Page 1

®

Wingspan: 78 in [1980mm]

Wing Area: 674 sq in [43.5 dm2]

Weight: 27–30 oz. [765–850 g]

WARRANTY

Carl Goldberg Products guarantees this kit to be free from defects in both material and workmanship at the date

of purchase. This warranty does not cover any component parts damaged by use or modifi cation. In no case shall

Carl Goldberg’ s liability exceed the original cost of the purc hased kit. Further, Carl Goldberg reserves the right

to change or modify this warranty without notice.

In that Carl Goldberg has no control over the fi nal assembly or material used for fi nal assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the fi nal user-assembled product. By

the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is

advised to return this kit immediately in new and unused condition to the place of purchase.

To make a warranty claim Hobby Services

send the defective part 3002 N. Apollo Dr., Suite 1

or item to Hobby Services Champaign, IL 61822 USA

at this address: (217) 398-8970 Ext. 5

Include a letter stating your name, return shipping address, as much contact information as possible (daytime

telephone number, fax number, e-mail address), a detailed description of the problem and a photocopy of the

purchase receipt. Upon receipt of the package, the problem will be evaluated as quickly as possible.

Wing Loading: 5.8–6.4 oz/sq ft [17.7–19.5 g/dm2]

Length: 41-3/4 in [1060mm]

Radio: 2-channel with standard servos

www.carlgoldbergproducts.com

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Page 2

TABLE OF CONTENTS

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . . 2

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Hardware and Accessories . . . . . . . . . . . . . . . . . . . . . . 2

Adhesives and Building Supplies . . . . . . . . . . . . . . . . . . 2

Optional Supplies and Tools . . . . . . . . . . . . . . . . . . . . . . 2

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ASSEMBLE THE WING . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INST ALL THE FIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INST ALL THE ST ABILIZER. . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALL THE RADIO SYSTEM . . . . . . . . . . . . . . . . . . . . 5

FINISH THE SAILPLANE . . . . . . . . . . . . . . . . . . . . . . . . . 8

Canopy Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Apply the Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

GET THE MODEL READY TO FLY . . . . . . . . . . . . . . . . . 11

Check the Control Directions . . . . . . . . . . . . . . . . . . . . 11

Set the Control Throws. . . . . . . . . . . . . . . . . . . . . . . . . 11

Balance the Model (C.G.). . . . . . . . . . . . . . . . . . . . . . . 12

Balance the Model Laterally. . . . . . . . . . . . . . . . . . . . . 13

CHECKING FOR WARPS . . . . . . . . . . . . . . . . . . . . . . . . 13

PREFLIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Identify Your Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Charge the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ground Check & Range Check . . . . . . . . . . . . . . . . . . 14

AMA SAFETY CODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Radio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mount the Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Trim Flights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Your First Hi-Start Launches . . . . . . . . . . . . . . . . . . . . 16

First Flights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal Flying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Facts About Thermals . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal Soaring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

POINTERS FOR CONTEST FLYING. . . . . . . . . . . . . . . . 17

Ballasting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

HARDWARE AND ACCESSORIES

Following is additional hardware and accessories required

to fi nish the Sophisticated Lady ARF. Order numbers are

provided in parentheses.

1/4" Foam Rubber (GPMQ1000)

#64 Rubber Bands (HCAQ2020)

ADHESIVES AND BUILDING SUPPLIES

In addition to common household and hobby tools, this is the

“short list” of the most important items required to assemble

the Sophisticated Lady ARF. Great Planes Pro™ CA glue is

recommended.

Thin CA (1/2 oz. [15g] Thin Pro CA, GPMR6001)

Medium CA (1/2 oz. [15g] Medium Pro CA+,

GPMR6007)

6-minute Pro Epoxy (4oz [113.4g] GPMR6042)

30-minute Pro Epoxy (4oz [113.4g] GPMR6043)

Mixing Sticks (GPMR8055)

Epoxy Brushes (GPMR8060)

Epoxy Mixing Cups (GPMR8056)

Paper Towels

Masking Tape

CA applicator tips (HCAR3780)

Threadlocker thread locking cement (GPMR6060)

#11 blades (5-pack, RMXR6930)

#1 Hobby knife (RMXR6900)

#44 or 3/32" [2.4mm] drill bit

Denatured Alcohol

Wax Paper

Needle-nose Pliers

OPTIONAL SUPPLIES AND TOOLS

Here is a list of optional tools mentioned in the manual that

will help you build the Sophisticated Lady ARF.

ADDITIONAL ITEMS REQUIRED

RADIO EQUIPMENT

The Sophisticated Lady ARF requires a two-channel radio

system with standard size servos. The following servos are

recommended. A square receiver battery or a small fl at receiver

battery is required to fi t the narrow fuselage.

(2) Futaba® S-3004 Standard Servo (FUTM0004)

(1) HydriMax™ 1600mAh NiMH fl at receiver battery

(HCAM6308)

Stick–on segmented lead weight (GPMQ4485)

Hobby paints/paint brushes for painting the pilot

CA debonder (GPMR6039)

CG Machine™ (GPMR2400)

RC 56 Canopy Glue

High Start (GPMP8015)

A model airplane covering iron with a protective covering

sock may also be necessary to retighten the covering and

remove any wrinkles that may have formed after the model

was originally covered at the factory. If you don’t already have a

covering iron, the 21st Century® sealing iron (COVR2700) and

the 21st Century iron cover (COVR2702) are recommended.

