Page 1

™

Wingspan: 60.5 in [1540 mm]

Wing Area: 667 sq in [43.0 dm2]

Weight: 5.5–6.5 lb [2490–2950 g]

Wing Loading: 19–22 oz/sq ft [58–67 g/dm2]

Length: 55 in [1395 mm]

Radio: 4-channel minimum with 4–5 servos and standard size receiver

Engine: .40–.55 cu in [6.5–9cc] two-stroke, .70 cu in [11.5cc] four-stroke,

RimFire™ .46 (42-60-800) brushless out-runner motor

WARRANTY

Carl Goldberg Products guarantees this kit to be free from defects in both material and workmanship at the date

of purchase. This warranty does not cover any component parts damaged by use or modifi cation. In no case shall

Carl Goldberg’s liability exceed the original cost of the purchased kit. Further, Carl Goldberg reserves the right

to change or modify this warranty without notice.

In that Carl Goldberg has no control over the fi nal assembly or material used for fi nal assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the fi nal user-assembled product. By

the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is

advised to return this kit immediately in new and unused condition to the place of purchase.

To make a warranty claim Hobby Services

send the defective part 3002 N. Apollo Dr., Suite 1

or item to Hobby Services Champaign, IL 61822 USA

at this address: (217) 398-8970 Ext. 5

Include a letter stating your name, return shipping address, as much contact information as possible (daytime

telephone number, fax number, e-mail address), a detailed description of the problem and a photocopy of the

purchase receipt. Upon receipt of the package, the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Page 2

TABLE OF CONTENTS

THINGS TO CONSIDER

THINGS TO CONSIDER

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Power System Recommendations . . . . . . . . . . . . . . . . 2

Propeller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Batteries and Charger . . . . . . . . . . . . . . . . . . . . . . . . . 3

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . . 3

Required Hardware and Accessories . . . . . . . . . . . . . 3

Adhesives and Building Supplies. . . . . . . . . . . . . . . . . 3

Optional Supplies and Tools. . . . . . . . . . . . . . . . . . . . . 3

Building Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

BUILD THE WING PANELS . . . . . . . . . . . . . . . . . . . . . . . . 4

Install the Ailerons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Install the Aileron Servos and Pushrods . . . . . . . . . . . 5

Join the Wing Panels . . . . . . . . . . . . . . . . . . . . . . . . . . 8

How To Cut Covering From Balsa . . . . . . . . . . . . . . . . 9

Install the Main Landing Gear . . . . . . . . . . . . . . . . . . . 9

BUILD THE FUSELAGE . . . . . . . . . . . . . . . . . . . . . . . . . 10

Install the Tail Surfaces . . . . . . . . . . . . . . . . . . . . . . . 10

Install the Tail Servos and Pushrods . . . . . . . . . . . . . 13

Install the Nose Gear . . . . . . . . . . . . . . . . . . . . . . . . . 14

Glow Engine Installation. . . . . . . . . . . . . . . . . . . . . . . 15

Brushless Motor Installation. . . . . . . . . . . . . . . . . . . . 18

FINISH THE MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Apply the decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

GET THE MODEL READY TO FLY . . . . . . . . . . . . . . . . . 20

Install and Operate the Motor Battery

(Brushless Only) . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Battery Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Check the Control Directions . . . . . . . . . . . . . . . . . . . 21

Set the Control Throws. . . . . . . . . . . . . . . . . . . . . . . . 22

Balance the Model (C.G.). . . . . . . . . . . . . . . . . . . . . . 22

Balance the Model Laterally. . . . . . . . . . . . . . . . . . . . 23

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fuel Mixture Adjustments . . . . . . . . . . . . . . . . . . . . . 23

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

This is a partial list of items required to fi nish the Tiger 2 ARF

that may require planning or decision making before starting

to build. Order numbers are provided in parentheses.

RADIO EQUIPMENT

The Tiger 2 ARF requires a minimum 4-channel radio system

with four 44 oz.-in. [3.2 kg-cm] minimum standard servos.

If you are installing a glow engine, an additional standard

servo is required for the throttle.

In addition, two 9" [229mm] servo extensions are required for

the aileron servos. A Y-harness is also required to connect

the aileron servos together into a single radio channel.

A charge jack receptacle is optional, but is useful for recharging

the receiver pack without removing the hatch or wing and

is shown in the assembly of the plane. Recommended part

numbers for the radio components are provided below:

Futaba® S3003 Servo Standard (FUTM0031)

Futaba 9" Servo Extension J (FUTM3910)

Futaba 6" Dual Servo Extension J (FUTM4130)

Ernst Charge Receptacle Futaba J FM (ERNM3001)

POWER SYSTEM RECOMMENDATIONS

The recommended engine/motor size for the Tiger 2 ARF is

a .40-.55 cu in [6.5-9cc] two-stroke engine, .70 cu in [11.5cc]

four-stroke engine, or a RimFire .46 (42-60-800) brushless

outrunner motor. Engine and motor order numbers are

provided below:

O.S.® .46 AX ABL w/Muffl er (OSMG0547)

Great Planes® RimFire .46 (42-60-800) Out-Runner

Brushless (GPMG4725)

Great Planes Brushless Motor Mount Medium Motors

(GPMG1255)

Ideal as a fi rst low-wing trainer and as a terrifi c everyday sport

plane, the Tiger 2 ARF combines docile fl ight characteristics

with the aptitude for super-smooth, exciting aerobatics. This

ARF has been designed to keep building time to a minimum.

With only fi nal assembly and radio and engine installation

required, you will soon be fl ying a tiger that “growls as you

grow”. The better you get, the more fun it gives you!

If using the recommended brushless motor, a 60A brushless

ESC is required:

Great Planes Silver Series 60A Brushless ESC High Volt

(GPMM1850)

PROPELLER

If you are installing a glow engine, choose a prop based

on the engine manufacturer’s recommendation. If you are

installing the recommended RimFire brushless motor, we

suggest an 11x5.5E APC propeller.

APC 11x5.5 Electric Propeller (APCQ1055)

2

Page 3

BATTERIES AND CHARGER

ADHESIVES AND BUILDING SUPPLIES

For a brushless motor installation, a 5S battery confi guration

can be used as an economy setup for moderate power and

extended fl ight time. A 6S battery confi guration can be used

for better performance at a cost of fl ight time. For a 5S battery

confi guration, one 3200mAh 11.1V Lithium Polymer battery

pack and one 3200mAh 7.4V Lithium Polymer battery pack

will need to be connected in series. Two 3200mAh 11.1V

Lithium Polymer battery packs need to be connected in

series to create a 6S confi guration. Order numbers for the

battery packs and series connector are provided below:

Great Planes LiPo 7.4V 3200mAh 20C Discharge w/

Balance (GPMP0622)

Great Planes LiPo 3200mAh 11.1V 20C Discharge w/

Balance (GPMP0623)

Great Planes Series Deans U 2 to 1 Adapter

(GPMM3143)

A cell balancer is required for the LiPo battery packs

listed above:

Great Planes ElectriFly™ Equinox™ LiPo Cell Balancer

1-5 (GPMM3160)

A suitable charger is also required. The Great Planes

PolyCharge4™ is designed for LiPo packs only. However, it

is able to charge four LiPo packs simultaneously. The Great

Planes Triton2™ charger will only charge one pack at a time.

