Page 1

©2003

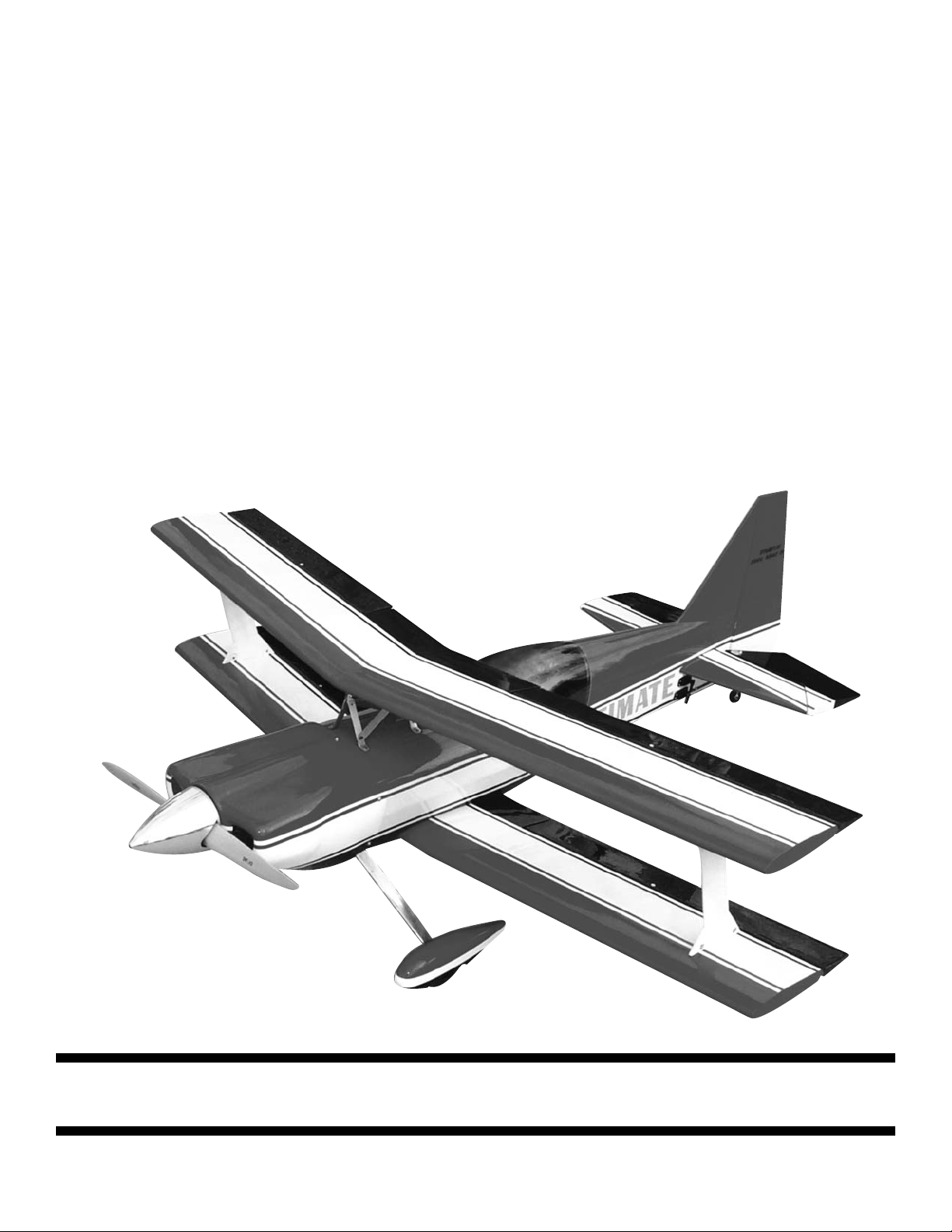

UUllttiimmaattee

UUllttiimmaattee

Carl Goldberg Products Ltd.

30%

10-300

CARL GOLDBERG PRODUCTS, LTD.

P.O. Box 818 Oakwood, GA 30566 Phone # 678-450-0085 www.carlgoldbergproducts.com

Page 2

2

30% Ultimate ARF

WARNING! THIS IS NOT A TOY!

THIS IS NOT A BEGINNERS AIRPLANE

This R/C kit and the model you will build from it is not a toy! It is capable of

serious bodily harm and property damage. It is your responsibility, and yours

alone - to build this kit correctly, properly install all R/C components and

flying gear (engine, tank, radio, pushrods, etc.) and to test the model and fly

it only with experienced, competent help, using common sense and in accordance with all safety standards as set forth in the Academy of Model

Aeronautics Safety Code. It is suggested that you join the AMA and become

properly insured before attempting to fly this model. If you are just starting

R/C modeling, consult your local hobby dealer or write to the Academy of

Model Aeronautics to find an experienced instructor in your area.

