Page 1

1

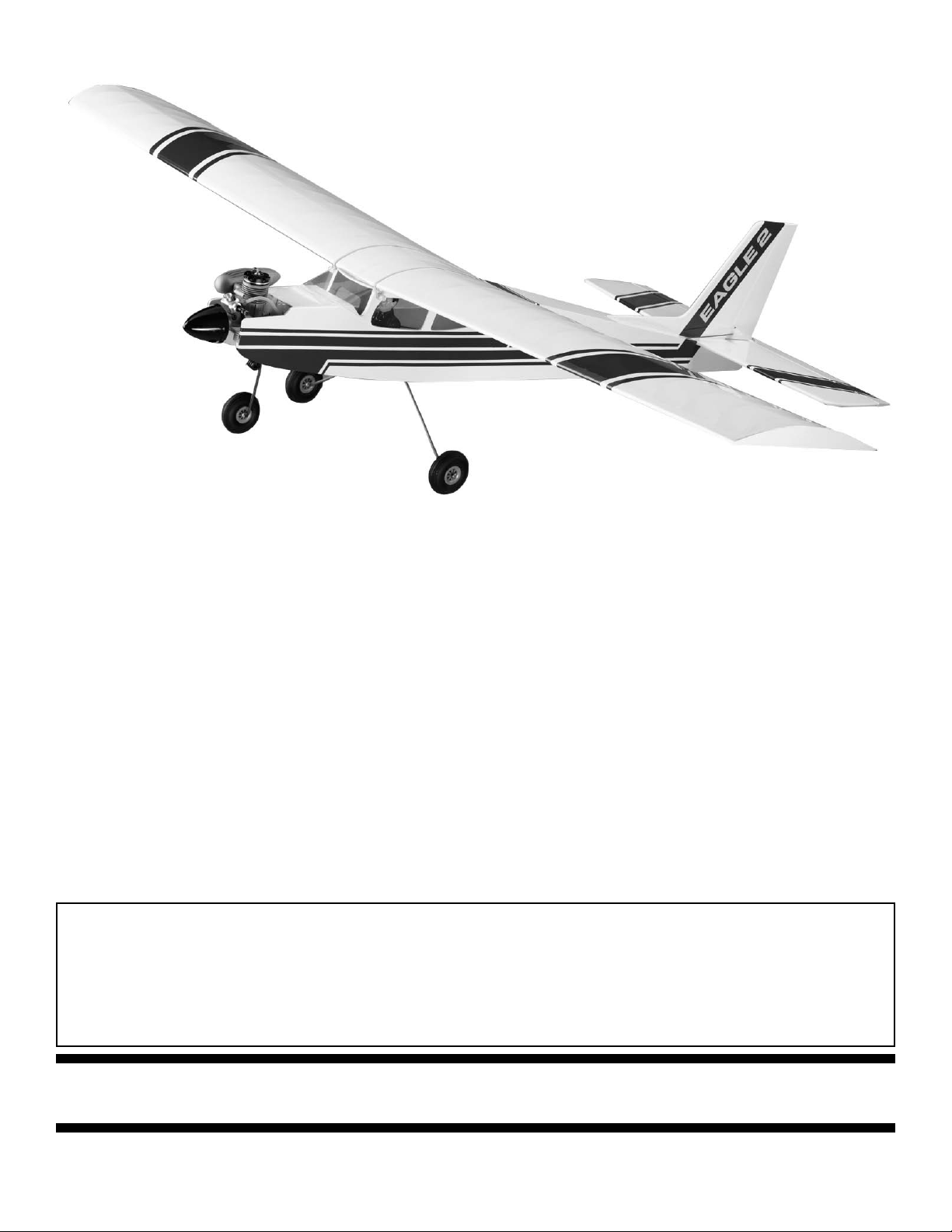

Congratulations on choosing the Eagle 2 ARF! This aircraft has been carefully engineered to provide you with all the terrific flight characteristics of the Goldberg Eagle 2 kit, a plane that has helped

thousands of R/C pilots earn their wings. Your Eagle 2 ARF's sure-footed ground handling, superb

stability, and super-slow landings will help make your early attempts at R/C flying successful. But

first, take the time to read carefully through this booklet. It will speed the assembly process, help

ensure that the plane you take to the field performs properly, and will increase your understanding of

the challenging and fun sport of R/C flying.

EAGLE 2

ARF

CARL GOLDBERG PRODUCTS, LTD.

P.O. Box 88 Oakwood GA 30566 Phone #678-450-0085 Fax # 770-53-63 www.carlgoldbergproducts.com

© Copyright 1999 Carl Goldberg Products LT.

WARNING

A radio-controlled model is not a toy and is not intended for persons under 16 years old. Keep

this kit out of the reach of younger children, as it contains parts that could be dangerous. A radiocontrolled model is capable of causing serious bodily injury and property damage. It is the buyer's

responsibility to assemble this aircraft correctly and to properly install the motor, radio, and all other

equipment. Test and fly the finished model only in the presence and with the assistance of another

experienced R/C flyer. The model must always be operated and flown using great care and common

sense, as well as in accordance with the Safety Code of the Academy of Model Aeronautics (5151

Memorial Drive, Muncie, IN 47302, 1-800-435-9262). We suggest you join the AMA and become properly insured prior to flying this model. Also, consult with the AMA or your local hobby dealer to find an

experienced instructor in your area. Per the Federal Communications Commission, you are required

to use only those radio frequencies specified "for Model Aircraft."

LIMITED WARRANTY

Carl Goldberg Products has inspected and certified the components of this aircraft. The company urges the buyer to perform his

own inspection, prior to assembly, and to immediately request a replacement of any parts he believes to be defective for their

intended use. The company warrants replacement of any such components, provided the buyer requests such replacement within a period of one year from the date of purchase and provided the defective part is returned, if so requested by the company.

No other warranty, expressed or implied, is made by the company with respect to this kit. The buyer acknowledges and understands that it is his responsibility to carefully assemble the finished flying model airplane and to fly it safely. The buyer hereby

assumes full responsibility for the risk and all liability for personal or property damage or injury arising out of the buyer's use of the

components of this kit.

Instructions

Page 2

ITEMS NEEDED TO COMPLETE

THIS AIRCRAFT

1 RADIO GUIDANCE SYSTEM (4

CHANNEL MINIMUM REQUIRED)

1 ENGINE .40-.45 2-CYCLE, AND

MUFFLER

(a 4-cycle engine is NOT recommended)

1 CA ACCELERATOR

1 2 OZ. BOTTLE CA GLUE

1 1/2 OZ. BOTTLE CA GLUE

1 20-MINUTE EPOXY

20 #64 RUBBER BANDS

OPTIONAL

1 PIECE OF MEDIUM SANDPAPER

PAINTS FOR PILOT FIGURE &

COCKPIT

HEAT GUN OR IRON (for covering

touch-up)

1/2” FOAM RUBBER

SWITCH HARNESS

2

TOOLS AND SUPPLIES

REQUIRED FOR ASSEMBLY.

ROLL OF WAXED PAPER

MODELING OR UTILITY KNIFE

WORK SURFACE (24" x70")

ELECTRIC DRILL

1/8", 1/16", 3/32" DRILL BITS

SMALL STANDARD & PHILLIPS

SCREWDRIVERS

MASKING TAPE

NEEDLE NOSE PLIERS

YARD STICK

FLEXIBLE STRAIGHT-EDGE

30-60-90° x 6"

ENGINEERING TRIANGLE

SOFT PENCIL

A FEW STRAIGHT OR "T" PINS

ADJUSTABLE WRENCH

WIRE CUTTER (DYKES)

HAIR DRYER

(OR OPTIONAL HEAT GUN)

ACID BRUSH

Page 3

ARC: Almost Ready to Cover

ARF: Almost Ready to Fly

AILERON: the control surface on the wing that rolls (or

banks) the plane

AIRFOIL: the shape of the wing as seen from the end

ANGLE OF ATTACK: the angle at which the wing meets

the air flow

BEVEL: to sand to an angle shape

BURR: the rough edges on a piece of wood or metal after

it is cut

CAP STRIP: a thin strip glued to the edges of the ribs to

shape the wing

CONTROL HORN: a device attached to each control surface to provide an attachment point for the pushrod

COWL (COWLING): the nose section of the fuselage that

encloses the engine

DECALAGE: the difference between the incidence of the

wing and stabilizer

DIHEDRAL: the upward angle of the wings, as seen from

the front

ELEVATOR: the moveable part of the horizontal tail, which

controls pitch

EMPENNAGE: the tail of the plan

FIN: the fixed vertical part of the tail

FIREWALL: the plywood former at the front of the fuselage, to which the engine is mounted

FORMER: a piece which shapes the fuselage; and to

which the sides of the fuselage are attached.

GUSSET: a small triangular piece glued into a corner to

strengthen it

INCIDENCE: the angle of the wing or the tail in relation to

the thrustline

LAMINATE: to glue two thin pieces of material together to

form a thicker, stronger piece

LEADING EDGE (L.E.): the front edge of the wing that

first meets the airflow

LONGERON: a stringer that runs the length of the fuselage

PITCH: an up and down movement of the nose of the

plane, which is controlled by the elevator

PROTOTYPE: the full scale airplane from which the model

design was taken

PUSHROD: the long, stiff dowel or wire that connects the

servo with the control horn

RECEIVER ("Rx"): Receives radio signal

RETRACTS: (Retractable Landing Gear) devices for

extending and retracting the wheels on command

3

RTF: Ready to Fly

RIB: the airfoil-shaped piece that connects the leading

edge, spars and trailing edge of the wing together and

holds them in shape

ROLL: tilting of the plane as viewed from the front, controlled by the ailerons

RUDDER: the moveable vertical tail of the plane, which

controls yaw

SERVO: the part of the airborne radio system that moves

the control surfaces

SERVO ARM (OUTPUT ARM, SERVO WHEEL): the

piece that attaches to the servo and connects it to the

pushrod

SHEAR WEB: wood sheeting that connects the top and

bottom spars to stiffen the wing

SHIM: a thin piece of wood or other material inserted

between two other pieces to improve their fit

SPAR: a wooden stick running lengthwise through the

wing that serves as its backbone

SPINNER: the rounded cone that fits over the propeller

hub

STABILIZER (STAB): the fixed horizontal part of the tail

STALL: a situation in which the plane is flying too slowly

to move sufficient air across the wing to produce lift

STRINGER: a long piece of wood attached to the formers

to shape the fuselage

THRUSTLINE: a line drawn from the center of the propeller hub straight through the airplane

TORQUE: a rolling tendency caused by the spinning propeller

TRAILING EDGE (T.E.): the edge of the wing that faces

the rear of the plane

TRANSMITTER ("Tx"): Transmits radio signal to servos

TRIM: small adjustments made to the control surfaces to

cause the plane to fly straight and level by itself

WASHIN: a twist in the wing that makes the trailing edge

lower than normal

WASHOUT: a twist in the wing that makes the trailing

edge higher than normal

WING SADDLE: the shaped part of the fuselage in which

the wing rests

WHEEL COLLAR: a metal ring that holds the wheel on

the axle

YAW: a right-to-left movement of the nose, controlled by

the rudder

GLOSSARY

of common modeling terms

Page 4

USING THIS INSTRUCTION MANUAL

Before you begin assembling your Eagle 2

ARF, take some time to read through this entire

instruction book. It is designed to take you stepby-step through the process and to give you

added information on engine and radio selection

and set-up, balancing your aircraft, and flying

your model. The time you spend will speed the

assembly process and help you avoid problems.