However, it is capable of charging NiCd, NiMH, LiPo, and Pb

acid batteries. Order numbers for both are provided below:

Great Planes PolyCharge4 DC Only 4 Output LiPo

Charger (GPMM3015)

OR

Great Planes ElectriFly Triton2 DC Comp Peak Charger

(GPMM3153)

ADDITIONAL ITEMS REQUIRED

REQUIRED HARDWARE AND ACCESSORIES

This is the list of hardware and accessories required

to finish the Tiger 2 ARF. Order numbers are provided

in parentheses:

R/C foam rubber 1/4" [6mm] (HCAQ1000)

3’ [900mm] standard silicone fuel tubing (GPMQ4131)

(Glow engine installation only)

This is the list of Adhesives and Building Supplies that are

required to fi nish the Tiger 2 ARF:

1/2 oz. [15g] Thin Pro™ CA (GPMR6001)

Pro 30-minute epoxy (GPMR6047)

Masking tape (TOPR8018)

Threadlocker thread locking cement (GPMR6060)

Denatured alcohol (for epoxy clean up)

Drill bits: 1/16" [1.6mm], 5/64" [2mm], 3/32" [2.4mm],

11/64" [4.4mm]

Dead Center™ Engine Mount Hole Locator (GPMR8130)

Small metal fi le

#1 Hobby knife (HCAR0105)

#11 blades (5-pack, HCAR0211)

Medium T-pins (100, HCAR5150)

Top Flite® MonoKote® sealing iron (TOPR2100)

Top Flite Hot Sock™ iron cover (TOPR2175)

220 grit sandpaper

Great Planes Velcro Hook & Loop 1x6" (2) (GPMQ4480)

(Brushless installation only)

Panel Line Pen (TOPQ2510)

DuraTrax® Servo Tape Wide 1x36" (DTXR1215)

Heat shrink tubing or electrical tape

OPTIONAL SUPPLIES AND TOOLS

Here is a list of optional tools that will help you build the Tiger

2 ARF:

1/2 oz. [15g] Thick Pro CA- (GPMR6013)

2 oz. [57g] spray CA activator (GPMR6035)

4 oz. [113g] aerosol CA activator (GPMR6034)

CA applicator tips (HCAR3780)

CA debonder (GPMR6039)

Pro 6-minute epoxy (GPMR6045)

Epoxy brushes 6, (GPMR8060)

Mixing sticks (GPMR8055)

Mixing cups (GPMR8056)

Diagonal Sprue Cutter 5" (HCAR0630)

Rotary tool such as Dremel

Rotary tool reinforced cut-off wheel (GPMR8200)

Servo horn drill (HCAR0698)

Hobby Heat™ Micro Torch II (HCAR0755)

Precision Magnetic Prop Balancer (TOPQ5700)

AccuThrow™ Defl ection Gauge (GPMR2405)

CG Machine™ (GPMR2400)

Hobbico Flexible 18" Ruler Stainless Steel (HCAR0460)

Top Flite MonoKote trim seal iron (TOPR2200)

Top Flite MonoKote heat gun (TOPR2000)

Hobbico Pin Vise 1/16 Collet w/6 Bits (HCAR0696)

3

Page 4

Hobbico 7-Piece Ball Tip Hex L Wrench Metric

(HCAR0521)

Great Planes Clevis Installation Tool (GPMR8030)

BUILDING STAND

A building stand or cradle comes in handy during the build.

We use the Robart Super Stand II (ROBP1402) for all our

projects in R&D, and it can be seen in pictures throughout

this manual.

BUILD THE WING PANELS

INSTALL THE AILERONS

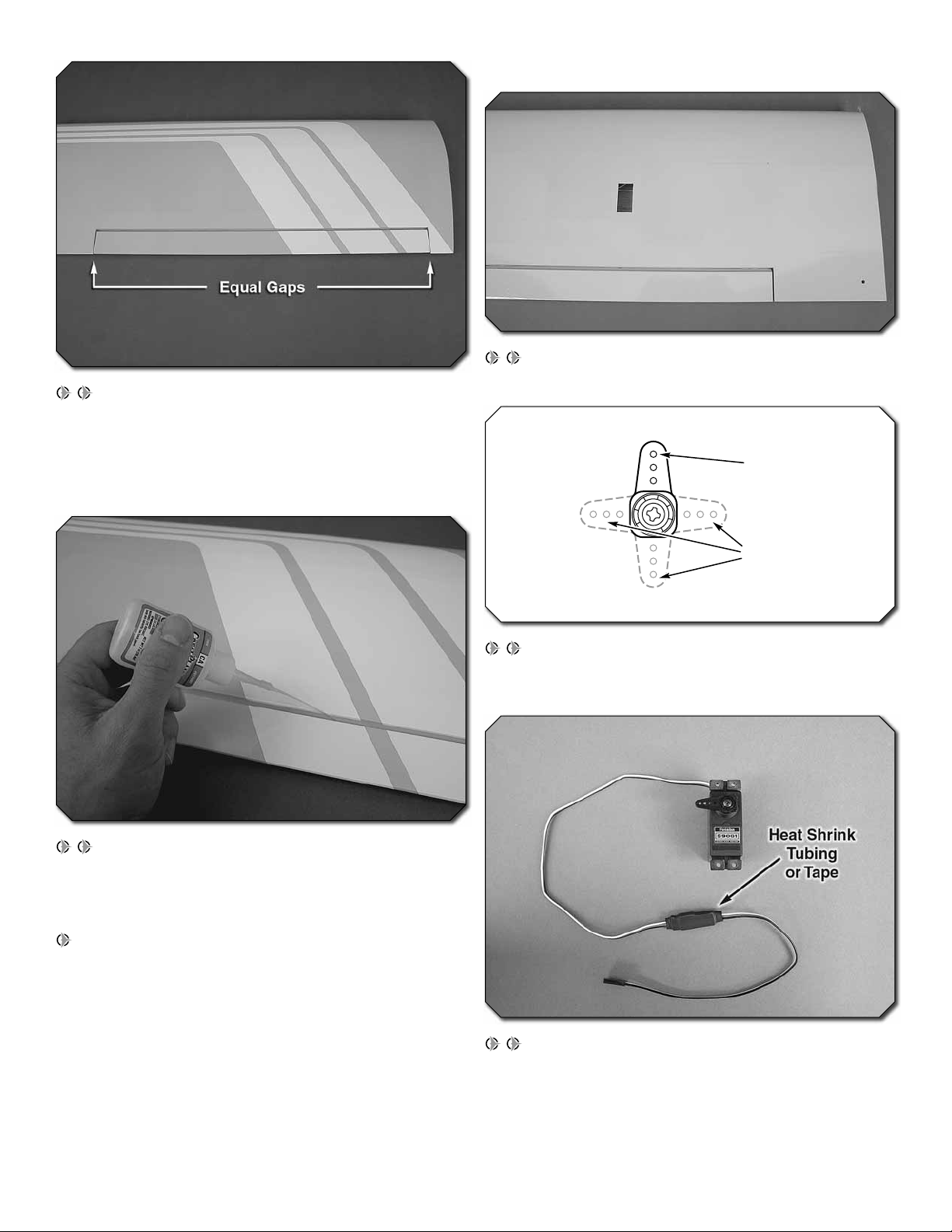

Do the right wing fi rst so your work matches the photos

the fi rst time through. You can do one wing at a time, or

work on them together.

PREPARATIONS

1. If you have not done so already, remove the major parts

of the kit from the box and inspect for damage. If any parts

are damaged or missing, contact Product Support.

2. Remove the tape and separate all the control surfaces.

Use a covering iron with a covering sock on high heat to

tighten the covering if necessary. Apply pressure over sheeted

areas to thoroughly bond the covering to the wood.

