Page 1

1

Instructions

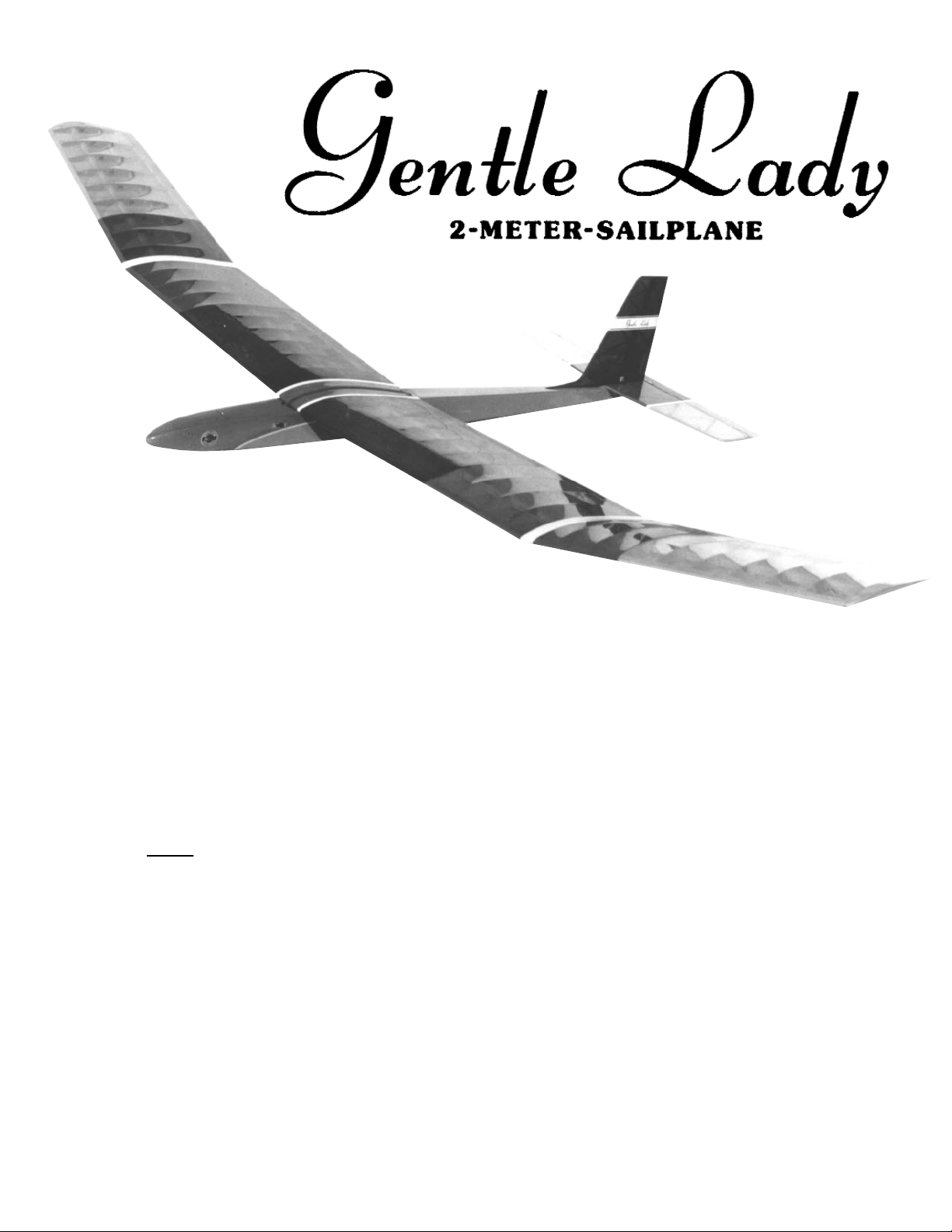

Introduction. The Gentle Lady sailplane was designed to be a gentle trainer for the beginning R/C modeler, yet to possess

competition capability in the hands of the experienced glider pilot. As a very efficient machine, she reacts quickly to rising air

( called lift, or thermals). To stay in the thermal, she can circle very tightly without falling off. The model has good penetration into

the wind and can really “cruise” when desired. Before starting to build, read through these instructions and familiarize yourself with

the plans. If a 6-1/2 ft. wing will not fit into your car, you will want to build the wing version with removable tips.

The

Gentle Lady can be flown a number of ways: hand tow, high-start, slope soar, or power. The simplest method is hand tow,

which resembles towing a kite into the air. High-start is a combination of elastic cord and tow line. When stretched, the high-start

will gently tow the model up to an altitude of several hundred feet from which a flight of three minutes or more in dead air ( no

Thermals) can be obtained. A variation of the high-start is the more expensive powered winch, popular with glider clubs. If you live

near unobstructed hills or ridges, slope soaring is easily possible, so long as you have a suitable landing area. Hand launching the

model off the upwind side of the slope, directly into the wind, will enable you, with practice, to soar back and forth along the slope

in the rising air for as long as the wind remains. Finally, the use of power is an excellent option, and this book and the plan show

typical installations. For the modeler who wishes to power fly the

Gentle Lady at all times, nose mounting of engine is recom-

mended. Pod mounting has two advantages: the power pod assembly can be easily removed for flying the model as a pure glider,

and engine oils are less likely to dirty the fuselage.

Warning

A radio-controlled model is not a toy. It is capable of causing serious bodily injury and property damage. It is the buyer’s responsibility to build this kit correctly and to properly install the motor, radio, and all other equipment. The first test flights should be made

only with the assistance of an experienced R/C flyer. The model must always be operated and flown in accordance with the safety

standards of the Academy of Model Aeronautilcs.

Per the Federal Communications Commission, you are required to use only those radio frequencies specified “for Model Aircraft.”

Pt. #2044- 2/97

© Copyright 1981 Carl Goldberg Products, P.O. Box818 Oakwood, Ga. 30566 Phone 678 450 0085

Page 2

2

Items needed to complete this kit.

1 Radio Guidance system( 2 channel

minimum required)

2 Rolls covering material

1 2oz. bottle CA glue

1 CA accelerator

1 30 minute epoxy

1 Tub Balsa-tinted CGP Model Magic™.

1 Box #64 Rubber bands.

1 Servo mounting Tape

1 1/4 x 8 x 12” CGP Foam Padding

CGP Scuff Guard ( To Protect Bottom From

Scratching)

For Removable Tip Option

1 1/8” x 3” x 18” Balsa Sheet

1 Piece 3/32” Dia. x 6” Music Wire

1 3/32” x 6” GCP Nylon Reinforcing Tape

For Engine Power

Engine, Propeller, Mounting Screws, Nuts, and

Washers

For Servo Mounting

CGP #360 Pushrod Connectors

Selecting Radio Control

Equipment

Radio sets are battery powered with either dry cells or the more

reliable, rechargeable nickel-cadmium (ni-cad) batteries.

Although ni-cad powered units are more expensive, the cost of

routinely replacing worn out batteries may be much higher in the

long run. Many of the radio systems now available feature

“servo reversing” switches which allow you to reverse the

response of the servo. This simplifies radio installation and is

worth considering. Exponential or dual rates are popular features

which , if used properly, can help smooth out the flight of a sensitive model. Your local hobby dealer should be able to help you

select the proper radio for your needs and skill level. And be

sure to get a system designed for aircraft, as only certain frequencies are available for model aircraft.

Necessary Tools and Supplies.

