Page 1

1

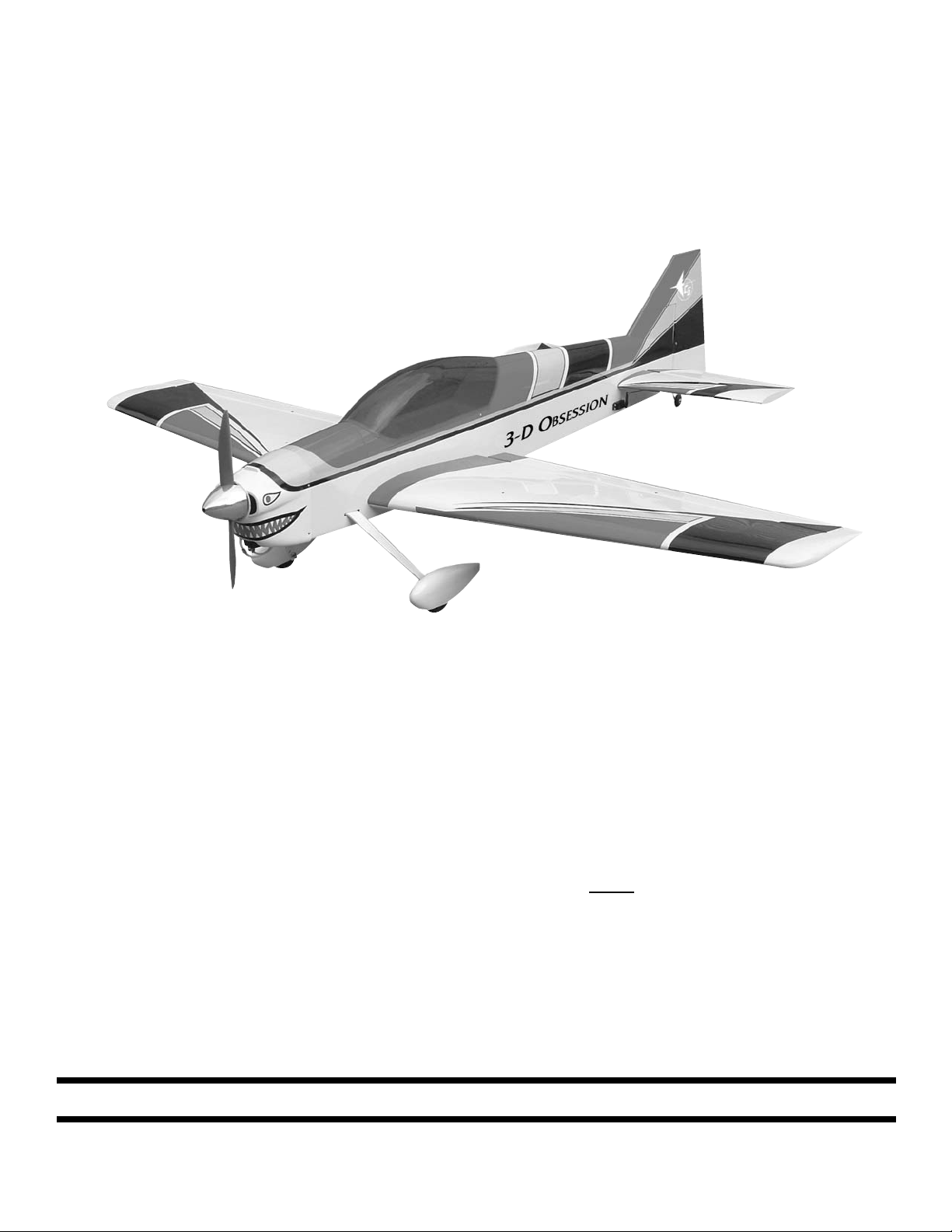

Congratulations on your purchase of the Obsession 3D ARF. This is a very unique dual-purpose

aircraft, capable of flying any FAI pattern sequence with ease, while exhibiting remarkable 3-D capabilities. Every effort has been made to produce a lightweight, straight, easy to assemble aircraft.

Because of its oversize control surfaces which are double beveled to allow for extreme throws, great

care must be taken in the set-up and flying of this airplane. Quality hardware components have

been provided to allow for 3D set-up while maintaining adequate mechanical advantage to eliminate

flutter. It is you responsibility as an advanced pilot to fly the aircraft in an intelligent manner. THROT-

TLE MANAGEMENT IS A MUST!!!!!!! Carl Goldberg Products has flown the Obsession 3D ARF

through a very rigorous flight-testing schedule and have stressed the airframe beyond all practical

parameters without a single failure. Carl Goldberg Products will NOT

warrant the Obsession 3D

ARF against flutter due to improper set-up or excessive speed maneuvers. having said that, we

believe you will find the Obsession 3D ARF to be one of the most responsive, in-the-grove aircraft

on the market. The Obsession 3D ARF excels at high-alpha maneuvers including Harriers (both

upright and inverted), high-alpha rolls, and high-alpha knife edge. Torque rolls, waterfalls, knife edge

loops and elevators are all within the performance parameters of this unique aircraft. Just remember

to use common sense when flying this high performance machine.

