Page 1

™

Wingspan: 79 in [2005mm]

Wing Area: 674 sq in [43.5 dm2]

Weight: 2.0–2.25 lb [910–1020g]

Wing Loading: 7–8 oz/sq ft [21–24 g/dm2]

Length: 41 in [1040mm]

Radio: 2-channel minimum with 2 servos and standard size receiver

™

WARRANTY

Great Planes guarantees this kit to be free from defects in both material and workmanship at the date of purchase.

This warranty does not cover any component parts damaged by use or modifi cation. In no case shall Great Planes’

liability exceed the original cost of the purchased kit. Further, Great Planes reserves the right to change or

modify this warranty without notice.

In that Great Planes has no control over the fi nal assembly or material used for fi nal assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the fi nal user-assembled product. By

the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is

advised to return this kit immediately in new and unused condition to the place of purchase.

To make a warranty claim Hobby Services

send the defective part 3002 N. Apollo Dr., Suite 1

or item to Hobby Services Champaign, IL 61822 USA

at this address: (217) 398-8970 Ext. 5

Include a letter stating your name, return shipping address, as much contact information as possible (daytime

telephone number, fax number, e-mail address), a detailed description of the problem and a photocopy of the

purchase receipt. Upon receipt of the package, the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Page 2

TABLE OF CONTENTS

ADDITIONAL ITEMS REQUIRED

THINGS TO CONSIDER . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . . 2

Required Hardware and Accessories . . . . . . . . . . . . . 2

Adhesives and Building Supplies. . . . . . . . . . . . . . . . . 2

Optional Supplies and Tools. . . . . . . . . . . . . . . . . . . . . 2

Building Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

JOIN THE WING PANELS . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALL THE TAIL SECTION . . . . . . . . . . . . . . . . . . . . . . 4

INSTALL THE SERVOS AND PUSHRODS . . . . . . . . . . . . 6

INSTALL THE RECEIVER AND BATTERY . . . . . . . . . . . . 9

FINISH THE MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

APPLY THE DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

GET THE MODEL READY TO FLY . . . . . . . . . . . . . . . . . 10

Check the Control Directions . . . . . . . . . . . . . . . . . . . 10

Set the Control Throws. . . . . . . . . . . . . . . . . . . . . . . . 11

Balance the Model (C.G.). . . . . . . . . . . . . . . . . . . . . . 12

Balance the Model Laterally. . . . . . . . . . . . . . . . . . . . 12

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Trim Flights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hi-Start Launch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First Flights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

THERMAL FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Facts About Thermals . . . . . . . . . . . . . . . . . . . . . . . . 14

Thermal Soaring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

POINTERS FOR CONTEST FLYING. . . . . . . . . . . . . . . . 15

SLOPE SOARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Slope Landings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ballasting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

The Gentle Lady ARF sailplane was designed to be a gentle

trainer for the beginning modeler, yet to possess competition

capability in the hands of the experienced glider pilot. The

Gentle Lady is very effi cient and reacts quickly to rising air

(called lift, or thermals). To stay in a thermal, the Gentle Lady

can circle very tightly without falling off. The model has good

penetration into the wind and can “cruise” when desired.

THINGS TO CONSIDER

The Gentle Lady ARF requires a minimum 2-channel radio

system with two 44 oz.-in. [3.2 kg-cm] minimum standard

servos. A charge jack receptacle is optional, but is useful for

quickly checking and recharging the receiver pack without

removing the radio hatch. Recommended part numbers for

the radio components are provided below:

REQUIRED HARDWARE AND ACCESSORIES

This is the list of hardware and accessories required to

fi nish the Gentle Lady ARF. Order numbers are provided

in parentheses:

R/C foam rubber 1/4" [6mm] (HCAQ1000)

Dynafl ite™ Up-Start 2M (DYFP8305)

Hobbico® #64 rubber bands (HCAQ2020)

ADHESIVES AND BUILDING SUPPLIES

This is the list of Adhesives and Building Supplies that are

required to fi nish the Gentle Lady ARF:

1/2 oz. [15g] Thin Pro™ CA (GPMR6001)

Pro 30-minute epoxy (GPMR6047)

Denatured alcohol (for epoxy clean up)

Drill bits: 1/16” [1.6mm], 5/64” [2mm]

#1 Hobby knife (HCAR0105)

#11 blades (5-pack, HCAR0211)

Top Flite® MonoKote® sealing iron (TOPR2100)

Top Flite Hot Sock™ iron cover (TOPR2175)

Panel Line Pen (TOPQ2510)

OPTIONAL SUPPLIES AND TOOLS

Here is a list of optional tools that will help you build the

Gentle Lady ARF:

1/2 oz. [15g] Thick Pro CA– (GPMR6013)

2 oz. [57g] spray CA activator (GPMR6035)

4 oz. [113g] aerosol CA activator (GPMR6034)

CA applicator tips (HCAR3780)

CA debonder (GPMR6039)

Pro 6-minute epoxy (GPMR6045)

Epoxy brushes (GPMR8060)

Mixing sticks (GPMR8055)

Mixing cups (GPMR8056)

Pliers with wire cutter (HCAR0630)

Servo horn drill (HCAR0698)

CG Machine™ (GPMR2400)

Hobbico® fl exible 18" ruler stainless steel (HCAR0460)

Top Flite MonoKote trim seal iron (TOPR2200)

Top Flite MonoKote heat gun (TOPR2000)

Hobbico pin vise 1/16 collet w/6 Bits (HCAR0696)

Great Planes® Clevis Installation Tool (GPMR8030)

Futaba® S3004 Servo Standard (FUTM0004)

Ernst Charge Receptacle Futaba J FM (ERNM3001)