Miscellaneous Rubber Bands

Roll of waxed Paper

Modeling Knife and Single Edge Razor Blade

Sandpaper( assorted grits, including Medium(150) and

Fine(220-320)

Sanding Block

“T” Pins (at least 50)

Building Board (24”x70”)

Electric Drill

1/16” Drill Bit

1/8” Drill Bit

Allen Wrench (.050 for #4 socket set screw)

Small Screwdriver (1/8” Blade Tip)

Covering Iron and Heat Gun

Masking Tape

Pliers

Flexible Straight-Edge

30-60 Degree x 6” Triangle

Pencil

Limited Warranty

Carl Goldberg Models takes pride in the care and attention given

to the manufacture of components for its model airplane kits.

The company warrants replacement of any materials found to be

defective for their intended use, prior to their use in construc-

tion of the aircraft, provided the buyers requests such replacement within a one year period from the date of purchase and

provided the defective part is returned, if so requested by the

company.

No other warranty, expressed or implied, is made by the

company with respect to this kit. The buyer hereby assumes full

responsibility for the risk and all liability for personal or property damage or injury arising out of the buyer’s use of the components of this kit.

Page 3

Using This Instruction Manual

Before you start gluing and sanding, take some time to look

through this entire instruction booklet. It is designed to guide you

through the construction process step by step, so build in the order

given in this book. Radio selection and installation, covering, and

balancing and flying the model are all covered. Also spend time

becoming familiar with the plans.

Like a full-size airplane, the Gentle Lady is built from basic

structures (stablizer, fin, wing, etc.), which are then assembled

into the complete airplane.

Special procedures or comments will usually be explained

before a step, so you will be prepared. If a step begins with a

statement like “Note,” “Warning,” or “Important,” it is a good

idea to read through the step before doing it.

A check-off box appears at the beginning of each step. Check

these boxes as you build, so you can tell at a glance what steps

you have completed. Some steps require you to repeat them, as

in the case of the left and right wing panel.

Some of the instructions deal with general procedures. Boxes

are not needed for these sections.

How to read the plan

The plan shows the Fuselage ( Body), the Wing, and the Tail

Parts. Everything on the plan is drawn to full-size and shape

and shows how the finished parts fit together.

The plan is drawn to show the model completely assembled,

but as a result, the areas inside or underneath are covered up,

making it hard to understand how these parts fit together.

Therefore, for clarity, some parts are drawn with hidden lines ,

others with breakway views, and some are entirely removed

from the structure and shown separately.

For example, on the fuselage, the left side of the completed

model has been removed to show the details inside. Sometimes

a surface is broken away to reveal the detail behind or underneath. Dashed lines indicate details that are hidden behind or

under another part of the surface.

The model is made from four varieties of wood: balsa, bass,

birch, and various plywoods. Each kind of wood has its own

characteristic end grain pattern (as viewed from the end) which

has been drawn on the plan.You can easily use these end grain

patterns to identify what kind of wood is shown for a part, if

you are in doubt.

How to use the plan

The plan is used in several ways. The wings, stabilizer, and fin

are assembled directly over the plan. Each wood part is

matched over its corresponding location printed on the plan

and pinned in place. To prevent ruining your plan from gluing

your wings, etc. to it, cover the area you are working on with

waxed paper or plastic kitchen wrap.

The paper the plan is printed on can expand or contract slightly with changes in temperature or humidity. Because of this, a

preformed part such as the notched wing trailing edge may not

exactly match the plan. This is no problem, as slight deviations

in the outline or size will not noticeably affect flight performance.

Because the fuselage plugs together and is self-aligning, it is

not built directly over the plan. However, make sure the stabilizer and fin are mounted square and true to the fuselage. As

you assemble the fuselage, you will find the plan helpful in

identifying parts and how things fit together.

The plan also shows the installation of a typical radio, battery and

all remaining equipment and hardware needed to complete the

model. By referring to the examples shown, you should be able to

install your own radio, etc., even if it is not the same as what is

shown on the plan.

Identifying Parts

Parts for the wing are bundled together; likewise, parts for the tail

assembly are also grouped. Die-cut plywood and balsa sheets of

common sizes are bundled together, so they are less likely to be

damaged during shipping and handling.

The various screws, hinges, and fittings are packaged in plastic

bags.

Preparing For Assembly

Place a flat, warp-free pinning board on your work bench. Any

material that accepts pins, such as insulation board, soft plywood,

or dry-wall (sheet rock) will work. Important: any warps or

bends in the pinning board will result in wings or tail surfaces

that are also warped or bent, making your model more difficult

to fly. Make sure that the pinning board is flat by laying a straight

edge across it. You may be able to correct a warped board by shimming its low areas.

Position the area of the plan (such as the stabilizer) on which you

are going to build over the pinning board and tape it in place so the

plan lies flat and wrinkle free.

Place a sheet of waxed paper or plastic kitchen wrap over the work

area to prevent CA from sticking to your plan and ruining it.

Construction Tips

If you have never assembled a built-up model before, the following tips will prove helpful.

IMPORTANT: ALWAYS READ A FEW STEPS AHEAD. This

will alert you to coming instructions and will help you plan accordingly.

You may find it convenient to empty all of the small parts from the

hardware bags into a common container, such as a margarine tub.

This will help you find items quickly.

When drilling any 1/16” holes in balsa, you may find it easier to

twist the drill between your thumb and index finger. This procedure

allows more control in positioning the drill on the center mark.

Punch out only the die-cut (D/C) parts you need as you proceed.

This will help you keep track of parts, especially the small ones.

After completing each section of the aircraft, you may want to go

back and reglue the joints, just in case some area has been missed.

Be careful not to use too little glue, which will leave the model

weak or too much glue, which can make the model heavy.

Properly glued joints are important to the overall strength of the

model. CA is recommended for most parts of the assembly,

although epoxy may be used when more time is needed for careful

placement.

