Instruction manual

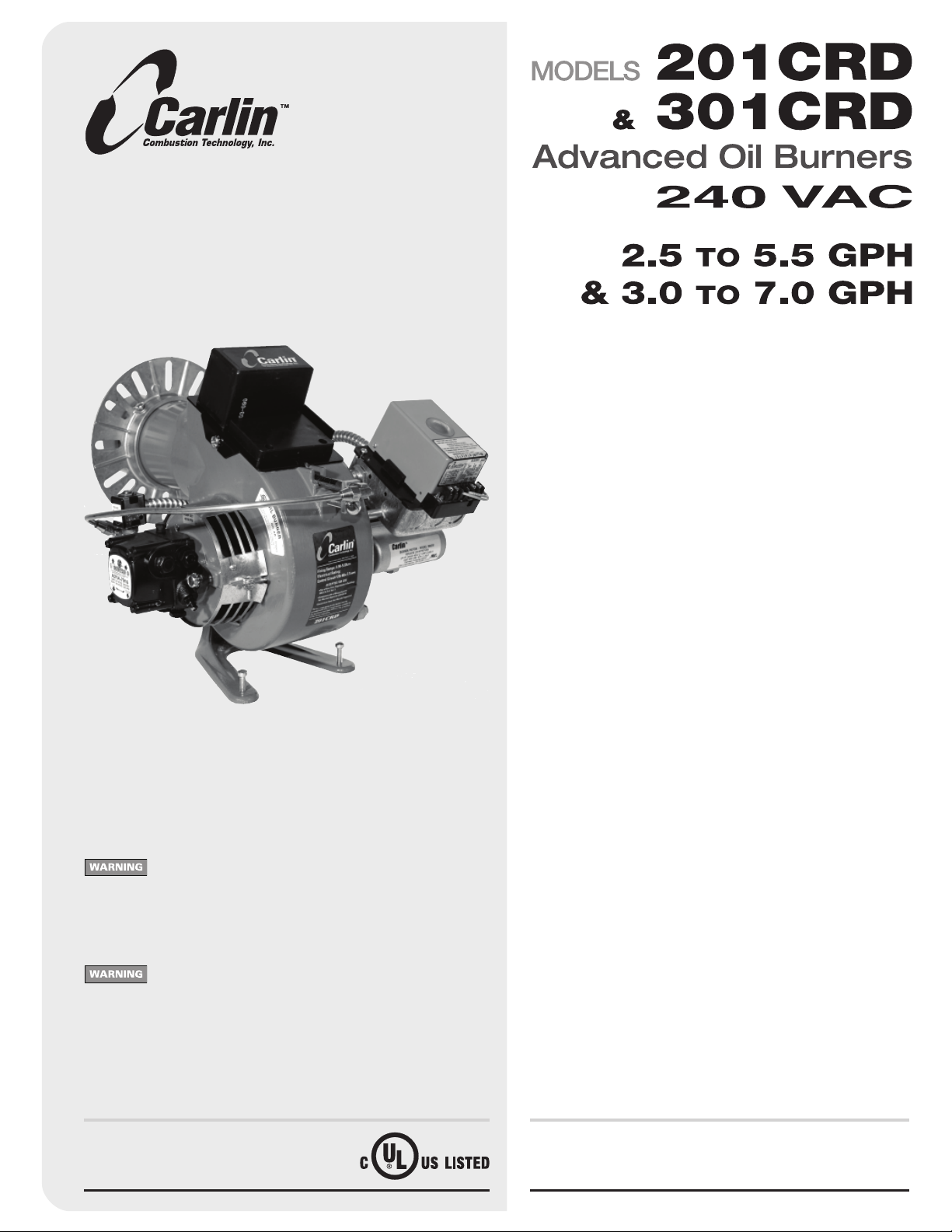

™

Installer/servicer — Except where specifi cally stated other-

wise, this manual must be used only by a qualifi ed service

technician. Failure to comply with this or other requirements

in this manual could result in severe personal injury, death or

substantial property damage.

User — Refer only to User care and maintenance on back

page for information regarding operation of this burner. The

burner Instruction Manual is intended only for your service

technician. The burner and heat exchanger must be inspected

and started at least annually by your service technician.

Ratings

Input: 201CRD.......................................... 2.50 to 5.00 GPH

301CRD (3¼’’ air cone) ................. 3.00 to 6.00 GPH

301CRD (3½’’ air cone) ................. 4.00 to 7.00 GPH

Fuels: U.S. ........................................ No. 1 or No. 2 Fuel oil

Canada .............No. 1 Stove oil or No. 2 Heating oil

Fuel unit: ....................................................................... Suntec

.................................100 to 150 PSIG nozzle pressure

...............................................Factory set at 150 PSIG

Electrical: Power ................................240V, 50/60 Hz, 1-Phase

Motor........................ Carlin PSC, 1/4 HP, 3450 RPM

Total current at 240V, 50/60 Hz, 1-Phase:

201CRD ............................... Approx. 1.6 amps

301CRD ............................... Approx. 1.6 amps

Ignition: ....... Carlin Model 42000 electronic — 14,000 volts

Control: ........................................U.L. primary safety control

Agencies: ....................................... UL Listed (US and Canada)

© Copyright 2010 — Carlin Combustion Technology, Inc.

Carlin Combustion Technology, Inc.

70 Maple Street East Longmeadow, MA 01028

Ph 413-525-7700 Fx 413-525-8306

TECH SUPPORT 800-989-2275

carlincombustion.com

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

PLEASE read this fi rst . . .

Contents

PLEASE read this fi rst .............................................................2

General information ................................................................3

Before installing or servicing . . .

Codes and standards ..............................................................3

1. 201 & 301 Oil nozzles ........................................................3

2. Prepare site • assemble burner • mount burner ......4

3. Prepare burner .................................................................10

4. Wire burner • start burner –

50240 primary control .....................................................16

60240 primary control .....................................................18

5. Adjustment and verifi cation .............................................20

6. Annual start-up and service ............................................21

7. Repair parts .....................................................................22

8. Maintenance/service procedures ....................................24

Warranty ...............................................................................27

User care and maintenance .................................... Rear cover

Special attention fl ags . . .

Please pay particular attention to the following when you see them throughout this manual.

Notifi es you of hazards that WILL cause severe personal injury,

death or substantial property damage.

Should overheating occur:

(1) Shut off the oil supply to the burner.

(2) Do not shut off the control switch to the circulator

or blower.

Follow the guidelines below to avoid potential severe

personal injury, death or substantial property damage.

Installer/service technician . . .

• Read all instructions before proceeding. Perform all procedures, and

in the order given to avoid potential of severe personal injury, death or

substantial property damage.

• Before leaving the site after startup or service, review the User care and

maintenance page with the user. Make the user aware of all potential

hazards and perform the training outlined below.

Installer/service technician — Train the user . . .

• To properly operate the burner/appliance per this manual and the

appliance instructions. See User care and maintenance.

• To keep this manual at or near the burner/appliance for ready access

by the user and service technician.

• To contact the service technician or oil dealer if he encounters problems

with the burner/appliance.

• To keep the appliance space free of fl ammable liquids or vapors and

other combustible materials.

• To never use laundry products, paints, varnishes or other chemicals in

the room occupied by the burner/appliance.

• To contact the service technician at least annually for startup and

burner/appliance service.

– 2 –

Notifi es you of hazards that CAN cause severe personal injury,

death or substantial property damage.

Notifi es you of hazards that WILL or CAN cause minor personal

injury or property damage.

Notifi es you of special instructions on installation, operation or

maintenance that are important, but are not normally related

to injury or property damage hazards.

When servicing the burner . . .

• Disconnect electrical supply to burner before attempting to service to

avoid electrical shock or possible injury from moving parts.

• Burner and appliance components can be extremely hot. Allow all

parts to cool before attempting to handle or service to avoid potential

of severe burns.

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

General information 1. 201 & 301 Oil nozzles

Burner applications

Follow all instructions in this manual, the primary control data sheet and

the appliance manual.

Verify the burner is correct for the appliance being used and for all applicable codes/standards.

Damage or shortage claims

The consignee of the shipment must fi le damage or shortage claims immediately against the transportation company.

When calling or writing about the burner:

Please provide us with the UL serial number and burner model number

to assist us in locating information. This information can be helpful when

troubleshooting or obtaining replacement parts.

Codes and standards

Certifi cation

201CRD and 301CRD burners are U.L. listed for the U.S. and Canada,

certifi ed to comply with ANSI/UL 296, for use with #1 or #2 heating oil

(per standard ASTM D396).

Burner labels list compliance, when required, with special local, state or

provincial approvals.

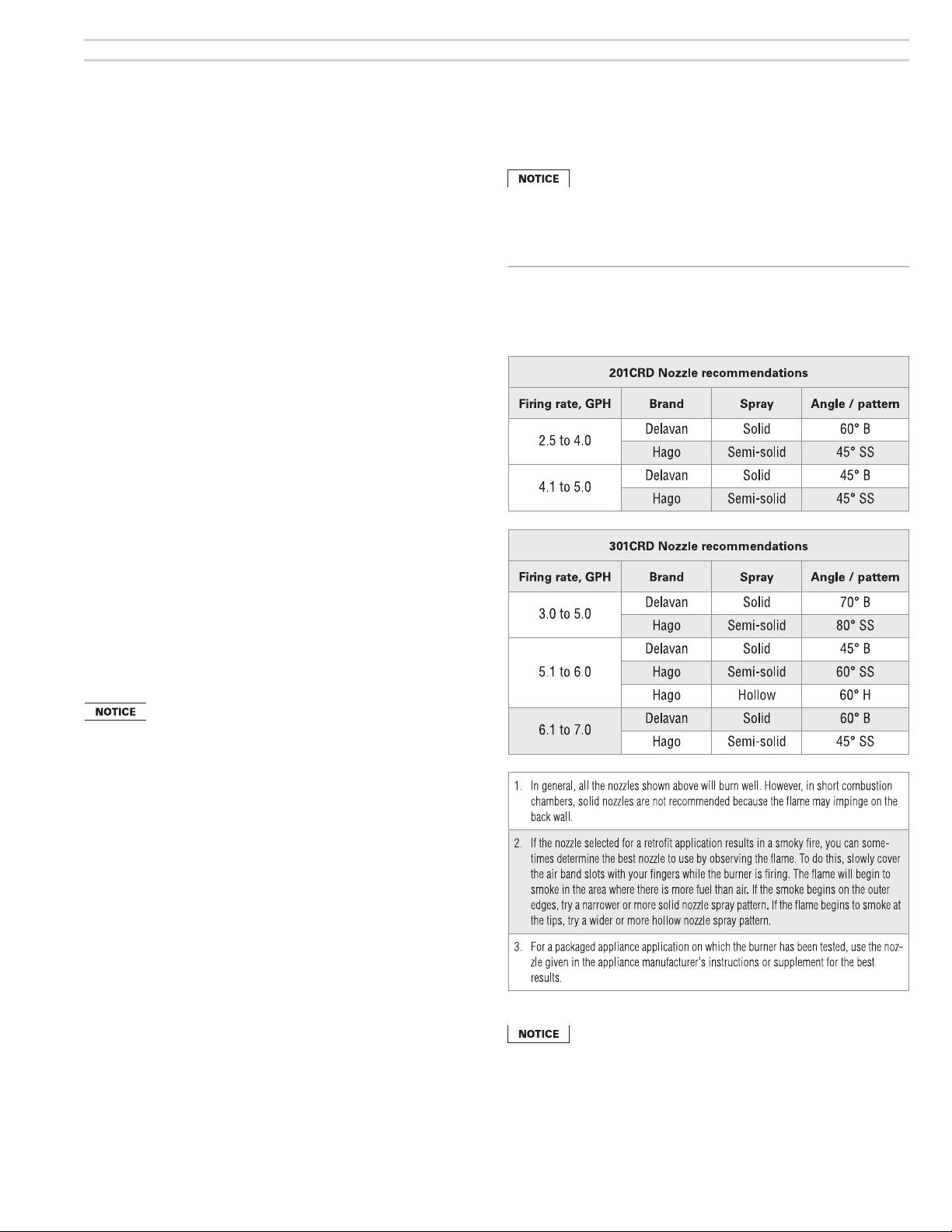

Use the selections in Table 1 ONLY when heating appliance

manufacturer specifi c nozzle selection data is not available,

either in the appliance manual or the Carlin OEM Spec Guide.