2

Page 3

REPLACEMENT PARTS

GPMA4148 Wing

GPMA4149 Fuselage

GPMA4150 Tail Surfaces

GPMA4151 Canopy

GPMA4152 Decals

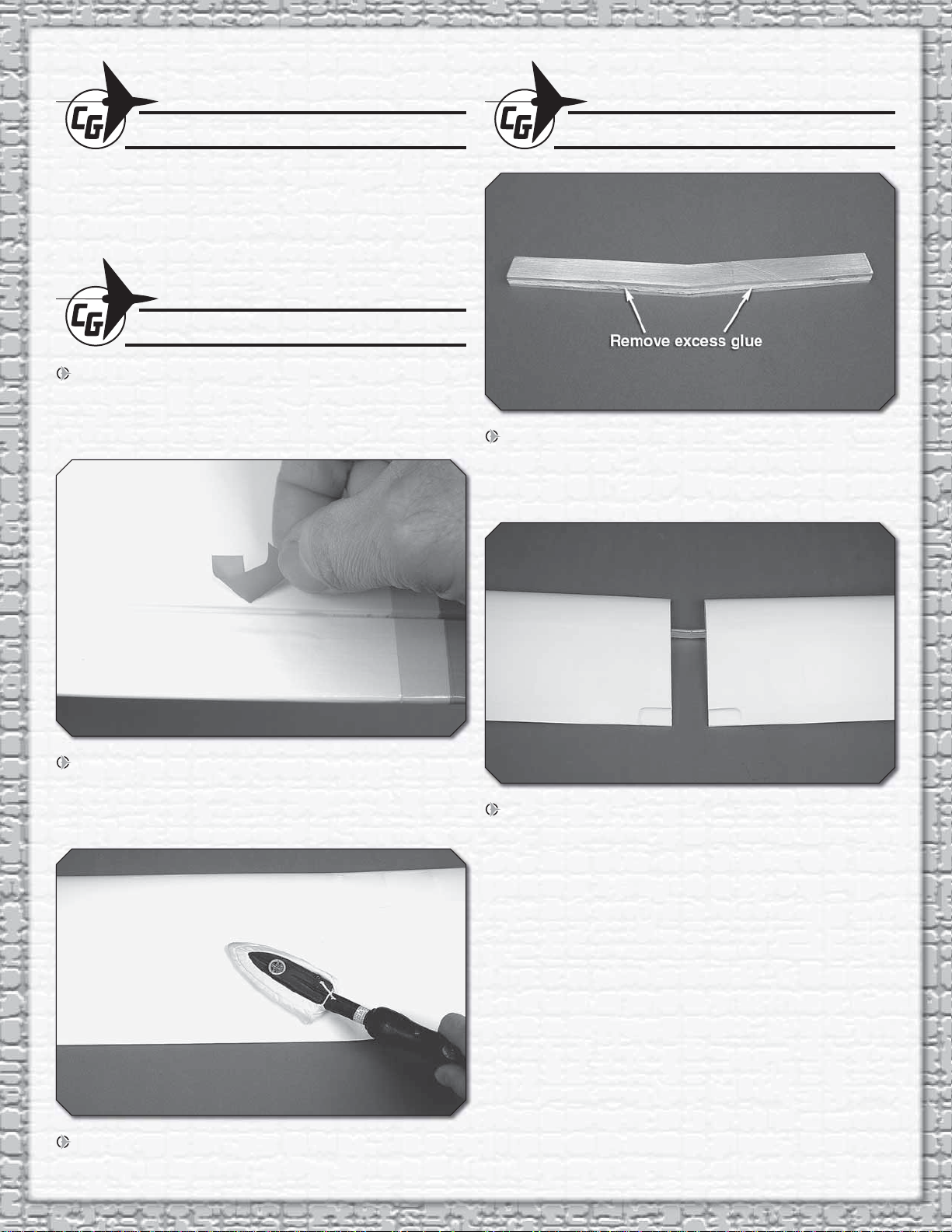

PREPARATION

1. Lay three or four paper towels over each other and cut

the stack into small squares. The small paper towel squares,

dampened with denatured alcohol, will come in handy for

epoxy cleanup and other general cleanup during assembly.

ASSEMBLE THE WING

1. Using 220-grit sandpaper, remove any excess glue from

the sides, top and bottom of the aluminum and plywood wing

joiner. Clean the wing joiner with denatured alcohol and a

paper towel.

2. Remove the masking tape holding all the control surfaces

to their main parts. If necessary, clean off any residual tape

glue with a couple of your paper towel squares dampened

with naptha (lighter fl uid).

3. Using a sealing iron, remove any wrinkles in the covering

before assembly.

2. Check the fi t of the wing joiner in the wing panels. Remove

any excess material from the joiner to allow the panels to fi t

together. Gather everything required for gluing the wing joiner

and wing together, including 30-minute epoxy, mixing sticks,

epoxy brush, 12" [304mm] long dowel or wire, denatured

alcohol and paper towels. Mix up 1/2 oz. [14.8cc] of 30-minute

epoxy. Working quickly, pour a generous amount into the

joiner pocket of one wing half. Use your wire or dowel to

thoroughly distribute the epoxy, coating all surfaces inside

the joiner pocket. Coat the root rib and one half of the wing

joiner that goes into the wing. Insert the joiner in the wing.

Coat the joiner pocket in the other wing half and the other

end of the wing joiner. Join the wing halves together. Then,

stand the wing on end with one of the wing tips resting on

the fl oor. Use a piece of R/C foam or something similar to

cushion and stabilize the wing so it won’t slide around. Hold

the two wing halves together with masking tape. Wipe off any

excess epoxy with a paper towel dampened with denatured

alcohol. After the epoxy has hardened, apply the included

white tape around the joint.

3

Page 4

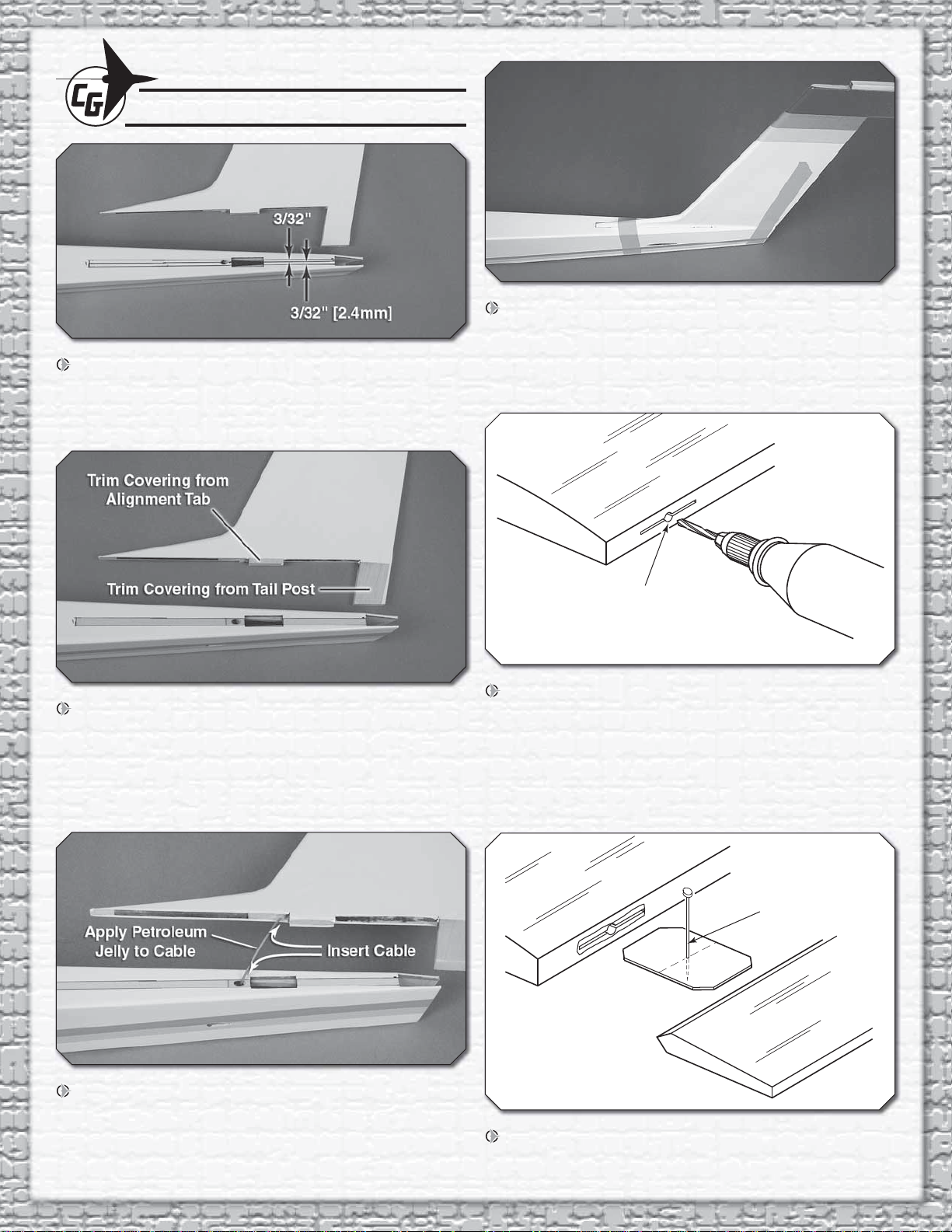

INSTALL THE FIN

Drill a 3/32" Hole

1/2" Deep, in the Center

of the Hinge Slot

Temporary Pin

to Keep Hinge

Centered

1. Use a felt tip pen to draw a centerline on the top aft end

of the fuselage. Draw a line 3/32" [2.4mm] on both sides of

the centerline. Position the fi n on the fuselage and mark on

the top of the fuselage, all the way around the fi n.