3

Introduction

Page 4

4

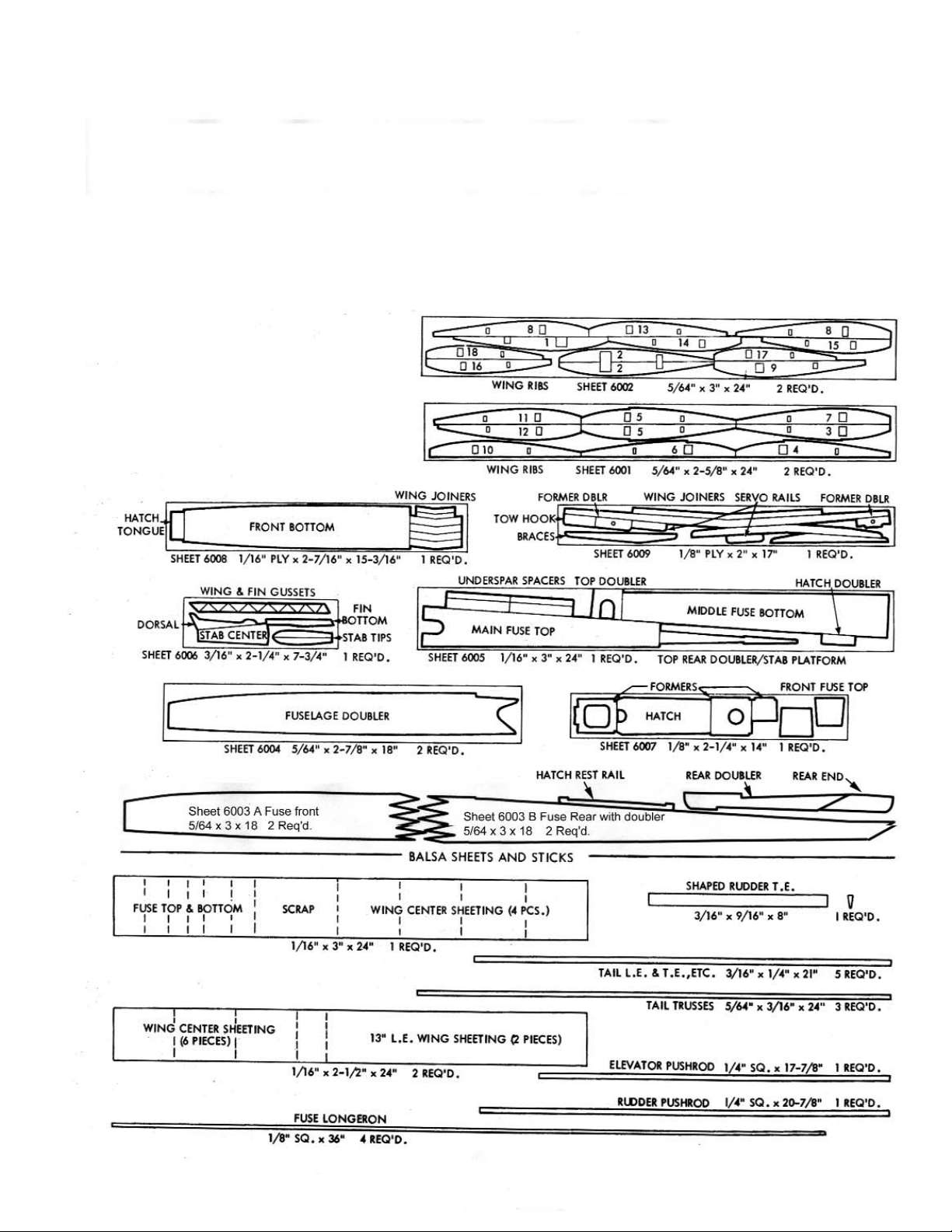

Wood Parts

Be careful when removing parts (such as fuselage sides) from

the die-cut sheets. Long parts are fragile until glued into a structural unit. If necessary, use a razor knife or razor saw to assist in

the removal of parts from the sheet. Sometimes a little trimming

and sanding can improve parts, where desired. Save scrap until

the model is completed, in case a part is missing or damaged.

Also, scrap is used in some building steps. Solid lines indicate

die-cut parts; dashed lines indicate cuts to be made as described.

Some easily recognized pieces, such as nose block, are not

shown.

Parts Identification: Heavy lines indicate die-cut parts.

Dashed lines indicate cuts to be made as described in the instructions.

About The Wood In The Kit

We strive to supply good quality materials in your kit. Wood

parts are inspected with regard to the function they will serve. If

an imperfection is spotted in a scrap corner of a die-cut sheet

and doesn’t affect actual parts, the sheet is considered acceptable. Also, internal stresses in wood are relieved as it is cut into

parts. These relieved stresses may cause some parts to bow.

Bows in wood parts (such as leading edges) readily straighten

out as they are glued into a structural unit.