Follow all instructions provided with the appliance.

Table 1 Apply the guidelines below to select a nozzle when

appliance-specifi c nozzle data is not available from the

manufacturer or in the Carlin OEM Spec Guide. See

notes at end of table for application tips.

Install this burner in accordance with all local codes and

authorities having jurisdiction. Regulations of these authorities take precedence over the general instructions provided

in this manual.

United States installations

Burner/appliance installations in the United States must comply with the

latest editions of NFPA 31 (Standard for the Installation of Oil-Burning

Equipment), ANSI/NFPA 70 (National Electrical Code), and all applicable

local codes.

Canadian installations

Burner/appliance installations in Canada must comply with the latest editions

of CSA B139 (Installation Code for Oil Burning Equipment), CSA standard

C22, Part 1 (Canadian Electrical Code), and all applicable local codes.

The fuel unit is factory-set at 150 PSIG. The

nozzle selected must consider the fuel unit pressure. See

nozzle sizing in Table 4, page 13.

Carlin part number MN2301A Rev. 10/21/10

– 3 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

2. Prepare site • assemble burner • mount burner

Vent system

General

Do not install this burner unless you have verifi ed the

entire vent system and the appliance are in good condition and comply with all applicable codes.

• The vent and chimney must be sized and constructed

in accordance with all applicable codes.

• Do not install or use an existing manual damper in

the breeching (vent connector) or chimney.

• Do not connect the appliance vent connector to a

chimney or vent serving a fi replace, incinerator or

solid-fuel-burning apparatus.

• In a cold climate, do not vent into a masonry chimney

that has one or more sides exposed to the outside.

You must install a listed stainless steel liner in the

chimney to vent the fl ue products.

• A defective vent system could result in severe personal

injury, death or substantial property damage.

Prepare vent/chimney

• Secure all metal vent joints with screws, following the vent manufacturer’s instructions.

• Seal all joints in the vent system and chimney.

• Repair masonry chimney lining and repair all mortar joints as

needed.

• Install a double-acting barometric draft regulator in the vent piping if

specifi ed in the appliance manual. (The damper must be located in

the same space as the appliance.)

• Provide support for the vent piping. Do not rest the weight of any of

the vent piping on the appliance fl ue outlet.

Combustion and ventilation air

openings

General

Check appliance manual and applicable codes for required sizing,

design and placement of combustion/ventilation air openings. You can

use the following general guidelines, taken from NFPA 31, provided

they meet all local requirements.

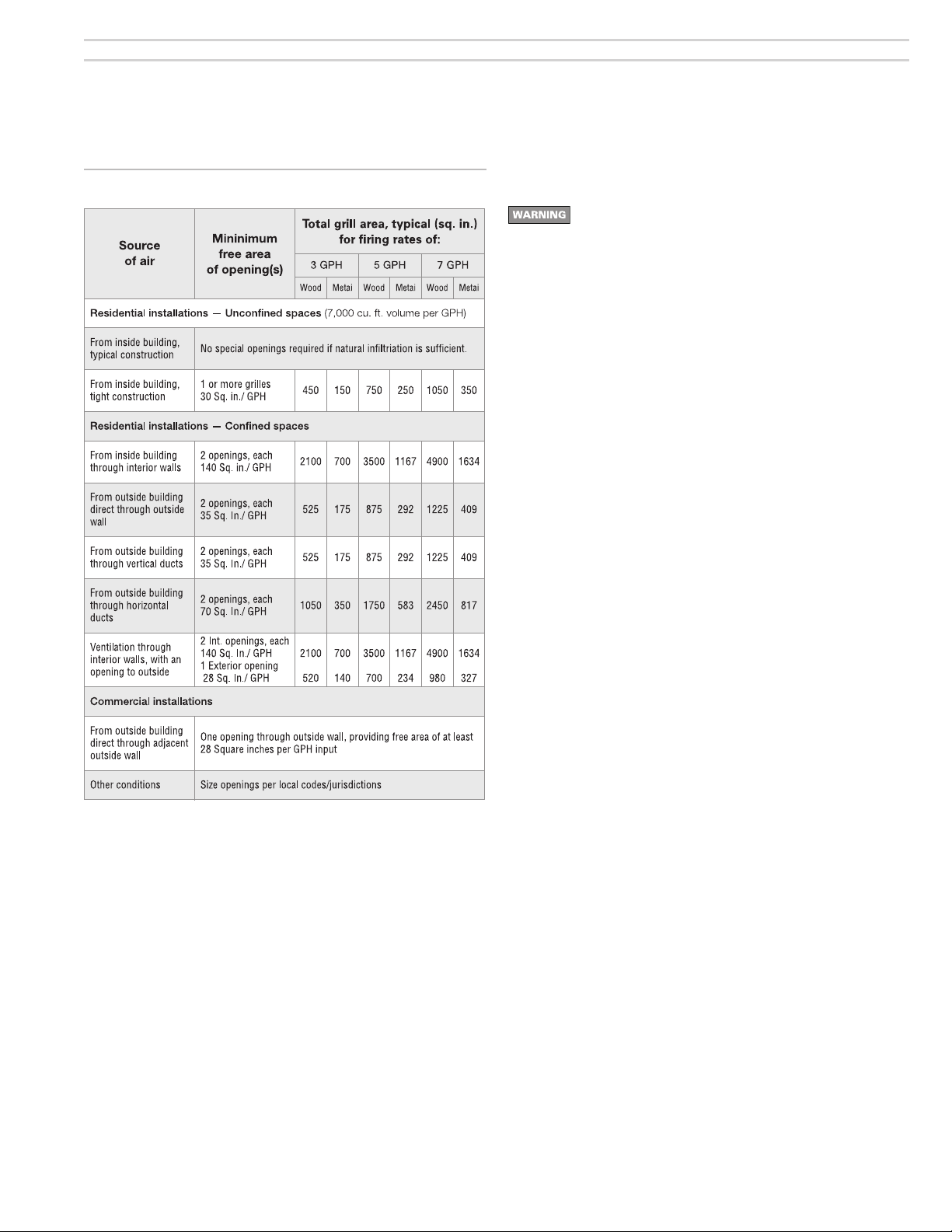

Free area — Louvers and screens

• Air opening sizes are always given in free area. This means after

deduction for louver obstruction. If you can’t fi nd the louver reduction

for the grilles used, assume free area is 20% of total for wood louvers,

or 60% of total for metal louvers.

• Screens can be no fi ner than ¼-inch mesh, and must be accessible

for cleaning.

Residential installation air openings

Residential — Unconfi ned spaces (at least 7,000 cubic feet per GPH)

• An unconfi ned space means a room with at least 7,000 cubic feet volume for

each GPH input (or 50 cubic feet per MBH) of all appliances in the room.

Example: For a boiler room housing a 6.00 GPH input burner/appliance, multiply

6 times 7,000 cubic feet, equals 42,000 cubic feet. The room must have a

volume of 42,000 cubic feet to be classifi ed as an unconfi ned space. (If the

boiler room has an 8-foot ceiling height, the room would have to have 5,250

square feet, or about 73 feet square.)

• Most boiler rooms do not provide this much volume, and must be treated as

confi ned spaces, requiring dedicated combustion air openings, sized as in the

following.

• Open residential basements and crawl spaces are often large enough, and

will generally allow enough air infi ltration, so special provisions will seldom be

required.

• If the building is tightly constructed, you will have to provide outside air openings into the building regardless of the boiler room volume. The total free area

of these openings must be at least 1 square inch per 5,000 Btuh (28 square

inches per GPH) of all appliances in the space.

• See Table 2 for a summary.

Residential — Confi ned spaces (less than 7,000 cubic feet per GPH)

• Air taken from inside building only —

• Provide two openings — one near the fl oor, the other near the ceiling. Provide

free area of 140 square inches per GPH input.

• If the building is tightly constructed, provide dedicated air opening(s) into the

building with at least 30 square inches free area per GPH.

• Air taken from outside —

• Direct through outside wall or vertical ducts:

Provide two openings — one near the fl oor, the other near the ceiling. Provide

free area of at least 35 square inches per GPH input.

• Through horizontal ducts:

Provide two openings — one near the fl oor, the other near the ceiling. Provide

free area of at least 70 square inches per GPH input.

• Ventilation air from inside, with combustion air from outside

• Size openings to interior to provide 140 square inches free area per GPH

input.

• Size the outside combustion air duct to provide 28 square inches free area per

GPH.

• See Table 2 for a summary.

Commercial installation air openings

Commercial — Air openings directly from outside to boiler room

• Provide one opening that provides a free area of at least 28 square inches

per GPH input.

Example: For a boiler room housing boilers totalling 10 GPH fuel oil input,

the area opening must have a free area of no less than 10 times 28, or

280 square inches. If the opening is wood louvered, divide by 20%, or the

opening must be 1400 square inches (about 38 inches by 38 inches). If

the opening is metal louvered, divide by 60%, or the opening must be 467

square inches (about 22 inches by 22 inches).

– 4 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

2. Prepare site • assemble burner • mount burner (continued)

Table 2 Minimum combustion/ventilation air openings

Combustion/ventilation air checklist

The burner may operate successfully under momentary

downdraft conditions, but sustained downdraft is unsafe.

• This can occur with an inadequate or incorrectly installed

chimney/vent.

• It can also occur in rooms/buildings equipped with exhaust

fans or unsealed return air ducts.

• Always check operation of the burner under all conditions

to verify vent system operates correctly.

• You may have to interlock the burner with exhaust fans to

shut burner off when fan operates; or provide make-up air

to the appliance room suffi cient to prevent any negative

pressure in the space.

• Failure to correct downdraft or negative room pressure

operation could result in severe personal injury, death or

substantial property damage.

Verify that openings are unobstructed.

Verify that appliance space and air source spaces are free of:

• Gasoline or other fl ammable liquids or vapors.

• Combustible materials.

• Air contaminants and chemicals, such as laundry products, paint, thinner,

varnish, etc.