4. Use 6-minute epoxy to glue the fi n to the top of the

fuselage. Wipe off the excess epoxy with a paper towel

dampened with rubbing alcohol. Use masking tape to hold

the fi n in position, aligned with the centerline of the fuselage

and parallel to the sides.

2. Using a hobby knife with a fresh blade, cut and remove

the covering only between the two outside lines. DO NOT

cut the wood under the covering as this will weaken the

structure. Also, insert the fi n in the fuselage and mark the

tail post where it exits the fuselage. Trim the covering from

the tail post and alignment tab.

3. Insert the elevator control cable into the nylon outer

control tube in the fuselage and the fi n. Apply petroleum jelly

to the cable to insure epoxy doesn't adhere to it. Position

the fi n on the fuselage and move the cable to check that it

moves freely.

5. Drill a 3/32" [2.4mm] hole, 1/2" [13mm] deep, in the

center of the fi n and rudder hinge slots. If you use a Dremel®

Rotary Tool for this task, it will result in a cleaner hole than if

you use a slower speed drill. Drilling the hole will twist some

of the wood fi bers into the slot, making it diffi cult to insert the

hinge. Insert a hobby knife blade in the slot, working it back

and forth a few times to clean out the slot.

6. To keep the hinges centered, insert a pin in the center

of the hinges.

4

Page 5

7. Insert three hinges in the rudder and attach the rudder to

Assemble, then Apply 6 Drops

of Thin CA to the Center of

the Hinge, on Both Sides

the fi n. Remove the pins, making sure there is approximately

a 1/64" [0.4mm] gap between the rudder and fi n.

8. Defl ect the rudder 1-1/2" [38mm] in one direction and

apply six drops of thin CA to the center of the hinges. Defl ect

the rudder in the other direction and again apply six drops

of thin CA to the center of the hinges. Use a paper towel to

absorb excess CA from the hinge gap before it hardens. Do

not use CA accelerator. Allow the CA to harden slowly.

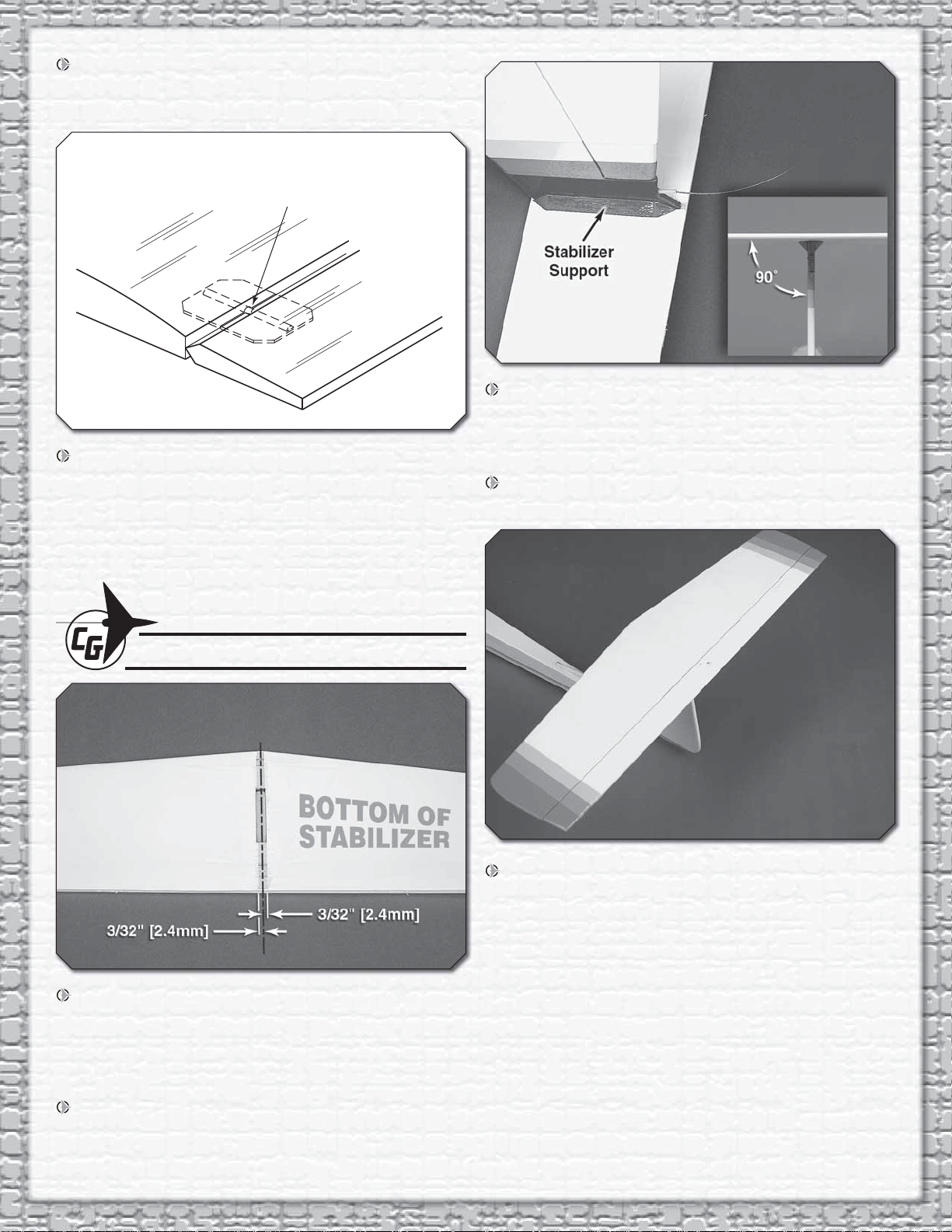

3. Position the two stabilizer supports under the stabilizer

against the fi n. Mark the outline of the supports on the fi n

and stabilizer. Use a sharp hobby knife to trim and remove

the covering 1/16" [1.5mm] inside the outline.

4. Use 6-minute epoxy to glue the stabilizer supports to

the fi n and stabilizer.

INSTALL THE STABILIZER

1. Draw a centerline on the bottom of the stabilizer. Draw

a line 3/32" [2.4mm] on each side of the centerline. Use a

hobby knife to cut and remove the covering only between the

two outside lines. DO NOT cut the wood under the covering

as this will weaken the stabilizer, causing it to fail.

5. Install the elevator using the same hinging method used

on the rudder.

2. Use 6-minute epoxy to glue the stabilizer to the top of the

fi n. Use a square to check that the stabilizer is perpendicular

to the fi n.