Page 5

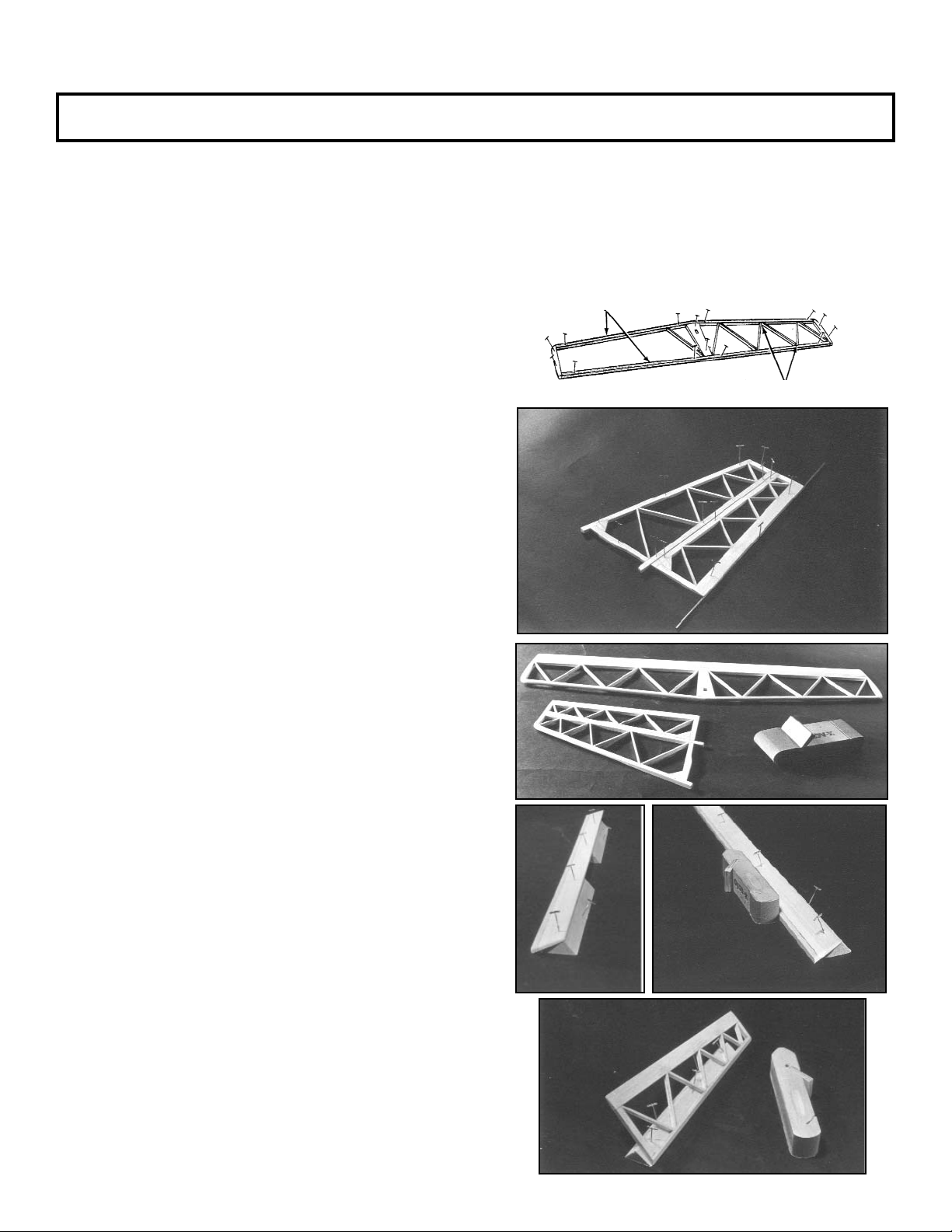

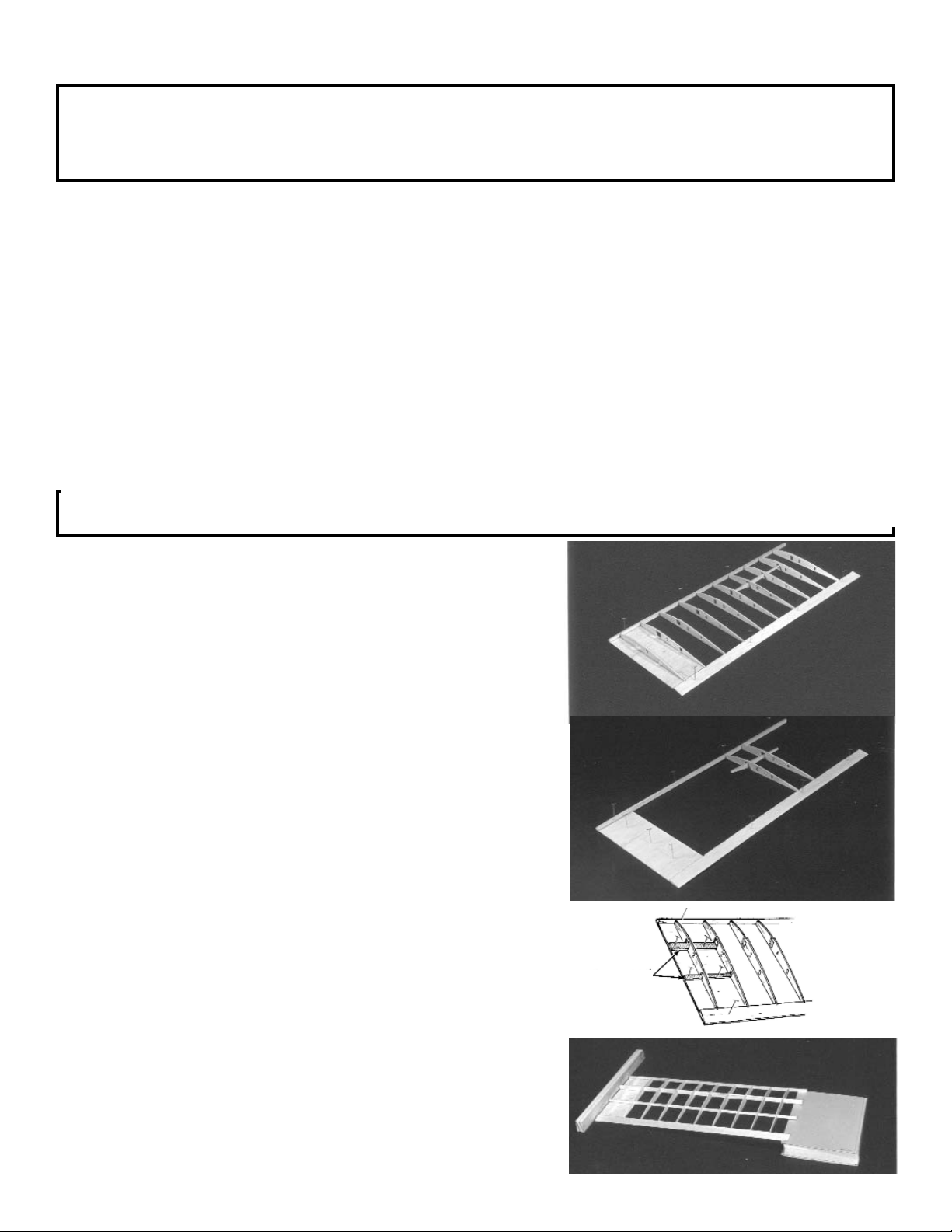

1. Collect all of the items you will need to construct the HORIZONTAL STABILIZER. They include:

(1) D/C Sheet 6006 (3/16” Balsa) Pt.#3455 (5) TAIL L.E. & T.E. (3/16” X1/4” X21”) PT. #4697

Includes: (1) STAB CENTER (3) TAIL TRUSSES (5/64” X3/16” X24”) PT. #4698

(2) STAB TIPS (1) RUDDER T.E. (3/16” X9/16” X8”) PT.#4701

(1) DORSAL (1) ELEVATOR GUSSETS PT#4696

(1) FIN BOTTOM

2.

Lie the horizontal stabilizer portion of the plan over the

building board and place the waxed paper over the plan.

The main members of the tail assembly are 3/16” x 1/4”

balsa strips. Check to see which strips are the strongest,

and use these for the stabilizer. Lighter ones can be used

in the fin and rudder.

Pin in position and glue at center joint.

Using die-cut stab tips, the center platform and 3/16” x 1/4”

balsa, assemble stab outline.

In cutting the diagonal trusses for the tail, trim them to fit

well. If a bit oversize, don’t force them in place. The

pieces should fit before gluing. It’s better to have them not

meet at the points than to force them in.

Let all parts dry thoroughly.

3.

Assemble fin and rudder in same manner.

Note: Trailing edge of rudder is tapered.-use 1/16” x12” wire

for shim as shown.

Add gussets and let dry throughly.

4.

Temporarily tack-cement elevator to stab, and rudder

to fin (to be removed later). Flat sand parts for uniform

smooth surfaces. Then sand edges, rounding corners and

blending surfaces. Important: Do Not sand the lower

2” of fin L.E. at this time.

Carefully separate elevator and rudder from main units.

5.

Lie the widest side of both 3/4” x 3/4” tri-strips down. Align

strips using a straight edge and separate them by about 3”.

Pin in position.

Position elevator so that its trailing edge rests on top of

tri-strips. Pin elevator in place.

Using a square cornered block, sand front surface of

elevator to match with view on plan.

6.

Pin down 3/4” wide side of one tri-strip. Position rudder so

it rests against angled side of tri-strip. Pin in place.

Sand front surface of rudder to match with view on plan.

5

Horizontal and Vertical Stabilizer Construction (6 Steps)

Important: This booklet has recently been revised. Therefore, some of the steps in the booklet may not match what is shown

on the plan. Whenever you find such a divergence, follow the instructions in this booklet.

Beveling Rudder

Bevelling Elevator

Gussets

Select strongest pieces for stab L.E. and T.E.

Fit trusses carefully. Don’t force in place.

Page 6

2.

Place the plan on a building board or other flat surface. Working

over the

RIGHT INBOARD PANEL section of plan, pin inboard leading and

trailing edges (L.E. & T.E.) in place. Align notches in T.E. with

those shown on plan. Cut two pieces of bottom sheeting from 1/16”

x 2-1/2” x24” balsa. Then fit and trim one piece from 1/16” x3”

x24” balsa.

Assemble sheeting and glue to L.E. and T.E.

Glue ribs 6 and 7 to L. E. and T. E.

Position 1/8” ply spar brace in front slots, but DO NOT GLUE AT

THIS TIME.

3

Continuing to work on a flat surface, position and glue

remaining ribs 2 through 8.

Position 1/16” die-cut balsa spacers in rib slots, and glue to

bottom sheeting per sketch.

4.

Sand dihedral angle in one end of bass wood main and rear

spars, following angle indicated on plan.

Insert spars through ribs, with dihedral angle at wing center

joint. Use a flat block to sand spar ends flush with the

L.E. and T.E. at sheeted end.

Glue spars to ribs 5,6,7 and 8 Only.

6

Wing Construction (13 steps)

Wing Terms Defined

Dihedral-

The upward bend of the wings, which usually starts at wing center.

Polyhedral- Additional dihedral at the wing tips, often used with glider wings.

1.

Collect the items needed to construct the WING. They include:

(2) D/C Sheet 6001 (5/64” x3” x24”) PT.# 3450 (2) Tri-strips (5/16” x5/16” x4”) PT# 4876

Wing Rib (2) Inboard T.E. (L) PT# 4688

(2) D/C Sheet 6002 (5/64” x3” x24”) PT# 3451 (2) Outboard T.E. (S) PT# 4689

Wing Ribs (2) Inboard L.E. (L) PT#4690

(1) D/C Sheet 6005 (1/16” x3” x24”) PT# 3454 (2) Outboard L.E. (S) PT#4691

Includes: Double Spar Spacers (2) Inboard Main Spar (1/4” x7/16” x20-3/4”)

(1) D/C Sheet 6008 (1/16”Ply x 2-7/16” x 15-3/16”) PT# 3457 (Bass wood) PT#4692

Includes:Wing Joiners (2) Inboard Rear Spar (1/8” x1/4” x20-3/4”

(1) D/C Sheet 6009 (1/8” Ply x2” x17”) PT# 3458 (Bass wood) PT# 4693

Includes: Wing Joiners and Braces (2) Outboard Main Spar

(1) Wing, Fuse Top & Bottom Sheeting PT# 4686 (1/4” x7/16” x17-5/8”) PT# 4694

(1/16” x3” x24”) (2) Outboard Rear Spar

(2) Wing Sheeting (1/16” x 2-1/2” x24”) PT#4687 1/8” x1/4” x 17-5/8”) PT# 4695

1/16” spacers

Page 7

7

Stuff double thickness of wing rib scrap into rib slots as

shown in sketch to center spars in their respective slots.

