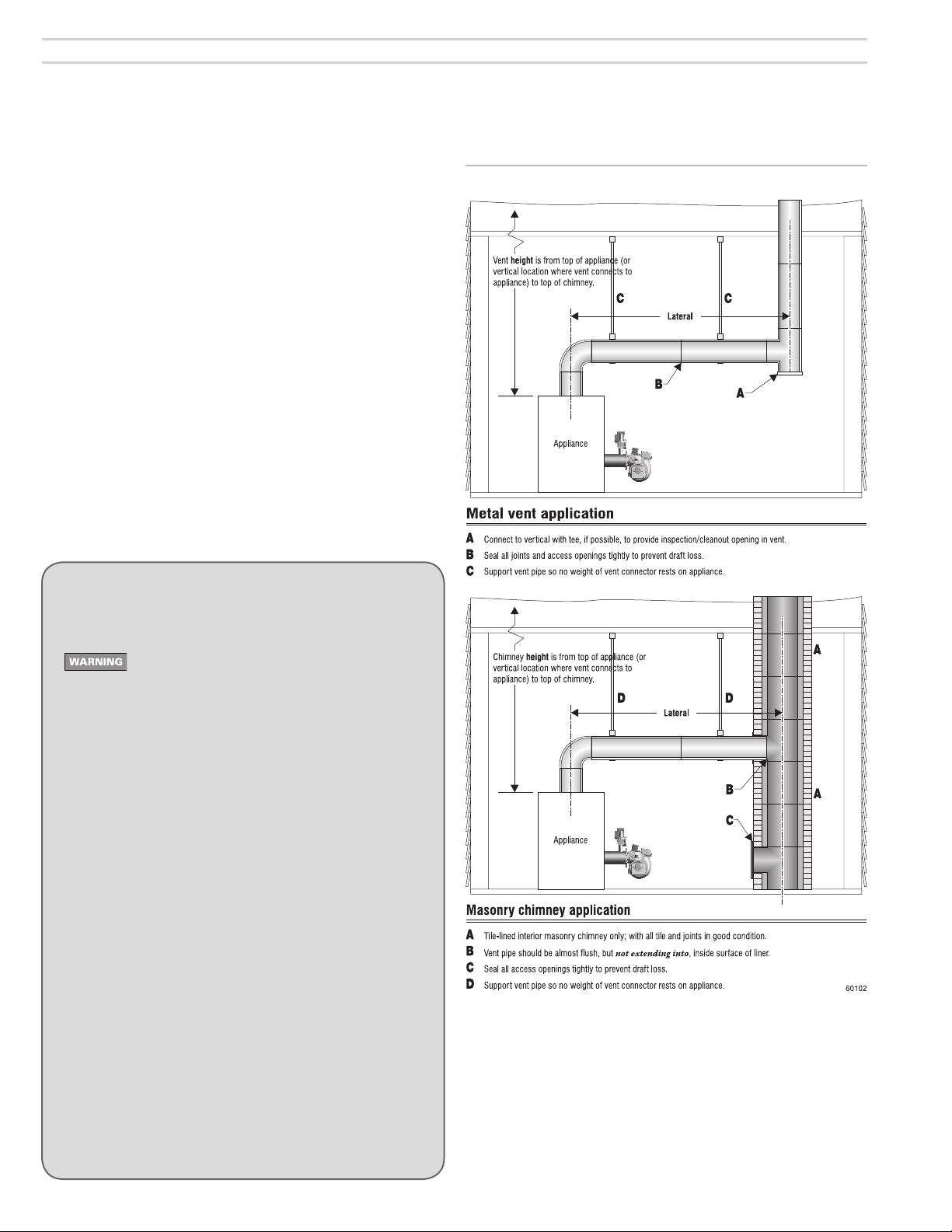

Vent system

Vent/chimney sizing

1. Follow all local codes when sizing the vent and chimney.

2. Refer to the appliance manufacturer’s manual, when available, for venting

recommendations.

Prepare vent/chimney

1. Secure all metal vent joints with screws, following the vent manufacturer’s

instructions. Seal all joints in the vent system and chimney. Repair masonry

chimney lining and repair all mortar joints as needed.