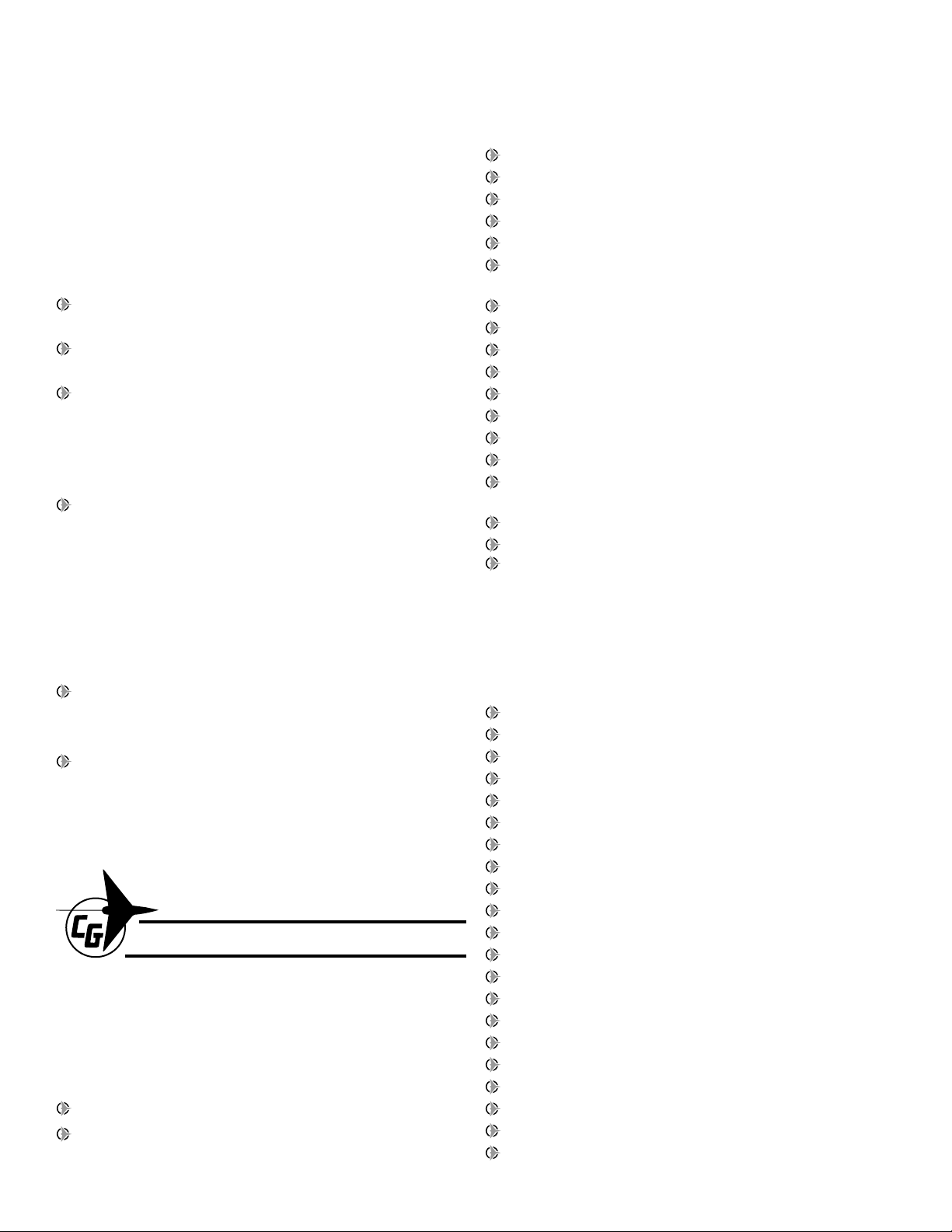

1. Drill a 3/32" [2.4mm] hole 1/2" [13mm] deep into the

center of each hinge slot in the aileron and wing panel. Trim

the covering away from each hinge slot to ensure that the

hinges will be properly glued in place.

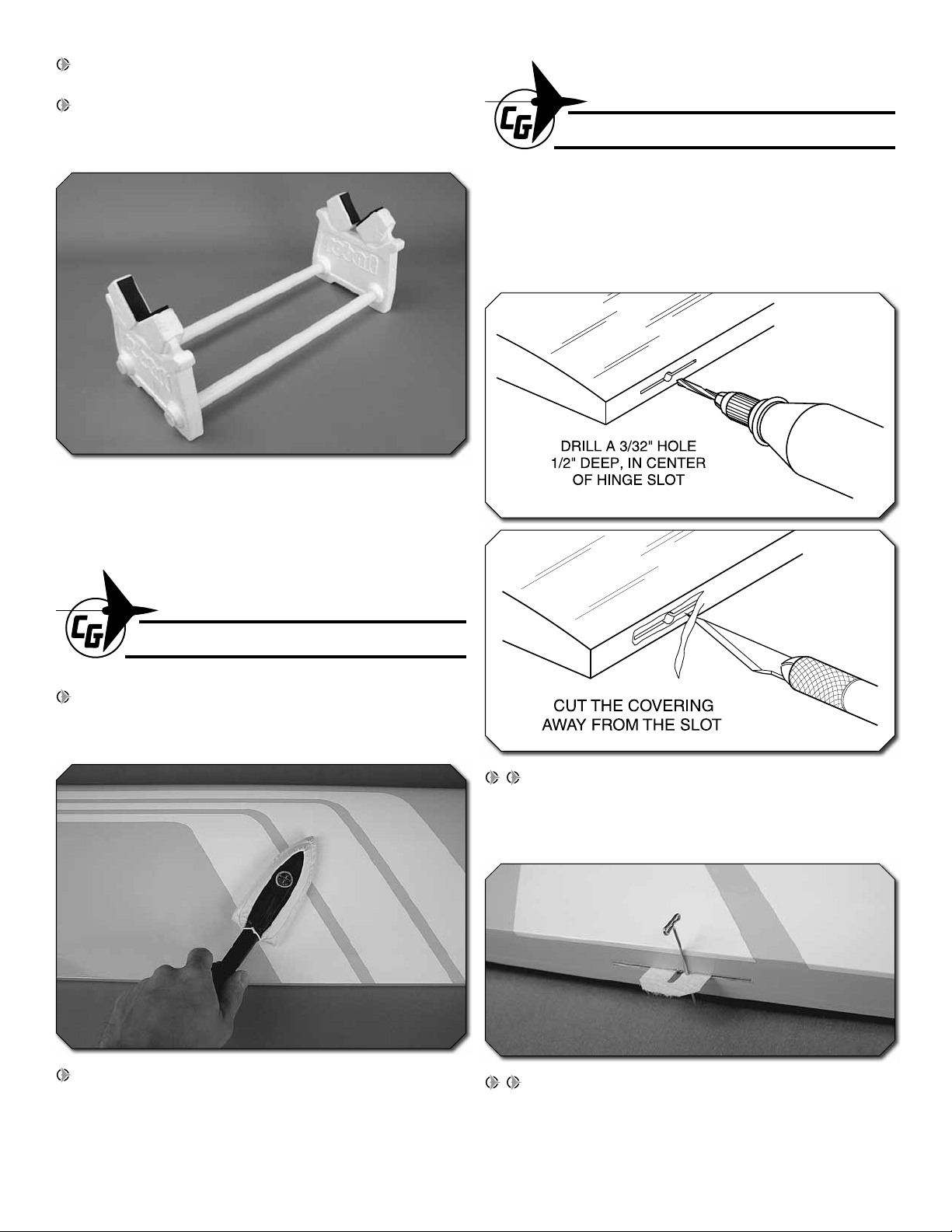

2. Test fi t a CA hinge into each of the hinge slots in the

wing panel and aileron. If necessary, enlarge the slots with

a hobby knife. When satisfi ed with the fi t, insert a CA hinge

halfway into each hinge slot in the wing panel. Push a pin

through the middle of each hinge to keep them centered.

4

Page 5

3. Join the aileron to the wing panel and remove

Cut off

unused

arms

Enlarge to

5/64" [2mm]

the pins from the hinges. Center the aileron on the wing.

Remove the pins and adjust the aileron so there is a small

gap between the LE of the aileron and the wing. The gap

should be small, just enough to see light through the gap or

to slip a piece of paper through.

INSTALL THE AILERON SERVOS AND PUSHRODS

1. Trim the covering from the aileron servo bay on the

underside of the wing panel.

4. Apply six drops of thin CA to the top and bottom of

each hinge without using accelerator. After the CA glue has

hardened, confi rm that the aileron is secure by pulling on it

and defl ecting it up and down.