Glue spar bottoms to spacers.

Glue spar brace firmly to spar. Let dry thoroughly.

5.

Using a square-cornered sanding block, lightly sand L.E.

and T.E. to match with spar angles.

6.

Pin RIGHT OUTBOARD L.E. and T.E. in place over

plan.

Position and glue ribs 10 through 18. Add gusset at corner

of rib 18 and T.E.

Sand one end of spars for proper polyhedral angle shown

on plan.

Slide spars in place (angled ends at rib 9 position), but

do not yet glue.

Lightly sand L.E. and T.E. to conform to spar polyhedral

angles. Proceed directly to Step 8.

NOTE: Some people have wondered why we show an optional 3-piece

wing. The reason is that, in a 2-piece wing, the structural requirements

at the center are very high. This leads to a more difficult structure, and

a heavier one. Having removable outboard panels is much simpler and

lighter.

NOTE:IF YOU ARE MAKING THE WING WITH THE

REMOVABLE TIP OPTION, OMIT THE NEXT 3 BOXES AND

PROCEED DIRECTLY TO STEP 7.

IMPORTANT

THIS STEP IS FOR THE REMOVABLE TIP OPTION ONLY!

7.

Cut four new #9 ribs from 1/8” hard balsa, using rib

pattern at upper right corner of plan labeled

“REMOVABLE TIP

OPTION.” Do not use die-cut

rib #9.

Use SANDING ANGLE TEMPLATE (cut or copy

from

right corner of plan) and 1/8” ply scrap to establish

proper sanding block angle, as shown in sketch.

Slide outboard spars in place, but do not glue yet.

Gently sand polyhedral ends of spars, L.E.’s and T.E.’s

for uniform vertical surfaces.

Scrap material for spacing-Do not glue

Page 8

8

Position outboard and inboard panels together at polyhedral

joint. Raise wing tip end of outboard panel 4” off work

surface. With outboard spars touching inboard spars, glue

outboard spars to ribs.

Position 3/32” x3” wire on back of spars as shown, and

mark wire location on spars. Carefully groove spars for wire

and brass tube respectively, as shown in TIP OPTION

detail on plan.

Tack-cement wire to outboard spar, and brass tube to

inboard spar. Plug wing panels together, re-check wing

tip height (4”), and observe that wing structures butt evenly

at polyhedral joint. If corrections are necessary, rework

grooves slightly, then reglue metal parts in place.

Position the #9 ribs on spars and plug wing panels together.

Butt these ribs at the polyhedral joint, tilting them slightly

towards the inboard panel, so that they match the spar

angles. Carefully glue ribs to their respective wing panels.

BE CAREFUL TO AVOID gluing the panels together.

Remove outboard panel. Using 3/4” wide nylon fabric and

CA or Epoxy, securely bond wire and brass tube

in place. Securely glue #9 ribs in place.

Add gussets.

NOTE: Later on, after wing parts have been covered, the

removable tip panels are fastened to inboard wing sections using

vinyl electrical tape. This tape holds firmly, yet can be removed without damaging covering material.

PROCEED DIRECTLY TO STEP 9.

NOTE: Some people have tried to get a slightly better glide with the

Gentle Lady by flattening the polyhedral of the wing somewhat.

Unfortunately, this degrades the turning ability of the ship and it is

no longer able to respond quickly. We recommend keeping the polyhedral measurements as indicated.

8.

Position rib #8 on inboard spars, and slide it over next to

rib #8.

Position outboard and inboard panels together at polyhedral

joint. Raise wing tip 4” off work surface. Join inboard to

outboard spars using 1/16” ply joiners. Clamp until dry.

Glue L.E. and T.E.’s together.

Glue rib #9 at polyhedral joint and add gussets.

Glue outboard spars to ribs.

9.

Repeat steps 2 through 8 for left inboard and outboard

panels

10.

Trim off excess spar material extending beyond ribs #18.

Glue balsa tri-strips in place on wing tips.

Carve and sand, following top contour of rib (see plan).

4”

Page 9

9

11.

DO NOT USE GLUE YET. Temporarily join wing

panels, using 1/8” ply joiners. Observe and correct fit and

placement of parts for proper dihedral angle. (Each tip

should be about 6-3/8” above the work surface.) Separate

panels and remove joiners.

Now, permanently glue joiners into one side of wing.

Working carefully, apply a slow setting glue, such as

Slow ZAP, to joiners and slide them into position. Clamp

until dry.

Apply glue to joiners, ect., and join both wing halves.

Again check for correct dihedral-each wing tip should be

about 6-3/8” above the table. Clamp joiners and let wing

assembly dry thoroughly.

Glue ribs #2, 3 and 4 to spars and joiners. Turn wing

upside down and glue ribs #3 through #18 to spar

bottoms. Examine entire wing, top and bottom, for any

joints which still need to be glued.

12.

Glue two of rib 1 together to make double thickness rib.

Glue doubled rib 1 at dihedral joint.

Cut L.E. sheeting from 2-1/2” balsa. Glue sheeting

securely to L.E., ribs and center joint.

From 2-1/2” and 3” wide balsa, make remaining sheeting

pieces and glue in place.

13.

Cut and sand a recess in T.E. at dihedral joint for

rubber bands.

Flat sand entire wing smooth.

NOTE: If you’re going to fly a lot in windy weather or use a

powerful winch, you may want to strengthen the wing as follows.

Before adding the sheeting in step 12, notch each rib from the top

down to the spar, on ribs #1,2,2,3, 4 and 5. Glue to the top of the

spar a strip of hard balsa 3/16”x1/4”x10-3/4” (not furnished),and

sand it lightly to match the rib curvature. When the sheeting is

glued in place, glue it also to the 3/16” strip.

Balsa strip

Typical Rib

Notching

From two 3/16”x1/4” strips

(not furnished)

cut 10-3/4” pieces

Page 10

10

FUSELAGE CONSTRUCTION (18 Steps)

1.

Collect all of the items you will need to construct the FUSELAGE. They include:

(1) D/C Sheet 6008 Front Bottom/Triplers PT.#3457

( 1/16”x2-7/16”x15-3/16” ply)

(1) D/C Sheet 6009 (1/8”plyx2”x17”) PT#3458

Doublers/Servo rails

(1) D/C Sheet 6005 (1/16”x3”X24”) PT#3454

Main fuse top/Middle fuse bottom

(2) D/C Sheet 6004 (5/64”x2-7/8”x18”) PT#3453

Fuselage doubler

(2) D/C 6003 (5/64”x2-7/8”x36”) PT#3452

Fuselage Side 2 front and 2 rear

(1) D/C Sheet 6007 (1/8”x2-1/4”x14”) PT#3456

Formers/Hatch

(1) Balsa sheet/Fuse top (1/16”x3”x24”) PT#4686

(1) Firewall (1/8”x1-7/16”x1-9/16”ply) PT#4685

(1) Nose Block PT#4704

(4) Fuse longeron (1/8”SQ. x36”) PT#4705

(2) Dowel (3/16”x3/4”) PT#1746

Fuselage side construction

2.

Locate the front and rear half of each fuselage side. They will need to be glued together at the finger joint

to form a complete side.

Trial fit the front and rear half of the fuselag sides.

3.

Lay out a piece of wax paper over the plans long enough to cover the fuselage sideview.

Use the plans as a guide to make sure the fuselage sides are straight. When everything is aligned properly glue with

thin CA glue. You don’t have to take the sides apart, the thin CA will “wick” right into the joint.

After the glue has cured, use a sanding block and make sure the joint is smooth.

Page 11

11

4.

Glue rear pieces of fuselage (fuse) sides.

Temporarily position doublers and check for fit and

correct placement (flush along top edge).