2

Page 3

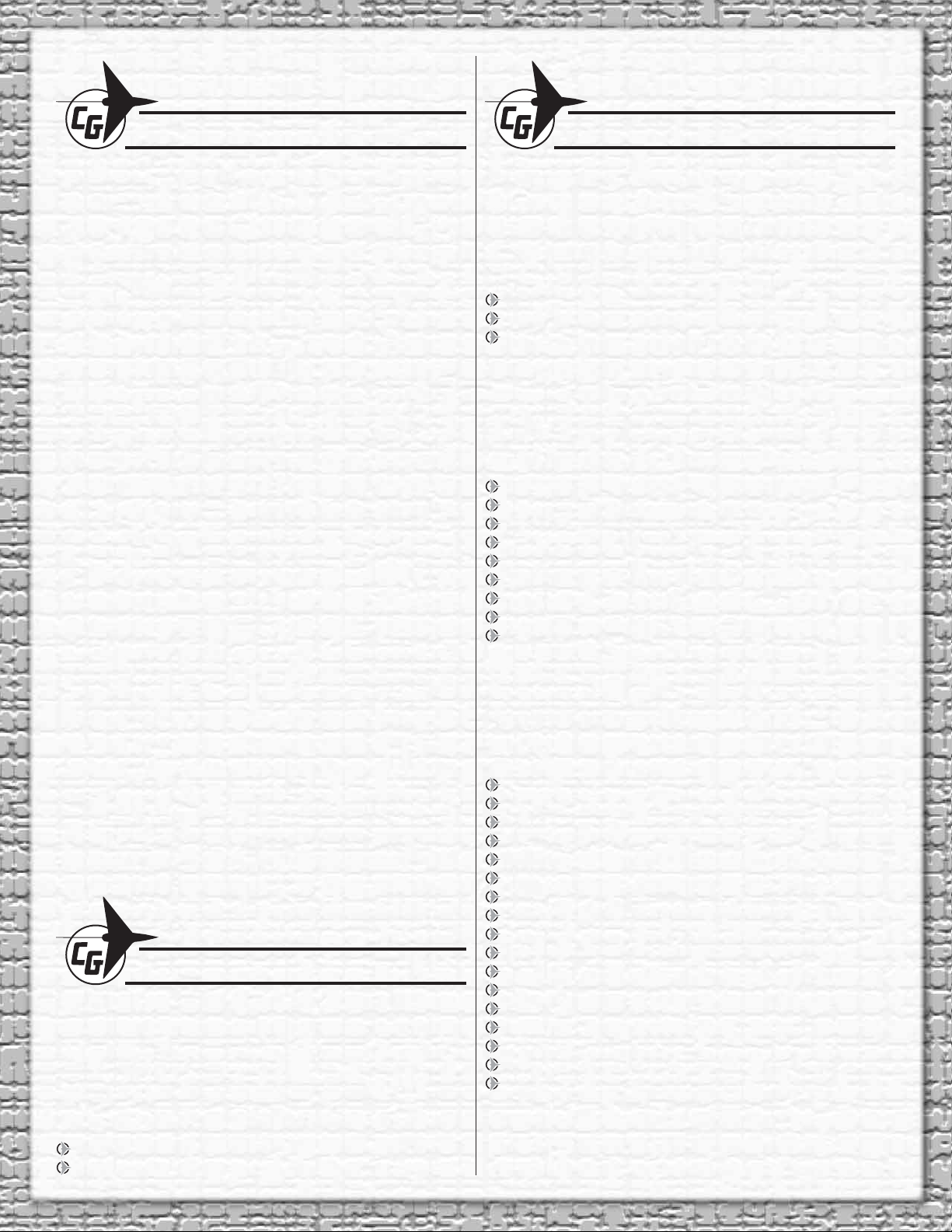

BUILDING STAND

JOIN THE WING PANELS

A building stand or cradle comes in handy during the build.

We use the Robart Super Stand II (ROBP1402) for all our

projects in R&D, and it can be seen in pictures throughout

this manual.

PREPARATIONS

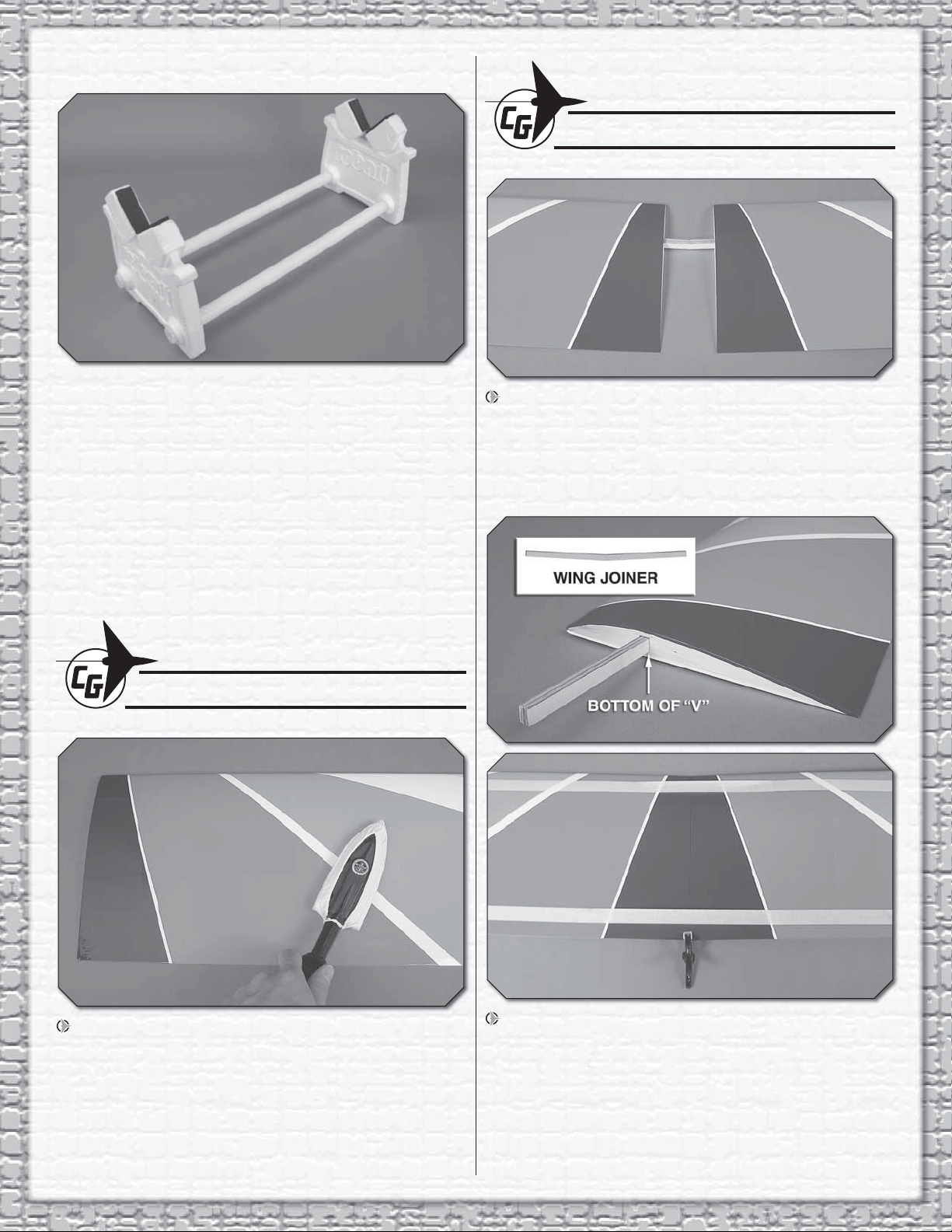

1. Test fi t the wing joiner into the wing panels. The point

of the “V” shaped joiner should point to the bottom of the

wing panels. Sand the wing joiner or root ribs if necessary

to achieve the correct fi t. The root ribs should join together

tightly with no gaps and the joiner should be just slightly

loose in the joiner pockets to allow room for epoxy.