©Copyright 2004

OBSESSION

OBSESSION

3D ARF

3D ARF

P.O. Box 818 Oakwood GA 30566 Phone #678-450-0085 Fax # 770-532-2163 www.carlgoldbergproducts.com

CARL GOLDBERG PRODUCTS, LTD.

Page 2

2

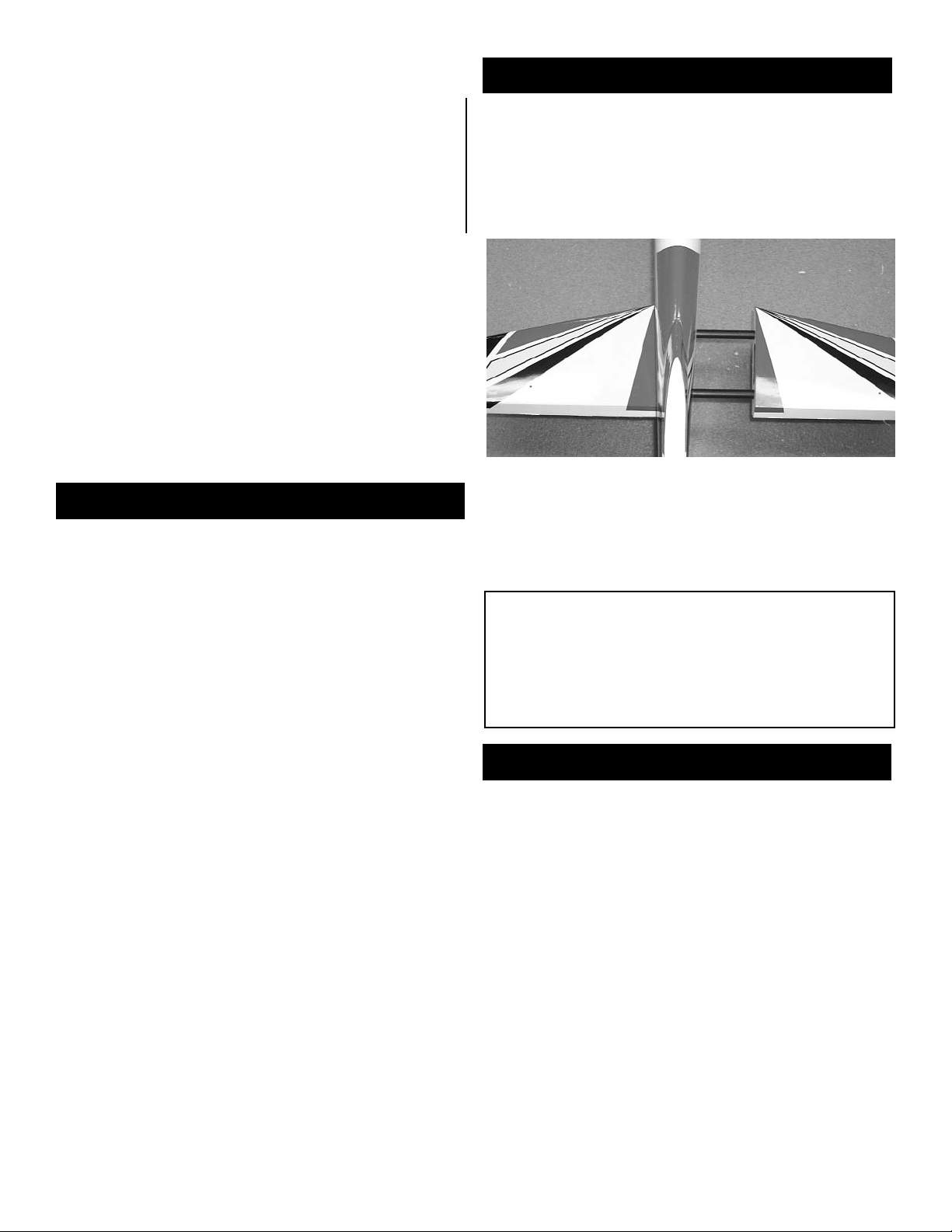

We are very proud of the construction of the Obsession 3D ARF and all of our other