2. Where draft fluctuations are likely, install a double-acting barometric draft

regulator in the vent piping. (The damper must be located in the same

space as the appliance.) Install a manual reset spill switch in the top of

the draft regulator outlet. Wire the switch into the appliance limit circuit to

shut off the appliance/burner if sustained downdraft should occur. Refer

to the appliance manufacturer’s instruction manual for recommendations

regarding the need for a barometric draft regulator.

3. Provide support for the vent piping. Do not rest the weight of any of the

vent piping on the appliance flue outlet.

Inspect, repair and/or replace vent

system

Figure 1 Vent and vent connector installations, typical

Do not install this burner unless you have veri-

fied the entire vent system and the appliance are in

good condition and comply with all applicable codes.

And . . .

The vent and chimney must be sized and constructed in

accordance with all applicable codes. If intended for use

with an oil burner as well, the vent system must comply

with relevant codes for both gas and oil firing.

The vent system must not be pressurized unless the vent

piping and vent system are designed accordingly. The vent

must provide draft at all times (negative pressure in vent).

Seal the appliance: Seal all flue-gas containing joints. Seal

all connections to the vent piping or breeching.

Do not install or use an existing manual damper in the vent

connector or vent.

Do not connect the appliance vent connector to a chimney

or vent serving a fireplace, incinerator or solid-fuel-burning

apparatus.

In a cold climate, do not vent into a masonry chimney that

has one or more sides exposed to the outside. Install a

listed stainless steel liner to vent the flue products.

A defective vent system could result in severe personal

injury, death or substantial property damage.

Clearances

Check codes, standards and the equipment

manual

• Verifythat theburner/appliancewillmaintainall clearances tocombustible walls or floor and all clearances required for service/maintenance as

required in the appliance manual and applicable codes.