PREPARING FOR ASSEMBLY

You will need a work table of approximately 24 x 70" which has been covered to protect it

from adhesive and paint drips, as well as cuts

and other damage. Many people cover their

work area with a sheet of dry wall (sheet rock)

and/or waxed paper to prevent CA glue and

Epoxy from ruining the work surface.

4

INTRODUCTION

CONSTRUCTION TIPS

If you have never assembled a built-up

model before, the following tips will prove helpful.

IMPORTANT: ALWAYS READ A FEW

STEPS AHEAD. This will alert you to coming

instructions and will help you plan accordingly.

Using the Parts Identification section,

familiarize yourself with the various items included in your kit box.

As you work, CHECK OFF EACH STEP

in the box provided, so that you are sure you do

not forget anything.

Do not hesitate to ask questions. Your

local hobby dealer and area flyers will most likely

by happy to help, as they want you to have a

successful flying experience. You may also

receive technical assistance from Carl Goldberg

Products via e-mail (questions@goldbergproducts.com) or by telephone 1-678-450-0085.

SELECTING RADIO CONTROL EQUIPMENT

CHOOSING A RADIO

IMPORTANT: When selecting a radio, remember

that there are many radio frequencies available,

but not all of these frequencies can be used

legally to operate model airplanes. Be sure to

tell your dealer that you want a radio with a

"Model Airplane" frequency.

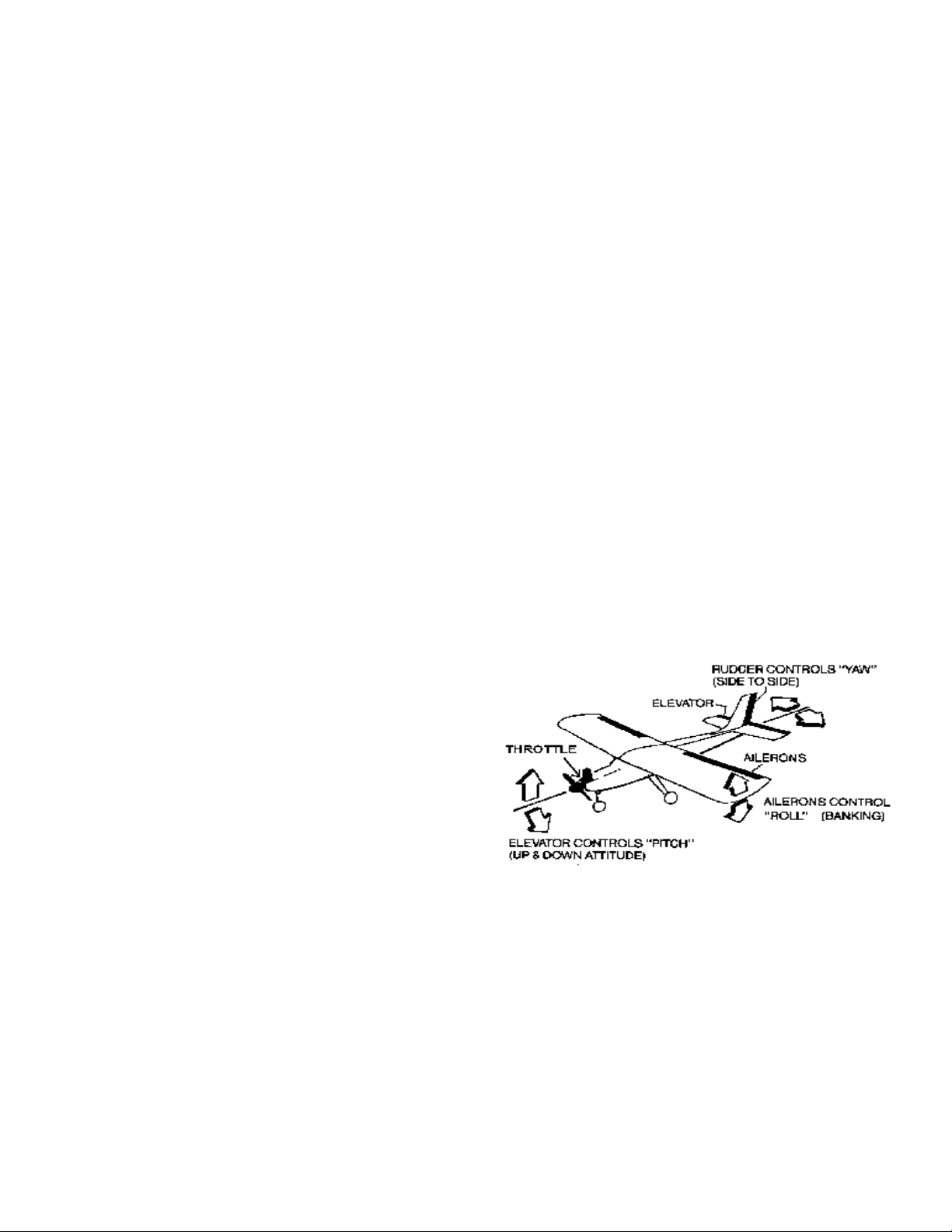

Your model was designed to use a four-channel

radio. In flight, the model is controlled primarily

by using the ailerons and the elevator (see drawing). One radio channel controls the aileron,

which is the primary turn control. It rolls, or

"banks" the model. Another channel operates the

elevator, which controls the pitch (climbing, level

flight, and descent). The third channel is for the

engine throttle and controls the engine speed. A

fourth channel is used for rudder, which assists

the ailerons in turning the aircraft. The new R/C

flyer probably will use the rudder only for steering

the model on the ground.

Radios are battery powered with rechargeable

nickel-cadmium batteries (ni-cads). Such sets

come equipped with a recharging unit. Also,

many of the radio systems now available feature

"servo reversing" switches which allow the pilot

to reverse the response of the servo. This feature simplifies installation and is a worthwhile

consideration when selecting a radio system.

Other radios come with a variety of sophisticated

features, such as dual rates, exponential and

control mixing, etc. These features are typically

used by more advanced flyers and are not necessary for flying the Eagle 2 ARF

Page 5

5

ENGINE & PROPELLER

Your plane flies well using any 2-cycle engine size from .35

to .45. (We do not recommend a 4-cycle engine for this

aircraft, due to the more complicated set-up required.) The

numbers .35 to .45 refer to the amount of space the piston

moves through inside the cylinder of the engine. This

space is called displacement; larger displacement generally means more power. If you live in a hot climate, or your

flying field is approximately 3,000 feet or more above sea

level, you should stay with a .45 engine. It's a good idea to

select an engine that is popular at the flying field, so that if

you have any engine problems, other modelers will be

familiar with the engine and be able to help.

The propeller size must be matched to the engine. For

example, a .35 may use a 9" diameter prop while a .45 can

use a 10" prop. Refer to the information that is supplied

with your engine for recommended propeller sizes. It's

wise to buy a few spare props, as everyone breaks them

occasionally, and particularly often when learning to fly.

Balancing your propeller helps to protect your radio from

the damaging effects of vibration. There are good, easy to

use prop balancers on the market. Follow the instructions

that are supplied with the prop balancer. Never carve or cut

a prop near the hub for any reason (such as to fit a spinner).

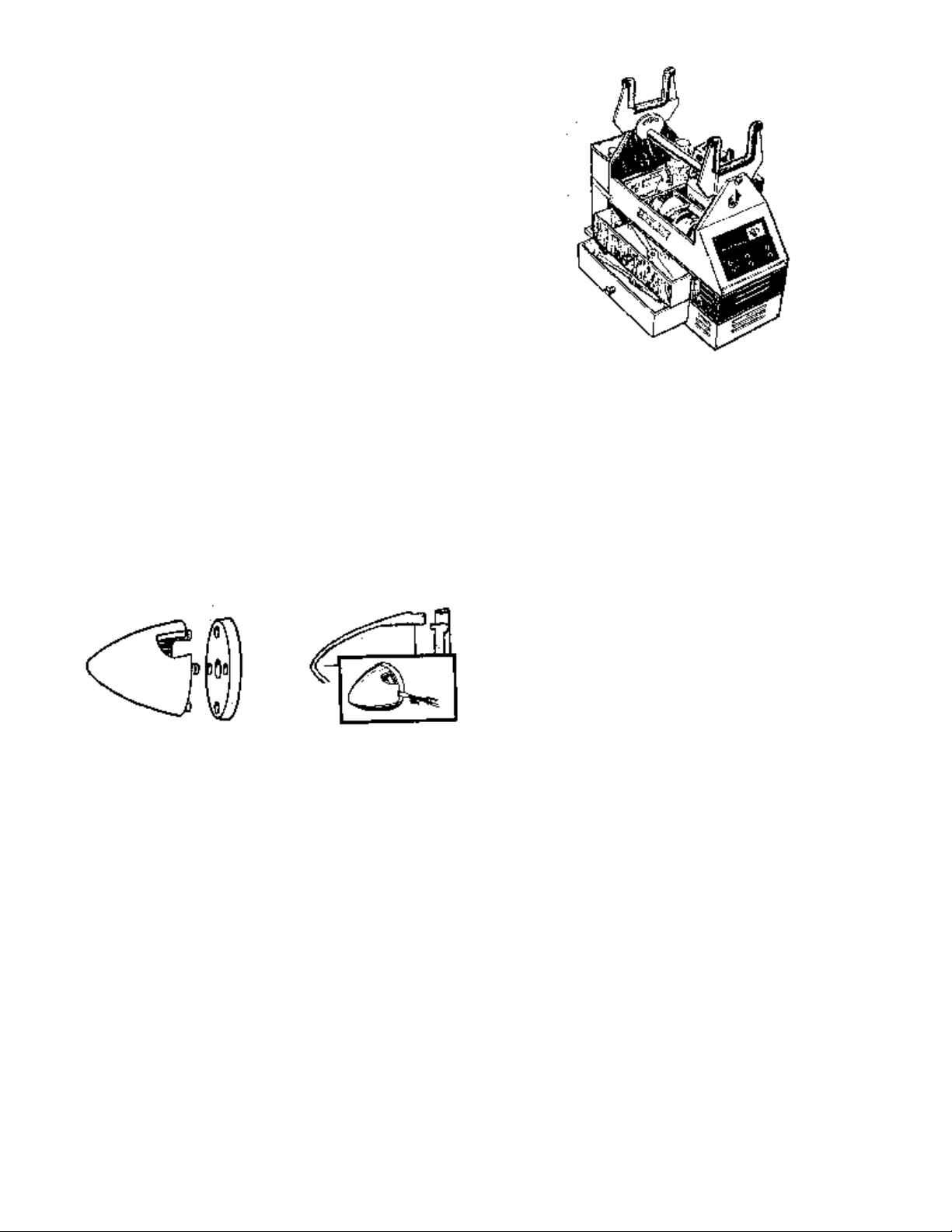

A 2-1/4" CGP 4-Pin Snap-On Spinner is included

in the Eagle 2 ARF. It is a rugged precision molded spinner that does not require any special mounting nuts or

screws. Carefully read the spinner instructions and warnings included in this book. Although a spinner helps

reduce the chance of injury from a rotating prop, extreme

caution always must be used when the engine is running.