5

Page 6

INSTALL THE RADIO SYSTEM

Hinge Line Hinge Line

CORRECT INCORRECT

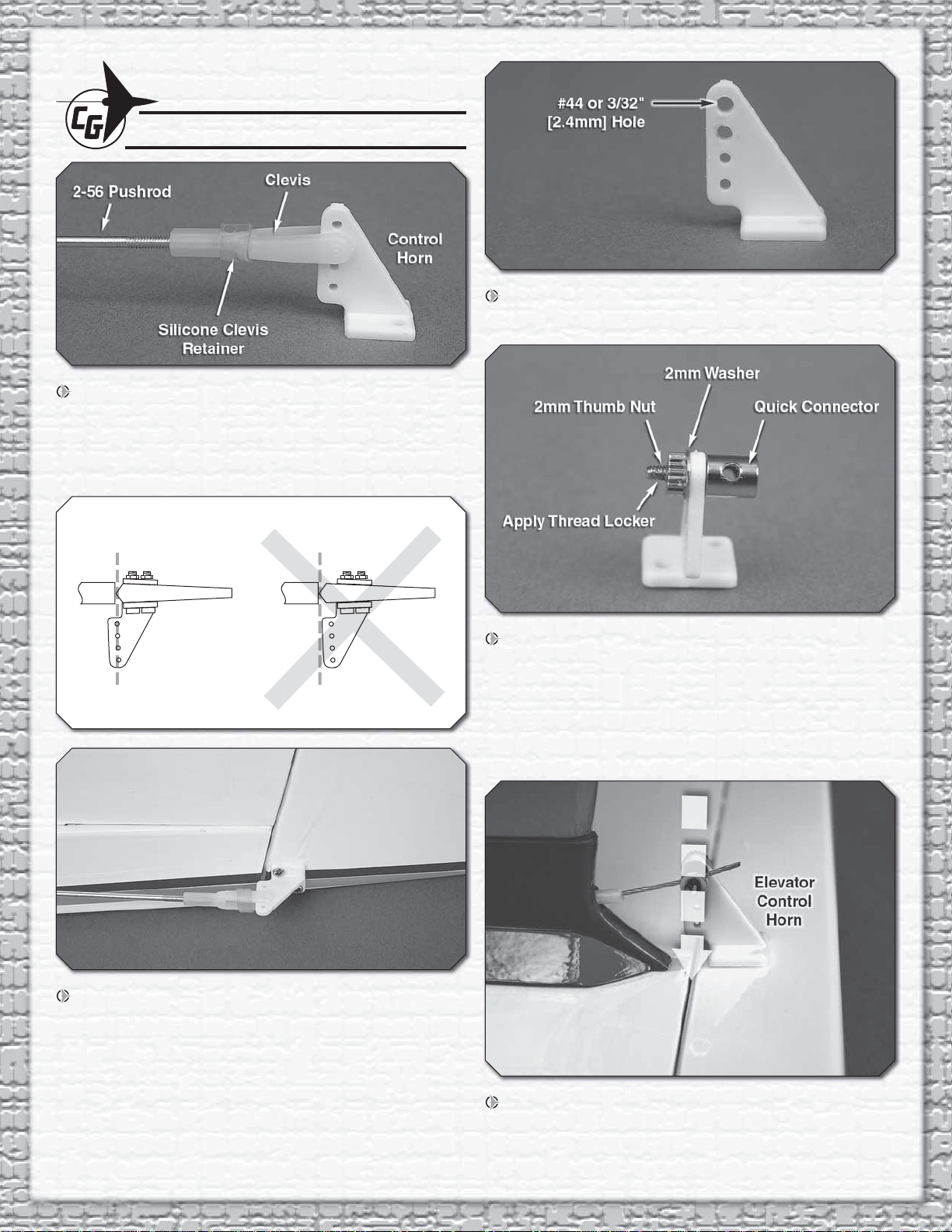

1. Separate the back plate from one of the nylon control

horns. Thread a nylon clevis 14 turns onto the 2-56 metal

pushrod. Slide a silicone clevis retainer over the end of the

clevis. Attach the clevis in the third hole from the bottom of

the control horn.

3. Use a #44 or 3/32" [2.4mm] drill bit to enlarge the outer

hole in the second nylon control horn.

2. Use a sharp hobby knife to remove the covering from

the end of the rudder guide tube. Insert the pushrod into the

rudder pushrod guide tube. Position the control horn on the

rudder so that the four holes in the control horn are aligned

with the hinge line. Drill two 3/32" [2.4mm] holes through the

rudder using the control horn as a guide. Remove the control

horn and harden the holes by applying two or three drops of

thin CA in each hole. After the CA has cured, attach the control

horn to the rudder using two 2-56 x 3/8" [9.5mm] screws and

the control horn back plate.

4. Insert the quick connector through the previously drilled

hole in the control horn. Install a 2mm washer on the quick

connector. Put a drop of threadlocker on the threads and

secure the quick connector with a 2mm thumb nut. Tighten

the nut and then slowly back it off until the quick connector

rotates freely. The threadlocker will prevent the nut from

coming loose.

5. Slide the elevator cable through the hole in the quick

connector and position the elevator control horn so that the

four holes are aligned with the elevator hinge line. Use a felt

tipped pen to mark the location of the holes.

6

Page 7

6. Drill two 3/32" [2.4mm] holes through the elevator using

Servo

Grommet

Brass Eyelet

Servo Tray

Screw

the control horn as a guide. Remove the control horn and

harden the holes by applying two or three drops of thin CA

in each hole. After the CA has hardened, attach the control

horn to the elevator using two 2-56 x 3/8" [9.5mm] screws

and the control horn back plate.

8. Wrap the receiver and receiver battery in 1/4" [6.4mm]

thick foam. Position the receiver and receiver battery in the

fuselage as shown. Remove the receiver switch cover from

the receiver switch. Position the switch cover on the outside

of the fuselage, between the receiver and receiver battery.

Mark the two mounting screw holes and the switch opening

on the fuselage. Use a sharp hobby knife to cut out the switch

opening and a 3/32" [2.4mm] drill bit to drill out the screw holes.

Mount the receiver switch on the inside of the fuselage with

the switch cover on the outside.

7. Install the servos using the hardware included with your

radio system. Again, apply a couple of drops of thin CA to

harden the screw holes.

9. Switch on the transmitter and receiver. Center the elevator

and rudder trims on the transmitter. Remove the servo arm

screw and position the servo arm so that it is perpendicular to

7

Page 8

the centerline of the servo. Cut the servo arm so it does not

touch the fuselage side, approximately 7/16" [11.1mm] from

the center of the arm. Remove the unused arms and reinstall

the servo arm. Reinstall the servo arm screw. With the rudder

centered and rudder aligned with the fi n, mark the pushrod

wire at the servo arm.

14. Install the servo arm on the elevator servo. Route the

elevator cable through the quick connector on the elevator

control horn and the elevator servo arm. Apply a drop of

threadlocker on a 3 x 5mm machine screw. Install the machine

screw in the quick connector on the elevator control horn and

tighten it against the elevator cable.

10. Bend the wire up at the mark. Cut the wire 5/16" [7.9mm]

above the bend. Secure the pushrod to the servo arm with

a nylon FasLink™. Make sure the FasLink does not hit the

fuselage side or bind against the servo arm.

11. Slide the two plywood outer pushrod tube supports

over the elevator outer pushrod tube.

12. Center the elevator servo. Trim a servo arm to fi t

perpendicular to the elevator servo. Remove the other unused

servo arms.

15. Use CA to glue the two plywood elevator outer tube

supports in the slots in the fuselage side.

13. Install a quick connector on the elevator servo arm

following the same procedure used to install it on the elevator

control horn.

8

Page 9

16. Center the elevator servo arm and the elevator. Apply

a drop of threadlocker on a 3 x 5 mm machine screw. Install

the machine screw in the quick connector on the elevator

servo arm and tighten it against the elevator cable. Trim off

the excess cable.

CANOPY INSTALLATION

1. Paint the cockpit with the color scheme of your choice.

Test the paint on a piece of plastic that was cut off of the

cockpit to make sure it will not affect the plastic. RC car

paints usually work well for this. Do not paint the edges of

the cockpit where the canopy will attach or the glue will not

hold as well. After the canopy is glued on, the canopy frame

decal will cover the glue joint. After the paint has dried, apply

the instrument decal to the instrument panel.

FINISH THE SAILPLANE

1. Use 6-minute epoxy to glue the nylon tail skid on the aft

bottom of the fuselage.