– 6 –

Carlin part number MN702G Rev. 03/14/11

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

2. Prepare site • assemble burner • mount burner (continued)

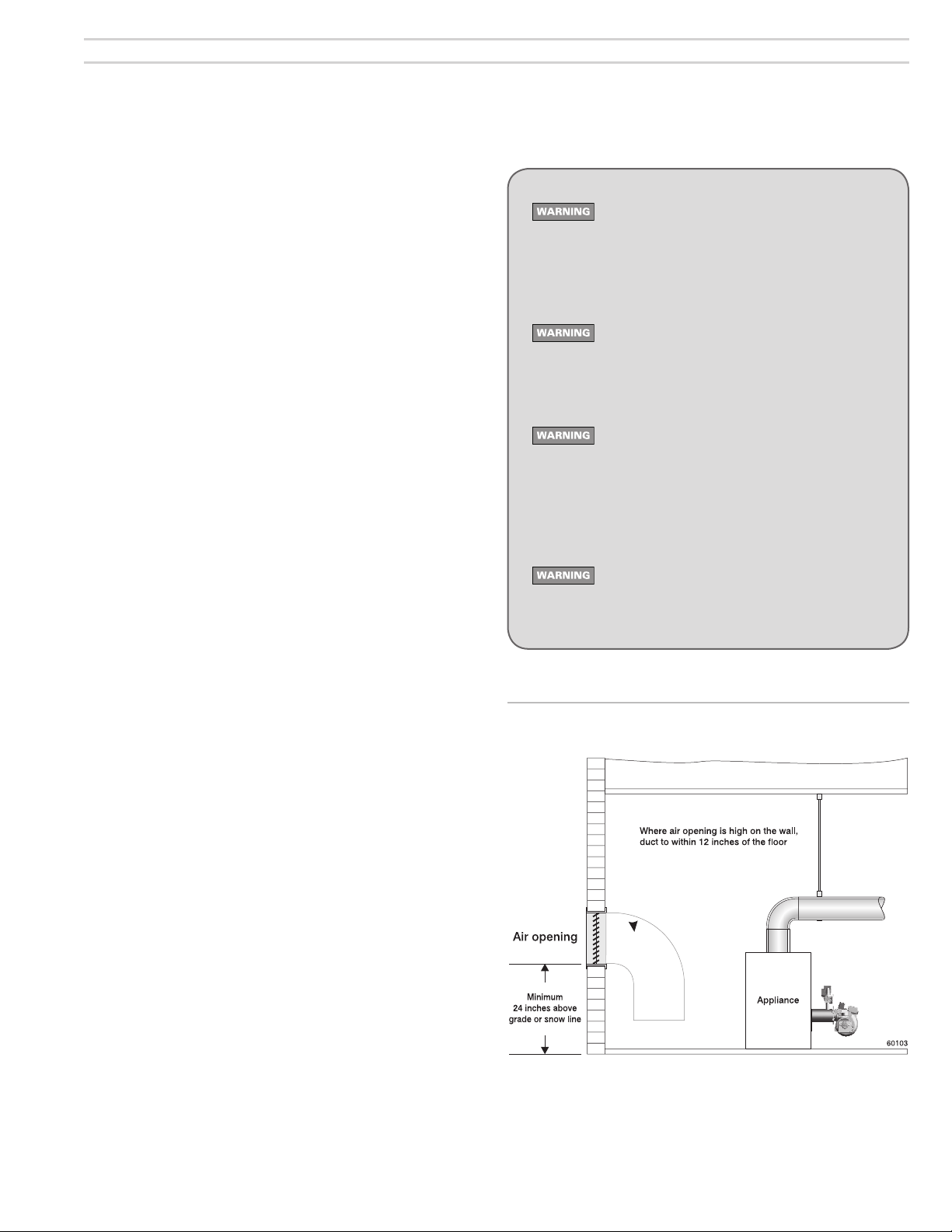

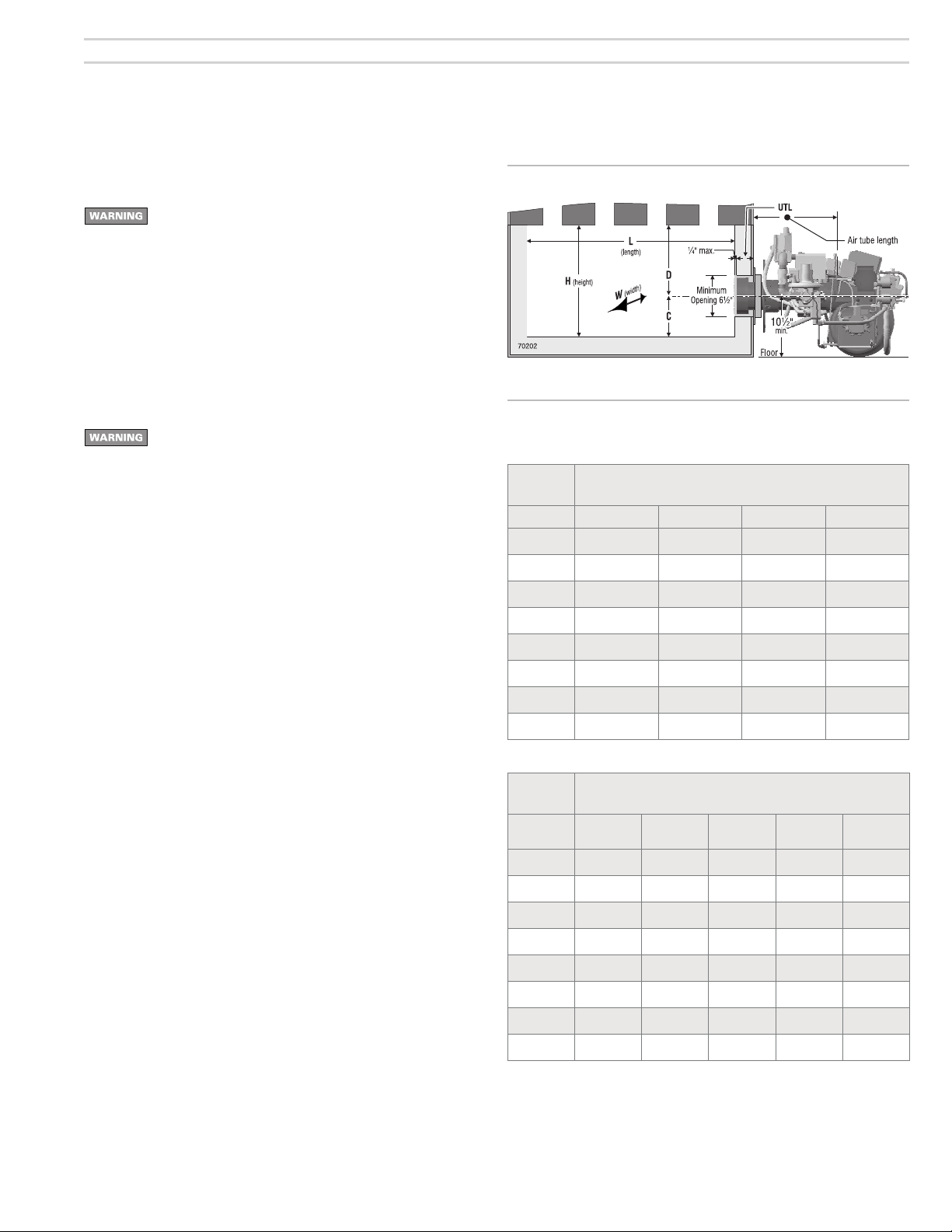

Combustion air/ventilation openings

Sizing air openings

Follow all applicable codes and the appliance instruction manual (when

available) to size combustion air openings. Use the following guidelines

when appliance instructions are not available.

• All air from inside building (building must be well-ventilated):

Size air openings for a free area (after louver deduction) of at least 1

square inch per 1,000 Btuh input of all appliances in the space.

• All air through openings directly from outside the building through an

adjacent outside wall:

If air openings connect directly to outside, provide two openings, one

within 12 inches of the ceiling, the other within 12 inches of the floor.

Each opening must have a free area (after louver deduction) of:

• If directly through side wall: 1 square inch for each 4,000 Btuh of all ap-

pliances in the space.

• If through vertical ducts: 1 square inch for each 4,000 Btuh of all appli-

ances in the space.

• If through horizontal ducts: 1 square inch for each 2,000 Btuh of all ap-

pliances in the space.

Locating air openings

Follow all applicable codes and the appliance instruction manual (when

available) to size combustion air openings. Refer to Figure 2 when appliance

instructions are not available.

Installing the burner/appliance in a space that does

not provide enough air for combustion and ventilation can result in severe personal injury, death or

substantial property damage. Follow all applicable

codes and guidelines below to ensure space has

sufficient air openings.

Exhaust fans and negative pressure conditions —

Isolate the boiler room from areas subject to negative

pressure. Size combustion air openings to ensure

neutral air pressure in the boiler room whenever the

burner operates.

Make sure the space provides enough ventilation

to prevent overheating of the appliance, burner and

controls. If there is risk of overheating, you must

install ventilation air openings sized large enough

to provide air for cooling the equipment. Failure