The following equipment will be needed at the flying field

to start your engine, make adjustments, and clean your

model after flying.

FLIGHT BOX: Something sturdy in which to carry

your equipment. CGP's quick-building MiniTote carries the

basics: fuel, starter and battery, and a few essential tools.

The larger CGP SuperTote or Monster Tote are both economical, easy to build, and pack lots of utility into little

space. They hold fuel, transmitter, starter & battery, as

well as many tools, in a balanced load that is easy to carry.

STARTING BATTERY AND GLO-PLUG CLIP: A 11/2 volt battery is required to heat your engine's glo-plug

for starting. Wires connect the glo-plug clip to the battery.

Because engine starting draws a lot of electric power from

the battery, rechargeable ni-cad batteries are recommended. Although they cost more initially, they are more economical in the long run than frequently replacing dry-cell

batteries.

FUEL: For best engine performance, use the fuel

recommended by your engine's manufacturer. 2 and 4cycle engines require different fuel blends. Ask your dealer to recommend a good quality 5-10% Nitro fuel.

FUEL PUMP: Needed to transfer fuel from the fuel

can to the model's fuel tank. A simple squeeze-type bulb

will do for small tanks, whereas manual crank or electric

pumps fill larger tanks more quickly.

FUEL LINE: Have about 3 feet of silicone fuel line

to make connections between the fuel pump, the fuel can,

and the model's fuel tank.

EXTRA PROPS: Experts always have a few

spares on hand, so flying doesn't have to stop due to a

broken propeller.

Page 6

6

Page 7

7

NOTE: If the covering on your aircraft has wrinkled in transit, refer to the "Covering" section earlier in this book.

1. Collect the following wing parts, as shown

above:

(1) Right wing

(1) Left wing

(3) Wing joiners

(1) Aileron servo plate

(2) Aileron servo plate supports

2. Although the control surfaces of the Eagle

ARF have been glued in at the factory, apply a drop of

Instant (thin) CA glue at each hinge location, for added

security. Allow the glue to wick into the hinge slot.

3. When dry, make sure the hinge installation

is firm by gently pulling on each hinge location.

4. Holding the three wing joiner pieces

together, with the angle cut facing up, insert them into the

joiner pockets in both the right and the left wing halves.

The joiners should fit easily in the pockets and the wing

halves should meet in the middle, with the wing dihedral

forming a broad "V".

5. Working on a protected surface, and with

paper towel handy for cleaning fingers, THOROUGHLY

mix 1-2 large (soup) spoons each from bottle A and bottle

B of 30 min. Epoxy. (Use equal amounts of each part, mix

with a stick in a plastic or paper cup or on a sheet of

waxed paper.)

6. Spread the epoxy on the three joiners and

laminate them to form a single piece. Then put additional

epoxy in each wing pocket and spread a thin layer along

one side of the entire center joint area. Immediately proceed to next step.

7. Working rapidly, so that the epoxy does

not set before you are finished, slide the laminated wing

joiner into one wing pocket and then slide the other wing

half onto the joiner until the wing halves are touching.

Wing Assembly

Page 8

8

8. Using masking tape, tape the wing halves

together at the trailing edge and close to the leading edge

together, as shown. This will help keep the wing from twisting.

9. Next, place additional tape at several locations across the center seam of the wing, so that the

halves stay firmly together while the epoxy is setting.

NOTE: The wing dihedral will force one side of the wing up

off the tabletop. Place a book under the high side to help

support the wing and keep the halves in the proper position. Caution: Do not distort the wing by blocking it too high

and do not touch until the epoxy dries.

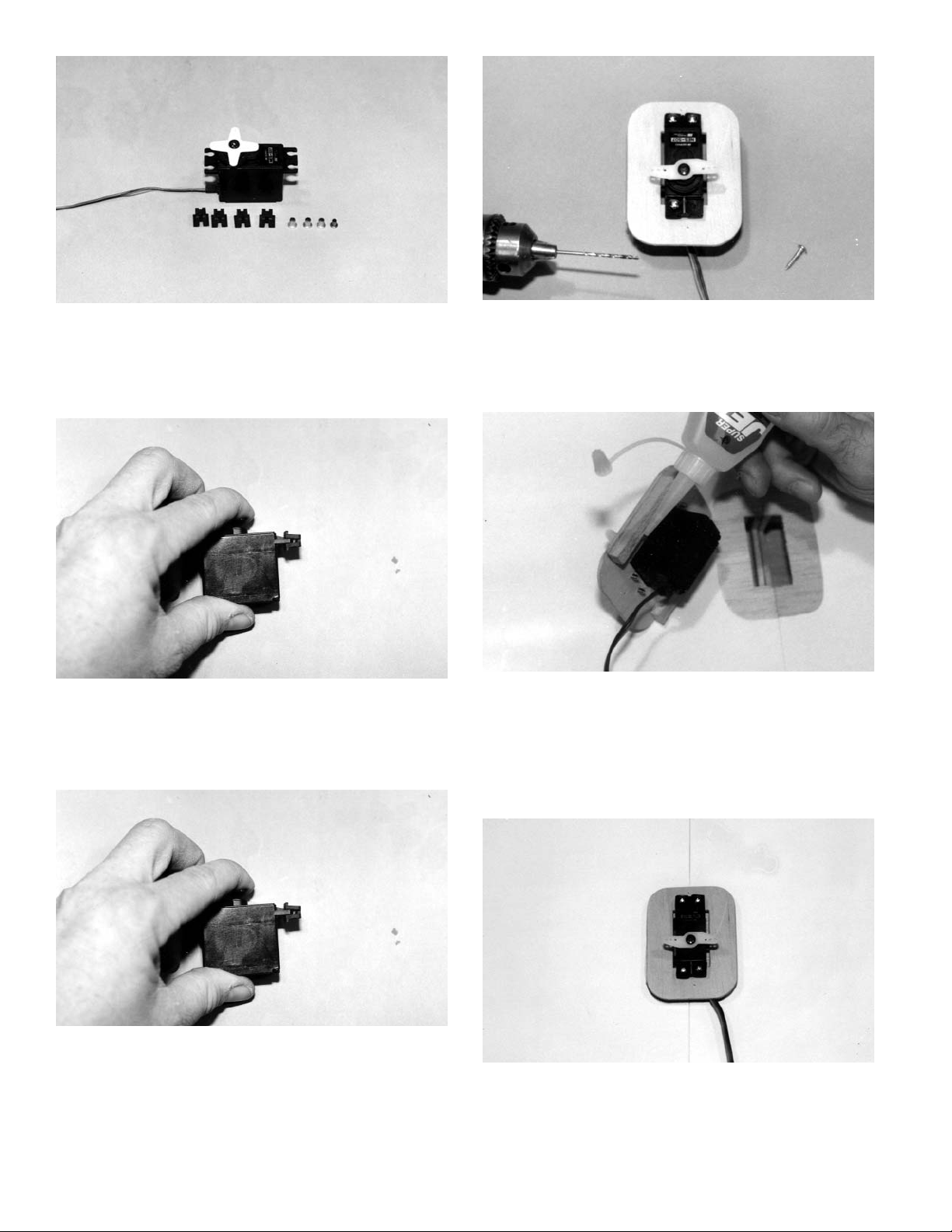

NOTE: Each radio manufacturer has its own way to mount

the servos. Therefore, read the instruction manual included with your radio to understand exactly how the servo

should be mounted.

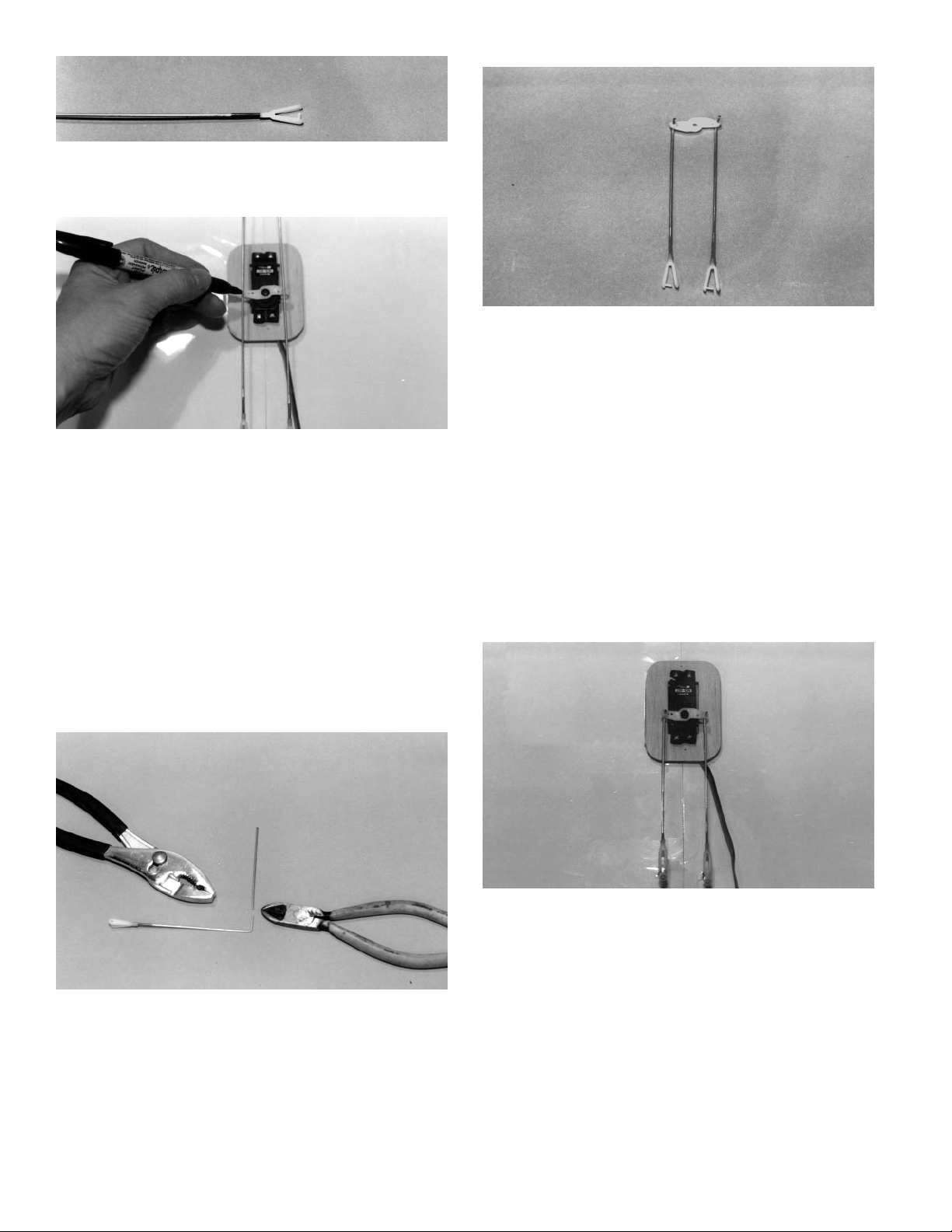

1. Collect the following parts:

(1) Horn bracket

(1) Servo tray

(2) ¼" sq. x 1-3/4" wood servo tray supports

(2) Snap links

(2) 7" wires threaded on one end

(1) Snap nut star tree.