Write to: Academy of Model Aeronautics, 5151 Memorial Dr. Muncie, IN

47302

LIMITED WARRANTY

Carl Goldberg Products is proud of the care and attention that goes into

the manufacture of parts for its model kits. The company warrants that for

a period of 90 days, it will replace, at the buyers request, any part or material shown to the company's satisfaction to have been defective in workmanship or material at the time of purchase.

No other warranty of any kind, expressed or implied, is made with respect to

the merchandise sold by the company. The buyer acknowledges and understands that he is purchasing only a component kit from which the buyer will

himself construct a finished flying model airplane. The company is neither

the manufacturer of such a flying model airplane, nor a seller of it. The

buyer hereby assumes the risk and all liability for personal or property damage or injury arising out of the buyers use of the components or the finished

flying model airplane, whenever any such damage or injury shall occur.

Any action brought forth against the company, based on the breach of the

contract of sale to the buyer, or on any alleged warranty there under, must

be brought within one year of the date of such sale, or there after be

barred. This one-year limitation is imposed by agreement of the parties as permitted by the laws of the state of Georgia.

Important Information

Covering coming loose is Not COVERED UNDER WARRANTY. Due to temperature changes the plane may develop some wrinkles in the covering that you

will need to remove with an iron. Be sure to seal the edges down first so that

you do not cause the covering to shrink and leave exposed areas of wood.

Please inspect the plane before beginning to assemble to make sure you are

happy with it. Af

ter assembly has begun you cannot return the kit

. If you find

a problem before beginning to assemble the plane you must contact us,

please do not return it to the dealer.

Page 3

3

30% Ultimate ARF

30% Ultimate ARF 3-D ARF

30% Ultimate ARF 3-D ARF

Congratulations on your purchase of the Goldberg Ultimate ARF 3-D ARF.

This is a very unique aircraft, with great 3-D capabilities. Every effort has

been made to produce a lightweight, straight, easy to assemble aircraft.

Because of its oversize control surfaces which are double beveled to allow

for extreme throws, great care must be taken in the set-up and flying of this

airplane. Quality hardware components have been provided to allow for 3D

set-up while maintaining adequate mechanical advantage to eliminate flutter.

It is your responsibility as an advanced pilot to fly the aircraft in an intelligent manner. THR

OTTLE MANAGEMENT IS A MUST!!!!!!!! We at Carl goldberg

have put the 30% Ultimate ARF through a very rigorous flight-testing schedule and have stressed the airframe beyond all practical parameters without

a single failure. Carl goldberg will NOT warrant the Ultimate ARF against

flutter due to improper set-up or excessive speed maneuvers. having said that,

we believe you will find the Ultimate ARF to be one of the most responsive, inthe-grove aircraft on the market. The Ultimate ARF excels at high-alpha

maneuvers including Harriers (both upright and inverted), high-alpha rolls,

and high-alpha knife edge. Torque rolls, waterfalls, knife edge loops and elevators are all within the performance parameters of this unique aircraft.

Just remember to use common sense when flying this high performance

machine.