ARF aircraft. Each aircraft is jig built to insure a straight true airframe. Every effort is

made to build as light an aircraft as possible. As with any professional builder, glue is

used sparingly. Please take a moment during assembly and run a bead of CA or

aliphatic resin into the high stress joints, such as the landing gear plate, servo

mounting trays, wing hold down blocks, etc. Also, during the course of shipping

from the manufacturer to our facility in the United States, it is not uncommon for the aircraft to experience several changes in climate. This may cause the iron-on covering to

develop wrinkles. This is not a fault of the manufacturer. Please take a few minutes with

your heating iron and heat gun to iron down the seams and re-shrink the covering

where needed. The results will be a beautiful aircraft with a breathtaking finish that you

will be proud to display at your flying club.

Important Information

Covering coming loose is not COVERED UNDER WARRANTY. Due to temperature

changes the plane may develop some wrinkles in the covering that you will need to

remove with an iron. Be sure to seal the edges down first so that you do not cause

the covering to shrink and leave exposed areas of wood. Please inspect the plane

before beginning to assemble to make sure you are happy with it. After assembly has

begun you cannot return the kit. If you find a problem before beginning to assemble

the plane you must contact us, please do not return it to the dealer.

Page 3

3

Parts List

1. Fuselage

2. Fiberglass Cowl

3. Wing (Right & Left) with ailerons

4. Stab (Right & Left) & elevator assembly

5. Rudder

6. Fiberglass wheel pants

7. Canopy

8. Canopy Hatch

1. (2) Motor Mounts

2. (4) 8-32 x 1” Socket Head Bolts

3. (4) #6 x 3/4 Socket Head Screws

4. (4) #8 lock washers

5. (4) #8 flat washers

Motor Hardware

Landing Gear

1. Main Gear 1 left 1 right

2. (4) 4-40 x 1/2”” Button Head Bolts

3. (4) 4-40 Blind Nuts

4. (6) 8-32 x 1/2” Socket Head Bolts

5. (2) 3-1/4” main wheels

6. (2) 5/32 x 1-1/4” Axles

7. (2) Axle Locking Nuts

8. (2) 4mm flat washers

9. (2) 5/32 Wheel Collars

10. (2) 4-40 x 1/8 Set Screws

Tail wheel

1. (1) Tail wheel bracket

2. (1) 1-1/2” tail wheel

3. (2) 6-32 x 3” threaded rod

4. (2) 6-32 Hex Nut

5. (2) #6 Washer

6. (6) 1/8” Adjustable Horn bracket

Wing

1. (1) 1-1/2” x 25-3/16” Wing Tube

2. (2) 4-40 x 1/2” Bolt

COWL HARDWARE

1. (4) 4-40x 1/2”Button Head Screws

Control System

1. (5) Nylon Adjustable Control horns

2. (5) 6-32 x 2-1/4” Allen head Bolt

3. (5) Nylon Nut

5. (5) Nylon Cup Washer

6. (2) 4-40 x 2-3/16” double Threaded Rod

(Aileron)

7. (2) 4-40 x 4-7/8” Double Threaded Rod

(elevators)

8. (1) 4-40 x 6-1/4” Double Threaded Rod

(Rudder)

9. (5) 4-40 Hex Nut

10. (5) 4-40 Metal Clevis

11. (5) Metal Clevis Clips

12. (1) 2-56 x 15” Threaded Rod

(Throttle Pushrod)

13. (1) 1/8 I.D. x 14” Nylon Tubing

(Throttle Pushrod)

14. (1) EZ connector (Throttle)

Fuel Tank

1. (1) Fuel Tank

2. (1) Rubber stopper

3. (2) Metal caps for stopper

4. (1) Screw

5. (1) Clunk

6. (3) Aluminum fuel tubes

7. (1) Silicone fuel line

1. (1) 1/2” x 15-9/16” Rear Stabilizer Tube

2. (1) 1/2” x 8-11/16” Front Stabilizer Tube

2. (2) 4-40 x 1/2” Bolt

Stabilizer

Additional Items Needed

1. (5) Servo arm extensions

2. (1) Fuel Tubing 36”

3. Electrical Straps (various sizes)

4. 1/2” Foam Rubber

5. (3) 24” Servo Extensions

6. (2) 12” Servo Extensions

7. (1) Y-Harness

8. (1) 24” Thread

Page 4

4

Before beginning assembly of your Obsession

3D ARF, we highly recommend that you study

this manual in its entirety. You should begin

planning your radio installation based on your

choice of engine and equipment from the beginning.