5. Repeat steps 1– 4 for the other wing panel.

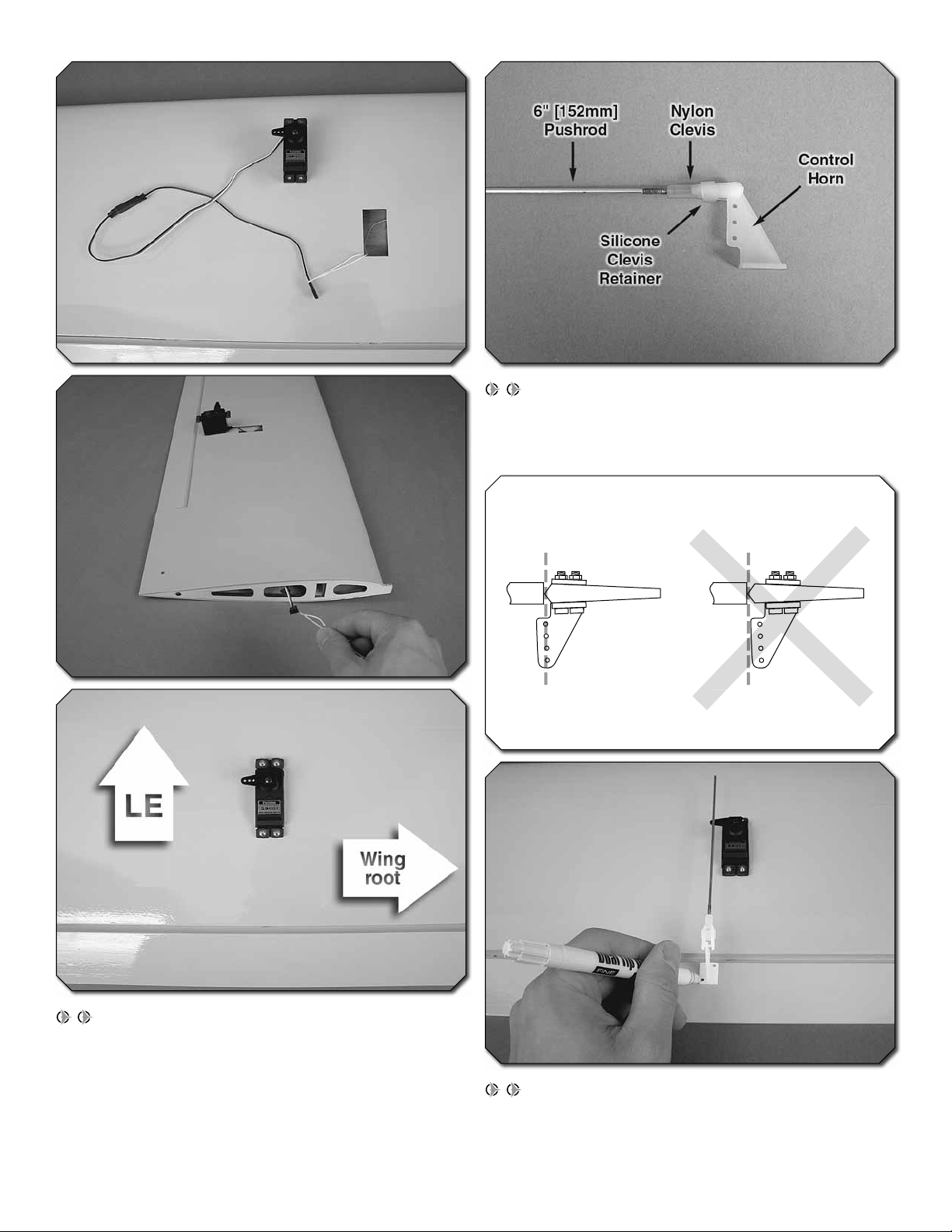

2. Cut three arms from a four-armed servo arm for the

aileron servo. Enlarge the outer hole of the remaining arm

with a 5/64" [2mm] drill bit.

3. Attach a 9" [229mm] servo extension to the aileron

servo and secure the connector using tape, heat shrink tubing

(not included), or a product designed specifi cally for securing

servo lead connections. Center the servo with your radio

system and install the servo arm to the servo perpendicular

to the servo case as shown. Be sure to reinstall the servo

arm screw into the servo.

5

Page 6

5. Thread a nylon clevis 20 complete turns onto a

Hinge Line Hinge Line

CORRECT INCORRECT

6" [152mm] pushrod. Slide a silicone clevis retainer onto

the clevis and connect the clevis to the outer hole of a

control horn.

4. Use the string taped inside the aileron servo bay to

pull the servo lead through the wing ribs. Fit the servo into

the servo bay with the spline toward the LE of the wing. Drill

1/16" [1.6mm] holes through the mounting tabs on the servo

case into the wing. Thread a servo mounting screw (included

with the servo) into each hole and back it out. Apply a drop

of thin CA to each hole to harden the wood. When the CA

has dried, install the servo using the hardware supplied with

the servo.

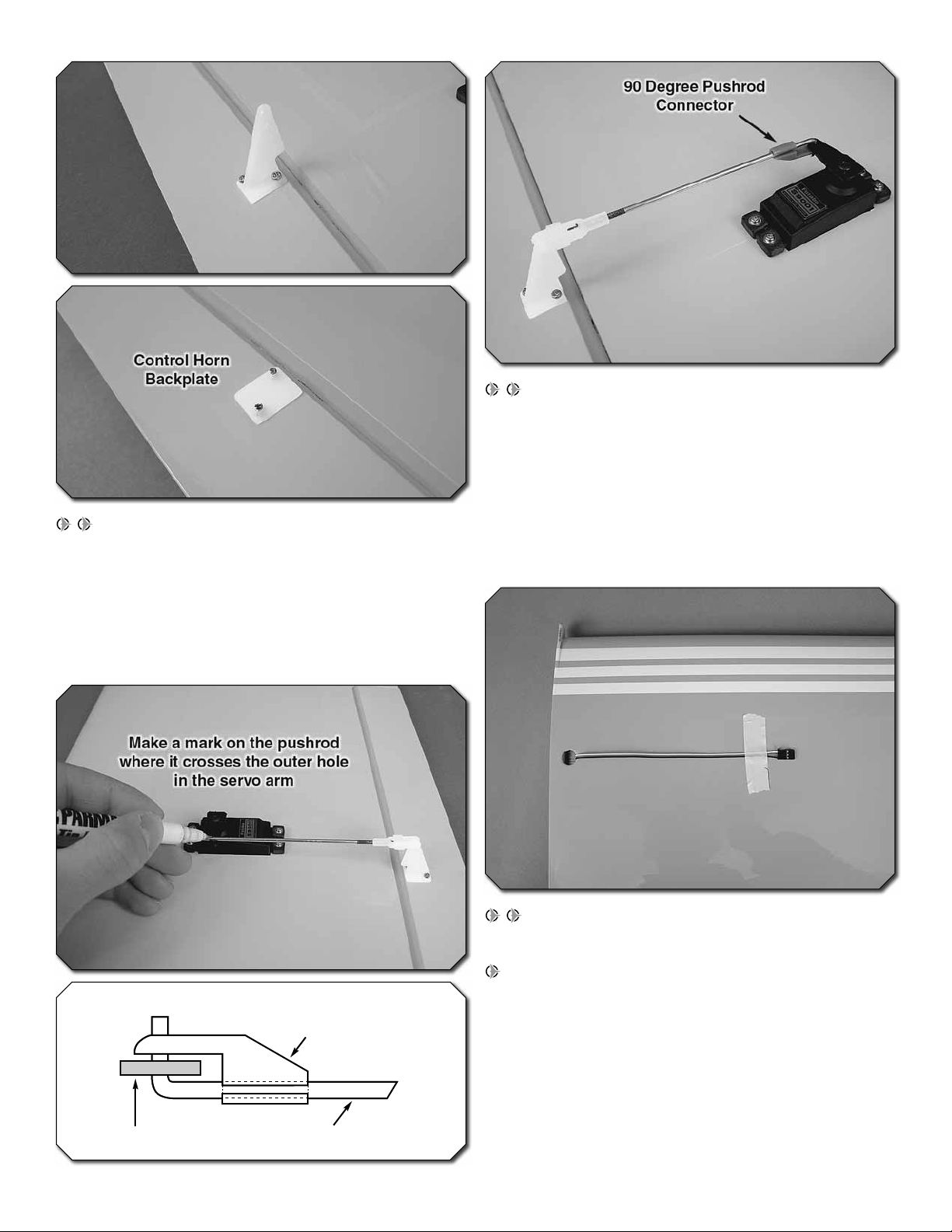

6. Position the control horn onto the aileron using the

position of the servo arm as a guide. Align the holes in the

control horns directly over the aileron hinge line and mark

the location of the control horn mounting holes.

6

Page 7

7. Drill 5/64" [2mm] holes at the marks you made

Servo Horn Pushrod Wire

90 Degree

Pushrod

Connector

through the aileron (drill perpendicular to the aileron chord

line). Apply a couple drops of thin CA glue to each hole to

harden the surrounding wood. When the glue has dried,

install the control horn onto the aileron using two 2 x 20mm

machine screws and a control horn backplate. The excess

length of screw protruding beyond the backplate can be

cut off.

8. Use tape or a small clamp to hold the aileron in

the neutral position. Make a mark on the pushrod where it

crosses the outer hole in the servo arm. Make a 90 degree

bend at the mark on the pushrod and cut off the excess

pushrod 1/4" [6mm] beyond the bend. Attach the pushrod to

the servo arm using a 90 degree pushrod connector. Thread

the clevis up or down on the pushrod as necessary to center

the aileron with the servo arm centered. When satisfi ed,

slide the silicone clevis retainer to the end of the clevis to

secure it.

9. Route the servo lead through the hole in the top of

the wing panel and tape it back and out of the way.

