Page 1

Lightnin’ Bug

Instructions

Warning

A radio-controlled airplane is not a toy. It is capable of causing serious bodily injury

and property damage. It is the buyer’s responsibility to build this kit correctly and

install the motor, radio, and other equipment. The first test flights should be made

only with the assistance of an experienced R/C flyer. The model must always be

operated and flown in accordance with the safety standards of the Academy of

Model Aeronautics.

Per The Federal Communications Commission, you are required to use only those radio

frequencies specified “for Model Aircraft”.

Copyright 2002

PO Box 818 4462 Oakwood Rd Oakwood, GA 30566 Phone 678-450-0085

1

Page 2

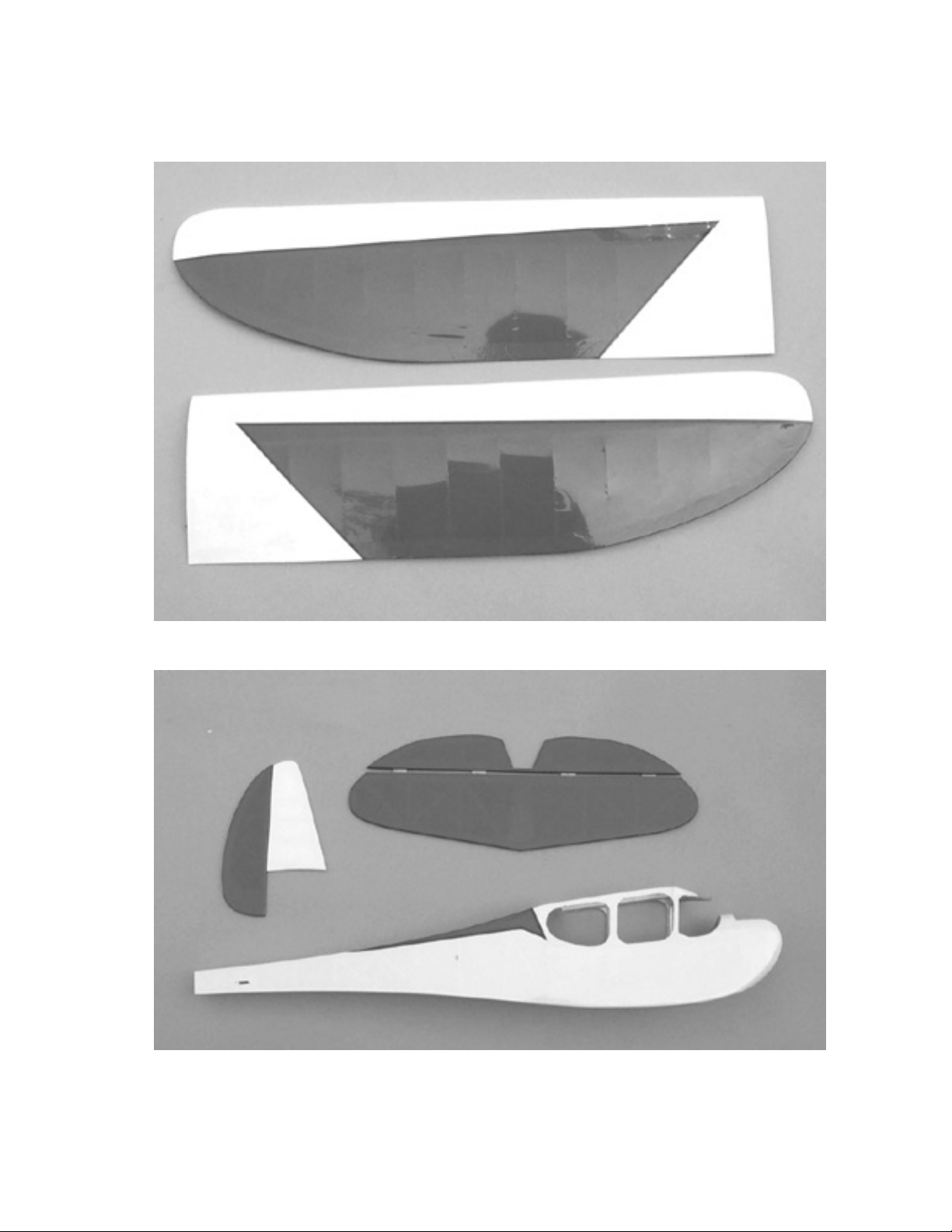

Parts Identification

Wing Panels

Fuselage, Stabilizer/elevators, & Fin/rudder

2

Page 3

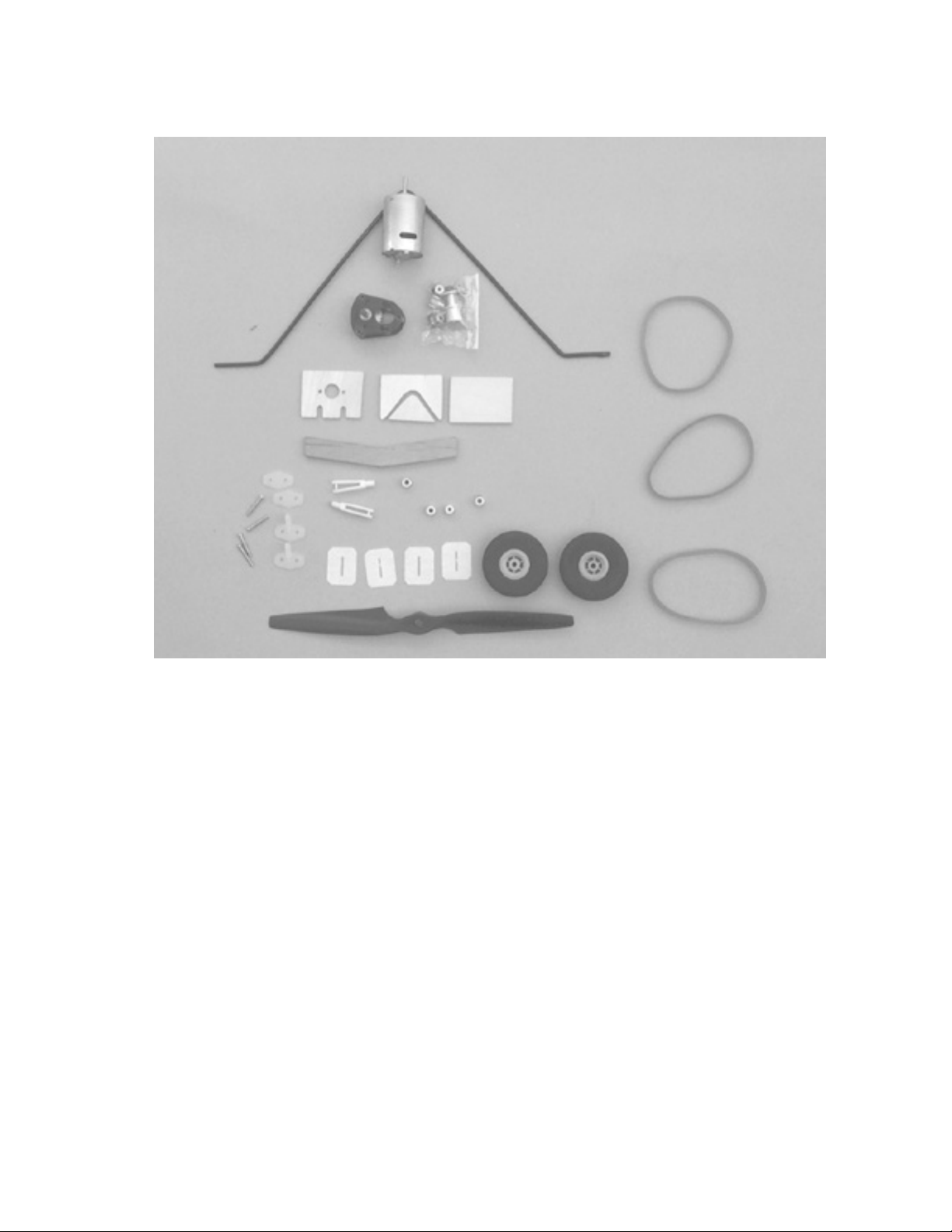

Included Hardware

Speed 400 motor

Gearbox with 3 gear ratios

Propeller

Prop adapter

Main Wheels (2)

Wire Landing Gear

Wire pushrods (2)

Nylon Clevis (2)

Nylon Control Horns (2)

CA Hinges

Wheel Collars (4)

Nylon EZ Clips (2)

#64 Rubber Bands

Wing Panels

Fuselage Assembly

Horizontal Stabilizer and elevators

Vertical Fin and rudder

(Wire pushrods not shown).