2. Using a needle nose pliers, open the eyelet slightly

so that a rubberband can be installed on the eyelet. Thread

each eyelet into the round plywood doubler until it just starts

to come out the back.

2. Remove the covering from over the wing dowel holes.

Center the wing dowels in the fuselage. Use thin CA to glue

them in position.

3. Use medium CA to glue one of the eyelets to the bottom

of the fuselage between the receiver and receiver battery. Glue

the second eyelet on the bottom of the cockpit aligned with

the eyelet in the fuselage. After the CA has hardened, thread

the eyelets in three or four turns more.

9

Page 10

4. Attach one of the rubberbands to the eyelets. It will have

to be doubled or tripled to create enough tension to hold the

back of the cockpit against the fuselage.

5. Trim the canopy 1/4" [6.4mm] outside the scribe lines.

Set the canopy over the cockpit and mark the outline of the

cockpit on the canopy. Trim the canopy to the line.

7. Remove the canopy and install the wing. Only a couple

of large rubberbands are needed to hold the wing at this time.

You will need to use at least eight rubber bands for fl ying.

8. Trim the aft end of the canopy to follow the shape of

the wing.

6. Remove the canopy and the cockpit from the fuselage.

Glue the cockpit between the lines on the canopy using canopy

glue such as J&Z R/C-56 Glue, Pacer RIC 560 Canopy Glue

or 6-minute epoxy. Use the glue sparingly.

9. Attach the threaded tow hook to the bottom of the

fuselage by threading a 3mm nut and a 3mm washer all the

way onto the tow hook. Apply a drop of threadlocker to the

threads and tighten the tow hook into the front blind nut for

the fi rst fl ights. With the tow hook threaded almost all the way

into the blind nut, make sure the tow hook is facing straight

back and tighten the 3mm nut to secure it. After the fi rst fl ights

the tow hook can be moved back to the center hole for most

10

Page 11

fl ying conditions. For contest fl ying, you may want to try the

ELEVATOR

MOVES DOWN

RUDDER

MOVES RIGHT

2-Channel

Radio Set-Up

(Standard Mode 2)

rear hole as it can help achieve a higher launch. But be careful,

as the sailplane will climb at a steeper angle and be more apt

to “pop-off” the line.

APPL Y THE DECALS

1. Use scissors or a sharp hobby knife to cut the decals from

the sheet.

2. Be certain the model is clean and free from oily fi ngerprints

and dust. Prepare a dishpan or small bucket with a mixture

of liquid dish soap and warm water—about one teaspoon of

soap per gallon of water. Submerse the decal in the soap and

water and peel off the paper backing. Note: Even though the

decals have a “sticky-back” and are not the water transfer type,

submersing them in soap & water allows accurate positioning

and reduces air bubbles underneath.

3. Position decal on the model where desired. Holding

the decal down, use a paper towel to wipe most of the

water away.

3. Make certain that the control surfaces respond in the

correct direction as shown in the diagram. If any of the controls

respond in the wrong direction, use the servo reversing in the

transmitter to reverse the servos connected to those controls.

Be certain the control surfaces have remained centered. Adjust

if necessary.

SET THE CONTROL THRO WS

4. Use a piece of soft balsa or something similar to squeegee

remaining water from under the decal. Apply the canopy trim

on the canopy.

GET THE MODEL READY TO FLY

CHECK THE CONTROL DIRECTIONS

1. Turn on the transmitter and receiver and center the trims.

If necessary, remove the servo arms from the servos and

reposition them so they are centered. Reinstall the screws

that hold on the servo arms.

To ensure a successful fi rst fl ight, set up your

Sophisticated Lady according to the control throws

specifi ed in this manual. The throws have been

determined through actual fl ight testing and accurate

record-keeping, allowing the model to perform in the

manner in which it was intended. If, after you have

become accustomed to the way the Sophisticated Lady

fl ies, you would like to change the throws to suit your

taste, that is fi ne. However, too much control throw could

make the model too responsive and diffi cult to control,

so remember, “more is not always better.”

1. Use an airplane stand or something similar to raise up

the fuselage so the horizontal stab is level.

2. With the transmitter and receiver still on, check all the

control surfaces to see if they are centered. If necessary, adjust

the clevises on the pushrods to center the control surfaces.

2. Measure the high rate elevator throw fi rst. Hold a ruler

vertically on your workbench against the trailing edge of the

elevator. Note the measurement on the ruler.

11

Page 12

3. Move the elevator up with your transmitter and move the

The pushrod farther out

means More Throw

The pushrod closer in

means Less Throw

At the Servos

The pushrod farther out

means Less Throw

The pushrod closer in

means More Throw

At the Control Surfaces

These are the recommended control surface throws:

HIGH RATE LOW RATE

ELEVATOR

3/8"

[9.5mm]

22 deg

Up

3/8"

[9.5mm]

22 deg

Down

3/16"

[4.8mm]

11 deg

Up

3/16"

[4.8mm]

11 deg

Down

RUDDER

1-1/2"

[38mm]

24 deg

Right

1-1/2"

[38mm]

24 deg

Left

1"

[25.4mm]

16 deg

Right

1"

[25.4mm]

16 deg

Left

ruler forward so it will remain contacting the trailing edge. The

distance the elevator moves up from center is the “up” elevator

throw. Measure the down elevator throw the same way.

5. Measure and set the low rate elevator throws and the

high and low rate throws for the rudder control surface the

same way.

If your radio does not have dual rates, we recommend

setting the throws at the high rate settings.

NOTE: The throws are measured at the widest part of

the elevator and rudder.

BALANCE THE MODEL (C.G.)

More than any other factor, the C.G. (center of gravity/

balance point) can have the greatest effect on how a

model fl ies and could determine whether or not your fi rst

fl ight will be successful. If you value your model and wish

to enjoy it for many fl ights, DO NOT OVERLOOK THIS

IMPORT ANT PROCEDURE. A model that is not properly

balanced may be unstable and possibly unfl yable.

At this stage the model should be in ready-to-fl y condition

with all of the components in place including the complete

radio system.

4. If necessary, adjust the location of the pushrod on the

servo arm or on the elevator horn, or program the ATVs in

your transmitter to increase or decrease the throw according

to the measurements in the control throws chart.

1. If using a Great Planes C.G. Machine, set the rulers to

3-5/8" [92mm]. If not using a C.G. Machine, use a fi ne-point

felt tip pen to mark lines on the bottom of the wing on both

sides of the fuselage 3-5/8" [92mm] back from the leading

12

Page 13

edge. Apply narrow (1/16" [2mm]) strips of tape over the lines

3-5/8" [92mm]

so you will be able to feel them when lifting the model with

your fi ngers.

This is where your model should balance for the fi rst

fl ights. Later, you may experiment by shifting the C.G. 1/8"

[3mm] forward or 1/8" [3mm] back to change the fl ying

characteristics. Moving the C.G. forward will improve

the smoothness and stability, but the model will then be

less sensitive (which may be fi ne for less-experienced

pilots). Moving the C.G. aft makes the model more

maneuverable and improves the sailplane’s response to

air currents. In any case, start at the recommended

balance point and do not at any time balance the model

outside the specifi ed range.

increasing amounts of weight on the top of the fuselage over

the location where it would be mounted inside until the model

balances. The Sophisticated Lady has a weight compartment

in the nose where lead or BBs can be added. Once the amount

of weight that is required in the nose is determined, the BBs

can be glued in using white glue.

4. IMPORT ANT: If you found it necessary to add any weight,

recheck the C.G. after the weight has been installed.