Remove the tape and separate all the control surfaces.

Use a covering iron with a covering sock on high heat to

tighten the covering if necessary. Apply pressure over sheeted

areas to thoroughly bond the covering to the wood.

2. Use a mixing stick or something similar to coat the

inside of the wing joiner pockets of both wing panels with

30-minute epoxy. Thoroughly coat one half of the wing joiner

with 30-minute epoxy and insert it into the joiner pocket of

one wing panel with the bottom of the “V” shape pointing to

the underside of the wing. Coat the root ribs of both wing

panels and the protruding end of the wing joiner with epoxy.

Slide the wing panels together and use tape to hold them

tight while the epoxy cures.

3

Page 4

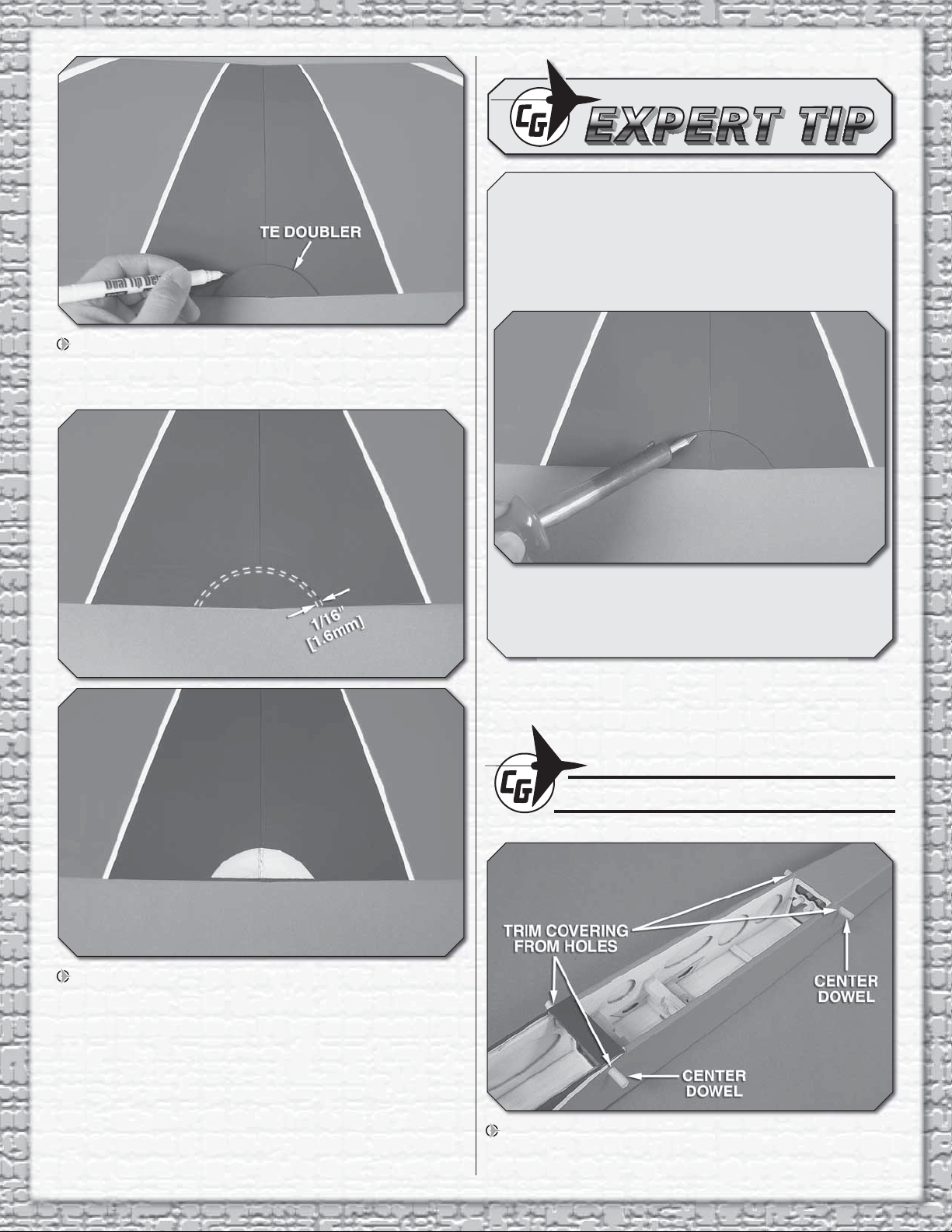

3. Center the plywood TE doubler along the TE of the

wing as shown. Use a felt-tip pen to trace around the doubler

onto the wing.

HOW TO CUT COVERING FROM BALSA

Use a soldering iron to cut the covering from the area

beneath the wing bolt plate. The tip of the soldering iron

doesn’t have to be sharp, but a fi ne tip does work best.

Allow the iron to heat fully.

Guide the soldering iron at a rate that will just melt the

covering and not burn into the wood. The hotter the

soldering iron, the faster it must travel to melt a fi ne cut.

Peel off the covering.

4. Use a sharp #11 hobby knife or use the following Expert

Tip to cut the covering 1/16" [1.6mm] inside of the lines you

marked. Use care to cut only the covering and not into the

wood. Use alcohol to wipe away the lines. Glue the doubler

in position with CA or epoxy.

