Page 1

CCAARRLL GGOOLLDDBBEERRGG PPRROODDUUCCTTSS LLTTDD..CCAARR

P.O. Box 818, Oakwood, GA 30566 • 678-450-0085 • Fax: 770-532-2163 • www.carlgoldbergproducts.com P.O.

Wild Stick 120

Wild Stick 120

©copyright 2004 Carl Goldberg Products.

Page 2

2

Wild Stick 120

WARNING! THIS IS NOT A TOY!

THIS IS NOT A BEGINNERS AIRPLANE

This R/C kit and the model you will build from it is not a toy! It is capable of

serious bodily harm and property damage. It is your responsibility, and yours

alone - to build this kit correctly, properly install all R/C components and

flying gear (engine, tank, radio, pushrods, etc. and to test the model and fly

it only with experienced, competent help, using common sense and in accordance with all safety standards as set forth in the Academy of Model

Aeronautics Safety Code. It is suggested that you join the AMA and become

properly insured before attempting to fly this model. If you are just starting

R/C modeling, consult your local hobby dealer or write to the Academy of

Model Aeronautics to find an experienced instructor in your area.

Write to: Academy of Model Aeronautics, 5151 Memorial Dr. Muncie, IN

47302

LIMITED WARRANTY

Carl Goldberg Products is proud of the care and attention that goes into

the manufacture of parts for its model kits. The company warrants that for

a period of 90 days, it will replace, at the buyers request, any part or material shown to the company's satisfaction to have been defective in workmanship or material at the time of purchase.

No other warranty of any kind, expressed or implied, is made with respect to

the merchandise sold by the company. The buyer acknowledges and understands that he is purchasing only a component kit from which the buyer will

himself construct a finished flying model airplane. The company is neither

the manufacturer of such a flying model airplane, nor a seller of it. The

buyer hereby assumes the risk and all liability for personal or property damage or injury arising out of the buyers use of the components or the finished

flying model airplane, whenever any such damage or injury shall occur.

Any action brought forth against the company, based on the breach of the

contract of sale to the buyer, or on any alleged warranty there under, must

be brought within one year of the date of such sale, or there after be

barred. This one-year limitation is imposed by agreement of the parties as permitted by the laws of the state of Georgia.

Important Information

Covering coming loose is not COVERED UNDER WARRANTY. Due to temperature changes the plane may develop some wrinkles in the covering that you

will need to remove with an iron. Be sure to seal the edges down first so that

you do not cause the covering to shrink and leave exposed areas of wood.

Please inspect the plane before beginning to assemble to make sure you are

happy with it. After assembly has begun you cannot return the kit. If you find

a problem before beginning to assemble the plane you must contact us,

please do not return it to the dealer.

Page 3

3

Wild Stick 120

Wild Stick

Wild Stick

Congratulations on your purchase of the Lanier Wild Stick 120. This is a very

unique aircraft, with great 3-D capabilities. Every effort has been made to

produce a lightweight, straight, easy to assemble aircraft. Because of its

oversize control surfaces which are double beveled to allow for extreme

throws, great care must be taken in the set-up and flying of this airplane.

Quality hardware components have been provided to allow for 3D set-up

while maintaining adequate mechanical advantage to eliminate flutter. It is

you responsibility as an advanced pilot to fly the aircraft in an intelligent

manner. THROTTLE MANAGEMENT IS A MUST!!!!!!!! We at Lanier have put the

Wild Stick 120 through a very rigorous flight-testing schedule and have

stressed the airframe beyond all practical parameters without a single failure. Lanier will NOT warrant the Wild Stick 120against flutter due to improper set-up or excessive speed maneuvers. having said that, we believe you will

find the Wild Stick 120 to be one of the most responsive, in-the-grove aircraft

on the market. The Wild Stick 120 excels at high-alpha maneuvers including

Harriers (both upright and inverted), high-alpha rolls, and high-alpha knife

edge. Torque rolls, waterfalls, knife edge loops and elevators are all within

the performance parameters of this unique aircraft. Just remember to use

common sense when flying this high performance machine.