Confi rm with the building owner that the area will be kept free of these

materials at all times and that air openings will be kept unobstructed.

Verify clearances

Verify that the burner/appliance will maintain all required clearances:

Verify clearance from combustible construction, as specifi ed by appliance

manufacturer and local codes.

Verify clearances for service and maintenance as required in the appliance

manual and applicable codes.

Vent system components must maintain all necessary clearances to

combustible construction, including the correct design of thimbles and

insulation where penetrating combustible walls.

Carlin part number MN2301A Rev. 10/21/10

– 5 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

2. Prepare site • assemble burner • mount burner (continued)

Verify combustion chamber

Chamber dimensions and construction

• If retrofi tting the burner to an appliance, install the burner in accordance

with the appliance instruction manual, when available. If no specifi c

application data is available from the appliance manufacturer, read the

guidelines below to check whether the burner is likely to work acceptably

in the application.

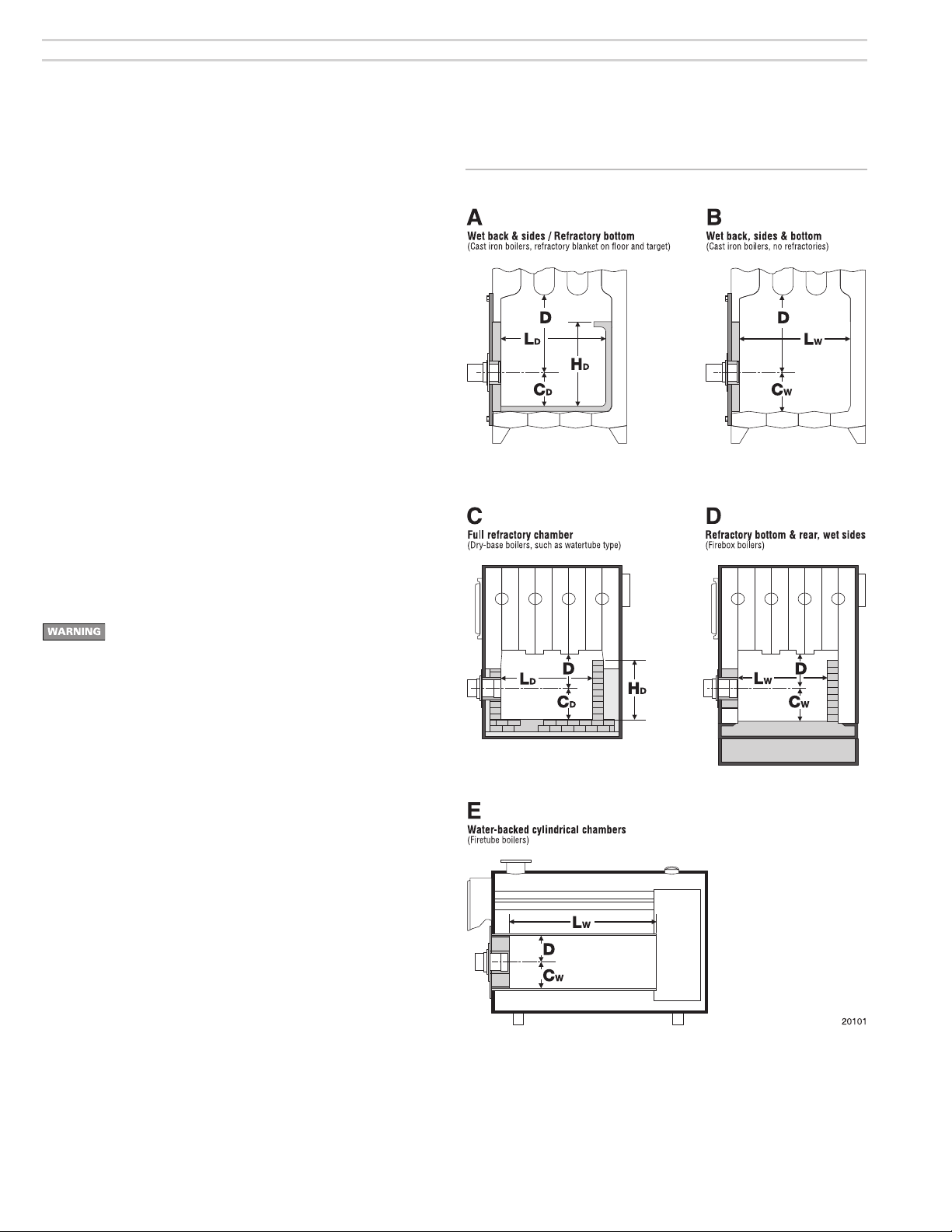

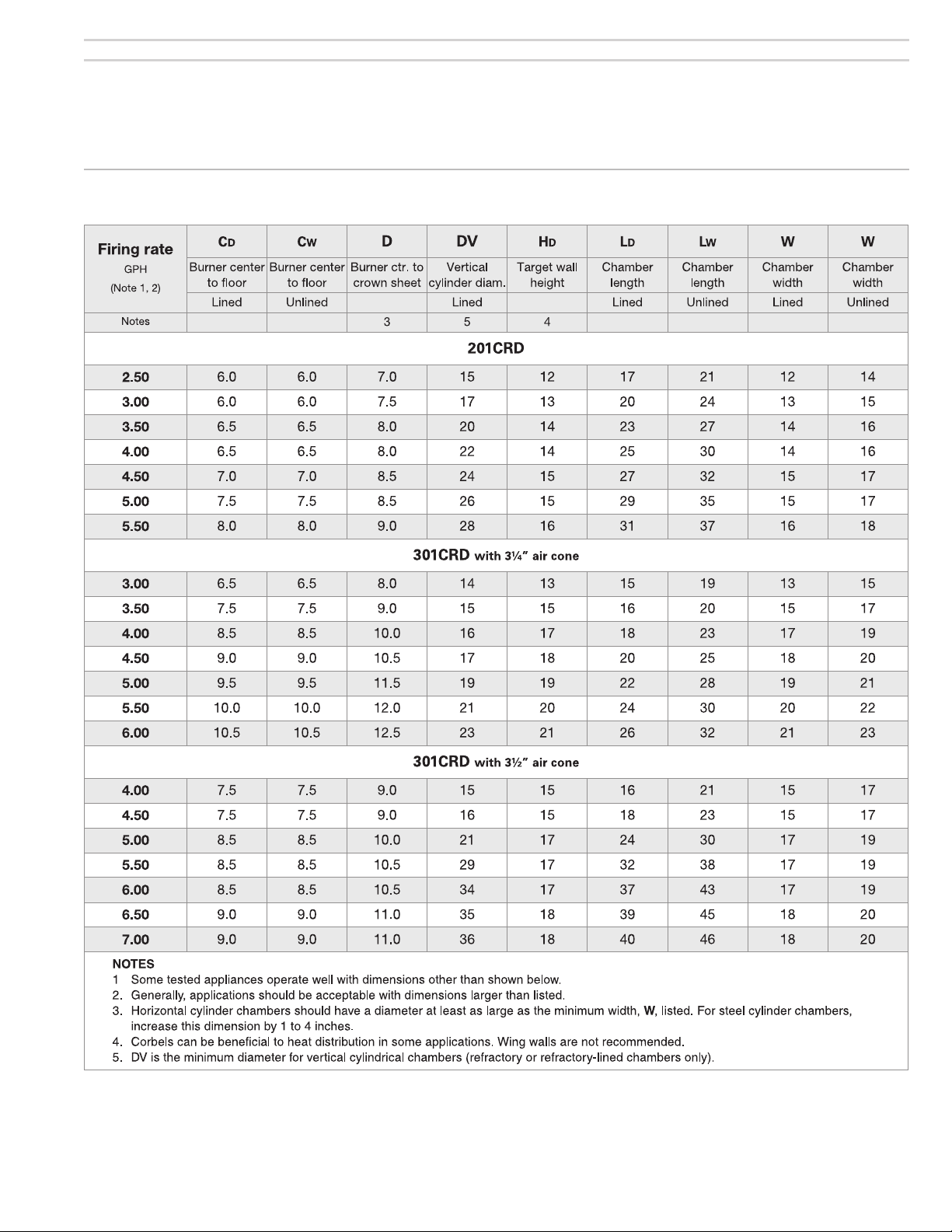

• Illustrations A to E in Figure 1 show different chamber confi gurations, with

and without refractory linings. The chamber dimensions listed in Table 3

depend on whether the chamber is lined or water-backed, as shown.

• Do not attempt to fi re the burner in a chamber with dimensions smaller

than shown in Table 3 unless the application has been specifi cally tested

and listed by the appliance manufacturer and/or Carlin.

• Chambers with dimensions larger than shown in Table 3 should not have

much effect on combustion/performance.

General guidelines

• Clean all appliance fl ues and heating surfaces thoroughly, removing all

soot and scale.

• Seal all joints and gaps using furnace cement to prevent excess air

infi ltration.

Read the WARNING on page 26 before handling or applying

ceramic fi ber materials.

Figure 1 Combustion chamber confi gurations, typical

Using chamber linings

• When using refractory liners or lightweight chambers, use insulating-type

refractory rated 2600°F minimum, or as specifi ed by the appliance manufacturer.

• You must install a target wall liner if fl ame length is close to the length of

the chamber.

• Use a fl oor liner when possible. The fl oor liner will improve fi ring in most

applications. Extend fl oor liner 3 to 4 inches up the side walls.

• Target wall liners — Extend target wall liners at least 3 to 4 inches above

the center of the fl ame corbel the top 1½ to 2½ inches deep.

• Use preformed chamber liners when available. Lining the fl oor and target

wall water-backed combustion chambers with lightweight insulating refractory will accomplish the same.

• When converting coal-fi red units, install a combustion chamber in the ashpit

area, or fi ll the ashpit with sand up to 2 inches above the “mud ring” of the

boiler (fi ring through the door). Install a lightweight refractory liner on the

target wall as in Figure 2D.

– 6 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

2. Prepare site • assemble burner • mount burner (continued)

Table 3 201CRD and 301CRD Minimum combustion chamber dimensions (all dimensions in inches) - See Figure 1 for combustion

chamber confi gurations

Carlin part number MN2301A Rev. 10/21/10

– 7 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

2. Prepare site • assemble burner • mount burner (continued)

Inspect burner and components

General

• Check the air tube length. Verify the usable length of the tube UTL will be

long enough (see “Mount burner in appliance”).

• Visually inspect all burner components and wiring.

• Verify that wiring is intact and leads are securely connected.

• Verify that all burner components are in good condition.

Do not install or operate the burner if any component is

damaged or if burner does not comply with other guidelines

of this manual and the appliance manual.