INSTALL THE TAIL SECTION

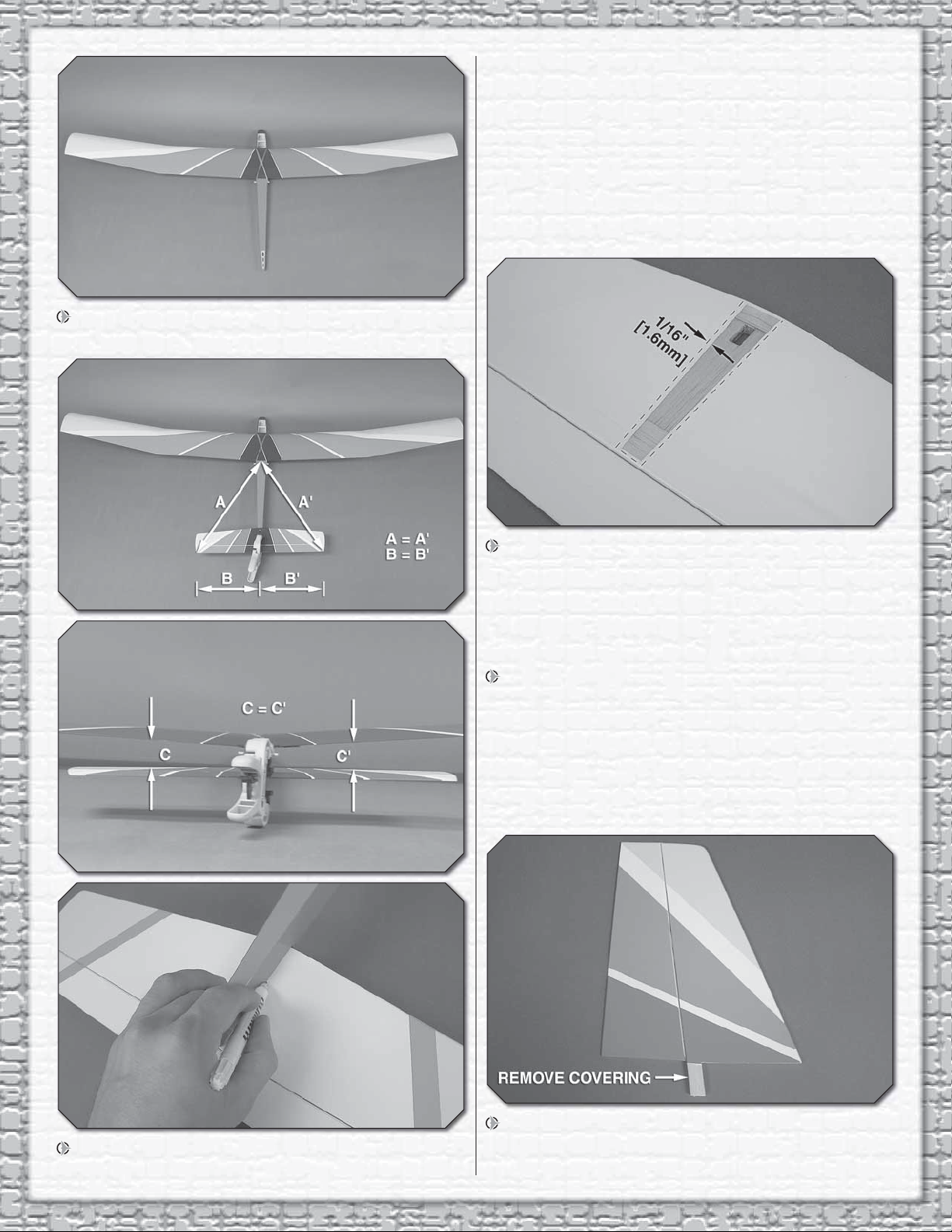

1. Trim the covering from the rubber band dowel holes in

the sides of the fuselage. Center the dowels in the holes as

shown and glue them in place with CA or epoxy.

4

Page 5

2. Center the wing on the fuselage and secure it using

two crisscrossed rubberbands as shown.

a center mark on the stab is helpful) and make the distance

between the fuse center and stab tips equal on both sides.

Stand back 5-6 ft [1.5 - 1.8m] and view the model from

behind. Confi rm that the stab and wing are parallel. If not,

sand the fuselage as necessary until they are parallel. When

satisfi ed, use a felt-tip pen to trace around the saddle where

it meets the underside of the stab. We used a small clamp to

hold the stab in place while we did this.

4. Remove the stab from the fuse and trim the covering

1/16" [1.6mm] inside the lines you drew. Be careful not to cut

into the wood structure beneath the covering. Use denatured

alcohol to wipe away the lines.

5. Coat the stab saddle on the fuselage and the area

where you removed the covering from the stab with 30-minute

epoxy. Put the stab back into place on the saddle and recenter its position. Use clamps or weights to hold the stab in

place while the epoxy cures. Wipe away any excess epoxy

with alcohol.

3. Place the horizontal stabilizer onto the stab saddle

as shown. Center the stab left and right on the fuse (making

6. Trim the covering from the vertical fi n post as shown.

Be careful not to cut into the wood.

5

Page 6

7. Fit the fi n post into the slot in the stab. Trace around

SCREW

SERVO

SERVO

TRAY

BRASS

EYELET

GROMMET

the fi n, being sure it is aligned over the fuse center line (a

reference line drawn on the fuselage is helpful to keep the

fi n aligned with the center of the fuselage. Cut the covering

1/16" [1.6mm] inside the lines you drew and use alcohol to

wipe away the lines.

INSTALL THE SERVOS & PUSHRODS

1. Select a servo arm that offers a hole location of 13/32"

[10mm] from the center. Remove all but one of the arms of

the servo arm. Trim the servo arm beyond the hole that is

13/32" [10mm] from the center. Use a fi le or sandpaper to

round over the corners of the arm. Enlarge the outer hole

with a 5/64" [2mm] drill bit. Center the rudder servo with your

radio system and install the servo arm perpendicular to the

servo case as shown.

8. Epoxy the fi n in place. Confi rm that the fi n is

perpendicular to the stab. Use tape if necessary to hold the

fi n square to the stab while the epoxy cures.

2. Prepare the elevator servo arm

in the same manner, but select an arm

with a hole 5/16" [8mm] from the center

and trim the excess length of arm from

beyond the hole. Enlarge the hole with a

5/64" [2mm] drill bit.

3. Position the servos onto the servo rails in the orientation

shown. Drill servo mounting holes using a 1/16" [1.6mm] drill

6

Page 7

bit. Thread a servo mounting screw (included with the servo)

CORRECT INCORRECT

into each hole then remove it. Remove the servos and apply

a drop of thin CA to each hole to harden the wood. When

the CA has hardened, install the servos using the hardware

included with the servos.

4. Trim the covering from the rudder and elevator pushrod

exit slots.

6. Insert the rudder pushrod into the rudder outer pushrod

tube from the aft end. Align the holes in the control horn over

the rudder hinge line and mark the locations of the control

horn mounting holes onto the rudder. Drill two 5/64" [2mm]

holes at the marks on the rudder. Apply a drop of thin CA into

each hole to harden the balsa.

5. Thread a nylon clevis onto a 31-1/2” [800mm] pushrod

20 complete turns. Slide a silicone clevis retainer over the

clevis. Temporarily attach the clevis to the second inner hole

of a control horn (separate the control horn backplate from

the control horn).

7. Install the control horn using two 2x10mm machine

screws and the control horn backplate.

7

Page 8

8. Use a small clamp or tape to hold the rudder in the

neutral position. Mark the pushrod where it crosses the outer

hole in the rudder servo arm.

10. As you did with the rudder pushrod, thread a nylon

clevis onto a 31-1/2" [800m] pushrod 20 complete turns.

Slide a silicone clevis retainer over the clevis. Temporarily

attach the clevis to the second inner hole of a control horn.