Because the Obsession 3D ARF is intended

for those with some degree of modeling experience, every little detail will not be covered. This

is not a basic trainer. Assembly of this aircraft

will be easy for the experienced modeler, and

by following the instructions within this manual

and using the skills you’ve gained during your

modeling career you will be able to produce a

first class aircraft.

Building supplies needed

Hobby knife w/#11 blades

Thin CA

Medium CA

Canopy glue

30 minute epoxy

Thread lock

Diagonal wire cutters

Pliers

Assorted drill bits

Various sized screwdrivers( both Phillips and

standard head)

Tape measure

Dry-erase marker

Paper towels

Rubbing alcohol

Electrical tape

4-40 Tap & Die Set

3/32, 7/64, 9/64 & 3mm Allen wrench

1. Begin construction by Inserting the front and

rear stabilizer tubes through the fuselage. (The

short tube goes in front).

2. Trial fit each side of the stabilizers onto the

tubes. Lightly sand the tube openings if necessary.

Note:

Now is the time to decide if you want

to glue the stabilizer to the tubes and

the fuselage, or if you wish to have

removable stabilizers.

1. Using a pencil, make an outline where the

stabilizer rest against the fuselage.

2. Remove both stabilizers from the tubes.

3. Remove the tubing from the fuselage.

4. Lightly sand the tubing using 220 sand paper.

5. Remove the covering from the fuselage

inside the outline that you made.

6. Mix up epoxy and slide the stabilizer assembly together again, allow to dry.

Mounting Stab

Collect the following parts:

(1) Left Stabilizer

(1) Right Stabilizer

(1) 1/2” x 8-11/16” Front Stabilizer Tube

(1)1/2” x 15-9/16” Rear Stabilizer Tube

(2) 4-40 x 1/2 bolts

Gluing Stabilizer

Page 5

5

Removable Stabilizer

1. Using a drill for a 4-40 tap, drill through the

hole located on top of the stabilizer.

2. Tap the hole with a 4-40 tap.

3. Making sure that the stabilizers stay tight to

the fuselage, repeat for the other side.

4. Before flying place clear plastic tape over

the screw holes to keep the screws from

vibrating out.

Installing Elevators

Collect the following parts:

(1) Left Elevator

(1) Right Elevator

(8) C/A Hinge

(2) Nylon Adjustable Control horns

(2) 6-32 x 2-1/4” Allen head Bolt

(2) Nylon Nut

(2) Nylon Cup Washer

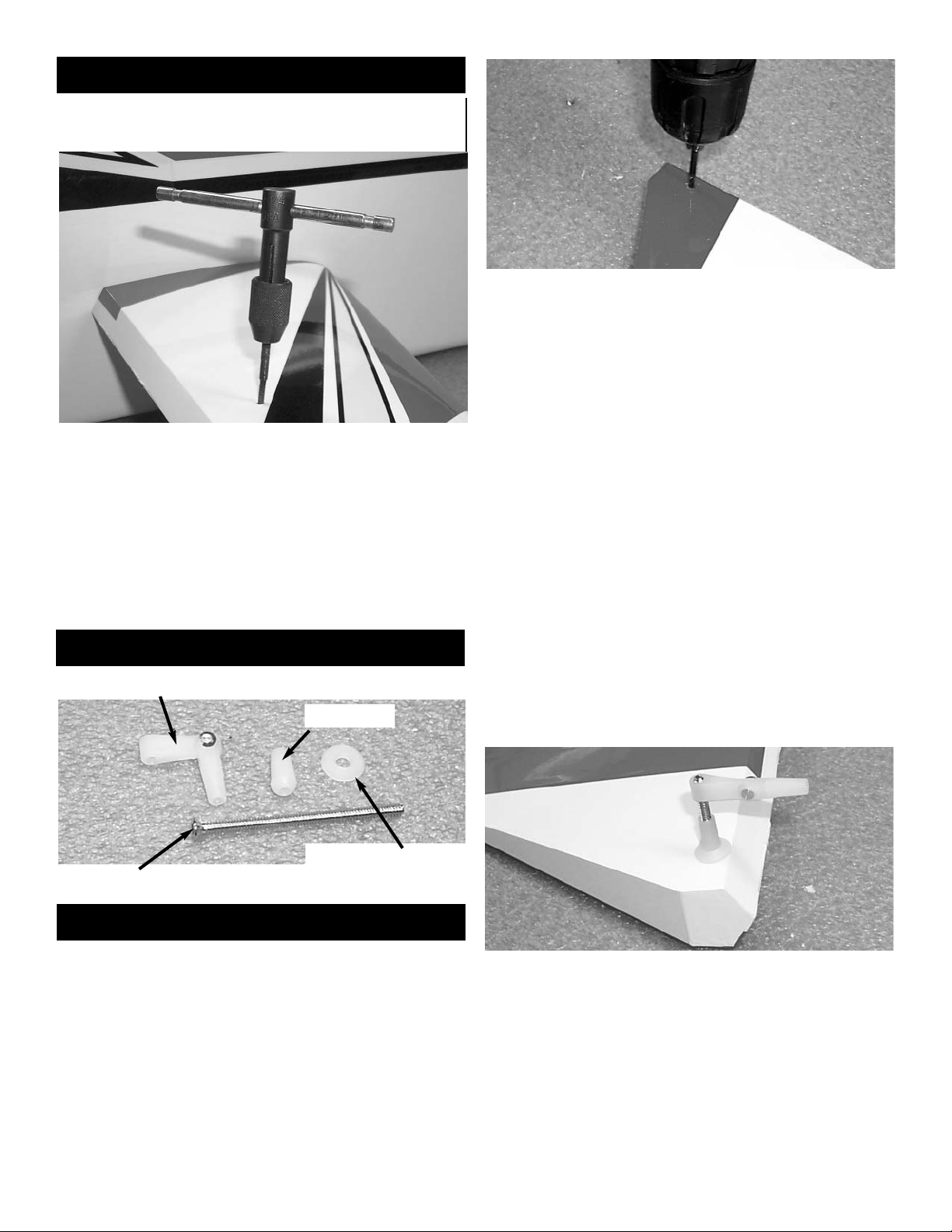

Control Horn Part Names

Nylon Adjustable Control Horn

6-32 x 2-1/4” Allen head Bolt

Nylon Nut

Nylon Cup Washer

1. At the corner of the elevator, on the top and

bottom, feel for the pre-drilled hole in the plywood stiffener.

2. Using a 1/8” drill, drill half way through the

elevator hole from both top and bottom till the

drill pass through the elevator.

3. Insert the 6-32 x 2-1/4 allen head bolt into the

top of the elevator.

4. Thread the bolt all the way till the head is

flush with the top of the elevator.

5. On the bottom of the elevator, place first the

cup washer then the nylon nut onto the 6-32

bolt.

6. Using a metric allen wrench tighten the nylon

nut all the way down till it rest in the cup washer

and is tight to the elevator.

7.Thread the nylon adjustable control horn onto

the bolt.(Note: Thread the side that you can

see the cut threads in the nylon onto the

bolt)

Page 6

6

8. Insert four hinges with pins in the center into

the elevator and slide the elevator on to the correct stabilizer.

9. Place 3 drops of thin CA on both sides of

each hinge. Remove the pins.

10. Repeat steps 1 thru 9 for the other elevator.

Elevator Servo

Collect the following parts:

(2) Servos with mounting screws

(2) 24” Extensions

(2) 4-40 Metal Clevis

(2) 4-40 Hex Nut

(2) Metal Clevis Clips

(2) 4-40 x 4-1/2” Double Threaded Rod

1. Remove the covering over the elevator servo

hole just below the leading edge of the stabilizer.

2. Plug the 24” servo extension onto the servo

plug and tape securely.

3. Mount your servo using the hardware supplied with the radio.

IMPORTANT!

To ensure that any connections located

inside the Fuselage will not come loose,

either when the wires are pulled, or during

flying, always tape them securely together

with electrical tape.

3. Thread the 4-40 x 4-7/8” double threaded rod

into the nylon adjustable control horn.

9. Place a 4-40 hex nut and a metal clevis on

the other end of the threaded rod.

10. Mount the clevis to the servo arm and place

the clevis clip on th clevis.

11. Repeat 1 thru 10 for the second elevator

servo.

Note:

The servo arms that are shown are after mar-

ket arms to help increase the the amount of

servo movement.

Rudder Installation

Collect the following parts:

(1) Rudder

(3) C/A Hinge

(1) Nylon Adjustable Control horn

(1) 6-32 x 2-1/4” Allen head Bolt

(1) Nylon Nut

(1) Nylon Cup Washer

Page 7

7

Rudder Servo

Collect the following parts:

(1) Servos with mounting screws

(1) 24” Extensions

(1) 4-40 Metal Clevis

(1) 4-40 Hex Nut

(1) Metal Clevis Clips

(1) 4-40 x 6-1/4” Double Threaded Rod

1. Measure up from the bottom of the rudder

approximately 5” to locate the rudder control

horn hole.

2. Using a 1/8” drill, drill half way through the the

hole from both sides till the drill pass through the

rudder.

3. Insert the 6-32 x 2-1/4 allen head bolt into the

left side of the rudder.

4. Thread the bolt all the way till the head is

flush with the side of the rudder.

5. On the side of the rudder, place first the cup

washer then the nylon nut onto the 6-32 bolt.