(1) Servo and the necessary mounting hard

ware (grommets, brass eyelets) supplied

with the radio.

2. Place the servo tray over the servo opening in the center of the wing, as shown. Trace the outline

of the servo tray.

3. Being extremely careful not to cut into the

wood underneath, cut the covering along the outline and

remove the covering in the area where the tray will fit.

4. Using CA glue, glue the servo tray supports to the bottom of the servo tray, as shown.

AILERON SERVO INSTALLATION

Page 9

9

5. Gather one servo, four rubber grommets,

and four eyelets from your JR radio box. If using another

brand of radio, use the parts called for in the radio instructions.

6. Place the rubber grommets over each

mounting lug on the end of the servo. These rubber grommets will prevent the lugs from breaking when the servo

moves around.

7. Working from the bottom of the mounting

lug, put an eyelet into each hole. This prevents the mounting screw from being over-tightened when the servo is

mounted.

8. Place the servo into the servo-mounting

tray and enlarge the opening, if needed. Mark the location

of the mounting screws. Using a 1/16" drill bit, drill the

holes for the screws which have been supplied with your

radio. Then mount the servo into the servo tray, as shown.

9. With the servo arm positioned nearest the

trailing edge, place the servo assembly in the wing opening and check the fit. Enlarge the opening, if needed. The

wire should exit under the tray, allowing the servo to fit

down into the wing. When satisfied with the fit, apply CA

glue to each tray support and glue assembly in place.

NOTE: The servo arm on the top of your servo must be

similar to the one shown in the photo above. If it is not,

choose another arm from the selection in your radio box.

Twist the servo arm until it is positioned as shown above.

Page 10

10

10. Thread the mini-snap links onto the two 7"

threaded wires until the wire shows in the middle of the

snap link.

11. Thread the horn brackets on the aileron

torque rods. Be sure to screw them down until they are

flush with the top of the torque rods.

12. Referring to the above photo, install the 7"

pushrod with the snap links connecting to the horn brackets.

13. To make pushrod installation easier, tape

the ailerons to the wing in the center (level) position .

14. Lay the pushrods on the top of the servo

arm and mark where the rod meets the outside hole.

15. Remove the pushrods from the horn bracket. Make

a 90° bend at the mark. Then, cut off the NON

THREADED end at approximately ½" from the

bend.

16. For ease of installation, remove the servo

arm, as shown, and take two snap nuts from the snap nut

tree.

17. Insert the pushrod through the bottom of

the servo arm and then push (snap) the snap nut on top,

to hold the pushrod is held in place. (Pliers may be helpful.)

18. Starting at the top of the servo opening,

press the wide white vinyl tape down over the joined wing

seam. MAKE SURE THE MIDDLE OF THE TAPE COVERS THE CENTER JOINT OF THE WING, WITH HALF

OF THE TAPE ON EACH SIDE OF THE SEAM. Apply the

tape all the way around the wing, stopping at the bottom of

the servo hole. Cut off any excess tape. Peel off the clear

tape on the surface of the white tape.

19. Re-install the servo arm on the top of the

servo and reattach the push rods to the control horns. Be

sure to REMOVE THE TAPE FROM YOUR AILERONS, so

they will be able to move later, when you are setting up

your radio.

This completes your wing.

Page 11

11

1. Collect the required parts.

(1) Fuselage

(1) Wing

(1) Stabilizer/Elevator assembly

(1) Fin

(1) Large control horn with nut plate attached

(2) 2-56 x ½ "screws

NOTE: Prior to assembly, the stab assembly has no top or

bottom. Use either side to begin.

2. As with the ailerons, the stab/elevator

hinges have been glued at the factory, However, for added

security, apply a drop of Instant 30 min.. (thin) CA at each

hinge location. Allow the glue to wick into the hinge slot.

When dry, check the installation by gently

pulling on each hinge location to confirm that it is secure.

3. Locate the center of the stab and mark it

at the hinge line.

With the stab assembly on end, use your

triangle to draw a line across the stab, as shown.

4. Continue the line across the elevator and

around the Leading Edge of the stab to the top side, to

help in locating the control horn.

5. Cut off the nut plate attached to the large

control horn.

6. Locate the centerline of the control horn

right over the centerline on the elevator. With a pencil,

mark the location of the holes on the base of the control

horn onto the elevator.

7. Drill a 3/32" diameter hole through the elevator at each hole location.

8. Place the large control horn on the elevator and push the 2-56 x ½" screws through the holes.

TAIL ASSEMBLY & INSTALLATION

MOUNTING THE STABILIZER

Control

Horn

Nut Plate

#2-56 x 1/2”

Machine Screws

Page 12

12

9. Holding the screws in place, turn the ele-

vator over and place the back plate (cut from the control

horn) over the screws. Tighten the screws, a little at a time,

until the wood just starts to dent. Set the stab aside for

now.

10. Mark a centerline down the stab platform

area, as shown. Be sure to extend the line onto the covering on top of the fuse and onto the back of the fuse, so

that you will be able to locate the center once you have put

the stab in place.

11. Using a twisting motion, insert the wing

dowels through the fuselage cabin. The dowels should

protrude an equal distance on either side of the cabin.

When satisfied with the location, glue in place.

OPTIONAL: Before flying your airplane, seal the exposed

ends of the wing dowels and any other unprotected wood

surfaces with fuel proof paint .

12. Mount the wing on the fuse, using #64

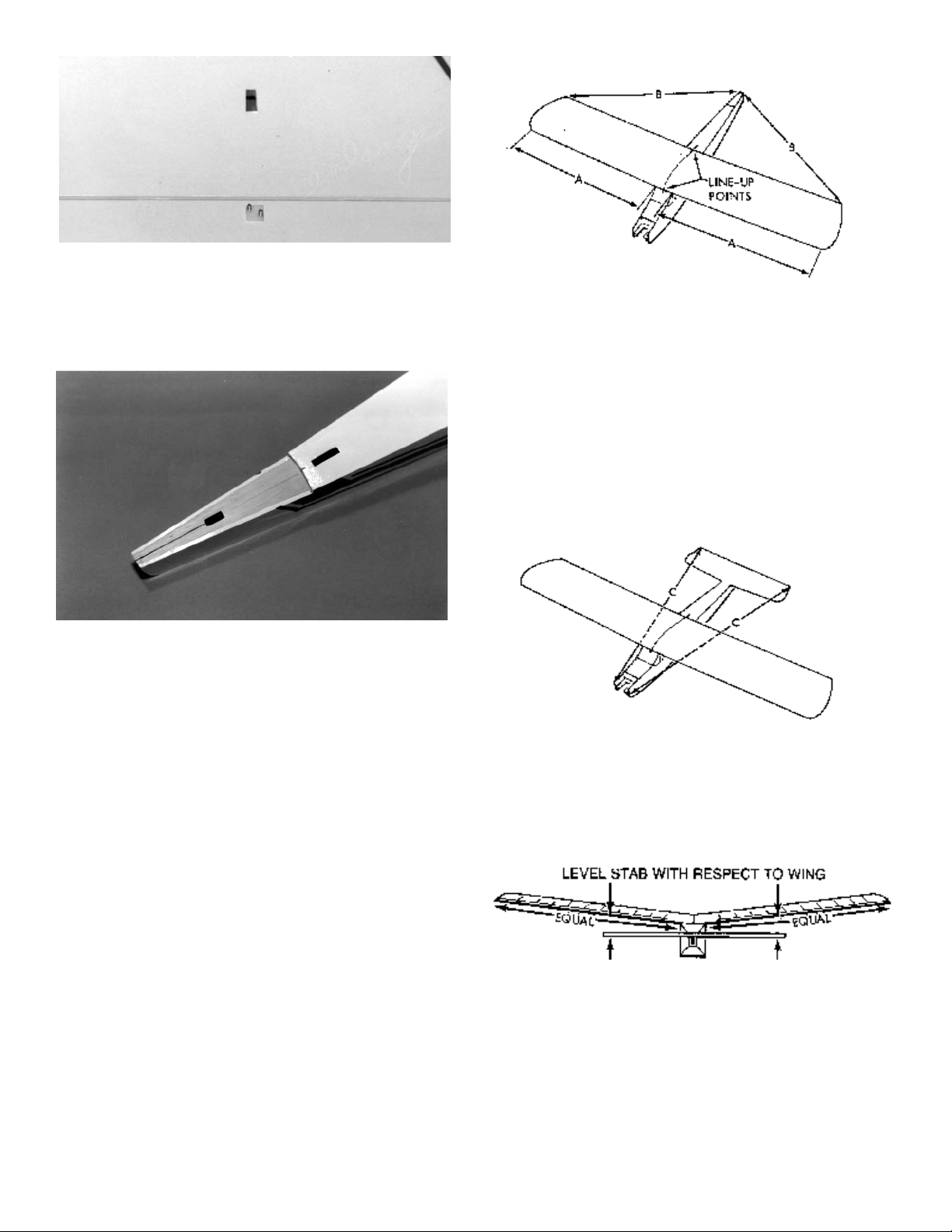

rubber bands. Measure carefully, as shown above, from

the fuselage sides out to the wing tips ("A" arrows) to be

sure the wing is centered. Then measure from the wing

tips to the back end of the fuselage ("B" arrows) to make

sure the wing is square with the fuse.

13. Using masking tape or a washable marking pen, mark the wing center at the leading and trailing

edges. Mark the top of the fuselage at the wing centerpoint.