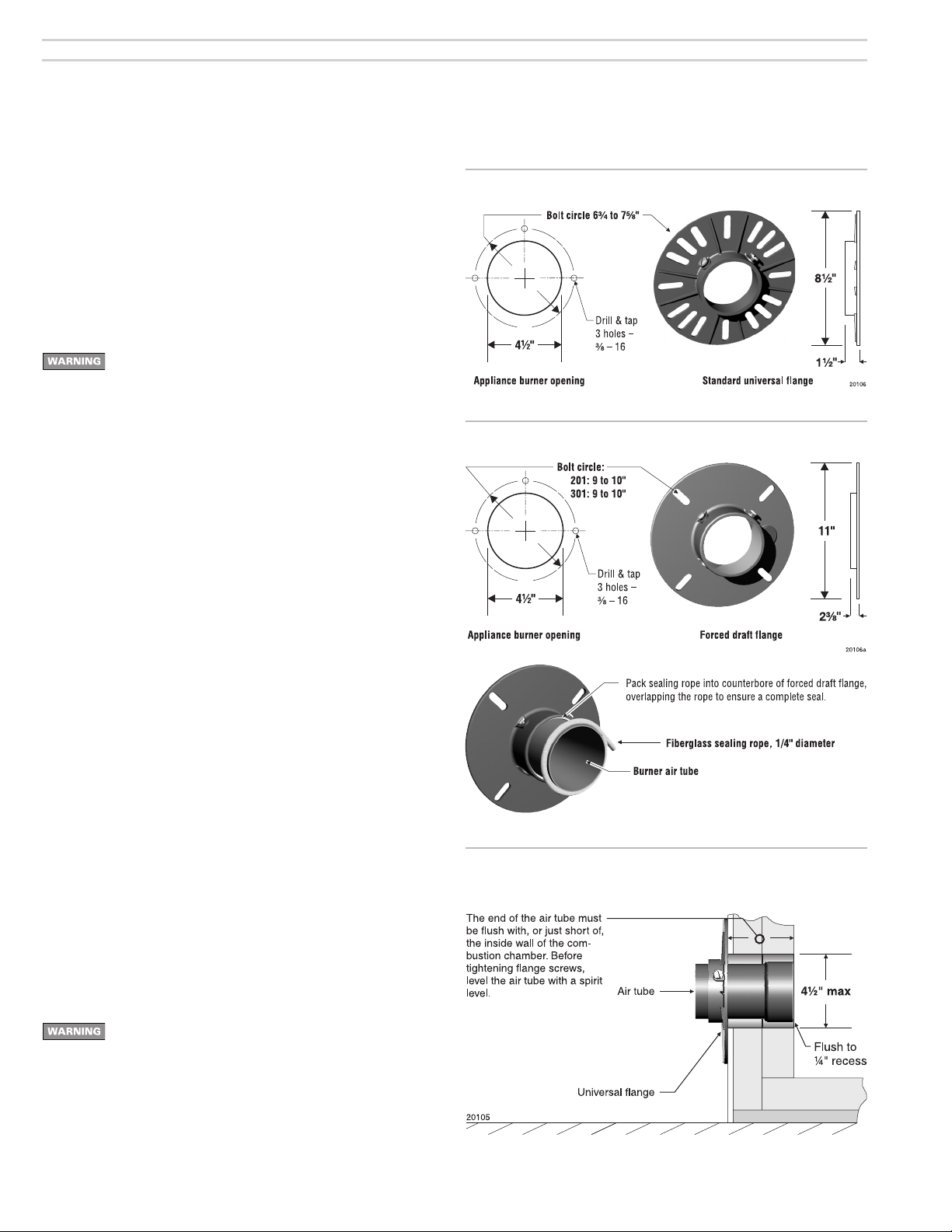

Install/check burner fl ange

Welded-fl ange burners

1. Verify the bolt pattern on the appliance chamber matches the fl ange pattern.

2. Verify the insertion depth (UTL) matches the depth of the appliance opening (so the end of the air tube is fl ush with, or slightly short of, the inside

surface of the combustion chamber).

Figure 2 Standard adjustable fl ange (universal fl ange)

Figure 3 Adjustable forced draft fl ange

Burners with adjustable fl anges

1. See Figure 2 for standard adjustable fl ange (universal fl ange) dimensions.

See Figure 3 for adjustable forced draft fl ange dimensions.

Verify the fl ange mounting slots line up with the appliance bolts.

2. Slip the adjustable fl ange onto the air tube.

3. Measure the distance from the inside of the combustion chamber to the

outside of the appliance mounting plate.

4. Position the adjustable fl ange at this distance from the end of the air

tube.

5. Tighten the locking screws fi nger tight.

6. Insert the air tube/fl ange assembly into the appliance opening and level

the air tube with a spirit level (see Figure 4). Adjust fl ange if needed.

7. The end of the air tube should be fl ush, or almost fl ush, with the inside of

the combustion chamber wall.

8. Verify the air tube is level and inserted the correct depth. Adjust if necessary.

Then tighten the fl ange locking screws securely.

9. Remove the fl ange/air tube assembly from the opening.

10. Forced draft adjustable fl anges: Use ¼-inch diameter fi berglass sealing

rope, as shown in Figure 3, to seal the fl ange to the air tube.

A forced draft adjustable fl ange must be sealed to the air

tube to prevent possible leakage of fl ue products. Failure

to comply could result in severe personal injury, death or

substantial property damage.

Figure 4 Mark insertion depth on air tube when using universal

fl ange mounting

– 8 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

2. Prepare site • assemble burner • mount burner (continued)

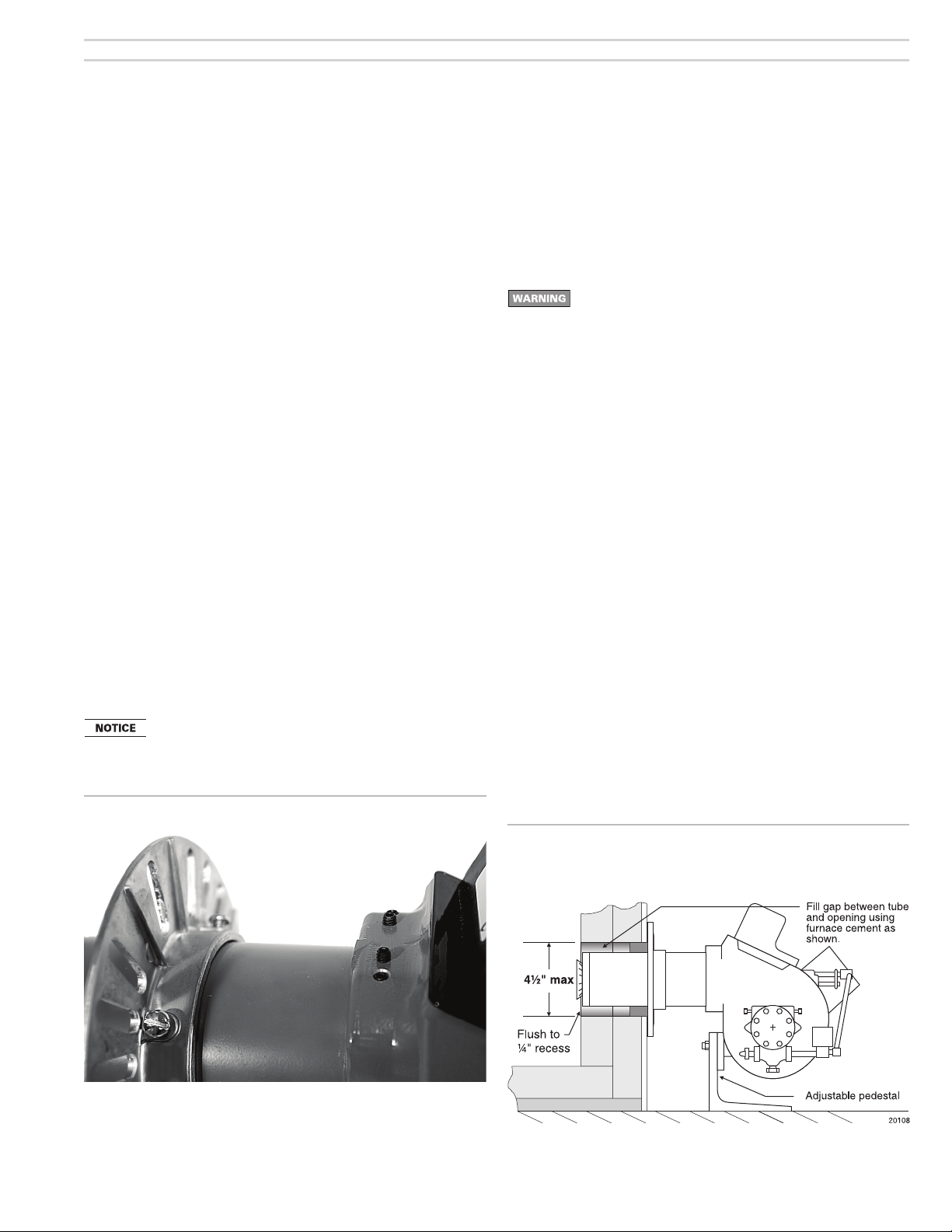

Pedestal-mounted burners

1. Check the diameter of the appliance opening. If larger than 4½ inches,

rebuild the opening so the open is reduced to 4½ inches maximum.

2. Insert the air tube into the appliance opening as in Figure 4. Do not attach

air tube to housing yet.

3. Slide the tube in until the end of the tube is fl ush with, or up to ¼ inch short

of, the inside of the combustion chamber.

4. Level the air tube using a spirit level.

5. Mark the air tube position with a pen or pencil around the circumference

of the tube.

6. Remove air tube from the opening

Attach air tube to housing

1. See Figure 5. Loosen the four hex set screws on the top front of the burner

chassis.

2. Open the ignitor cover plate by loosening the retainer screw on the left side

of the burner housing.

3. Swing the ignitor plate open.

4. Locate the drip hole in the burner air cone (301 burners) or throttle ring

(201 burners). Rotate the air tube so the drip hole is at the bottom.

5. Insert the air tube into the housing.

6. Make sure the air tube is inserted completely, butting against the air tube

socket ledge. If necessary, tap on the end of the air tube with a block of

wood until properly seated.

7. Secure the air tube by tightening the four hex set screws on the top front

of the burner housing.

On burners with welded fl anges, you can bolt the air tube/

fl ange to the appliance fi rst — then attach the housing to

air tube.

Figure 5 Attaching air tube to burner housing

Mount burner in appliance

Welded fl ange-mounted burner

1. Place gasket over burner air tube and insert burner into appliance opening.

Secure in place with hardware supplied with appliance.

Universal fl ange or pedestal mount — these insertion methods

are intended only for negative overfi re pressure. For pressurized fi ring, you must obtain a burner with a welded fl ange,

designed for use with the specifi c appliance. Failure to comply

could result in severe personal injury, death or substantial

property damage.

Adjustable fl ange-mounted burner

1. Place gasket over burner air tube.

2. Insert burner into appliance.

3. Verify burner is seated level and straight. Adjust fl ange slightly if necessary.

4. Secure fl ange to appliance with hardware supplied with appliance.

Pedestal-mounted burner

1. Assemble the pedestal to the burner and tighten the bolt. Insert a screw

into each of the two holes in the pedestal feet if needed to level the assembly.

2. Adjust the pedestal so the air tube is level and the center of the tube is at

the same height as the center of the appliance opening.

3. Tighten the pedestal bolt.

4. Insert the burner/air tube into the appliance opening until pen/pencil line is

even with appliance front (so end of air tube is fl ush with, or slightly short

of, the inside of the chamber).

5. Seal the space around the air tube with furnace cement or equivalent

(Figure 6).