Insert the elevator pushrod into the elevator outer pushrod

tube from the aft end. Confi rm that the elevator clevis moves

easily in and out of the fuselage. If there is any rubbing, use

a hobby knife to remove wood from the sides of the opening.

When satisfi ed, align the holes in the control horn over the

elevator hinge line and mark the locations of the control

horn mounting holes onto the elevator. Drill two 5/64" [2mm]

holes at the location, harden the holes with CA and install

the control horn using two 2x10mm machine screws and the

control horn backplate.

9. Remove the clevis from the rudder control horn and

remove the pushrod from the fuselage. Make a “Z” bend at

the mark on the pushrod and cut off the excess pushrod 1/4"

[6mm] beyond the bend. The “Z” bend can be made using

needle nose pliers or “Z” bend pliers designed specifi cally for

that purpose (GPMR8025). Fit the Z-bend into the servo arm

as shown. Remove the clevis from the pushrod and reinsert

the pushrod into the pushrod guide tube from the front this

time. Reinstall the clevis onto the pushrod by 20 turns and

attach to the control horn and secure with a clevis retainer.

Thread the clevis up or down on the pushrod as necessary

to center the rudder with the servo arm centered. Slide the

silicone clevis retainer to the end of the clevis to secure it.

11. With the elevator in the neutral position, mark the

pushrod where it crosses the hole in the elevator servo arm.

Remove the pushrod from the fuse. Make a “Z” bend in the

pushrod and reinstall the pushrod. Make any adjustment to

the clevis necessary so the elevator is centered when the

servo is centered. Be sure to slide the silicone clevis retainer

to the end of the clevis and that the servo arm screw in the

elevator is installed.

8

Page 9

INSTALL THE RECEIVER & BATTERY

1. Mount the radio switch in a location that will not

interfere with the installation of the receiver and battery. Use

the switch plate as a guide to drill the two holes and to cut a

slot for the on/off switch. After you have drilled the mounting

holes for the switch, apply a drop of thin CA to each hole to

harden the wood surrounding the holes. Be sure that the CA

is completely dry before installing the switch.

3. Connect the battery to the switch. It is highly

recommended to secure the connection using tape, heat

shrink tubing (not included), or a clip designed specifi cally for

that purpose. Connect the elevator and rudder servo leads

to the receiver. Wrap the receiver in foam rubber and install

it behind the battery using pieces of the 6x6x200mm stick.

We used a zip tie (not included) to neatly bundle the excess

wires behind the receiver. A rubberband could also be used.

2. Wrap your receiver battery in 1/4" [6mm] foam rubber

(not included). Fit it into the front radio compartment. Cut

pieces from the included 6x6x200mm balsa stick and glue

them along the top and back of the battery to hold it in place

using CA or epoxy. When gluing the sticks, be sure that the

radio hatch cover can be installed without interference.

4. If you installed a 2.4GHz receiver, follow the radio

manufacturer’s instructions for routing the antenna wires. If

you are using an AM or FM system, drill a small hole through

the bottom of the fuse just behind the receiver. Route the

receiver antenna wire out the hole and tape it down the

length of the fuselage as shown. Install a “strain relief” (made

from a leftover servo arm) inside the fuselage as shown in

the sketch. Be sure that the antenna will not interfere with the

tow hook locations.

9

Page 10

FINISH THE MODEL

4. This completes the assembly!

1. A small hole is pre-drilled behind the radio hatch

opening. Thread the 2.5x5mm self-tapping screw into the

hole and remove it. Apply a drop of thin CA to the hole to

harden the wood. When the glue has hardened, install the

nylon radio hatch cover clip using the 2.5x5mm screw and

2.5mm washer. The screw should be tight, but still allow the

clip to swivel on the screw. Fit the hatch cover in place and

secure it with the clip as shown.

2. Two tow hook positions are provided on the underside

of the fuselage. For the fi rst few fl ights, the forward position

should be used. When you are accustomed to the launch

and fl ying characteristics of the Gentle Lady, the tow hook

position can be moved back to aft position for a higher

launch. Be careful as the plane may be more apt to “pop-off”

the line when using the aft position.

APPLY THE DECALS

1. Use scissors or a sharp hobby knife to cut the decals from

the sheet.

2. Be certain the model is clean and free from oily fi ngerprints

and dust. Prepare a dishpan or small bucket with a mixture

of liquid dish soap and warm water—about one teaspoon of

soap per gallon of water. Submerse the decal in the soap and

water and peel off the paper backing. Note: Even though the

decals have a “sticky-back” and are not the water transfer

type, submersing them in soap & water allows accurate

positioning and reduces air bubbles underneath.

3. Position decal on the model where desired. Holding the decal

down, use a paper towel to wipe most of the water away.

4. Use a piece of soft balsa or something similar to squeegee

remaining water from under the decal. Apply the rest of the

decals the same way.

3. Trim the covering from the forward tow hook hole

(approximately 11-13/16" [300mm] back from the front of the

fuse). Thread the 3mm nut and 3mm washer all the way onto

the tow hook. Tighten the tow hook into the blind nut. With

the hook threaded almost all the way into the blind nut and

pointing straight back, tighten the 3mm nut to secure it.

GET THE MODEL READY TO FLY

CHECK THE CONTROL DIRECTIONS

1. Turn on the transmitter and receiver and center the

trims. If necessary, remove the servo arms from the servos

and reposition them so they are centered. Reinstall the

screws that hold on the servo arms.

2. With the transmitter and receiver still on, check all the

control surfaces to see if they are centered. If necessary, adjust

the clevises on the pushrods to center the control surfaces.

10

Page 11

ELEVATOR

MOVES DOWN

RUDDER

MOVES RIGHT

2-CHANNEL RADIO SET UP

(STANDARD MODE 2)

3. Make certain that the control surfaces respond in

These are the recommended control surface throws:

ELEVATOR

HIGH RATE LOW RATE

1/2"

[13mm]

21˚

Up

1/2"

[13mm]

21˚

Down

3/8"

[10mm]

16˚

Up

3/8"

[10mm]

16˚

Down

RUDDER

1-5/8"

[41mm]

35˚

Right

1-5/8"

[41mm]

35˚

Left

1"

[25mm]

21˚

Right

1"

[25mm]

21˚

Left

the correct direction as shown in the diagram. If any of

the controls respond in the wrong direction, use the servo

reversing in the transmitter to reverse the servos connected

to those controls. Be certain the control surfaces have

remained centered. Adjust if necessary.

SET THE CONTROL THROWS

NOTE: The throws are measured at the widest part of the

elevator and rudder. If you are using a ruler to set your control

surface throws, the defl ection distance is measured as the

height from the center trailing edge of the control surface

when moved from the neutral position as shown in the sketch.