10. Repeat steps 1-9 for the other wing panel.

7

Page 8

JOIN THE WING PANELS

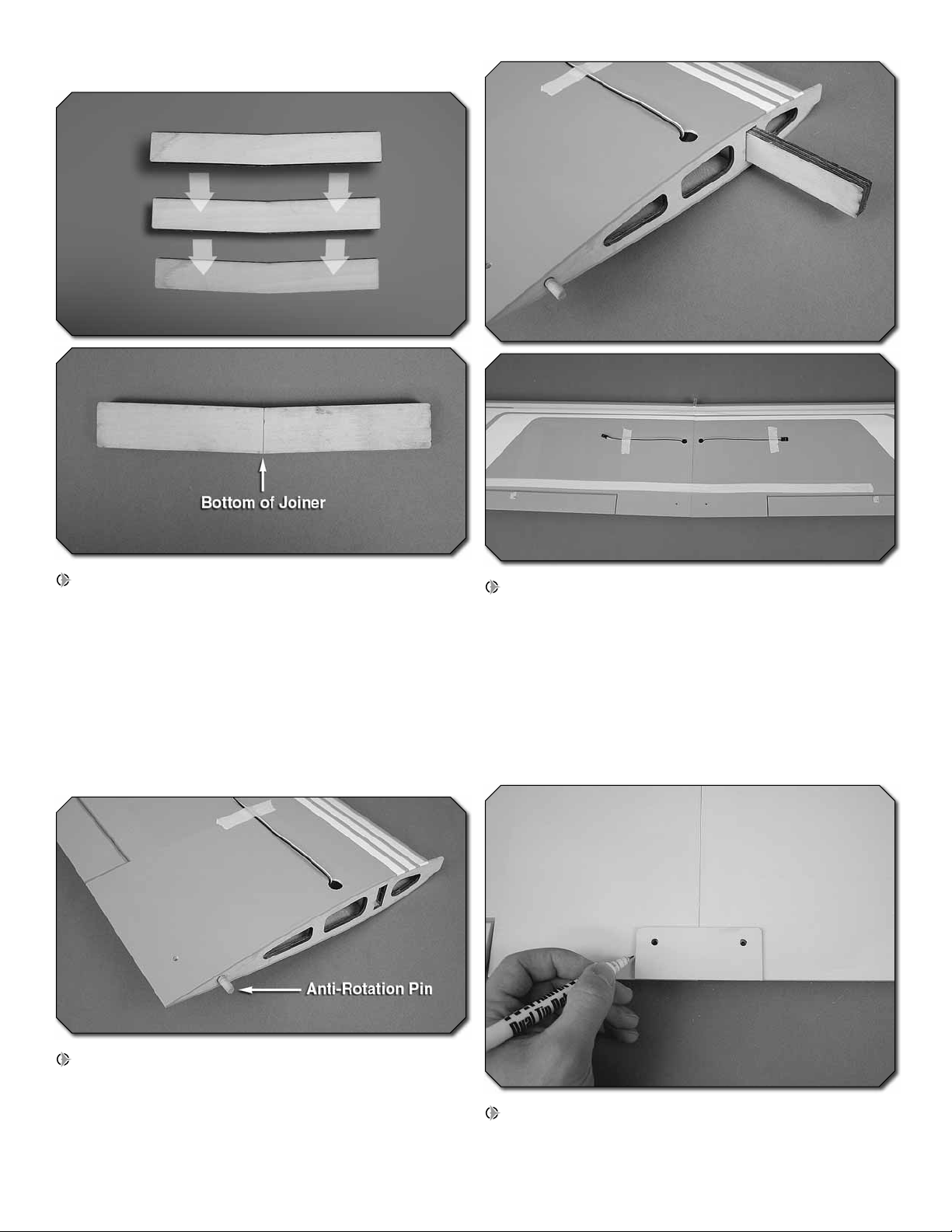

1. Locate the three plywood wing joiner pieces. Glue the

three pieces together using epoxy. Note that the joiner has

a slight “V” shape that will give the wing a small amount of

dihedral when assembled. The point of the “V” shape is the

bottom of the joiner. Wipe away any excess epoxy with a

cloth dampened with denatured alcohol and use clamps to

hold the pieces together while the epoxy cures. Be sure that

the joiner pieces are glued so the edges are fl ush with each

other. Mark a centerline on the assembled wing joiner. The

centerline is used to confi rm that the wing joiner fi ts halfway

into each wing panel.

3. Use a mixing stick or something similar to coat the

inside of the wing joiner pockets of both wing panels with

30-minute epoxy. Thoroughly coat one half of the wing joiner

with 30-minute epoxy and insert it into the joiner pocket of

one wing panel with the bottom of the “V” shape pointing to

the underside of the wing. Coat the root ribs of both wing

panels and the protruding end of the wing joiner with epoxy.

Slide the wing panels together and use tape to hold them

tight while the epoxy cures. Wipe away any excess epoxy

with denatured alcohol.

2. Read all of step 3 and dry fi t the parts together to ensure

a proper fi t before gluing. Sand the wing joiner or root ribs if

necessary to achieve the correct fi t. The root ribs should join

together tightly with no gaps. When satisfi ed, glue the antirotation pin halfway into the hole of one of the wing panels

as shown.

4. Trim the covering from the holes in the plywood wing

bolt plate as shown. Position the wing bolt plate over the

wing bolt holes on the underside of the wing and use a felttip pen to trace around it.

8

Page 9

5. Use a sharp #11 hobby knife or use the following Expert

Tip to cut the covering 1/16" [1.6mm] inside of the lines you

marked. Use care to cut only in the covering and not into

the wood. Use alcohol to wipe away the lines. Glue the wing

bolt plate in position. If necessary, clean out the wing bolt

holes using a 11/64" [4.4mm] drill bit.

HOW TO CUT COVERING FROM BALSA

Use a soldering iron to cut the covering from the area

beneath the wing bolt plate. The tip of the soldering iron

doesn’t have to be sharp, but a fi ne tip does work best.

Allow the iron to heat fully.

INSTALL THE MAIN LANDING GEAR

1. Slide a 4mm wheel collar onto each main landing

gear wire followed by a wheel and another 4mm wheel

collar. Center the wheels on the landing gear wires and mark

the position of the wheel collars onto the wires. Use a fi le

or rotary tool to grind fl at spots at the marks you made. The

wheel collar screws will tighten against the fl at spots on the

wires. Use four 3x5mm machine screws and thread locking

compound to tighten the wheel collars onto the landing gear

wires. The wheels should rotate freely on the wires. Oil the

axles if necessary.

Use a straightedge to guide the soldering iron at a rate

that will just melt the covering and not burn into the wood.

The hotter the soldering iron, the faster it must travel to

melt a fi ne cut. Peel off the covering.

2. Press the landing gear into the slots on the underside

of the wing.

9

Page 10

3. Position two landing gear straps evenly spaced apart

over each landing gear and mark the location of the strap

holes onto the wing. Drill holes at your marks using a 1/16"

[1.6mm] bit. Thread a 2.5x10mm self-tapping washer head

screw into each hole and back it out. Apply a drop of thin CA

to each hole to harden the wood. When the glue has dried,

install the straps using eight 2.5x10mm self-tapping washer

head screws.

BUILD THE FUSELAGE

INSTALL THE TAIL SURFACES

1. Temporarily install the wing onto the fuselage using two

4x25mm machine screws and two 4mm fl at washers. The

wing will be used to properly align the horizontal stabilizer

onto the fuse.

2. Place the horizontal stab onto the stab saddle as shown.

Center the stab left and right on the fuse (making a center

mark on the stab is helpful) and make the distance between

wing and stab tips equal on both sides. When satisfi ed, use

a felt-tip pen to trace around the saddle where it meets the

underside of the stab. We used a small clamp to hold the

stab in place while we did this.

3. Stand back 5-6 ft [1.5 - 1.8m] and view the model from

behind. Confi rm that the stab and wing are parallel. If not,

sand the fuselage as necessary until they are parallel.

10

Page 11

4. Remove the stab from the fuse and trim the covering

1/16" [1.6mm] inside the lines you drew. Be careful not to cut

into the wood structure beneath the covering. Use denatured

alcohol to wipe away the lines.

5. Coat the stab saddle and the area where you removed

the covering from the stab with 30-minute epoxy. Put the stab

back into place on the saddle and re-center its position. Use

clamps or weights to hold the stab in place while the epoxy

cures. Wipe away any excess epoxy with alcohol.