BALANCE THE MODEL LATERALLY

1. With the wing level, have an assistant help you lift the

model by the nose and the bottom of the fuse under the TE

of the fi n. Do this several times.

2. If one wing always drops when you lift the model, it means

that side is heavy. Balance the airplane by adding weight

to the other wing tip. An airplane that has been laterally

balanced will track better.

2. With the wing attached to the fuselage, and all parts of

the model installed (ready to fl y), place the model right side

up on a Great Planes CG Machine, or lift it at the balance

point you marked.

3. If the tail drops, the model is “tail heavy.” Weight will need

to be added to the nose to get the model to balance. If the

nose drops, the model is “nose heavy.” If needed, the receiver

and receiver battery can be moved aft of the servos. If weight

is required use Great Planes “stick-on” lead (GPMQ4485).

To fi nd out how much weight is required, place incrementally

CHECKING FOR WARPS

This is a very important step and should be done occasionally

throughout the fl ying season. A sailplane’s wing is most effi cient

when it is not twisted or warped at all. “Washout” (the wing’s

trailing edges are twisted up at the tips) helps make a poor

wing design fl y better by adding some stability (preventing

stalls) at slow speeds but it cuts down on the wing’s effi ciency

at normal speeds. The Sophisticated Lady ARF’s wing is

designed to fl y well at slow speeds without any washout, and

therefore we recommend you check to make sure the wings

are “fl at” using the following procedure:

Set the wing so an inner panel is resting on a fl at surface. Any

warp (twist) will show up by causing a corner of the panel to

rise off the work surface.

To remove the warp, gently twist the wing in the opposite

direction while a helper glides an iron or heat gun over the

covering on both the top and the bottom of the panel to reshrink the covering. Hold the twist until the covering cools

and then recheck for warps. It may take several tries to get a

warp out, but it is worth it as you will end up with a sailplane

that fl ies straight and true and responds to air currents like a

high performance sailplane should.

Follow the same procedure to check all four wing panels and

then go back and double check them. Sometimes you put a

warp in one wing panel while trying to fi x another. You should

also look at the tail surfaces as they too can warp.

13

Page 14

PREFLIGHT

IDENTIFY Y OUR MODEL

No matter if you fl y at an AMA sanctioned R/C club site or if

you fl y somewhere on your own, you should always have your

name, address, telephone number and AMA number on or inside

your model. It is required at all AMA R/C club fl ying sites and

AMA sanctioned fl ying events. Fill out the identifi cation tag on

page 18 and place it on or inside your model.

CHARGE THE BA TTERIES

Follow the battery charging instructions that came with your

radio control system to charge the batteries. You should always

charge your transmitter and receiver batteries the night before

you go fl ying, and at other times as recommended by the

radio manufacturer.

CAUTION: Unless the instructions that came with

your radio system state differently, the initial charge on

new transmitter and receiver batteries should be done

for 15 hours using the slow-charger that came with

the radio system. This will “condition” the batteries

so that the next charge may be done using the fastcharger of your choice. If the initial charge is done with

a fast-charger the batteries may not reach their full

capacity and you may be fl ying with batteries that are

only partially charged.

GROUND CHECK AND RANGE CHECK

Always ground check the operational range of your radio

before the fi rst fl ight of the day following the manufacturer’s

instructions that came with your radio. If the control surfaces

do not respond correctly, do not fl y! Find and correct the

problem fi rst. Look for loose servo connections or broken

wires, corroded wires on old servo connectors, poor solder

joints in your battery pack or a defective cell, or a damaged

receiver crystal from a previous crash.

an observer shall be utilized to supervise fl ying to avoid having

models fl y in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the

fl ying site I use, and I will not willfully and deliberately fl y my

models in a careless, reckless and/or dangerous manner.

5) I will not fl y my model unless it is identifi ed with my name

and address or AMA number, on or in the model. Note: This

does not apply to models while being fl own indoors.

7) I will not operate models with pyrotechnics (any device that

explodes, burns, or propels a projectile of any kind).

RADIO CONTROL

1) I will have completed a successful radio equipment ground

check before the fi rst fl ight of a new or repaired model.

2) I will not fl y my model aircraft in the presence of spectators

until I become a qualified flier, unless assisted by an

experienced helper.

3) At all fl ying sites a straight or curved line(s) must be

established in front of which all fl ying takes place with the

other side for spectators. Only personnel involved with fl ying

the aircraft are allowed at or in the front of the fl ight line.

Intentional fl ying behind the fl ight line is prohibited.

4) I will operate my model using only radio control frequencies

currently allowed by the Federal Communications

Commission.

5) I will not kno wingly operate my model within three miles

of any pre-existing fl ying site except in accordance with

the frequency sharing agreement listed [in the complete

AMA Safety Code].

CHECK LIST

AMA SAFETY CODE (EXCERPTS)

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code. For the complete Safety

Code refer to Model A viation magazine, the AMA web site or

the Code that came with your AMA license.

GENERAL

1) I will not fl y my model aircraft in sanctioned events, air

shows, or model fl ying demonstrations until it has been

proven to be airworthy by having been previously, successfully

fl ight tested.

2) I will not fl y my model aircraft higher than approximately

400 feet [122m] within 3 miles [4.8km] of an airport without

notifying the airport operator. I will give right-of-way and avoid

fl ying in the proximity of full-scale aircraft. Where necessary,

During the last few moments of preparation your mind

may be elsewhere anticipating the excitement of the fi rst

fl ight. Because of this, you may be more likely to overlook

certain checks and procedures that should be performed

before the model is fl own. To help avoid this, a check list

is provided to make sure these important areas are not

overlooked. Many are covered in the instruction manual,

so where appropriate, refer to the manual for complete

instructions. Be sure to check the items off as they are

completed (that’s why it’s called a check list!).

1. Check the C.G. according to the measurements provided

in the manual.

2. Balance your model laterally as explained in the

instructions.

3. Use threadlocking compound to secure critical fasteners

such as the tow hook.

4. Make sure all hinges are securely glued in place.

14

Page 15

5. Reinforce holes for wood screws with thin CA where

appropriate (servo mounting screws, control horn screws, etc.).

6. Confi rm that all controls operate in the correct direction

and the throws are set up according to the manual.

7. Make sure there are silicone retainers on all the clevises

and that all servo arms are secured to the servos with the

screws included with your radio.

8. Make sure any servo leads do not interfere with other

systems (servo arms, pushrods, etc.).

9. Place your name, address, AMA number and telephone

number on or inside your model.

10. Cycle your receiver battery pack (if necessary) and

make sure it is fully charged.

11. If you wish to photograph your model, do so before

your fi rst fl ight.

12. Range check your radio when you get to the

flying field.

FLYING

MOUNT THE WING

Mount the wing to the fuselage with included eight #64 rubber

bands. Install them from front to back, crisscrossing the last

two. Never use torn or cracked rubber bands. After removing

the rubber bands from your model, store them in a container

with talcum powder or clay-type kitty litter to keep them fresh

for the next fl ying session.

If the rubber bands you will be using are different from those

recommended, consult an experienced modeler to make

certain they are strong enough, and that you have used enough

of them. If uncertain, force the front of the wing off of the wing

saddle. There should be considerable resistance! If the wing

can be forced from the fuselage without having to strain your

hands, then there are probably not enough rubber bands.

IMPORTANT: Flying a model with too few rubber

bands can be dangerous. If the wing momentarily lifts

from the fuselage and acts as though a large amount of

“up” elevator has suddenly been applied because there

are not enough rubber bands or they are too weak,

internal structural damage may result. Even worse, the

wing could actually detach from the fuselage resulting in

a crash. If the model exhibits any tendencies that indicate

there are not enough rubber bands, immediately land

and closely inspect the model for damage. If no damage

is found, add more rubber bands.