to provide ventilation can result in severe personal

injury, death or substantial property damage.

The space and combustion air supply must not

contain corrosive contaminants, such as laundry

products, paints, varnishes or other chemicals.

Estimating free area

When specific information on the free area of louvers is not available,

estimate free area as follows:

1. Wood louvers — free area = area times 0.25.

2. Metal louvers or grilles — free area = area times 0.60.

3. Screens, when used must be no smaller than ¼ inch mesh.

Motorized vent dampers

Wire the vent damper end switch to prevent operation of the burner until

the air opening louvers are fully open.

Combustion air/ventilation opening checklist

• Verify that air openings are unobstructed.

• Verify that appliance space and air source spaces are free of:

• Gasoline or other flammable liquids or vapors.

• Combustible materials.

• Air contaminants, such as laundry products, paint, thinner, varnish, etc.

• Confirm with user that the area will be kept free of these materials at all

times.

Figure 2 Locating combustion air/ventilation openings

Carlin part number MN702G Rev. 03/14/11

– 7 –

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

2. Prepare site • assemble burner • mount burner (continued)

Prepare the appliance

Burner input: Install a burner sized for the normal input rating

of the appliance. Do not install a burner with a higher firing

rate than the appliance rating. Do not install a burner with a

firing rate more than 10% lower than the appliance rating.

The appliance and vent system could be damaged due to

condensation.

Clean the appliance: Clean the appliance thoroughly. Test

all electrical components and verify the relief valve works

(boilers only).

Seal the appliance:

all connections to the vent piping or breeching.

Verify combustion chamber dimensions comply with the

minimum dimensions recommended on page 9. Install or

replace chamber liner if required by the appliance manufacturer. The burner must not extend into the combustion

chamber. The end of the burner air tube must be within ¼”

of the inside face of the chamber. If the space around the

burner air tube is more than ¼”, wrap the burner air tube

with minimum 2300-°F-rated ceramic fiber blanket to seal

off the gap.