Material List

Front Clear plastic windshield

Clear Side windows, 2 left and right

Hardwood dihedral brace

Wire tailskid

Additional Items Required

5-minute epoxy

30-minute epoxy

Medium CA glue

Thin CA glue

Canopy glue

Xacto knife with #11 blade

Masking tape

Small square

15-amp speed control

Radio Equipment

3

Page 4

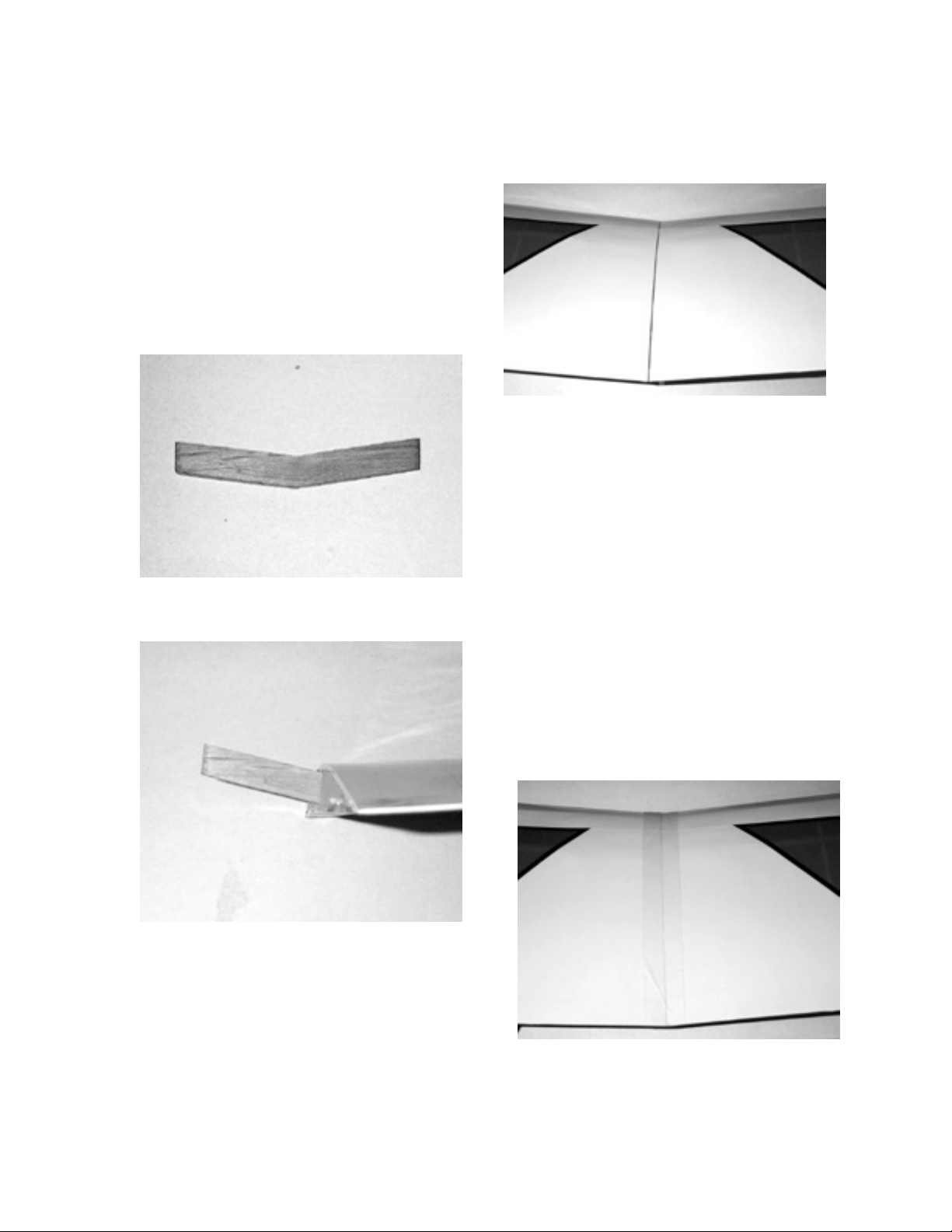

Wing Construction

We begin construction with the

wing. Before starting construction, it is

a good idea to place wax paper on the

building surface to prevent gluing the

wing to the building board.