Page 4

4

Wild Stick 120

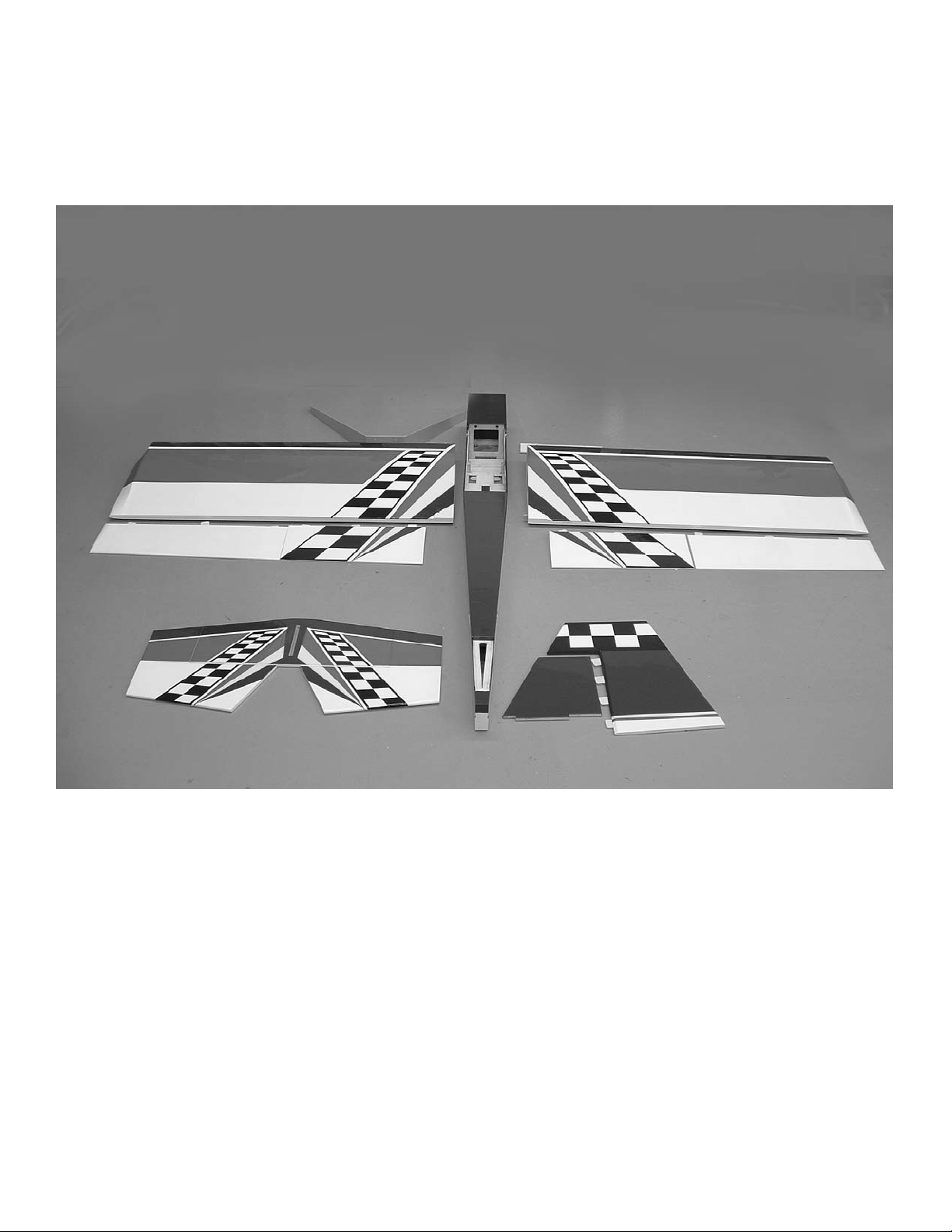

Parts Layout

Fuselage 1

wing panels 2

ailerons 2

Flaps 2

Stabilizer 1

Elevators 2

Fin 1

Rudder 1

landing Gear 1

Colors

Red True red #866

White #870

Black #874

Blue Deep Blue #873

yellow Bright Yellow #872

Page 5

5

Wild Stick 120

Landing Gear 1

4mmx12mm bolts 4

4mm washers 6

4mm wheel collars 4

4mm axels 2

4mm lock nuts 2

3.5” wheels 2

Motor Mounts 2

4mmx20mm bolts 4

4mmx25mm bolts 4

4mm blind nuts 4

4mm flat washers 8

4mm lock nuts 4

Flying Wires

1.8mmx16mm bolts 6

1.8mm nuts 6

1.8mm washers 12

metal brackets 12

nylon swing in keepers 8

1.6mmx10” pushrod with clevis 4

1.6mmx7” pushrod with clevis 4

metal plate(bottom bracket) 1

silicone clevis keepers 8

2mmx10mm screws 2

Control horns 8

control horn plates 6

2mmx20mm screws 14

2mm nuts 2

Pushrods

3mmx10cm pushrods(aileron) 4

3mmx20cm pushrods(elevator) 2

3mm metal clevis 12

3mm jam nuts 12

Braided cable feet 6

Rigging couplers 2mm 4

cable swages 4

2mm clevises 5

2mm jam nuts 5

Silicone clevis keepers 17

2mmx50cm throttle pushrod 1

Pushrod connector(e-z connector)1

plastic tube 4mmx25cm 1

Hardware List

Wing bolts

4mmx40mm 2

4mm flat washers 2

Fuel tank with hardware 1

Tail wheel

Tail wheel bracket

metal rudder horn

spring wire axel

springs (2)

wheel collar

tiller arm bracket

threaded rod (tiller arm)

nylon pushrod ends (2)

2mm x 10mm screws (5)

flat washers (5)

Page 6

6

Wild Stick 120

BUILDING

INSTRUCTIONS

Before starting to build this kit, we

urge you to read through these

instructions. They contain some

important building sequences as well

as instructions and warnings concerning the assembly and use of the

model.

We expect that you have some building experience to take on this model.

However, every minute detail is not

covered. This is not a basic trainer.

The instructions together with the

simplicity of this kit will allow you to

produce a first class Wild Stick 3-D.

BUILDING SUPPLIES NEEDED

Hobby knife w/ #11 blade

Thin Zap CA

30 Minute Z-poxy

Thread lock

Wire cutters

Pliers

Drill with bits: 1/8", 5/32", 1/16”

5/64”

Phillips and standard screwdriver

Small clamps