6. Using a metric allen wrench tighten the nylon

nut all the way down till it rest in the cup washer

and is tight.

7.Thread the nylon adjustable control horn onto

the bolt.(Note: Thread the side that you can

see the cut threads in the nylon onto the

bolt)

8. Hinge the rudder to the fuselage using 3 CA

hinges and thin CA glue.

1. Remove the covering on the right side of the

fuselage over the rudder servo hole. The hole is

just above the elevator hinge line of the stabilizer.

2. Plug the 24” servo extension onto the servo

plug and tape securely.

3. Mount your servo using the hardware supplied with the radio.

Note:

There is a rudder servo hole on both the left

and right side of the fuselage. Using two rudder servos will give the rudder more authority for 3 D aerobatics but, will also place more

weight in the tail, which could cause CG problems.

If you choose to mount two servos then low

profile servos will probably be need to fit. Or

blocks of wood to move the rudder servos

farther apart inside the fuselage.

We have only supplied to you the hardware

for one servo horn.

4. Connect the pushrod hardware to the rudder

and servo same as you did with the elevators.

Page 8

8

Collect the following items:

(2) 6-32 x 3” All threaded rod

(2) Small White Adjustable Horn

(1) Tailwheel Bracket

(2) #4 x 1/2” Sheet Metal Screw

(2) #6 Flat Washer

(2) 6-32 Hex Nut

(2) 1/8” Wheel Collars

(2) 4-40 x 1/8 Cup Screw

(2) Tailwheel Springs

Mounting Tailwheel

1. Mark the center of the fuselage and locate

the tailwheel bracket so the the first bend is on

the rudder hinge line.

2. Mark two hole locations and make two holes

using a 3/32” bit.

3. Mount the bracket to the fuselage using the

#4 x 1/2” sheet metal screws.

4. Thread the 6-32 x 3” rod into brass nob that

is on top of the axle on the bracket.

5. Place on both ends of the threaded rod a

white horn bracket.

6. Drill a 1/8” hole located at 3/4” back from the

hinge line and 1/2” up from the bottom of the

rudder.

7. Insert the second 6-32 x 3” all threaded rod

and center it using the #6 washer with a 6-32

hex nut.

Use thread lock on the nuts.

8.Place on both ends of the threaded rod a

white horn bracket.

9. Connect one side of the spring to the horn

bracket.

10. Then cut the springs to length so that there

is a slight tension in the spring.

11. Connect the springs between the two

adjustable horn brackets.

12. Insert a 4-40 x 1/8” cup screw into each of

the 1/8” wheel collars.

13. Place one of the 1/8” wheel collars onto the

tailwheel bracket axle.

14. Slide the wheel onto the axle and place the

second wheel collar into the axle.

15. Center the wheel on the axle and tighten the

wheel collars next to the wheel.

Main Landing Gear

Collect the following items:

(2) Right & Left Landing Gear

(4) 8-32 x 1/2” Socket Head Bolts

1.Remove the covering over the screw holes for

the main landing gear on the bottom of the fuselage.

2. Remove the covering over the landing gear

slots on the side of the fuselage.

Page 9

9

3. Insert the landing gear through the slot on

the side of the fuselage.

4. Using the 8-32 x 1/2” socket head bolts and

thread lock, screw the landing gear into the blind

nuts that are already installed in the fuselage.

Wheel Pants

Collect the following items:

(2) 5-32 x 1-1/4” Axle with Locking Nut

(4) 5/32 Wheel Collars

(4) 4-40 x 1/8” Cup Screws

(4) 4-40 Blind Nuts

(4) 4-40 x 1/2” Button Head Screws

(2) 3-1/4” Wheels

1. Mount the axle to the landing gears.

2. Place the wheel pant onto the axle.

3. Align the bottom of the wheel pant with the

bottom of the landing gear.

4. Mark the hole locations on the wheel pants.

5. Drill 1/8” holes on the marks you just made.

6. Insert the 4-40 blind nuts inside the wheel

pants.

Wheel Collars

Wheel Pant

Wheel

Landing Gear

7. Mount the wheel pants back on the landing

gear along with the wheel collars and wheels.

8. Center the wheel on the axle.

Page 10

10

Engine Installation

Collect the following items:

(2) Nylon Motor mounts

(4) 8-32 x 1” Socket Head Screw

(4) #8 Washer

(4) #8 Lock Washer

(4) #6 x 3/4” Socket Head Sheet Metal Screw

Note:

The firewall is pre-drilled for the motor

mounts. the distance between the motor

mount is 1.915, this will work for the OS 120

FS or the YS 140 or any other motor needing

that clearance.