Defl ection in degrees is also provided for an alternative

measuring method.

IMPORTANT: The Gentle Lady ARF has been

extensively fl own and tested to arrive at the throws at

which it fl ies best. Flying your model at these throws

will provide you with the greatest chance for successful

fi rst fl ights. If, after you have become accustomed to the

way the Gentle Lady fl ies, you would like to change the

throws to suit your taste, that is fi ne. However, too much

control throw could make the model diffi cult to control,

so remember, “more is not always better.”

Use a Great Planes AccuThrow (or a ruler) to accurately

measure and set the control throw of each control surface

as indicated in the chart that follows. If your radio does not

have dual rates, we recommend setting the throws at the

low rate setting.

11

Page 12

BALANCE THE MODEL (C.G.)

More than any other factor, the C.G. (balance point)

can have the greatest effect on how a model fl ies, and

may determine whether or not your fi rst fl ight will be

successful. If you value this model and wish to enjoy it for

many fl ights, DO NOT OVERLOOK THIS IMPORTANT

PROCEDURE. A model that is not properly balanced

will be unstable and possibly unfl yable.

Note: Do not rely upon the adhesive on the back of the lead

weight to permanently hold it in place. Over time, the weight

may fall off. Use #2 sheet metal screws, RTV silicone or

epoxy to permanently hold the weight in place.

4. IMPORTANT: If you found it necessary to add any weight,

recheck the C.G. after the weight has been installed.

BALANCE THE MODEL LATERALLY

At this stage the model should be in ready-to-fl y condition

with all of the systems in place including the engine or

brushless motor, landing gear, and the radio system (and

battery pack if applicable).

1. Use a felt-tip pen or 1/8" [3mm]-wide tape to accurately

mark the C.G. on the bottom of the wing on both sides of the

fuselage. The C.G. is located 3-5/8" [92mm] back from the

leading edge of the wing.

This is where your model should balance for the fi rst

fl ights. Later, you may wish to experiment by shifting the

C.G. up to 1/4" [6mm] forward or 1/2" [13mm] back to

change the fl ying characteristics.

2. With the wing attached to the fuselage and all parts

of the model installed (ready to fl y), place the model on a

Great Planes CG Machine, or lift it at the balance point you

marked, using your fi ngertips.

3. If the tail drops, the model is “tail heavy” and the battery

pack and/or receiver must be shifted forward or weight must

be added to the nose to balance. If the nose drops, the model

is “nose heavy” and the battery pack and/or receiver must be

shifted aft or weight must be added to the tail to balance. If

possible, relocate the battery pack and receiver to minimize

or eliminate any additional ballast required. If additional

weight is required, use Great Planes (GPMQ4485) “stick-on”

lead. A good place to add stick-on nose weight is at the front

of the radio compartment. Begin by placing incrementally

increasing amounts of weight on the fuse over this area

until the model balances. Once you have determined the

amount of weight required, it can be permanently attached.

If required, tail weight may be added by cutting open the

bottom of the fuse and gluing it permanently inside.

1. With the wing level, have an assistant help you lift the

model by the nose and the bottom of the fuse under the TE

of the fi n. Do this several times.

2. If one wing always drops when you lift the model, it

means that side is heavy. Balance the airplane by adding

weight to the other wing tip. A glider that has been laterally

balanced will track better in fl ight.

FLYING

CAUTION (THIS APPLIES TO ALL R/C AIRPLANES):

If, while fl ying, you notice an alarming or unusual sound

such as a low-pitched “buzz,” this may indicate control

surface fl utter. Flutter occurs when a control surface

(such as an aileron or elevator) or a fl ying surface (such

as a wing or stab) rapidly vibrates up and down (thus

causing the noise). In extreme cases, if not detected

immediately, fl utter can actually cause the control

surface to detach or the fl ying surface to fail, thus

causing loss of control followed by an impending crash.

The best thing to do when fl utter is detected is to slow

the model immediately by reducing speed, then land as

soon as safely possible. Identify which surface fl uttered

(so the problem may be resolved) by checking all the

servo grommets for deterioration or signs of vibration.

Make certain all pushrod linkages are secure and free

of play. If it fl uttered once, under similar circumstances

it will probably fl utter again unless the problem is fi xed.

Some things which can cause fl utter are; Excessive

hinge gap; Not mounting control horns solidly; Poor fi t

of clevis pin in horn; Side-play of wire pushrods caused

by large bends; Excessive free play in servo gears or

insecure servo mounting.

Try to fi nd an experienced pilot to help you with your fi rst fl ights.

Although the Gentle Lady is very easy to fl y, an experienced

pilot can save you a lot of time and possible aggravation by

helping you get your model in the air smoothly.

12

Page 13

TRIM FLIGHTS

It is a good idea to do a couple of trim fl ights before each

fl ying session to make sure the plane is still in trim and the

radio is working properly. The model will survive a hard

landing from 5 feet much better than it will one from several

hundred feet. The fi rst few trim fl ights should be done over a

grass fi eld. The longer the grass the better (more cushion).

Turn on the transmitter fi rst and then the receiver. Hold the

fuselage of the Gentle Lady ARF under the wing with the

nose pointed slightly down and directly into the wind. It is

very important that you launch the model with the wings

level and the nose pointing at a spot on the ground about

50 feet in front of you. Have a friend stand off to the side of

you and tell you whether the nose is pointing up or down. If

the sailplane is launched with the nose up or launched too

hard it will climb a few feet, stall and fall nose-fi rst straight

down. With the nose pointed down slightly, the sailplane

will accelerate down until it picks up enough fl ying speed

and then level off and glide forward. The plane should be

launched with a gentle push forward. With a little practice

you will be able to launch it at just the right speed so it soars

straight ahead in a long and impressive glide path. Adjust the

trims on your transmitter to get the plane to fl y straight ahead

in a smooth glide path.

Once you get the hang of launching it you can try turning the

plane during the trim fl ights by gently applying a “touch” of right

or left rudder. You can also try “fl aring” the landings by slowly

applying a touch of up elevator (pull the stick back) as the

plane nears the ground. The Gentle Lady ARF will continue

to fl y just a few inches off the ground for a surprisingly long

distance. It is important you don’t “over-control” the model.

Make any control inputs slowly and smoothly rather than

moving the transmitter sticks abruptly.

YOUR FIRST HI-START LAUNCH

A hi-start is the most popular way to launch your Gentle Lady

ARF. It consists of 25' – 100' of rubber tubing and 200' – 400'

of string with a parachute or streamer at the end. One end of

the rubber is staked down directly upwind of the launch point.

One end of the string is attached to the other end of the

rubber and the end of the string with the parachute has a loop

or ring and is attached to the tow hook on the sailplane.