Masking tape

Tape measure

Washable marker

Paper towels

Rubbing alcohol

Wing Construction

Collect the following parts:

1. left and right wing panel

2. dihedral brace

3. wing holddown bolts(2)

1. Trial fit the dihedral brace in the

slot on one wing. The wing is flat (no

dihedral) so the brace should fit

either way. Slide the other wing

panel in place and make sure the

joint in the center is closed.

2. Mix some 30 minute epoxy and

spread on all sides of the dihedral

brace, front back and edges.

Page 7

7

Wild Stick 120

3. Spread epoxy on the root rib of

each wing panel. Use a thin scrap of

wood and work some of the epoxy

down into the slots for the dihedral

brace on each panel.

4. Use masking tape to hold the wing

panels firmly together while the

epoxy set. Lay the wing flat on the

floor or work bench while the epoxy

cures. Do not stand the wing on one

tip, all the glue will run to one end

and give you a poor joint.

5. locate the two 4mm x 40mm bolts

and two 4mm flat washers.

6. After the epoxy has cured, bolt the

wing in place on the fuselage..

Tail construction

locate the following parts;

1. stabilizer with elevators

2. Fin with rudder

3. Nylon control horns

4. nylon nut plates

5. 2mm x 20mm screws

6. Silicone clevis keepers

1. locate the control horns on the

inside edge of the elevators on the

bottom side. make sure the holes for

the clevis are aligned over the hinge

line. Mark the location of the holes

and drill a 3/32” hole at the four

locations. use the 2mm screws and

nut plates to mount the control

horns.

Page 8

8

Wild Stick 120

Align holes over

hinge line

2. Remove the elevators from the

stab and make sure all the hinges are

centered in the slots. To make sure

the hinges are centered, use a

straight pin in the middle of the hinge

when pushing the elevator onto the

stab.

3. Flex the elevator to the full

extent of its travel in one direction.

make sure the hinge line stays closed

as close as possible. Apply a drop of

thin CA to each hinge. Turn the stab

over, flex the elevator to the full

travel in the other direction and

apply glue to each hinge. go back and

apply another drop of glue to each

hinge.