14. Using no glue, and with the control horn

pointing down, trial fit the stab onto the fuse, adjusting it as

needed to line up with the wing. Measure from the stab

tips to the fuse front ("C" arrows) to make sure the stab is

square with the fuse.

15. View the model from the rear, as shown,

to see if the stab is level, with respect to the wing. If not,

cut paper strips about ¼ x 1" and shim under the low side

until the stab is level.

Page 13

13

16. When satisfied with the fit, draw match-up

lines on both the stab and the fuse to show the correct

location of the stab on the fuselage.

17. Using a sharp-bladed hobby knife, strip

covering from the stab at the points where the stab and

fuse mate, being sure to leave 1/8" to 3/16" of covering

overlap, as shown above. Erase any marks that will show

after the installation.

18. Mix epoxy as before (about 2 large spoon-

fuls), and glue the stab in place on the fuselage. Check

again to make certain the tail assembly is level and

straight. Allow epoxy to dry THOROUGHLY.

1. Collect the following parts:

(1) Fin/rudder assembly

(1) Small control horn

(2) #2-56 x ½" screws

2. Remove the wing. Add a drop of thin CA

to the fin/rudder hinges, as you have done with the aileron

and elevator hinges. When dry, CHECK TO MAKE SURE

THE HINGES ARE SECURELY GLUED by pulling gently,

but firmly, on the rudder.

3. Making sure your rudder/fin assembly is

facing the same direction as the above photo, measure up

from the bottom of the rudder ½" (12 mm.) Put a mark,

next to the hinge line, for the location of the control horn.

4. Separate the nut plate from the small control horn.

CAUTION: In the following step, take great care to avoid

cutting into the wood structure underneath the covering!

INSTALLING THE FIN

Page 14

14

5. Place the control horn on the rudder, as

shown above, and mark the hole locations on the rudder,

just as was done on the elevator. Then drill 3/32" holes

and mount the control horn, screwing through the rudder to

the nut plate.

6. Slide the fin mounting posts into the top of

the fuselage and check the fit. The fin should fit easily into

each slot and should stand upright by itself. Enlarge the

holes, if necessary. When satisfied with the fit, draw lines

on both sides of the fin, showing its location on top of the

fuselage.

7. Remove the fin and carefully trim away the

covering where the fin mounts on the fuselage and stab,

being sure to avoid cutting into the wood structure

underneath.

8. Remount the fin back on the fuselage and

put a 90° triangle against the fin to make sure it is mounted perpendicular to the stab.

9. When satisfied with the fit, mix up a couple

of spoonfuls of epoxy.

10. Remove the fin and apply a thin, even

coat of epoxy on the bottom of the fin and along both sides

of the fin mounting posts. Be careful not to apply too thick

a coat of epoxy, to avoid the glue squeezing out from

underneath the fin.

11. Mount the fin on the fuselage and place

the 90° triangle against the fin. Use masking tape to hold

the triangle in place until the epoxy dries. Make sure to

not glue the triangle!

Page 15

15

CAUTION: The spinner, propeller, and engine, if improperly

installed, or if misused, may result in serious injury to you

or to others. Follow the spinner assembly instructions, and

other instructions and warnings elsewhere in this book,

carefully.

General Precautions:

· Never use a spinner where the cut-out is too small

for the propeller you are using.

· Follow the engine and prop mounting instructions.

· Inspect frequently, and discard any prop with nicks,

scratches, splits, cracks, or any other signs of damage.

Never repair a prop!

· Inspect for loosening and retighten using a prop

wrench.

· Make sure you and any spectators are not in the

plane of rotation of a prop.

· Protect you eyes with safety glasses.

· Get expert advice from your dealer or equipment

manufacturer, if you have any questions or concerns

regarding the spinner, engine, or propeller.

1. Open the spinner by carefully pushing a

small screwdriver (one that does not exceed the width of

the slot) straight into all four slots. DON'T TWIST! For

safety, hold the screwdriver close to the tip.

2. Examine the Retaining Pins closely for

possible tiny threads and remove.

Rub fingers around the Retaining Pins, to

give them a little lubrication.

3. "Work in" the spinner by assembling and

disassembling three or four times, rotating the pins each

time before snapping the spinner to the backplate. The

spinner will be quite stiff, at first. You may also boil it in a

pan of water for 20 minutes to rehydrate the nylon and

make it more workable.

4. Place the backplate on the engine. It

should fit snuggly. If it does not, add one of the

bushings provided, using a drop of glue to secure it, if necessary.

5. Set the prop against the locator pins and

hold while tightening the nut. The prop may turn away

from the pins, as you tighten. If this happens, secure the

prop with a small drop of CA glue. If you are not satisfied

with the prop-to-spinner match-up using the locator pins,

rotate the prop 90° and adjust prop as desired.

6. Large cutouts have been molded into the

spinner for propeller clearance. Make sure the prop you

have selected has clearance all around.

INSTALLING FUSELAGE COMPONENTS

SPINNER ASSEMBLY

Push Stright Into

Slots

Finger Lube Pins

Retaining

Pin

Thread

Repeat This Sequence

Bushings Furnished

With 2” to 3” Spinners

only

Select

Best

Bushing

Bushing

Locating Pins

Clearance All Around

Page 16

16

2. With the "R" facing up and on the right

side of the aircraft, as shown, place the motor mount in the

fuselage. but do not glue at this time. Position your engine

on top of the motor mount.

NOTE: The motor mount cutout will accept most standard size motors. However, if your motor is wider than

the mount, carefully trim equal amounts from both

sides of the opening, until your engine fits. Preserve

the right offset, as described above.

3. Slide the engine to the rear of the opening

until the back of the spinner has clearance of approximately 1/8".

4. When you are satisfied with the fit, use a

pencil to mark straight down through the engine mounting

holes onto the motor mount.

7. Close the spinner by positioning the

spinner with the retaining pin at the top and

squeezing the backplate onto the nose cone.

Rotate the next pin to the top and repeat, until all

four pins are secure.

8. Examine the spinner for good fit.

Make sure there is no distortion evident. Look

for a slight separation between the spinner cone

and the backplate, as shown above.

NOTE: Make sure the tail assembly is thoroughly

dry before removing the triangle and continuing.

1. Place the wooden motor mount on

your work surface, exactly as shown above. The

cut out for the motor should offset, so that there

is a little more wood in the lower the right corner.

This will give your engine right thrust. Write the

letter "R" in the upper right hand corner to mark

the top and the right side of the motor mount.

MOTOR MOUNT INSTALLATION

Page 17

17

5. Remove the engine from the motor mount

and the motor mount from the fuse. At the marked hole

locations, drill four 1/8" holes through the motor mount.

HINT: Place scrap ply under the motor mount to avoid

splintering when drilling.

6. Using a toothpick, apply a drop of Vaseline

in each blind nut hole and on the top engine screw hole to

keep epoxy out of the openings.

7. Mix up approximately 2-3 spoonfuls of

epoxy and making sure the "R" is facing up, glue the motor

mount in place. The epoxy should cover all areas of contact between the motor mount and the rail on which it is sitting.

8. Finally, put a thin coat of epoxy over all the

wood surfaces: above and below the motor mount, on the

wood firewall, and on the fuse sides. This will protect these

areas from fuel and oil when your engine is running.

1. Collect the following items:

(1) Nosegear block

(4) 4-40 x ½ socket head screws

(4) 4-40 blind nuts

(1) # 4 washer

2. Turning fuse upside down and using the

Allen wrench supplied with this kit, screw the nosegear

block to the firewall with the 4-40 x ½" screws and the #4

washers. Screw the bolts part way until the ends are just

coming through the backside of the firewall. Refer to photo

for correct installation.

9. After the epoxy dries, permanently install

four blind nuts in the bottom of the engine mount, using

socket head screws and washers to pull the blind nuts up

into the screw holes, as shown. After tightening the blind

nuts, remove the screws.

NOSEGEAR BLOCK

INSTALLATION

Page 18

18

3. Turn the fuse right side up and place the

4-40 blind nuts on the ends of the screws, with the teeth

pointed toward the firewall.

1. Collect the following items:

(2) Plywood servo trays

(3) Servos

(12) Servo rubber grommets

(12) Servo eyelets

(12) Servo screws

(1) ¼ x½ x 3-5/8 wood servo rail

2. Set up the three servos in the same man-

ner as the wing servo was prepared. Review the Wing

Assembly section of the book, if necessary. Also refer to

the specific instructions included with your radio.

3. Using Ca Glue, laminate the two plywood

servo trays together. Hold flat and allow to dry.for approximately one minute.

4. Place the servos in the tray and install with

screws, as shown. Make sure the servo arms and wheels

on your servos look approximately like the ones in the

photo. If necessary, change the arms and wheels to

match.

5. Position the ¼ x ½ x 3-5/8" wood servo

rail inside the fuselage, fitting it into the notches in the side

doublers. If the rail is too tight, sand to fit. When satisfied,

glue in place.

6. Slide the servo tray into the fuselage, placing the back of the servo tray into the notches in the rear

cabin former. After making sure the tray is straight in the

fuselage, CA glue in place by putting glue on top of the rail

and at the notches in the rear cabin former.

SERVO INSTALLATION

Page 19

19

1. Collect the follow parts:

(1) Hatch hold-down

(3) #2 x 3/16" sheet metal screw

(1) Hatch cover

2. Position the hatch cover on the fuse.

Press hold-down against the front of the firewall and up

against the bottom of the hatch cover, as shown. The

"straight action" end should point towards the fuse bottom.

Tape in position on firewall.

Remove the hatch cover and apply CA

glue to the hold down. Replace the hatch cover on fuse,

gluing it to the hold-down. Allow to dry.

3. When dry, remove the hold-down/hatch

assembly from the firewall and drill two 1/16" pilot holes.

Secure the hold-down to the hatch with the two 3/16"

screws.

4. Reposition the hatch on the fuse. Mark

the location for the #2 screw and install the screw on the

firewall, as shown. Be sure to leave enough of the

unthreaded shank to engage the hold-down. Snap on and

off several times, to make sure the screw is properly

secured.

1. Collect the following parts:

(1) 1/8" x 10-1/2" nylon tube

(1) .072 x 19" threaded rod

(1) nylon mini-snap link

2. Remount the engine into the front of the

fuselage.

3. Screw the mini-snap link onto the threaded

rod.

4. Referring to the photo, start at the hole in

the right side of the firewall and slide the throttle guide

tube into the fuselage and through the upper notch on the

side of the front cabin former. The nylon guide tube should

protrude 1/8" out of the firewall as shown in the following

drawing.

HATCH INSTALLATION THROTTLE PUSHROD

INSTALLATION

#2 Shoulder Screw as Mounted in Firewall

Note: Unthreaded Shank

#2 x 3/16 Sheet

Metal Screw

#2 x 3/16 Sheet

Metal Screw

Hatch

Hold - Down

“Straight Action”

End

Page 20

20

5. Referring to the drawing, and starting at

the firewall, slide the threaded rod into the nylon tube.