Carlin part number MN2301A Rev. 10/21/10

Figure 6 Seal opening around burner air tube when pedestal

mounting (burner shown with tube attached to housing

and installed)

– 9 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

3. Prepare burner

Removing/installing head assembly

Use care when handling burner components after the burner

has been fi ring. Components can be hot and could cause

severe personal injury.

Removing the combustion head assembly

You will need to remove the combustion head assembly for inspection of

the assembly, replacement of the oil nozzle or adjustment of electrodes.

To remove the assembly:

1. Loosen the screw on the left side of the burner housing that secures the

ignitor plate in place. Swing the ignitor plate open.

2. See Figure 7.

3. Unscrew the oil line fi tting from the elbow at the end of the oil tube.

4. Remove the combustion head assembly by pulling the assembly up and

out of the housing.

7. Handle the assembly with care to avoid bending or moving the electrodes,

or damaging the electrode ceramic insulators.

8. Inspect the gasket on the bottom of the ignitor plate. The gasket prevents

air from escaping from the housing. Replace the gasket if not in good

condition.

9. Inspect the ignitor contact clips. Clean or replace if necessary to ensure

reliable contact with the electrodes.

Figure 7 Removing/inserting combustion head assembly

Figure 8 Inserting combustion head assembly

Replacing the combustion head assembly

To replace the combustion head assembly, reverse the sequence above.

• Make sure the oil line bracket seats into the slot on the adjusting screw.

• See Figure 8. You will have to lift the end of the assembly to guide it through

the throttle ring or air cone at the end of the air tube. DO NOT FORCE.

Use care when tightening the oil line fi tting to oil tube extension.

Tighten securely, but do not cross-thread or over-tighten.

– 10 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

3. Prepare burner (continued)

Install nozzle/check electrodes

1. Loosen the clamp screw on the retention ring assembly (see Figure 9,

step 1). Slide the retention ring assembly off of the nozzle adapter.

2. Install and tighten the nozzle listed in the appliance instruction manual or

Carlin OEM Spec Guide.

3. If nozzle information is not available, begin with the nozzle listed in Table 1,

page 3. (You may have to change the nozzle later if combustion results are

not acceptable.)

3. Hold the nozzle adapter securely as shown in Figure 9, steps 2 and 4, when

removing or replacing the nozzle. Take care not to damage the electrode

insulators or to bend the electrodes in the process.

Inspect the nozzle adapter before replacing the nozzle. If the

threads have been damaged or show score marks, replace

the nozzle line/adapter assembly.

4. Install the retention ring assembly by slipping one of the riveted arms

through the gap between the electrode tips. Align this arm straight up, with

the ring clamp fi rmly against the nozzle adapter shoulder (see Figure 10).

Then tighten the clamping screw.

5. Check the electrodes and reposition if necessary. Position the electrodes

as shown in Figure 10. These settings are critical in ensuring a reliable

ignition. Once the electrodes are set, check all clamps to be sure they are

securely tightened.

6. Insert the combustion head/nozzle assembly into the burner.

Figure 9 Replacing the oil nozzle —

1 – Remove retention ring from nozzle adapter

2 – Support the assembly carefully and remove the nozzle

using 5/8-inch and 3/4-inch open-end wrenches.

3 – Insert and fi nger-tighten the new nozzle.

4 – Support the assembly and tighten the nozzle using the

open-end wrenches.

NOTE: Do Not over tighten.

Figure 10 Electrode sett ings

Carlin part number MN2301A Rev. 10/21/10

– 11 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

3. Prepare burner (continued)

Set initial burner air settings

Combustion head (“A” dimension)

1. The combustion head adjusting screw is used to set the spacing between

the retention ring and throttle ring (or air cone), regulating how much air

passes around the retention ring.

2. See Figure 11.

3. Rotate the head adjusting screw until the distance from the housing detent

to the beginning of the scale equals the value given in Table 4, page 13

(“A” dimension).

Air band

1. See Figure 12. Loosen the air band locking screw and rotate the air band

until the opening equals the percent opening given in Table 4, page 13.

Final adjustments

1. The burner is now adjusted to the approximate air settings for the fi ring

rate chosen.

2. When you check combustion with instruments during start-up or servicing,

you may have to adjust the head and/or air band slightly to achieve the

desired effi ciency.

• Increase the combustion head setting (“A” dimension) to increase air. If

additional adjustment is needed, open the air band slightly.

• Decrease the combustion head setting (“A” dimension) to decrease air. If

additional adjustment is needed, close the air band slightly.

3. See “Adjust burner using test instruments,” page 20.

4. Note that positive pressure overfi re will reduce air fl ow, requiring more air

opening.

Figure 12 Air band setting

Figure 13 Combustion head/air tube combinations, typical

Figure 11 Combustion head setting

– 12 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

3. Prepare burner (continued)

Table 4 Approximate air band and combustion head settings

• Check all connections and joints to ensure they are air-tight.

• Use fl are fi ttings. DO NOT use compression fi ttings.

• Never use pipe sealing tape. Fragments can break off and plug fuel line

components.

• Install a shut-off valve at the tank and one near the burner. (Use fusible

handle design valves when possible or when required by codes.)

• Install a large capacity fuel fi lter (rated for 50 microns or less) near the

burner.

Fuel supply to multiple burners

• When possible, use separate fuel supply lines for each oil burner. Using

manifolded oil supply lines can create problems. If the lines are undersized,

operating vacuum will exceed limits. If the lines are oversized, fuel units

may have diffi culty priming. Because the lines must be sized to handle the

capacity of all the burners, the line size will almost always be too large

when only a single burner is running.

• If manifolding cannot be avoided, carefully size the lines following the fuel

units manufacturer’s instructions.

Fuel unit bypass plug

The fuel unit is shipped with its bypass plug not installed,

intended for a one-line oil system. Install the bypass plug

only if connecting to a two-line oil system. Operating with

the plug in place on a one-line system will damage the fuel

unit and could lead to oil leakage and fi re hazard.

Inspect/install fuel supply

Inspect the oil supply system. Ensure that the fuel lines are

correctly sized and installed and that the fuel fl ow is unobstructed, the oil tank is clean and only # 1 or # 2 heating oil

are supplied. Failure to supply a reliable oil fl ow could result

in loss of heat and potential severe equipment damage.

General guidelines:

• When installing oil lines, use continuous runs of heavy-wall copper tubing

if possible.

• Check fuel unit (oil pump) data sheet for recommended line sizing, lift

limitations and maximum length.

If the fuel line or fuel supply is above the burner, never exceed

3 PSIG pressure at the fuel unit inlet. Install a suitable OSV to

reduce the pressure. Operating the fuel unit with higher inlet

pressure could result in fuel unit seal damage, oil leakage

and potential fi re hazard.

Fuel unit vacuum limitations

• The sizing information in this manual applies only to the fuel units listed.

For other fuel units, refer to the manufacturer’s installation instructions.

• Attach a vacuum gauge to either of the fuel unit inlet ports, and verify the

vacuum does not exceed the limit below for all fi ring conditions.

• The vacuum at the fuel unit inlet port must not exceed the value below.

• One-line installations:

Model A2YA pump or B2YA pump 6 in. Hg

Model J pump or H pump 2 in. Hg

• Two-line installations:

Model A2YA pump or J pump 12 in. Hg

Model B2YA pump or H pump 17 in. Hg

Carlin part number MN2301A Rev. 10/21/10

– 13 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

3. Prepare burner (continued)

One-line fuel system requirements

• See Figure 14.

• The standard burner fuel unit is a single-stage, 3450-RPM oil pump. Apply

this fuel unit only on one-line systems where the fuel supply is on the same

level with, or higher than, the burner. This ensures oil fl ow by gravity.

• Also make sure the total lift does not exceed 8 feet (height difference from

bottom of oil tank to fuel unit) when the fuel unit is a Model A2YA or B2YA;

or 2 feet when the fuel unit is a Model J or H.

• For other conditions, you must provide a two-line fuel system. You may also

have to change the fuel unit to a two-stage type.

One-line oil systems must be air-tight, to avoid air leaks into

the system or loss of prime. Use pipe dope where necessary,

but never use tape sealants. Verify the operating vacuum

does not exceed the limit given in this manual or the fuel

unit manufacturer’s instructions. Failure to comply could

result in sever personal injury, death or substantial property

damage.

Figure 14 One-line fuel system

Figure 15 Two-line fuel system

Table 5 Two-line fuel system maximum lengths for copper tubing

distribution. Use only for burners equipped with the

Suntec fuel units listed. See fuel unit data sheet for any

other fuel unit.

Two-line fuel system requirements

• See Figure 15 and Table 5. Use Table 5 only for burners equipped with the

Suntec fuel units listed. For burners using other fuel units, follow the fuel

unit manufacturer’s instructions for line sizing.

• Follow the guidelines in this manual regarding maximum lift and maximum

operating vacuum. If the fuel system exceeds the limits given in this manual

or the fuel unit manufacturer’s instructions for a single-stage pump (standard), install a two-stage fuel unit. If limits are still exceeded, follow the

fuel unit manufacturer’s instructions for installation of transfer pump(s) if

necessary.

• Always size fuel lines using an oil fl ow rate based on the fuel unit gearset

capacity, not the burner fi ring rate. See fuel unit data sheet for information.

Install the fuel unit bypass plug when connecting to a two-line

system. The plug is shipped in a bag attached to the fuel unit,

along with a fuel unit data sheet.

– 14 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

3. Prepare burner (continued)

Oil fl ow schematics / fuel unit connections

• Figures 16, 17 and 18 show oil fl ow for Carlin 201 and 301 burners and

show port functions for Suntec Model A, B, J and H pumps.

• Figure 18 applies only for optional NYC-DAR pressure regulation kits.

Figure 16 201/301 burner with Suntec Model J or H fuel unit

Figure 18 201/301 burner with NYC-DAR pressure regulation kit

Obtain pressure regulator kits for New York City Department

of Air Resources. Kits must be set for the proper nozzle pressure.

Perform checkout procedures

Figure 17 201/301 burner with Suntec Model A or B fuel unit

Verify before starting burner:

Should overheating or an emergency occur, immediately:

• Shut off oil supply line valve.

• Under some circumstances power should remain on for

water pumps or blowers. Determine proper response before

attempting start-up.

• If burner fails ignition on several attempts, use burner

blower to purge appliance chamber before restart.

Checklist

Burner/appliance installed per appliance instruction manual?

Burner nozzle verifi ed per appliance manufacturer’s instructions,

Carlin OEM Spec Guide or Table 1, page 3?

Burner/appliance installed per all applicable codes?

Installation site has adequate combustion/ventilation air openings

and vent system?

Fuel supply line in good condition and sized/designed correctly?

Oil tank has oil and oil line valves are open.

Carlin part number MN2301A Rev. 10/21/10

Wiring installed per burner manual and appliance instructions?

Burner, appliance and all components inspected and in good

condition?

– 15 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

4. Wire burner • start burner — 50240 primary control

Turn off power to appliance when servicing burner. Failure to comply could result in severe personal injury, death or substantial property damage.

Wire burner — 50240 primary control

1. All wiring must comply with:

• In the U.S — the National Electrical Code, ANSI Z223.1/NFPA 54.