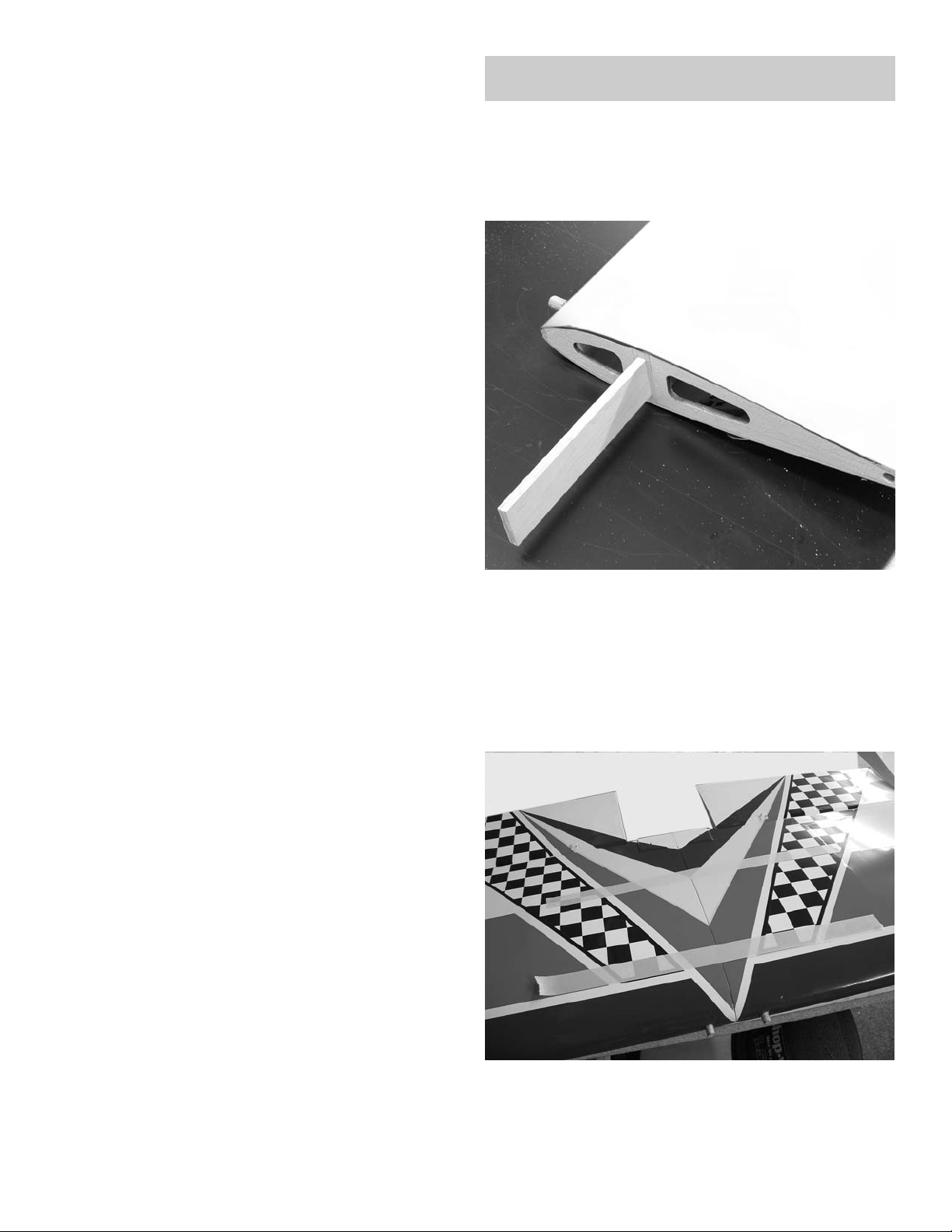

4. Set the stab in place in the slot on

the rear of the fuselage.

5. measure the stab to make sure it is

centered in the fuselage. Make sure

the slot for the fin in centered on

the fuselage. Move the stab until

dimension X-X are the same. This will

have the stab square to the fuselage.