Repair or replace damaged appliance components.

Inspect the appliance thoroughly. Follow appliance manufacturer’s guidelines for repair or replacement of any component

found defective.

When cleaning the appliance or working with ceramic fiber

refractories or fiberglass insulation, see WARNING on this

page.

Failure to comply with the above could result in severe per-

sonal injury, death or substantial property damage.

Seal all flue-gas containing joints. Seal

Avoid breathing dust and avoid contact with skin

Ceramic fiber removal: To prevent airborne dust,

Avoid blowing, tearing, sawing or spraying

Ceramic fiber or

Fiberglass insulation

Ceramic fiber materials, such as chamber liners, may

contain carcinogenic particles (chrystobalites) after

exposure to heat. Airborne particles from fiberglass

or ceramic fiber components have been listed as

potentially carcinogenic by the State of California.

Take the following precautions when removing,

replacing and handling these items.

or eyes. Wear long-sleeved, loose-fitting clothing,

gloves and eye protection. Use a NIOSH N95 certified

respirator. This respirator meets requirements for protection from chrystobalites. Actual job requirements

or NIOSH regulations may require other or additional

protection. For information, refer to the NIOSH website,

http://www.cdc.gov/niosh/homepage.html.

thoroughly wet ceramic fiber with water before

handling. Place ceramic fiber materials in a plastic

bag and seal to dispose.

fiberglass or ceramic fiber materials. If such operations are necessary, wear extra protection to prevent

breathing dust.

Prepare appliance for burner mounting

Positive overfire pressure applications: When firing with posi-

tive overfire pressure, do not exceed the pressure specified

in the appliance manual.

Positive overfire pressure reduces maximum burner capacity.

See Page 3 for estimated reduction in burner capacity with

pressurized firing and high altitude applications.

Failure to comply could result in severe personal injury, death

or substantial property damage.

– 8 –

Wash work clothes separately from other laun-

dry. Rinse clothes washer thoroughly afterwards to

prevent contamination of other clothing.

NIOSH First aid procedures:

Eye exposure — irrigate immediately

Breathing — fresh air.

Carlin part number MN702G Rev. 03/14/11

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

2. Prepare site • assemble burner • mount burner (continued)

Prepare burner and components

Do not install or operate the burner if any component is damaged

or if burner does not comply with the specifications of Table 2

and other guidelines in this manual.

Combustion chamber minimum dimensions

1. For applications that have not been specifically tested (OEM applications),

verify that the combustion chamber provides the minimum dimensions

shown in Table 2 and Figure 3. For specific OEM applications, the

appliance testing ensures suitability of the chamber.

2. Chamber dimensions may be larger than listed in Table 2, but should not

be excessively large.

Combustion chambers should be sized as recommended in

Table 2. They should be constructed of refractory materials with

the capacity to withstand 2600°F or higher.

It is difficult to include all possible chamber constructions in this

manual. Therefore, you should use the information presented

in this manual combined with commonly practiced techniques

when determining chamber design. If certain conditions are in

question, consult the factory.

Using chamber linings

1. When using refractory liners or lightweight chambers, use insulatingtype refractory rated 2600°F minimum, or as specified by the appliance

manufacturer.

2. You must install a target wall liner if flame length is close to the length of

the chamber.

3. Use a floor liner when possible. The floor liner will improve firing in most

applications. Extend floor liner 3 to 4 inches up the side walls.

4. Target wall liners — Extend target wall liners at least 3 to 4 inches above

the center of the flame corbel the top 1½ to 2½ inches deep.

5. Use preformed chamber liners when available. Lining the floor and target

wall water-backed combustion chambers with lightweight insulating refractory will accomplish the same.

6. When converting coal-fired units, install a combustion chamber in the

ashpit area, or fill the ashpit with sand up to 2 inches above the “mud

ring” of the boiler (firing through the door). Install a lightweight refractory

liner on the target wall.

Air tube insertion length (UTL)

1. Usable air tube length (UTL) is the distance from mounting flange to end of

air tube. Verify that the end of the air tube will be flush with, or no more than

¼ inch short of, the inside of the appliance combustion chamber front wall

when the burner is mounted. See Figure 3 for further information.