Glue doublers to fuse sides using CA or epoxy.

Apply CA smoothly in a series of ribbons or

stripes to the doubler. Then, when the doubler is

set carefully in correct position and pressed down fimly,

the adhesive is squeezed into a very thin layer and

sets up almost instantaneously. (Epoxy allows more

time for application and adjustment.)

Lie fuse sides over side view on plan and mark

locations of formers 2 and 3.

5.

Refer to plan for locations, then glue 1/16” ply

tongue and balsa brace to hatch.

Glue balsa hole doubler to fuse top.

Glue the 1/16” ply triplers to formers 2 and 3. Then

glue the 1/8” ply doublers to the formers as shown.

Carefully drill 3/16” dowel holes through formers using

die cut holes in doublers as guides. When drilling, lay

formers on scrap wood to prevent break out.

Fuselage

Flush

Match up notches

equal spacing

flush

Page 12

12

6.

Refer to plan for correct location, then cut and glue 1/8”

square longerons to sides. Top longeron starts at former 3

and bottom longeron starts at fuse front. Both longerons

stop at notches in rear doubler.

Glue formers 2 and 3 to right side. Refer to plan to

see which way ply doublers face when properly installed.

Important: Make sure formers stand straight (not tilted) until dry.

Glue left fuse side to formers 2 and 3 and let dry

throughly. Make sure formers 2 and 3 are glued firmly to

fuse sides. Re-glue the joints for additional strength.

7.

From 1/8” die-cut sheet scrap, cut a spacer 1/2” square.

Position fuse assembly over top view outline on plan.

Pull fuse nose together, gluing former 1 in place. Use tape

to hold joint.

Pull tail end together with spacer tack-cemented between

(to be removed later). Spacer should be centered between

fuse top and bottom. Hold with tape.

8.

Position and glue hatch rests so that tops of spacing lugs

are flush with fuse top, and rear lugs butt against former 2.

When dry, trim spacing lugs off hatch rests.

9.

Glue 3/16” dowels securely in formers 2 and 3.

Glue front fuse top in place.

spacer

Page 13

13

Glue main fuse top, and top rear doubler/stab platform in

place, and let fuse dry thoroughly. Note: Stab platform

fits between the fuse sides.

10.

Remove fuse from work surface, and glue 1/16” ply

bottom and main balsa bottom in place. If necessary,

spread sides in the hatch area to match the width of the

1/16” ply bottom.

From plan, locate the correct position for 1/8” ply tow hook

doubler, and glue securely in place inside fuse.

11.

From 1/8” square balsa cut two wing rails, and glue to

fuse sides as shown on plan. Note: front end of rails is

tapered.

Temporarily tack-cement hatch in place (it must be

removed later!)

Glue nose block to fuse front (unless, of course, you

intend to mount an engine there! In that case see next

step).

NOSE-MOUNTED ENGINE OPTION

12.

Remove tank and rotate it 90 degrees so you can sidemount engine. Side-mounting helps to keep gunk off

model.

Center engine on 1/8” ply mount. Mark and drill 3/32”

holes for engine mounting screws.

Install engine on mount using screws, washers and nuts as

shown on the plan. Press mounted engine in position to

impress nut locations into former 1. Make recesses in

former 1 for nut clearance.

Gently sand fuse front to remove rough spots. Securely

glue engine mount to fuse front. Let dry.

Remove engine for easier sanding of fuse.

13.

From 1/16”x3”x18” balsa, cut rear top and bottom sheet-

ing

(grain running across fuse). Glue sheeting in place.

Rear dooubler/stab platform

Wing rest rails

This step for nose mounted engine

installation only.

Page 14

14

14.

Remove 1/2” square spacer from tail end of fuse.

Carefully drill or carve 1/4” hole at bottom of tail

opening for pushrod exit.

NOTE: AFTER SANDING

in Step 13, harden pushrod exit area

using CA.

15.

Carve nose to shape as shown in top and side views.

Install wing, holding it in position with rubber bands.

Trim hatch rear to match wing dihedral, so hatch will be

held down by wing, yet can be slid back under wing 1/4”.

Flat sand hatch, nose and complete fuse. For easier

covering, keep nose flat surfaced, with minimal rounding of

corners. (Caution: excess sanding or trimming of stab

mounting area can alter the incidence angle which has

been die-cut on the fuse sides. Sand this area as little as

possible).

16.

Rubber band wing in place on fuse. Viewing model from

rear, see if stab sets level with respect to wing.

Sand stab platform area as may be necessary to provide a

good level fit for stab. Do not alter pre-set stab incidence

angle (exactly horizontal in side view).

Center stab on fuse using a tape measure to obtain equal

distance from side to side, and from nose to rear corner of

each stab tip. Pin in place. DO NOT GLUE AT THIS

TIME.

From 1/8” scrap make a stab leading edge fairing and glue

in place on fuse. (DO NOT GLUE TO STAB).

17.

With stab centered on fuse, mark through stab center hole.

Remove stab and cut hole in fuse top to receive fin trailing

edge.

Re-position stab on fuse and hold in place with pins. Insert

fin trailing edge in stab center hole. View model from front

and carefully align fin so it points exactly straight ahead.

Pin in position.

Mark location, then cut hole for fin leading edge in fuse top.

*For better understanding, see hatch

photo at bottom of

page 14

Page 15

15

Trial fit fin in place. Glue dorsal fin to fin, but not to fuse.

When dry, watch grain and very carefully trim off die-cut

bumps. Finish sanding.

18.

For rudder pushrod, bend 10” threaded rod as

accurately as possibel over plan. Cut off excess,

leaving about 3/16” at right angle.

Cut 1/16”x12” wire into two 6” pieces.

Make 3/16” bend in one end of 1/16” wire “A”. Drill

holes near each end of balsa pushrod, and make a

groove to recess wires part way.

Glue wire “A” and threaded rod to balsa pushrod.

When dry, taper both ends of pushrod, and round

off corners. Bind with strong thread, and re-glue.

Repeat process for elevator pushrod (Note: it is longer).

HATCH OPERATION

The hatch is held in place by the ply tongue at the

front and by the wing at the rear. In order to open

the hatch without removing the wing, the hatch

rear is trimmed to allow it to slide back under the

wing, thus releasing the hatch front from the fuse

(see sketch below). After hatch is covered, a 1/4”

Push-Pull Screw is installed at the front for fingertip manipulation (after installing screw in hatch, file

point off bottom).

Page 16

16

POWER POD OPTION

Make saddle from 1/16” ply x 2” x9-1/4”, grain going the

2” direction. Make center notches front and back for

centering with wing hold down bands. Position 1/16” ply

on wing with an approximately 1/4” overlap at leading

edge, and tape or band to curve of wing. While in this

position, add platform of 1/8” ply x 1-3/8” x1-3/4” with

1/8” ply or hard base wedge underneath front to provide

approximately 2 degrees upthrust. Center platform

directly over main spar and cement to saddle. Drill four

holes in base of power pod and screw to saddle platform.

After fuel-proofing, finish, etc. Add four pieces of

1/16” by 1/2” foam tape on underside of saddle to protect

top of wing surface.

COVERING

A good covering job should be preceded by careful sanding. Filling nicks and dents with MODEL MAGIC™, then more sanding.

Any irregularities in the wood surface will show on the covering, so a smooth sanding job is a must for appearance. A simple color

scheme, such as one main color plus some trim, is recommended for the novice.

COVERING THE WNG

1. First read the directions which are supplied with every roll of

covering. Cut a piece of covering slightly larger than one inboard

panel and remove backing.

2. Position covering on bottom of wing and, using a covering

iron (set at proper temperature), tack covering across center of

wing. Working outward, firmly tack the covering to all ribs, and

to the perimeter edges of the wing, gently smoothing out the larger wrinkles as you go. Besides sticking the film firmly to the end

of the panel, run some of the film down the vertical side of the

rib.