6. When you have the stab square to

the fuselage, make a mark along the

side of the fuselage on the bottom of

the stab.

Page 9

9

Wild Stick 120

7. use a razor blade or e-xacto knife

to carefully remove the covering

inside the marks on the bottom of the

stab. Cut carefully so as not to cut

the wood, just the covering.

8. mix some 30 minute epoxy and apply

to the bare wood on the bottom of

the stab and in the slot on the rear

of the fuse. Reinstall the stab and

check to make sure it is square. use

pins to hold in place. Check the

alignment with the wing by sighting

from the front and rear. Apply pressure to one side if necessary to make

stab parallel to wing.

remove covering

9. Remove the covering from the bottom portion of the rudder where it

plugs into the stab.

remove covering

10. Fit the fin in place and make a

mark around it. Remove the covering

inside the marks on both the stab and

the rear portion of the fuselage

behind the stab.

Page 10

10

Wild Stick 120

11. Epoxy the fin in place making sure

it is square to the stab and centered

on the fuselage in the rear.

Flying Wires

Locate the following parts:

Aluminum bracket for fuse bottom 1

2mmx10mm screws 2

angle brackets 12

1.8x16mm bolts 6

1.8mm nuts 6

flat washers 12

nylon swing in keepers 8

2mm pushrods with clevis x 10” 4

2mm pushrods with clevis x 7” 4

silicone clevis keepers 8

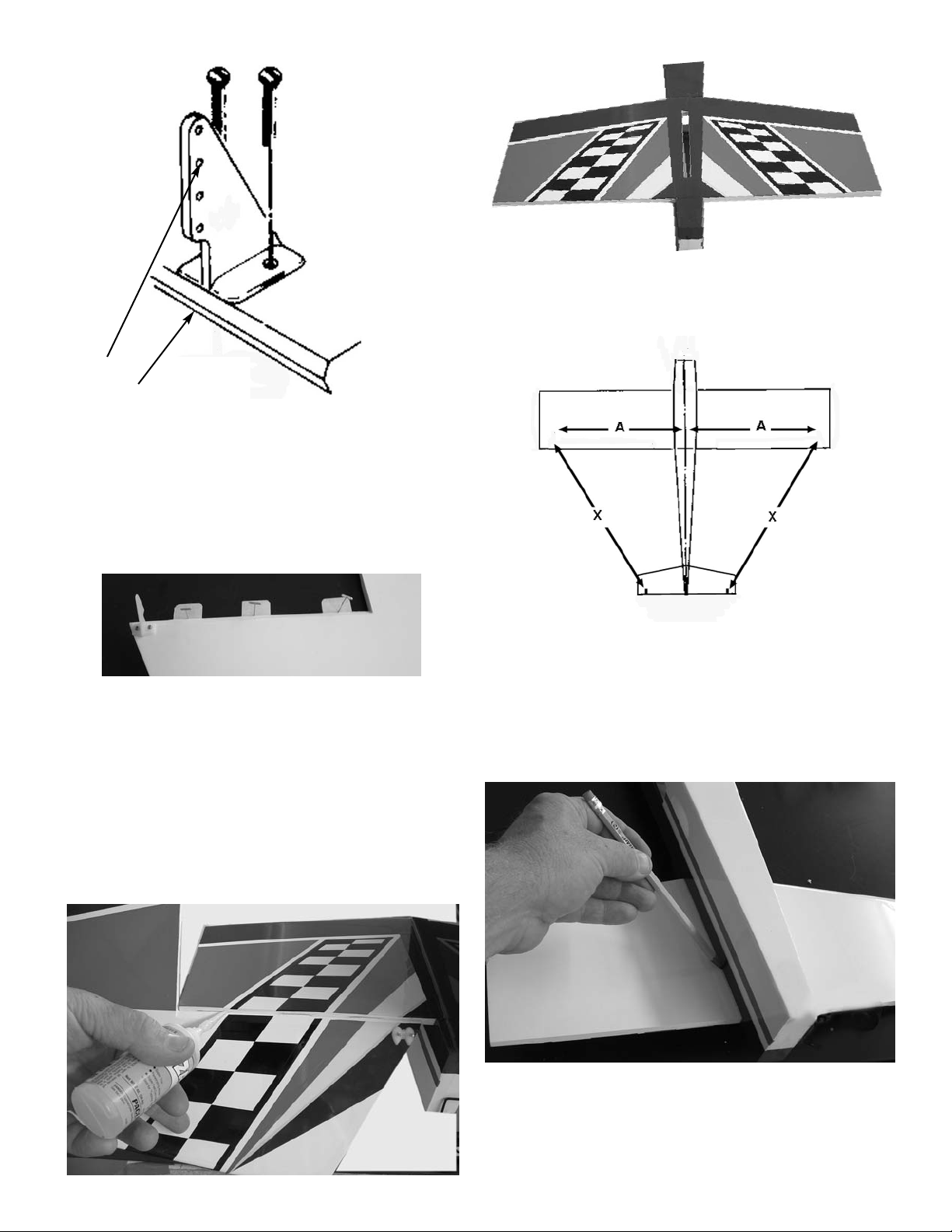

1.Take four of the angle brackets, two

screws, two nuts and four flat washers and bolt to the top of the fin in

the predrilled holes. You will have to

locate the holes under the covering.

Put two brackets on each side of the

fin.

2.Repeat with the other brackets on

the end of the stab. Put brackets on

both sides top and bottom.

Page 11

11

Wild Stick 120

3.Mount the aluminum bracket on the

bottom of the fuselage using the two

2mmx10mm screws.

Use the tail wheel bracket to align

the flying wire bracket at the front

edge of the mounting block. Align the

tail wheel bracket at the rear edge

of the fuselage and mount the aluminum bracket at the front edge.

Page 12

12

Wild Stick 120

4.Take one of the 7” pushrods and

make sure the clevis is screwed on

with about 1/16” of threads showing

on the inside. Install the clevis on the

angle bracket and mark the location