Locate the two wing halves

and the ¼” dihedral brace taped to one

wing panel.

Trial fit the dihedral brace in

one of the wing halves.

When you are satisfied with the

fit, remove the wing panels from the

dihedral brace. Mix about one ounce

of 30-minute epoxy and coat the

inside of the slot in each wing panel,

the dihedral brace, and the root rib of

each wing.

Now slide the dihedral brace

into one wing panel. Wipe away any

excess epoxy that may have oozed

out from inside the slot. Slide the

other wing panel onto the brace,

wiping away any excess epoxy with

a paper towel wet with alcohol. Tape

in place with masking tape until the

epoxy has cured.

Now slide the other wing panel

onto the dihedral brace until it meets

the other wing root. Check for

alignment. If necessary, slightly sand

the corners of the dihedral brace for

proper fit.

When the epoxy has cured,

remove the masking tape and set the

4

Page 5

wing aside. The wing assembly is

now completed.

Tail Construction

Locate the horizontal stabilizer,

elevator, fin & rudder. Notice that

the hinges are installed but not

glued.

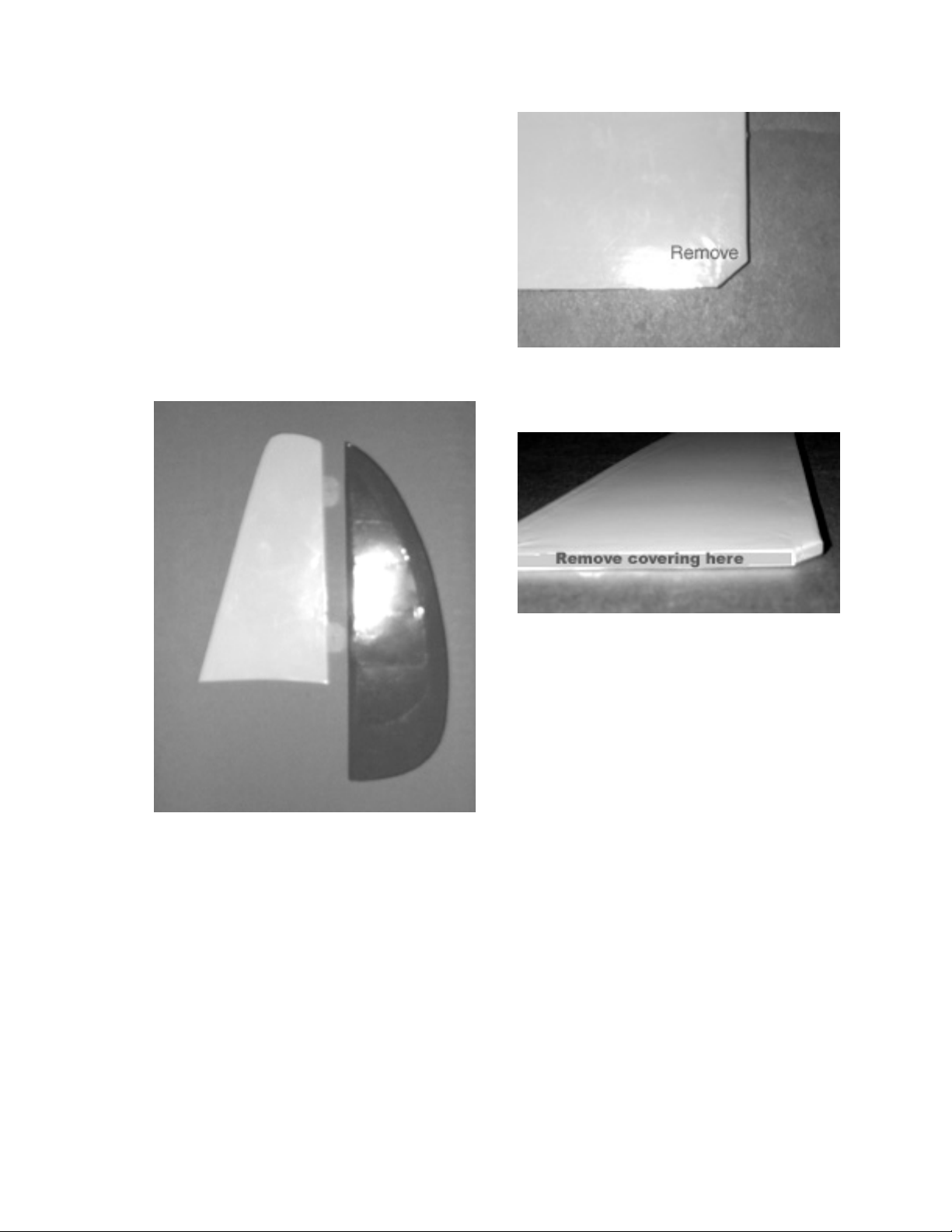

Next, with a sharp #11 Xacto

Blade, remove the covering from the

bottom of the fin.