Connect the mini-snap link to the engine throttle arm.

6. Again referring to the drawing, move the

pushrod back and forth to simulate servo action. If the

pushrod does not move freely, adjust the wire bend where

necessary. Test the front and rear "limits" of the throttle

arm, to have a feel for what they are.

NOTE: Later, when setting the controls, make sure to set

the throttle servo linkage within the range of the throttle

arm movement.

7. Glue the nylon tube to the firewall and to

the second former.

8. Remove the servo wheel from the throttle

by removing the screw on the center of the arm and then

pulling up gently on the arm.

9. Install the push rod connector on the servo

arm as shown.

10. Guide the throttle pushrod wire though the

pushrod connector and slide the servo arm up to the throttle servo.

11. Replace the servo arm on the throttle

servo and twist the servo arm clockwise until it stops.

Reposition the servo arm, as well, so that it is in the same

position as shown in the photo. Then replace the screw

into the center of the servo arm.

12. Pull the throttle pushrod back through the

untightened pushrod connector until it stops, and then

tighten the setscrew on top of the pushrod connector.

13. When the setscrew is tight, twist the throttle servo arm counter-clockwise until the servo stops. Now

look at the carburetor in the front of your engine. The carburetor should be open (high speed) all the way, just as

shown above.

14. Now twist the throttle servo arm clockwise

until the servo stops. At this point, the carburetor should be

closed (slow speed).

NOTE: The throttle servo will be adjusted more accurately

after the radio installation.

Simulating

Servo Action

Nylon Guide Tube

Throttle Rear Limit

(usually Idle Position)

Front Limit

(usually Full

Power

Nylon Tube protrudes 1/8” Out Firewall

Pushrod

Connector

Broken View Through

Servo Wheel To Show

Installation

Page 21

21

15. Cut the excess throttle pushrod wire sticking out beyond the pushrod connector. Leave about a ½"

of wire, to allow for adjustments.

1. Gather the necessary items:

(1) Fuselage

(2) Main gear wire struts

(2) ¾" landing gear straps (measure hole to

hole)

(4) #2 x 5/16 sheet metal screws

(1) Nylon nosegear steering arm

(1) Wheel collar

(1) 6-32 x 3/16 socket head screw

(1) 5/32 nosegear strut

(1) Nylon snap nut

(1) 16-3/4" wire

2. Making sure the side holes are aligned,

press the steel collar into the pocket in the nylon steering

arm.

Thread the #6-32 x 3/16" socket head

screw in a few turns.

3. Make a ¼" bend at one end of the 16-3/4"

wire. Then, referring to the photo, bend the wire at approximately a 20° angle about 1" back from the first bend.

4. With the fuselage bottom-side up, insert

the unbent end of the wire into the hole on the opposite

side from the throttle pushrod and nearest the bottom of

the fuselage.

5. With the fuselage right side up, make sure

the pushrod is going through the side slot closest to the

fuselage bottom in the front cabin former.

6. With the fuse UPSIDE DOWN, Place the

wire on the outermost hole on the nylon steering arm.

Fasten the nylon snap nut on the end of the wire to hold

the steering arm in place.

Steel Collar

#6-32 x 3/16 Socket Head Screw

Steering Arm

Page 22

22

7. Install the steering arm in the bearing.

Slide the nosegear strut though both the steering arm and

the nosegear bearing. With the fuse bottom-side up, tighten the socket head screw with the Allen wrench.

8. Put the nosegear strut into the nosegear

block, pushing it down until the spring is approximately ½"

off the bottom of the fuselage. Make sure the nosegear

steering arm is approximately ½" away from the firewall

and that the nosegear strut is positioned as shown in the

photo.

9. Using the 6-32 Allen wrench, tighten down

the setscrew in the steering arm to hold the strut in place.

12. Bend the wire towards the correct hole in

the rudder servo wheel., but DO NOT CUT IT. Move the

pushrod to check for free movement and correct, if necessary.

13. With the nose wheel pointing straight

ahead, the end of the steering arm should be ½" away

from the firewall. Adjust, if necessary. At the servo, mark

where the pushrod meets the hole on the servo wheel and

make a 90° bend in the pushrod at that point.

14. Remove the servo wheel to insert the

pushrod, and then remount. Later, during taxi tests, you

can adjust the nose wheel steering by loosening the steering arm socket head screw.

Fuel Tank

1. Collect the following items:

(1) Fuel tank

(2) Brass tube

(1) Large nylon cap

(1) Small nylon washer

(1) Rubber stopper

(1) #4 x 1” screw

(1) Fuel tank klunk

(1) 6” length of white fuel tubing

#2 x 5/16

Sheet Metal

Screw

Installing Main Gear

Struts In Fuse Bottom

Page 23

23

1. Collect the following items::

(1) ½ x 8 x 12" foam rubber (Not Included)

(1) Assembled fuel tank

(1) 10" length of fuel tubing

CAUTION! The white neprene stopper and the fuel

tubing provided with this kit are FOR GLOW FUEL

ONLY; DO NOT USE THESE PARTS FOR GASOLINE.

2. Insert both brass tubes through the wide end of the

rubber stopper. Leave 1/2” extending out the front

of the tank.

Place the small nylon washer on both tubes, as

shown, making sure that one of the tubes extends

1” past the washer. This tube will be for the klunk

pickup.

Cut tube as necessary.

3. Bend the other tube, at the angle shown, until it

nearly reaches to the fuel tank wall. This is the

vent/overflow tube.

4. Insert the stopper assembly into the fuel tank until

the vent tube is up inside the “bubble” in the fuel

tank wall. Remove the assembly and trim the vent

tube, if necessary.

5. Install the klunk on the white fuel tubing.

Mount the other end of the fuel tubing onto the brass

outlet tube in the stopper.

6. Again place the stopper assembly into the fuel tank.

If the klunk is touching the back wall of the tank, trim

it as needed.

7. Place the large nylon cap onto the two brass tubes.

When satisfied with the fit of the entire stopper

assembly, tighten the #4 x 1” screw into the center

of the stopper. Take care to not over-tighten the

screw.

FUEL TANK INSTALLATION

Page 24

24

2. From the ½ X 8 X 12", cut a strip 2-1/2" x

12" long. Next, cut a 2" wide strip across the bottom of the

leftover piece.

3. Remove the hatch and put the 2-1/2" wide

foam in the bottom of the fuel tank compartment in the

fuselage.

4. Fold the foam in so that it forms a "Z"

shape.

5. Place the fuel tank down inside the hole

on top of the "Z" folded foam. Fold the 2" foam piece in

half and push it down on top of the fuel tank.

6. Insert both fuel line ends through the holes

on each side of the firewall, forming a loop around the

engine. Place the ends of the fuel tubing on the brass

tubes on the front of the fuel tank, as shown above.

7. With a scissors, cut the fuel line 1" beyond

the carburetor. The shorter line connects to the carburetor

pick up; the longer line goes to the muffler back-pressure

pickup. Replace the hatch.

Replace the hatch on the fuselage.

Page 25

25

1. Gather the necessary parts:

(1) Radio switch

(1) Switch mount

(1) Switch cap

(1) Switch mount bolt

(1) Switch push-pull

(2) #2 washer

2. Remove the screws and the switch cover

(if your radio has one) from the top of the switch.

3. Using the screw that you just removed and

the #2 washer, put the switch mount together, as shown.

The switch mount has one slotted hole and

two holes on the other side. Mount your switch so that the

switch itself will move back and forth and you can feel and

hear the click.

4. Locate the hole on the left side (as you

look out the windshield) of the fuselage and make an "X"

cut in the covering. Push the switch mount bolt through the

hole.

5. Place the switch unit on the screw on the

inside of the fuselage, as shown.

6. Insert the push-pull mechanism through

the center hole in the switch mounting bolt and place the

switch cap over the switch. Screw the push-pull into the

cap. Test for good movement.

NOTE: There is a small hole on the side of the switch cap

for the push-pull to screw into. Also, the switch has two different size holes in the top and bottom to enable it to fit

over large or small switches. Choose the opening that best

fits your switch and allows it to move easily in and out.

RADIO SWITCH

INSTALLATION

The switch holder shown is not included in the

kit. You can purchase the switch holder at your

local hobby shop. For installation without the

switch holder, cut a hole through the side of the

fuselage to mount the switch.

Page 26

26

Page 27

27

1. Collect the pieces:

(1) LONG wooden pushrod dowels with wires

attached

(1) SHORT wooden pushrod dowels with

wires attached

(2) 10" threaded rod

(2) Black shrink tubing, not shown

(2) Mini snap link

(1) Full-scale pushrod drawing

2. Thread the snap link onto one of the

threaded rods. The end of the rod should show in the middle of the snap link.

NOTE: In the following steps, take care to match each

bend as closely as possible to the drawing.

3. Using the Rudder Pushrod Drawing #1,

place the threaded rod over the SIDE VIEW and mark the

location of the first bend next to the snap link.

4. Make a slight bend at the mark and compare it to the drawing.

5. When satisfied with the bend, mark the

next bend location and make the bend accordingly.

6. Repeat the process for the next bend, as

shown.

7. Mark the fourth bend and then, holding the

wire over the TOP VIEW on the drawing with pliers, twist

the wire until it matches the drawing. Then bend the final

angle down.

PUSHROD INSTALLATION

NOTE: in the following steps, take care to match each

bend as closely as possible to the drawing.

Page 28

28

8. Cut off the wire to the length in the SIDE

VIEW drawing.

9. Referring to the above photo, insert the

bent wire end into the hole and slot in the SHORT wooden

pushrod and CA glue in place.

10. Slide the black shrink tubing over the wire

and wooden rod assembly and shrink with a hair dryer.

Once the tubing is tightly shrunk, glue the edges of the

shrink tubing with thin CA glue.

11. Examine the top of the fuselage and locate

the hole on the LEFT SIDE, under the covering, 1-1/2" in

front of the stab.

Study the photo. Making sure you are

working on the LEFT SIDE of the aircraft, carefully remove

the covering over the hole.

12. Remove the mini snap link and, inserting

the pushrod assembly through the windshield opening,

thread it down into the tail section. Twist the rod so that it

exits through the hole in the top of the fuselage.

13. Replace the mini-snap on the rod, screwing it in until the end of the rod is just showing in the middle of the snap-link. Attach the snap link to the outside

hole on the control horn.

14. Referring to the above photo, drill a 1/16"

hole in the servo wheel opposite where the nosegear

pushrod will be installed.

15. Remove the center screw from the servo

wheel and twist the pushrod end onto the servo wheel

Page 29

29

16. Looking down at the top of the fin, make

sure the rudder is in a straight line with the fin. Adjust if

necessary by twisting the snap link in and out.

Examine the nosegear to make sure the

wheel position is straight forward. Adjust, if necessary.