Follow the directions that came with the hi-start and lay it

out directly into the wind. Place the stake at the far upwind

edge of the fl ying fi eld so the parachute will blow back onto

the fl ying fi eld.

Turn on your transmitter and then your receiver and hook the

parachute onto your plane’s tow hook. Pull the plane back

approximately twice as far as the rubber is long (i.e., 100' of

rubber = pull back 200') or whatever the hi-start instructions

state. A “fi sh scale” is handy for determining the correct

amount of pull. For your fi rst fl ights pull the plane back until

there is approximately 8 lbs. of tension. More tension can be

used after you get acquainted with the launching procedure.

Hold the plane above your head with the wings level and

the nose pointed slightly up and directly into the wind.

Give the plane a healthy push forward to get it fl ying and

it will climb up like a kite. You should not have to touch the

elevator during the launch but use the rudder stick to keep it

going straight up. As the rubber relaxes the plane will fl y off

the hi-start and the parachute will bring the end of the string

back towards you.

FIRST FLIGHTS

Find a BIG, OPEN fi eld for your fi rst fl ights – the bigger the

better, as you won’t have to worry about where you need

to land. Ground based objects (trees, poles, buildings, etc.)

seem to attract model airplanes like a magnet. Again, we

would like to recommend that you fi nd an experienced

pilot to help you with these fi rst fl ights.

Note: You need to remember that your radio control

responds as if you were sitting in the cockpit. When

you push the transmitter stick to the right, the rudder

moves to the plane’s right! This means that when the

plane is fl ying towards you it may seem like the rudder

controls are reversed (when you give “right” rudder the

plane turns to your left–which is the plane’s “right”). It is

sometimes easier to learn to fl y the plane if you always face

your body in the direction the plane is fl ying and look over

your shoulder to watch the model.

Don’t worry about accomplishing very much on your fi rst

fl ights. Use these fl ights to get the “feel” of the controls and

the Gentle Lady ARF’s fl ying characteristics. Try to keep

the plane upwind and just perform some gentle “S-turns”

(always turning into the wind) until it is time to set up for

landing. Have a helper adjust the trims on your transmitter

(a little at a time) until the plane will fl y straight and level with

the transmitter sticks in their neutral positions. It can be very

hard for a beginner to fl y a plane straight towards him as

he would have to do if the plane were downwind and every

mistake takes the plane a little farther downwind. When it is

time to land, just continue performing the gentle “S-turns”

upwind and let the plane glide onto the ground. Don’t worry

about where the plane lands–just miss any trees, etc.

Practice fl ying directly into the wind (upwind of yourself)

without letting the plane get off course, and then turn and

come downwind until the plane is even with you and try it

again. When you are comfortable with fl ying directly into

the wind, start letting the plane go behind you (downwind)

a little before you start back upwind. Continue this until

you can fl y directly towards you from downwind without

getting disoriented. At this point you can start to establish

a “landing pattern” and bring the sailplane in for a landing

from downwind. This enables the plane to be fl own as slowly

(ground speed) as possible for accurate landings.

13

Page 14

THERMAL FLYING

Thermal soaring is one of the most intriguing of all aspects

of fl ying and the Gentle Lady ARF was designed to excel at

thermal soaring even in the hands of a novice. It can be hard

for the average person to understand how a plane can fl y for

hours and gain altitude without a motor!

FACTS ABOUT THERMALS

Thermals are natural phenomena that happen outside,

by the millions, every single day of the year. Thermals are

responsible for many things including forming several types

of clouds, creating breezes, and distributing plant seeds and

pollen. If you have ever seen a dust devil (which is nothing

more than a thermal that has picked up some dust), you have

seen a thermal in action. Their swirling action is very similar

to that of a tornado but of course much gentler. Most thermals

have updrafts rising in the 200 – 700 feet per minute range

but they have been known to produce updrafts of over 5,000

feet per minute (that’s over 50 miles/hour straight up!) These

strong thermals can rip a plane apart or carry the plane out

of sight before the pilot can get out of the updraft.

Thermals are formed by the uneven heating of the earth and

buildings, etc. by the sun. The darker colored surfaces absorb

heat faster than the lighter colors which refl ect a great deal of

the sun’s energy back into space. These darker areas (plowed

fi elds, asphalt parking lots, tar roofs, etc.) get warmer than the

lighter areas (lakes, grassy fi elds, forests, etc.). This causes

the air above the darker areas to be warmer than the air over

the lighter areas and the more buoyant warm air rises as the

cooler, denser air forces its way underneath the warmer air. As

this warm air is forced upward it contacts the cooler air of the

higher altitudes and this larger temperature difference makes

the thermal rise quicker. The thermal is gradually cooled by the

surrounding cooler air and its strength diminishes. Eventually

the thermal stops rising and any moisture contained in the

once warm air condenses and forms a puffy cumulus cloud.

These clouds, which mark the tops of thermals, are usually

between 2000 and 5000 feet high.

THERMAL SOARING

It takes a lot of concentration to thermal soar effectively. A

sailplane can fl y along the edge of a thermal and unless the

pilot is carefully watching the model he may not realize the

opportunity to gain some altitude. Because most thermals

are relatively small (a couple hundred feet in diameter or

less at 400' altitude) compared to the rest of the sky, the

sailplanes will rarely fl y directly into the thermal and start

rising. Generally, the sailplane will fl y into the edge or near a

thermal and the effects the thermal has on the plane may be

almost unnoticeable. As the sailplane approaches a thermal,

the wing tip that reaches the rising air fi rst will be lifted before

the opposite wing tip. This causes the plane to “bank” and

turn away from where we would like the plane to go.

When you are thermal soaring, try to fl y as smoothly and

straight as possible. Trim the plane to fl y in a straight line

and only touch the controls when you have to. Watch the

sailplane carefully and it will tell you what it is encountering.

When the sailplane fl ies directly into a thermal it will either

start rising or stop sinking. Either case is reason enough to

start circling (especially in a contest where every second

counts). Fly straight ahead until you feel like you are in the

strongest lift, fl y a couple of seconds farther (so your circle

will be centered in the strongest lift) and then start circling in

a fairly tight but smooth turn. When the sailplane is low the

turns have to be tighter to stay in the strongest lift. As the

plane gains altitude, the turns can be larger and fl atter. The

fl atter the turn, the more effi cient the plane is fl ying, but don’t

be afraid to really “crank” it into a steep bank when you are

low. If you see the plane falling off on one side of the turn,

move your circle over into the stronger lift. Thermals move

along with the wind so as you circle you will be swept along

with it. Be careful when thermaling, that you don’t get so far

downwind you can’t make it back to the fi eld to land.