Remove the rudder from the

fin. At the rear bottom edge if the

fin, it is necessary to remove the

corner with a razor blade to allow

clearance for the elevator. ¼ inch in

and ¼ inch up is enough.

Locate the fuselage and the

stabilizer. Use masking tape on top

of the stab and measure from each

tip to locate the centerline of the

stab. Place the stab on top of the

fuselage and center it using the

marks on the masking tape as a

guide. Check the alignment, and

temporarily tape it in place with

masking tape. The trailing edge of

the stab should be inset ¼” from

the rear of the fuselage.

5

Page 6

Mark the top of the fuselage

where the leading edge of the stab is

located. Now turn the fuselage over

and mark the stab along the fuselage

sides.

Remove the stab from the

fuselage and very carefully with a

#11 Xacto blade remove the

covering between the lines. By

removing the covering you are

gluing to the wood and not the

covering, giving you a much stronger

joint. Cut about 1/16” inside the

lines. Be careful not to cut the wood.

Now carefully remove the

covering at the rear of the fuselage.

Be careful not to remove the

covering too far in front of the stab.

Mix a small amount of 30 minute epoxy and spread a thin coat

on the exposed area of the stabilizer.

Carefully place the stab on the

fuselage and again tape in place.

Make sure it is square with the

fuselage and level with the wing

saddle. Set aside until the epoxy is

dry.

6

Page 7

Using the fin as a guide, mark

the top of the stabilizer so you will

know where the front edge of the fin

stops. (Notice that the notch you cut

earlier is flush with the trailing edge

of the stab, which is ¼” in from the

rear of the fuselage.)

Using a straight edge, draw a

line down the center of the stab from

the mark you just made to the

trailing edge of the stab. Remove the

covering 1/16” out on each side of

the centerline. Be careful not to

remove the covering forward of the

front of the fin.

Mix a small amount of 5minute epoxy and spread a thin coat

on the stab where you removed the

covering. Using a square, set the fin

in place and hold with masking tape

until dry. The front of the notch in

the fin you cut earlier should be even

with the rear of the stab.

Locate the elevator and four (4)

hinges.

Install the hinges in the pre-cut

slots in the elevator and slide them

into the slots in the stab trailing edge.

Leave about a 1/32” gap (a

matchbook cover makes an ideal

gauge). Apply 2-3 drops of thin CA

glue to both the elevator and stab

side of all the hinges. When the CA

is dry, flex the elevator back & forth

to loosen it up.

7

Page 8

Next, install the rudder using

the method described above. Make

sure the elevator does not bind on the

rudder before you glue the hinges.

(Note, your kit may differ slightly

from the prototype from which this

manual was written. Your pieces

may already be assembled, in which

case you only need to glue the gear

to the pre-assembled plate and epoxy

it to the firewall.)

Locate the wood landing gear

mounting pieces and the wire

landing gear.

Remove a ¼” triangle from the

rear of the stab platform, just like

you did the bottom of the fin.

Now CA the rudder hinges on

both sides. The tail section is now

finished.

Fuselage Construction

8

Page 9

Trial fit the gear mounting

plate in the nose of the fuselage. It

should be flush with the bottom of

the fuselage and snug with the

former. You may have to sand the

edges slightly for a good fit.

When you are satisfied with the

fit, epoxy in place with 5-minute

epoxy.

When the epoxy is dry, tack the

landing gear in place with medium

CA glue.

Next trial fit the cover plate. A

little sanding of the edges may be

needed for a good fit. Epoxy in place

with 5-minute epoxy, using the

epoxy to fill in any gaps between the

landing gear and the mounting

plates. Set the assembly aside until it

is dry.

Next trial fit the filler plate.

Again slight sanding may be needed

for a snug fit. When you are satisfied

with the fit, epoxy in place with 5minute epoxy.