• In Canada — the Canadian Electrical Code Part 1, CSA standard C22.1.

• All applicable local codes/standards.

2. Wire the burner following Figure 20 and any special instructions or wiring

diagram provided with the appliance, burner or other components.

3. The burner requires a 240 VAC/60 hz/single-phase power supply, with a 5-amp

fuse. The current draw (equipped with Carlin PSC motor) will be approximately

1.6 amps.

4. The 50240 thermostat terminals provide a 200ma for thermostat power source.

Never apply external power to these terminals under any circumstances. To

avoid this problem when using zone valves, disconnect fi eld wires from 50240

thermostat terminals. Then connect a voltmeter across terminals. Operate all

zones and verify that there is never a voltage reading at the meter. A voltage

reading indicates incorrect wiring that must be corrected before attempting to

operate the burner.

5. Alarm terminals provide a 24 vac-rated dry contact, suitable for use with

security/fi re alarm systems such as Carlin SecureHeat™.

6. Make sure the burner and appliance are correctly wired and the line switch is

properly fused for the load.

To start burner

Do not start the burner if the combustion chamber contains

oil or oil vapor.

1. Turn service switch OFF.

2. Perform inspections and checkouts on pages 18 and 19.

3. Slip one end of a 3/16-inch I.D. clear plastic hose over end of bleed valve, the

other end into a container. Then open bleed valve.

4. Set thermostat (operating controls) to call for heat.

5. Turn service switch ON.

6. Bleed oil line until plastic line is free of bubbles; then another 15 seconds longer.

(Should the primary control timing cause a lockout during purging, restart the

burner following the primary control data sheet instructions.)

7. Close bleed valve. The burner should cycle through the sequence given in the

primary control data sheet.

8. Perform primary control fl ame failure lockout and safety timing tests per instructions in primary control data sheet.

9. Should control/burner fail to operate correctly, see page 19 for suggestions in

troubleshooting.

Figure 20 201CRD and 301CRD burners wiring using Carlin 50240 primary control (see appliance manual or separate wiring information

for burner equipped with a primary control not covered in this manual)

– 16 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

Start-up & operation

Do not start the burner if the combustion chamber contains

oil or oil vapor.

Per UL requirements, the control will not turn on if the cad

cell senses fl ame during the self-test. If the cad cell sees

light, the control will remain in self-test mode until the cad

cell no longer senses light (fl ame). The amber LED will re-

main on, but blink off momentarily

Check 50240 control label for trial for ignition (TFI)timing.

Power ON Open all manual oil line valves. Close the line switch. (If Red light

Self-test 1 Each time the limit circuit sends power to the black wire, the con-

Stand-by (Thermostat circuit open, limit circuit closed) If Self-test 1 is

Call for heat Set thermostat to call for heat. Thermostat circuit must close (and

Self-test 2 The amber LED turns on. For the fi rst 3 to 4 seconds, the control

Burner on After the self-test, amber LED turns off. The ignitor starts, fol-

TFI The cad cell must sense fl ame within the TFI time limit (trial for

Run The burner continues fi ring during call for heat if the cad cell

Lockout If cad cell does not sense fl ame within 15 seconds after burner

To Reset Push in and hold reset button for 1 second, then release.

Latch-up If the control locks out 3 times during a single call for heat, latch-

After the LED’s begin fl ashing, continue holding the reset button

Push in and hold the reset button for about 10 seconds. The

Flame failure If the cad cell loses fl ame signal during operation (after the TFI),

End cycle Set thermostat (or aquastat) to stop call for heat. The burner shuts

Stand-by Control remains in stand-by mode until limit circuit sends power to

Carlin part number MN2301A Rev. 10/21/10

turns on constant

trol performs a “boot-up” test to verify internal operation. About 4

seconds after power application, the amber LED turns on. The test

continues for about 6 more seconds. If the test fails, the control

turns the amber LED off and repeats this test sequence until successful. (This test occurs on every call for heat cycle if burner is

operated by a limit control (terminals “T-T” jumpered).

successful, amber LED turns off and control waits for thermostat

circuit to close.

black wire must receive power from the limit circuit).

performs a self-test. If the cad cell senses fl ame, the control

repeats this test until fl ame is no longer detected. During this time,

the amber LED remains on, but blinks off momentarily

to 4 seconds. If the control detects motor contacts closed, lockout

occurs.

lowed 1 second later by the motor. The electronic time delay relay

allows the oil valve to open 4 seconds later.

ignition). After cad cell senses fl ame, the ignitor stays on another

10 seconds (fl ame stabilization period).

senses fl ame. LED’s are off during normal running.

starts, lockout occurs. The control turns the red LED on constant,

and closes the alarm contact.

up occurs. The control turns on both the amber and red LED’s

constant. You must use the special procedure below to reset the

control after latch-up.

Reset after latch-up — Only a qualifi ed service techni-

cian should attempt to reset the control after latch-up. The

problem that caused the repeated burner problems must be

corrected before returning the burner to normal operation.

amber and red LED’s will begin to fl ash alternately.

for about another 20 seconds. The LED’s will turn off. Release the

reset button and the control will restart. (Releasing the button before the LED’s turn off will cause the control to remain in latch-up.)

The 50240 control will not reset from lockout or latch-up if power is

interrupted.

the red LED fl ashes. The burner shuts off within 2 seconds. Re-

cycle: Control waits for 65 seconds (with red LED fl ashing), then

begins again at Self-test 2. Red LED goes off

off within 2 seconds after end of call for heat.

the black wire (call for heat).

, control is in lockout. See below to reset.)

every 3 to 4 seconds.

every 3

.

Model 50240 diagnostic LED’s

– Red OFF – Red ON – Red FLASHING

– Amber OFF – Amber ON – Amber FLASHING

– Amber BLINKING (blinks off momentarily every 3 to 4 seconds)

Service & Troubleshooting

Burner (control) will not come on

No power to control

• Check line voltage to the control (at least 102

VAC).

• Check all electrical connections.

Control is in lockout

• Red LED will be on. Press the reset button for 1 second.

• If the control returns immediately to lockout, The Safety

Monitoring Circuit may have detected an internal control problem. Replace the control.

CAD cell seeing light

• Amber LED blinks off each 3 to 4 seconds. Remove

one yellow lead from FF terminal on the control.

If the amber LED remains on

with a wire detached,

the control is defective.

If amber LED goes off

• light is leaking into the burner housing,

, control is OK, and:

OR

• CAD cell is defective, OR

• there is a problem with the CAD cell wiring or holder.

• If appliance was recently shut down, CAD cell may

see residual hot spots in chamber.

To troubleshoot:

• Check CAD cell by unplugging it and measuring

the resistance across its pins: dark resistance at

least 50

10

KOHMS; room light resistance less than

KOHMS. Replace if necessary. If the CAD cell

functions properly, reinstall the cell and close the

burner housing.

• Check for stray light by measuring the CAD cell

resistance looking into the inactive combustion

chamber. It should read at least 50

KOHMS.

Repeated fl ame failures ( fl ashing red LED)

Check for:

• CAD cell is defective.

• Air leaking into oil line causing fl ame out — Check oil line

connections and fi lter gasket.

• Defective nozzle causing fl ame to be erratic — Change

nozzle.

• Excessive airfl ow or draft causing fl ame to leave burner

head — Check for proper air shutter setting and draft.

• Excessive back pressure causing fl ame to be erratic —

Check appliance and fl ue for sooting/plugging.

Control locks out after TFI ( red LED on)

Check for:

• No oil to burner — Check oil supply, fi lter, lines.

• Shorted electrodes — Inspect for cracked porcelain and

• Poor spark — Check electrode spacing and condition per

• Nozzle clogged — Replace nozzle.

• Airfl ow too high — Check air shutter setting.

• Ignitor module defective — Replace if no spark.

• CAD cell defective.

• Oil valve stuck in closed position.

• Check wiring connections.

replace as needed.

burner manual. Replace or realign if necessary.

– 17 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

4. Wire burner • start burner — 60240 primary control

Turn off power to appliance when servicing burner. Failure to comply could result in severe personal injury, death or substantial property damage.

Wire burner — 60240 primary control

1. All wiring must comply with:

• In the U.S — the National Electrical Code, ANSI Z223.1/NFPA 54.

• In Canada — the Canadian Electrical Code Part 1, CSA standard C22.1.

• All applicable local codes/standards.

2. Wire the burner following Figure 21 and any special instructions or wiring

diagram provided with the appliance, burner or other components.

3. The burner requires a 240 VAC/60 hz/single-phase power supply, with a 5-amp

fuse. The current draw (equipped with Carlin PSC motor) will be approximately

1.6 amps.

4. The 60240 thermostat terminals provide a 200ma for thermostat power source.

Never apply external power to these terminals under any circumstances. To

avoid this problem when using zone valves, disconnect fi eld wires from 60240

thermostat terminals. Then connect a voltmeter across terminals. Operate all

zones and verify that there is never a voltage reading at the meter. A voltage

reading indicates incorrect wiring that must be corrected before attempting to

operate the burner.

5. Alarm terminals provide a 24 vac-rated dry contact, suitable for use with

security/fi re alarm systems such as Carlin SecureHeat™.

6. Make sure the burner and appliance are correctly wired and the line switch is

properly fused for the load.

To start burner

Do not start the burner if the combustion chamber contains

oil or oil vapor.

1. Turn service switch OFF.

2. Perform inspections and checkouts on pages 20 and 21.

3. Slip one end of a 3/16-inch I.D. clear plastic hose over end of bleed valve, the

other end into a container. Then open bleed valve.

4. Set thermostat (operating controls) to call for heat.

5. Turn service switch ON.

6. Bleed oil line until plastic line is free of bubbles; then another 15 seconds longer.

(Should the primary control timing cause a lockout during purging, restart the

burner following the primary control data sheet instructions.)

7. Close bleed valve. The burner should cycle through the sequence given in the

primary control data sheet.

8. Perform primary control fl ame failure lockout and safety timing tests per instructions in primary control data sheet.

9. Should control/burner fail to operate correctly, see page 21 for suggestions in

troubleshooting.

Figure 21 201CRD and 301CRD burners wiring using Carlin 60240 primary control (see appliance manual or separate wiring information

for burner equipped with a primary control not covered in this manual)

– 18 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

Start-up & operation

Do not start the burner if the combustion chamber contains oil or

oil vapor.

Per UL requirements, the control will not turn on if the cad cell

senses fl ame during the self-test. If the cad cell sees light, the

control will remain in self-test mode until the cad cell no longer

senses light (fl ame). The amber LED will remain on, but blink off

momentarily

Check 60240 control label for trial for ignition (TFI), pre-purge

and post-purge timings.

Power ON Open all manual oil line valves. Close the line switch. (If Red LED turns

Self-test 1 The control performs a “boot-up” test to verify internal operation each

Stand-by (No call for heat) If Self-test 1 is successful, amber LED turns off and

Call for heat Set thermostat (or limit) to call for heat. Thermostat circuit must be

Self-test 2 The amber LED turns on. For the fi rst 3 to 4 seconds, the control per-

Burner on After the self-test, amber LED turns off. The ignitor starts, followed 1

Pre-purge The oil valve opens after the valve delay-on period (pre-purge).