Page 4

4

30% Ultimate ARF

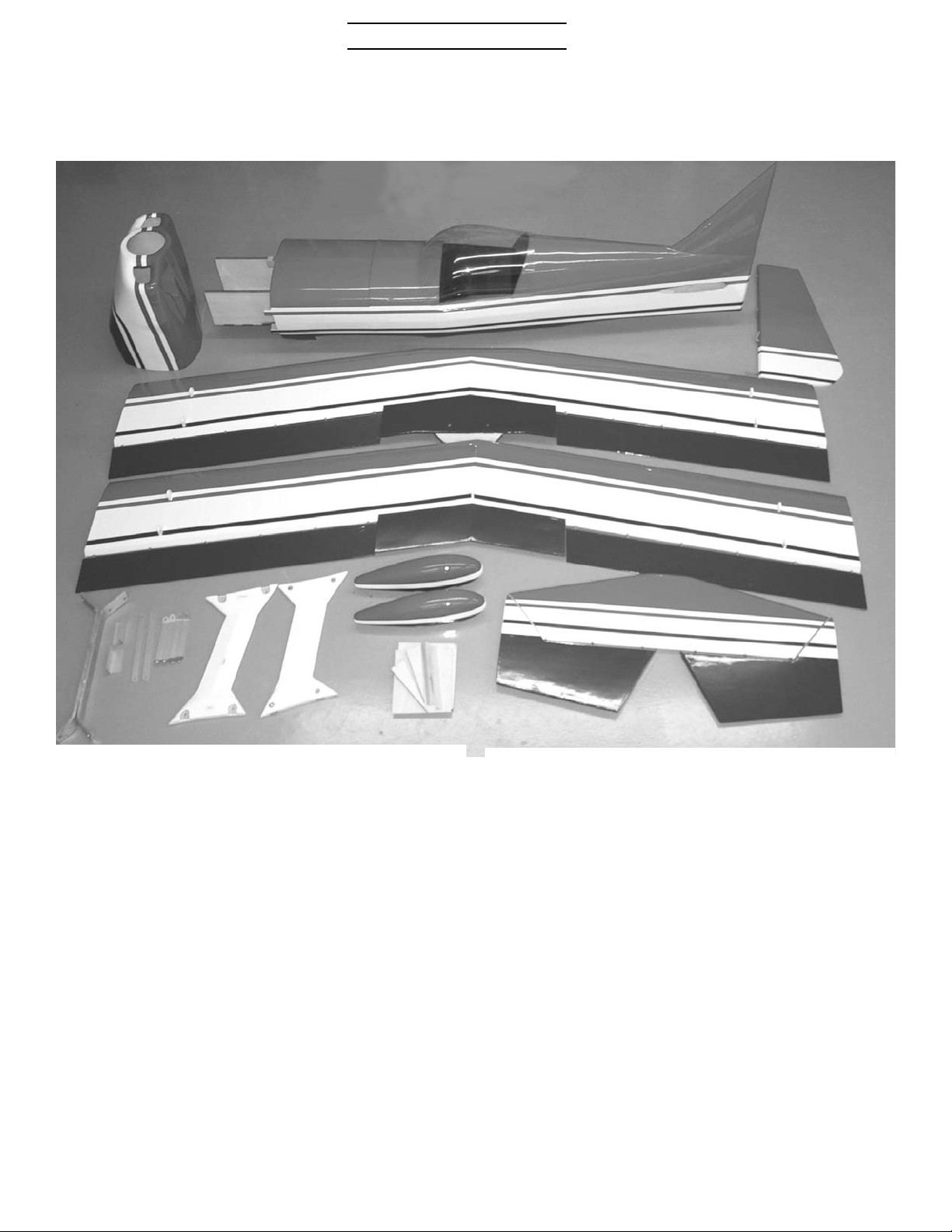

Parts Layout

1.Fuselage

2.Removable cockpit

3.Cowl

4.Top wing

5.Bottom wing

6.Rudder

7.Stabilizer

8.Elevator (2)

9.I-Struts (2)

10.Clear Canopy

11.Wheel pants (2)

12.Landing gear (2)

13.Aluminum angles (2)

14.Cabane struts (6) pcs.

15.Firewall

16.Hardware bag (not

shown)