over the hole on the fuselage bracket. Make a 90 degree bend and cut at

3/8”. install the wire in the aluminum

fuse bracket and retain with the

nylon swing in keeper. Adjust the

length so you don’t pull the stab out

of alignment.

5.Repeat for all four wires on the bottom side.

6.Take the 10” pushrods and attach to

brackets on stab. Bend 90 degrees at

brackets on fin and cut to 3/8”.

Retain with nylon swing in keepers.

Repeat for other side.

7.After all wires are installed they

can be adjusted by putting a level in

the center of the stab and leveling

the plane. Move the level to the tip of

the stab and adjust wires till level.

Page 13

13

Wild Stick 120

1. Fit the landing gear to the bottom

of the fuselage and install the four

screws and flat washers. Use locktit

on the screws.

2. install the axels using the aircraft

lock nuts.

3. install the wheels using one wheel

collar on the inside and one on the

outside of the wheel.

locate the following parts:

1. landing gear

2. Two wheels

3. Two axels

4. two axel nuts

5. Four wheel collars

6. Six flat washers

7. Four mm screws

landing Gear

Page 14

14

Wild Stick 120

Tail wheel

Locate the following Parts:

Tail wheel bracket

tail wheel

rudder tiller arm

wire axel

3mm wheel collar

nylon control horn brackets 2

springs 2

tail wheel tiller arm

tail wheel tiller arm collar

2mm screws 5

2mm washers 5

1. Insert the tail wheel wire into the

bracket and fit the collar on

top.align the hole for the tiller arm

so it is parallel to the axel.

2. Center the tiller arm in the collar

and tighten the set screw. Screw the

nylon horn brackets on each end.

Install the tail wheel using the 3mm

collar to retain.

3. Mount the bracket flush with the

rear of the fuselage using the three

screws.

Page 15

15

Wild Stick 120

Engine Installation

locate the following parts:

1. Two motor mounts

2. Four 4mmx20mm screws

3. Four 4mm blind nuts

4. Four 4mmx25mm bolts

5. Four 4mm aircraft lock nuts.

6. 8 4mm flat washers

1. Clamp your engine to the two

motor mount making sure that both

sides of the mounts sit squarely on

the table. Make sure the engine is not

offset to the left or right in the

mount. Mark the location of the four

holes.

2. Drill four holes and mount the

engine using the four 4mm bolts and

aircraft lock nuts.