If you are fl ying with other fl yers check to make sure they are

not fl ying or testing on the same frequency as your model.

If you are an inexperienced pilot try to fi nd an experienced

pilot to help you with your fi rst fl ights. Although the

Sophisticated Lady is very easy to fl y, an experienced pilot

can save you a lot of time and possible aggravation by helping

you get your model in the air smoothly.

CAUTION (THIS APPLIES TO ALL R/C AIRPLANES):

If, while fl ying, you notice an alarming or unusual sound

such as a low-pitched “buzz,” this may indicate control

surface fl utter. Flutter occurs when a control surface

(such as an aileron or elevator) or a fl ying surface

(such as a wing or stab) rapidly vibrates up and down

(thus causing the noise). In extreme cases, if not

detected immediately, fl utter can actually cause the

control surface to detach or the fl ying surface to fail,

thus causing loss of control followed by an impending

crash. The best thing to do when fl utter is detected is

to slow the model immediately, then land as soon as

safely possible. Identify which surface fl uttered (so the

problem may be resolved) by checking all the servo

grommets for deterioration or signs of vibration. Make

certain all pushrod linkages are secure and free of

play. If it fl uttered once, under similar circumstances it

will probably fl utter again unless the problem is fi xed.

Some things which can cause fl utter are; Excessive

hinge gap; Not mounting control horns solidly; Poor fi t

of clevis pin in horn; Side-play of wire pushrods caused

by large bends; Excessive free play in servo gears;

Insecure servo mounting.

TRIM FLIGHTS

It is a good idea to do a couple of trim fl ights before each fl ying

session to make sure the plane is still in trim and the radio is

working properly. The model will survive a hard landing from

5 feet much better than it will from several hundred feet. The

fi rst few trim fl ights should be done over a grass fi eld, the

longer the grass the better (more cushion). If possible, have a

friend hand launch the sailplane the fi rst few trim fl ights. This

will allow you more time to make adjustments.

Switch the transmitter on fi rst and then the receiver. Hold the

Sophisticated Lady ARF under the wing with the nose pointed

slightly down and directly into the wind. It is very important

that it be launched with the wings level and the nose pointed

at a spot on the ground about 50 feet [15.2m] in front of you.

If the sailplane is launched with the nose up or launched too

hard, it will climb a few feet, stall and fall nose fi rst straight

down. With the nose pointed down slightly the sailplane will

accelerate down until it picks up enough fl ying speed then

level off and glide forward. With a little practice you will be

able to launch it at just the right speed so it soars straight

ahead in a long and impressive glide path. Adjust the trims

on your transmitter to get the plane to fl y straight ahead in a

smooth glide path.

Once you get the hang of launching it you can try turning the

plane during the trim fl ights by gently applying a “touch” of

right or left rudder. You can also try “fl aring” the landing by

slowly applying a touch of up elevator (pull the stick back)

15

Page 16

as the plane nears the ground. The Sophisticated Lady ARF

will continue to fl y just a few inches off of the ground for a

surprisingly long distance. It is important you don’t “over control”

the model. Make any control inputs slowly and smoothly rather

than moving the transmitter sticks abruptly.

YOUR FIRST HI-START LAUNCH

A hi-start is the most popular way to launch your Sophisticated

Lady ARF. It consists of 25'–100' [7.6 –30.5m] of rubber tubing

and 200'– 400' [61–121.9m] of string with a parachute or

streamer at the end. One end of the rubber is staked down

directly upwind of the launch point. One end of the string is

attached to the other end of the rubber tubing and the end of

the string with the parachute has a loop or ring and is attached

to the tow hook on the sailplane.

Follow the directions that came with the hi-start and lay it

out directly into the wind. Place the stake at the far upwind

edge of the fl ying fi eld so the parachute will blow back onto

the fl ying fi eld.

Switch on your transmitter and then the receiver and hook

the parachute onto the plane’s tow hook. Pull the sailplane

back approximately twice as far as the rubber tubing is long

(i.e., 100' [30.5m] of rubber tubing = 200' [61m] of pull back)

or whatever the hi-start instructions state. A “fi sh scale” is

handy for determining the correct amount of pull. For your fi rst

fl ights pull the plane back until there is approximately 8 lbs. of

tension. More tension can be used after you get acquainted

with the launching procedure.

Hold the plane above your head with the wings level and the

nose pointed slightly up and directly into the wind. Give the

plane a healthy push forward to get it fl ying and it will climb

up like a kite. You should not have to touch the elevator during

the launch but use the rudder to keep it going straight up. As

the rubber tubing relaxes the plane will fl y off the hi-start and

the parachute will bring the end of the string back towards

you. If it does not come off the high start, apply down elevator

to dip the nose of the sailplane down. The ring should then

come off the tow hook.

FIRST FLIGHTS

Find a BIG, OPEN fi eld for your fi rst fl ights - the bigger the

better as you won’t have to worry about where you need to

land. Ground based objects (trees, poles, buildings, etc.) seem

to attract model airplanes like a magnet. Again, we would

like to recommend that you fi nd an experienced pilot to

help you with these fi rst fl ights.

Note: You need to remember that your radio control

responds as if you are sitting in the cockpit of the sailplane.

When you push the transmitter stick to the right, the

rudder moves to the plane’ s right! This means that when

the plane is fl ying towards y ou it may seem like the rudder

controls are reversed (when you give “right” rudder the

plane turns to your left – which is the plane’ s “right”). It is

sometimes easier to learn to fl y the plane if you always face

your body in the direction the plane is fl ying and look over

your shoulder to watch the model.

Don’t worry about accomplishing very much on your fi rst

fl ights. Use these fl ights to get the “feel” of the controls and the

Sophisticated Lady ARF’s fl ying characteristics. Try to keep the

plane upwind and just perform some gentle “S-turns” (always

turning into the wind) until it is time to set up for landing. Have

a helper adjust the trims on your transmitter, a little at a time,

until the plane will fl y straight and level with the transmitter

sticks in their neutral positions. When it is time to land, just

continue performing the gentle “S-turns” upwind and let the

plane glide onto the ground. Don’t worry about where the

plane lands – just avoid hitting anything.

Practice fl ying directly into the wind, without letting the plane

get off course. Then, turn and come downwind until the plane is

even with you and try it again. When you are comfortable with

fl ying directly into the wind, let the plane go past you before

you start back upwind. Continue this until you can fl y directly

towards you from downwind without getting disoriented. At this

point you can start to establish a landing pattern and bring

the sailplane in for a landing from downwind. This enables the

plane to be fl own as slowly as possible for accurate landings.

THERMAL FLYING

Thermal soaring is one of the most intriguing of all aspects of

fl ying and the Sophisticated Lady ARF was designed to excel

at thermal soaring even in the hands of a novice. It can be

hard for the average person to understand how a plane can

fl y for hours and gain altitude without a motor.

FACTS ABOUT THERMALS

Thermals are a natural phenomenon that happens outside,

by the millions, every single day of the year. Thermals are

responsible for many things including forming several types

of clouds, creating breezes and the distributing plant seeds

and pollen. If you have ever seen a dust devil, you have seen

a thermal in action. Their swirling action is very similar to that

of a tornado but of course much gentler. Most thermals have

updrafts rising in the 200'–700' [61–213.4m] per minute range

but they have been known to produce updrafts of over 5,000’

per minute. The strong updrafts can tear apart a sailplane or

carry the sailplane out of sight before the pilot can get out of

the updraft.