1

2

10

5

4

6

7

8

8

9

9

3

11

12

13

14

15

Page 5

5

30% Ultimate ARF

Hardware List Quantity per kit Use

6-32x3/4" Socket head screws 20 2 canopy hold down

8 I-Struts

4 cabane struts at fuselage

2 top wing mount at cabane

4 Landing gear aluminum

angles

6-32x1/2" Socket head screws 6 4 cabane strut braces

2 Wheel pant mounts

6-32 lock nuts 6 4 cabane struts

2 top wing mount

6-32 blind nuts 2 wheel pant mount

6-32x 3/4" sheet metal screws 2 tail wheel mount

6-32x 1/2” sheet metal screws 5 cowl mount

1/4-20x1-1/2" socket head screw 4 Landing gear mounts

1/4-20x1" Socket head screws 2 lower wing mount

1/4-20 lock nuts 4 landing gear mount

1/4" flat washers 4 landing gear mount

Tail wheel assembly 1

tail wheel 1

tail wheel tiller spring 1

1/8” wheel collars 2

set screws 2

3/16" axles 2

axle nuts 2

3/16" wheel collars 4

set screws 4

4" wheels 2

6-32x2" Flat head screws 6 4 aileron horns

2 elevator horns

6-32x3" threaded rod 1 rudder horn

6-32 nuts 12 4 aileron horns

2 elevator horns

4 Landing gear aluminum

angles

2 rudder horn

Page 6

6

30% Ultimate ARF

#6 flat washers 17 8 Control horns

4 Landing gear aluminum

angles

5 cowl mount

4-40 golden clevis 16 8 aileron

4 elevator

4 rudder

4-40 jam nuts 16

clevis retainers 16

EZ connector body 1 throttle

screw 1

snap nut 1

2-56x12" throttle push rod 1

nylon snap link 1 throttle

4-40x2-1/8" pushrod 4 ailerons

4-40x5" pushrods 2 elevators

4-40x7-1/2" pushrods 2 rudder

24 oz tank-gasoline 1

14" tie wraps 2 fuel tank mount

laser cut tank mount 1

3/8" sq x1” spruce block 2 Throttle servo mount

Laser cut throttle servo mount 1

Goldberg horn bkts 10 4 aileron horns

2 elevator horns

2 rudder horns

2 tail wheel steering

#4 x1/2” sheet metal screws 10 Motor box cover

#4 flat washers 10 Motor box cover

1/8” dowel x 12” 1 Firewall pins

Page 7

7

30% Ultimate ARF

BUILDING

INSTRUCTIONS

Before starting to build this kit, we

urge you to read through these

instructions. They contain some

important building sequences as well

as instructions and warnings concerning the assembly and use of the

model.

We expect that you have some building experience to take on this model.

This means, every minute detail is not

covered. This is not a basic trainer.

The instructions together with the

simplicity of this kit will allow you to

produce a first class Ultimate .

BUILDING SUPPLIES NEEDED

Hobby knife w/ #11 blade

Thin Zap CA

30 Minute Z-poxy

Thread lock

Wire cutters

Pliers

Drill with bits: 1/8", 5/32", 5/64”

9/64”

Phillips and standard screwdriver

Small clamps

Masking tape

Tape measure

Washable marker

Paper towels

Rubbing alcohol

Begin construction by locating the

two 1/4-20 x 1” socket head bolt used

to bolt the bottom wing on. Put the

bottom wing in place and remove the

covering over the mount holes at the

trailing edge. Bolt the wing down.

Next locate the stabilizer and fit into

opening in fuselage. Check alignment

with wing, it should be parallel when

sighted from the rear. It should not

be necessary to remove any material

to achieve alignment, simply pushing

up or down on one tip should do it. If

necessary remove material from the

bottom of the stab saddle on one side

to achieve alignment.

Page 8

8

30% Ultimate ARF

Remove the stab and using a sharp

#11 blade, cut the covering about

1/8” inside the line you drew and

remove the covering. Be careful and

do not cut too deep and cut into the

balsa as this will weaken the stab.

Do this top and bottom. Check the

stab saddle in the fuselage and

remove the covering where the stab

will be sitting. Mix some 30 minute epoxy and apply to the bare wood on

the stabilizer where you removed the

covering. Slide the stab back into the

fuselage and align using the marks

you made. Use masking tape pulled to

the top of the fin and bottom of the

fuselage to hold parallel to wing.

Use rubbing alcohol and paper towels to clean up the excess epoxy.

Recheck your alignment and set aside

to dry.

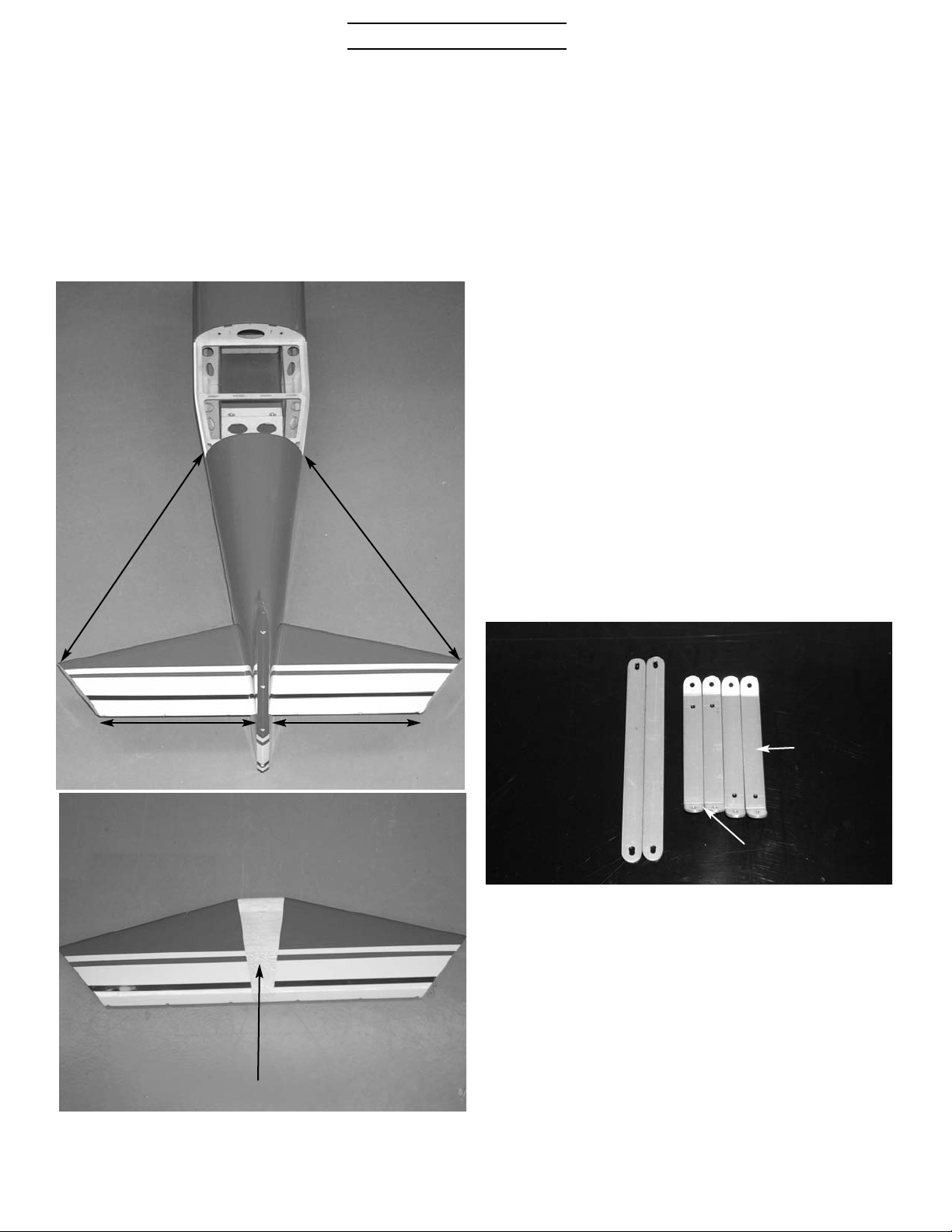

When satisfied with the alignment,

measure to make sure the stab is

square and centered. Measurement A

should be the same on both sides and

measurement B should be the same on

both sides. When stab is aligned, use a

marker and draw a line on top and

bottom of the stab, on both sides next

to the fuselage.

A

A

B

B

remove covering

Top Wing Mounting

Locate the aluminum brackets that

make up the cabane struts. It consist

of six pieces. The two long straight

pieces are the diagonal supports. The

two longer of the pieces with angles

go to the rear and the two shorter

ones go to the front. The sharper of

the two angles are the bottom of the

strut.

rear

brackets

front brackets

Page 9

9

30% Ultimate ARF

Take a straight pin and stick through

the blind nut inside the fuselage to

locate the holes for the struts.

Using the four 6-32x3/4” socket

head cap screws, mount the struts to

the top of the fuselage, short ones in

front longer ones in rear. Do not

tighten the screws down tight at this

time. Leave them loose until the top

wing is mounted.

Locate the two I-Struts and the eight

6-32x3/4” socket head cap screws.

The I-Struts are identified left and

right, top and bottom with small

stickers.

Fit the tabs on the top wing between

the brackets front and rear and

install a 6-32x3/4” socket head cap

screw through the holes. Do not

install nuts now.

Page 10

10

30% Ultimate ARF

Fit the I-Struts in place paying attention to left and right and top and bottom. The I-Struts have recesses in

them that fit over the tabs in the

wings. Install the four 6-32x3/4”

socket head cap screws in each strut.

With the I-Struts screwed in place,

install the nuts on the screws that

hold the top wing to the cabanes and

tighten. Install the diagonal braces

using the four 6-32x1/2” socket head

cap screws and 6-32 aircraft lock

nuts. After these are tight remove

the screws holding the struts to the

fuselage one at a time and apply

thread locker. Reinstall and tighten.

This sequence of install and tightening the bolts will make sure that the

struts are aligned and not under

stress.

Page 11

11

30% Ultimate ARF

Control Surfaces

Locate the predrilled hole for the

aileron, elevator, and rudder horns.

Open the hole up with a 9/64” drill.

Locate the 6-32 x 2” flat head

screws, #6 washers, and 6-32 nuts.

Install the 6-32 bolt through the elevator and secure with a flat washer

and nut. Put a drop of CA on the nut

to make sure it does come loose.

Install the horn bracket flush with

the end of the bolt.

All surfaces are drilled to accept

the large hinge points. To ensure the

proper alignment of the hinges, first

apply petroleum jelly to the pivot

points and then put 30-minute epoxy

into the holes drilled in the stab and

the elevator. Put a little on both tips

of the hinge point and insert the

hinge into the stab and elevator

while flexing the surface up and

down and sliding it into place. This

causes the hinge points to rotate into

perfect alignment.

The rudder horn is a 3” long 6-32

threaded rod. Install with a flat

washer and nut on each side. Use Ca

on the nuts. Install two horn brackets on each side. One faces forward

for the rudder, the other faces rearward for the tail wheel. Hinge the

rudder to the fin using the same

method as the elevator hinges.

The ailerons use the same 6-32 x 2”

bolt, washers, and nuts as the elevators. Install the horn brackets and

hinge all four ailerons using the

same method as the elevators.

Page 12

12

30% Ultimate ARF

Locate the two landing gear legs

and the two 1”aluminum angles.

Using four 6-32x3/4” socket head

cap screws, four #6 washers, and

four 6-32 nuts, mount the aluminum

angles flush against the landing

gear plate and the motor box sides.

Drill two 9/64” holes on each side

through the motor box sides and centered up on the aluminum bracket. It

may be necessary to remove glue

build up in the corner and file the

sharp edge off the corner of the aluminum bracket to make it fit flush.

Landing Gear

Turn the plane upside down and draw

a line down the center of the motor

box and along the front edge of the

gear plate

gear 1/8” off bulkhead on

corner

hole centered over aluminum

bracket

Page 13

13

30% Ultimate ARF

Flat part of gear leg must be

parallel to center line of airplane.

Align the gear so the outside hole

will go through the center of the

aluminum bracket. Align the inside

edge of the gear parallel to the center line. It will be approximately 1/8”

out side the line, don’t worry about

the spacing. The gear should be

approximately 1/8” off the bulkhead

at the rear. Mark and drill the outside hole. Install the 1/4-20 x 1-1/2”

socket head cap screw and secure on

the inside with a flat washer and aircraft lock nut. Just snug the nut up

at this time. Do not drill the inside

hole yet. Install the other gear in the

same manner.

Check that the flat part of the gear

leg is parallel to the center line of

the plane. You can move the gear by

letting it pivot on the one bolt. When

the gear is aligned, drill the other

bolt hole and install the bolt, washer and nut and tighten. You can now

finish tightening the other bolt.

Install the axles on the gear legs. Be

careful and don’t over tighten the

nuts. It looks like a big bolt but the

center is drilled out to accept the

axle and can be over tightened easily.

Locate the tail wheel spring and cut

into two equal pieces. Bend a loop

into each end.

Page 14

14

30% Ultimate ARF

Locate the tail wheel bracket and

align the bend in the strut at the

rear of the fuselage. Center the

mount on the fuselage and drill two

5/64” holes at the hole location.

Harden the holes by using a couple of

drops of thin CA in each hole. Mount

the tail wheel bracket using the two

#6x3/4” pan head screws.

Install the tail wheel with a wheel

collar on both sides.

Attach the tail wheel steering

springs to the horn brackets on the

rudder horn and the tiller arm on

the tail wheel bracket.

Wheel Pants

wood block

Locate the wheel pants and identify

the left and right. The wood mount

block will be on the inside portion of

the wheel pant. Left wheel pant

shown.

Page 15

15

30% Ultimate ARF

Drill a 1/2” hole at the dimple on the

side with the wood block. If you have

a forstner bit you can drill the 1/2”

hole directly, if using a regular drill

start with a small bit and work you

way up slowly or grind out with a

dremel too to prevent damaging the

fiberglass. Support the wood block

on the inside when drilling to prevent knocking the block loose. If this

happens just epoxy back into place.

Block the fuselage up level on your work bench and fit the wheel pants on

the axles with out the wheels. The 1/2” hole will fit over the nut part of the

axle at the landing gear. Block the wheel pants up so they are level and parallel to each other.

Take a 1/8” drill and mark the location of the hole through the predrilled hole in the landing gear.

Remove the wheel pant and drill a

3/16” hole on the mark. Install the

blind nut by pulling it into place with

the 6-32 x 1/2” socket head screw

with a washer on the outside. When

the nut is seated glue in place with

CA being careful not to get glue in

the threads. Put a 3/16” wheel collar on the axle, put the wheel pant

half way on and slip the four inch

wheel on the axle. Install the outside

wheel collar and adjust both so the

wheel is centered in the wheel pant.

Rotate the wheel pant into place and

secure with the 6-32 x 1/2” screw. Be

sure and use thread lock on the

screw.

Page 16

16

30% Ultimate ARF

Cowl Mounting

Slide the cowl into place and mark

the location of the landing gear on

the bottom. Using a dremel tool, cut

slots in the cowl to fit around the

landing gear. The cowl should overlap the fuselage 1/2”.

Cut 5 strips of heavy paper 3/4” wide

and tape in position on the fuselage

so one end is flush with the cowl

mount blocks. Make a mark over the

center of the cowl mount block.

Slide the cowl into position overlapping the fuselage 1/2”. Use masking

tape to hold in place. Make sure the

stripes are aligned on each side. Let

the strips of paper be on the out side

of the cowl. Use a straight edge and

align the top of the cowl with the top

of the fuselage. Make sure stripes

are straight from fuselage to cowl

on each side. Check the left and right

alignment to make sure it is straight

with the center line of the fuselage.

When satisfied with the alignment,

use the mark on the strip of paper to

locate the mounting holes in the

cowl. Drill a 1/16” hole through the

paper, cowl, and into the mounting

block. Open the hole in the cowl up

to 9/64” and install a #6x1/2” sheet

metal screw with a #6 washer. Do

this in 5 places. Make sure firewall

is not touching the cowl on top.

Page 17

17

30% Ultimate ARF

Engine mounting

Locate the firewall, motor box covers, tri stock, and top firewall supports.

With the cowl mounted, measure

from the F1 former to the front of

the cowl ring. Write this number

down.

Measure the engine length from the

mounting plate to the thrust washer.

Subtract this number from the

length of the measurement of the

cowl from former F1. That number is

where you cut the motor box sides.

You will need to add about 1/8” to

the length of the motor box sides for

clearance between the the spinner

backplate and the cowl ring. On

most engines the cylinder will be

behind the engine mount at the bottom and will hit the firewall if the

firewall is not notched out.

Use a square to draw a line on the

motor box sides. Be sure and keep it

square to the box sides as this will

adjust the up and down thrust. Mark

the left side 3/16” longer than the

right to give the desired right thrust.

Page 18

18

30% Ultimate ARF

Epoxy the firewall in place making

sure to keep it square with the sides.

Add the triangle top supports on

both sides and the tri stock on the

back side. Drill 1/8” holes 1” deep in

five places on each side of the motor

box and pin the firewall using 1/8”

dowels and glue.

dowels four

places each

side

You will probably need to notch the

firewall to clear the cylinder head.

If you plan to use a Pitts style muffler you will have to notch the bottom of the firewall. Just cut the firewall and motor box sides to accept

the muffler and then box the area

back in with 1/8” plywood with tri

stock on the inside.

Attach the motor box top covers

using the 10 #4x1/2” screws and #4

washers.

You can cut a hole in the motor box

side to pass the spark plug lead and

fuel line through to the engine.

Page 19

19

30% Ultimate ARF

Shim the engine out if necessary to

get approximately 1/8” clearance.

Move the engine left or right and up

and down till the spinner back plate

matches the cowl. When satisfied

with the fit, use a long drill to drill

the motor mount holes. Remove the

dry wall screws one at a time and

drill and install the motor mount

bolts.

Measure the firewall and draw a

line down the center. Off set this

line 1/8” to the left side of the

plane. Measure up 4-1/2” from the

bottom of the firewall and draw a

line across the firewall. Center the

engine up on the two lines. The best

way to get the engine perfectly

aligned with the cowl is to attach the

engine to the firewall with #6x3/4”

dry wall screws. You don’t have to

drill a pilot hole, just put one in the

top and one in the bottom. They make

such a small hole that you can move

the engine slightly and put another

one in. Install the cowl making the

cutouts for the cylinder head and

muffler and check the fit of the cowl

to the spinner back plate.

Page 20

20

30% Ultimate ARF

Locate the fuel tank and hardware.

Assemble the tank with three lines.

Take one of the pieces of brass tube

and cut into two equal lengths. Bend

the other tube so it will go to the top

of the tank and fit into the raised

portion of the tank. The other two

tubes will just extend past the cap on

both ends. Connect the pickup tube

and clunk to one tube. After the

tank is installed, the vent line (tube

to top of tank) can be plumbed out

the bottom of the fuselage just in

front of the landing gear. The pickup

line (tube with line and clunk) can be

routed to the carburetor, and the

fill line can be routed to a filler

valve, fuel dot or just routed out the

bottom of the fuselage. The fill line

will have to be plugged to prevent

fuel from running out, the vent line

must be left open.

There is a laser cut tank mount furnished with the plane. It is marked

front.

Tip the plate on edge and it will fit in

the cut out in the motor box sides.

Glue in place. This will place the

tank over the CG of the plane.

Page 21

21

30% Ultimate ARF

Place the tank between the holes

and use the two 14” tie wraps to

secure the tank to the mount.

Servo mounting

Locate the laser cut throttle servo

mount and the two 3/8” x1” bass

wood blocks. Epoxy the blocks to the

plate with the triangles underneath.

Epoxy the servo mount to the motor

box side in the proper position to line

up with your throttle arm. Put the E-Z

connector on the output arm of the

servo and connect the 2-56 push rod.

Locate the 2-56x10” throttle

pushrod and nylon snap link. Drill a

hole in the firewall in line with your

throttle arm and connect pushrod.

Page 22

22

30% Ultimate ARF

Locate the two servo cutouts on

each side of the fuselage just under

the stab. Remove the covering with a

sharp knife.

Install the two servos with the output shaft to the rear. You will need

four 24” servo lead extensions.

Locate the two 4-40 x 5” pushrods,

four 4-40 nuts, four 4-40 golden clevises, and four clevis retainer clips.

install a nut and clevis on each end

and with the servo centered, connect

to servo and elevator horn.

Locate the two 7” 4-40 pushrods and

install nuts and clevises on each end.

Attach to rudder output and rudder

horn. After controls are adjusted

install the clevis retainer clips on

all clevises. Tighten the nuts against

the clevises.

Page 23

23

30% Ultimate ARF

Locate the four aileron servo

cutouts in the bottom side of both

wings. Remove the covering with a

sharp knife. You will need four 14”

servo lead extensions. There is a

string located in each cutout to pull

the wire through to the center section. Locate the two 3/4” holes in the

top side of the bottom wing in the center and the bottom of the top wing in

the center. Remove the covering over

these holes. Attach the string you

your servo lead and pull through

wing. Mount the servo with the hardware supplied with the radio with the

output arm to the rear.

Locate the two 4-40 x 2-1/8”

pushrods, clevises, nuts, and retainers. Attach the pushrod between

servo arm and aileron control horn.

After controls are adjusted tighten

the nuts against the clevis and

install retainers.

Locate the two switches, one radio

one motor, just below the hatch rail

just in front of the turtledeck bulkhead on one side. You can glue a couple of rails (not supplied) across the

fuselage in this area to mount the

receiver and two batteries on. The

CG will probably require this area to

be used. You will need an 18” servo

lead extension to reach the throttle

servo, a y-connector to plug in the

two rudder servos, two y-connectors

to plug in the ailerons, plus two 12”

extensions. If you have a computer

radio you can plug the elevator servos into different channels, if not

you will need a servo reverser.

There is a hole in the balsa just

inside the right rear cabane strut.

You can remove the covering and

pass the y-connector through. Cable

tie the y-connector to the cabane

struts so the two ends are at the top

where the leads come out of the top

wing.

Page 24

24

30% Ultimate ARF

Trim the clear canopy to fit hatch.

Install pilot(not supplied) if desired.

Canopy should fit flush with the turtledeck bulkhead at the read and the

canopy frame at the bottom. Do not

glue canopy on with frame off plane.

canopy mount bolt

With hatch bolted in place, put wax

paper between the turtle deck and

hatch and between bottom of hatch

and fuselage side to prevent gluing

hatch to fuselage. If you do not have

the hatch bolted in place when gluing the canopy on , it is very easy to

warp the hatch with the canopy and

then it will not fit on the fuselage.

use a pin through the holes inside the

fuselage to locate the canopy mount

hole. Remove covering from hole and

attach the hatch using the two 6-32 x

1” socket head screws. The blind nut

are already installed in the hatch.

Final Set Up

The CG is 7” behind the leading edge

of the top wing measured in the center section of the wing.

The elevator throw should be set at

1” low rate, 2-1/2” high rate,rudder

2” low rate, 5” high rate, and

ailerons 1/2” low rate, 1-1/4” high

rate.

The cabane struts attach to the top

wing with 6-32 aircraft lock nuts. The

I-strut bolts should be attached

using low strength thread lock.

Regular thread lock may be too

strong and cause the blind nut to

pull out when the bolts are removed.

The canopy should also be attached

using the low strength thread lock.

The cabane struts should already

have regular thread lock on the

bolts where they are attached to the

fuselage, if not be sure and thread

lock them. There is a lot of vibration

with a single cylinder gas motor and

care must be taken to make sure all

the bolts stay put. Run the engine and

range check the radio. Run it at full

throttle to check the vibration and

Page 25

25

30% Ultimate ARF

minutes. Shut the engine down and

check all your bolts, clevises, servos

and linkage. Pull the wing off and

check all the attach points, joints

around the motor box, wing hold

down block, firewall, and any other

joints in the fuselage. Check linkage

to make sure there is no “slop” that

can cause flutter.When satisfied at

all is secure go fly and have fun.

Our models have flown on 4.2 CID

engines both Fox and Precision Eagle

using the Slimline Pitts style muffler.

You will need a 5” Ultimate style spinner like the one shown from TruTurn. We have found the 22-12 Bolly

prop to preform very well on these

engines. You should use at least

1200mah batteries on both the radio

and the engine. Servos should be at

least 70 oz-in or better. We used

Futuba 9151 digital servos.

Loading...

Loading...