4. Attach the two springs to the

tiller on one end and the two nylon

horn brackets on the other. Pull the

bracket along the bottom of the rudder until the springs have a little

tension on them. Mount the bracket

at this point. Drill two holes with a

#54 drill and harden the holes with

thin CA. Mount the bracket with the

two 2mmx1mm screws and flat washers.

Page 16

16

Wild Stick 120

3. Center the engine on the firewall

and mark the location of the four

mounting bolts.

4. install the four blind nuts in the

firewall. The best way to install the

nuts is to use a piece of wire to pull

the nuts into place .

5. pull the nuts up with the wire then

install the bolt and washer through

the hole and tighten to finish pulling

the blind nut into the hole.

6.After all four nut are pulled tight,

install the engine using the four 4mm

bolts and washers. Use lock tite on

the bolts.

Radio Installation

1. For the Ailerons you will need

four servos and two 18” servo extensions.

Page 17

17

Wild Stick 120

2. install the servos using the hardware supplied with the radio. Use the

stings installed in the wing to pull

the wires through to the center of

the wing.

3. hinge the ailerons using the same

method used on the elevators. Center

all hinges and use thin CA to glue in

place making sure you have full

deflection in both directions and a

tight hinge line.

4. Use a straight edge to mark the

location of the four aileron horns in

line with the output arm. install the

four horns using the 2mm bolts and

nylon plates. Align over the hinge

line as we did on the elevators.

Page 18

18

Wild Stick 120

5. Locate one of the 3mm pushrods,

metal clevis, two 3mm nuts and silicone clevis keeper. Make sure the

clevis is screwed on the pushrod with

about 1/16” of threads showing on

the inside of the clevis. Install the

clevis on the control horn and the

servo arm. make sure the servo is centered and the aileron is in neutral

and adjust length. Tighten the 3mm

nuts against the clevis to lock in

place.

6. Install the rudder servo in the

tray in fuselage using hardware supplied with radio. The tray is set up for

double rudder servos is you wish. The

throttle servo can be mounted on

either side to suit your engine.

7. Hinge the rudder using the same

method we did on the ailerons and

elevators. Move the rudder from

side to side before gluing the hinges

to make sure the counter balance

clears the top of the fin. Use thin CA

on all the hinges.

cable exit

8. Locate the rudder cable exit holes

in the fuse side under the covering.

Align the rudder horn with the slot

and mark the location of the holes.

Bolt the horns to the rudder, one on

each side, with two 2mm bolts and

nuts.

Page 19

19

Wild Stick 120

9. Locate the pull-pull cable, cable

ends and cable swages. Take two of

the rigging couplers and two of the

swages and insert the cable through

the swage, through the rigging coupler and loop back through the

swage. Crimp the swage in two places

on opposite sides to secure the cable

in place.

swage

rigging coupler

10. Install a nut and clevis with silicone keeper on the rigging coupler

and attach to rudder horn. Thread

the other end of the cable through

the slot in the fuse and pull forward

to the rudder servo. Repeat on the

other side.

11. Take the other two rigging couplers and install the nut and clevis.

Attach to the rudder arm and install

the silicone keeper. Tape the rudder

in place with it centered and center

the servo. Thread the pull-pull cable

through the swages and rigging couplers on both sides. Pull both cables

tight, get as much slack as possible

out now. When tight crimp both

swages.

Page 20

20

Wild Stick 120

2. On Four stroke engines you need to

bend a z-bend in the pushrod and

attach to the throttle arm.

Throttle servo

1. Use a long drill for the throttle

pushrod hole and align with throttle

arm.

3. On two stroke engines you can use

the clevis and silicone keeper and

install on the threaded rod.

Page 21

21

Wild Stick 120

5. Slide the 5mm plastic tube on the

throttle pushrod until it extends

1/4” through the firewall. Install

the pushrod connector on the servo.

Open the throttle full and set the

throttle servo to full. Tighten the

set screw on the pushrod connector

onto the pushrod. Cut the pushrod

off about 1/4” pass the connector.