Thermals are formed by the uneven heating of the earth

and buildings, etc. by the sun. The darker colored surfaces

absorb heat faster than the lighter colored surfaces which

refl ect a great deal of the sun’s energy back into space. These

darker areas (plowed fi elds, asphalt parking lots, tar roofs,

etc.) get warmer than the lighter areas (lakes, grassy fi elds,

forests, etc.). This causes the air above the darker areas to

be warmer than the air over the lighter areas and the more

buoyant warm air rises as the cooler, denser air forces its way

underneath the warmer air. As this warm air is forced upward

it contacts the cooler air of the higher altitudes and this large

temperature difference makes the thermal rise quicker. The

thermal is gradually cooled by the surrounding cooler air and

16

Page 17

its strength diminishes. Eventually the thermal stops rising

and any moisture contained in the once warm air condenses,

forming puffy cumulus clouds. These clouds, which mark the

tops of thermals, are usually between 2000' and 5000' high.

the airframe but it will enable it to lose altitude very quickly.

This is especially helpful if the sailplane gets sucked into a

cloud or it gets too high to see. The twirling action will give the

sun a better chance of fl ashing off of the wing and catching

your attention.

THERMAL SOARING

It takes a lot of concentration to thermal soar effectively. A

sailplane can fl y along the edge of a thermal and unless the

pilot is carefully watching the model he may not realize the

opportunity to gain some altitude. Because most thermals

are relatively small, a couple hundred feet [60m] or less at

400' [121.9 m] altitude) compared to the rest of the sky, the

sailplane will rarely fl y directly into the thermal and start rising.

Generally, the sailplane will fl y into the edge or near a thermal

and the effects the thermal has on the plane may be almost

unnoticeable. As the sailplane approaches a thermal, the

wing tip that reaches the rising air fi rst will be lifted before the

opposite wing tip. This causes the sailplane to “bank” and turn

away from where we would like the sailplane to go.

When you are thermal soaring, try to fl y as smooth and straight

as possible. Trim the sailplane to fl y in a straight line and only

touch the controls when you have to. Watch the sailplane

carefully and it will tell you what it is encountering.

When the sailplane fl ies directly into a thermal it will either start

rising or stop sinking. Either case is reason enough to start

circling, especially in a contest where every second counts.

Fly straight ahead until you feel like you are in the strongest

lift, fl y a couple of seconds farther, so that your circle will

be centered in the strongest lift, and then start circling in a

fairly tight but smooth turn. When the sailplane is low the turns

have to be tighter to stay in the strongest lift. As the plane

gains altitude, the turns can be larger and fl atter. The fl atter

the turn, the more effi cient the plane is fl ying. If you see the

sailplane falling off on one side of the circle, move your circle

over into the stronger lift. Thermals move along with the wind

so as you circle you will be swept along with it. Be careful

when thermaling, that you don’t get so far downwind you can’t

make it back to the fi eld to land.

In a gentle thermal, when you are high enough and want to

leave the thermal, add a little down trim to pick up speed and

fl y 90 degrees to the direction of the wind. If you are not real

high and want to fi nd another thermal, you may want to look

upwind of the last thermal. The same source that generated

the fi rst thermal is probably producing another. Just watch out

for “sink” which is often found behind and between thermals.

As you might expect, with all this air rising, there is also air

sinking. This air is the sailplane pilot’s nightmare that can

really make soaring challenging. Sinking air is usually not as

strong as the thermal in the same area, but can be very strong.

Down drafts of many hundreds of feet (meters) per minute

are common on a good soaring day. These down drafts can

make a sailplane look like it is falling out of the air. Because

of this, it is important that you do not let the sailplane get too

far downwind.

When encountering sink, immediately turn and fl y 90 degrees

to the direction of the wind. Apply a little “down elevator” and

pick up some speed to get out of the sink as fast as possible.

Every second you stay in the sink is precious altitude lost.

POINTERS FOR CONTEST FLYING

Pay Attention: Pay close attention to the sailplanes fl ying

before you. Watch them and try to establish where and when

the thermals are being formed. The thermals are often formed

in cycles and are fairly regular, so if you keep track of the

time intervals you will have a good idea of when and where

a thermal may be generated.

If the sailplane is fl ying along straight and all of a sudden turns,

let the plane continue to bank. You may have to add some

rudder to keep it banked. Continue turning until the sailplane

has completed a 270 degree turn, ¾ of a circle. Straighten

out the bank and fl y into whatever turned the plane. If you

encounter lift, and you won’t every time, start circling just as

you did when fl ying directly into a thermal.

Thermals are generated all day long, but the strongest thermals

are produced when the sun is directly overhead. Some of

these thermals can be very large and you may fi nd it hard

to get out of them. If you fi nd your sailplane getting too high,

don’t dive the plane to get out of the lift. Sailplanes are very

effi cient aircraft and they will build up a lot of speed and could

come apart in the rough air of a thermal. The easiest way to

lose altitude is to apply full rudder and full up elevator. This

will put the sailplane into a tight spin that will not over stress

Watch The Birds: Thermals suck up small insects that many

birds love to eat. A bunch of swallows fl ying around in one

area may indicate a thermal. Soaring birds such as hawks,

vultures and eagles are the best thermal indicators. They not

only show you where the thermal is but they also show you

where the center is. These “Masters of the sky” will often fl y

right along with the sailplanes.

Practice Those Landings: Most thermal contests are won or

lost during the landing. Establish a particular landing pattern

and try to stick to it for all landings. Learn to shift your pattern

to account for the wind and particular fl ying fi eld characteristics.

Concentrate: Keep your eye on your sailplane during your

contest fl ights. Have a helper or your counter watch the other

sailplanes in the air. Sometimes your sailplane will wiggle so

quickly or gently that you may miss it if you are not paying

17

Page 18

close attention. If you fi nd a productive thermal, don’t leave it

because your helper tells you that someone else has found

a different one.

Know Your Sailplane: Learn what your sailplane will and

won’t do and fl y within this envelope. This will allow you to ride

thermals downwind while knowing when you have to head

back to make your landing safely.

Learn From The Wind: Keep track of which way the wind is

blowing. If the wind suddenly shifts, there is some thermal

activity close to you. The air is probably being either sucked

up into a thermal or falling out of some sink. In either case it

is often a good idea to fl y in the direction the wind is blowing

if your sailplane is in the general area. This will take you

towards a thermal if there is one or away from the sink, both

of which are desirable.

BALLASTING

In strong wind conditions, you may want to add ballast (weight)

to the sailplane to increase its wing loading which increases

its normal fl ying speed. Increasing the weight of your sailplane

does not change its “glide ratio” but it does make it fl y faster.

Because of the faster sink rate, you need to be very cautious

when ballasting for a thermal contest. In duration type contests

only use ballast on very windy days that also have a lot of

thermal activity.

Add the weight as near as possible to the C.G. of the plane.

Adding 6 – 8oz (170 – 225g) will make a noticeable difference

in the sailplane’s fl ying speed and more can be added later,

if needed. Make sure to recheck the C.G. of the plane after

adding the ballast – it should not change.

Have a ball! But always stay in control

and fl y in a safe manner.

GOOD LUCK AND GREAT FLYING!

Name

Address

City, State, Zip

This model belongs to:

AMA Number

Phone Number

18

Page 19

19

Page 20

www.carlgoldbergproducts.com

Entire Contents © 2011 Hobbico,® Inc. All rights reserved. GBGA1059 v1.1 Mnl

Loading...

Loading...