TFI The cad cell must sense fl ame within the TFI time limit (trial for ignition).

Run The burner continues fi ring during call for heat if the cad cell senses

Lockout If cad cell does not sense fl ame within the TFI time limit after burner

To Reset Push in and hold reset button for 1 second, then release.

Latch-up If the control locks out 3 times during a single call for heat, latch-up

Push in and hold the reset button for about 10 seconds. The amber and

After the LED’s begin fl ashing, continue holding the reset button for

Flame failure If the cad cell loses fl ame signal during operation (after the TFI), the

Post-purge Set thermostat (or aquastat) to stop call for heat. The oil valve (if

Stand-by Control remains in stand-by mode until limit circuit sends power to the

Carlin part number MN2301A Rev. 10/21/10

on constant

time power is applied to the red/white wire. About 4 seconds after

power application, the amber LED turns on. The test continues for

about 6 more seconds. If the test fails, the control turns the amber LED

off and repeats this test sequence until successful.

control waits for heat call.

closed and power coming to black wire from limit circuit.

forms a self-test. If the cad cell senses fl ame, the control repeats this

test until fl ame is no longer detected. During this time, the amber LED

will remain on, but blink off momentarily

control detects motor contacts closed, lockout occurs.

second later by the motor.

After cad cell senses fl ame, the ignitor stays on another 10 seconds

(fl ame stabilization period).

fl ame. Both LED’s are off during normal running.

starts, lockout occurs. The control turns the red LED on constant, and

closes the alarm contact.

occurs. The control turns on both the amber and red LED’s constant.

You must use the special procedure below to reset the control after

latch-up.

Reset after latch-up — Only a qualifi ed service technician should

attempt to reset the control after latch-up. The problem that

caused the repeated burner problems must be corrected before

returning the burner to normal operation.

red LED’s will begin to fl ash alternately.

about another 20 seconds. The LED’s will turn off. Release the reset

button and the control will restart. (Releasing the button before the

LED’s turn off will cause the control to remain in latch-up.)

The 60240 control will not reset from lockout or latch-up if power is

interrupted.

red LED fl ashes. The oil valve closes within 2 seconds. The motor re-

mains on for the motor delay off period, then shuts off. (If no oil valve is

wired to the control, the burner shuts down within 2 seconds.) Recycle:

Control waits for 65 seconds (with red LED fl ashing), then begins again

at Self-test 2. Red LED goes off

installed) will turn off within 2 seconds. The motor remains on for the

motor delay off period (post-purge), then turns off. (If no oil valve is

wired to the control, the burner shuts off within 2 seconds after end of

call for heat. There is no post-purge.)

black wire and thermostat circuit closes (call for heat).

every 3 to 4 seconds.

, control is in lockout. See below to reset.)

every 3 to 4 seconds. If the

.

Model 60240 diagnostic LED’s

– Red OFF – Red ON – Red FLASHING

– Amber OFF – Amber ON – Amber FLASHING

– Amber BLINKING (blinks off momentarily every 3 to 4 seconds)

Service & Troubleshooting

Burner (control) will not come on

No power to control

• Check line voltage to the control (at least 102

VAC).

• Check all electrical connections.

Control is in lockout

• Red LED will be on. Press the reset button for

1 second.

• If the control returns immediately to lockout, the

Safety Monitoring Circuit may have detected an

internal control problem. Replace the control.

CAD cell seeing light

• Amber LED blinks off each 3 to 4 seconds. Remove

one yellow lead from FF terminal on the control.

If the amber LED remains on

with a wire de-

tached, the control is defective.

If amber LED goes off

• light is leaking into the burner housing,

, control is OK, and:

OR

• CAD cell is defective, OR

• there is a problem with the CAD cell wiring or

holder.

• If appliance was recently shut down, CAD cell

may see residual hot spots in chamber.

To troubleshoot:

• Check CAD cell by unplugging it and measuring the resistance across its pins: dark resistance at least 50

less than 10

KOHMS; room light resistance

KOHMS. Replace if necessary. If

the CAD cell functions properly, reinstall the

cell and close the burner housing.

• Check for stray light by measuring the CAD

cell resistance looking into the inactive combustion chamber. It should read at least 50

KOHMS.

Repeated fl ame failures ( fl ashing red LED)

Check for:

• CAD cell is defective.

• Air leaking into oil line causing fl ame out — Check oil

line connections and fi lter gasket.

• Defective nozzle causing flame to be erratic —

Change nozzle.

• Excessive airfl ow or draft causing fl ame to leave

burner head — Check for proper air shutter setting

and draft.

• Excessive back pressure causing fl ame to be erratic

— Check appliance and fl ue for sooting/plugging.

Control locks out after TFI ( red LED on)

Check for:

• No oil to burner — Check oil supply, fi lter, lines.

• Shorted electrodes — Inspect for cracked porcelain

and replace as needed.

• Poor spark — Check electrode spacing and condition

per burner manual. Replace or realign if necessary.

• Nozzle clogged — Replace nozzle.

• Airfl ow too high — Check air shutter setting.

• Ignitor module defective — Replace if no spark.

• CAD cell defective.

• Oil valve stuck in closed position.

• Check wiring connections.

– 19 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

5. Adjustment and verifi cation

Adjust burner using test instruments

1. Operate burner for 15 minutes before making fi nal adjustments using test

equipment.

2. Check for leaks in fuel piping.

Inspect fuel piping system for leaks. Repair any leaks to avoid

fi re hazard from oil leakage or combustion problems due to

air infi ltration into oil.

3. Inspect fl ame

• Look at fl ame through appliance combustion chamber observation port.

The fl ame should be well-defi ned and should not impinge on any appliance

surface. (If you make air changes later, inspect the fl ame again.)

Do not attempt to confi rm combustion simply by inspecting

the fl ame visually. You must use combustion test instruments.

Failure to properly verify/adjust combustion could allow unsafe

operation of the burner, resulting in severe personal injury,

death or substantial property damage.

4. Insert test probe into vent sample opening to sample fl ue products.

5. With the burner equipped with the correct oil nozzle, combustion head

setting and air band setting, the fl ue products will usually contain between

11% and 12% CO

6. Use combustion test equipment to verify that burner is properly set up for

your installation, within the range listed in Table 3. Appliances with positive

pressure in the chamber may require a wider air opening. See appliance

instructions for details. Verify/adjust settings by testing with instruments.

a. Check smoke. It should be zero on the Bacharach scale.

b. Set the appliance fl ue damper or barometric draft regulator so the draft or

pressure in the vent complies with the appliance manufacturer’s instructions.

c. If no draft setting information is available, set the draft to –0.01 to –0.02

inches w.c. at the appliance fl ue outlet.

(5.9% and 3.8% O2) and zero (Bacharach) smoke.

2

Firing against positive overfi re

pressure

1. Burner rating maximum inputs are based on operation with zero to slightly

negative pressure overfi re, typically 0.01 to 0.03 inches w.c.

2. When a burner is applied to an appliance that operates with a higher pressure overfi re, the maximum fi ring rate decreases because the maximum

available air fl ow from the burner blower decreases.

3. Read the graph below in Figure 22 to fi nd the maximum burner fi ring rate

at positive overfi re pressures.

Do not apply 201CRD or 301CRD burners at positive overfi re

pressure higher than shown in Figure 19 unless the application has been factory pretested.

Figure 22 Maximum fi ring rate decreases as overfi re pressure

increases

Heating units designed for natural draft operation are normally

set for a slightly negative pressure, usually –0.01 to –0.02

inches w.c. draft at the combustion chamber test port. Appliances designed for forced draft (positive pressure in the

chamber) must be air-tight to prevent exfi ltration of harmful

combustion products. Failure to properly set draft for the

appliance could result in severe personal injury or death.

d. Check percent of CO2 (or O2). Fine tune the burner, if necessary, by slightly

adjusting the head position for more or less air.

e. Each time you change the burner air band or combustion head setting,

you will have to check and possibly adjust the draft.

f. Recheck smoke (should be zero) and fl ue or chamber pressure/draft (adjust

if necessary and retest).

All installations should be checked after one to two weeks of

operation to ensure the appliance/burner units are operating

correctly.

– 20 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

5. Adjustment and verifi cation (cont.)

Verify burner/appliance operation

Check burner / appliance / controls

operation

Test operating and limit controls on appliance as specifi ed in appliance

instructions.

Check operation of the primary control by forcing lockout to occur. For

primary controls that enter latch-up after multiple lockouts, force latch-up

to occur as well. Reset primary control per control data sheet instructions

after each test.

Start and stop the burner several times, allowing the primary control to

sequence through normal operation. Verify correct operation of burner and

primary control throughout.

Verify vent system operation

Verify vent is operating correctly and fl ue products are properly exhausted

from building. If the building contains any exhaust fans or conditions that

could affect vent performance, check burner/appliance/vent operation with

exhaust fans (or other conditions) operating.

Combustion/ventilation air

Verify combustion/ventilation air openings are not/will not be obstructed.

Verify air opening louvers are fully open.

If louvers are motor-operated, verify motor and end switch are interlocked

with appliance/burner wiring to prevent operation of the burner if the air

louvers are not fully opened.

Prepare burner for normal operation

Cycle burner off with appliance controls.

Turn off power to the appliance.

Seal the appliance fl ue test opening.

Verify all components and wires are in place and burner is ready for opera-

tion.

Restore power to the appliance.

6. Annual start-up and service

Annual start-up & service

This burner must be started and serviced at least annually

by a qualifi ed service technician. Failure to properly maintain

and service the burner could result in severe personal injury,

death or substantial property damage.

Discuss burner/appliance operation with user to determine any problems

that may have occurred during the previous season and to verify user is

aware of proper operation and care of the burner/appliance.

Review proper operation of the appliance/burner unit with the user.

Turn off power to appliance.

Remove combustion head assembly to clean and adjust if necessary. (See

procedure on page 10.)

If the inside surface of the air tube and/or retention ring need to be cleaned,

clean them with a vacuum cleaner with brush attachment while the combustion head assembly is out of the burner.

Replace the oil nozzle with the correct size specifi ed in this manual or the

OEM guide.

Inspect and adjust the ignition electrodes and insulators per instructions

on page 11 of this manual. Replace if proper spacing cannot be achieved

or if components are damaged.

Close the housing cover plate and secure in place.

Inspect the fuel line oil fi lter. Replace if necessary.

Oil line fi lters — Use a non-bypassing fi lter to prevent nozzle

plugging caused by poor oil fi ltration. Non-bypassing fi lters

prevent small foreign particles from bypassing the fi lter, a

common problem with fi ber element type fi lters. Another

problem of some fi lters is the fi ber from fi lter element tears

can break away and plug the nozzle or fuel unit.

Perform the complete checkout procedures of pages 13 to 21, including

system inspection and checks.

Inform the user of any problems found.

Train the user

Train the user to operate the burner and appliance under normal conditions.

Explain procedure to shut down burner/appliance when required.

Review the back cover of this manual (and the appliance manual) with the

user.

Verify the user is aware of all procedures specifi ed in the manuals.

Verify user will not store or use combustible liquids or materials or con-

taminants in the vicinity of the burner/appliance.