3. After sealing all edges, glide iron (or use a heat gun) over interior area to tighten the covering. Trim and iron edges.

4. When the bottom of the panel has been completed, repeat the

process on the top side. Follow the same procedure for all wing

panels.

Whenever overlapping one piece of the film on top of another,

make sure you have at least 1/8” of the top firmly stuck to the

one below for the full width of the joint. Otherwise, with little

carelessness in tightening, you can find yourself having developed an opening to be patched. Where two transparent colors

join, use CGM ColorStripe 1/4” wide to cover joint lines.

TRUING WING AND SETTING WASHOUT

Truing the wing is an important step, and should not be

rushed or omitted. Also, “washout” (explained below)

improves the wing’s efficiency, and increases the glider’s

stability at slow speeds (prevents tip stalls).

1. Set inboard panel on a flat surface to detect warp. To

counter any warp found, twist panel slightly in direction

opposite to the warp, and hold position while gliding iron

over covering to re-tension structure. Repeat process

until panel is true.

2. Follow same procedure with other inboard panel.

3. Check first panel and correct any change caused by truing

second panel.

4. Block up wing as shown so polyhedral break and outboard

panel leading edge are flat on table. As necessary, twist

wing while gliding iron over covering. Repeat process

untill 1/4” washout is achieved

5. Follow same procedure for other outboard panel.

Page 17

17

Covering the Tail

The rudder and elevator can be hinged using the film covering

hinge technique. This combines covering and hinging into one

operation. Conventional hinges may be used if you perfer. In

that case, center beveling is recommended. The instructions

below apply to fin and rudder also.

1.

Make sure stab trailing edge and elevator leading edge

are perfectly straight. Otherwise binding will occur.

2.

Position 1/32” thick cardboard spacer along top of stab

trailing edge and at least 1/16” back from edge (to avoid

the film adhesive.

3.

Apply covering to bottom of stab, up and around

hinge joint, and elevator bottom.

4.

Flop elevator full down, and remove spacer from stab

top.

5.

Apply top covering, and seal hinge and edges.

6.

Complete covering by trimming off excess film, and

adhering covering firmly to all wood structure except

truss and ribs. Check for trueness on a flat surface,

and correct as necessary.

COVERING THE FUSELAGE

A non-transparent film should be used on the fuse to avoid

showing discolored areas where filler materials were used.

1. Cover the fuse areas in the following order: bottom first,

then the sides, and the top last. Do not cover stab

platform.

2. To minimize abrasion in landing, triple cover the underside from

the nose to about 6” back.

Finally, it’s a very good idea to place your name, address, phone number , AMA number and the word REWARD! permanently on the

inside wall of the servo compartment. Then if your Gentle Lady

should fly away for any reason, you’ll have a chance of getting it

back!

1.

Obtain some 1/16”x1/4” wing seating foam tape and

attach it to the wing rest areas of the fuselage. This

prevents unexpected shifting of the wing.

2.

Mount wing on the fuse using rubber bands (five

#64s are used for flying). Measure carefully from

the fuselage sides out to the polyhedral breaks

(arrows ‘A’) to be sure that the wing is centered.

Then measure from the polyhedral breaks to the

back end of the fuse (arrows ‘B’) to make sure wing

is square with fuse. Mark the wing and fuse with

matching line-up points. The prototype uses white

Color Stripe to indicate clearly when the wing is

lined up.

FINAL ASSEMBLY

DECAL INSTRUCTIONS

Clean model surfaces thoroughly before applying

decals. Cut decal sheets apart in sections as needed.

Fold decal in half, front to rear. Open at fold and lay

decal out straight, the protective backing will bubble

away from decal at fold location. Using scissors, cut

backing along bubble, removing about 1” wide strip of

backing. Carefully position decal on model and stick in

place. Working from center, rub decal down while

peeling off backing.

Page 18

18

2.

Trial fit stab in place on fuse, marking it for center,

and adjust as necessary to line up with wing. Then

measure from the stab tips to the fuse front (arrows

‘C’) to make sure stab is square with fuse. To provide

a firm, balsa-to-balsa glue joint, strip covering

(minimum 1/8”) to retain firm covering bond to stab

center. Be certain to leave enough covering bond

to stab center. Likewise, if stab area on fuse was

covered, remove covering. Glue stab firmly to fuse

and let dry.

3.

Trial fit fin in place on fuse/stab (arrow “D”). Strip

covering from fin bottom (if covered) and

respective area on fuse/stab. Glue fin firmly in place,

and square with stab. Let dry.

4.

After covering and final assembly, glue 4” long tri-strip

in place as show above. Cover the top of the tri-strip

with film before placement.

5.

Remove the wing, and make hole on left side of fin

for the rudder pushrod exit guide at location shown

on plan. Trim off one side of the exit guide flange,

so guide will fit flush against the fin.

6.

Try the pushrods in working positon inside the

fuse, but without mini-snaps. Make adjustments as

necessary so threaded rods head right for their

control horns. Move pushrods back and forth to

simulate servo action, and remove and adjust

pushrods as necessary for smooth operation. If

required, trim out channel inside fuse, going

forward from exit guide hole, to make it easier to

get threaded rod up to and out exit guide hole.

When operation is satisfactory, glue exit guide in

place.

Re-install pushrods, and add mini-snaps to the

threaded ends of pushrods.

7.

To open mini-snap, insert small screw driver blade,

then twist. Refer to plan for elevator control horn

location. Connect mini-snap to bottom hole in

horn, and hold horn in place on elevator. Move

elevator up and down to observe control horn and

mini-snap clearance through fuse tail exit. Shift

control horn or trim exit as necessary. Mark

location and install control horn on elevator.

8.

Refer to plan for rudder horn location, and install

horn.

9.

Adjust rudder pushrod as necessary, and connect

mini-snap to 2nd closest hole to hinge.

Page 19

19

RADIO INSTALLATION

Prepare for installation

1.

The pushrods should be in place in the fuselage

and connected to the control horns. The wires at

the front end of the pushrods should have some

excess length, reaching close to former #2.

2.

Read and follow the instructions that come with your

radio.

3.

If your batteries are dry cells, they should be fresh;

if they are rechargeable nicads, they should be

fully charged.

Radio Pre-Check

Assemble and try the radio before installation.

1.

Move the control stick from side to side. Apply

tape (on which you can write) to the particular plug

from the receiver which goes to the servo that

moves. Mark that plug “RUD”.

If your receiver doesn’t have separate plugs coming from

it, but does have places for the servos to plug in, apply a piece of

tape nearby that you can mark “R” opposite the

appropriate plug-in location.

2.

Move the control stick up and down (away from

you, and towards you). Mark the appropriate plug

or plug -in location “ELEV” or “E”.

NOTE: The servo functions are determined by where they

are plugged into the receiver. Be sure to assemble them the

same way each time so that the servos give you the proper

responses.

Radio Protection

Locate and protect airborne part of radio. Begin by

installing the servo rails.

1.

With pushrods installed, tape the front wires up out

of the way beneath the 1/8” sq. wing rest strips.

2.

Insert the soft rubber grommets into the mounting

holes of your servos.

Measure from the bottom of your servo to the

underside of a grommet. Add 3/16” to this

measurement. The total is the height of the tip of

the servo rail above the fuselage floor.

Mark the inside of the fuselage for the height of

rails.

3.

Notch one rail as necessary to clear the cables

where they exit from the servo. This will be the

forward rail.

Glue the forward rail in place with CA or

epoxy.

4.

Place one servo on the rail. Allow 1/16”

clearance from the back of the servo.

Glue the rear rail in place.