The throttle can be adjusted by loosening the screw on the pushrod connector if necessary.

nylon tube

4. locate the pushrod connector and

attach it to a servo arm. It has a

washer on top of the arm, the bottom

of the arm, then install nut. Use a

drop of CA glue on nut to make sure

it does not come loose. Make sure the

pushrod connector will rotate in the

servo arm.

Elevator servos

Collect the following items:

3mmx20 pushrods 2

3mm nuts 4

3mm clevises 4

silicone clevis keepers 4

1. Install the elevator servos in each

side of the fuselage using the hardware supplied with the radio.

2. Thread a nut and clevis on each

end of the two elevator pushrods.

Page 22

22

Wild Stick 120

Fuel Tank

1. Locate the fuel tank and hardware.

2. Assemble the tank cap with the big

washer, the rubber stopper, and the

little washer in the rear. For a two

line system we will only use the long

piece of aluminum tube and one short

one.

3.Insert the tubes through the stopper and attach the silicone tubing on

the short one. Cut the tubing so that

when the clunk is attached it will be

about 1/4” off the bottom of the

tank when held vertically. Leave the

tubes out the front of the cap about

3/4” and bend the long tube at a 45

degree angle so it goes to the top of

the tank when installed.

3. Attach the pushrod to the control

horn on the elevator and the output

arm on the servo. Center the servo

and the elevator and adjust length.

When correct tighten the jam nut

against the clevis on both ends and

apply a drop of lock tite. Slide the silicone keeper over the clevis.

4. you will need two 24” servo extensions to reach forward to the receiver.

The switch can be mounted in the side

of the fuselage on either side depending on which side your throttle servo

is on. You can also mount the switch

in the servo tray beside the throttle

servo if you wish.

Radio Switch

Page 23

23

Wild Stick 120

4.Install stopper in tank and tighten

the bolt in the center until stopper is

snug. Don’t over tighten. Clunk

should move freely and vent tube

should be to the top of the tank.

5. Install the tank in the fuselage

with the cap in the hole in the firewall.

6. If necessary for balance , the battery can be installed under the tank

before it is installed.

7. Install the receiver and battery in

the area in front of servo tray and

behind tank. use form around receiver. if necessary for balance the battery can be moved under the tank.

Final Setup

The CG should be between 5.75” and

6.5” behind the leading edge of the

wing.

The control throws should be :

Elevator Low Rate +or- 1”

High Rate All you can get

Ailerons Low Rate +or- 1/2”

High Rate All you can get

Rudder Low Rate +or- 2”

High Rate All you can get

The four aileron setup gives you several options. If you want to fly the

plane in a normal setup, just use

three y-connectors and connect all

four aileron servos into the aileron

channel. This will give a normal

aileron setup. Because of the large

size the roll rate will be really

rapid. If you want just flaps and

ailerons you can use two y-connectors and plug the two outside servos

into the aileron channel and the two

inboard into the flap channel.

If you have a computer radio you can

explore several other flight modes.

In the following modes you will need

to plug all four aileron servos into

different channels. Consult you

radio manual for the proper channels.

(1). Flaperons. in this mode you will

couple the two inboard aileron servos with the elevator servo. Adjust

the radio so that up elevator causes

both flaps to go down, down elevator will cause the flaps to go up. This

set up allows very tight loops and

very square corners.

Page 24

24

Wild Stick 120

(2). Crow. In this mode the two outboard ailerons move to the up position and the flaps move to the down

position. This is a very high drag condition and will allow you to make

very steep descents, then slow to a

crawl to land. It is also used to do

the “Harrier”. In this maneuver you

slow the plane down, flip the switch

for the crow configuration, and

slowly feed in full up elevator. The

plane will get into a very high angle

of attack , 50 to 60 degrees. you will

have to use the throttle to maintain

the attitude. The crow set-up make

the plane very stable in this attitude.

It is recommended that before trying

these different modes that you fly

the plane with a standard set-up to

get used to the plane. When turning

on the different flight modes be sure

to have plenty of altitude for your

first tries. Because of the large control surfaces, the plane can get out

of control very quickly if you are not

ready for it or if you have something

not set up correctly. If the flight

modes are not set-up correctly, the

plane could be unflyable in that configuration, so be ready to turn it off

if you cannot handle it.

Thank you buying the Wild Stick 120

so go have some fun.

Loading...

Loading...