Install the snap nut on the nosegear

pushrod at the servo end.

17. Mount the snap-link onto the remaining

threaded rod. The end of the rod should show in the middle of the snap-link.

18. Lay the wire over the Elevator Pushrod

Drawing #2 and mark the location of the bend. Bend the

wire at the mark and cut off to the length on the drawing.

19. As with the rudder pushrod assembly,

insert the bent wire end into the hole and slot in the

remaining (LONG) wooden pushrod. CA glue the wire in

place and slide the black shrink tubing over the pushrod

assembly. Shrink with a hair dryer and, when the tubing is

tight, glue the edges of the shrink tubing using thin CA

glue.

20. Thread the pushrod assembly through the

fuselage and exiting out the end, as shown. Attach the

snap link to the outside hole on the elevator control horn.

21. As before, drill a 1/16" hole in the elevator

wheel. Remove the center screw from the elevator servo

arm and twist the pushrod onto the servo arm.

Page 30

30

22. Check the stab and elevator to make sure

they are in a straight line. If necessary, adjust the elevator

up or down by screwing the snap link in or out. Replace

the center screw into the servo.

1. Collect the following required items :

(1) Radio receiver

(1) Aileron extension WIRE

(1) Receiver battery

(1) Remaining piece of foam rubber

(2) Rubbers bands

(1) T-pin

2. Place the receiver near the edge of the

foam rubber and mark a cut line, so the foam area is ½"

larger than the receiver.

3. Open the antenna and stretch it out.

4. Cut the foam and wrap it around the

receiver, securing with a rubber band. Leave the receiver

sticking out, so that you are able to plug the servos in without interference.

5. Following the instructions and diagrams for

your radio, plug all the servo wires into the receiver. Take

care to connect each servo wire to the proper device, i.e.

to connect the rudder servo to the rudder plug, the elevator

servo to the elevator plug, and the aileron extension wire

to the aileron plug.

6. Connect one switch plug to the battery

location on the receiver.

7. With the remaining foam, cut and wrap the

battery pack, just as you did with the receiver.

8. Plug the battery wire into the switch wire.

9. Tuck the battery and the receiver all the

way into the foam wrapping.

Place both the receiver and the battery

pack into the bottom of the fuselage just behind the front

cabin former. Route the receiver antenna through the fuselage cabin and out the top of the fuselage behind the wing.

Both the aileron extension wire and the charging jack wire

should be sticking outside of the fuselage.

10. Take a pin and push it into the top of your

fin with a slight lean towards the back. Attach the rubber

band to the end of the antenna and put the rubber band

around the pin. Pull tight on the antenna.

RECEIVER & BATTERY

INSTALLATION

NOTE: Never change the antenna length. The

length is tuned to the receiver.

NOTE: The remaining wire on the switch is

the charging jack and needs to be KEPT

ACCESSIBLE.

PILOT PLATFORM

INSTALLATION

1. Collect the following required Items:

(1) ¼" x ½" x 3-5/8" wood rail

(1) Plywood pilot platform

(1) #2 x 5/16 sheet metal screw

2. Place the ¼" x ½" x 3-5/8" wood rail inside

the fuselage, fitting it into the notch on the side doublers.

CA glue in place.

Page 31

31

3. Insert the front of the pilot platform into the

notches in the front cabin former with the back resting on

the wood rail.

4. Drill a 1/16" hold through the pilot platform

and the rail.

Screw the back of the platform to the sup-

port rail, using the #2 x 5/16" screw.

2. Tack glue the figure by applying a few

drops of CA glue at key joint areas. When dry, remove

tape and apply a small amount of glue all along the seam.

PILOT ASSEMBLY AND

INSTALLATION

The pilot figure included with your airplane adds an extra

touch of realism.

APPLY DABS OF GLUE

AT JOINTS

WHEN DRY, REMOVE

TAPE AND COMPLETE

GLUING

PAINT PILOT AS

DESIRED

3. Using artist's acrylics or modeling enamels, which are available in many colors without needing to

mixing required, paint the pilot to suit your fancy. WARNING: Do not use lacquer-based paints, which will destroy

the plastic.

4. When dry, CA glue the pilot in place on the

platform. You also may paint the interior of the cockpit, if

added realism is desired.

HINT: When painting the pilot's face, leave the eyes white.

Later, when the face has dried, carefully add eye details

with a fine bush or toothpick.

WHEEL INSTALLATION

1. Collect the following items:

(3) 2-1/2" wheels

(3) 5/32 wheel collars

(3) 6-32 x 1/8" Allen head set screw

(3) 5/32 eyelet

(1) .050 Allen wrench (Not Included)

1. Cut pilot halves apart at the bottom and

trim off scrap. Gently sand the edges of each half, so that

they will be smooth for joining. Carefully align the front

and back pieces and hold together with tape, as shown.

2. Install the wheels on the axles, as

shown: eyelet first, then wheel, wheel collar, and

set screw. Glue the eyelet in place with a drop of

CA glue.

Eyelet

Axle

Wheel

Set Screw

Wheel Collar

Page 32

32

1. Carefully trim the windshield, as shown,

along the OUTER cut lines provided.

2. Temporarily set the windshield in place on

the fuselage. Make sure the wing dowels do not interfere

with the correct placement of the windshield, and note

where it contacts the fuse.

6. Carefully remove the side windows from

the plastic sheet, again making sure to follow the cut lines

provided. Cut front and back windows apart for ease of

installation.

7. Test fit the windows. When satisfied with

the fit, tack glue in place and then glue around the entire

edge, as described above. Again, use only a thin bead of

glue and take care to avoid smearing any glue on the plastic.

INSTALLING THE WINDSHIELD

& SIDE WINDOW

CAUTION: Follow these instructions carefully to

avoid cutting errors or other damage to the plastic.

Cut along outside line

Outer cut line

OPTIONAL: For added gluing strength, make a series of

pinhole punctures through the covering, at the contact

points. This will allow the glue to penetrate to the wood

underneath.

3. Making sure the windshield is properly

centered, tack glue in place at each of the tack points

shown above.

4. After the windshield has been tacked in

place, go slowly around the entire windshield, applying a

VERY THIN line of glue at the edge of the plastic. (It will

"wick" under and secure the windshield.) Glue a small

area at a time, using minimal amount of glue, keeping

hands clean, and taking care that no glue is smeared on

the plastic. When the CA glue has dried, if a trace of

white film appears inside the windshield, wipe off with a

damp cloth.

APPLYING DECAL

1. Using glass cleaner and a soft cloth, clean

model surface thoroughly before applying the decal.

2. Cut the decal sheets apart in sections, as

needed. Fold the decal in half, front to rear. Open at the

fold and lay the decal out straight. The protective backing

will bubble away from the decal at the fold.

3. Using a scissors, cut the backing along the

bubble, removing a strip of backing about 1" wide.

Carefully position the decal on the model and stick it in

place. Then, working from the center, rub the decal down

while peeling off the remainder of the backing.

MUFFLER INSTALLATION

1. Following your engine manufacturer's

instructions, mount the muffler on the engine.

2. If your muffler has a fuel-line type fitting on

it, use it to "pressure feed" fuel to the engine for smoother

and more reliable running. In this case, the vent line is

connected to the muffler fitting

Page 33

33

The transmitter is the part of the radio that the pilot holds.

It usually consists of two sticks that can be moved in 360°

circles, along with slide tabs that help center each movement of the stick for each servo. The following diagrams

illustrate how the radio stick movements control the servos

and the movements of the control surfaces on the aircraft.

SERVO MOVEMENTS

As mentioned in the introductory section of this book, radio

systems with "servo reversing" simplify radio installation.

With a non-reversing system, each pushrod must match its

corresponding servo's rotation. With "servo reversing,"

pushrods can be hooked up to either side of the servo's

output wheel, and after checking the control response, a

servo responding in the wrong direction is easily switched

to the correct action. See your radio manufacturer's

instructions for more detailed information.

The following procedure will help you set up and fine tune

your radio system.

First, remove all servo arms and wheels.

THROTTLE SERVO

1. Turn on the transmitter (Tx) and receiver

(Rx).

2. Move the left stick of your Tx all the way

up to the top of its movement. This stick should have a

ratchet feel to it and will stay in any position, up or down,

in which it is placed. In addition, move the trim tab, located to the right of the throttle stick, all the way to the top of

its movement.

3. Move the throttle pushrod until the engine

carburetor is open all the way.

4. Remount the servo arm back on the throttle servo, but do not put the screw back in the center of the

arm at this time.

5. Move the transmitter throttle stick all the

way to the bottom of its movement and observe the opening in the carburetor. The opening should be 1/16" to 1/8".

If, on the other hand, the carburetor is full open, find the

radio's servo reversing switch (see radio instructions) and

switch it.

If the servo is moving in the right direction,

but the movement is not enough, change where the

pushrod is mounted on the servo arm so that the amount

of movement that the pushrod gets from the servo is more

or less. The farther out from the center of the arm that the

pushrod is mounted, the greater the movement. For

example, if the carburetor opening was greater than 1/8"

when the throttle stick was all the way down, the pushrod

needs to be mounted further out on the servo arm; if the

opening was less than 1/16", the pushrod needs to be further in on the servo arm.

In addition, most engines have two holes

on the throttle arm, where the pushrod is hooked up to the

carburetor. The farthest out hole gives the least movement when the pushrod is moved.

6. When the carburetor is opening correctly,

move the trim tab all the way down to the bottom of its

movement. The carburetor open should be completely

closed. This safety feature allows the running motor to be

turned off

RADIO, ENGINE & AIRCRAFT SET-UP

Page 34

34

7. When you are satisfied with the responses,

replace the center screw back into the throttle servo.

RUDDER SERVO

The same Tx stick that regulates the throttle, when the

stick is moved up and down, also moves the rudder and

the nosegear steering, when the stick is moved to the right

or to the left. The stick will spring back to the center position when it is released. Also, note that under the

rudder/throttle stick is another trim tab. This trim tab

moves from right to left and will help center the rudder and

keep it in place.

1. Move the rudder trim tab into the center of

its movement range.

2. Remount the servo wheel onto the servo,

making sure the wheel placement allows the pushrods to

be centered on the servo, just as they were earlier, when

the pushrods were mounted.

3. Hold the rudder stick to the left and see if

the rudder trailing edge, when viewed from behind the

plane, has moved to the left. If it has moved to the right,

then push the servo-reversing switch to correct the movement.

4. Once the rudder is correctly responding to

the stick movements, look down from the top of the rudder/fin and make sure they are in a straight line with each

other. If not, adjust the snap link in or out on the pushrod

that is hooked to the rudder control horn.

The rudder should move approximately ½"

to each side of center when the transmitter stick is moved.

If your rudder needs more movement, move the snap link

on the control horn toward the inside holes.

When all adjustments have been made,

replace the center screw into the servo wheel.