Foam

Wrappings

Hold cables down

with foam

batttery

Receiver

Charging Jack

(Note notches in forward rail)

Page 20

5.

With both servos in position, and approximately

1/16” between them, mark through the grommets

for the location of the servo mounting screws.

Remove the servos. With a 1/16” drill bit, drill

through the rails for the screws.

6.

Determine which is the elevator and which is the

rudder servo. Locate the rudder servo on the left,

and the elevator servo on the right, as shown in the

plans.

Fasten gently with #2 x 3/8” sheet metal screws.

Untape the pushrod wires from the fuselage sides

and hook them up to the servos as shown.

Next, protect the battery pack. Remember, you must have

fresh dry cells or fully charged nicads for flying.

1.

Wrap your battery pack in polyethylene foam or

foam rubber to cushion it against shock. If you are

going to use an engine with your model, foam

rubber is preferable because it is much better at

protecting against vibration. Use scotch or

masking tape to hold the ends of the foam in place.

2.

Because the battery pack is the heaviest piece, it

should be mounted as far forward as possible.

Installing the Receiver

1.

Do not cut the antenna wire attached to the

receiver.

2.

Wrap the receiver carefully in foam, as was done

for the battery pack. Then place the receiver

just to the rear of the battery pack.

3.

Lead the antenna back just under the hatch rest.

Drill a small hole in former #2, and lead the

antenna further back, just under the 1/8”

sq. balsa wing rest rails.

20

4.

Just ahead of former #3, drill a small hole in the

fuselage side for the antenna to exit.

Lead the antenna to the top of the fin and scotch

tape in place.

Installing the Switch and Charging Jack

1.

Mark fuselage side for switch location.

Cut hole through fuselage side, and make it long

enough for switch button to move to On an Off

positions.

2.

Determine On and Off positions of switch. Mount

switch with On positon forward.

Install switch screws.

3.

On the outside of fuselage, identify On and Off

positions with decals provided.

4.

Mount the charging jack for the battery in the fuselage

side by the same method.

Cable Storage

1.

Gather all excess cables together behind receiver,

and hold down with foam.

Set Control Surfaces

1.

With elevator trim tab on transmitter set in the

center position, adjust elevator mini-snap until top

of elevator is flat with top of stab.

2.

With rudder trim tab on transmitter set in center

position, adjust rudder mini-snap until rudder points

dead straight ahead.

With everything installed, mount the wing and carefully

check the Center of Gravity (CG). One way is to perch the

model on the thumb and forefinger of your left hand (if

you’re right handed), while steadying the model with the

other. A much better way is to use a balancing set-up,

which can be made with a couple of 1/4” dowels with

rounded tops, spaced just enough apart to clear the fuse.

Mark the desired CG on the underside of the wing, and

then set the model on the dowels at that location. Add

weight if necessary for balance. The least weight is

needed when added as far forward or back as possible.

DO NOT attempt to fly the model with the CG EVEN

SLIGHTLY BEHIND the rearmost recommended

position.

Before going to the field to fly, with batteries fully

charged, turn on receiver and transmitter and actuate all

controls many times until you are satisfied with all

functions.

Prior to the beginning of each day’s flying, make a

range check of your equipment in accordance with the

manufacturer’s instructions in general, with antenna

collapsed, you should have at least 100 feet range on the

ground. To check this, set the model facing away from

you, turn on both the trasmitter and receiver switches, and

walk away while transmitting signals. Watch to see that no

signals are missed until you are at least 100 feet away. Do

not attempt any flights unless the equipment works perfectly.

Be careful not to use your transmitter when someone

else on the field is flying or testing on the same frequency.

RADIO CHECK

BALANCING

Model Balance Stand

Make from 1/4” dowels

6” long and 1/4” ply or

hard balsa base

Page 21

21

FLYING YOUR GENTLE LADY

IMPORTANT: Always check to be sure no one else is using the same frequency as you, before operating your radio.

Make hand launched test flights before first high-start or powered flight.

With transmitter and receiver switched on, hand launch the

model directly into the wind. Gently correct the flight path

as necessary. Make any adjustments indicated in the

rudder or elevator by means of the clevises.

In flight control, most of the beginner’s trouble comes from overcontrolling or holding a signal too long. It is better to operate

your transmitter slowly and smoothly.

A troublesome tendency is letting the model get downwind.

New flyers should try to keep the model upwind at all times

prior to the landing approach. It is more difficult to fly a

model when it is downwind, and if a mistake is made, the model

will end up farther downwind, making it impossible to fly it back

to the field.

If you are a novice, seek the help of an experienced flyer.

If nothing else, ask one of the better flyers at the field for

help. Usually, they are glad to spend a little time to get

somebody started right, and they very likely were helped in

the same manner themselves.

Here are some additional tips from Dave Brown, a multiple

R/C Pattern National Champion, which have helped many

fliers get started. They are reprinted by permission of R/C

Modeler Magazine and are excerpted from Dave’s

article, “Learning How to Fly”, which appeared in the RCM

October 1979 issue.

from “Learning How To Fly”

by Dave Brown

Although Dave strongly recommends learning to fly with

the help of an instructor, he feels that if you must teach

yourself, a powered glider is the best type of plane to learn

on

Set the airplane up with a very minimal amount of

control surface throw, particularly on elevator. Now,

before you fly it, spend a considerable amount of time

“hanger flying”it simply by pointing it at many different

angles (including coming straight at you) and working

the controls, imagining that it is flying and you are trying

to steer it around the sky. If possible, it’s better if you

can mount the airplane up on a camera tripod while

doing this to get the perspective of the airplane being

above you as well as it climbing, diving, or banking. I

realize you may feel ridiculous while doing this and it

probably should be done out of sight of other sane

people to retain your stature in the community, but

believe me, it is important and it works. I still use this

system when trying to straighten out a particular

problem or maneuver.

Now...you must get the airplane trimmed out by test

gliding it over some tall grass. Only when you can

consistently throw the airplane at the right speed to

make it glide smoothly to the landing without dropping

like a brick or stalling and dropping in, are you ready to

continue. During all these test glides it is best to have

the radio turned on, but leave the transmitter on the

ground, using it only in emergency to get the model out

of a thermal! Don’t laugh, I’ve seen this happen. After

you can consistently throw in this manner, try it holding

the transmitter in the other hand and try steering it just a

little. Don’t make any sharp turns, but rather try to

make it do very shallow S-turns, never exceeding about

10 to 15 degrees from that straight line. Don’t touch the

elevator control yet and don’t move the rudder stick any

more than about half its travel.

Reprints of Dave’s complete article may be obtained by

calling Carl Goldberg Products. Dave closes with his “ten

commandments” for the self-taught R/C pilot. We think

most of them make sense and should be heeded everyone!

1) Thou shalt get help if at all possible.

2) Thou shalt fly only a trainer type airplane,

preferable a motorglider

3) Thou shalt fly only when it is calm.

4) Thou shalt fly only in a very large open area with its

owner’s permission.

5) Thou shalt not fly to impress friends.

6) Thou shalt proceed slowly and with caution.

7) Thou shalt not panic; let the airplane fly itself out of

trouble.

8) Thou shalt steer the model carefully and delicately,

using only rudder at first.

9) Thou shalt check thy equipment frequently and

change batteries faithfully.

10) Thou shalt be patient, lest thee bust thy toy!

REMEMBER.....

FLY ONLY IN AREAS SUITABLE AND/OR

SANCTIONED FOR R/C AND KNOWN TO BE FREE

OF RADIO INTERFERENCE. Great help can be found in

all phases of building and flying by reading R/C Modeler

Magazine’s “Flight Training Course, Vol. 1.” There also are a

number of videos (“Old Buzzard Goes Flying!” deals specifically with sailplanes) and flight simulation programs availabel to help you. Happy Flying!

Loading...

Loading...