Next locate the two main

wheels and four wheel collars. Install

the wheels onto the main gear, using

9

Page 10

two wheel collars on each side.

Make sure the wheels turn freely.

Next, at the rear of the fuselage

under the stab, you need to cut away

the covering for the pushrod slots,

one on each side.

to locate the elevator and rudder

control horns. Mount the control

horns with the two #2 screws and

nylon backing plate from the parts

pack.

(Note: It may be necessary to put a

slight “Z” bend in the pushrod like

shown above to make it operate

smoothly.

Now it is time to install the

servos. We used the Maxx Products

MX-50 servos in the prototype.

Locate the two 1/8 x ¼ x 2-1/4

spruce servo rails.

Locate the two wire pushrods

and the nylon clevis. Install a clevis

halfway onto the threaded end of

each pushrod. Slide the pushrod into

the openings and use them as a guide

10

Use your servo as a spacer and

glue in the two servo rails using 5minute epoxy.

Page 11

Next, using the hardware

supplied with the servos, mount them

to the servo rails.

Next, center the elevator and

rudder and secure them with

masking tape.

Center the servo arms and

make a 90° bend in the rod. It may

be necessary to cut off some of the

excess rod. Using two keepers from

the hardware pack, attach the

pushrods to the servo arms.

Motor Installation

Prior to installing the motor, it

is necessary to hook up the speed

control. We used the Maxx Products

# MX-9115. Follow the instructions

supplied with your speed control

prior to installing the motor in the

airplane.

Locate the motor and gearbox.

There are three gear ratios. We used

the middle gear (2.5 to 1), but you

can experiment to get the

performance you prefer.

11

Page 12

Slide the gear on the motor

shaft and secure with the set screw.

Use the gearbox as a guide to set the

proper location on the shaft.

Next, attach the motor to the

gearbox using two of the supplied

screws. Cut a ¼” wide strip of

magazine page to use as a gauge for

the gear spacing. The gears should

be snug but not bind.

(Note: Trial fit the prop on the

adapter and ensure that the prop

clears the nose. If it doesn’t, break

the firewall loose, shim it out for

proper prop clearance and re-glue.)

Install the prop on the adapter

and tighten.

Next, mount the motor to the

firewall. You may have to enlarge

the center hole slightly for the prop

adapter to clear.

12

Locate the front windshield and

trial fit. It may be necessary to trim it

slightly for a good fit. Apply a thin

bead of RC56 Canopy Glue® along

the edge of the windshield and tape

in place with masking tape overnight

to dry.

Page 13

Next install the side windows.

They have been pre-cut but slight

trimming may be necessary. When

you are satisfied with the fit, apply a

thin bead of RC56 Canopy Glue®

around the edge of the window

frames and insert the windows. Tape

in place if necessary and allow the

glue to dry overnight.

Finishing The Model

Now all that’s left is to install

the receiver and battery pack. We

used an eight-cell 1100ma square

pack (Maxx Products #8KR1100AAU) wrapped in foam rubber

directly behind the motor, with the

receiver and speed control just to the

rear of the battery.

With All radio gear and battery

pack installed, the model should

balance 2- 3/8” behind the leading

edge of the wing measured at the

fuselage, or just slightly behind the

wing spar.

Follow your radio

manufacturer’s instructions for

setting up your radio. Set the

elevator throw for up/down 3/8” and

the rudder throw left/right ¾” for the

initial flights. You may wish to

adjust the throws further after the

first few flights. Be sure to use a

minimum of 4, preferably 6 #64

rubber bands to secure the wing on

the fuselage.

1/2A Conversion

For those of you who wish to

fly the Lightnin’ Bug with one of the

fine 1/2A glow motors, we have

included a firewall for mounting the

motor. It is a laser cut piece of 1/8”

lite plywood. The vertical center line

and thrust line are marked.

13

Page 14

Mount your 1/2A motor on the

firewall, using the laser-etched lines

as a guide. You will need 4 #2 x 3/8”

wood screws (not supplied).

Remove the motor from the

firewall and epoxy the firewall to the

front bulkhead using 5-minute

epoxy.

When the 5-minute epoxy has

cured, coat the entire engine

compartment with 30 minute epoxy

to fuel proof the bare wood.

Now re-mount the motor to the

firewall and make sure the prop will

clear the nose of the airplane.

14

Loading...

Loading...