Carlin part number MN2301A Rev. 10/21/10

– 21 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

Item Description

Part

No.

201

CRD

301

CRD

Item Description Part No.

201

CRD

301

CRD

1 Blower housing

Consult

factory

14

Flame retention ring assemblies

2

Air band Flame retention ring assembly 55418S •

Air band 47001S • • Flame retention ring assembly 55715S •

3

Combustion head assemblies

15

Flanges (mounting)

7" nominal, approx. 16-³⁄₄" OAL 54155 • 4” Mounting flange universal 4” ID, 8¹⁄₂” OD 59642 • •

9" nominal, approx. 18-³⁄₄" OAL 54205 • 4” Mounting flange for forced draft 4” ID, 11” OD (not shown) 59444S • •

11" nominal, approx. 20-³⁄₄" OAL 53975 • 4” Mounting flange for UV scanner (not shown) 59444UV • •

15" nominal, approx. 24-⁵⁄₁₆" OAL 54031 •

16

Gaskets (flange)

6" nominal, approx. 16-³⁄₄" OAL 55574 • Gasket for universal flange 40287 • •

8" nominal, approx. 18-³⁄₄" OAL 55616 • Gasket for forced draft flange and UV scanner (not shown) 40246 • •

10" nominal, approx. 20-³⁄₄" OAL 55434 •

15

+

16

Flange and gasket combinations

14" nominal, approx. 24-³⁄₄" OAL 55491 • 4” Universal flange and gasket 23259S • •

3 +

4 or 5

Air tube/combustion head assemblies 4” Pressure flange and gasket 23184S • •

7” Nominal 22046 •

17

Blower wheels (fans)

9” Nominal 22053 • Blower wheel, 5-³⁄₄” OD x 4” W, ¹⁄₂” Bore 28563 • •

11” Nominal 22012 •

18

Fuel units

15” Nominal 22020 • Suntec, 1 stage, J3BB-100 23325S • •

B-Style 6” Nominal 22293 • Suntec, 1 stage, NYC, J3BB-100 100PSIG 74435S • •

B-Style 8” Nominal 22327 • Suntec, 2 stage, H3BB-100 23341S • •

B-Style 10” Nominal 22202 • Suntec, 2 stage, NYC, H3BB-100 100PSIG 74427S • •

B-Style 14” Nominal 22236 • Suntec, 2 stage, NYC, H3BB-100 150PSIG 74427HP • •

C-Style 6” Nominal 22442 • Suntec, 1 stage, A2YA-7916 23234S • •

C-Style 8” Nominal 22475 • Suntec, 1 stage, NYC, A2YA-7916 100PSIG 74443S • •

C-Style 10” Nominal 22350 • Suntec, 1 stage, NYC, A2YA-7916 150PSIG 74443HP • •

C-Style 14” Nominal 22384 • Suntec, 2 stage, B2YA-8916 23267S • •

4

Air tubes, 201 Suntec, 2 stage, NYC, BY2A-8916 100PSIG 74459S • •

7" nominal, approx. 8" OAL 46128 • Suntec, 2 stage, NYC, B2YA-8916 150PSIG 74559HP • •

9" nominal, approx. 10" OAL 46144 •

19

Motor

11" nominal, approx. 12" OAL 46052 • 220/240 vac, 1/4 hp, 3450 RPM, Carlin PSC 99220 • •

15" nominal, approx. 16" OAL 46078 •

20

Nozzle line/adapter assemblies

5

Air tubes, 301 14⁷⁄₃₂” OAL, for nominal 7”-201 / 6”-301 58727S • •

B-Style, 6" nominal, approx. 6-¹³⁄₁₆" OAL 46383 • 16⁷⁄₃₂” OAL, for nominal 9”-201 / 8”-301 58743S • •

B-Style, 8" nominal, approx. 8-¹³⁄₁₆" OAL 46417 • 18⁷⁄₃₂” OAL, for nominal 11”-201 / 10”-301 58685S • •

B-Style, 10" nominal, approx. 10-¹³⁄₁₆" OAL 46326 • 22⁷⁄₃₂” OAL, for nominal 15”-201 / 14”-301 58701S • •

B-Style, 14" nominal, approx. 14-¹³⁄₁₆" OAL 46342 •

21

Oil lines

C-Style, 6" nominal, approx. 6-¹³⁄₁₆" OAL 46490 • Oil valve to combustion head, A and B pump 34785S • •

C-Style, 8" nominal, approx. 8-¹³⁄₁₆" OAL 46573 • Oil valve to combustion head, H and J pump 75333S • •

C-Style, 10" nominal, approx. 10-¹³⁄₁₆" OAL 46433 •

22

Oil valves

C-Style, 14" nominal, approx. 14-¹³⁄₁₆" OAL 46458 • Carlin oil valve SVC2OFF • •

6 Electrode bracket w/hardware 23135S • • 23 Brass nipple, ¹⁄₈” PT x 2” long 44529 • •

7

Couplings 24 Carrying tube, 2¹⁄₄” Long 34405 • •

¹⁄₂” ID x ⁷⁄₁₆” ID x 3¹⁄₈” L (H or J pump) 28712 • • 25 Elbow, male, ¹⁄₈” PT x ³⁄₁₆” tube 29926 • •

¹⁄₂” ID x ⁵⁄₁₆” x 4⁹⁄₁₆” L (A or B pump) 28720 • •

8 Nozzle (obtain locally) 26 CAD cell assembly 1440700K • •

9 Pedestal w/hardware 23358S • • 27 Screw for adjusting combustion head assembly 47167 • •

10 Terminal for ignition transformer 24471 • •

11 Yoke for adjusting combustion head 54916 • • 28 Ignitor cover plate 9778900 • •

12 Junction box, 4" square x 1¹⁄₂” deep 33902 • • 29 Ignitor (208 - 240 vac) 40700 • •

13

Electrode sets • • 30 Ignitor adapter 98061A • •

Set of 2, 7/6” nominal, approx. 8¹⁄₂” OAL 82776S • •

Set of 2, 9/8” nominal, approx. 10³⁄₄” OAL 82784S • • NS Time delay 4 Sec., solid state 35741 • •

Set of 2, 11/10” nominal, approx. 12¹⁄₂” OAL 82792S • • NS NYC/BAR nozzle pressure regulator kit, 150PSI, field installed 91637 • •

Set of 2, 15/14” nominal, approx. 16¹⁄₂” OAL 82818S • •

Set of 2, 18/17” nominal, approx. 19¹⁄₂” OAL 82826S • •

7. Repair parts

– 22 –

For parts not shown or listed, contact factory and/or check separate documentation supplied with appliance/burner unit.

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

7. Repair parts (cont.inued)

Carlin part number MN2301A Rev. 10/21/10

– 23 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

8. Maintenance/service procedures

Turn off power to appliance when servicing burner. Failure to comply

could result in severe personal injury, death or substantial property

damage.

Cleaning blower wheel

1. The blower wheel accumulates dust and debris from normal operation. You will

need to clean the wheel blades periodically to prevent reduction in airfl ow.

• Inspect the blower wheel by removing the blower wheel access cover.

• To remove the cover, open the ignitor plate and loosen the blower wheel

access cover screw about three turns.

• Inspect the blower wheel to see if it needs to be cleaned. Dirt and lint on

the wheel reduce air fl ow, and must be removed if the burner is to operate

correctly.

2. To clean blades, remove the two bolts securing the motor to blower housing.

a. Slide the motor out and rotate to remove and access blower wheel.

b. Use a brush and vacuum to clean each blade and the blower housing

interior.

c. Install motor/wheel in blower housing and secure with the two bolts.

d. Push wire slack back into junction box.

Replacing blower motor or wheel

1. If either the blower wheel or motor must be replaced, remove the two bolts

securing the motor to housing.

2. Disconnect the motor wires in the burner junction box.

3. Loosen the Allen screw securing the blower to the motor shaft and remove the

wheel.

4. When assembling the replacement assembly, slide the wheel onto the motor

shaft and use feeler gauges to set space between the blower wheel and the

motor face. This space must be:

201CRD – 1/8” 301CRD – 1/8”

5. Install the motor/wheel assembly in the housing, wire the motor leads and

secure the motor with the two bolts.

Ceramic fi ber materials

The appliance may contain ceramic fi ber and/or fi berglass

materials. Ceramic fi ber materials, such as chamber liners, may

contain carcinogenic particles (chrystobalites) after exposure

to heat. Airborne particles from fi berglass or ceramic fi ber

components have been listed as potentially carcinogenic by

the State of California. Take the following precautions when

removing, replacing and handling these items.

Avoid breathing dust and avoid contact with skin or eyes. Wear

long-sleeved, loose-fi tting clothing, gloves and eye protection.

Use a NIOSH N95 certifi ed respirator. This respirator meets

requirements for protection from chrystobalites. Actual job

requirements or NIOSH regulations may require other or additional protection. For information, refer to the NIOSH website,

http://www.cdc.gov/niosh/homepage.html.

Ceramic fi ber removal: To prevent airborne dust, thoroughly

wet ceramic fi ber with water before handling. Place ceramic

fi ber materials in a plastic bag and seal to dispose.

Avoid blowing, tearing, sawing or spraying fi berglass or ceramic

fi ber materials. If such operations are necessary, wear extra

protection to prevent breathing dust.

Wash work clothes separately from other laundry. Rinse clothes

washer thoroughly afterwards to prevent contamination of other

clothing.

NIOSH First aid procedures:

Eye exposure — irrigate immediately

Breathing — fresh air.

Motor maintenance

• The Carlin PSC motor is constructed with permanently-lubricated bearings,

and requires no oiling. Should you replace the original motor with another type

of motor, occasional oiling may be required, depending on motor design and

manufacturer’s recommendations.

• Any time you replace a component or disassemble any part of the burner for

service/maintenance, perform a complete operational test after reassembly to

verify the burner operates correctly. Failure to verify operation could result in

severe personal injury, death or substantial property damage.

Checking the ignitor

Never test an ignitor by placing a screwdriver (or other metallic

object) across the high voltage clips. Check 40700 ignitors only by

observing spark at appliance ignition electrodes, with fuel supply

OFF. Using any other method could cause ignitor damage and severe

personal injury.

– 24 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

Carlin part number MN2301A Rev. 10/21/10

– 25 –

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

– 26 –

Carlin part number MN2301A Rev. 10/21/10

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

Limited Warranty

Carlin Combustion Technology, Inc. (Carlin) warrants its products, to the original purchaser, to be

free from defects in material and workmanship, under normal use and service for 36 months from

the date of manufacture, except for commercial Products (over 3 GPH) that are warranted for 12

months from the date of manufacture; and except for EZ-Pro™ Burners that are warranted for 36

months from the date of manufacture, plus an extended period of two (2) additional years (total of

fi ve (5) years).

This warranty does not extend to equipment subjected to misuse, neglect, accident or water damage;

nor does this warranty apply unless the product covered by it is properly installed by a qualifi ed,

competent technician, who is licensed where state or local codes require, and who is experienced in

making such installations, in accordance with NFPA No. 31 of the National Fire Protection Association and in accordance with all applicable local, state and national codes. Parts that are defective in

material or workmanship and within the warranty period will be repaired or replaced as follows: