Page 1

1

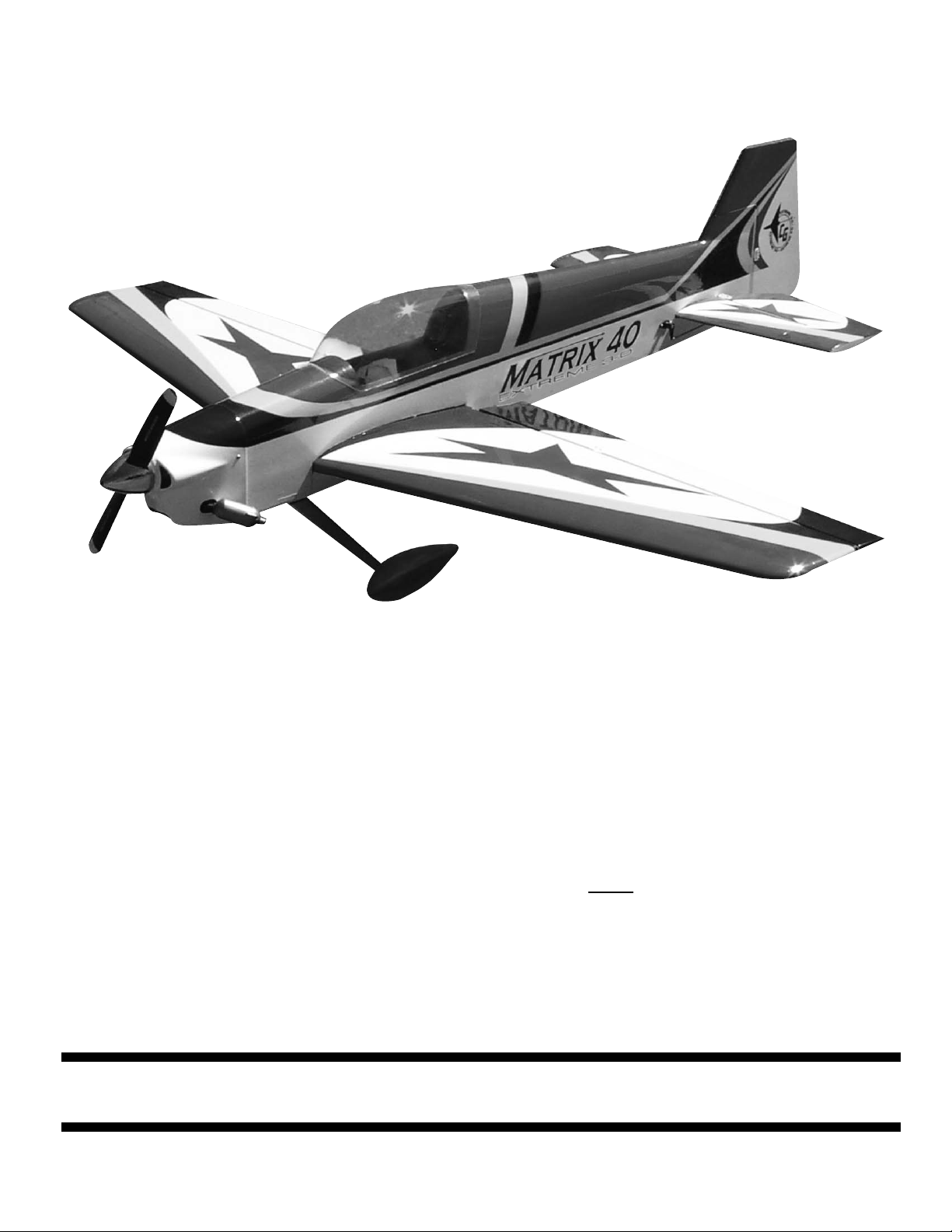

Congratulations on your purchase of the Matrix 40 Extreme 3-D ARF. This is a very unique dualpurpose aircraft, capable of flying any FAI pattern sequence with ease, while exhibiting remarkable

3-D capabilities. Every effort has been made to produce a lightweight, straight, easy to assemble

aircraft. Because of its oversize control surfaces which are double beveled to allow for extreme

throws, great care must be taken in the set-up and flying of this airplane. Quality hardware components have been provided to allow for 3D set-up while maintaining adequate mechanical advantage

to eliminate flutter. It is you responsibility as an advanced pilot to fly the aircraft in an intelligent manner. THROTTLE MANAGEMENT IS A MUST!!!!!!! Carl Goldberg Products has flown the Matrix 40

through a very rigorous flight-testing schedule and have stressed the airframe beyond all practical

parameters without a single failure. Carl Goldberg Products will NOT

warrant the Matrix 40 against

flutter due to improper set-up or excessive speed maneuvers. having said that, we believe you will

find the Matrix 40 to be one of the most responsive, in-the-grove aircraft on the market. The Matrix

40 excels at high-alpha maneuvers including Harriers (both upright and inverted), high-alpha rolls,

and high-alpha knife edge. Torque rolls, waterfalls, knife edge loops and elevators are all within the

performance parameters of this unique aircraft. Just remember to use common sense when flying

this high performance machine.

MA

MA

TRIX 40

TRIX 40

PT. #6135 6/03

CARL GOLDBERG PRODUCTS, LTD.

P.O. Box 88 Oakwood GA 30566 Phone #678-450-0085 Fax # 770-53-63 www.carlgoldbergproducts.com

'Copyright 2003 Carl Goldberg Products, Ltd.

EXTREME 3-D ARF

EXTREME 3-D ARF

Page 2

2

We are very proud of the construction of the Matrix 40 and all of our other ARF aircraft. Each aircraft is jig built to insure a straight true airframe. Every effort is made to build as light an aircraft as

possible. As with any professional builder, glue is used sparingly. Please take a moment during

assembly and run a bead of CA or aliphatic resin into the high stress joints that you can reach

such as the landing gear plate, servo mounting trays, wing hold down blocks, etc. Also, during

the course of shipping from the manufacturer to our facility in the United States, it is not uncommon

for the aircraft to experience several changes in climate. This may cause the iron-on covering to develop wrinkles. This is not a fault of the manufacturer. Please take a few minutes with your heating iron

and heat gun to iron down the seams and re-shrink the covering where needed. The results will be a

beautiful aircraft with a breathtaking finish that you will be proud to display at your flying club.

Important Information

Covering coming loose is not COVERED UNDER WARRANTY. Due to temperature changes the

plane may develop some wrinkles in the covering that you will need to remove with an iron. Be sure

to seal the edges down first so that you do not cause the covering to shrink and leave exposed

areas of wood. Please inspect the plane before beginning to assemble to make sure you are happy

with it. After assembly has begun you cannot return the kit. If you find a problem before beginning to

assemble the plane you must contact us, please do not return it to the dealer.

Page 3

3

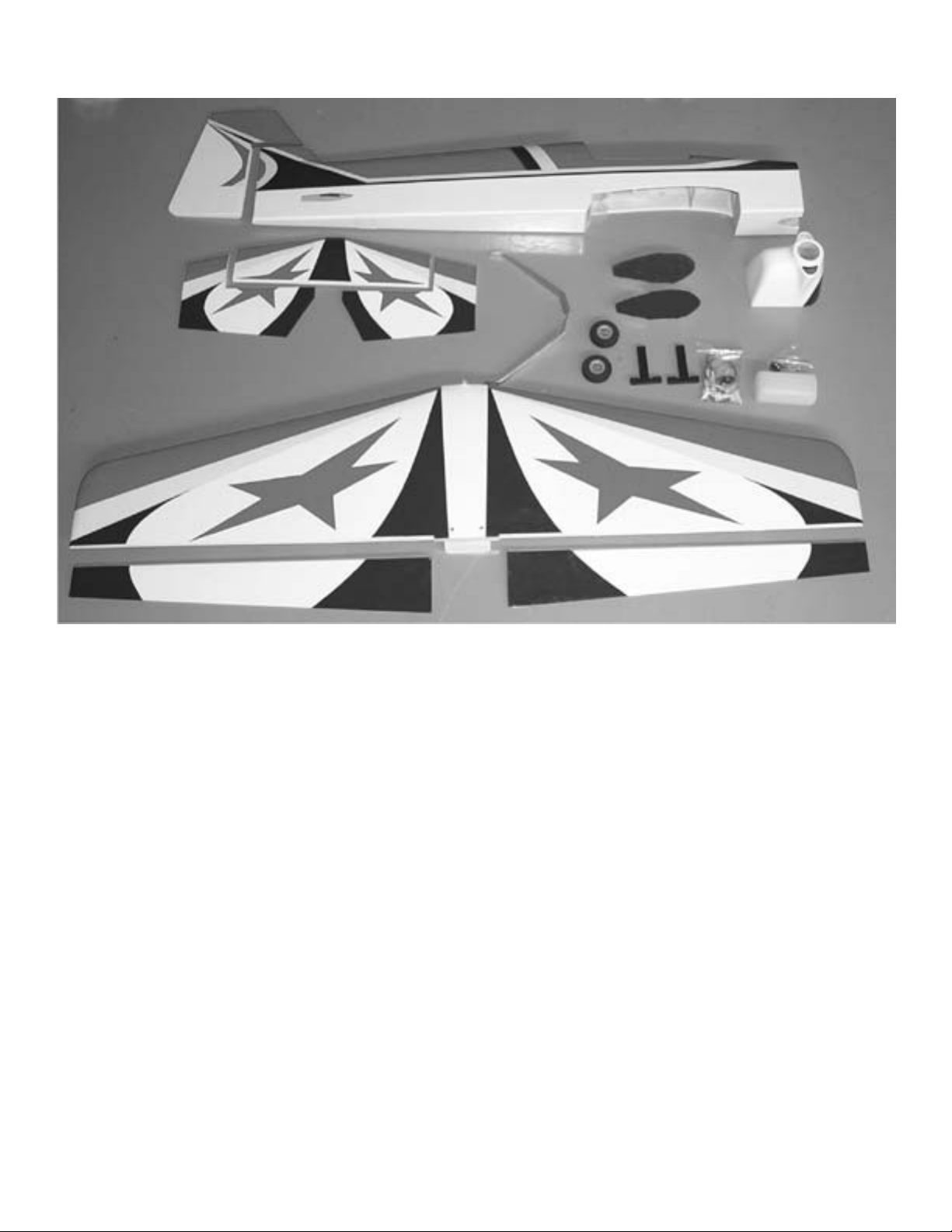

Parts List

1. Fuselage

2. Fiberglass Cowl

3. One piece wing /ailerons

4. Stab/elevator assembly

5. Rudder

6. Fiberglass wheel pants

7. Canopy

8. Fiberglass landing gear cover

Hardware List

1. (2) Motor Mounts

2. (4) 4mm x25mm bolts

3. (4) 4mm blind nuts

4. (4) 4mm lock washers

5. (4) 4mm flat washers

Motor Hardware

Landing Gear

1. Main Gear 1 left 1 right

2. (4) 3mm x12mm bolts

3. (4) 3mm flat washers

4. (4) 3mm blind nuts installed in fuselage

5. (2) 2-1/4” main wheels

6. (2) 4mm x40mm bolts (axles)

7. (2) 4mm nuts

8. (2) 4mm flat washers

9. (2) 4mm wheel collars

Tail wheel

1. (1) Tail wheel bracket

2. (1) 7/8” tail wheel

3. (2) 2mm x10mm screws

4. (2) 2mm wheel collars

Wing

1. (2) 5mm x40mm wing bolts

2. (2) 5mm washers

Elevator pull-pull hardware

1. (2) 2-56 x 29” Threaded Rod

2. (2) Nylon Clevis

3. (1) bellcrank assembly with hardware

4. (2) Nylon swing in keepers

COWL HARDWARE

1. (4) 2mm x10mm screws for cowl mounting

Control System

1. (5) Nylon control horns

2. (5) Nylon control horn plates

3. (8) 2-56 x 3/4” Bolts

5. (7) Nylon clevis

6. (7) Silicone clevis keepers

7. (3) Nylon swing in keepers

8. (2) E-Z connectors

9. (1) 1.25mm x50cm Throttle rod

10. (1) 3.25mm x41.5cm nylon tube

11. (1) 2-56 x 10” Rudder push rod threaded

12. (2) 2-56 x 10” Elevator pushrods threaded

13. (2) 4-40 x 4” Double Threaded Rod Aileron

pushrods.

14. (4) 4-40 Golden Clevis

15. (2) 4-40 Nut

16. (2) Clevis Keeper

Fuel Tank

1. (1) Fuel Tank

2. (1) Rubber stopper

3. (2) Metal caps for stopper

4. (1) Screw

5. (1) Clunk

6. (3) Aluminum fuel tubes

7. (1) Silicone fuel line

Page 4

4

Before beginning assembly of your Matrix 40,

we highly recommend that you study this manual in its entirety. You should begin planning your

radio installation based on your choice of

engine and equipment from the beginning, as

space is limited within the fuselage of the

Matrix 40.

Because the Matrix 40 is intended for those

with some degree of modeling experience,

every minute detail will not be covered. This is

not a basic trainer. Assembly of this aircraft will

be easy for the experienced modeler, and by

following the instructions within this manual and

using the skills you’ve gained during your modeling career you will be able to produce a first

class aircraft.

Building supplies needed

Hobby knife w/#11 blades

Thin CA

Medium CA

Canopy glue

30 minute epoxy

Thread lock

Diagonal wire cutters

Pliers

Assorted drill bits

Various sized screwdrivers( both Phillips and

standard head)

Tape measure

Dry-erase marker

Paper towels

Rubbing alcohol

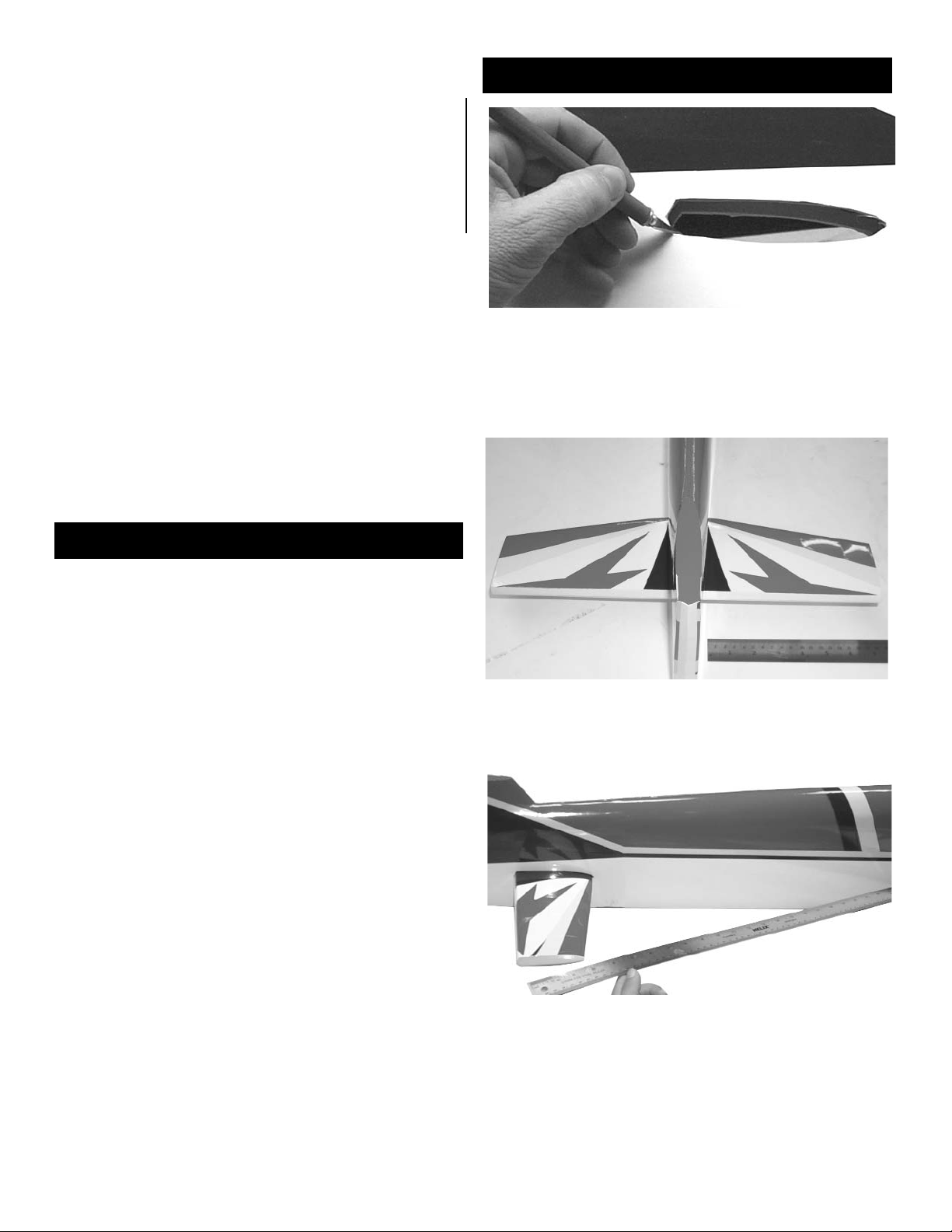

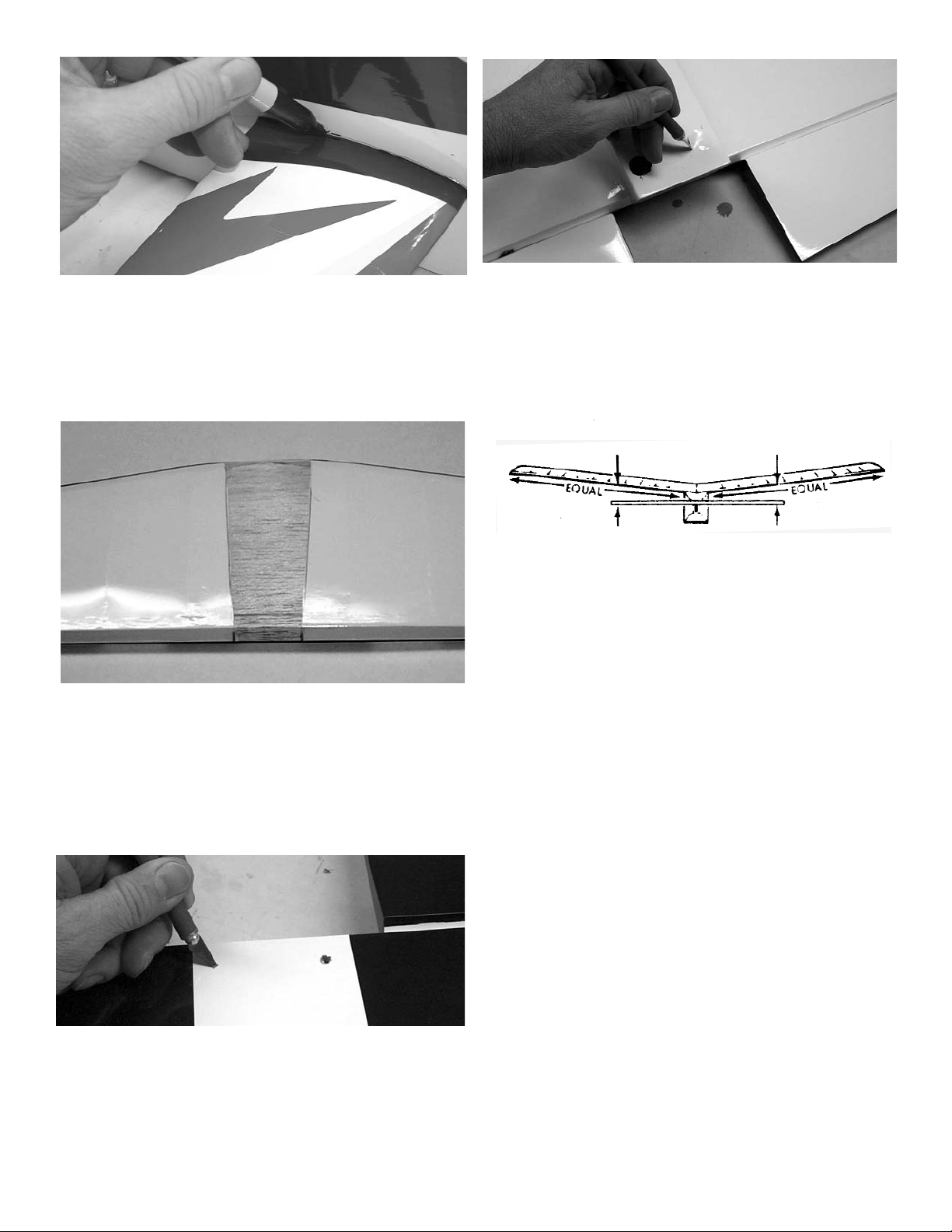

1. Begin construction by locating the fuselage,

wing, wing bolts, washers, and the horizontal

stab. Using a #11 blade, remove the covering

from the stab location at the rear of the fuselage.

2. Insert the stab into the slot and center using

a tape measure or ruler to measure from the

fuselage side to the tip of the stab.

3. With the stab centered, measure from one tip

to the back of the wing cut out. Move stab until

this figure is the same on both sides.

Mounting Stab

Page 5

5

4. When satisfied with the alignment, use a dryerase marker to draw a line on side of the stab,

top and bottom where it meets the fuselage.

Remove stab from opening.

5. Using the #11 blade, remove the covering on

the top and bottom of the stab between the

lines. Cut about 1/8” inside the lines so that

there is no exposed wood when glued in place.

Be careful to cut only the covering and not into

the wood of the stab as this would weaken the

stab.

8. Insert the stab into the fuselage one more

time before gluing and check alignment with

wing. Wing and stab should be parallel. When

satisfied with alignment, remove stab. Mix some

30- minute epoxy and apply to stab opening in

fuselage and to bare balsa on the stab. Reinsert stab into fuselage and check alignment

using all previous methods. Wipe away any

excess epoxy using rubbing alcohol and a paper

towel. Use masking tape to maintain alignment

while glue dries.

6. Using the #11 blade, remove the covering

over the rear wing bolt holes on the top of the

wing.

7. Turn the wing over and remove the covering

over the wing bolt holes. Slide the front wing

dowels in to the holes in the fuselage saddle.

Push down on the rear of the wing till it sits in

the fuselage. Using two wing bolts and washers,

screw the wing down to the fuselage.

Page 6

6

1. While the epoxy dries on the stab, mount the

control horns on the elevators. Align on the

inside edge of elevator on the bottom side, with

the holes on the horn aligned over the hinge line.

Use a square to check alignment of holes over

hinge line, this is important to maintain even

throw on both elevators. Use a long drill, piece of

wire, or pencil to mark the holes through the con-

trol horn. Remove the horn and drill the holes

using a 5/64” drill.

Mount the horns to the elevators using the 2-56

x3/4” bolts and the nylon plates on top of the

elevator.

2. Install the e-z hinges in the stab using a pin

in the center of each to make sure they stay

aligned.

3.Install the elevators on the hinges and with the

elevators pushed tightly against the stab,

remove the pins. Using thin CA, glue each hinge

in place by applying two to three drops on each

hinge. Have the elevators deflected to full up

when gluing the bottom side of the hinges and

deflected to full down when gluing the top side

of the hinges. This will insure that you can get

full throw later.

PLACE CONTROL HORN

AT HINGE LINE

2-56 x 3/4” SCREWS

SNAP LINK

CONTROL

HORN

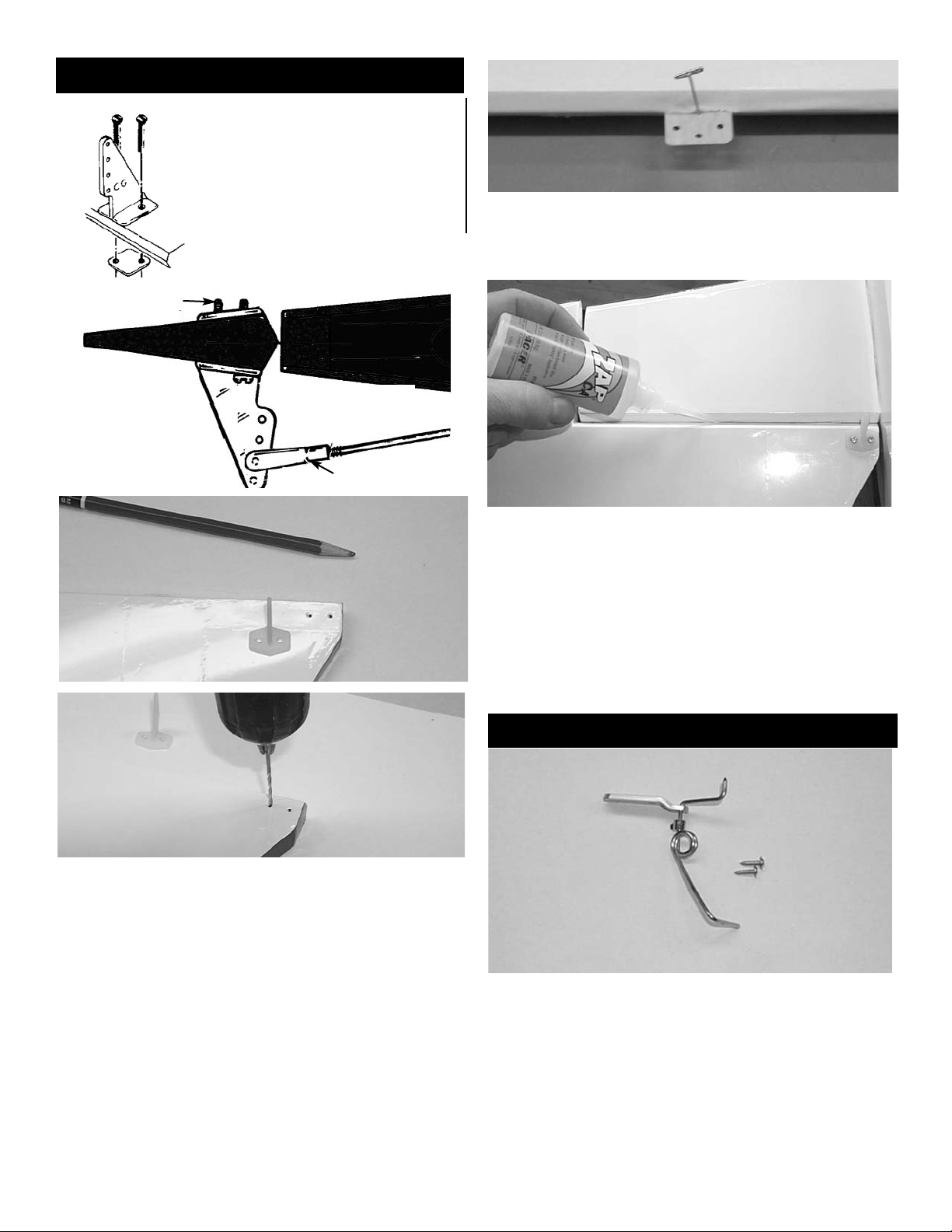

1. Locate the tail wheel bracket, mounting screws,

wheel and wheel collar.

TTAIL

AIL

WHEEL

WHEEL

BRACKET

BRACKET

Control Horns

Page 7

7

3. Place tailwheel on the bottom of the fuselage

so that the wire is flush with the back of the

fuselage and centered on the bottom.

Drill two 1/16” holes in the location of the

two mounting holes and install the tail wheel

using the 2mm screws.

6. Locate the rudder horn 5” from the bottom

edge of the rudder on the left side. Mark the

holes and drill using 5/64” drill as was done with

the elevator. Mount the horn using the 2-56 x 1”

bolts and nylon plate. Twist the control horn so

that it is facing the rudder servo hole.

5 inches

4. Mark the location of the tail wheel wire on the

rudder and drill a 5/64” hole into the rudder to

accept the tail wheel wire.

5. using pins to center the hinges as was done

with the elevators, install the rudder.

Deflect to full throw and glue the hinges in place

using thin CA.

Page 8

8

Elevator Bellcrank

Elevator Bellcrank

1. Locate the elevator bellcrank hardware.

3. Locate the center tiller arm and the two 2-56 x

29” threaded rod with two nylon clevis.

Install the tiller set screw into the tiller arm.

Thread the nylon clevis onto each of the rods

then snap the clevises to the center tiller arm.

Push the center tiller arm through the fuselage

towards the tail starting at the radio compartment.

2. The aluminum shaft has a hole on one end,

make sure that the hole size is 3/32” by using a

drill in the hole. Install one of the control arms

on the end with the hole using a 2mm screw.

The screw should go all the way through the

arm.

#2 x 1/2” Screw

#2 x 1/2” Screw

#2 x 1/2” Screw

4-40 Set Screw

4-40 Set Screw

You may need

only one spacer

Plastic Collar

Elevator Pull-Pull Wire

Crimp the brass tube

3/32”

Mark and drill a 3/32” hole

through the aluminium

shaft, then mount the control hore with a #2 x 1/2”

screw.

Page 9

9

5. Install the shaft through the mounts by first

putting a washer, then the ball shaped

bearing,and inserting in one side. You must

then install the tiller arm on the shaft as it passes through the fuselage. On the other side install

the ball shaped bearing, another washer and

then the other control arm. You must now mark

the location of the hole on the aluminum shaft

and drill a 3/32” hole to accept the 2mm screw.

Install the screw through the shaft and into.

Rotate the shaft so as both control arms point to

the bottom of the fuse. Through the access hole

on the bottom of the fuse. Center the tiller arm in

the fuselage and tighten the set screw. (See

Drawing on top of page 8)

6. you can mount the hatch cover on the bottom

of the fuselage using clear tape or screws (not

included)

open hole

4. Using your #11 blade, open the hole on both

sides of the fuselage. Install the mounts in both

sides using the 2mm screws supplied. There is

an access hole in the bottom of the fuselage for

installing the plate on the inside.

Note: You may need to make the hole slightly larger. Use a dowel with sand paper to

help open the hole. Do not open the hole

more than required.

7. Center the elevator servo in the tray and

mount the servo using the hardware supplied

with the radio.

Place the elevator pushrods on top of the servo

arm.

8. Making sure that the elevators are level, mark

the outer hole location on the pushrods and

make a 90 degree bend.

9. Insert the pushrods through the bottom of the

servo arm and install the nylon swing in keepers.

Cut off the remainer of the wire so 3/8” is showing.

Page 10

10

11. Locate the two 2-56 x 10” elevator pushrods

and thread a clevis on each. Install the clevis on

the elevator horn and mark the location of the

bend at the bellcrank. Bend the rod 90 degrees

and cut to a length of 3/8”.

12. Install the elevator pushrod using the two

short nylon swing in keepers on the bellcrank

end.(Don’t forget to use the silicone retain-

ers)

Rudder Servo

1. Remove the covering over the rudder servo

cutout with your #11 blade. It is just above the

elevator bell crank hole on the right side of the

plane.

2. Install the rudder servo using the hardware

supplied with the radio. You will need an 18”

extension added to the servo lead.

3. Locate the 2-56 x 10” pushrod and thread a

clevis on the end.(Don’t forget the silicone

keeper) Install a servo arm on the servo and

center the servo. The servo arm should be

positioned pointing up parallel to the rudder

hinge line. Mark the location for the bend and

make a 90 degree bend. Cut off at 3/8” and

install in the servo arm using the swing in nylon

keeper to retain it. The hole in the servo arm

will need to be drilled to a 5/64”.

Page 11

11

Ailerons

1. Hinge the ailerons on to the wing using pins

and Thin CA just like the elevators and rudder.

2. Locate the servo hole in the wing and remove

the covering with a #11 blade.

8-1/4”

4”

3. Install the servo using the hardware supplied

with the radio. Inside the cutout you will find a

piece of nylon fishing line to pull the aileron

lead to the center of the wing. Tape your servo

lead to the fish line and pull it out the hole in

the center of the wing.

Bottom side of wing

4. Install a control horn on the servo and center

the servo with the arm paralle to the hinge line.

Locate the position for the control horn by laying

a 90 degree triangle down. Keeping the bottom

of the triangle parallel to the hinge line and the

top even with the outer servo arm hole.

Aileron

5. Mark the location and drill two 5/64” holes.

Mount the horns using the 2-56 x 3/4” screws

6. Screw a 4-40 nut and metal clevis on each

end of the 4-40 pushrod. Adjust the length of the

pushrod till the aileron is level.

Tighten the nuts against each clevis.

Place the clevis clip onto each of the 4-40 clevises.

Page 12

12

Landing Gear and Wheel Pants

1. Locate the landing gear and bolt in place

using the four 3mm x12mm bolts and flat washers. Use thread lock compound. The blind

nuts are already installed in the fuselage.

2. Locate

2- wheels

2- axles (4mm bolts)

2 4mm nuts

2 4mm washers

2 4mm wheel collars

2 Wheel pants

4 #6 washers

3. Locate the two fiberglass wheel pants. Look

inside the wheel pant and identify the plywood

pad. This pad is on the inside portion of the

wheel pant and goes against the landing gear.

The pants are just alike except for this mounting

pad. drill a 5/32” hole into this mounting pad,

1/4” up (or into the bottom of that pad) from the

bottom edge and centered on the wheel opening.

4. Insert 4mm bolt through landing gear and

hole in wheel pant. Place the washer over the

bolt and start the nut on the end. You will now

have to put the two #6 washers and the wheel

into the wheel pant and let the bolt go into the

wheel as you tighten the nut down. When the

nut is tightened all the way down, it will clamp

the wheel pant to the landing gear leg. You can

rotate the wheel pant into the correct position

and finish tightening the nut. A drop of thread

lock works well here. You can then install the

4mm wheel collar on the end of the bolt to hold

the wheel in place.

Note: The wheels provided are good for asphalt

run ways but not for some grass fields. Use a 23/4” wheel for grass run ways. You might have

too open the bottom of the wheel pants more.

Page 13

13

Engine Mounting

1. Locate

2- motor mounts

4- 4mm x25mm bolts

4- flat washers

4- lock washers

4- blind nuts.

4- #6 x 3/4” Screws

2.Mark the firewall as shown above.

3. Place you engine in the mounts and adjust till

the prop washer is 4-3/4” from the firewall.

Clamp the engine in place and and mark the

location of the mounting holes. Drill using a

7/64” bit.

Screw the engine onto the motor mounts

using the #6 x 3/4” screws.

3-9/6”

1-15/16”

Centerline

4-3/4”

Note: The distance that is shown is for using a

Carl Goldberg spinner. If you are going to use a

different spinner, the front of the cowl needs to

be 4-5/8” from the firewall.

4. Keeping the engine perpendicular to the table

top, clamp the other motor mount to the engine.

Mark and drill the second motor mount then

screw the mount to the engine.

Page 14

14

6. Drill a 9/64” hole in the firewall in position with

the throttle arm. Insert the 3.25mm nylon sleeve

in the hole. Install an e-z connector in the throttle arm and install the 1.25mm x50cm pushrod.

drill your fuel line holes at this time.

5. Align the motor on the firewall. Center the

engine on the off center vertical line and the horizontal line. Drill holes on the marks using a

3/16” drill. Insert the blind nuts into the rear of

the fire wall and tighten using washers and lock

washer (use thread lock).

Glue the nylon sleeve to bulkhead

7. Mount the throttle servo in the servo tray

ahead of rudder servo. Position the servo so

that the servo arm is on the same side as the

throttle pushrod. This may vary depending on

the engine used. Glue the nylon sleeve to the

bulkhead to prevent flexing of the rod. Install

another e-z connector on your servo arm and

attach to the throttle pushrod.

Fuel Tank

1. Locate the fuel tank and hardware.

2. Assemble the cap by inserting the screw

through the large washer, through the black rubber and threading into the small washer on the

back side. Insert the three metal fuel lines into

the holes in the cap. The short line will be the

pickup line and will have the silicone tubing

attached to the back end. On the other end of

the silicone tube install the clunk. This should be

adjusted in length so the clunk is about 1/4” off

the bottom of the tank. One of the long tubes

should be bent so it rest against the top of the

tank. This is the vent line. The other tube will be

the fill line. Insert the stopper in the tank and

mark the fill, vent, and pickup line so you don’t

get them mixed up later. If you are using a YS

engine which pressurizes the tank, you should

wrap the tank in strapping tape with a couple of

loops going around the cap to make sure it does

not blow off.

Page 15

15

3. Install the tank in the fuselage in the notches

provided in the bulkhead, and hold in place with

foam(not provided). Attach the fuel lines(not

provided) to the three metal lines and route

through the hole in the firewall and to your

engine. If you are using an engine without a

pump or pressure system you will probably

have to mount the tank in the nose of the plane.

Cowl installation

1. The easiest way to cut the opening for the

muffler, needle valve, and head is to use a

piece of cardboard and cut it to fit around the

part you are fitting. Tape the cardboard to the

fuselage about 1” behind where the cowl will

end. You can now remove the muffler, slide the

cowl in place and transfer the hole to the cowl

from the paper template. You will need to start

with the head because the cowl will not go on

until the head clearance is cut. A Dremel tool

with a cutter and a sanding drum does the best

job.

2. After all the cutouts are made in the cowl, you

can use the same method to mount the cowl.

Tape the paper templates to the fuse side and

make a hole that will be in line with the firewall.

This needs to be about 1/8” back from the front

edge of the firewall so the screws will hit the

solid wood of the firewall and not just the soft

balsa of the sides. With the templates in place,

install the cowl and put your spinner back plate

in place. Place a 1/8” shim between the cowl

and spinner backplate and tape in place. When

satisfied with the alignment of the cowl, transfer

the holes from the paper templates to the cowl.

Remove the cowl and drill 5/64” holes at this

location. Reinstall the cowl and tape back into

position. Use a 1/16” drill to drill pilot holes for

the screws through the holes in the cowl. Install

with the 2mm screws provided. It is a good idea

to remove the cowl and harden the mounting

holes by dropping a couple of drops of thin CA

into each hole. Let cure before reinstalling.

Page 16

16

Canopy

1. Locate the canopy and trim to the scribe line.

It is a good idea to trim about 1/8” outside the

line at first and then trim to fit so as not to get it

too small.

2. Position canopy and check fit. When happy

with fit glue in place with ZAP canopy glue. Use

masking tape to hold in place till glue dries.

Decal Location

1 Clean model surfaces thoroughly before

applying decals.

2 Cut decal sheets apart in sections, as

needed.

Fold decal in half, front to rear. Open at

fold and lay decal out straight. The protective

backing will bubble away from the decal at the

fold. Using a scissors, cut the backing along the

bubble, removing a strip of backing about 1"

wide. Carefully position the decal on the model

and stick in place. Then, working from the center, rub the decal down while peeling off the

backing.

Balancing

Your model should balance at 5-1/2” to start. For extreme 3D you may want to move

the CG back to 6-1/2” or more. Just remember that the further back you go the more

sensitive it will become. With extreme throws the model can get beyond the ability of

novice pilots very quickly.

Start with the controls set at low rate with the ailerons plus or minus 3/8”, the elevator plus or minus 1/2” and the rudder plus or minus 1-1/2”. High rate should be all

you can get.

Good Luck and I hope you enjoy flying the Matrix 40 3D.

Page 17

17

The Elevator

This maneuver has your plane drop vertically in

a nose high attitude, depending on wind conditions any where from a 45 degree angle in low

wind to almost backwards in higher wind conditions. To perform it, at a high altitude with high

rates on, pull your throttle back and feed in the

elevator until you have the full high rate applied.

Use the rudder to guide the plane, and adjust

attitude with minor throttle inputs. You will loose

altitude quickly, to recover, apply full power and

fly out level. Watch out for getting too low or

applying too much rudder, it could cause the

plane to snap.

The Harrier

This maneuver has your plane in very slow forward flight in a nose high 45 degree attitude. To

perform it, enter the same way as you would an

elevator, then feed in power until the plane maintains altitude and starts to fly forward at a nose

high attitude. Maintain it by holding up elevator

and adjusting power, use the rudder to change

direction. Using ailerons may cause the plane to

snap and should be avoided. Add power and

push the nose back over to recover.

Page 18

18

The Waterfall

This maneuver has your plane flipping around

the axis of the wing, while dropping. Starting

from a high altitude, go to low throttle and gradually pull the nose up to near vertical. Just

when the plane is about the stall, give it full

down elevator and full power. Make attitude

corrections with the rudder and ailerons to keep

the plane flipping on axis. Cut the throttle and

hold full down elevator as the plane flips around

to nose high again, add power to flip it over

again. Watch your altitude as to not get too

close to the ground. Neutralize the elevator

and add power to recover.

The Blender

This is a violent maneuver that starts with a

vertical rolling dive that stops the descent as it

changes into a flat spin. Start at a good high

altitude, go to low throttle and push the nose

down into a straight dive. Feed in full left

aileron and complete 3 rolls, then immediately

move your transmitter sticks to an inverted

snap position, down elevator, left aileron, right

rudder, all full throw. Now feed in high throttle

to flatten the spin and stop the altitude loss.

Recover by neutralizing the rudder and

ailerons, and holding a little down elevator.

After you gain some airspeed you can roll out

to upright. Use caution as this is a violent and

high G maneuver that will put a great deal of

stress on the

Loading...

Loading...