New blind nuts can easily be installed

in the back of the firewall if your choice of

motor does not fit. Measure between the

screw holes to find the vertical center line.

Locate the horizontal centerline by placing a

motor mount on the firewall and marking the

location that the outer line meets the firewall.

1. Install the motor mounts to the firewall using

the 8-32 x 1” socket head screws and the #8

washers. Use thread Lock on the screws

2. Place your engine on the motor mounts so

that the prop drive washer is 5-3/4” from the

firewall.

3. Mark the motor screw locations and drill a

3/32” hole at each location.

4. Screw the motor to the mounts using the #6 x

3/4” socket head screws.

5. Drill a 3/16” hole at the throttle pushrod location.

Throttle Servo

Collect the following items:

(1) Throttle Servo with mounting hardware

(1) .062 x 15” Wire

(1) 1/8 x 12” Tubing

1. Install the throttle servo inside the fuselage

using the hardware provided by the radio manufacturer.

2. Insert the throttle pushrod tubing through the

firewall and route it back to the throttle servo.

3. Install the EZ connector to the throttle servo

arm. Use Thread Lock

4. Make a bend at one end of the 15” wire.

5. Install the pushrod wire.

Note:

depending on the motor used your pushrod

may not be in the same location as shown.

Page 11

11

Cowl

Collect the following items:

(1) Fiberglass Cowl

(4) .#2 x 5/16” Sheet metal Screws

1. Install the fiberglass cowl onto the fuselage.

2.It helps if you make small cut outs in the fiber-

glass then slowly increase the sizes of the holes

till the cowl fits over the motor.

3. Make sure the cowl has at least a 1/16” clearance behind the spinner.

4. Screw the cowl to the fuselage using the #2 x

5/16” screws.

Fuel Tank Assembly

1. Locate the fuel tank and hardware.

the silicone tube install the clunk. This should be

adjusted in length so the clunk is about 1/4” off

the bottom of the tank. One of the long tubes

should be bent so it rest against the top of the

tank. This is the vent line. The other tube will be

the fill line. Insert the stopper in the tank and

mark the fill, vent, and pickup line so you don’t

get them mixed up later. If you are using a YS

engine which pressurizes the tank, you should

wrap the tank in strapping tape with a couple of

loops going around the cap to make sure it does

not blow off.

2. Assemble the cap by inserting the screw

through the large washer, through the black rubber and threading into the small washer on the

back side. Insert the three metal fuel lines into

the holes in the cap. The short line will be the

pickup line and will have the silicone tubing

attached to the back end. On the other end of

Mounting Fuel Tank

Collect the following items:

(1) Fuel Tank

(1) .Velcro® Strap

(1) 36” Fuel Line

1. Join the velcro together to make a long strip.

2. Thread the velcro® through the slots from the

bottom on either side of the fuel tank opening in

the tray.

3. Slide the fuel tank into the middle of the fuselage tray and under the center former.

4. Strap the Velcro® tight around the fuel tank.

5. Push the fuel tubing through the holes in the

firewall and pull them back to the fuel tank and

attach.

6. Hold the fuel lines in place using electrical

straps.

Page 12

12

Installing Receiver & Battery

Receiver

Battery

In our plane we wrapped the receiver and battery

in 1/2” foam then we mounted the receiver in

front of the fuel tank with the battery behind the

tank. Use electrical straps to hold them both in

place.

Plug a Y-harness into the receiver and pull one

plug out each side of the fuselage from the hole

just behind the wing tube hole.

Aileron Installation

Collect the following parts:

(1) Left & Right Wing

(1) Left & Right Aileron

(10) C/A Hinge

(2) Nylon Adjustable Control horns

(2) 6-32 x 2-1/4” Allen head Bolt

(2) Nylon Nut

(2) Nylon Cup Washer

1. Measure 16-3/8” from the end of the aileron to

find the hole for the control horn.

2. Using a 1/8” drill, drill half way through the

hole from both top and bottom till the drill pass

through the aileron.

3. Insert the 6-32 x 2-1/4 allen head bolt into the

top of the aileron.

4. Thread the bolt all the way till the head is

flush with the top of the aileron.

5. On the bottom of the aileron, place first the

cup washer then the nylon nut onto the 6-32

bolt.

6. Using a metric allen wrench tighten the nylon

nut all the way down till it rest in the cup washer

and is tight to the aileron.

7.Thread the nylon adjustable control horn onto

the bolt.(Note: Thread the side that you can

see the cut threads in the nylon onto the

bolt)

8. Insert five hinges with pins in the center into

the aileron and slide the aileron on to the correct wing half.

9. Place 3 drops of thin CA on both sides of

each hinge. Remove the pins.

10. Repeat steps 1 thru 9 for the other aileron.

1. Remove the covering over the aileron servo

hole on the bottom of each wing.

2. Plug the 12” servo extension onto the servo

plug and tape securely.

3. Tie 24” of sewing thread to one of the 4-40

nuts with the other end tied to your servo extension wire.

Aileron Servo Installation

Collect the following parts:

(2) Servos with mounting hardware

(2) 4-40 x 2-3/16” double Threaded Rod

(2) 4-40 Metal Clevis

(2) 4-40 Hex Nut

(2) Clevis Clips

Page 13

13

6. Thread the 4-40 x 4-7/8” double threaded rod

into the nylon adjustable control horn.

79. Place a 4-40 hex nut and a metal clevis on

the other end of the threaded rod.

8. Mount the clevis to the servo arm and place

the clevis clip on th clevis.

9. Repeat 1 thru 8 for the second aileron servo.

4. Insert the nut through the aileron servo hole

and let the nut fall through the wing and out the

hole at the root.

5. Mount your servo using the hardware supplied with the radio.

Mounting Wing to Fuselage

1. Insert the tube into one of the wing halves.

2. Trial fit each side of the wing through the fuse-

lage.

3. Lightly sand the tube openings if necessary.

4. Drill and tap the wing to the tube one side at

the time (Keep the wing tight to the fuselage).

5. Before flying place clear plastic tape over

the screw holes to keep the screws from

vibrating out.

Collect the following parts:

(1) Left & Right Wing

(1) 1-1/2” x 25-3/16” Wing Tube

(2)4-40 x 1/2” Bolt

Canopy & Hatch

Collect the following parts:

(1) Canopy

(1) Hatch

(2)4-40 x 1/2” Bolt

1. Place the hatch on the fuselage and secure

using 4-40 x 1/2 bolts.Don’t forget thread lock

2. Cover the fuselage with wax paper around the

hatch area.

8. Glue the canopy to the hatch.

Caution:

Make sure that no glue touches the

fuselage.

Page 14

Balancing & Control Throws

Your model should balance at 9-3/8” at the fuselage side to start. For extreme

3D flying you may want to move the CG back even farther after you are use to the

Obsession 3D. Just remember that the further back you go the more sensitive it will

become. With extreme throws the model can get beyond the ability of novice pilots

very quickly.

Start with the controls set at low rate with the ailerons plus or minus 1/2”, the

elevator plus or minus 1” and the rudder plus or minus 1-1/2”. High rate should be all

you can get.

Good Luck and I hope you enjoy flying the Obsession 3D.

14

The Elevator

This maneuver has your plane drop vertically in

a nose high attitude, depending on wind conditions any where from a 45 degree angle in low

wind to almost backwards in higher wind conditions. To perform it, at a high altitude with high

rates on, pull your throttle back and feed in the

elevator until you have the full high rate applied.

Use the rudder to guide the plane, and adjust

attitude with minor throttle inputs. You will loose

altitude quickly, to recover, apply full power and

fly out level. Watch out for getting too low or

applying too much rudder, it could cause the

plane to snap.

The Harrier

This maneuver has your plane in very slow forward flight in a nose high 45 degree attitude. To

perform it, enter the same way as you would an

elevator, then feed in power until the plane

maintains altitude and starts to fly forward at a

nose high attitude. Maintain it by holding up

elevator and adjusting power, use the rudder to

change direction. Using ailerons may cause the

plane to snap and should be avoided. Add

power and push the nose back over to recover.

Page 15

15

The Waterfall

This maneuver has your plane flipping around

the axis of the wing, while dropping. Starting

from a high altitude, go to low throttle and gradually pull the nose up to near vertical. Just

when the plane is about the stall, give it full

down elevator and full power. Make attitude

corrections with the rudder and ailerons to keep

the plane flipping on axis. Cut the throttle and

hold full down elevator as the plane flips around

to nose high again, add power to flip it over

again. Watch your altitude as to not get too

close to the ground. Neutralize the elevator

and add power to recover.

The Blender

This is a violent maneuver that starts with a

vertical rolling dive that stops the descent as it

changes into a flat spin. Start at a good high

altitude, go to low throttle and push the nose

down into a straight dive. Feed in full left

aileron and complete 3 rolls, then immediately

move your transmitter sticks to an inverted

snap position, down elevator, left aileron, right

rudder, all full throw. Now feed in high throttle

to flatten the spin and stop the altitude loss.

Recover by neutralizing the rudder and

ailerons, and holding a little down elevator.

After you gain some airspeed you can roll out

to upright. Use caution as this is a violent and

high G maneuver that will put a great deal of

stress on the Plane

Page 16

16

Loading...

Loading...