Figure 3 Chamber dimensions & tube configurations

Table 2 Minimum combustion chamber dimensions

(see Figure 3)

High re

input

Gas–MBH

840 21 15.0 7.5 15

910 23 15.5 8.0 16

966 25 16.0 8.0 16

1092 28 17.0 8.5 17

1218 31 17.5 9.0 18

1330 34 18.0 9.0 18

1456 38 19.0 9.5 19

1600 43 20.0 10.0 20

High re

input

Gas–MBH

840 21 25 17.0 8.5 10.5

910 23 27 17.5 9.0 11.0

966 25 29 18.0 9.0 11.0

1092 28 32 19.0 9.5 11.5

1218 31 35 19.5 10.0 12.0

1330 34 38 20.0 10.0 12.0

1456 38 42 21.0 10.5 12.5

1600 43 47 22.0 11.0 13.0

Refactory combustion chamber applications

“L” “W” “C” “H”

Refactory combustion chamber applications

“L”

W/ target

(all dimensions in inches)

(all dimensions in inches)

“L”

No target

“W” “C” “D”

Carlin part number MN702G Rev. 03/14/11

– 9 –

Model 702GAS Advanced gas burners — Instruction manual

Where appliance instructions differ from this manual, follow the appliance instructions.

2. Prepare site • assemble burner • mount burner (continued)

Inspect burner and components

• Check the air tube length. Verify the usable length of the tube UTL will be

long enough (see “Mount burner in appliance”).

• Visually inspect all burner components and wiring.

• Verify that wiring is intact and leads are securely connected.

• Verify that all burner components are in good condition.

Do not install or operate the burner if any component is

damaged or if burner does not comply with other guidelines

of this manual and the appliance manual.