7. Roughen the ends of the joiner wire with 220 grit

sandpaper and clean them off with alcohol. As you did with

the ailerons, dry fi t the elevator halves onto the stabilizer

using CA hinges and the elevator joiner wire. When satisfi ed

with the fi t, mix up a small batch of epoxy and coat the ends

of the joiner wire. Insert the joiner wire into the elevator halves

and wipe away any excess epoxy. Fit the elevator halves to

the stabilizer with CA hinges and apply 6 drops of thin CA to

both sides of every hinge.

6. Trim the covering away from the elevator joiner wire

slots at the LE of the elevator halves. Confi rm that the joiner

wire fully seats into the slot. Use a hobby knife to enlarge

the slot as necessary. When satisfi ed, test fi t both elevator

halves onto the joiner wire and lay them on a fl at surface.

If both elevator halves do not lay fl at, “tweak”, or bend the

joiner wire until they do. Do not attempt to bend the joiner

wire with it inside the elevators.

8. Trim the covering from the vertical fi n slots in the

fuselage. If necessary, remove the covering from the sides

of the tabs on the vertical fi n.

11

Page 12

horizontal stabilizer. If necessary, use tape to hold the fi n

square while the epoxy cures.

11. Trim the covering from the tail servo pushrod exits on

the left and right sides of the fuselage. Temporarily insert

a 29-1/2" [749mm] pushrod into the elevator outer pushrod

tube that exits the left side of the fuselage. Use the position

of the pushrod to mark the location for the elevator control

horn onto the underside of the elevator.

9. Fit the vertical fi n onto the fuselage and use a felt-tip

pen to trace around it onto the fuselage. Remove the covering

1/16" [1.6mm] inside the lines you drew.

10. Use 30-minute epoxy to glue the fi n into place. Be sure

to put a coating of epoxy along the entire underside length of

the fi n as well as the side of the tabs. Wipe away any excess

epoxy with denatured alcohol. Use a triangle or measure to

confi rm that the vertical fi n is installed perpendicular to the

12. Drill 5/64" [2mm] holes at your marks through the

elevator. Apply a couple drops of thin CA to each hole to

harden the surrounding wood. Install a control horn and

backplate onto the underside of the elevator using two

2x20mm machine screws.

13. Install a control horn onto the right side of the rudder

in the same manner.

12

Page 13

INSTALL THE TAIL SERVOS AND PUSHRODS

1. Cut fi ve arms from a six-armed servo arm and enlarge

the outer hole and inner hole of the remaining arm with a

5/64" [2mm] drill bit. Install a screw-lock pushrod connector

into the inner hole of the servo arm. The plastic screw-lock

pushrod connector retainer may need to be trimmed down to

clear the center of the servo arm. Center the rudder servo with

your radio system and install the servo arm perpendicular to

the servo case as shown. As you did with the aileron servos,

install the rudder servo onto the left side of the servo tray.

clevis. Then insert the pushrod into the rudder outer pushrod

tube and connect the clevis to the third outer hole of the

rudder control horn. As you did with the aileron pushrods,

use tape or a small clamp to hold the rudder in the neutral

position. Make a mark on the pushrod where it crosses the

outer hole in the servo arm. Make a 90 degree bend at the

mark on the pushrod and cut off the excess pushrod 1/4"

[6mm] beyond the bend (removing the pushrod from the

fuselage will make this easier). Attach the pushrod to the

servo arm using a 90 degree pushrod connector. Thread the

clevis up or down on the pushrod as necessary to center the

rudder with the servo arm perpendicular to the servo case.

When satisfi ed, slide the silicone clevis retainer to the end of

the clevis to secure it.

3. Install the elevator servo next to the rudder servo using

the hardware included with the servo. Be sure that the two

servos are not touching each other.

4. Install the elevator pushrod in the same manner as you

installed the rudder pushrod.

2. Thread a nylon clevis 20 complete turns onto a 29-1/2"

[749mm] pushrod. Slide a silicone clevis retainer onto the

13

Page 14

INSTALL THE NOSE GEAR

1. Trim the covering from the nose gear exit at the front

underside of the fuselage.

2. Push a 3mm blind nut into the back of each nose gear

bearing block mounting hole in the fi rewall. Use a 3x12mm

washer head machine screw to draw the blind nuts tight

against the fi rewall.

4. Fit the nylon steering arm between the two nose gear

bearing block halves. Slide the nose gear wire up through

the bearing blocks and the steering arm. Square the axle of

the nose gear wire with the length of the fuselage. Rotate

the steering arm so it is approximately 20 degrees to the

fi rewall as shown. Mark the location of the threaded hole in

the steering arm onto the nose gear wire.

3. Cut apart the nose gear bearing block halves and rotate

them around 180 degrees. Install the bearing block halves

onto the fi rewall using four 3x12mm washer head machine

screws and thread locking compound.

5. Remove the nose gear wire from the bearing blocks. As

you did with the main gear, install two 4mm wheel collars and

a wheel onto the nose gear wire and mark the positions of

the wheel collar screw holes onto the axle. Grind fl ats spots

for the wheel collar screws at your marks as well as for the

14

Page 15

steering arm screw. Install the wheel and wheel collars onto

Top of tank

Vent

Fill and carb lines

the axle using two 3x5mm machine screws and thread locking

compound. Loosely thread a 3x8mm machine screw with

thread locking compound into the steering arm. Install a screwlock pushrod connector into the middle hole in the steering

arm. Reinstall the nose gear wire into the nose gear bearing

blocks and steering arm. Tighten the screw in the steering arm

against the fl at spot you made on the nose gear wire.

1. The fuel tank can be assembled as a two line system

consisting of a vent (pressure) line to the muffl er and a

carb line. Filling and emptying of the tank would need to be

done through the carb line, or an optional fuel fi ll valve (not

included). The tank can also be assembled as a three line

system having a vent line, carb line, and fi ll line. If installing

a fi ll line, puncture the top of the stopper above the sealed

off fuel tube hole. The fi ll and carb lines should extend out

1/2" [13mm] beyond the stopper and the vent line should be

bent upwards. With the tubes installed in the stopper, fi t the

stopper plates loosely in place with the 3 x 20mm phillips

screw to hold the assembly together.

6. Slide the 16-1/4" [413mm] unthreaded pushrod

through the screw-lock pushrod connector on the steering

arm, through the steering outer pushrod tube, and through

the screw-lock pushrod connector on the rudder servo,

positioning the end of the pushrod 1/4" [6mm] beyond the

screw-lock connector on the servo arm. Center the rudder

servo and the nose wheel. Tighten the screws in the screwlock pushrod connectors and cut off the excess pushrod 1/4"

[6mm] beyond the steering arm pushrod connector.

GLOW ENGINE INSTALLATION

The Tiger 2 ARF is designed to be fl own with a .40 –.55

[6.5– 9cc] two-stroke glow engine, .70 [11.5cc] four-stroke

glow engine, or a brushless out-runner motor. If you plan to

install a brushless motor, skip this section as it only contains

information relevant to installing a glow engine.

2. Fit the stopper assembly into the tank with the vent

line pointing toward the top of the tank, but not touching.

The fuel tubing and clunks (fuel pickup) on the carb and fi ll

lines should almost reach the back of the tank but not touch.

The clunks must be able to move freely inside the tank when

assembled. Adjust the length of the fuel tubing accordingly.

When satisfi ed, remove the stopper from the tank. It will need

to be reinstalled after the tank is fi t into the fuselage.

15

Page 16

3. Use a 4x20mm machine screw, engine mount half, and

a 4mm fl at washer to draw the four 4mm blind nuts tight into

the engine mounting holes. Confi rm that the holes you are

using line up with the holes in the engine mount halves (the

unused holes are for a brushless motor mount). Install the

motor mount halves using four 4x20mm machine screws,

four 4mm fl at washers, and thread locking compound.

screw into each hole and back it out. Apply a drop of thin CA

to each hole to harden the wood. Install the hatch cover using

two 2.5x10mm washer head self-tapping screws.

6. Attach a 6" [152mm] piece of fuel tubing to each of the

tubes in the fuel tank stopper.

4. Cut a piece of 1/4" [6mm] foam rubber (not included)

to fi t the fuel tank. Lay the foam rubber inside the fuel tank

compartment. Fit the fuel tank into the compartment and pull

the fuel tank neck through the hole in the fi rewall. Install the

stopper into the tank (be sure the correct side is facing up).

Do not over-tighten the stopper screw.