5. The nosegear must also be centered. If

adjustments are necessary, loosen the setscrew in the

steering arm and twist the nosegear until it is straight.

When satisfied, retighten the setscrew.

ELEVATOR SERVO

The right stick on the transmitter controls the elevator

servo. Pulling down on this stick will make the plane climb

and pushing up on the stick will put the model into a dive.

1. Move the trim tab to the right of the stick,

so that it is centered

2. Remount the servo wheel onto the servo,

making sure the wheel placement allows the pushrod to be

centered on the servo, just as it was earlier, when the

pushrod was mounted.

3. Pulling down on the stick should cause the

elevator to point up. If it goes down, use your reversing

switch to correct the problem.

4. View the edge of the stab and the elevator

to see that they are in a straight line with each other. Twist

the snap link on the elevator control horn in or out, to

adjust the elevator level with the stab.

5. The full range of elevator movement is

approximately 3/8" up and 3/8" down. If more movement

is needed, move the snap link on the control horn toward

the inside holes.

6. When all necessary adjustments have

been made, replace the center screw into the servo wheel.

AILERON SERVO

The same stick that moves the elevator also controls the

ailerons. Moving this stick to the right or left will turn the

aircraft to the right or left. The aileron trim tab, located

beneath the aileron stick, helps the model maintain

straight, level flight.

1. Move the aileron trim tab to the center

position.

2. Remove the center screw and the servo

arm.

3. With the wing resting up against the fuselage, plug the aileron servo into the extension wire coming

out of the receiver.

4. Remount the servo arm onto the aileron

servo, making sure the arm placement allows the pushrods

to be centered on the servo, just as they were earlier,

when they were mounted.

5. Set the wing on the fuselage, by do not

secure it with rubber bands.

6. Holding the aileron stick to the left, check

to see that the left aileron trailing edge is pointing up and

the right aileron trailing edge is pointing down. If your

ailerons are reversed, use your servo-reversing switch to

make the correction.

7. The correct range of motion for the

ailerons is approximately ¼" up or down. If more movement is needed, screw the adjustable horn brackets (into

which the snap links are hooked) down on the wires,

toward the wing.

8. When all adjustments have been made,

replace the center screw into the servo arm.

Page 35

35

ENGINE SET-UP

DO NOT ATTEMPT TO FLY YOUR MODEL UNTIL THE

ENGINE RUNS DEPENDABLY. It should idle without stopping, and the transition through all engine speeds should

be smooth.

WARNING: The turning propeller can cause serious injury,

such as deep cuts. Avoid wearing loose clothing (such as

baggie shirts or neckties) or jewelry which could be caught

by or could fall into the spinning propeller. Children and

spectators should be kept away from a running engine. No

one should stand in line with the propeller. A broken propeller blade becomes a bullet and can seriously hurt someone.

IMPORTANT: NEVER NEGLECT THIS STEP WITH ANY

AIRPLANE. If you try to fly a plane with the balance point

behind the recommended range, you run the risk of having an unstable aircraft and the strong likelihood of a

crash. TAKE THE TIME TO PROPERLY BALANCE

YOUR MODEL!

There are four basic adjustments which contribute to making your engine run well. First, familiarize yourself with the

above drawing, locating the following four parts.

1. Throttle "barrel" opening. The rotating

cylinder inside the carburetor is called the "throttle barrel."

It has a hole in the middle to admit air. By rotating the barrel, the throttle can be "wide open" or completely "closed."

2. Idle/Slow Speed/Stop screw. This screw

allows you to set how much the barrel can close.

3. High Speed Mixer or Needle Valve. This

control regulates the mixture of fuel and air at high engine

speeds.

4. Low Speed Mixer. This control regulates

the fuel/air mixture at idle engine speed.

Follow the break-in instructions included with your engine

make sure it is running well before you go out to fly

BALANCING YOUR MODEL

1. Place the fully assembled aircraft on a

model balancing stand, as shown above. You can make

this simple set-up with a couple of ¼" dowels with rounded

tops, spaced 5" apart. Alternatively, lift the model under the

wing near the fuse by your finger tips.

NOTE: Attach the wing to the fuselage with #64 rubber

bands. Use seven rubber bands on each side of the

fuselage. Always check rubber bands prior to each flight.

2. Referring to the recommended balance

range (4" back from the L.E.) move the position of the

plane on the balance stand until the model is level.

If you need to support the model outside

the recommended balance range, remove the wing and

shift the R/C equipment away from the heavy end of the

model and recheck until the model will balance within the

acceptable range.

3. If shifting the R/C gear still doesn't balance

the model, add weight to the far end of the nose or tail,

respectively, until the model is correctly balanced. The

least weight is needed when added as far back or forward

as possible. Fasten the weight permanently in place.

Page 36

36

Flight batteries, fresh or fully charged

Radio transmitter

Fresh 1 ½ volt starting battery & glo- plug clip

Fuel bulb or pump

Tools for tightening any parts that can vibrate and

loosen

Paper toweling for clean up

Extra #64 rubber bands

Extra props and an extra spinner

Prop wrench

WHERE TO FLY

Fly only in areas sanctioned for R/C and known to be free of

radio interference. Ask your hobby dealer or other modelers if

there is an R/C flying field that is used by a local R/C club. This

is the ideal place to fly. If you don't know of an R/C club nearby,

contact the Academy of Model Aeronautics (AMA), at the address

on the front of this booklet, for information on a club in your area.

Remember: R/C flying fields need to have rules to help prevent

accidents, so ask about them before you turn on any of your

equipment! DO NOT TEST your transmitter in the parking lot or

anywhere nearby until you are sure no one else is using your

radio frequency. This could cause another flyer to crash and

make you very unpopular!

If there is no club or other R/C flying site available, locate a

square area (preferably a grassy field), at least four or five football fields long, which is free of power lines, trees, poles, houses,

busy streets and other obstructions. It must be at least three

miles away from any areas where other R/C models, such as

boats or cars, are operated. It should also have a relatively

smooth surface, as it will take practice to learn precision landings. If you find a suitable location, turn your receiver on for 2 or

3 minutes to check that no one in the vicinity is operating an R/C

device which could affect your receiver and cause your plane to

crash.

LEARNING TO FLY

Your chances of success are enormously increased if you have

an instructor. Learning to fly is harder than it looks, and a mistake can seriously damage or destroy your model. Even fullscale pilots have problems learning to fly models because it's different-they're not in the cockpit. It's worth real effort to find

someone to teach you. Many clubs have authorized instructors

and there are even some R/C flight schools. Ask your dealer, or

even check on the Internet to see if there is someone who can

help. Only if there is no other way should you attempt to learn on

your own.

CHECK YOUR EQUIPMENT

Prior to going to the flying field, with radio batteries fully charged,

turn on both receiver (Rx) and transmitter (Tx) and actuate all

controls many times until you are satisfied with all functions.

Before beginning each day's flying, make a range check of your

equipment in accordance with the manufacturer's instructions. In

general, with transmitter antenna collapsed to 6"-8", you should

have an at least 100 foot range on the ground. To check this,

turn on both the transmitter and the receiver switches, set the

model heading away from you, and walk away while transmitting

signals. Watch to see that no signals are missed until you are at

least 100 feet away. Only if the equipment works perfectly

should any flights be attempted. Again, be careful to not use

your transmitter when anyone else at the field is flying or testing

on the same frequency!

After the range check, stand behind the model and make sure

the control responses are correct. Moving the control stick to the

right should give right rudder (on a 3-channel set-up) or the right

aileron should go up (on a 4-channel set-up). Moving the stick

back or down on the Tx should move the elevator up, and vice

versa.

FLYING YOUR AIRPLANE

WHAT TO TAKE TO THE FIELD

Page 37

37

Check also to see that your nose wheel turns to the right when

you give right rudder. Your throttle should open to permit full

power when the stick or tab is moved forward or up. Finally,

make sure that everything on your aircraft is neatly and firmly in

place-motor fastened down, servos snugged down, receiver and

battery wrapped in foam rubber, tank properly supported, etc.

Prop and spinner must be tight. The receiver antenna must be

extended, not coiled up inside the model. Nothing should be

loose, or unfinished, or unchecked.

With everything ready, the engine should be started and broken

in for a least a tank or two at no more than moderate speed.

While the engine is running, make sure the control surfaces do

not jitter or move until you command them and that the throttle

also responds properly to your command.

GROUND STEERING PRACTICE

For a couple of hours, practice taxiing the model around at low

speed. This is a very helpful step in making you feel more at

ease in controlling the model. Do not rush it. Use a parking lot

rather than a street where you are likely to run into a curb and

damage your model. Practice taxiing in light breezes or when the

air is calm; as strong or gusty winds can catch a wing and flip

your plane over. Apply minimum throttle that just keeps the model

moving at a walking pace. With the rudder stick and rudder trim

in neutral position, the model should move straight ahead. If it

constantly turns left or right, the nose wheel is not pointing

straight forward and should be adjusted by loosening the steering

arm.

When the plane is pointing at you, the steering will seem

"reversed." When you give right rudder, the plane turns to your

left-but the model actually is turning to its right. With practice,

you will become accustomed to this. When the model comes

toward you, simply push the stick left or right, in whichever direction the ship is turning. Another helpful technique is shown in

Sketch A. "Head-on disorientation" is dangerous in the air, where

things can happen pretty quickly. Before flying, it is wise to

spend some time familiarizing yourself with orientation by operating the controls, with the plane set on a table, while you view it

from different positions. The more familiar you become with the

behavior of the model as you control it on the ground, the better

prepared you will be for flying.

After taxi runs are completed, thoroughly examine the model and

tighten any loose screws, etc. First flights should be made on a

day that is not very windy or gusty. There should be very few

people or other distractions around; you will need to concentrate.

Your success doesn't depend on following the instructions here to

perfection, but you should have a flight sequence in mind. Think

ahead of the model ¾ don't chase it around the sky, always one

though and one control command behind it.

GENERAL FLIGHT TECHNIQUES

In flying, it is very important to make all your control movements

slow and measured. Rapid movements tend to throw the model

out of control. Try to make all turns gentle, not tilting (banking)

the wing very much. If you increase the bank, making the turn

steeper, there will be a corresponding weight increase and reduction of lift. Therefore, when you bank your plane, it will start to

descend. To maintain altitude in a turn, add enough back stick

(up elevator) to hold the nose "up" through the turn

Page 38

38

NOW THAT YOU'RE READY...

It is important to have a total flight plan in mind. Look at the flying sketches here to get an idea of the take-off direction and

space you will need when flying at your field.

1. Start your engine. Point the model directly into the wind

and advance the throttle smoothly, steering on the ground with

rudder. The plane will gain speed rapidly.

Remembering to operate the controls smoothly, add

slight back stick pressure, if necessary, to keep the model from

descending. When it is about 100 feet away from you, it will start

to gently climb. Be patient; let it climb slowly, as a steep climb