If the sailplane is fl ying along straight and all of a sudden

turns, let the plane continue to bank (you may have to

give it some rudder to keep it banking) until it has turned

270-degrees (3/4 of a full circle). Straighten out the bank and

fl y into whatever turned the plane. If you encounter lift, and

you won’t every time, start circling just as you did when fl ying

directly into a thermal.

Thermals are generated all day long, but the strongest thermals

are produced when the sun is directly overhead. 10:00 am

– 2:00 pm seems to be the best time to get those “killer”

thermals. Some of these thermals can be very large and you

may fi nd it hard to get out of them. If you fi nd yourself getting

too high, don’t dive the plane to get out of the lift. Sailplanes

are very effi cient aircraft and they will build up a lot of speed

and could “blow up” in the rough air of a thermal. The easiest

way to lose altitude is to apply full rudder and full up elevator.

This will put the plane into a tight spin that will not over stress

the airframe but it will enable it to lose altitude very quickly.

This is especially helpful if the sailplane gets sucked into a

cloud or it gets too high to see. The twirling action will give the

sun a better chance of fl ashing off of the wing and catching

your attention. When you are high enough and want to leave

the thermal, add a little down trim to pick up some speed and

fl y 90 degrees to the direction of the wind. If you are not real

high and want to fi nd another thermal, you may want to look

upwind of the last thermal. The same source that generated

this thermal is probably producing another. Just watch out for

“sink” which is often found behind and between thermals.

As you might expect, with all this air rising, there is also air

sinking. This air is the sailplane pilot’s nightmare that can really

make soaring challenging. “Sink” is usually not as strong as

the thermals in the same area, but it can be very strong. Down

drafts of many hundreds of feet per minute are common on

a good soaring day. These down drafts can make a sailplane

look like it is falling out of the air. Because of this, it is important

that you do not let the sailplane get too far downwind.

14

Page 15

When encountering sink, immediately turn and fl y 90 degrees

to the direction of the wind (towards you if possible). Apply

a little “down elevator” and pick up some speed to get out of

the sink as fast as possible. Every second you stay in the

sink is precious altitude lost.

POINTERS FOR CONTEST FLYING

SLOPE SOARING

Slope soaring is a type of fl ying that is very popular in hilly

regions and along the coasts. This type of soaring is possible

when the wind is blowing directly up a hill or cliff. As the wind hits

the slope it is forced up, producing lift which can be utilized by

real sailplanes, hang gliders, birds and even model sailplanes.

Pay Attention! – Pay close attention to the sailplanes fl ying

before you, watch them and try to establish where and when

the thermals are being formed. Thermals are often formed in

cycles and can be fairly regular, so if you keep track of the

time intervals you will have a pretty good idea of when and

where a thermal may be generated.

Watch The Birds! – Thermals suck up small insects that

many birds love to eat. A bunch of swallows fl ying around

in one area may indicate a thermal. Soaring birds (hawks,

vultures, eagles etc.) are the best thermal indicators. They

not only show you where the thermal is but they also show

you where the center is. These “Masters of the Sky” will often

fl y right along with sailplanes.

Practice Those Landings! – Most thermal contests are won

or lost during the landing. Establish a particular landing pattern

and try to stick to it for all landings. Learn to shift your pattern to

account for the wind and particular fl ying fi eld characteristics.

Spoilers can be very useful during contest landings. They

allow you to bring the sailplane in for a landing higher or faster

than normal to guard against any last minute sink or gusts and

dump the extra altitude and speed at the last second. They can

also be used to help control your skid. Opening the spoilers will

stop the plane from sliding a little quicker. You can also “steer”

the plane while it is sliding along the ground. Don’t expect to

be able to “horse it around” but you can gain valuable inches

by using the rudder to guide it toward the spot as it slides to a

stop. Be very careful not to “ground loop” the plane since you

will lose your landing points if the plane fl ips over.

To be able to slope soar, you need a slope with a smooth

piece of land (or water) out in front of it and a breeze blowing

pretty close to straight up the slope. The higher and steeper

the hill or cliff the better. Also the larger and smoother the

land out in front the better. The air fl owing along hits the

hill, is forced up and can generate a very large area of lift.

Behind the hill is a large area of turbulent air that can be very

dangerous to try to fl y in. The faster the wind is blowing, the

stronger the lift and turbulence will be.

To fl y off a slope, stand near the edge and throw the sailplane

(nose down) into the wind. As the sailplane fl ies out into the

“band” of lift it will begin to gain altitude. Turn and fl y parallel to

the slope and make all of your turns into the wind (especially

when you are close to the slope). You will be surprised at

the altitude you can gain just from slope lift. Thermals will

often be “popped loose” by these slopes. If you catch a

thermal and follow it downwind, be very careful to stay high

enough to make it back to the slope without fl ying through

the turbulent air behind the slope. If you don’t have enough

altitude you may want to land a good distance behind the

slope if possible to avoid this turbulent air.

SLOPE LANDINGS

Landings can be very tricky on some slopes. On gentle slopes

you can often fl y very close to the top of the slope and “slide”

into the top of the slope without encountering any turbulent air.

On steeper slopes you may have to be a little more aggressive

to get the plane out of the lift. In any case it is a good idea to

plan your landing before launching your plane.

Know Your Sailplane! – Learn what your sailplane will and

won’t do and fl y within this envelope. This will allow you to

ride thermals downwind while knowing when you have to

head back to make your landing safely.

Learn From The Wind! – Keep track of which way the wind

is blowing. If the wind suddenly shifts, there is some thermal

action fairly close to you. The air is probably being either

sucked up into a thermal or falling out of some sink. In either

case it is often a good idea to fl y in the direction the wind is

blowing if your sailplane is in the general area. This will take

you towards a thermal if there is one or away from the sink,

both of which are desirable.

BALLASTING

In strong wind conditions, you may want to add ballast

(weight) to the sailplane to increase its wing loading which

increases its normal fl ying speed. Increasing the weight of

your sailplane does not change its “glide ratio” but it does

make it fl y faster which makes it sink a proportional amount

faster. Because of this faster sink rate, you need to be very

cautious when ballasting for a thermal contest. In duration

type contests only use ballast on very windy days that also

have a lot of thermal activity.

Add the weight as near as possible to the C.G. of the plane.

Adding 6 – 8 oz. will make a noticeable difference in the

sailplane’s fl ying speed and more can be added later, if

needed. Make sure to recheck the C.G. of the plane after

adding ballast–it should remain where it was.

Have a ball! But always stay in control and fl y in a safe

manner. GOOD LUCK AND GREAT FLYING!

15

Page 16

www.carlgoldbergproducts.com

© 2011 Hobbico®, Inc. All rights reserved. GPMA1960Mnl

Loading...

Loading...