5. Line the top and sides of the tank with additional foam

rubber. The tank should be held securely by the foam rubber.

Fit the fuel tank hatch cover in place and drill two 1/16" [1.6mm]

pilot holes through the forward end of the hatch cover and into

the fi rewall. Thread a 2.5x10mm washer head self-tapping

7. Position your engine 4-1/4" [108mm] from the fi rewall.

Use a Great Planes Dead Center Hole Locator to mark the

location of the engine mount holes onto the engine mount

halves. If necessary, carve away any portion of the fuselage

that interferes with the needle valve or exhaust. Drill 1/8"

[3.2mm] holes through the marks you made.

8. Attach the engine to the engine mount halves using four

3x25mm machine screws, eight 3mm fl at washers, and four

16

Page 17

3mm nylon insert lock nuts. Use a lock nut and washer on

the underside of the engine mount halves on each screw.

9. Mount the throttle servo onto the servo tray. Make sure

that it is not touching the elevator servo. Use your radio

system to center the servo.

into the second outer hole of the servo arm. Thread a nylon

clevis 20 complete turns onto the remaining 16-1/4" [413mm]

pushrod. Slide a silicone clevis retainer onto the base of the

clevis. Slide the pushrod through the throttle outer pushrod

tube pre-installed in the fuse. Fit the aft end through the

screw-lock pushrod connector installed on the throttle servo.

Make any necessary bends to the forward end of the pushrod

and connect the clevis to the throttle arm on the carburetor.

Adjust the pushrod in the screw-lock connector so the servo

properly opens and closes the carburetor. When satisfi ed,

tighten the screw-lock connector screw, slide the silicone

clevis retainer to the end of the clevis, and cut the excess

pushrod 1/4" [6mm] behind the screw-lock connector.

10. Cut fi ve arms from a six-armed servo arm and

enlarge the second outer hole of the remaining arm with a

5/64" [2mm] drill bit. Install a screw-lock pushrod connector

11. Make any fi nal connections to the engine such as the

pressure line to the muffl er, carb line, etc. If you assembled

the fuel tank with a fi ll line, cut the fi ll line to length and plug

the line with a fuel line plug (not included).

12. Install the bottom hatch cover with two 2.5x10mm

washer head self-tapping screws. Be sure to harden the

wood surrounding the holes with thin CA.

17

Page 18

BRUSHLESS MOTOR INSTALLATION

If you have installed a glow engine, skip this section as it only

contains information relevant to installing a brushless motor.

Be sure to read and understand the instructions that

come with the ESC and motor before attempting to

operate the system.

1. Attach the out-runner motor to the brushless motor

mount using the included 3 x 8mm machine screws and thread

locking compound. If you haven’t done so yet, install the prop

adapter to the motor case with the hardware included with

the motor and thread locking compound. Loosen the screws

that hold the two motor mount halves together and set the

distance from the back side of the mount to the front of the

prop washer to be 4-5/8" [117mm]. Retighten the screws

using thread locking compound.

3. Apply a thin coating of epoxy where you plan to mount

the ESC. This will improve the adhesion of the doublesided foam mounting tape (not included). Let the epoxy

cure undisturbed. Connect the ESC to the motor. This is a

good time to confi rm the correct rotation of the motor by

temporarily connecting the battery and radio system to the

ESC and powering the motor (without prop). If the motor

rotates the wrong direction, simply disconnect any two of the

three motor leads and swap their position. Use double-sided

foam mounting tape to secure the ESC in place.

2. Locate the pre-drilled holes in the fi rewall that match up

with the Great Planes medium motor mount. Use a 4x20mm

machine screw and a 4mm fl at washer to draw four 4mm

blind nuts tight into the holes. Attach the motor mount to the

fi rewall using four 4x20mm machine screws, four 4mm fl at

washers, and thread locking compound.

4. Apply a piece of self-adhesive hook and loop material

inside the battery compartment (don’t forget a coat of epoxy

to improve adhesion). Make a strap from the included hook

and loop strap material to fi t around your battery packs by

overlapping the mating ends by approximately 1" [25mm]. Fit

the strap ends through the slots in the battery tray. Cut the

strap to length as needed.

18

Page 19

5. Test fi t your battery packs in the battery compartment.

They can be secured together with additional self-adhesive

hook and loop material, but the packs may need to be

inserted into the compartment one at a time.

FINISH THE MODEL

1. Pre-cut slots are provided on both sides of the fuselage

for an on/off switch. The slots may need to be enlarged

depending on what brand switch harness you are using.

6. Fit the ESC hatch cover in place and drill through

the pre-cut mounting holes into the hardwood rail using a

1/16" [1.6mm] drill bit. Thread a 2.5x10mm washer head

self-tapping screw into each hole and back it out. Apply a

drop of thin CA to each hole to harden the wood. Install the

hatch cover using two 2.5x10mm washer head self-tapping

screws. Trim the covering from the cool air exit slots in the

hatch cover.

7. Mount the battery hatch cover using two 2.5x10mm

washer head self-tapping screws.

2. Wrap your receiver and receiver battery in foam rubber

(not included). Connect the battery to the switch and the

servos and switch lead to the receiver (be sure to secure the

connection between the battery and the switch using tape or

heat shrink tubing). Stuff the components into the fuselage

and use scrap sticks of wood to hold them securely in place.

It is recommended to only tack glue the sticks in place at this

time as the components may need to be shifted forward or

aft when balancing the plane. When the exact position of the

radio components is confi rmed, be sure to thoroughly glue

the sticks in place.

19

Page 20

2. Be certain the model is clean and free from oily fi ngerprints

OKAY

and dust. Prepare a dishpan or small bucket with a mixture

of liquid dish soap and warm water—about one teaspoon of

soap per gallon of water. Submerse the decal in the soap and

water and peel off the paper backing. Note: Even though the

decals have a “sticky-back” and are not the water transfer

type, submersing them in soap & water allows accurate

positioning and reduces air bubbles underneath.

3. Position decal on the model where desired. Holding

the decal down, use a paper towel to wipe most of the

water away.

3. Apply the instrument panel decal (see Apply the

Decals section). Use canopy glue to glue the canopy in

place as shown. Tape the canopy down and allow the glue

to dry overnight. The canopy can also be screwed into place

(additional screws not included).

4. Install the spinner backplate, propeller, prop washer,

prop nut, and spinner cone onto the engine crankshaft. The

spinner backplate (and propeller) may need to be drilled or

reamed larger to match the crankshaft diameter. Be sure to

balance your prop!

4. Use a piece of soft balsa or something similar to squeegee

remaining water from under the decal. Apply the rest of the

decals the same way.

GET THE MODEL READY TO FLY

INSTALL AND OPERATE THE MOTOR BATTERY

(BRUSHLESS ONLY)

IMPORTANT: If using multiple battery packs that are connected

with an adapter, never charge the batteries together through

the adapter. Always charge each battery pack separately.

Charge the batteries, then read the following precautions on

how to connect multiple packs for fl ying the model:

BATTERY PRECAUTIONS:

There are two ways to connect multiple battery packs: In

Series and in Parallel.

5. This completes the assembly of the Tiger 2 ARF!

APPLY THE DECALS

1. Use scissors or a sharp hobby knife to cut the decals from

the sheet.

❏ 1. Connecting batteries in “Series” means to connect

the +’s to the –’s and the –’s to the +’s. This combines the

batteries’ Voltages, but the capacity remains the same.

20

Page 21

OKAY

These are three 11.1V, 3200mAh batteries. When joined

in Series, the result will be a 33.3V, 3200mAh battery.

❏ 2. Connecting batteries in “Parallel” means to connect

NO!!!

NO!!!

NO!!!

FULL

THROTTLE

RUDDER

MOVES

RIGHT

ELEVATOR

MOVES DOWN

RIGHT AILERON

MOVES UP

LEFT AILERON

MOVES DOWN

/

4-CHANNEL RADIO SETUP

(STANDARD MODE 2)

the +’s to the +’s and the -’s to the -’s. This combines the

batteries’ capacities, but the Voltage remains the same.

LITHIUM BATTERY HANDLING & USAGE

WARNING!! Read the entire instruction sheet included with

the battery. Failure to follow all instructions could cause

permanent damage to the battery and its surroundings, and

cause bodily harm!

• ONLY use a LiPo approved charger.

• NEVER charge in excess of 4.20V per cell.

• ONLY charge through the “charge” lead. NEVER

charge through the “discharge” lead.

• NEVER charge at currents greater than 1C.