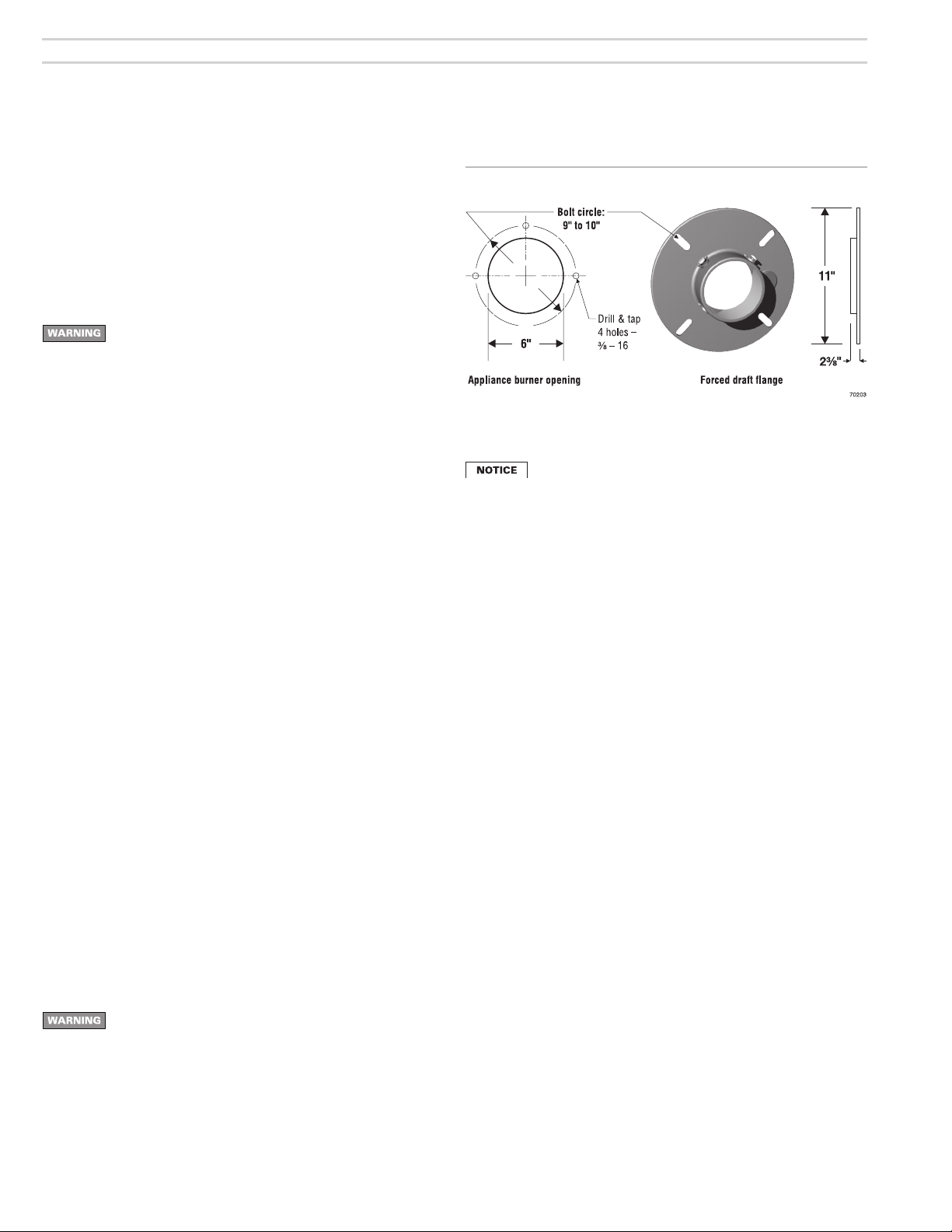

Mount burner in appliance

Welded-flange burners

1. Verify the bolt pattern on the appliance chamber matches the flange

pattern.

2. Verify the insertion depth (UTL) matches the depth of the appliance opening (so the end of the air tube is flush with, or slightly short of, the inside

surface of the combustion chamber).

3. Place gasket onto boiler front plate.

4. Slide the end of the air tube into the opening and secure the flange to the

boiler front plate.

Burners with adjustable flanges

1. Verify the flange mounting slots will line up with the appliance bolts. (See

Figure 4 for adjustable flange dimensions.)

2. Place the flange gasket in position on the appliance mounting plate.

3. Measure the distance from the inside of the combustion chamber to the

outside of the appliance mounting plate. Slide the adjustable flange on the

air tube until it is this distance from the end of the air tube.

4. Mark this position of the flange on the air tube with a pencil or pen so you

can verify the flange is correctly positioned as you complete the installation.

The end of the air tube must be flush, or almost flush, with the inside of

the combustion chamber wall. (See Figure 3, page 9)

5. Tighten the flange locking screws finger tight.

6. Insert the air tube/flange assembly into the appliance opening. (Rotate the

flange if needed to align with the mounting bolts.) Secure the flange to the

appliance front plate. Tighten the flange locking screws.

7. See the following instructions to install the burner pedestal, needed to

properly support the burner.

A forced draft adjustable flange must be sealed to the air

tube to prevent possible leakage of flue products. Failure

to comply could result in severe personal injury, death or

substantial property damage.

Figure 4 Adjustable flange

Install the burner pedestal

702GAS burners supplied with an adjustable flange are

also supplied with a pedestal for supporting the burner. (The

pedestal is available as an option for a burner equipped with

a welded flange.)

1. Adjust the pedestal so that the height of the air tube matches the location

of the burner opening.

2. The pedestal has approximately 3” of adjustment. If the burner opening is

too high for the pedestal to rest on the floor, then construct a base. Two

solid cement blocks, side by side, is recommended. Alternate the direction

as layers are put down.

3. Place a spirit level on the air tube. Adjust the pedestal so the air tube

slopes down slightly toward the appliance. The slope should be about

2 degrees.

4. Tighten the pedestal bolt securely.

Install the combustion head

assembly

1. Follow the instructions on page 22 to remove the combustion head assembly.

2. Check the position of the flame scanner sight pipe. The flame scanner sight

pipe assembly should be positioned so that the 3/8” pipe fits against the

retention ring assembly. Adjust if necessary. Then tighten the 1/8” Allen

screw to secure the tube in place.

3. Check the electrodes and reposition if necessary. Position the electrodes

as shown in Figure 5. These settings are critical in ensuring a reliable

ignition.

4. Once the electrodes are set, check all clamps to be sure they are securely

tightened.

5. Insert the combustion head assembly into the burner and secure in place.

See instructions on page 22.

– 10 –

Carlin part number MN702G Rev. 03/14/11

Loading...

Loading...