• ALWAYS set charger’s output volts to match

battery volts.

• ALWAYS charge in a fi reproof location.

• NEVER trickle charge.

• NEVER allow battery temperature to exceed

150° F (65° C).

• NEVER disassemble or modify pack wiring in any

way or puncture cells.

• NEVER discharge below 3.0V per cell

• NEVER place on combustible materials or leave

unattended during charge or discharge.

• ALWAYS KEEP OUT OF REACH OF CHILDREN.

CHECK THE CONTROL DIRECTIONS

NEVER connect battery packs with different Voltages in

Parallel–only combine in Series. Otherwise, the batteries

will try to “equalize” with the larger one trying to “charge” the

smaller one, thus causing heat and likely a fi re.

Also NEVER connect battery packs with different capacities

in Series or in Parallel.

1. Turn on the transmitter and receiver and center the

trims. If necessary, remove the servo arms from the servos

and reposition them so they are centered. Reinstall the

screws that hold on the servo arms.

2. With the transmitter and receiver still on, check

all the control surfaces to see if they are centered. If

necessary, adjust the clevises on the pushrods to center

the control surfaces.

3. Make certain that the control surfaces and the throttle

respond in the correct direction as shown in the diagram.

If any of the controls respond in the wrong direction, use

21

Page 22

the servo reversing in the transmitter to reverse the servos

These are the recommended control surface throws:

ELEVATOR

HIGH RATE LOW RATE

5/16"

[8mm]

11 deg

Up

5/16"

[8mm]

11 deg

Down

3/16"

[4.8mm]

7 deg

Up

3/16"

[4.8mm]

7 deg

Down

RUDDER

7/8"

[22mm]

13 deg

Right

7/8"

[22mm]

13 deg

Left

5/8"

[16mm]

9 deg

Right

5/8"

[16mm]

9 deg

Left

AILERONS

7/16"

[11mm]

14 deg

Up

7/16"

[11mm]

14 deg

Down

5/16"

[8mm]

10 deg

Up

5/16"

[8mm]

10 deg

Down

connected to those controls. Be certain the control surfaces

have remained centered. Adjust if necessary.

SET THE CONTROL THROWS

Use a Great Planes AccuThrow™ (or a ruler) to accurately

measure and set the control throw of each control surface

as indicated in the chart that follows. If your radio does not

have dual rates, we recommend setting the throws at the

low rate setting.

IMPORTANT: The Tiger 2 ARF has been extensively

fl own and tested to arrive at the throws at which it fl ies

best. Flying your model at these throws will provide you

with the greatest chance for successful fi rst fl ights. If,

after you have become accustomed to the way the Tiger

2 fl ies, you would like to change the throws to suit your

taste, that is fi ne. However, too much control throw could

make the model diffi cult to control, so remember, “more

is not always better.”

NOTE: The throws are measured at the widest part of

the elevators, rudder and ailerons. If you are using a ruler

to set your control surface throws, the defl ection distance

is measured as the height from the center trailing edge of

the control surface when moved from the neutral position as

shown in the sketch. Defl ection in degrees is also provided

for an alternative measuring method.

BALANCE THE MODEL (C.G.)

More than any other factor, the C.G. (balance point)

can have the greatest effect on how a model fl ies, and

may determine whether or not your fi rst fl ight will be

successful. If you value this model and wish to enjoy it for

many fl ights, DO NOT OVERLOOK THIS IMPORTANT

PROCEDURE. A model that is not properly balanced

will be unstable and possibly unfl yable.

At this stage the model should be in ready-to-fl y condition

with all of the systems in place including the engine or

brushless motor, landing gear, and the radio system (and

battery pack if applicable).

1. Use a felt-tip pen or 1/8" [3mm]-wide tape to accurately

mark the C.G. on the top of the wing on both sides of the

fuselage. The C.G. is located 3-7/8" [98mm] back from the

leading edge of the wing.

This is where your model should balance for the fi rst

fl ights. Later, you may wish to experiment by shifting

the C.G. up to 3/8" [9.5mm] forward or 3/8" [9.5mm]

back to change the fl ying characteristics. Moving the

C.G. forward may improve the smoothness and stability,

but the model may then require more speed for takeoff

and make it more diffi cult to slow for landing. Moving

the C.G. aft makes the model more maneuverable, but

could also cause it to become too diffi cult to control. In

any case, start at the recommended balance point

and do not at any time balance the model outside the

specifi ed range.

22

Page 23

2. With the wing attached to the fuselage, all parts of the

model installed (ready to fl y) and an empty fuel tank, place

the model upside-down on a Great Planes CG Machine,™ or

lift it upside-down at the balance point you marked.

3. If the tail drops, the model is “tail heavy” and the battery

pack and/or receiver must be shifted forward or weight must

be added to the nose to balance. If the nose drops, the model

is “nose heavy” and the battery pack and/or receiver must be

shifted aft or weight must be added to the tail to balance. If

possible, relocate the battery pack and receiver to minimize or

eliminate any additional ballast required. If additional weight is

required, nose weight may be easily added by using a “spinner

weight” (GPMQ4645 for the 1 oz. [28g] weight, or GPMQ4646

for the 2 oz. [57g] weight). If spinner weight is not practical or

is not enough, use Great Planes (GPMQ4485) “stick-on” lead.

A good place to add stick-on nose weight is to the fi rewall

(don’t attach weight to the cowl—it is not intended to support

weight). Begin by placing incrementally increasing amounts

of weight on the bottom of the fuse over the fi rewall until the

model balances. Once you have determined the amount of

weight required, it can be permanently attached. If required,

tail weight may be added by cutting open the bottom of the

fuse and gluing it permanently inside.

Note: Do not rely upon the adhesive on the back of the lead

weight to permanently hold it in place. Over time, fuel and

exhaust residue may soften the adhesive and cause the

weight to fall off. Use #2 sheet metal screws, RTV silicone or

epoxy to permanently hold the weight in place.

4. IMPORTANT: If you found it necessary to add any

weight, recheck the C.G. after the weight has been installed.

BALANCE THE MODEL LATERALLY

1. With the wing level, have an assistant help you lift the

model by the engine propeller shaft and the bottom of the

fuse under the TE of the fi n. Do this several times.

FLYING

The Tiger 2 ARF is a great-fl ying model that fl ies smoothly

and predictably. The Tiger 2 does not, however, possess the

self-recovery characteristics of a primary R/C trainer and

should be fl own only by experienced R/C pilots.

FUEL MIXTURE ADJUSTMENTS

A fully cowled engine may run at a higher temperature than

an un-cowled engine. For this reason, the fuel mixture should

be richened so the engine runs at about 200 rpm below

peak speed. By running the engine slightly rich, you will help

prevent dead-stick landings caused by overheating.

TAKEOFF

If you have dual rates on your transmitter, set the switches

to “high rate” for takeoff, especially when taking off in

a crosswind. Although this model has good low-speed

characteristics, you should always build up as much speed

as your runway will permit before lifting off, as this will give

you a safety margin in case of a “fl ame-out.” When you fi rst

advance the throttle the plane will usually turn left slightly.

Correct by applying suffi cient right rudder to hold it straight

down the runway. When the plane has suffi cient fl ying speed,

lift off by smoothly applying up elevator (don’t pull it hard into

a steep climb!), and climb out gradually.

FLIGHT

We recommend that you take it easy with your Tiger 2 ARF

for the fi rst several fl ights, gradually “getting acquainted”

with this realistic model as your engine gets fully brokenin. Add and practice one maneuver at a time, learning how

she behaves in each. For ultra-smooth fl ying and normal

maneuvers, we recommend using the “low rate” settings

as listed on page 22. Well before it’s time to land, fl y your

Tiger 2 ARF to a safe altitude. Cut the throttle to an idle

and check out the model’s low-speed characteristics. Do

this several times to become familiar with how the Tiger

2 ARF handles stalls. This also helps you learn what to

expect when landing.

LANDING

When it’s time to land, fl y a normal landing pattern and

approach. For your fi rst landings, plan to approach slightly

faster than stall speed and fl are a few inches off the runway

onto the main wheels.

2. If one wing always drops when you lift the model, it

means that side is heavy. Balance the airplane by adding

weight to the other wing tip. An airplane that has been

laterally balanced will track better in loops and other

maneuvers.

23

Page 24

www.carlgoldbergproducts.com

© Copyright 2009 GBGA1066Mnl

24

Loading...

Loading...